Page 1

LMS-509 series

Line Voltage Occupancy Sensor

INSTALLATION INSTRUCTIONS

WARNING & CAUTION

Risk of Electric Shock - Disconnect power supply before

servicing.

Open Type Photoelectric Switches.

AVERTISSEMENT & PRUDENCE

Risque de choc électrique -Débranchez l'alimentation avant

l'entretien.

Ouvrir Type commutateurs optoélectroniques.

OVERVIEW

The LMS-509 series member of the TRANS family is a line

voltage occupancy sensor designed for all-purposes energy

efficient lighting control. This occupancy sensor employs an

advanced High Frequency Doppler (HFD) sensing technology

to provide superior sensing performance of minor motions,

such as typing, writing, or reading. The HFD technology is

operating with high frequency radio waves which are capable of

detecting the occupant's presence and movements without

requiring unobstructed line-of-sight like PIR sensor.

The Accu-Set digitalized potentiometers make the sensor

setting easier, faster and more accurate than the conventional

analog ones. 4 levels of sensitivity can be selected via DIP

switch setting to provide different coverage. An exclusive Hybrid

Switching technology makes LMS-509 series perfect to control

the lighting with exceptionally high inrush current (HIC) while

switching on, such as multiple LED or CFL lightings connected

in parallel. The sensor comes with ambient light sensor (ALS) to

inhibit switching on the light if the ambient light level is higher

than the threshold set. Like all sensors in the TRANS family, the

LMS-509 series is also available in various mounting options.

Federal Communication Commission Interference Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: Any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate this

equipment.

This transmitter must not be co-located or operating in conjunction with any other

antenna or transmitter.

APPLICATION NOTES

Avoid placing the sensor in an area surrounded with

metallic wall which may block or absorb the radio

wave. If possible, place the sensor to the opening

as close as possible.

Fluorescent light may cause interference to the HFD

sensor operation, and result in lighting permanent

on. If possible, avoid placing the HFD sensor within

1m (3ft.) of fluorescent light.

Avoid sensor placement facing doors, corridors or

exits as HFD sensor may detect the traffics at

adjacent area.

HFD sensors are best for use in areas with partitions

and high dividers, or high level of minor motion

activities.

The HFD sensor is more sensitive to the movements

“toward” than “across” the sensor, so ensure to

place the sensor at the position “toward” the

movements of occupant.

DETECTION PATTERN

Mounting Height

Coverage*

*Sensitivity 100%

(m)

0

3

6

3 m (10 ft)

2

(2,000 ft2)

180 m

Minor motionMajor motion

6 m (20 ft)

100 m

2

(1,200 ft2)

6 969 3 30

20 302030 10 30

(ft)

0

10

20

(m)

(ft)

This product may be covered by one or more U.S. patents or patent applications.

Please visit www.irtec.com for more information.

P/N: 058-50904-004 Printed in Taiwanwww.irtec.com

Page 2

OPERATION

SENSOR SETTINGS

Sensitivity

The LMS-509S is an occupancy sensor designed to provide

switched line voltage power to switch on the controlled

lighting when it detects the presence of occupant. The

sensor will automatically turn off the light after the area is no

longer occupied for a period of time. An ambient light

sensor (ALS) is built-in to inhibit switching on the light if

daylighting level is higher than the threshold set.

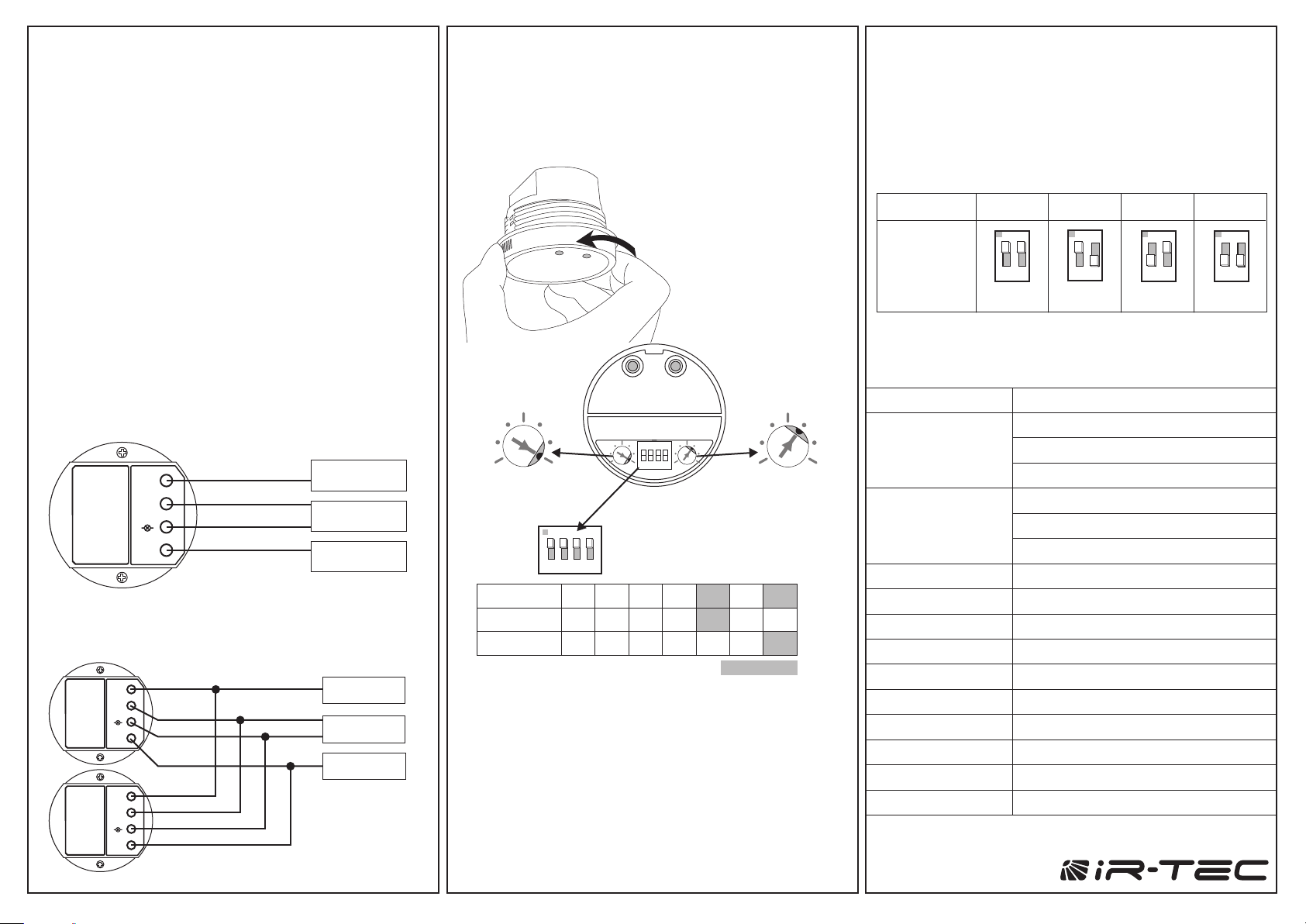

WIRING DIAGRAM

The LMS-509 series can be mounted with a junction box

into the ceiling, internally integrated or externally attached

to a fixture to control the lighting with specific mounting

bracket. Please refer to the mounting instructions

separately attached for details of mounting options

available.

A. Single sensor control

NL N

White

White

Red

LMS-509

B. Multiple sensors control

NL N

LMS-509

NL N

LMS-509

Black

White

White

Red

Black

White

White

Red

Black

Neutral

Load

Line

Neutral

Load

Line

The LMS-509 provides 7 different light-Off delay time and

daylight threshold settings via 2 potentiometers marked T

and L respectively. 4 levels of sensitivity can be set via

combination DIP switch #1 and #2.

Click!

4

3

2

1

5

6

7 1

To change the sensor

setting, rotate the front

cover counter-clockwise

to remove. Replace the

front cover after the

setting complete.

4

3

2

TL

5

6

7

TL

(Factory set)

ON

1 2

Position

T (min.)

L (lux)

*T=10 seconds shorten delay for testing convenience. The

sensor will automatically resume to the factory default delay

setting after 10 minutes, if the potentiometer has not been

adjusted to other position.

(Factory set)

SW1 & 2 (100% Sensitivity)

3 4

SW3 & 4 (No Function)

2

10

3

4 5 6 7

20

15

25 60

1

T* 1’ 3’ 5’ 10’ 20’ 30’

5

T - Delay Time

The potentiometer T sets the period of delay time that sensor

will turn off the connected lights after the area is vacated.

L - Ambient Light Level

The potentiometer L sets the ambient light level that the

sensor will activate occupancy sensing control.

(10 minutes)(ALS disabled)

24H

Factory Set

The sensitivity and detection pattern of HFD sensor

may vary with the furniture placement, partition layout,

wall material, and shape of the space. For example, the

detection pattern will become long rectangular if sensor is

placed in a long corridor. 4 levels of sensitivity can be set

via combinations of DIP switch #1 and #2.

Sensitivity

DIP switch

setting

NOTE: DIP switch #3 and #4 are not functional for LMS-509S.

100%

ON

1 2

ON-ON ON-OFF OFF-ON OFF-OFF

75%

ON

1 2

50%

ON

1 2

25%

1 2

SPECIFICATIONS

Power supply

Maximum Load

@ -40°C~55°C

(-40°F~131°F)

Maximum Load

@ 55°C~70°C

(131°F~158°F)

HFD sensitivity

Load switching

HIC protection

Detection range

Mounting height

Ambient light level

Delay time setting

Op. humidity

Op. temperature

Dimensions

120/230/277VAC

Incandescent/Halogen – 800/1200W

Fluorescent Ballast/CFL – 800/1200W

Ballast Electronic (LED) – 540/1200VA@120/277V

Incandescent/Halogen – 500/750W

(VA)

@120/277V

(VA)

@120/277V

(VA)

@120/277V

(VA)

Fluorescent Ballast/CFL – 500/750W

@120/277V

Ballast Electronic (LED) – 500/750VA@120/277V

25/50/75/100% selectable via DIP switch setting

Zero-cross Hybrid-Switching

Max. 80A for 16.7msec.

Up to 180 sq. m @ 3 m (2,000 sq. ft. @ 10 ft)

2.4 ~ 6 m (8 ~ 20 ft)

7 level Accu-Set digital potentiometer

T/1'/3'/5'/10'/20'/30' , T=10 sec. for testing

Max. 95% RH

-40°C~70°C (-40°F~158°F)

Ø60 x H42mm (2.36"x H1.65")

www.irtec.com

ON

Loading...

Loading...