Page 1

Tel: (800) 404-0204

www.ironwoodelectronics.com

GHz BGA Socket User Manual

P a g e | 1 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 2

Tel: (800) 404-0204

www.ironwoodelectronics.com

GHZ BGA SOCKET USER MANUAL

Table of Contents

Selecting a BGA socket 3

Socket Mechanics 3

PCB Requirements 4

Backing Plate 5

BGA Socket Assembly 5

MLF (QFN) Socket Assembly: 6

Torque Driver 7

Vacuum Pen 7

Elastomer Cleaning Procedure 8

Surface Mount (SM) Adaptor 10

Thru Hole (TH) Adaptor 13

GHZ socket Mechanical Specifications 14

Elastomer Specification 14

Heat Sink Specifications 15

P a g e | 2 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 3

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 1: GHz BGA Socket

Figure 2: SEM

Picture of Elastomer

Selecting a BGA socket

The IC package drawing is required to select the correct GHz socket. Go to www.ironwoodelectronics.com.

Select the “Products” link, then under the “Browse” menu, select the “GHz BGA & MLF socket” link. For

1.27mm, 1mm, 0.8mm and 0.75mm pitch BGA devices, select the “SG-BGA-6xxx” link. For 0.65mm, and

0.5mm pitch BGA device, select the “SG-BGA-7xxx” link. In the table, select the part number that corresponds

to your IC size (length mm x width mm), array size (rows x columns) and pitch (mm). Note: More than one

part number may match your criteria. A frame on the top of the page will show the socket price and links to

PDF and JPEG files.

The JPEG file is a picture of socket. The PDF file will have three pages. The first page shows the socket cross

sectional views and the material details. The second page shows the recommended PCB layout (Note: BGA

pads are not symmetrical to the mounting holes). The third page shows the compatible BGA specification.

Check the following four parameters.

1. IC co-planarity – the value should match or be less.

2. Maximum total height of IC should match or be less.

3. Maximum solder ball diameter of IC should match or be less.

4. Maximum and minimum solder ball height should fall within the range.

If any of the above parameters do not match, go back to the table and select a different part number that

matched the initial criteria and repeat the four parameter checks. If a part number cannot be found to match IC

parameters, please call Ironwood Tech Support @1-800-404-0204.

Socket Mechanics

GHz BGA sockets provide 6.5 to 10 GHz bandwidth in a small, cost

effective ZIF socket for prototype and test applications. The GHz

BGA socket is a simple mechanical socket based on elastomer

connector technology. The GHz socket is a solder-less socket that

can be mounted onto a PCB using screws and nuts. PCBs will require

mounting and alignment holes

at proper locations (see page 2

of the drawings for

recommended PCB layout

information). The typical

GHz socket is 5mm larger

than the maximum IC size. If

there are pre-existing holes in

the PCB, a GHz socket can be custom designed to accommodate those

holes (please call Ironwood Tech Support @1-800-404-0204).

Figure 1 shows a typical GHz BGA socket. The Z-axis conductive

elastomer used in the socket, as a contactor between the IC package and

the circuit board, is a low resistance (<0.01) connector. Figure 2 shows an SEM picture of the elastomer. The

elastomer consists of a fine pitch matrix (0.1mm x 0.1mm) of gold plated wires (40 micron diameter), which are

embedded at a 63-degree angle in a soft insulating sheet of silicone rubber. Another elastomer used for high-

P a g e | 3 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 4

Tel: (800) 404-0204

www.ironwoodelectronics.com

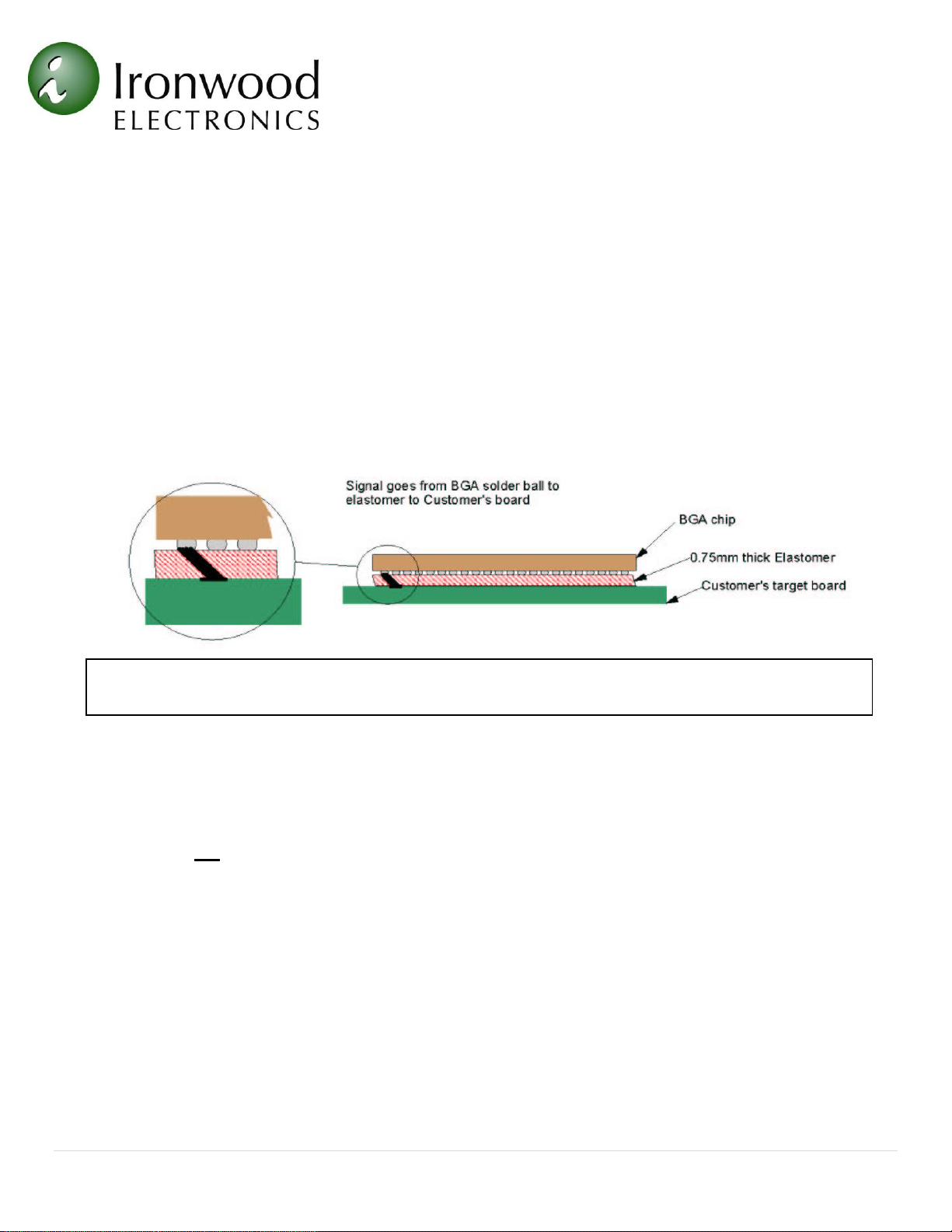

Figure 3: Elastomer cross-sectional side view

density application consists of an ultra fine pitch matrix (0.05mm x 0.05mm) of gold plated wires (20 micron

diameter), which are also embedded at a 63-degree angle in a soft insulating sheet of silicone rubber. The

insulation resistance between connections with 500V DC is 1000 M. The elastomer is ideal for high-current

(50mA per filament) applications where a thin, high-density anisotropic connector is required. The gold-plated

brass filaments protrude several microns from the top and bottom surfaces of the silicone sheet. The operating

temperature range for the elastomer is -35 to 100 C.

Solder balls from the IC package come in contact with the top end of elastomer wire. The bottom end of the

elastomer wire contacts the circuit board pad and thereby makes an electrical path for the signal. The number of

wire filaments making contact depends on the solder ball and circuit board pad diameters. Figure 3 shows the

cross-sectional side view of the elastomer with the BGA IC. The GHz socket can be summarized as a

mechanism in which a downward force applied to an IC compresses its solder balls onto an elastomer, which in

turn compresses on the circuit board, thereby making electrical connection.

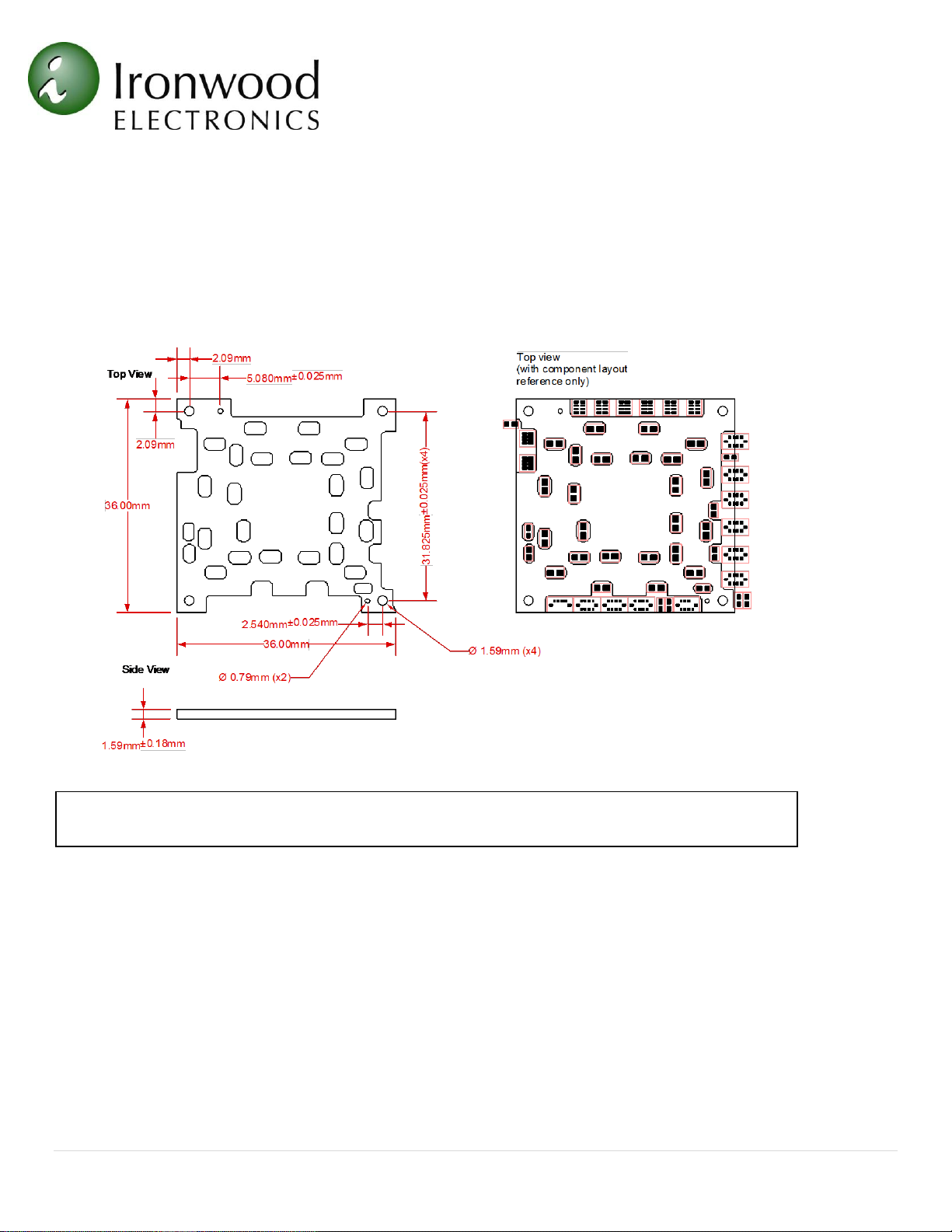

PCB Requirements

General

• Where IC body size is < 30.5mm: GHz socket requires 4 mounting holes.

• Where IC body size is > 30.5mm: GHz socket requires 8 mounting holes.

• Two alignment holes are employed in all sockets. (See drawing for location details).

• BGA pattern is not symmetrical with mounting holes due to angled wires in elastomer (see drawing for

layout details).

• Please refer to page 2 of the socket drawing for all PCB recommendations.

Thickness

1.6mm minimum. This will change as per customer's application, environment and usage.

Finish

SnPb plating or Immersion Au or Immersion Ag. Other plating may be used but testing may be required.

Ideally pad surface that is flush or higher than the solder mask is recommended.

Note: Our internal tests were successful with 0.001”-0.002” thick solder mask above the pad surface on 0.5mm

to 1.27mm pitch elastomer sockets.

Cleanliness

Isopropyl Alcohol or similar should be used to clean the board surface prior to attaching socket.

P a g e | 4 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 5

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 4: Example Insulation Plate

Backing Plate

For an IC body size of 19mm and above, the GHz socket requires a backing plate to prevent the deflection of

the target circuit board due to the high downward forces. If the backside of target PCB contains capacitors and

resistors, a custom insulation plate with cavities milled for those capacitors and resistors can be designed. The

insulation plate sandwiches between the backing plate and the target PCB. Figure 4 shows an example

insulation plate.

BGA Socket Assembly

Refer to figure 5 for graphical illustrations.

1. Install the socket base assembly on the target PCB with the base mounting hardware (provided).

Because of the asymmetrical location of the tooling holes, the socket can be assembled onto the target

PCB with only one orientation (rotation).

2. Place BGA package (solder ball side down) into the socket. NOTE: BGA orientation on target PCB is

critical. If IC frame (optional) supplied, place it over the BGA package.

3. Place the compression plate on top of the BGA package.

P a g e | 5 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 6

Tel: (800) 404-0204

www.ironwoodelectronics.com

4. Install the socket top assembly on to the socket base assembly and swivel to lock into the position. If

your socket contains a shoulder screw (silver in color), DO NOT tighten them – they are preset at our

factory. If your socket uses a black oxide socket head cap screw, tighten them until they make contact

with the lid.

5. Turn the compression screw clockwise, until it makes contact with the compression plate and/or the

BGA package.

6. Apply torque specified on page 1 of the part drawing using a torque driver (accurate) or hex key

(approximate) supplied with socket. Using hex key, turn an additional 1/8th to 1/4th of a turn.

7. The sockets between 19mm and 27mm will include hex nuts and washers for optional use without the

backing plate, it is recommended that the backing plate be used however.

MLF (QFN) Socket Assembly:

Refer to figure 5 for graphical illustrations.

1. Install the socket base assembly on the target PCB with the base mounting hardware (provided).

Because of the asymmetrical location of the tooling holes, the socket can be assembled onto the target

PCB with only one orientation (rotation).

2. Place the IC package into the socket using either a vacuum pen or tweezers. MLF type packages pad

side down. NOTE: The package orientation on the target PCB is critical.

2a. Center small IC packages inside the IC guide using tweezers. Use a microscope if needed.

2b. Press on top of the IC with tweezers. Begin by pressing on the area close to the center of the IC. Then

press slightly on all four corners of the IC. NOTE: If you are experiencing problems pressing the IC

package into the IC guide, it is an indicator that the IC package is not properly centered. Re-center

package if necessary.

3. If an IC compression frame (optional) is supplied, place it over the MLF package. Place the

compression plate on top of the IC package.

4. Install the socket top assembly on to the socket base assembly and swivel to lock into the position. If

your socket contains a shoulder screw (silver in color), DO NOT tighten them – they are preset at our

factory. If your socket uses a black oxide socket head cap screw, tighten them until they make contact

with the lid.

5. Turn the compression screw clockwise to the specified torque called out on page 1 of the drawing. Be

careful not to over-tighten compression screw. Over-tightening will damage the elastomer. NOTE: the

torque value on page 1 of the drawing is the maximum recommended torque value. Typically, the

socket should work with smaller torque settings.

P a g e | 6 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 7

Tel: (800) 404-0204

www.ironwoodelectronics.com

Part Number

Range

Increments

Included Hex Bits

TL-Torquedriver-01

20-100 in. oz.

16 in. oz.

1.27mm, 3mm, 5mm

TL-Torquedriver-02

48-240 in. oz.

3.2 in. oz.

1.27mm, 3mm, 5mm

TL-Torquedriver-03

80-640 in. oz.

8 in. oz.

1.27mm, 3mm, 5mm

TL-Torquedriver-05

8 in. oz. (preset)

NA

1.27mm, 3mm

TL-Torquedriver-06

16 in. oz. (preset)

NA

1.27mm, 3mm

TL-Torquedriver-09

6-24 in. oz.

0.2 in. oz.

1.27mm, 3mm, 5mm

Torque Driver

Select the appropriate Ironwood torque driver for your socket torque specified on page 1 of the part drawing.

The following adjustable drivers are sold separately and include hex bits listed in table. For other bits, please

call Ironwood Tech Support @1-800-404-0204.

P a g e | 7 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Figure 5: Exploded View Socket Assembly

Page 8

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 7: Vacuum Pen with

Attachments

Legend

HBA-¼” hex bit adaptor (accommodates other ¼” hex drive insert bits).

Torque Conversion Factors

1 in. lbs. = 16 in. Oz. = 0.113 Nm

Vacuum Pen

A vacuum pen is recommended for insertion/extraction of ICs.

Figure 7 shows a typical vacuum pen. TL-vacuumpen-01 can be purchased

separately. Hand insertion of ICs and extraction using a small tweezers are

also acceptable.

Tweezers:

A small tweezers is recommended for insertion/extraction of ICs having a

body size of 7x7mm or smaller. Figure 6 shows a typical small tweezers

with a GHz MLF socket.

Figure 6: Tweezers with SG-MLF socket

Elastomer Cleaning Procedure

Elastomer cleaning requirements vary with customer applications and are dependent on variables such as

contact force, BGA package condition and the environment it is used in. A light cleaning is recommended

every 200 to 300 cycles. A thorough cleaning is recommended every 1000 to 2000 cycles. These

recommendations are suggestions only, and should be increased or decreased based on observation.

P a g e | 8 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 9

Tel: (800) 404-0204

www.ironwoodelectronics.com

Required Tools: Scotch™ Magic™

Transparent tape or similar or poster putty –

Henkel™ DUCPTY2 Poster Putty,

Removable/Reusable, Nontoxic or a similar

brand. (For more thorough cleaning

technique use alcohol, De-Ionized (DI)

water, a stiff nylon brush, and clean, dry

shop air.)

The Elastomer can be quickly cleaned of

dust and debris with a piece of transparent

tape approximately 2 inches long. Remove

the complete socket assembly from the

board. Roll tape loosely around a fingertip,

adhesive side out. With finger positioned

parallel to the bottom of the elastomer, roll

the tape over the surface. (The bottom side

of the elastomer can be cleaned without

removing it from the socket base assembly).

After cleaning the bottom side, carefully

remove the elastomer guide and elastomer

from the base and clean the top side with a

fresh piece of tape.

To use the poster putty, you do not have to

remove the elastomer with the guide from

the socket base, simply take the socket off

the PCB to clean the bottom side of the

socket – roll the poster

putty around on the elastomer surface on the

bottom – and on the PCB. To clean the

inside of the socket, it is best if the socket is re-mounted to the PCB so you don’t push the elastomer off the

guide. Depending on how big the socket base is you can either use your fingers or some sort of longer tool

(pencil, or tweezers will work) and attach the poster putty on the end – be careful not to let the sharp point of

the tool stick out as you will damage the elastomer. Roll it around inside the socket or look through a

microscope to better see and collect the debris in the socket.

The Elastomer is assembled to the elastomer guide using a silicone adhesive. DO NOT remove the elastomer

from the guide substrate when cleaning. However, should the elastomer fall out, orientation back into the

elastomer guide is critical. The socket will not function properly if the elastomer orientation is incorrect. See

figure 8 to reinstall the elastomer into the elastomer guide should it fall out.

Caution: the elastomer will absorb liquids and may become deformed if it soaks too much. Do not apply

liquids directly to the elastomer or submerse the elastomer in liquid.

P a g e | 9 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 10

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 10: SM Adaptor Signal Path

Figure 9: Surface Mount Adaptor

For a more thorough cleaning, use the stiff nylon brush and a

solution of half DI water and half isopropyl alcohol. Wet the

brush, scrub the surfaces of the elastomer, and blow both sides dry

with clean, dry shop air. After allowing to fully dry, clean the

surfaces with the rolled tape method to remove any dust or lint

accidentally deposited in the drying process. Only perform the

thorough cleaning with the elastomer removed from the elastomer

guide.

Surface Mount (SM) Adaptor

See figure 9. If the target

circuit board already exists

or mounting holes cannot be

drilled on the board, then a

SM adaptor can be used with

a GHz socket. SM adapter

can only be made for IC size

27mm or below. SM adapter

has solder balls on the

bottom side and round pads

on the topside. It looks very similar to the actual IC except it is slightly

larger than the IC. It has threaded insert on four corners. GHz socket can

be mounted on to this adapter using the screws that mate into the threaded

insert.

Materials

Non-clad FR4, Phosphorous Bronze pins, 63Sn/37Pb Solder balls,

threaded insert. The solder balls from IC package come in contact with the

top end of elastomer wire. The bottom end of elastomer wire contacts the

SM adaptor board pad. The bottom side of the pad is connected to the target circuit board via solder ball and

thereby makes an electrical path for the signal. Figure 10 illustrates this concept graphically.

Assembly

Ironwood Electronics SMT adaptor can vary greatly in size, mass, and thickness. Because there are many

unknown variables for each customer’s situation, it is difficult to recommend an ideal temperature profile for

attaching an Ironwood adapter to a particular customer’s target board.

A few of the unknowns which make a profile suggestion difficult:

1) The target PCB size, mass

2) Number and size of components next to the adapter target pattern

3) Reflow oven type

4) Type of solder paste/flux used

5) Solder stencil characteristics (thickness and aperture size)

Therefore, we offer the following profiles as a guide / reference to mounting our standard and high temperature

ROHS Giga-snaP™ and BGA SMT adapters. While the following should work for most scenarios, Ironwood

P a g e | 10 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 11

Tel: (800) 404-0204

www.ironwoodelectronics.com

250

200

150

100

50

0

100 200 300 400 500

Preheat Flux Activation Reflow Cool-Down

<2°C

per Second

150 - 180 Seconds

<2°C

per Second

1° to 3°C

per Second

Time (seconds)

Temperature

(°C)

Maximum Package Body Temperature

Solder Temperature Melting Point

Figure 11: Recommended Reflow Profile – non RoHS

recommends contacting your solder paste / flux manufacturer for proper reflow profiles for your particular setup and equipment.

Recommended Reflow Profile – Low Temperature (Non-RoHS)

Ironwood's SMT adaptor closely emulates a BGA package and therefore can employ similar processes to attach

it to a target board. The steps involved in the soldering process are as follows:

(1) Using a flux dispenser, place a small amount of flux (water soluble or no clean) on the middle of the target

PCB lands. Spread the flux evenly over the PCB lands.

(2) Apply a small amount of TAC flux on opposite corners of the PCB lands.

(3) Note the target board land pattern orientation and the SM adaptor Pin 1 location. Place the adaptor (solder

ball side down) onto the flux and land pattern (align as closely as possible to the land pattern of the target PCB).

The SM adaptors are durable enough to

be handled by hand, however vacuum pen

or pick & place equipment can be used

for handling the part.

(4) Surface tension between the adaptor's

solder spheres and the target PCB's pads

will self-align the part during the reflow

process.

(5) Reflow as per (Figure 11):

Use caution when profiling to insure

minimal temperature difference

(<150 C and preferably <100 C)

between components

Forced convection reflow with

nitrogen preferred (50 - 75 PPM)

Preheat stage temperature ramp rate:

<20 C per second

Time required in Flux Activation

stage: 150 to 180 seconds

Flux Activation stage temperature range: 150 to 1830 C

Time required in Solder stage: 60 seconds

Maximum temperature 210 - 2200 C (Do not exceed 10 seconds at maximum temperature)

Cool-Down stage temperature reduction rate: <20 C/sec

NOTE: It may be necessary to adjust the amount of heat when attaching the part, due to the fact that the adaptor

mass is different from the actual IC package. Solder sphere spec = 63Sn, 37Pb and its melting point = 183 C

(6) Clean PCB with the flux manufacturers recommended process after reflow. Install the GHz socket on the

SM adaptor as per assembly instruction provided in the GHz socket assembly section.

P a g e | 11 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 12

Tel: (800) 404-0204

www.ironwoodelectronics.com

Recommended Reflow Profile – High Temperature (RoHS)

Figure 12: Recommended Reflow Profile – High Temperature (RoHS)

(4) Surface tension between the adapter's solder spheres and the target PCB's pads will self-align the part during

the reflow process.

(5) Reflow:

Use caution when profiling to insure minimal temperature difference (<150 C and preferably <100 C)

between components

Forced convection reflow with nitrogen preferred (50 - 75 PPM)

Preheat stage temperature ramp rate: <20 C per second

Time required in Flux Activation stage: 120 seconds

Flux Activation stage temperature range: 140 to 145 C

Time required in Solder stage: 30-60 seconds

Maximum temperature 230 - 249 C (Do not exceed 10 seconds at maximum temperature)

Cool-Down stage temperature reduction rate: <20 C per second

NOTE: It may be necessary to adjust the amount of heat when attaching the part, due to the fact that the

adapter mass is different from the actual IC package. Solder sphere spec = Sn96.5 Ag3.0 Cu0.5 and its

melting point = 219 C

(6) Clean PCB with the flux manufacturers recommended process.

P a g e | 12 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 13

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 14: TH Adaptor Signal Path

Figure 13: TH Adaptor

Figure 15: TH Adaptor + Receptacle

Signal Path

Thru Hole (TH) Adaptor

If the target circuit board exists with a thru-hole

pattern, then a TH adaptor can be used with a

GHz socket. TH adapter (See figure 13) has

terminal pins on the bottom side and round pads

on the topside. It is slightly larger than the IC

size. It has threaded insert on four corners. GHz

socket can be mounted on to this adapter using

the screws that mate into the threaded insert.

Materials

Non-clad FR4, Phosphorous Bronze pins,

threaded insert. The solder balls from IC

package come in contact with the top end of

elastomer wire.

The bottom end of elastomer wire contacts the

TH adaptor board pad. The bottom side of the

pad is connected to the target circuit board via

terminal pins and thereby makes an electrical

path for the signal. Figure 14 illustrates this

concept graphically.

TH adaptor can be plugged onto a socket

receptacle which is surface mount soldered on to

the target PCB. Figure 15 illustrates this concept

graphically.

P a g e | 13 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 14

Tel: (800) 404-0204

www.ironwoodelectronics.com

BGA Package

Depth of penetration (mm)

Force per ball (grams)

Typical 1.27mm pitch BGA

i

0.1

20.4

Typical 1.0mm pitch BGAii

0.1

16

Typical 0.8mm pitch BGA

iii

0.1

8.1

Electrical Specifications

0.5mm Thick

0.75mm Thick

Contact resistance:

23m

25m

Insulation resistance:

1000M

1000M

Self Inductance:

0.15nH3

0.28nH3

Bandwidth:

10.0GHz

8GHz3

Insertion loss:

1dB@10GHz

1dB@8GHz3

Mutual Capacitance (at PCB):

0.010pF5

0.011pF5

Mutual Capacitance (at device):

0.015pF5

0.015pF5

Current carrying capacity:

50mA/wire6

50mA/wire6

Ball pitch

(mm)

Ball diameter (mm)

Ball height (mm)

Wire pitch

(mm)

# of contacting wire

per ball

Total current carrying

capacity (mA)

1.2 7

0.6 – 0 .9

0.5 – 0 .7

0.1

9 - 16

450 - 800

1.0

0.5 – 0 .7

0.4 – 0 .6

0.1

9 - 16

450 - 800

0.8

0.3 – 0 .5

0.2 – 0 .3

0.1

4 - 9

200 - 450

0.5

0.2 5 – 0 .35

0.1 5 – 0 .25

0.0 5

4 - 9

200 - 450

0.4

0.2 – 0 .3

0.1 2 – 0 .18

0.0 5

4 - 9

200 - 450

GHZ socket Mechanical Specifications

Individual contact force

Notes: i 0.75mm Nominal solder ball diameter was used in the calculation.

ii

iii

Conductive Elastomer Life

Needs cleaning after 200 cycles. Shelf life: 1 year

Notes:

1

Maximum contact resistance with 0.2mm compression (contact resistance will decrease with increased compression). Measurements

were taken using 0.4mm square electrodes. The 0.75mm value is interpolated from a test of 0.5mm, 1mm, and 2.0mm elastomers.

2

compressed 0.35mm.

3

thicknesses ranging from 0.1mm to 2.0mm.

4

This is a conservative estimate based on 1mm thick elastomer test results with test probes spaced at 0.5mm.

5

thicknesses ranging from 0.1mm to 2.0mm.

6

of penetration. The following table shows typical BGA parameters and its current carrying capability.

0.6mm Nominal solder ball diameter was used in the calculation.

0.4mm Nominal solder ball diameter was used in the calculation.

The test used 0.5mm wide Au plated electrodes with a 0.5mm gap between them. 500VDC was used with a 1mm thick elastomer

Measurements were taken with a flat gold plated electrode. The 0.75mm value is interpolated from a test of several elastomer

Measurements were taken with test probes at 0.5mm pitch. The 0.75mm value is interpolated from a test of several elastomer

The wires are on a 0.1x0.1mm grid and 0.05x0.05mm grid. Multiple wires make contact per solder ball based on its size and depth

Elastomer Specification

Operating Temperature

Continuous usage: -35C to +85C, +100C for up to 250 hours

Compression set: 15 0 C for 22 hrs

Thickness change: -4.5%

P a g e | 14 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Page 15

Tel: (800) 404-0204

www.ironwoodelectronics.com

0

10

20

30

40

50

0 10 20 30 40 50

Thermal resistance

(deg C/W)

IC Size (mm)

Socket+Fan

Socket Only

Trend (Socket+Fan)

Figure 15: Heat Sink Characteristics

Vibration

Standard: MIL-STD202, METHOD 204, CONDITION A

No change in resistance and thickness

Humidity

Standard: MIL-STD202, METHOD 106

Resistance change: 26 m

Thickness change: -1%

Standard: MIL-STD202, METHOD 103, CONDITION A

Resistance change: 15 m

Thickness change: -6%

Thermal Shock

Standard: MIL-STD202, METHOD 107, CONDITION A

Resistance change: -19 m

Thickness change: -1%

Heat Sink Specifications

The graph (Figure 15) shows thermal resistance of the socket as well as socket with a fan (Papst 3412/9 GL,

35.9 CFM, 6” muffin) blowing directly on it. For high power dissipation, a specific heat sink lid can be

designed using QFIN software. Please call Ironwood Tech Support @1-800-404-0204.

P a g e | 15 S G B . d o c , R e v . R , V P , 1 1 / 5 / 1 0

Loading...

Loading...