Page 1

Tel: (800) 404-0204

www.ironwoodelectronics.com

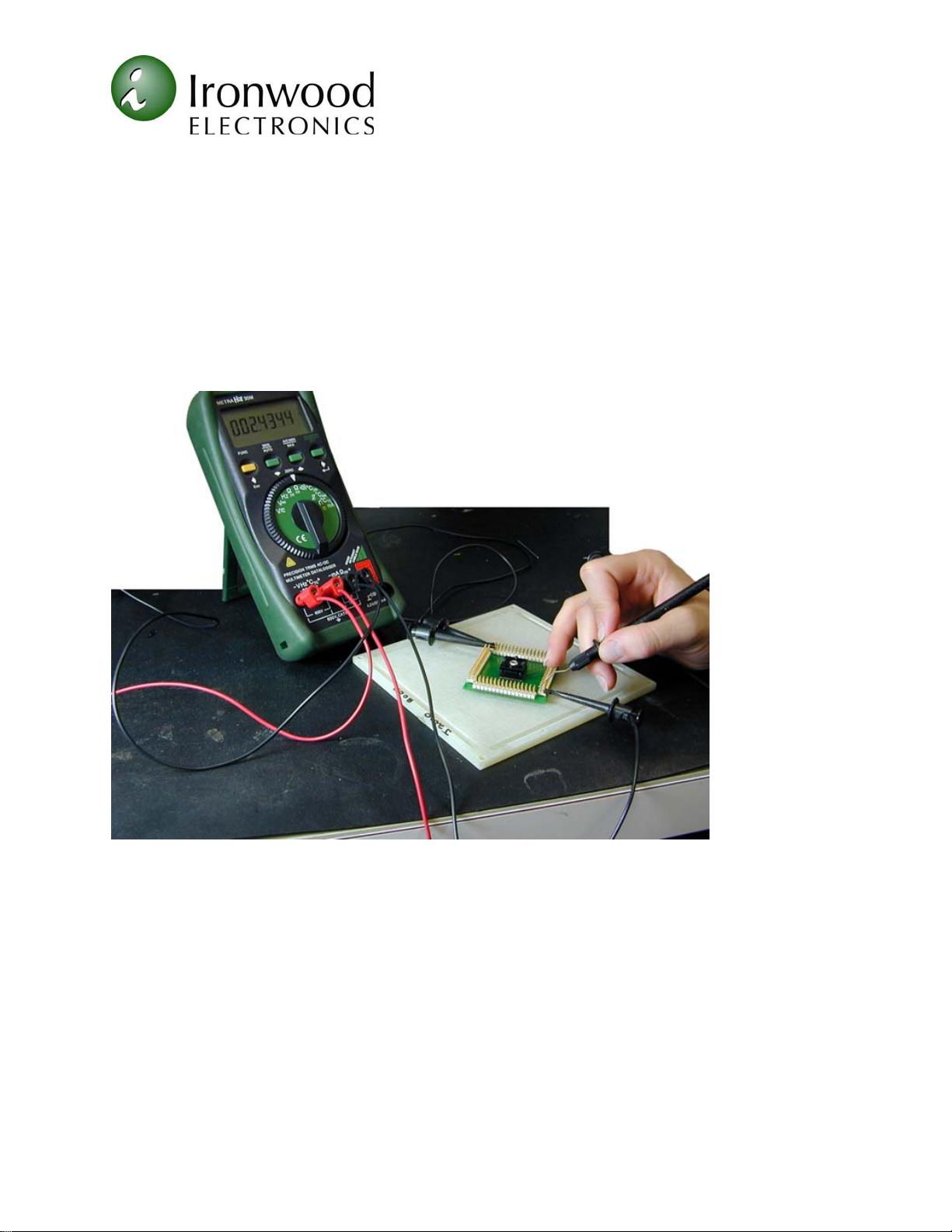

Kelvin Testing Using a GHz socket for MLF/QFN packages

A measurement method called Kelvin probing for measuring resistance allows very accurate

measurement of milliohm or sub-milliohm resistance. To accomplish this there are two

leads, which provide a current source across the load to be measured, and two more leads

across the load, which provide the sensing. This is shown in Fig. 1. The problem is that it

takes twice as many connections as with a two-wire measurement. There is no lead

resistance in the measurement as there is of course with the two-wire measurement. This can

easily be several tenths of an OHM, thus swamping out the milliohms that are to be

measured.

Figure 1: Test Setup.

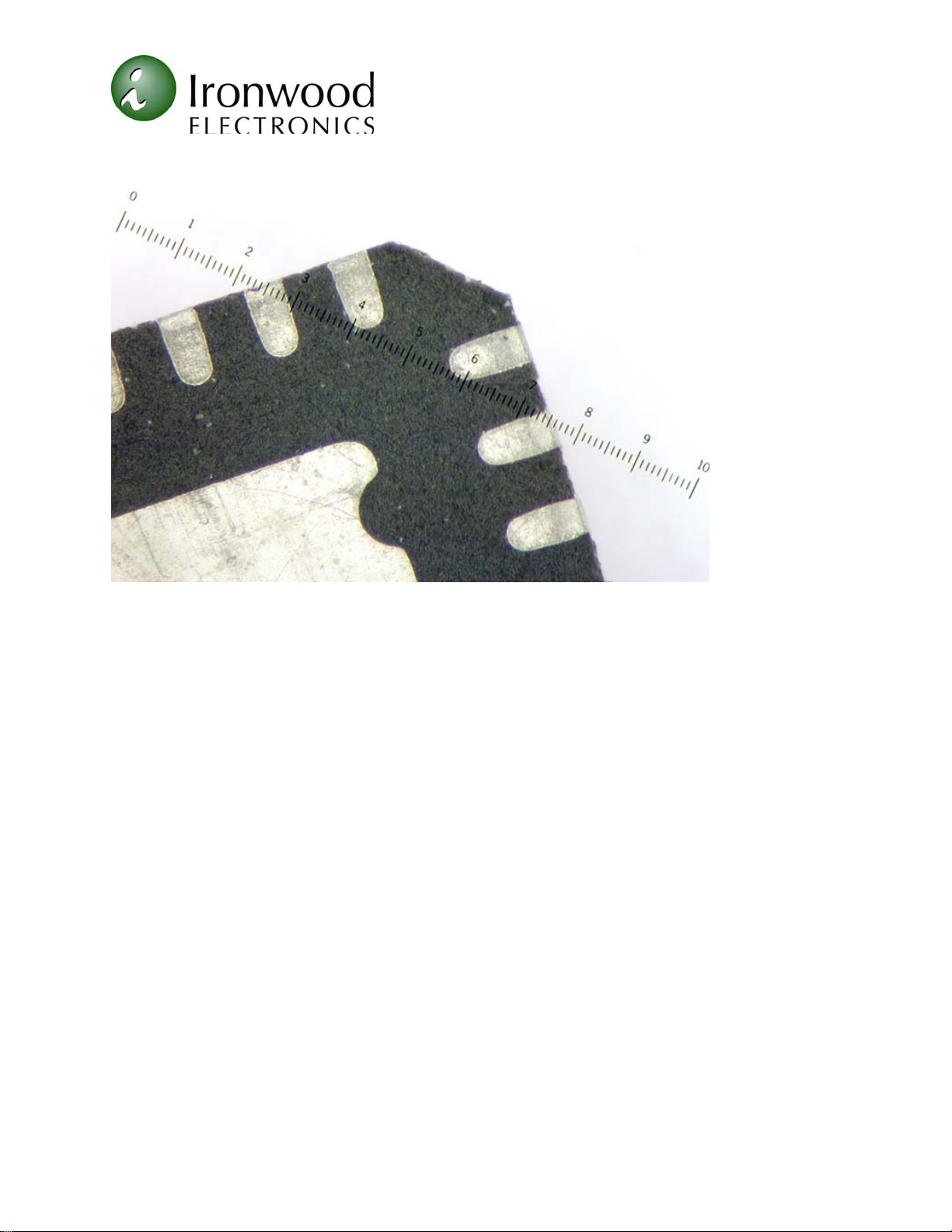

A further complication arises when accurate measurements are required in very small

packages. Many analog functions are being packaged in MLF/QFN packages. These

devices have pitches as low as 0.4mm and lead dimensions in the range of 0.5mm x 0.25mm.

A bottom view of an MLF/QFN package is shown in Fig. 2.

Page 2

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 2: MLF pad detail

Ironwood Electronics, Inc. has developed a socket for MLF device, which has two features

that allow the socket to be used for Kelvin probing in an MLF device. The first feature of the

socket is that it has a very high density contactor which consists of tiny gold plated wires

spaced 0.05mm apart or two thousandths of an inch mounted at a slight angle from vertical in

an elastomer material. This sea of wires provides the connection between two parallel

conductors forced together such as the lead on an MLF and a pad on a PCB with the

contactor between. The second feature is a patent pending method for precisely positioning

the MLF/QFN leads precisely over the pads on the target PCB. This socket was originally

designed as a 10 GHz bandwidth socket for testing very high frequency circuits in MLF/QFN

packages.

To use the GHz MLF socket as a Kelvin measurement device, the target board has to be

designed as shown in Figure 3. Figure 3A shows the layout for use as a standard socket.

Figure 3B shows the layout for use as a Kelvin measurement socket. The difference is that

the pads for Figure 3B are split in the center and a gap of 0.125mm are inserted between the

two sections of the pad. Each fragmentary section of the standard pad or two smaller pads is

then connected to the measuring circuitry as shown in the figure. The current source is

connected to one section of the pad and the sensing circuit is connected to the other section

Page 3

of the bisected pad.

Tel: (800) 404-0204

www.ironwoodelectronics.com

15.225mm

Socket size

Orientation Mark

±0.125mm sqr.

1.25mm

9.36mm

±0.13mm (x4)

1.68mm

7.78mm

5.08mm

12.725mm

1.25mm

MLF64A

±0.125mm (x4)

2.72mm*

7.78mm

9.36mm

±0.125mm (x4)

Figure 3A: Suggested PCB layout for SG-MLF-7008

0.5mm typ.

2.54mm

+

Ø 0.85mm

0.025mm

-

0.025mm

Non plated alignment hole

0.69 x 0.28 mm

Ø 1.61mm

+

-

Non plated mounting hole

(x 2 )

pad (x 64)

0.050mm

0.050mm

(x 4)

Figure 3B: Split pad layout

For our purposes, an SG-MLF-7008 was used with a 64-position MLF test chip. The chip

was set up in a daisy chain pattern and provides a resistance through spiral circuitry from

bottom to top of board (Figure 4). The target board allows Kelvin connections to every pin.

The results are shown below in Fig. 5.

Page 4

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 4: Test Chip layout

The MLF GHz sockets vary by package; call Ironwood Electronics, Inc. for assistance in

choosing the proper socket before laying out your board. Tooling holes, etc must be in the

correct locations to ensure the best test set-up. If needed, Ironwood Electronics, Inc. can also

provide a board for Kelvin testing. Call for a quote.

Figure 5: Test Data

Leads Resistance

1:2 2.3543 1:20 2.4028 1:38 2.3932 1:56 2.3499

Page 5

Tel: (800) 404-0204

www.ironwoodelectronics.com

1:3 0.0112 1:21. 0.0483 1:39 0.0844 1:57 0.026

1:4 2.3584 1:22 2.409 1:40 2.418 1:58 2.3544

1:5 0.0155 1:23 0.0512 1:41 0.0865 1:59 0.023

1:6 2.3672 1:24 2.4156 1:42 2.4094 1:60 2.3637

1:7 0.0211 1:25 0.0555 1:43 0.0913 1:61 0.019

1:8 2.3754 1:26 2.4228 1:44 2.434 1:62 2.3701

1:9 0.0246 1:27 0.0601 1:45 0.0954 1:63 0.0163

1:10 2.3853 1:28 2.4308 1:46 2.4269 1:64 2.3753

1:11 0.0294 1:29 0.0643 1:47 0.1055

1:12 2.3943 1:30 2.4381 1:48 2.4349

1:13 0.0331 1:31 0.0686 1:49 0.045

1:14 2.3984 1:32 2.4463 1:50 2.3341

1:15 0.0365 1:33 0.0712 1:51 0.0407

1:16 2.3944 1:34 2.3822 1:52 2.3402

1:17 0.0388 1:35 0.0752 1:53 0.0351

1:18 2.3933 1:36 2.3917 1:54 2.3457

1:19 0.0444 1:37 0.0812 1:55 0.0305

Conclusion: From the results in Figure 5, one can ascertain that using the GHz socket in

the described setup can in fact measure the Kelvin resistance between two points. The

test chip that was daisy chained in this pattern allowed us to see differences between

points because of the length of the trace (more length = more resistance), you can see that

the farther you got away from the first pin, the resistance increases slightly. It was used

expressly for that purpose; a typical MLF chip will also work in this application although

the results will be unique to that chip.

Loading...

Loading...