Page 1

Gull Wing Surface mount Foot Soldering Instructions

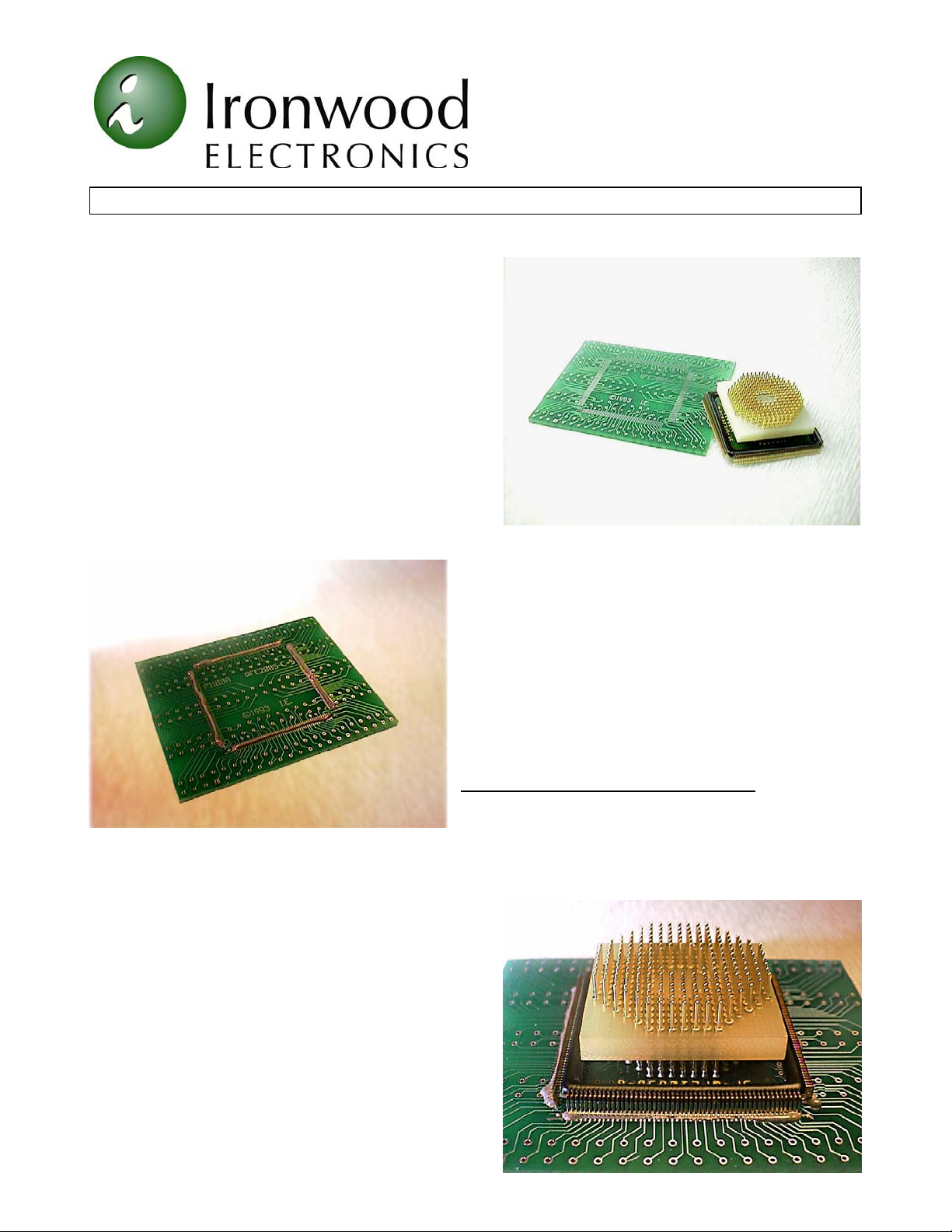

The gull wing style, surface mount foot (parts with a 'SF-'

prefix and a '-G' suffix) is designed to solder to a quad

flat pack (QFP) surface mount land pattern. The emulator

foot emulates the physical characteristics of a QFP gull

wing package very closely, allowing the foot to be

soldered to a target board land pattern using the methods

commonly employed in attaching actual QFP packages.

The recommended method is explained below with visual

aids showing the step-by-step process. This method has

produced very good results. Figure 1 shows the surface

mount emulator foot and a clean target printed circuit

board. The steps involved in the soldering process follow.

CAUTION: During secondary reflow (i.e. mounting the

emulator foot to a board), the temperature profile should

be tightly controlled. The gull wing leads are attached to

Tel: (800) 404-0204

www.ironwoodelectronics.com

Figure 1: Target PCB/Emulator Foot

the emulator foot with 95/5 tin/silver solder(melting point

245°C). If the temperature during reflow exceeds 245°C,

it will cause bridging between the leads or create opens at

the clip head. The peak temperature during reflow should

not reach more than 240°C. Peaks to 260°C are allowed

only if the residence time is less that 40 seconds above

240°C. If you are attaching the emulator board to a target

board using a hot soldering iron, this can easily happen.

We strongly recommend that furnaces are profiled every

day.

REFLOW OVEN - Soldering method #1

(a) Determine an appropriate temperature solder paste for

your application.

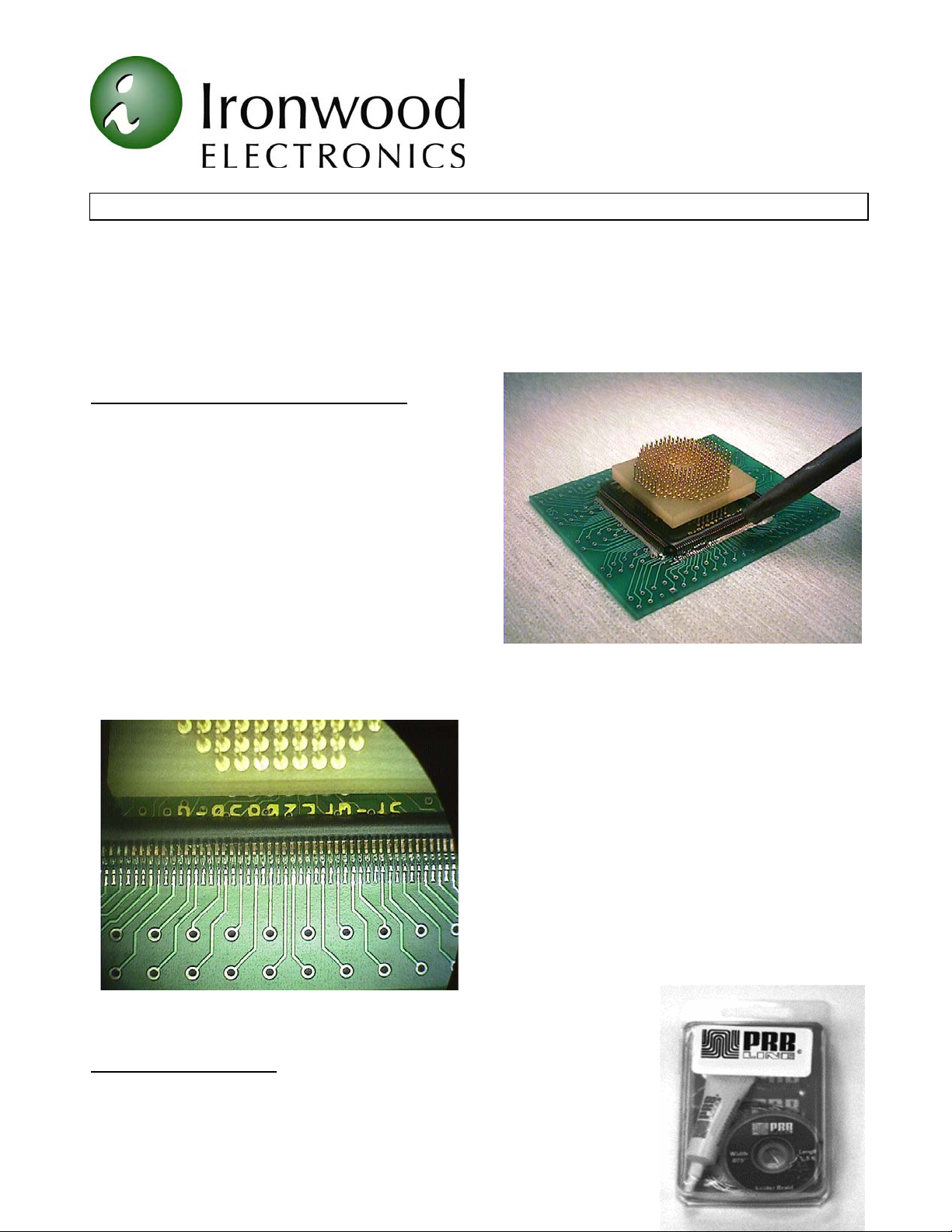

Figure 2: Apply Solder Paste

(b) Apply a continuous bead of paste to the target PCB

pads as shown in Figure 2. Cover approximately 1/3 of the

pad between the center of the pad and the outer edge. Begin with this amount and add additional paste after

reflow, if necessary (excessive paste on an initial trial will

be difficult to remove).

(c) Note the target PCB QFP land pattern and the

emulator foot Pin 1 locations.

(d) Align and place the emulator foot onto the solder

paste and land pattern as shown in Figure 3. 'Pick and

place' equipment or a vacuum pen, are recommended (if

they will accommodate the foot), but, handling the foot

by the gold pins and placing on the land pattern by hand

will suffice.

(e) Reflow target PCB with emulator foot in reflow oven

(convection, IR, etc.). The recommended reflow profile is

shown in the Figure 5. Time and temperature settings will

be determined by the manufactures of the solder paste and

Figure 3: Align foot on the lands

Page 2

Tel: (800) 404-0204

www.ironwoodelectronics.com

Gull wing Surface mount Foot Soldering Instructions (continued)

reflow oven. The Ironwood gull wing foot has a larger thermal mass than an actual QFP package, and therefore,

may require longer reflow time and/or higher temperature

settings.

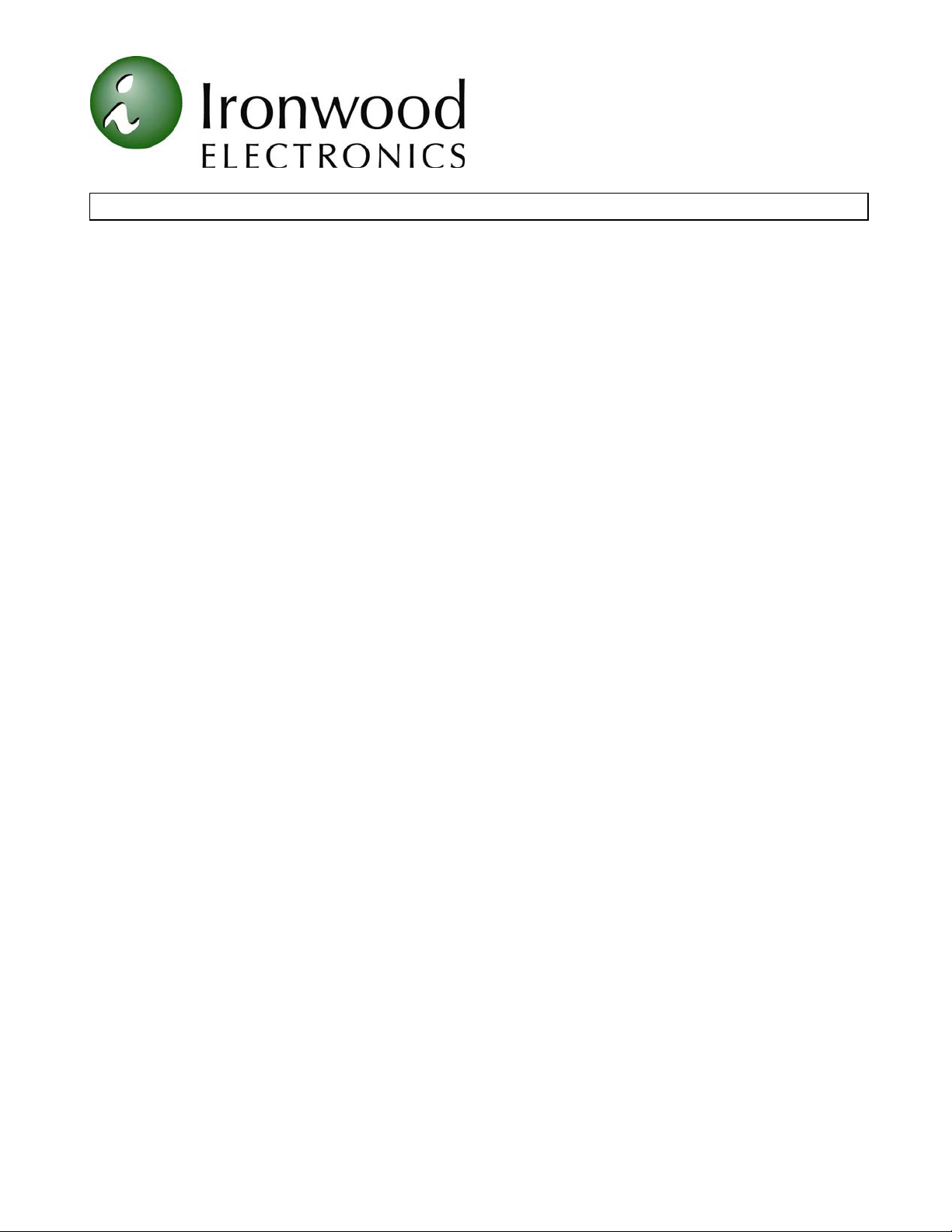

(f) Inspect solder fillets. Add additional solder paste to

solder deficient areas as needed or remove excess with

small tip solder iron and copper desoldering braid (Figure

4). If the solder has not completely reflowed, add solder

flux and repeat step (e).

Because of the construction of the emulator foot, a Low

Temperature solder paste must be used. Set reflow

equipment to the lowest setting that will reflow the solder

paste. Reflow the emulator foot with target assembly in a

temperature range of 185 - 210 degree C. This can be

varied depending upon the profile of the oven and the

Figure 4: Removing excess solder

the foot. It is recommended that reflow oven be set for a minimum time initially. If reflow was not complete,

reflux and reflow for a longer duration.

250

customer assemblies. The above temperature range is safe

for soldering the emulator foot without thermal damage to

Maximum Package Body Temperature

200

Solder Temperature Melting Point

1° to 3°C

150

150 - 180 Seconds

Temperature

(°C)

100

50

<2°C

per Second

Preheat Flux Activation Reflow Cool-Down

0

100 200 300 400 500

Time (seconds)

per Second

<2°C

per Second

Figure 5: Recommended Convection Oven Reflow Profile

HOT AIR TOOL - Soldering method #2

Repeat steps (a) through (d) in method #1. The surface tension present between the solder and the emulator

foot in method #1 will not be present in method #2, due to the fact that only a small portion of the solder in this

method will be liquid at one time. It is necessary therefore, to align the foot over the land pattern with greater

accuracy.

Page 2 of 4 GSI.doc, Rev. C

Page 3

Tel: (800) 404-0204

www.ironwoodelectronics.com

Gull wing Surface mount Foot Soldering Instructions (continued)

(e) Reflow, with a hot air wand/gun, the solder over a few of the pads in opposite corners (diagonally) of the land

pattern (Figure 6).

(f) Check the foot alignment.

(g) Continue by reflowing the remaining solder paste. Add or remove solder as needed (see step (f) in method

1.).

SOLDERING IRON - Soldering method #3

This method has produced very good results but may be

more time consuming than the other two methods.

Caution must be used when touching the soldering iron

tip to the emulator foot. Excessive heat or pressure may

damage the pads on the side of the foot.

(a) Using a small diameter solder wire (approx. 0.015" or

smaller) and a very fine tipped soldering iron, add enough

solder to two opposite corner (diagonal) pads to cover

them.

(b) Align and place the emulator foot over the QFP land

pattern (see steps (c) and (d) in method 1).

(c) Holding the foot in place, by pressing down gently on

the gold terminal pins, place the iron tip on the two pads

to reflow the solder. This will tack and keep the foot in

alignment.

(d) Under a microscope or magnifying lens, if available, solder the remaining edge pads of the foot to the target

Figure 7: Finished Solder Fillets

Removing or Desoldering

Conventional methods can be used to remove a surface mount foot from your

target board, however we recommend the use of PRB Line® D’SOLDER™.;

This SMT device removal product avoids the use of excessive heat that can

compromise the integrity of our product and your target board. The specially

Page 3 of 4 GSI.doc, Rev. C

Figure 6: Reflow using hot air tool

PCB land pattern using a liberal amount of solder (shorts

between adjacent pads can be removed later).

(e) Apply a generous amount of flux along the side of the

foot.

(f) Tilt the PCB and emulator foot at 30 - 45 degree

angle. Start at one corner and pull the tip of the iron

along the side of the foot to remove excess solder

deposits. Clean the tip of the iron often. Repeat this step

several times starting at a point on the foot ahead of the

excess solder. Continue along the side of the foot until

shorts are removed and a fillet is present between feet

and target PCB pads.

(g) Repeat steps (e) and (f) for the remaining three sides.

The finished solder connections are shown in Figure 7.

Page 4

Tel: (800) 404-0204

www.ironwoodelectronics.com

Gull wing Surface mount Foot Soldering Instructions (continued)

formulated alloy and flux make desoldering quick and easy. This solution can be a time and money saver for

many applications. (P/N TL-DS123)

3. filename: GSI.doc, Rev C” with footer autotext filename, Rev. C.Replaced pcb with PCB.

Page 4 of 4 GSI.doc, Rev. C

Loading...

Loading...