Page 1

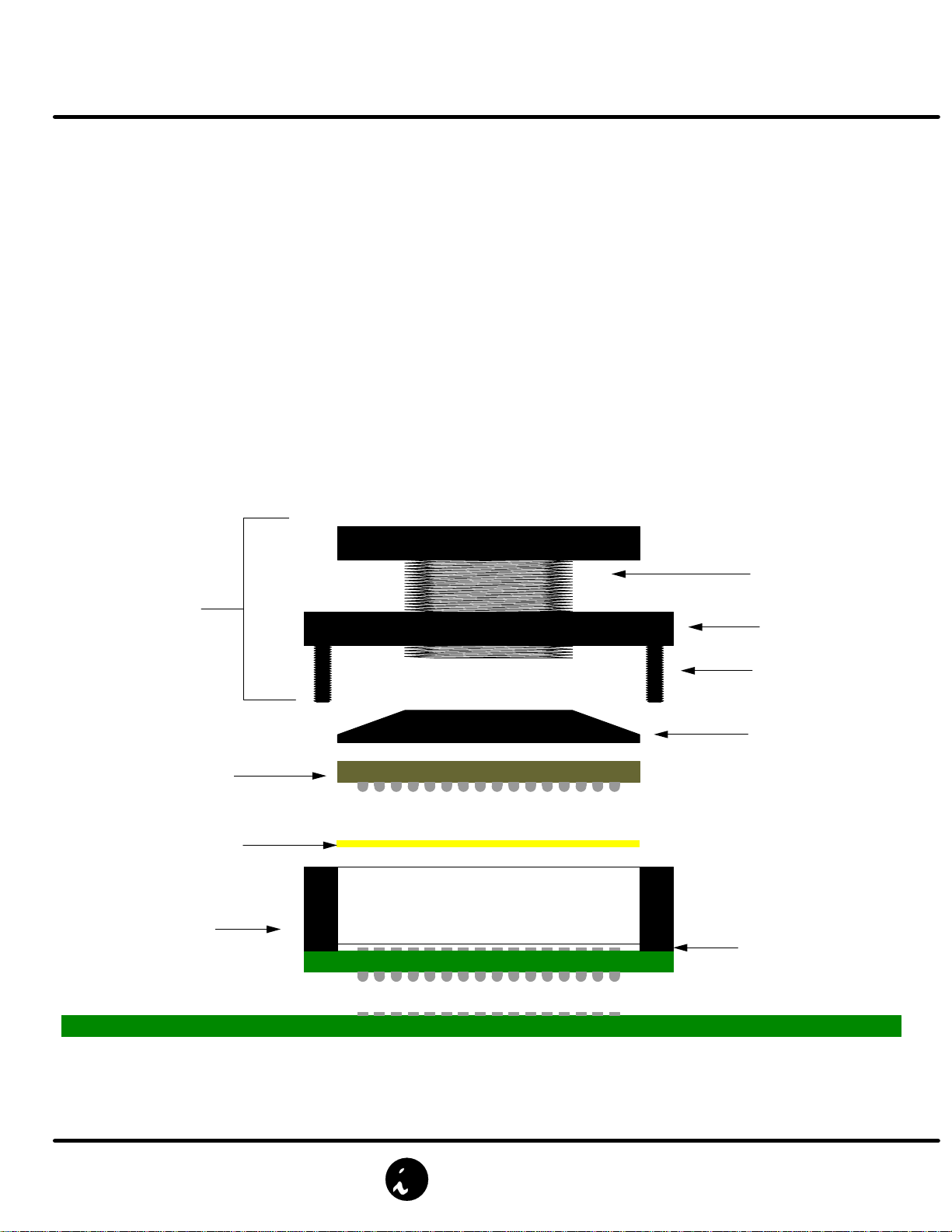

GHZ BGA Socket (surface mount)

Assembly Instructions

1. Reflow Socket Base assembly to the target PCB (see page 2 for reflow profile).

2. Place the square piece of elastomer provided into the socket base (rotation and 'side up' orientation are not critical).

Adjust the elastomer to sit into the alignment plate cavity.

3.

4. Place BGA package (solder ball side down) into the socket. NOTE: BGA orientati on on target PCB is critical.

5. Place the compess ion plate (if required*) on top of the BGA package.

6. Install the s ocket top assembly with the hardware provided (four 0-80 screws).

7. Turn the compression screw clockwi se, until it makes contact with the compression plate or the BGA package.

8. Turn an additional quarter-turn.

page 1 of 2

Socket

Top Assembly

BGA Package

Z-Axis Elastomer

Socket Base Assembly

Compression Screw

Socket Lid

Machine Screw

Compression plate

Alignment plate

Target PCB with SMT pads

*Ironwood Electronics technical staff will determine (from your package spec) if a compression or alignment plate is required

© 2000 IRONWOOD ELECTRONICS, INC.

Tele: (800) 404-0204

www.ironwoodelectronics.com

Filename: HSI.mcd, Rev A, 1/18/00, IP

Page 2

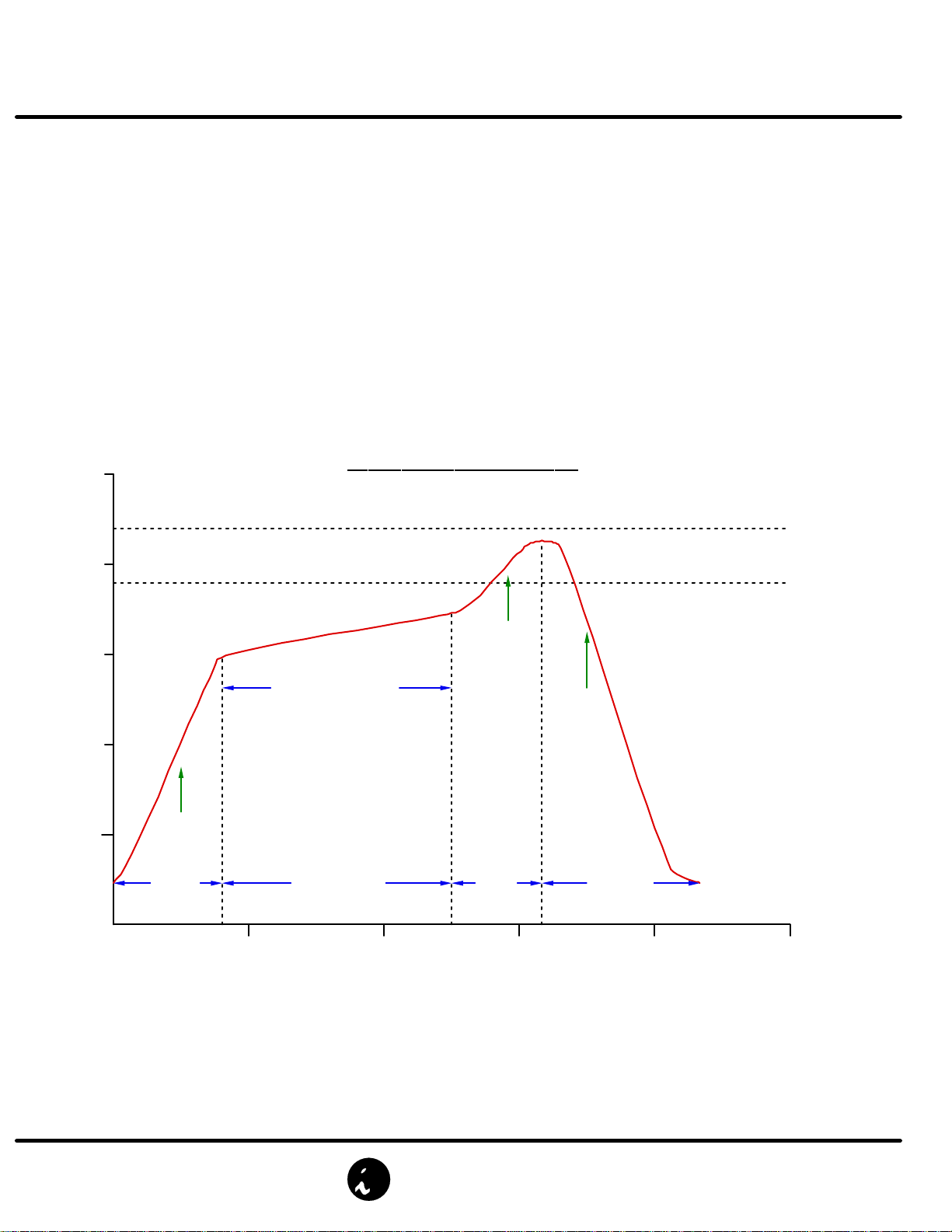

GHZ BGA Socket (surface mount)

Assembly Instructions

1. Use caution when profiling to insure minimal temperature difference (<15 C and preferably <10 C) between components

2. Forced convection reflow with nitrogen preferred (optional)

3. Preheat stage temperature ramp rate: <2 C per second

4. Time required in Flux Activation stage: 150 to 180 seconds

5. Flux Activation stage temperature range: 150 to 183 C

6. Time required in Solder stage: 60 seconds

7. Maximum temperature 210 - 220 C (Do not exceed 10 seconds at maximum temperature)

8. Cool-Down stage temperature reduction rate: <2 C per second

page 2 of 2

250

Maximum Package Body Temperature

200

150

100

Temperature (°C)

Solder Temperature Melting Point

50

<2°C

per Second

Preheat

150 - 180 Seconds

Recommended Reflow Profile

1° to 3°C

per Second

Flux Activation

<2°C

per Second

Reflow Cool-Down

0

100

200 300

Time (seconds)

400

500

NOTE:

It may be necessary to adjust the amount of heat when attaching the part, due to the fact that

the adapter mass is different from the actual IC package. Solder sphere spec = 63Sn, 37Pb

and its melting point = 183 C

© 2000 IRONWOOD ELECTRONICS, INC.

Tele: (800) 404-0204

www.ironwoodelectronics.com

Filename: HSI.mcd, Rev A, 1/18/00, IP

Loading...

Loading...