Ironton 46780 Owner's Manual

10” Multi-Slide Miter Saw

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS

before operating. Failure to follow the safety rules and other basic safety

precautions may result in serious personal injury.

Item# 46780

Thank you very much for choosing an Ironton product! For future reference, please complete the

owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual to

become familiar with this product before you begin using it.

This machine is designed for certain applications only. The distributor cannot be responsible for

issues arising from modification. We strongly recommend this machine not be modified and/or used

for any application other than that for which it was designed. If you have any questions relative to a

particular application, DO NOT use the machine until you have first contacted the distributor to

determine if it can or should be performed on the product.

For technical questions please call 1-800-222-5381.

CAUTION

Before using our miter saw, please read this

manual carefully to understand the proper use of

your unit.

Keep this manual handy.

TABLE OF CONTENTS

Safety symbols....................................................................................................................1

General safety instructions..................................................................................................2

Special safety instructions...................................................................................................4

Additional safety instructions...............................................................................................7

Electrical..............................................................................................................................8

Application...........................................................................................................................9

Specificatons and features.................................................................................................11

Assembly and adjustment .................................................................................................14

Operation ..........................................................................................................................24

Maintenance......................................................................................................................32

Trouble shooting................................................................................................................35

Warranty............................................................................................................................36

SAFETY SYMBOLS

1

NOTE: Some of these following

symbols may be used on this tool.

Please study them and learn their

meaning.

Proper interpretation of these symbols

will allow you to operate the tool better

and safer.

Symbol

Name

Designation / Explanation

Read the operator’s

manual

To reduce the risk of injury, user must read

instruction manual.

Hearing protection

Wear hearing protection to reduce the risk of

induced hearing loss.

Inhalation protection

Wear respiratory protection to reduce the

risk of inhalation of harmful dust.

Eye protection

Always wear safety goggles, safety glasses

with side shields, or a full face shield when

operating this product.

Hand protection

Wear gloves while handling saw blades and

rough material (recommendation that saw

blades should be carried in a holder

wherever practicable).

Class II construction

Double insulated construction

Safety alert

Precautions that involve your safety.

Do not use in rain

Do not expose and operate the tool in rain.

No hands symbol

Failure to keep your hands away from the

blade will result in serious personal injury.

Hot surface

To reduce the risk of injury or damage, avoid

contact with any hot surface.

WARNING! To ensure safety and reliability, all repairs should be performed by a

qualified service technician.

GENERAL SAFETY INSTRUCTIONS

2

WARNING! Read all these instructions

before attempting to operate this product

and save these instructions. When using

electric tools basic safety precautions

should always be followed to reduce the

risk of fire, electric shock and personal

injury including the following:

Keep guards in place and in working

order.

Keep work area clear. Cluttered areas and

benches can cause injuries.

Consider work area environment

- Do not expose tools to rain.

- Do not use tools in damp or wet locations.

- Keep work area well lit.

- Do not use tools in the presence of

flammable liquids or gases.

Guard against electric shock. Avoid body

contact with earthed or grounded surfaces

(e.g. pipes, radiators, ranges and,

refrigerators).

Make the workshop childproof with

padlocks and master switches, or by

removing starter keys.

Keep other persons away. Do not let

persons, especially children, not involved in

the work touch the tool or the extension

cord, and keep them away from the work

area.

Store idle tools when not in use. Tools

should be stored in a dry locked-up place,

out of reach of children.

Do not force the tool. The tool will perform

better and safer at the rate for which it was

intended.

Use the right tool

- Do not force small tools to do the job of a

heavy duty tool.

- Do not use tools for purposes not intended;

for example, do not use circular saws to cut

tree limbs or logs.

Personal Use

- For personal use only. Not intended for

commercial or professional work.

Dress properly

- Do not wear loose clothing or jewelry, these

can be caught in moving parts.

- Non-slip footwear is recommended when

working outdoors.

- Wear protective hair covering or pull hair

back to contain long hair.

Use protective equipment

- Use safety glasses.

- Use face or dust mask if working operations

create dust.

Connect dust extraction equipment. If

the tool is equipped with dust extraction

and collection features, ensure these are

connected and properly used.

Do not abuse the cord. Never yank the

cord to disconnect it from socket. Keep the

cord away from heat, oil and sharp edges.

Secure the work piece. Use clamps or a

vise to hold the work piece whenever

practical. These precautions are safer than

using your hands and frees both hands to

operate the tool.

Do not overreach. Keep proper footing

and balance at all times.

Maintain tools with care

- Keep cutting tools sharp and clean for

safety and improved performance.

- Follow instructions for lubricating and

changing accessories.

- Inspect tool cords periodically, and if

damaged have cords repaired by an

authorized service facility.

- Inspect extension cords periodically and

replace if damaged.

- Keep tool handles dry, clean and free from

oil and grease.

Disconnect tools before servicing and

when changing accessories (e.g. blades,

bits and, cutters).

Use recommended accessories. Consult

the information in this operator’s manual for

recommended accessories. The use of

improper accessories may cause a risk of

injury to persons.

GENERAL SAFETY INSTRUCTIONS

3

Remove adjusting keys and wrenches.

Form a habit of checking to see that keys

and adjusting wrenches are removed from

the tool before turning it on.

Avoid unintentional starting. Ensure

switch is in "off" position when plugging in.

Use intended extension cords. When the

tool is used outdoors, use only extension

cords intended for outdoor use and so

marked.

Stay alert. Watch what you are doing, use

common sense and do not operate the tool

when you are tired or impaired.

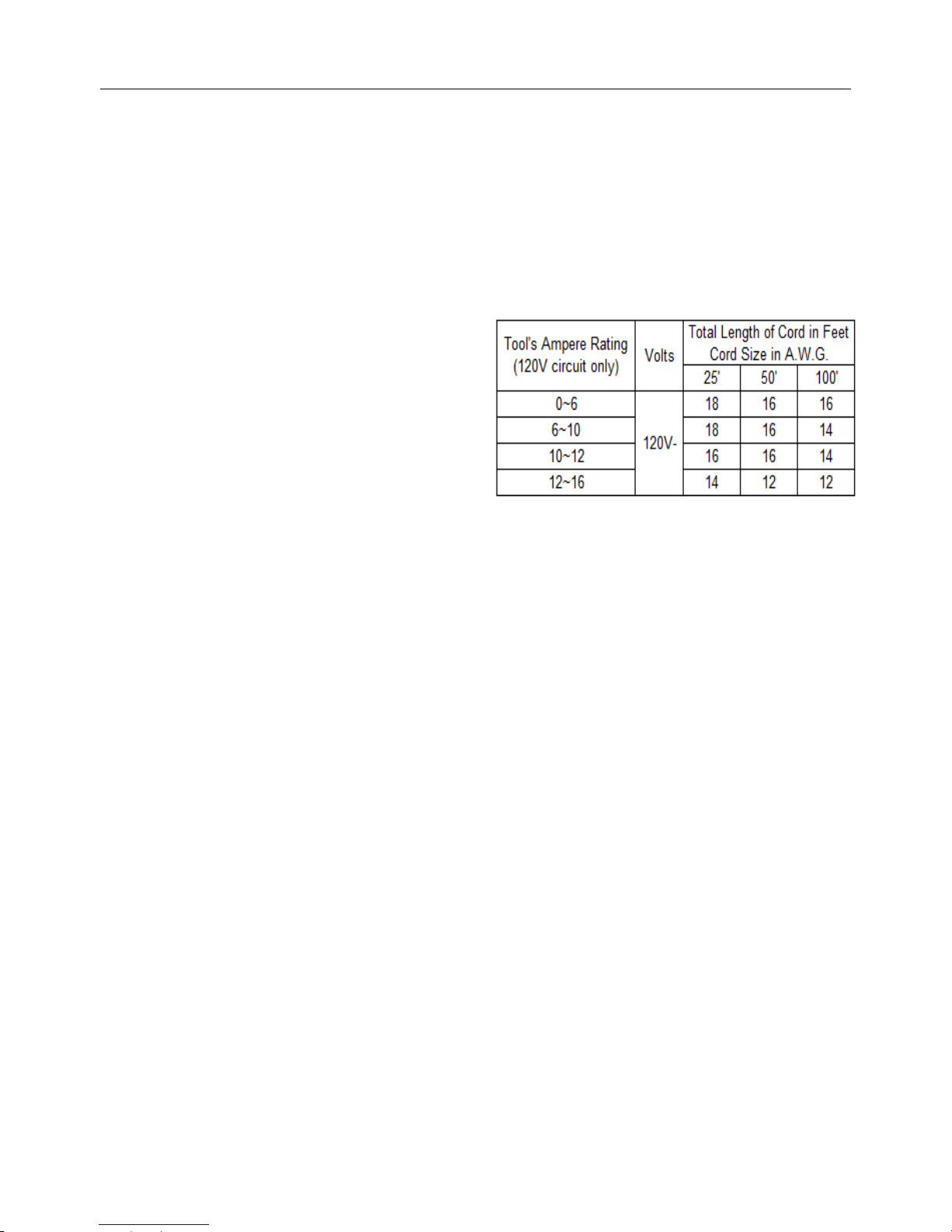

Use proper extension cord

Make sure your extension cord is in good

condition. When using an extension cord,

be sure to use one that is heavy enough to

carry the current your product will draw. An

undersized cord will cause a drop in line

voltage, resulting in loss of power and

overheating. Table 1.1 shows the correct

size to use depending on cord length and

nameplate ampere rating. If in doubt, use

the next heavier gauge. The smaller the

gauge number, the heavier the cord.

Table 1.1

Minimum gauge for cord

SPECIAL SAFETY INSTRUCTIONS

4

WARNING: The use of any

accessory or attachment other than one

recommended in this instruction

manual may present a risk of personal

injury.

Have your tool repaired by a

qualified person. This electric tool

complies with the relevant safety rules.

Repairs should only be carried out by

qualified persons using genuine spare

parts, otherwise this may result in

considerable danger to the user. For

replacement parts, call 1-800-222-5381.

Check damaged parts

- Before further use of tool, it should be

carefully checked to determine that it

will operate properly and perform its

intended function.

- Check the alignment of moving parts,

binding of moving parts, breakage

mounting and any other conditions of

parts that may affect its operation.

- A guard or other part that is damaged

should be properly repaired or replaced

by an authorized service center unless

otherwise indicated in this instruction

manual.

- Have defective switches replaced by

an authorized service center.

- Do not use the tool if the switch does

not turn it on and off.

Never stand on the tool. Serious injury

could occur if the tool is tipped or if the

blade is contacted unintentionally.

Direction of feed. Always feed work

into a blade or cut against the direction

of rotation of the blade or cutter.

Never leave a tool running

unattended. Turn the power off. Don’t

leave the tool until it comes to a

complete stop.

Make workshop kid proof with

padlocks, master switches, or by

removing starter keys.

Don’t force tool. It will perform better

and safer at the rate for which it was

designed.

Never use saw blades which are

damaged or deformed.

Replace the table insert when worn

Use only saw blades specified by the

manufacturer.

Never use saw blades manufactured

from high speed steel.

Wear suitable personal protective

equipment when necessary; this could

include:

i) Hearing protection to reduce the risk of

induced hearing loss;

ii) Eye protection;

iii) Respiratory protection to reduce the

risk of inhalation of harmful dust; and

iv) Gloves for handling saw blades and

rough material.

Connect the saw to a dust-collecting

device when cutting wood.

Select the correct saw blade for the

material to be cut.

Never use the saw to cut materials

other than those specified (See

APPLICATION section).

Only use the saw with guards in

good working order, properly

maintained, and in position.

Keep the floor area free of loose

material (e.g. chips and cut-offs).

Ensure the speed marked on the saw

blade is at least equal to the speed

required for the saw.

Ensure that any spacers and spindle

rings used are suitable for the

purpose as stated by the manufacturer.

Never remove any cut-offs or other

parts of the work piece from the

cutting area while the blade is moving

with an unguarded saw blade.

Do not operate the saw without the

guards in place.

Be sure to turn the tool off and wait

SPECIAL SAFETY INSTRUCTIONS

5

for the saw blade to stop before

moving the work piece or changing

the settings.

Be sure that the power is

disconnected before changing the

blade or servicing the saw.

Never reach around the saw blade.

Do not perform any operation free

hand. Always place the work piece to be

cut on the miter saw table, and position

it firmly against the fence as a backstop.

Always use the fence.

Always keep hands out of the path of

the saw blade. Do not reach under the

material being cut or into the blade’s

cutting path with your fingers or hand for

any reason.

To reduce the risk of injury, return the

saw arm to the full rear position after

each crosscut operation.

Always make sure that the miter table

and saw arm (bevel function) are

locked in position before operating

your saw. Lock the miter table by

securely tightening the miter-lock lever.

Lock the saw arm (bevel function) by

securely tightening the bevel locking

lever.

Be sure that the blade path is free of

nails. Always carefully inspect lumber

and remove all nails before cutting.

Always be sure that the blade clears

the work piece. Never start the saw with

the blade touching the work piece.

Always allow the motor to come to full

speed before starting a cut.

Support long work pieces when

cutting to minimize the risk of blade

pinching or kickback. The saw may

slip, walk or slide while cutting long or

heavy boards.

Never use a length-stop on the free

(scrap) end of a clamped work piece.

Never hold onto or bind the free (scrap)

end of the work piece in any operation. If

a clamp and a length-stop are used

together, ensure these are both installed

on the same side of the saw table to

prevent the saw from catching the loose

end and kicking up.

Never cut more than one work piece

at a time. Do not stack more than one

work piece on the worktable at a time.

Avoid awkward operations and hand

positions where a sudden slip could

cause your hand to move into the

blade. Always make sure that you have

good balance. Never operate the saw on

the floor or in a crouched position.

Only use the correct blades. Use the

correct blade size, style and cutting

speed for the material and the type of cut.

Do not use blades with incorrect size

holes. Never use blade washers or blade

bolts that are defective or incorrect.

Always keep blades clean and sharp

to minimize stalling and kickback.

Do not use dull or damaged blades.

Bent blades can break easily or cause

kickback. Inspect blade before each use.

Never hold a work piece by hand if too

small to be clamped. Always keep your

hands clear of the “no hands” zone.

Never apply lubricants to the blade

when it is running.

Never use solvents to clean plastic

parts. Solvents could dissolve or

otherwise damage the material.

Do not turn the motor switch on and

off rapidly. This could cause the blade

to loosen, which could create a hazard.

Should this ever occur, stand clear and

allow the saw blade to come to a

complete stop. Disconnect the saw from

the power source and securely tighten

the blade bolt.

Never leave saw unattended while it is

connected to a power supply. Turn

power off. Don’t leave the tool until it

comes to a complete stop.

SPECIAL SAFETY INSTRUCTIONS

6

Keep the motor air slots clean and

free of chips or dust. The motor should

be blown out or vacuumed frequently to

keep sawdust from interfering with the

motor ventilation. Disconnect the saw

from the power source before removing

dust.

Never lift this tool by gripping the

cutting handle or the miter fence. This

may cause misalignment. Always lock

the saw arm in the “DOWN” position and

then carry the saw by holding the base

or lift it using the carrying handle/

support bracket.

ADDITIONAL SAFETY INSTRUCTIONS

7

Know your power tool. Read the

Operator’s Manual carefully. Learn the

applications and limitations, as well as

the specific potential hazards related to

this tool. Following this rule will reduce

the risk of electric shock, fire or serious

injury.

Before beginning power tool

operation, always wear safety

goggles, safety glasses with a side

shield, or a full face shield when

needed. We recommend a Wide Vision

Safety Mask for use over eyeglasses or

standard safety glasses with side

shields. Always use eye protection

marked to comply with ANSI Z87.1.

Protect your lungs. Wear a face mask

or a dust mask if the operation

produces dust.

Protect your hearing. Wear

appropriate personal hearing protection

during use. Under some conditions and

duration of use, noise from this product

may contribute to hearing loss.

Protect your eyes. Wear eye

protection marked to comply with ANSI

Z87.1.

Protect your hands. Wear gloves

when handling blade. [Do not wear

gloves when operating saw]

All visitors and bystanders must

wear the same safety equipment that

the operator of the saw wears.

Inspect the tool cords periodically, if

damaged, have these repaired by a

qualified person.

Always check the tool for damaged

parts. Before further use of the tool, a

guard or other part that is damaged

should be carefully checked to

determine whether it will operate

properly and perform its intended

function. Check for misalignment or

binding of moving parts, broken parts,

and any other condition that may affect

the tool’s operation. A guard or other

part that is damaged should be properly

repaired or replaced by a qualified

person.

Save these instructions. Refer to

them frequently and use these to

instruct others who may use this tool. If

someone borrows this tool, make sure

he/she has these instructions also.

ELECTRICAL

8

WARNING: Do not permit fingers to

touch the terminal or the plug when

installing or removing the plug from an

outlet.

To reduce the risk of electric shock,

double-insulated tools are equipped with

a polarized plug (one blade is wider than

the other). This plug will fit into a

polarized outlet only one way. If the plug

does not fit in the outlet properly, reverse

the plug. If it still does not fit, contact a

qualified electrician to in

stall a polarized

outlet. Do not alter the plug in any way.

Double insulation eliminates the need for

the three-wire grounded power cord and

grounded power supply system.

Applicable only to Class II (doubleinsulated) tools. This compound miter

saw is a double-insulated tool.

WARNING: Double insulation does

not take the place of normal safety

precautions when operating this tool.

Before plugging in the tool, be sure that

the outlet voltage supplied i

s within the

voltage marked on the tool’s data plate.

Do not use “AC only” rated tools with a

DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your

body is grounded.

Do not expose power tools to rain or

wet conditions, and do not use power

tools in wet or damp locations. Water

entering a power tool will increase the

risk of electric sh

ock. This tool is

intended for indoor use only.

If operating a power tool in damp

locations is unavoidable, always use a

ground fault circuit interrupter to supply

power to the tool. Always wear

electrician’s rubber gloves and footwear

in damp conditions.

Inspect tool cords for damage. Have

damaged tool cords repaired by a

qualified person. Be sure to stay

constantly aware of the cord location,

and keep it away from the moving blade.

Do not abuse the cord.

Never use the

cord to carry the tool or to remove the

plug from the outlet. Keep the cord

away from heat, oil, sharp edges and

moving parts. Replace damaged cords

immediately. Damaged cords increase

the risk of electric shock.

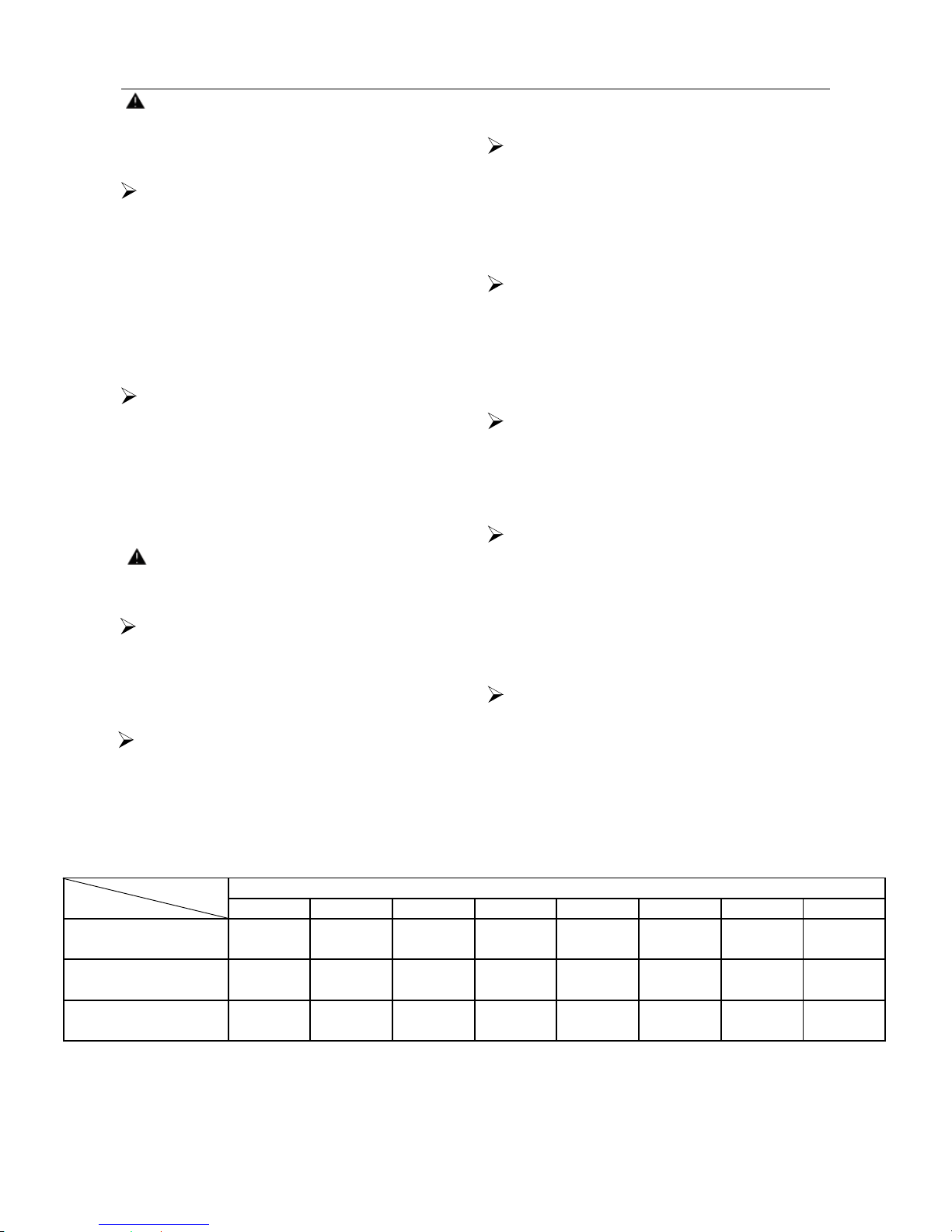

If you use an extension cord, make sure

to use only UL listed cords having the

correct gauge and length (see Table

1.2)

Table 1.2

Length

AMP RATING

25' 50' 75' 100' 125' 150' 175' 200'

18 18 16 16 14 14 12 12

Gauge Gauge Gauge Gauge Gauge Gauge Gauge Gauge

16 16 14 14 14 12 12 12

Gauge Gauge Gauge Gauge Gauge Gauge Gauge Gauge

14 14 12 12 12 12 12 -

Gauge Gauge Gauge Gauge Gauge Gauge Gauge Gauge

13.1-15

Total Extension Cord Length (in Feet)

0-10

10.1-13

APPLICATIONS

9

FUNCTION DESCRIPTIONS AND

INTENDED USE

This miter saw has been designed for

making straight lengthways and crossway

cuts in to wood.

The capacity of this miter saw is designed

for cuts into hardwood and softwood.

This miter saw is not suitable for cutting

aluminum or other non- ferrous metals, or

alloys.

OPERATOR’S GLOSSARY OF TERMS

Bevel Cut: A cutting operation made

with the blade at any angle other than

90° to the miter table.

Blade Flange: A ring or collar on a

spindle or arbor that permits other

objects, such as a blade, to be attached

to it.

Chamfer Cut: A cut that removes a

wedge from a block of wood so that the

end (or part of the end) is angled at

more than 90°.

Compound Miter Cut: A cut made

using both a miter angle and a bevel

angle at the same time.

Crosscut: A cutting operation made

across the grain of the work piece.

Freehand Cut: Performing a cut

without using a fence, miter gauge,

fixture, work clamp, or other proper

device to keep the work piece from

twisting or moving during the cut. Do

not perform any operation freehand.

Use a clamp or a vise whenever

possible.

Kerf: The material removed by the

blade in a through cut, or the slot

produced by the blade in a non-through

or partial cut.

Kickback: A hazard that can occur

when the blade binds or stalls, throwing

the work piece back toward the

operator.

Miter Cut: A cutting operation made

with the blade at any angle other than

90° to the fence.

No-Hands Zone: The area between

the marked lines on the left and right

side of the miter-table base. This zone

is identified by the No-Hands Zone

symbols inside the lines marked on the

miter table base.

Non-through Cut: Any cutting

operation where the blade does not

extend completely through the

thickness of the work piece.

Revolutions Per Minute (RPM): The

number of turns completed by a

spinning object in one minute.

Saw-Arm Locking Pin: Locks the saw

arm in the “DOWN” position.

Saw Blade Path: The area over, under,

behind, or in front of the blade, as it

applies to the work piece; the area that

will be or has been cut by the blade.

Set: The distance that the saw blade

tooth is bent (or set) outward from the

face of the blade.

Slide Bars: Guide the saw arm when

making a slide cut.

Spindle Lock: Allows the user to stop

the blade from rotating while tightening

or loosening the blade screw during

blade replacement or removal.

Throat Plate: A plate inserted in the

Miter Saw’s table that allows for blade

clearance.

Through Sawing: Any cutting

operation where the blade extends

completely through the thickness of the

work piece.

Work Piece or Material: The item on

which the cutting operation is

performed. The surfaces of a work

piece are commonly referred to as

faces, ends, and edges.

Loading...

Loading...