Ironton 45985 Owner's Manual

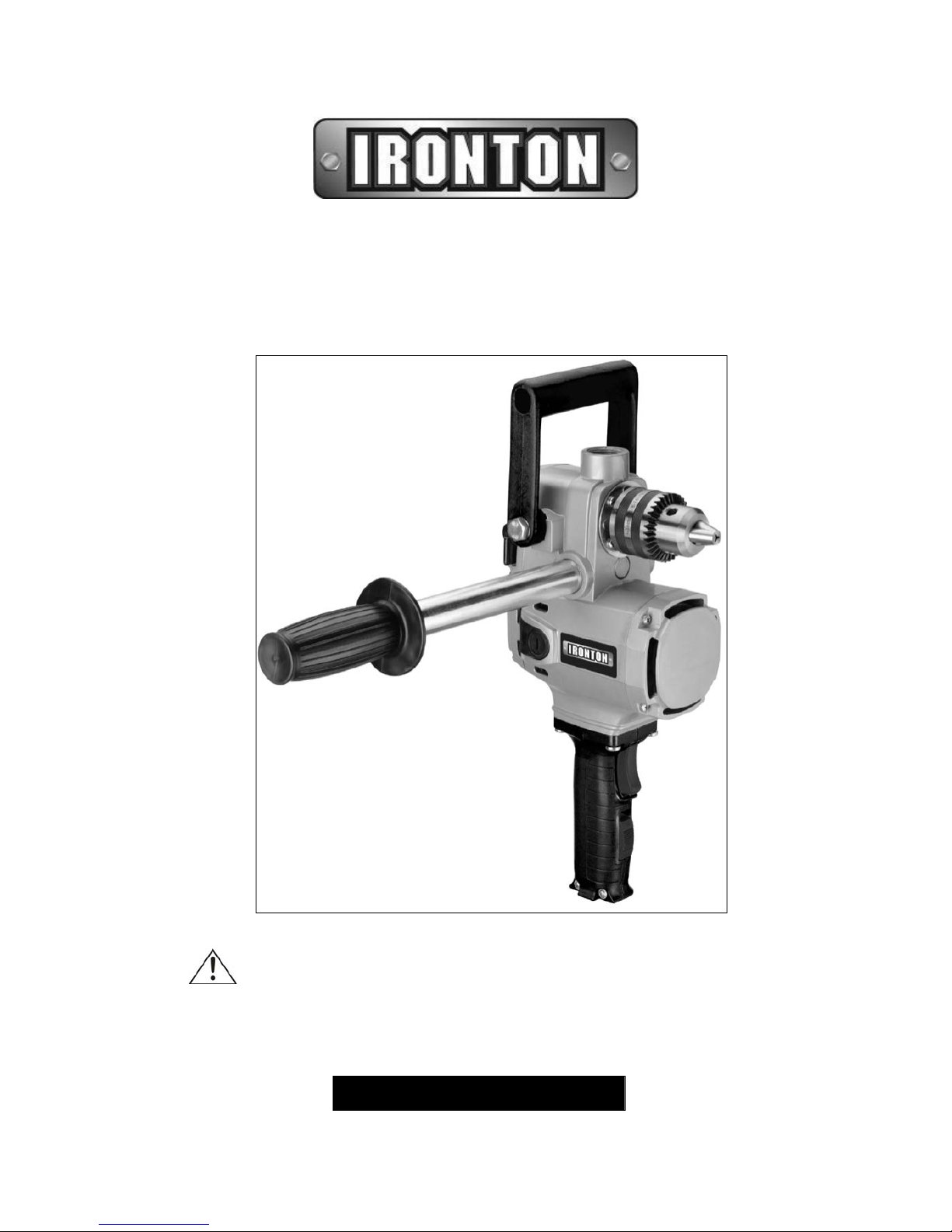

COMPACT RIGHT ANGLE DRILL

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

Item# 45985

Page of 13

2

Thank you very much for choosing an Ironton product! For future reference, please complete

the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This machine is designed for certain applications only. The distributor cannot be responsible for

issues arising from modification. We strongly recommend this machine not be modified and/or

used for any application other than that for which it was designed. If you have any questions

relative to a particular application, DO NOT use the machine until you have first contacted the

distributor to determine if it can or should be performed on the product.

For technical questions please call 1-800-222-5381.

INTENDED USE

This Compact Right Angle Drill is designed for drilling between studs and joints.

TECHNICAL SPECIFICATIONS

Voltage /Frequency:

120V / 60Hz

Power:

8 Amp

Rated running speed:

340 and 1375 RPM

Chuck size capacity:

1/8 in. to 1/2 in. Shank Diameter Drill Bits

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this Compact Right Angle

Drill until they have read this manual and have developed a thorough understanding of how

the Compact Right Angle Drill works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors that cannot be built into this

product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Page of 13

3

IMPORTANT SAFETY CONSIDERATIONS

WORK AREA

• Keep your work area clean and well lit. Cluttered and dark work areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks, which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

WARNING: Always check to ensure the power supply corresponds to the voltage on

the rating plate.

• Grounded tools must be plugged into an outlet properly installed and grounded in accordance

with all codes and ordinances. Never remove the grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to

whether the outlet is properly grounded. If the tools should electrically malfunction or break

down, grounding provides a low resistance path to carry electricity away from the user.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators.

There is an increased risk of electric shock if your body is grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not abuse the power cord. Never use the power cord to carry the tools or pull the plug from

an outlet. Keep the power cord away from heat, oil, sharp edges or moving parts. Replace

damaged power cords immediately. Damaged power cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A”or “W.”

These cords are rated for outdoor use and reduce the risk of electric shock.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

• Do not let your fingers touch the terminals of plug when installing or removing from the outlet.

• Ground fault circuit interrupters. If work area is not equipped with a permanently installed

Ground Fault Circuit Interrupter outlet (GFCI), use a plug-in GFCI between power tool or

extension cord and power receptacle.

PERSONAL SAFETY

• Stay alert. Watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving

parts. Air vents often cover moving parts and should be avoided.

• Avoid accidental starting. Be sure the power switch is off before plugging in. Carrying power

tools with your finger on the power switch, or plugging in power tools with the power switch on,

invites accidents.

Page of 13

4

• Remove adjusting keys or wrenches before turning the power tool on. A wrench or a Remove

adjusting keys or wrenches before turning the power tool on. A wrench or key that is left

attached to a rotating part of the power tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the power tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Nonskid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions. Always wear ANSI-approved safety impact

goggles and thick rubber boots during use and maintenance.

GROUNDING

WARNING: Improperly connecting the grounding wire can result in the risk of electric

shock. Check with a qualified electrician if you are in doubt as to whether the out- let is properly

grounded. Do not modify the power cord plug provided with the tool. Never remove the grounding

prong from the plug. Do not use the tool if the power cord or plug is damaged. If damaged, have it

repaired by a service facility before use. If the plug will not fit the outlet, have a proper outlet

installed by a qualified electrician.

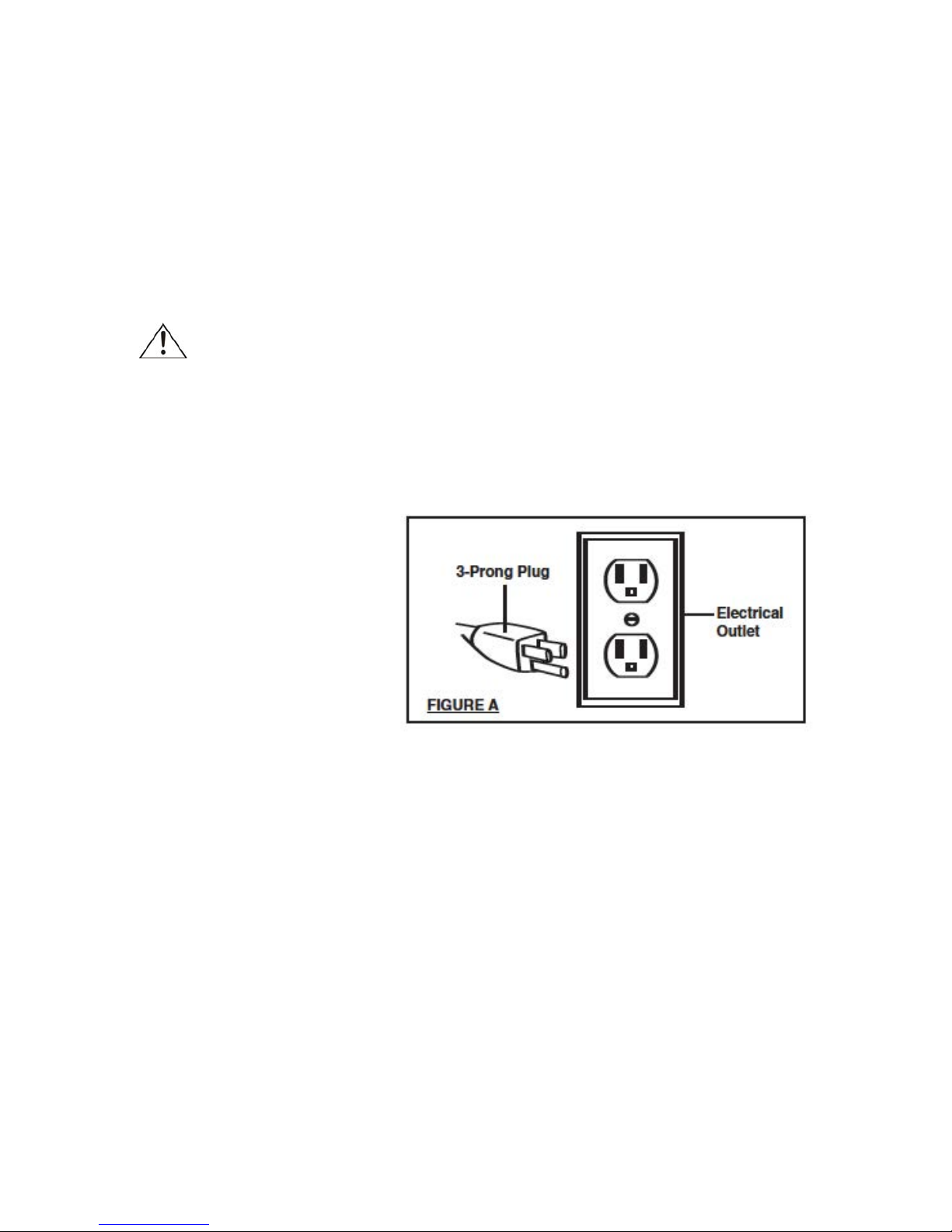

GROUNDED TOOLS: TOOLS WITH THREE-PRONG PLUGS

1. Tools marked with “Grounding

Required” have a three-wire cord

and three-prong grounding plug.

The plug must be connected to a

properly grounded outlet. If the tool

should electrically malfunction or

break down, grounding provides a

low resistance path to carry

electricity away from the user,

reducing the risk of electric shock.

(See Fig. A)

2. The grounding prong in the plug is connected through the green wire inside the cord to the

grounding system in the tool. The green wire in the cord must be the only wire connected to the

tool’s grounding system and must never be attached to an electrically “live” terminal. (See Fig. A)

3. Your tool must be plugged into an appropriate outlet, properly installed and grounded in

accordance with all codes and ordinances. The plug and outlet should look like that in the following

illustration. (See Fig. A)

EXTENSION CORDS

1. Grounded tools require a three-wire extension cord.

2. As the distance from the supply outlet increases, you must use a heavier gauge extension cord.

Using extension cords with inadequately sized wire causes a serious drop in voltage, resulting in

loss of power and possible tool damage. (See Fig. B next page)

3. The smaller the gauge number of the wire, the greater the capacity of the cord. For example, a

14-gauge cord can carry a higher current than a 16 gauge cord. (See Fig. B.)

Loading...

Loading...