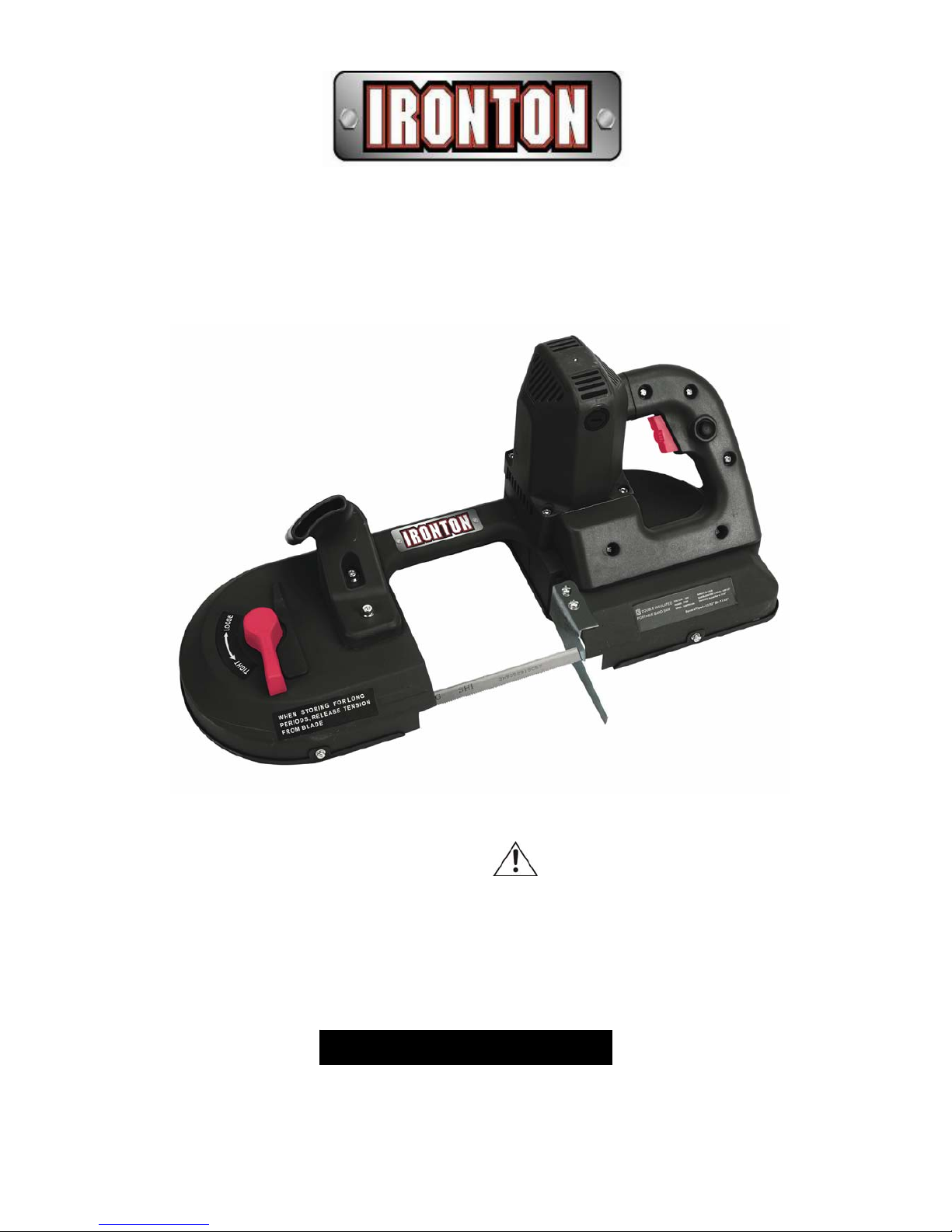

Ironton 45967 Owner's Manual

PORTABLE BAND SAW

OWNER’S MANUAL

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

Item# 45967

Page of 10 2

Thank you very much for choosing an IRONTON product! For future reference, please complete the

owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This machine is designed for certain applications only. The distributor cannot be responsible for

issues arising from modification. We strongly recommend this machine not be modified and/or

used for any application other than that for which it was designed. If you have any questions

relative to a particular application, DO NOT use the machine until you have first contacted the

distributor to determine if it can or should be performed on the product.

For technical questions please call 1-800-222-5381.

INTENDED USE

This Portable Band Saw features a needle bearing mounted spindle and 3 bearing blade guides

for smooth, accurate cuts. Light weight for easy transport to the job site.

TECHNICAL SPECIFICATIONS

ITEM DESCRIPTION

Voltage 120V / 60Hz

Power Input 660W

Blade Speed 230 FPM (feet per minute)

Max. Cutting Capacity

Round Pipe : 4-17/32"

Square Pipe : 4-17/32" x 4-17/32"

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this Portable Band Saw until

they have read this manual and have developed a thorough understanding of how the

Portable Band Saw works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors that cannot be built into this

product, but must be supplied by the operator.

Page of 10 3

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY CONSIDERATIONS

Metalworking can be dangerous if safe and proper operation procedures are not followed. As with

all machinery, there are certain hazards involved with the operation of the product. Using the

machine with respect and caution will considerably lessen the possibility of personal injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator

may result. Safety equipment such as guards, push sticks, hold–downs feather boards, goggles,

dust masks and hearing protection can reduce your potential for injury. But even the best guard

won't make up for poor judgment, carelessness or inattention. Always use common sense and

exercise caution in the workshop. If a procedure feels dangerous, don't try it. Figure out an alternate

procedure that is safe REMEMBER: Your personal safety is your responsibility.

This machine was designed for certain applications only. We strongly recommend that this machine

not be modified and /or used for any application other than that for which it was designed. If you

have any questions relative to a particular application: DO NOT use the machine until you have first

contacted the seller to determine if it can or should be performed by the product.

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS

PERSONAL INJURY. SAVE THESE INSTRUCTIONS.

1. FOR YOUR OWN SAFETY, READ THIS INSTRUCTION MANUAL BEFORE OPERATING

THE TOOL. Learn the tool applications and limitations as well as the specific hazards

particular to it.

2. KEEP GUARDS IN PLACE and in working order.

3. ALWAYS WEAR EYE PROTECTION.

4. REMOVE ADJUSTING KEYS AND WRENCHES. Make a habit of checking to see that all

adjusting tools are removed from the tool before turning it on.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

6. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet

locations, or expose them to rain. Keep work area dry.

7. KEEP CHILDREN AND VISITORS AWAY. All children and visitors should be kept a safe

distance from the work area.

8. MAKE WORKSHOP CHILDPROOF. Use padlocks, master switches, or by removing starter

keys.

9. DON'T FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

10. USE CORRECT TOOL. Don't force tool or attachment to do a job for which it was not

designed.

11. WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other

jewelry to get caught in moving parts. Nonskid foot wear is recommended. Wear protective

hair covering to contain long hair.

12. ALWAYS USE SAFETY GLASSES. Wear safety glasses (must comply with ANSIZ87.1)

Everyday eyeglasses are not impact resistant. Also use face or dust mask if cutting

operation is dusty.

13. SECURE WORK. Use clamps or a vise to hold work, when practical use both hands to

Loading...

Loading...