IRIS Spreaders VIKING-6000W, VIKING-4000, VIKING-6000WT, VIKING-8000, VIKING-4000W Operator's Manual

...

FERTILIZER SPREADER

Dry fertilizer Spreader for tractor - Mod. VIKING MODEL

OPERATOR'S MANUAL

& Please Read this operator's manual before operating the machine

- INDEX -

1. Introduction ....................................................................................... 1

2. Technical data ................................................................................... 2-4

3. Terminology ....................................................................................... 5

4. Operation ................................................................................................. 6-7

5. Important safety information .................................................. 8-9

6. Checkup ................................................................................................. 10

7. Storage ................................................................................................... 10

8. Trouble shooting ............................................................................... 11

9. Parts sales & After service .......................................................... 12

10. Complimentary check & Repair .............................................. 12

11. Certificate of quality assurance .......................................... 13-18

1. Introduction

1) Stainless steel hopper that does not rust.

2) Spreads dry granular fertilizer, organic compost, lime, pellet, etc.

3) Capacity : 2ton, 3ton, 4ton, 6ton, 8ton, 10ton

4) The stainless steel chain conveyor system allows exact transfer

of fertilizer to spread exact amount of it.

5) Width of stainless steel chain conveyor : 500mm, 800mm

6) Based on the wheel driving system, you can spread the same amount

of fertilizer regardless of working speed.

7) Conveys exact power by using a steel mesh wheel, without causing

a sip from the wheel.

8) Tandem axle (VIKING-8000, 8000W, 10000, 10000W)

Single axle (VIKING-2000, 3000, 4000, 4000W, 6000, 6000W)

9) Tandem axle available for VIKING-6000,6000W

10) Amount of fertilizer can be controlled in the tractor by using

the switchgear of oil hydraulic cylinder.

11) The size of the fertilizer opening is set in advanced, to spread

the exact amount of designated fertilizer.

- 1 -

Model

VIKING-2000

VIKING-3000

VIKING-4000

VIKING-4000W

Hopper Capacity

1.8㎥

2.7㎥

3.6㎥

3.6㎥

Nominal Capacity

2ton

3ton

4ton

4ton

Weight of

the Machine(㎏)

1135

1185

1450

1630

Width(㎜)

2250

2250

2360

2360

Height(㎜)

1570

1795

2115

2115

Length(㎜)

4326

4326

4373

4373

Feed Mesh Chain

Width(㎜)

500

500

500

800

Disc Size(mm)

600

600

600

800

Spreading Width(m)

20~30

AXLES

Single axle

TIRES

11.5/80-15.3 tires X 2

400/60-15.5 tires X 2

POWER

Ground Driven/Hydraulic

2. Technical date

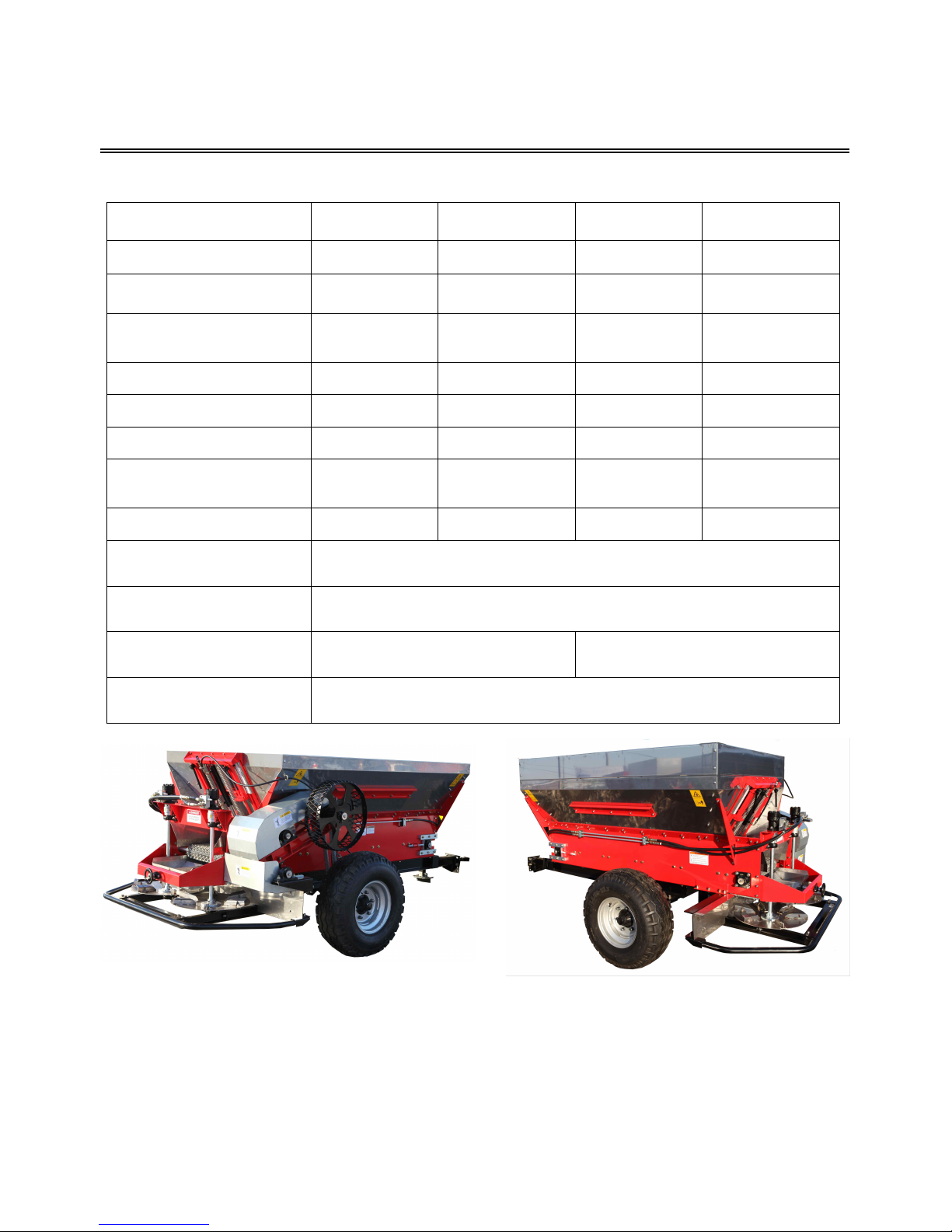

VIKING-2000 VIKING-4000

- 2 -

Model

VIKING-6000

VIKING-6000W

VIKING-6000T

VIKING-6000WT

Hopper Capacity

5.3㎥

5.3㎥

5.3㎥

5.3㎥

Nominal Capacity

6ton

6ton

6ton

6ton

Weight of

the Machine(㎏)

1760

1940

1910

2090

Width(㎜)

2460

2460

2460

2460

Height(㎜)

2450

2460

2450

2460

Length(㎜)

4810

4845

4810

4845

Feed Mesh Chain

Width(㎜)

500

800

500

600

Disc Size(mm)

600

800

600

800

Spreading Width(m)

20~30

AXLES

Single axle

Tandem axle

TIRES

500 X 17 tires X 2

11.5/80-15.3 tires X 4

POWER

Ground Driven/Hydraulic

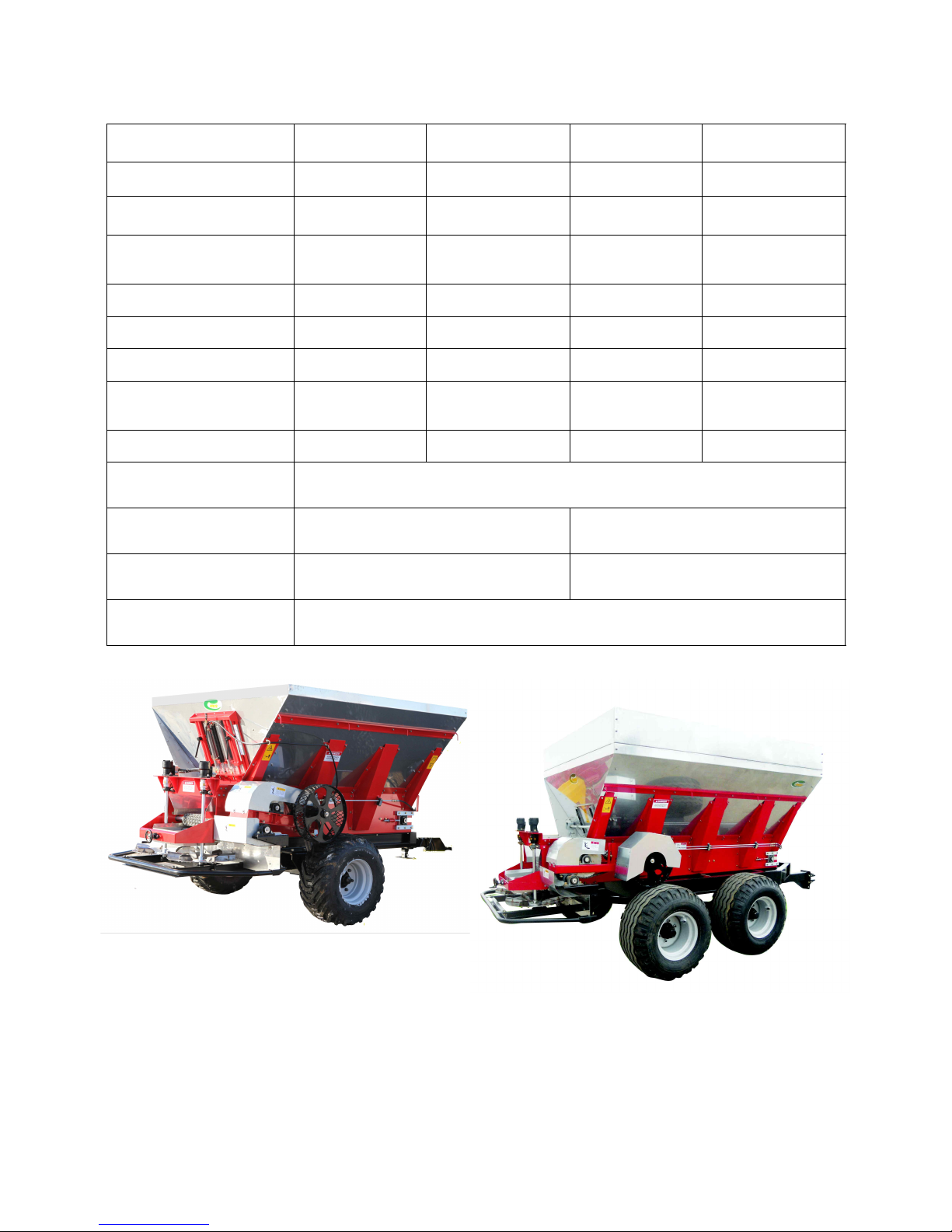

VIKING-4000 VIKING-6000T

- 3 -

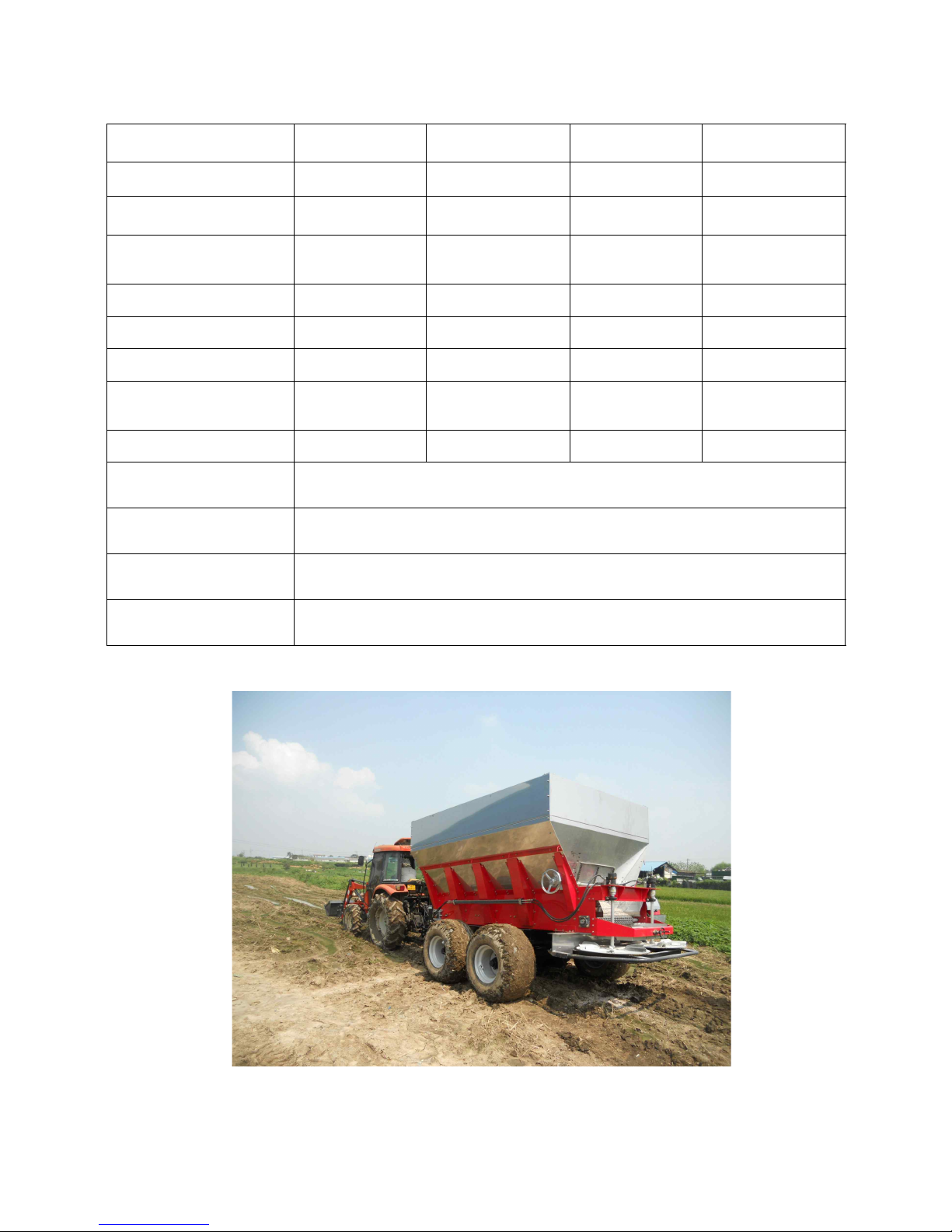

Model

VIKING-8000

VIKING-8000W

VIKING-10000

VIKING-10000W

Hopper Capacity

7㎥

7㎥

8.7㎥

8.7㎥

Nominal Capacity

8ton

8ton

10ton

10ton

Weight of

the Machine(㎏)

2380

2560

2470

2650

Width(㎜)

2500

2500

2500

2500

Height(㎜)

2430

2400

2680

2670

Length(㎜)

5540

5575

5540

5575

Feed Mesh Chain

Width(㎜)

500

800

500

800

Disc Size(mm)

600

800

600

800

Spreading Width(m)

20~30

AXLES

Tandem axle

TIRES

500 X 17 tires X 4

POWER

Ground Driven/Hydraulic

- 4 -

3. Terminology

VIKING MODEL

➀

➁

➂

➃ ➄

➅ ➆

➇

⑨

➀ Extension Hopper ➁ Stainless Hopper

➂ Hopper Brace ➃ Hydraulic Motor

➄ Steel Mesh Wheel ➅ Spreading Disc

➆ Drawbar ➇ Tire

⑨ Frame

- 5 -

4. Operation

1) Connect and fix the pintle behind the tractor with the pintle.

on the front of the fertilizer distributor with a pin.

2) Connect the pin plug of oil hydraulic motor and pin plug of the steel

mesh wheel driving cylinder to the pin plug socket of the tractor.

3) Check if the shutter is closed and load fertilizer and dry compost, etc.

in the hopper.

4) Put on the fixing stand and move it safely to the place you want to

spread.

5) Open and close the shutter according to the desired amount.

Handle Type Hydraulic Type

- Handle type: open and close the shutter by rotating the handle.

- Hydraulic type: rotate two handles and set it to the desired level; and

open and close the shutter in the tractor

(The shutter opens until the point marked on the gauge)

- 6 -

6) Operate the operation lever of steel mesh wheel driving cylinder on the

desired place, to contact the steel mesh wheel and the tire.

7) Operate the hydraulic motor lever and rotate the driving plate.

8) Run the tractor to spread fertilizer and dry compost, etc.

- 7 -

5. Important safety information

① Before Operation

1) Read the manual and instruction on the machine carefully and learn

how to use it properly

2) Wear simple clothes and safety device during operation.

3) When two or more people are working together, watch and check each

other during operation.

4) Make sure there is nobody and no obstacle within the working space of

the fertilizer distributor.

5) Avoid extreme operation and shock.

6) Do not remove the safety cover on the back of the gear chain.

7) If there is an error during operation, turn off the tractor engine,

stop the parking brake, and refer to the error and response.

(See 8. Trouble shooting Tips)

8) Do not remove the safety cover on the power transmission mesh wheel.

9) Inspect the machine before use. (Especially, the looseness of the bolt

and nut, joint pin, grease oil, etc.)

10) Comply with the traffic laws while driving.

11) Before starting to control each part, stop the tractor engine first.

12) Make sure there is nobody and no obstacle within the working

perimeter.

13) Check the machine’s operation by warm-up driving.

14) Excessive operation and shock can shorten the life of the machine.

15) Do not sit anywhere else than the driver’s seat.

16) Install and remove the oil hydraulic coupler after stopping the engine.

17) If an abnormal behavior of the machine is noticed, stop the engine

first before checking.

- 8 -

② During Operation

1) Drive at a safe speed on a slope or unsafe road.

2) Make sure to put on the luminous sign during the night driving.

3) Turn off the hydraulic unit lever when driving on the road.

4) When the equipment malfunctions, turn off the engine first and check.

5) If you have to leave the tractor during operation, make sure to stop

the engine and put on the parking brake. If there is no parking brake,

use the propping device on the front and back of the wheels.

6) Attaching or detaching of hydraulic unit’s coupler should be performed

after turn off the engine.

7) Do not sit anywhere on the tractor except driver’s seat.

③ After Operating

1) After operation is finished, wash with water and let it dry.

Inspect thoroughly and apply oil on the parts with risk of corrosion to

prevent problem for future operation.

2) Prop the main body and other parts so that they do not fall.

(Pay attention to the safety of children)

3) For long-term storage, put on the protection cover and store in

a storehouse away from rain and snow.

- 9 -

6. Checkup

1) Make sure to apply oil before operation and check the looseness

of bolt and nut, etc.

2) Place the spreader on the flat surface and check if it balances (left and

right) with the tractor.

3) Test-drive before operation to check if there is any error.

4) Check the air pressure of tires.

5) Before operation, check if the power transmission device (hydraulic-

device, chain, etc.) is properly installed.

6) After operation, wash the fertilizer distributor and dry. Apply rust

preventive oil to the parts with risk of corrosion and store in a

safe place

7. Storage

1) For long-term storage, apply rust preventive oil to the parts with risk

of corrosion.

2) When storing the fertilizer distributor and tractor separately, fix the

distributor prop.

3) Prop the fertilizer distributor properly on an even floor so that it does

not fall. Especially, make sure to prevent safety-related accident caused

by children.

4) For long-term storage, store in a storehouse and, when storing

outdoors, put it on an even floor and cover it to protect it from rain

and snow.

5) After use, clean thoroughly to prevent damage caused by animals.

6) Store in a way to prevent foreign substances from entering the power

transmission device.

- 10 -

Symptom

Inspection

Response

hydraulic motor is not

working well

Check if the valve of

the oil pipe is closed

If the oil supply line has

no problem, check if the

shaft is intact and

replace it

Oil is leaking from the

hydraulic coupler

Check if the coupler joint

is loosened

If loosened, fasten the

joint. If it is excessively

worn, replace the part

Chain makes noise when

rotating, and the chain

sprocket slips

Check if it is touched,

the wear of the chain,

adjustment of tension

- Remove the touched

part,

- Maintain the chain

tension

- If excessively worn,

replace the part or

raise the tension

Chain sprocket does not

rotate

Check the damage of the

axle joint, chain’s power

transmission part

Fix the key if it is

displaced

If the axle is damaged,

replace and fix it firmly

The spreading discs

direction is reverse

Check the damage of the

hydraulic check valve

Replace if it the check

valve is damaged

The driving plate

shakes too much

Check if it is touched or

shocked during operation

Replace if it is excessive

Oil is leaking from the

hydraulic motor

Check damage or wear

of the retainer

Replace if worn

excessively

The hydraulic motor

stops after rotating

Check the amount of

hydraulic pressure

Supply hydraulic oil

The distribution is not

even

- Replace the chain if it

is too old

- Check the wear of

chain sprocket and

replace if worn

excessively

The chain makes noise

Check if there is foreign

substance, wood chip, or

gravel stuck while

transportin the fertilizer,

and remove them

8. Trouble shooting

- 11 -

Model

Number

Description

Quantity

VIKING-4000

Vane

1

9. Parts sales & After service

Parts sales

1) The parts list provided is in compliance with VIKING MODEL

standards. Refer to this list when order any parts.

2) Follow next steps as below when order parts:

ex) We would like to order 1 unit of Vane

3) To purchase the parts, contact the dealer where you purchased the

equipment or our main office.

After service

1) If any malfunction occurs, please refer to “Trouble Shooting” section

first.

2) If “Trouble Shooting”does not solve the issue, contact authorized dealer

or manufacturer’s After Service Department.

10. Complimentary check up & Repair

1) The limited warranty is good for one year from the date the equipment

was delivered to the consumer.

2) Even after one-year warranty period, we would gladly check up and

repair the equipment at a reasonable price.

3) With a faith that any one-time customer is a customer for forever, we

would continue to take care of our company’s products for you until

they last.

- 12 -

CERTIFICATE OF QUALITY ASSURANCE

All products manufactured and sold by IRIS SPREADERS,

Co. are designed and assembled in accordance with

regulations on farm machinery under very strict quality

management. If the product is managed and used in

accordance with instructions on regular check-ups and

maintenance schedule provided in the owner’s operation

manual then we assure you that the product always will

be at its best condition and outstanding performance, and

safely maintained. Thus, we are pleased to offer you the

assurance terms as below.

1. SCOPE OF WARRANTY

If the product you purchased was managed and used in

accordance with instructions on regular check-ups and

maintenance schedule provided in the owner’s operation

manual AND the product is still within warranty period and

used less than allowed usage time for warranty AND

technical analysis reveals that the malfunction was caused

by quality of the parts or manufacturing defects, we will

repair it or exchange with our qualified replacement parts.

▶ On delivery the customer should check the censure that the

machine has not been damaged in transit, and that it

complies with that ordered as that it is complete with all the

accessories as specified in the purchase contract. If it is

found defective, a written complaint should be sent within

8 days of receipt of the same.

2. WARRANTY PERIOD: 1 FULL YEAR

When the product requires complementary repairs or

maintenance, simply Present “Certificate of Warranty” to

an authorized dealer or our main office for inspections

and repairs.

3. RESPONSIBILITIES OF THE OWNER

Since any unauthorized inspections or use of non-genuine

parts that are not prescribed in Owner’s Operation Manual may

decrease the performance of the parts or cause fatal damages

to the product, it is very critical to follow all the instructions

prescribed in the Owner’s Operation Manual and Certificate of

Quality Assurance.

4. EXCLUSIONS (Even within Warranty Period)

1) Items to be checked frequently for management :

cleaning fuel-related parts,

Items to be checked on regular basis :

inspection of breaks and adjustment

2) Wear and Tear parts

(except manufacturer’s defect):

filters, elements, rubber parts, vinyl parts, fuse, and wires.

3) Any malfunction or defect caused by using unspecified fuel

(low quality fuel or contaminated fuel)

4) Any malfunction caused by not complying with instructions

prescribed in Owner’s Operation Manual or Warning Signs

5) Any defect caused by unauthorized modification of the

product or use of non-genuine parts.

6) Any defect caused by negligence in storing and managing

such as damages due to extreme weather conditions.

7) Minor issues not related with the function (smell, vibrations,

shape, sensitivity)

8) Major discrepancies between the parts and its serial

numbers recorded in our data base.

9) Malfunction caused by natural calamities.

5. PROCEDURE FOR WARRANTY REPAIR

6. In case we upgrade the specifications of certain model, we do

not have any responsibility to upgrade

the already-sold-equipments.

7. TRANSFER OF WARRANTY

Since we honor the remaining warranty time even after the

transfer of ownership through sale or donation, it is very

important to acquire the Certificate of warranty when transfer of

the product takes place.

※ We will honor all the terms prescribed above. However if you

are not satisfied with the service provided to you, you may

contact our customer service center directly and we will do our

best to support you.

Name

Address

Model Name

Model #

Serial #

Date of

Purchase

Date of Service

Used

Time

Name

Address

Model Name

Model #

Serial #

Date of

Purchase

Date of Service

Used

Time

WARRANTY INFORMATION

○ In order for us to guarantee our highest quality on our products, we

offer complimentary inspections in designated agencies. If any

malfunction occurs caused by manufacturing defect during warranty

period, we will repair or replace the parts at free of charge.

○ WARRANTY EXCLUSIONS:

1. Modified products

2. Missed or skipped check-ups and measures

3. Damages or malfunction caused by negligence

Certificate of After Service ( 1 )

Please bring this certificate within 1 year from the date of purchase to

have routine inspection.

This certificate should be submitted when you request an inspection.

Certificate of After Service ( 2 )

Please bring this certificate within 1 year from the date of purchase to

have routine inspection.

This certificate should be submitted when you request an inspection.

DATE

PERFORMED

TECHNICIAN

CONFIRMED

After Service Execution Report

Loading...

Loading...