Page 1

216/316

USER GUIDE

Page 2

Contents:

PAGE! SECTION!

3! 1.01! ! INTRODUCTION

3! 1.02! ! MANUAL VALIDITY

3! 1.03! ! DETECTION RANGES

3! 1.04! ! CONVENTIONS

3! 1.05! ! IMPORTANT WARRANTY INFORMATION

4! 2.01! ! WARNINGS & IMPORTANT PRODUCT INFORMATION

5! 3.01! ! TYPICAL SYSTEM EXAMPLES

6! 4.01! ! CAMERA CONTROL DATA

6! 4.02! ! CABLING REQUIREMENTS

6! 4.03! ! SETTING CAMERA ADDRESS

6! 4.04! ! INSTALLATION CONSIDERATIONS

6! 4.05! ! PROTOCOL INFORMATION

7! 5.01! ! HARDWARE INSTALLATION

9! 6.01! ! CONNECTIONS

9! 6.02! ! VIDEO CONNECTIONS

9! 6.03! ! DATA CONNECTIONS

9! 6.04! ! POWERING UP

10! 7.01! ! CONTROLLING THE CAMERA

12! 8.01! ! PROTOCOL LIST

14! 9.01! ! CAMERA ADDRESS TABLE

15! 10.01! ! SPECIFICATIONS

16! -! ! BACK COVER / CONTACT DETAILS

Page 3

1.01 Introduction

IRIS216 and IRIS316 Thermal Imaging PTZ cameras convert

heat emitted and reflected from objects into a detailed visual

image. This means they can be used to provide visibility in

absolute zero light conditions.

They provide an incredibly powerful method to help navigate at

night and in low light or poor visibility conditions. Any changes in

temperature greater then 50mK are detected, meaning it's

possible to observe reflections of objects, footprints after a

person has left the area or even the texture of snow and ice.

A powerful sensor known as a Micro-bolometer picks up the long

range infra red waveforms omitted and reflected by all objects

and converts them into electrical signals which are used to build

up a visual screen. The amount of pixels on the sensor and their

proximity to each other determine the sensitivity of the unit and

the resolution of the picture. The IRIS216 has a 384x288

resolution and the IRIS316 has a 640x480 resolution. The

IRIS216 is referred to as a QVGA resolution, although in fact it

has 44% more pixels than a standard QGVA image. The

IRIS316 is referred to as a VGA camera. Both cameras have a

pixel pitch of 17µm.

Iris thermal imaging cameras are perfect additions to both

leisure marine and commercial marine navigational and

situational awareness set-ups. They are also used widely by the

military and emergency services. Iris Thermal cameras are

feature rich, high quality situational awareness and night vision

tools. Because the wavelengths used are twenty times longer

than the wavelengths in the visible part of the spectrum, the

radiation undergoes less scattering by particles in the

atmosphere and as a result, visibility through smoke, mist and

fog can also be improved.

Iris Innovations range of Thermal Imaging cameras employ

cutting edge technology to enhance on board safety and

security in a variety of ways never seen before in the marine

industry. Key features include:

• Continuous ʻSmoothʼ Digital Zoom, up to 36x

• 9 Colour Palettes, each with reverse polarity

• 5 Scene Modes offer contrast and gain settings specially

designed to enhance the image in different circumstances.

• 4 Automatic Scan and Sweep Modes

• Realtime Positional Indicator

• 360˚ Variable Speed Continuous Rotation

• 210˚ Variable Speed Tilt Mode

• Auto-Flip Feature to Automatically Correct the Camera

Orientation when the Tilt Passes itʼs Tilt Azimuth

• Video Freeze Feature

• User Programmable Pattern Tours

• IRIS216 Model features 44% Greater Resolution then

Standard QVGA Cameras

• IRIS316 features 17µm Pixel Pitch for Superior Picture

Clarity.

• Thermal Sensitivity <50mK

• Standard or Hanging Mounting

1.02 Manual Validity:

This manual covers the installation and operation of Iris

Innovations 216 and 316 series Thermal Imaging PTZ cameras,

covering the following models: IRIS216-75 (NTSC Low refresh

rate(7.5Hz)), IRIS216-30 (NTSC High refresh rate(30.Hz)),

IRIS216-83 (PAL Low refresh rate(8.3Hz)), IRIS216-25 (PAL

High refresh rate(25Hz)), IRIS316-75 (NTSC Low refresh rate

(7.5Hz)), IRIS316-30 (NTSC High refresh rate(30.Hz)),

IRIS316-83 (PAL Low refresh rate(8.3Hz)), IRIS316-25 (PAL

High refresh rate(25Hz))

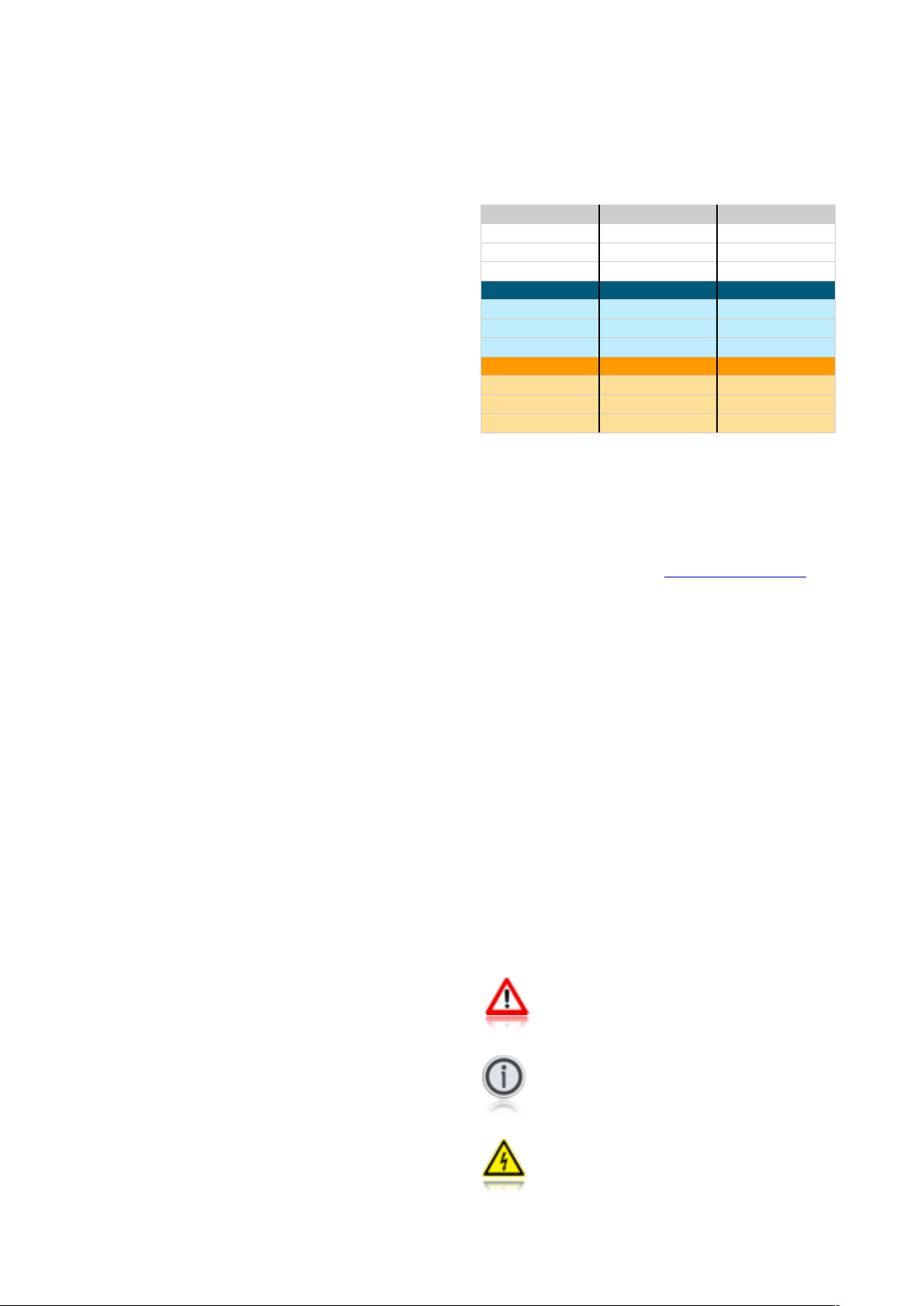

1.03 Detection Ranges

Based on NATO criteria for Human and Typical Vessel targets.

Actual range may vary depending on camera set up,

environmental conditions, user experience and type of monitor

or display used.

Model

IRIS216

IRIS316

Resolution & Pitch

384x288~25micron

640x480~17micron

Focal Length

18.5mm

25mm

HFOV

29.1˚

24.6˚

Person

1.8m H x 0.5m W

1.8m H x 0.5m W

Detection

454 Meters

897 Meters

Recognition

114 Meters

224 Meters

Identification

57 Meters

112 Meters

Boat / Vehicle

2.3m H x 2.3m W

2.3m H x 2.3m W

Detection

1289 Meters

2546 Meters

Recognition

322 Meters

637 Meters

Identification

161 Meters

318 Meters

1.04 Important Warranty Information.

This product is covered by a 1 year return to base warranty valid

from date of purchase. To qualify for an additional year warranty

free of charge beginning at the end of the original warranty

period and learn more about the terms and conditions of the

warranty, register your product at www.boat-cameras.com

1.04 Conventions:

At various points within this guide, the following icons will be

used to illustrate important or potentially dangerous information:

!!WA RNING

!!This symbol indicates a risk of damaging the

! ! camera or other items or an important issue that

! ! may effect the operation of the camera.

!!INFORMATION

!!This symbol points out important information

!!pertaining to the installation, operation and

! ! maintenance of the camera.

!!DANGER

!!This symbols alerts the user of a serious risk of

! ! damage or personal injury or death.

Page 4

2.01 Warnings & Important Product Information

WARNING: Installation and Operation

This product must be installed and operated in accordance with

these instructions. Failure to do so may result in poor product

performance, damage to the product or vessel and or personal

injury. Installation should only be carried out be qualified

personnel or by persons competent in electrical systems.

WARNING: Power Supply and Grounding

Ensure the boats power supply is switched off during

installation. Ensure suitably rated circuit breakers / fuses are

used in the installation of the product in accordance with the

electrical values shown in the technical specifications of the

product. Never switch on power until the power connections are

correctly terminated in accordance with the information provided

in this document. Do not connect or disconnect the product with

the power supply switched on. Never disconnect the DC ground

with the power supply on.

WARNING: Wiring terminations

Where the products video, power and data terminations are

extended, ensure that suitable connectors are used and that the

point of termination for each cable is adequately protected

against moisture ingress. Ensure correct polarity is strictly

observed. Do not cut or remove cable connectors without prior

permission from Iris Innovations Limited.

WARNING: Do Not Open the Unit

There are no user serviceable parts within the product so there s

no need to open the device other than temporarily removing the

Camera Address DIP Switch window whilst setting addresses.

Ensure the DIP switch window is correctly replaced and that the

rubber seal is not lost, pinched or damaged. The product has

been certified to IP66 standards, however, submersion or the

product or exposure to high pressure washing will invalidate the

warranty.

WARNING: Disclaimer

This product is intended to be used only as an aid to navigation

and must never be used as an alternative to correct navigational

practices and judgements made on the basis of approved

navigation methods. It is the users responsibility to observe

correct and proper navigational skill when using this product.

Only officially approved charts and notices to mariners contain

the current information required for safe navigation.

Operating the camera or viewing the video input whilst the

vessel is moving could cause a distraction and result in

accidental collision resulting in property damage, injury or death.

Iris Innovations cannot be held liable for any incidental, special,

indirect or consequential damages whether resulting from the

use, misuse or inability to use this product.

CAUTION: Service and Maintenance

This product contains no user serviceable parts. Please refer all

maintenance and repair issues to your authorized Iris

Innovations dealer. Any unauthoriZed work to the product may

affect the warranty.

CAUTION: Care and Cleaning

This product is a sensitive piece of electronic, imaging

equipment and must be handled and treated accordingly. Do not

drop or shake the unit during installation. Never manually alter

the pan or tilt position whilst the power to the unit is on as this

may permanently damage the motors. Avoid exposure of the

imager to direct sunlight where possible as this may degrade the

cameras performance over time.

When cleaning the device, ensure power is switched off to avoid

unintentional movement of the cameras motors. Clean the

camera housing with a soft cloth. Moisten the cloth and use a

mild detergent if required but take care not to get detergent on

the lens window. The lens window has a protective coating

which may suffer damage as a result of improper cleaning. To

clean the lens window use a soft cotton cloth. Moisten with clean

water if necessary. For further advise on cleaning the lens

window, contact Iris Innovations.

CAUTION: Export Controls

Variants of this product with a refresh rate in excess of 9Hz are

considered to be of Dual Use by various International Export

Control Authorities and may also fall under export regulations in

other countries. Failure to observe export controls have serious

consequences and could even result in criminal proceedings.

The UK Export List Classification for products within this range

with a refresh rate in excess of 9Hz is 6A003b4b.

Considerations to export control legislation must also be made

when re-exporting from licensed or exempt regions. These

products are controlled for export under US Department of

Commerce (DOC), Export Administration Regulations (EAR),

Export Control Classification Number (ECCN) 6A003.b.4.b.

These cameras contain a focal plane array controlled to

6A002.a.3.f.! U.S. Government authorization may be required

for all destinations except Canada.

INFORMATION: Product Disposal and Recycling

Dispose of this product in accordance with the WEEE Directive.

The Waste Electrical and Electronic Equipment (WEEE)

Directive requires the recycling of waste electronic and electrical

equipment. Iris Innovations supports the WEEE policy and

politely request you observe correct disposal methods. For

further information on how to correctly dispose of this product

please contact Iris Innovations.

Please recycle unwanted packaging and documentation. The

cardboard carton, all paper manuals and documents and the

protective plastic bag in which the camera is shipped are widely

recyclable. Please check with your local recycling plant for

confirmation.

Page 5

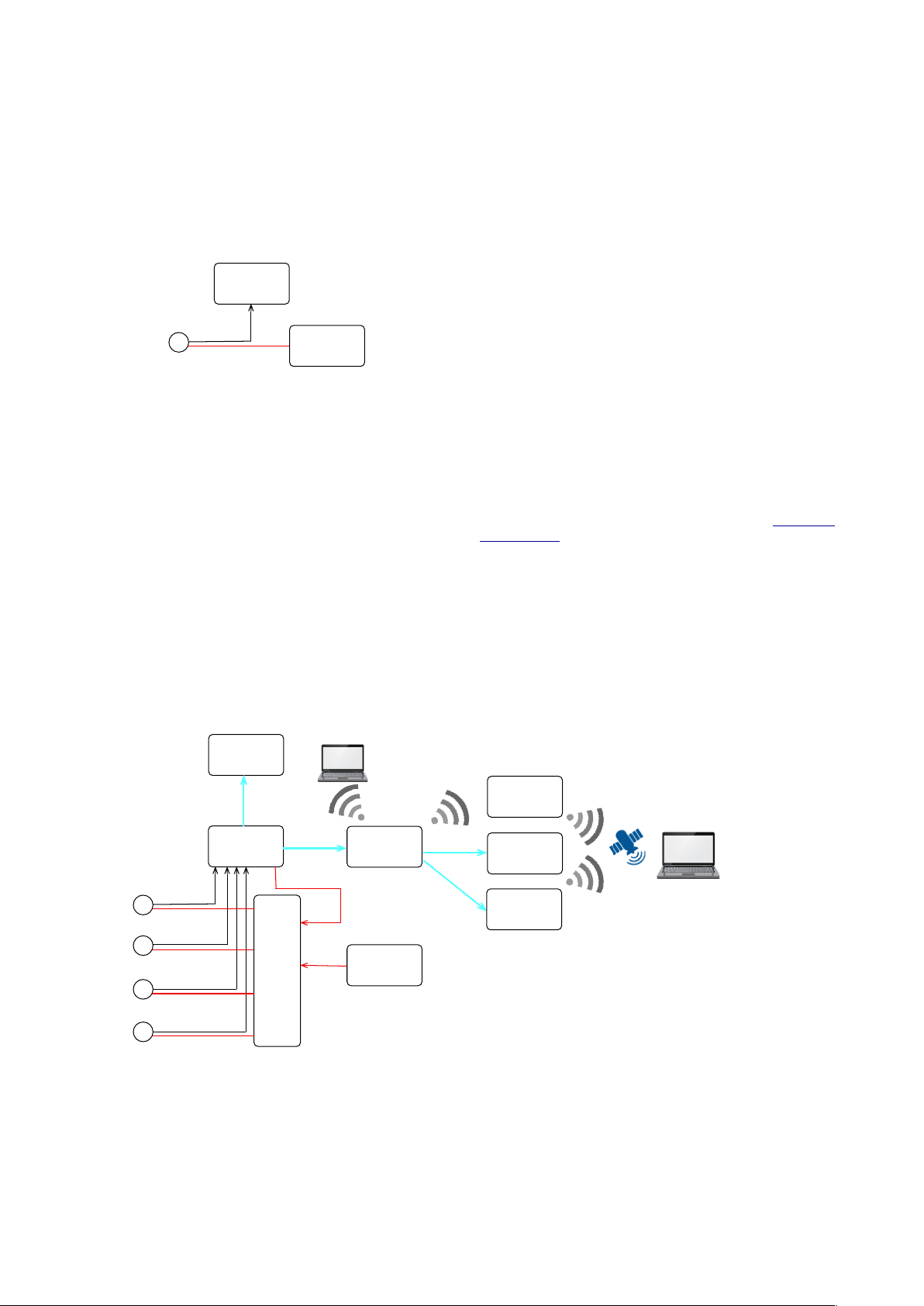

3.01 Examples of Typical Systems

A basic configuration will consist of a single camera, a camera

controller and a viewing medium (either a dedicated video

monitor or a multi-functional display (MFD)). The video feed

from the camera is routed directly into the MFD, and the control

data from the joystick is sent directly to the camera.

Systems become more complicated where there are multiple

cameras, monitors and/or controllers and where more complex

video and data transmission methods are employed such as

wireless or Internet Protocol (IP) conversions. The diagrams

below detail a number of different connection configurations.

In theory it is possible to have up to 255 controllable devices in a

system (cameras or controllers) and unlimited fixed cameras,

but this is obviously dependent on the video switching

equipment installed, the camera control data management and/

or the vessels on board LAN - and of coarse the size of the

vessel!

The key issue when installing multiple controllable cameras is

that they have individual addresses (see below). A popular

configuration would be something along the lines of 2 x

controllable cameras, 4 x fixed (static) cameras and 2 x

controllers. This would mean that the number of video inputs

required would exceed the amount of inputs offered by most

chart plotters and so a video switcher (such as the IRIS606 c

Camera switcher) would be required. Video from each camera is

routed into the video switcher and the output from the switcher is

then routed into a single input of the chart plotter. Switching is

controlled by a dedicated waterproof keypad connected to the

switcher. The data wires from each of the controllable cameras,

along with the data wires from the two controllers would then

need to be routed into a Serial Data Distributor (also known as

an Expander), such as the IRIS EXP0204. This simplifies

installation and prevents ʻcross-talkʼ and ʻreflectionsʼ and the

data line that can result in poor camera control and ʻover-runsʼ.

Full specifications for ancillary equipment such as video

switchers and data expanders can be found at www.boat-

cameras.com

Digital Video

Recorder / Video

Web Server

WiFi Router

Ethernet

Ethernet

Remote Connection:!

Home / Office!

Computer, iPad,

Cellphone etc...

Video Output!

(Live Video)

Chart Plotter !

/ Monitor

On Board Wireless

Network (iPad, Phone,

Laptop etc)

Pan Tilt Zoom!

Cameras

3G / 4G Cellular!

Modem

Ethernet

Satellite Internet

Tranceiver

Marina WiFi

Serial Data

Distributor

1

2

3

4

On-Board !

Camera !

Controller

Video

Video

Video

Video

Data

Data

Data

Data

Data

Data

Chart Plotter !

/ Monitor

Pan Tilt Zoom!

Camera

1

On-Board !

Camera !

Controller

Video

Data

Simple Camera to Monitor (Chart-Plotter)

Set Up

Complex Setup Depicting Local (On Board)

Functionality & Remote Functionality

Page 6

4.01 Camera Control Data

IRIS216/316 cameras are controlled via an RS485 serial data

connection, using a variant of the Pelco-D CCTV camera control

protocol. The Pelco-D protocol was designed to provide

accurate controls for a wide range of standard CCTV features,

such as pan, tilt, user preset features etc, but do not include

features specific to thermal imaging cameras and other

extended features supported by Iris cameras. Because of this,

Iris have mapped their product specific features to certain user

preset commands and to other modified Pelco-D commands.

This means that Iris thermal PTZ cameras can be controlled

either by a dedicated Iris joystick controller such as the IRIS516

or IRIS507, as well as other control devices, such as compatible

chart-plotters, multi-functional displays and third party joysticks.

For further information on compatible third party control

interfacing please contact Iris Innovations. For certain third party

interfacing, additional serial protocol convertors may be required

where NMEA0183 or NMEA2000 connections are used.

4.02 Cabling Requirements

The camera has a 3 meter tail into which a 50cm breakout cable

is connected. The breakout tail has the following connections:

Video (female 75Ω BNC connector), Data (2 x bare wires:

RS485+ (RED wire) and RS485- (Black wire)) and Power

(2.5mm DC Barrel Jack connector). Individual video, data and

power cables can be run back to the control position and power

distribution position or a combination cable (such as IRISCOMBPTZ-xx) can be used. Alternatively, an Active Video Balun

set can be used to allow a single CAT5 cable to be run. Please

note however that although Baluns facilitate the use of CAT5

cables, these should on no account be routed through ethernet

routing and switching hardware as this will cause permanent

damage. If Baluns are used, ensure the CAT5 cables are

managed completely separately from your IP network. Contact

Iris Innovations for further details.

Video cables need to be coaxial with an impedance of 75Ω such

as RG59, URM70 or similar.

Power cables need to be 2 core DC cable rated at 5A (maximum

voltage 36VDC)

Data Cables need to be twisted pair Belden style data cables

(0.5mm) or equivalent.

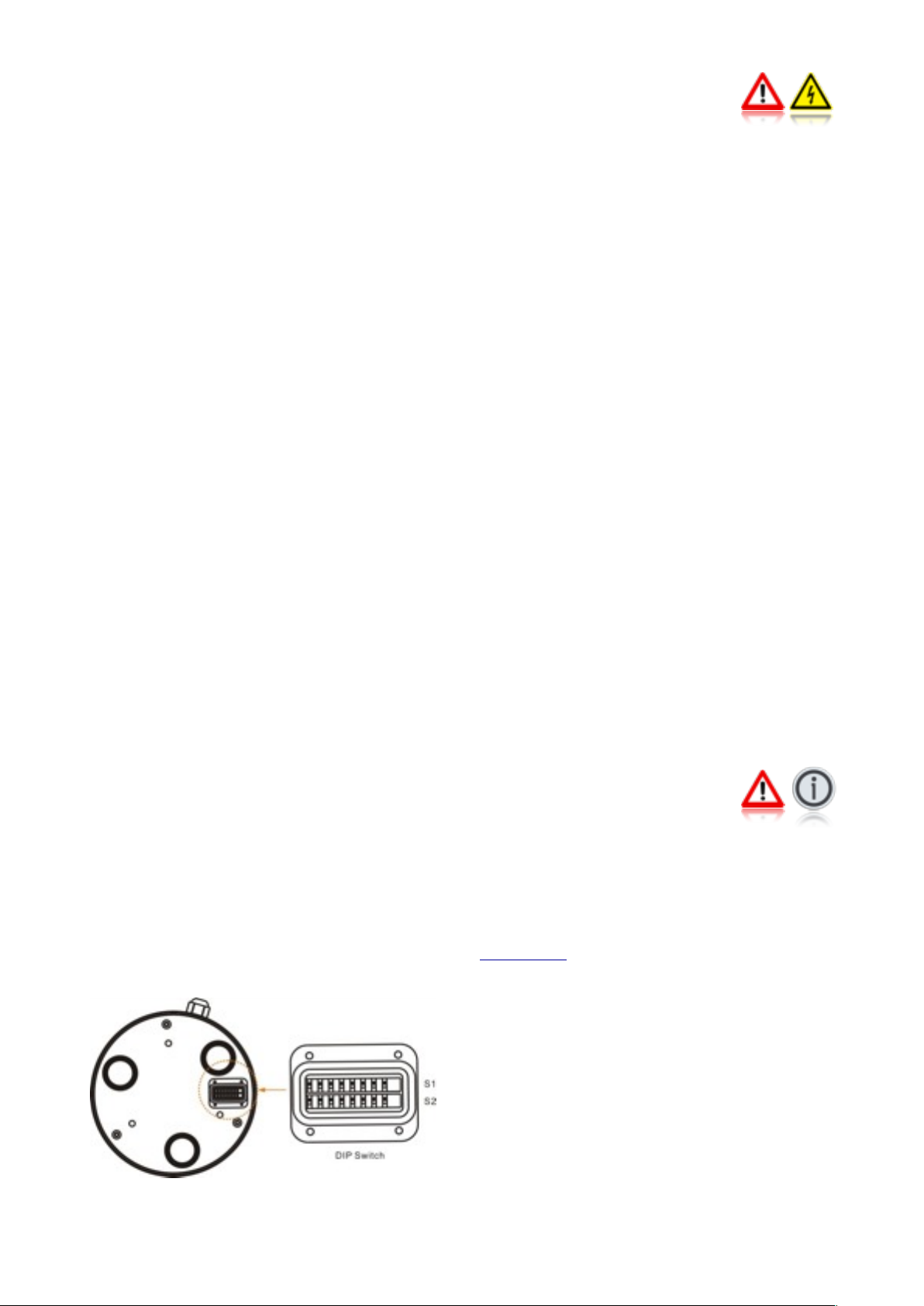

4.03 Setting Camera Address

Each camera must have itʼs own unique address so that only

control data intended for that camera is received and processed

by the camera. If multiple cameras had the same address, they

would all move together when pan and tilt commands are

transmitted.

To set the camera address, remove the DIP switch cover plate

on the base of the camera with a small cross-head screw driver,

taking care not to loose the 4 screws or the rubber ʻOʼ seal, and

set the DIP switches on switch bank 1 accordingly. A table

detailing the switch settings can be found at the end of this

document.

Once the desired address has been set, carefully replace the

DIP switch cover plate.

4.04 Installation Considerations

It's important to fully consider the intended position of the

camera and the desired fields of view prior to installation, in

terms of how you are going to get cables to the position, will the

camera be able to see the appropriate areas, will the camera

interfere with any other fixture such as a doorway or walkway

once it's fixed in place, or are there any obstructions behind the

surface onto which the camera is to be installed. It's strongly

recommended that if possible the camera should be temporarily

powered up prior to final installation and offered into position so

that these factors can be considered and any possible issue can

be addressed before holes are drilled and difficult, time

consuming and costly cable runs are attempted. Check third

party hardware to ensure it doesn't effect the operation of the

camera and vice versa.

4.05 Protocol Information

DIP switch bank 2 is reserved for setting the baud rate and

protocol details. This is factory set to 9600 Baud, Pelco-D

Protocol, N-8-1 (No Parity Bits, 8 Data Bits, 1 Stop Bit). Do not

attempt to change these settings as they are locked. Changing

the settings of Switch bank 2 could result in the camera not

responding to data commands.

Full details of the Pelco-D control protocol can be found at

www.pelco.com.

As well as the standard Pelco-D command set, Iris cameras use

their own commands based on the Pelco protocol to call

features that are specific to the model or are not covered by the

Pelco command set. For further details contact Iris Innovations.

Page 7

5.01 Hardware Installation

The different parts of your camera are labelled here:

Once youʼve established a suitable fixing position, use the fixing

plate as a template to mark off the three Surface Fixing

Positions and the cable clearance position.

The camera is supplied with 3 x Stainless Steel, anti-tamper, self

tapping screws. Drill pilot holes accordingly and use a 14mm

hole saw to create the cable entry hole.

Attach the camera to itʼs base plate using the M5 x 10mm

Countersunk screws supplied. Iris recommend that a screw

fixing agent is used to strengthen the fit (see diagram below).

When the cables are correctly terminated (see next section),

offer the camera up into the fixing position and firmly screw into

place.

Observe extreme caution when siting the camera. Ensure the

act of drilling the pilot holes and cable entry hole does not

infringe any cables, equipment or fixtures behind the panel onto

which the camera is to be installed.

To avoid moisture ingress between the bottom of the BRK-P160

fixing plate and the surface onto which the camera is to be

attached, apply a bead of suitable silicone sealant around the

edge of the plate to create a seal.

Fixing Plate (IRIS-BRK-P160)

For mounting onto flat surfaces, either standard or

hanging orientation.

Camera Fixing Points

3 x Counter sunk fixing holes for

attaching camera to fixing plate.

Surface Fixing Points

3 x Fixing holes for attaching the

fixing plate and camera to a flat

surface

Base Section

Contains the telemetry data circuitry

and Pan motor

Umbilical Cable (Gland only shown here)

3 meter cable tail. Video, Power and Camera

Control Data

Inner Dome

Contains the thermal camera

module and tilt motor

Germanium Lens Window

Protective lens window through which heat is

conducted. This is manufactured through a material

called Germanium - not glass. Thermal Imaging

cameras cannot ʻseeʼ through glass.

Protective Cowling

Shields the Inner Dome and Tilt

Pivot points

IRIS216 / 316 Thermal Imaging PTZ (Shown with BRK-P160 Fixing Plate in ʻHangingʼ Orientation).

This style of housing from Iris is known as the 116 Series housing.

Page 8

Hardware Installation

Fix camera to mounting plate, routing umbilical cable through cable entry hole, then fix mounting plate to surface. Camera can be

installed either in the hanging orientation as shown below, or in the ʻdesktopʼ orientation as shown in the inset.

M5 x 10mm Countersunk Screws

(Supplied) in 3 positions.

Fix Mounting Plate to base of camera

M5 x 10mm Countersunk Screws

(Supplied) in 3 positions.

Fix Mounting Plate to base of camera

Cable Entry

Route umbilical cable through here.

Standard (or ʻDesktopʼ) Orientation

The camera is factory set for installation in the ʻStandardʼ orientation as shown here.

To install in the hanging orientation as shown in the main image above, ensure the

cameras video output has been set to vertical flip. This can either be done via your

controller or via the DIP switches. Details are provide later in this document.

Page 9

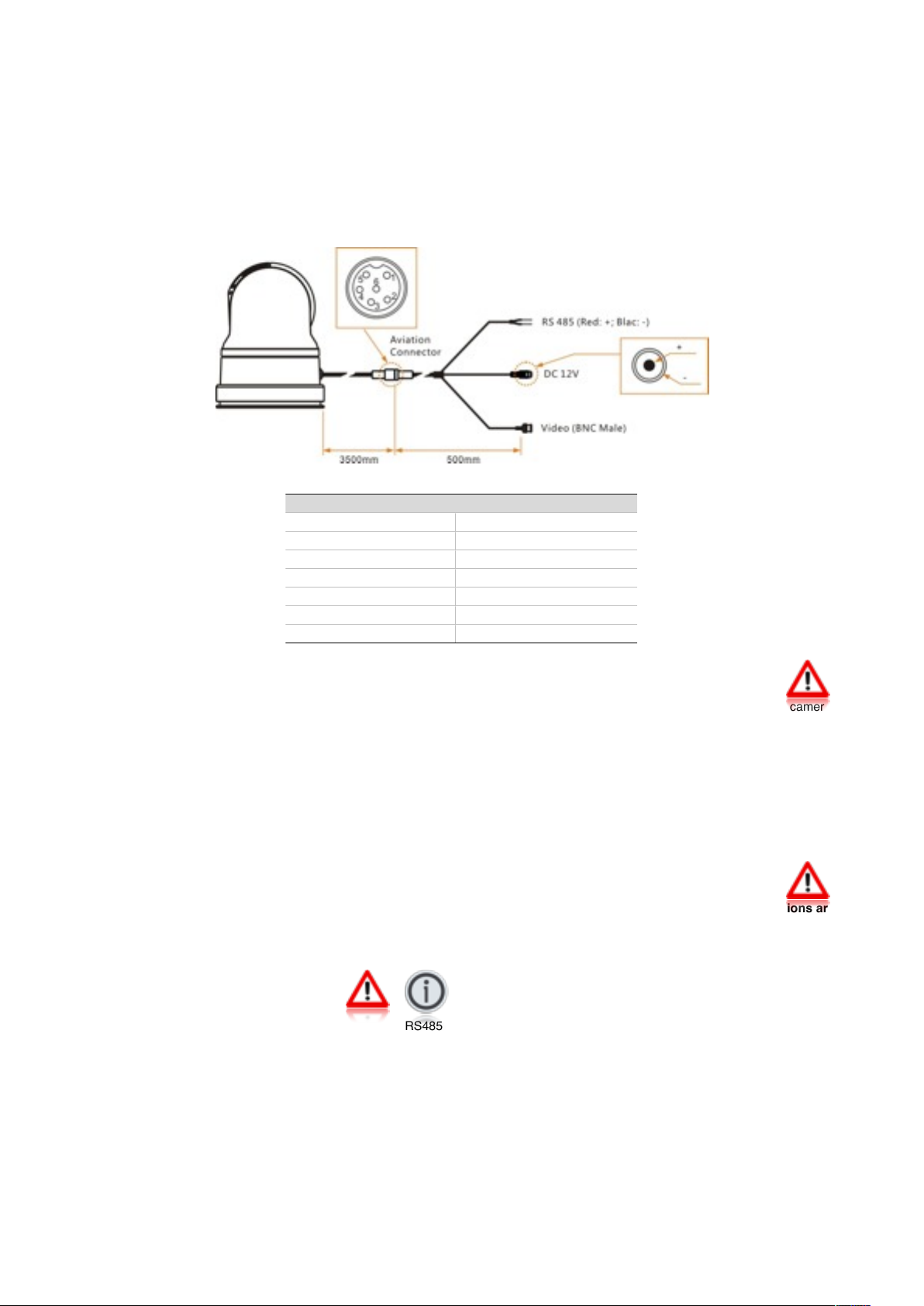

6.01 Connections

As shown in the diagram below, a 3.5 meter ʻumbilicalʼ cable tail

extends from the base of the camera and is terminated with a

water resistant circular ʻAviationʼ connector. Into this connects a

500mm ʻBreakoutʼ lead, which has three separate tails as

shown. One for Video, one for DC 12V Power, and a third for

RS485 Serial Data connection.

6.02 Video Connections

The camera breakout tail features a male BNC connector for the

video signal. When using coaxial video extension cables that are

usually also supplied with a male BNC connector, a BNC ʻThrupieceʼ adapter can be used to connect the two cables together.

The camera has a composite video output (1VP~P / 75Ω).

Ensure appropriate extension cables are used for this

specification. Contact Iris Innovations for further information if

you are unsure which cable to use.

Many Multifunctional Displays (MFDʼs) / Chart Plotters use RCA

(Phono) jacks for video inputs. In this case use a female BNC to

Phone Jack (Male) adapter. These are available from Iris

Innovations and can also be sourced from any good home

electronics / AV suppliers.

Video from Iris cameras can be viewed on most leading

manufacturers MFD / Chart Plotter products.

6.03 Data Connections

Ensure correct polarity is observed when connecting the RS485

serial data wires that provide control of the camera. Wires are

labelled RS485+ (Red) and RS485- (Black) for convenience.

The Transmit line (RS485+) should be connected to the Receive

line (RS485-) and vice versa. If, once connected you have no

control, reverse the polarity of the data wires as this is a

common error made during installations. Never connect the

RS485 wires to a power source as this could permanently

damage the camera or controller. Observe care when

connecting as the RS485 wires are coloured red and black and

could be confused for DC power lines.

Even if the cable connections are made in an internal location or

in an area that wouldnʼt usually be exposed to moisture, it is

recommended that the connections are protected from any

possible erosion or salt water / salt atmosphere conditions by

wrapping the terminations in a suitable tape of covering.

6.04 Powering Up

Upon switching on the circuit breaker that isolates the camera,

the unit will perform an initialization routine. During this routine,

which lasts approximately 30 seconds, the camera will pan and

tilt automatically in order to calibrate itself. You will notice the

mechanical shutter 'wiping' the image frequently for the first few

minutes as the unit warms up. This will eventually settle into an

automatic interval of wiping approximately every 15 minutes.

This only lasts for a fraction of a second and allows the camera

to calibrate itself for the best possible image in accordance with

the ambient temperature.

Never apply power to the camera unless all connections are

terminated correctly. Never disconnect the DC ground for

any reason whilst the camera is powered up.

When the camera has completed its boot-up routine, a text

overlay table will appear in the screen displaying the camera

address, protocol, baud rate and current firmware version. You

will also notice the positional indicator icon in the bottom left

hand corner of the screen and the zoom bar at the center

bottom of the screen. When this message appears the camera

is ready to use and you are able to control the device.

Pin Definition

Pin #

Definition

1

Video +

2

Power -

3

Power +

4

RS485 -

5

RS485 +

6

Video -

Page 10

7.01 Controlling the Camera

Your camera features positional controls and extended features.

Positional features such as Pan, Tilt and Zoom are usually

controlled via a compatible joystick controller, such as the

IRIS516 or IRIS507 controllers or via a compatible MFD / ChartPlotter - sometimes via touch-screen controls depending on the

make and model. Third party control methods may differ from

Iris controllers. For details of compatible third party control

interfaces please contact Iris Innovations. Control of extended

features depends on the type of controller you are using, but is

usually accessed via a menu system on the controller or third

party device (MFD / Chart-plotter etc). If using a third party

control interface consult the relevant user documentation for the

specific equipment for details.

A list of feature commands is included at the end of this

document.

Set-Up Features

The following features will only usually be called during the initial

set-up of the camera following installation:

• VIdeo Standard Set-up.

! PAL / NTSC

When changing the video standard, power the unit down and

then reboot for the adjustment to take place.

• Video Orientation

! UP / DOWN / UP+MIRROR / DOWN+MIRROR

Setting the vertical orientation (UP or DOWN) is determined by

the orientation of the camera (Standard = UP / Hanging (also

known as Ball Down) = DOWN). The mirror option is usually

only used when the camera is facing aft, and is usually only

applied to fixed cameras, as with a PTZ camera such as the 216

or 316, the camera pan position is frequently changing. Video

orientation can however easily be ʻflippedʼ as required with the

IRIS516 controller.

• Set Home Position

!

This feature lets you set the home position of the camera

following install. Usually this is aligned with the bow of the boat.

This calibrates the positional indicator with the direction of the

camera.

Proportional Speed Control (Pan / Tilt / Zoom)

IRIS216/316 Thermal Cameras feature extremely accurate

multi-speed control with a Proportional Speed function that acts

like a gear in order to automatically control speed ratios in

accordance with the current level of zoom. The further the

camera is zoomed in, the slower it will pan and tilt when

commanded and vice versa. This greatly improves control

accuracy when zoomed in.

Auto-Flip

When the camera is tilted past its azimuth the Auto-Flip feature

is triggered. This automatically pans the camera through 180˚ at

full speed (Proportional Control is disabled during this

procedure) to the original pan position and continues the tilt

movement as long as the camera is still being tilted. This

corrects the orientation of the camera module as if the unit kept

tilting past the azimuth without the automatic correction, the

module would be upside down.

Extended Features

Colour Palette Select:

Iris 216 / 316 Thermal Cameras feature multiple colour palettes

which can be used in different conditions and situations to

enhance the image.

• Monochrome (White Hot)

• Red Scale (Red Hot)

• Green Scale (Green Hot)

• Blue Scale (Blue Hot)

• Iron Bow

• Rainbow

• Hot Metal

• High Contrast

• Isotherm

Colour Palette Inverse:

The polarity of the 9 palettes above is reversible providing a total

of 18 colour palettes.

Scene Mode Select:

5 different preset ʻScene Modesʼ are provided to enhance the

image in the following conditions:

• Day Mode

! Default mode. Handles wide thermal dynamic range

! while maintaining optimum picture quality.

• Night Mode

! Normal level/span. Suitable to provide verification of

! vessels/buoys observed with radar or navigation lights.

! The camera handles hot objects in the ! scene i.e vessel

! exhausts and personnel on board decks (of other

! vessels being viewed), without loosing ! deta i l o f low

! contrast areas.

• Marina Mode

! Ability to distinguish low contrast objects i.e. marina

! pontoons, moorings etc. without hot objects in the field

! of view affecting picture i.e. persons, vehicles on-shore/

! dock or heat from power boats engines.

• Man-Over-Board Mode

! Maximum sensitivity and discrimination of low contrast

! targets/objects. Hot spot tracker (MOB) enabled.

• Fog Mode

! Maximum sensitivity and discrimination of low contrast

! targets/objects.

Video Pause

Freezes / Unfreezes the image in order to study an on screen

artifact.

Non Uniformity Correction Control (NUC)

Manually operates shutter in order to recalibrate the thermal

sensitivity. When the shutter closes, the camera re-calibrates itʼs

temperature threshold to the uniform temperature of the shutter.

No n U ni formity Correction (or NUCʼing) a ls o o cc ur s

automatically to maintain a sharp image.

Page 11

User Presets

The camera has a built in memory that can be used to store up

to 100 user ʻpresetʼ positions. A preset allows you to move the

camera to a favourite or important position and learn that

position so that the camera can be instructed to move at top

speed to that position at the touch of a button. For example, you

may want to point the camera so that itʼs facing directly aft so

you can take a look at whatʼs coming up behind you. By saving

this position as a Preset, you can send the camera back to this

position immediately by recalling the preset. Presets can also be

used to form ʻToursʼ, where the camera can be instruction to

step through each preset within the Tour in sequence with a predetermined dwell time between each position.

User presets are numbered 100-199. Usually the controller you

are using will have the ability to SET a Preset to learn the

position and then CALL a Preset to send the camera to that

position. This will depend on the model of controller you are

using. Consult the user guide of your controller for details.

System Presets

Certain functions of the camera that are not defined by the

Pelco-D Protocol are called by using Presets. A list of System

Presets can be found later in this document.

Scan Modes

The camera supports 4 different Scan Modes. Once activated,

tilt and zoom commands are still accepted by the camera but

you will not be able to pan the camera until the Scan has been

Stopped:

• 45˚ Auto Scan

! Camera pans back and forth 22.5˚ either side of the

! centre point (the position the camera is facing when the

! scan is activated.

• 90˚ Auto Scan

! Camera pans back and forth 45˚ either side of the

! centre point (the position the camera is facing when the

! scan is activated.

• 180˚ Auto Scan

! Camera pans back and forth 90˚ either side of the

! centre point (the position the camera is facing when the

! scan is activated.

• 360˚ Auto Scan

! Camera pans continuously through 360˚, pausing every

! 108˚.

There are three speed controls for each Scan. Slow, Medium

and Fast.

A command is also available to ʻRe-Centreʼ the scan. This can

be found in the command list.

Tours

A tour is a group of 10 user preset positions that are linked

together so that when activated, the camera will sequence to

each position with a 5 second dwell time between each preset.

There are 4 Tour patterns available. Each tour uses a range of

dedicated presets which must be set. Any unused presets wonʼt

be included in the tour. Reserved Tour presets are listed here:

Tou r 1

Preset Range 40 ~ 49

(Preset 84 Activates Tour 1)

Tou r 2

Preset Range 50 ~ 59

(Preset 85 Activates Tour 2)

Tou r 3

Preset Range 60 ~ 69

(Preset 86 Activates Tour 3)

Tou r 4

Preset Range 70 ~ 79

(Preset 87 Activates Tour 4)

Page 12

8.01 Protocol Command List

The table below lists features specific to IRIS216/316 Thermal Cameras that are not covered by the standard Pelco-D protocol and the

commands that have been mapped in IRIS camera software to operate those features. Values are shown in hexadecimal. The

checksum for all Pelco-D commands is the 8 bit (modulo 256) sum of the payload bytes (bytes 2 ~ 6) within the message. Refer to the

Pelco-D protocol document for further information.

Function

Value

Command

H

AddC1C2D1D2

CHK

Video Standard

PAL

Preset xx

FFAD000700C7CHK

NTSC

Preset xx

FFAD000700C8CHK

Video Orientation

Desktop Standard

Preset 236

FFAD000700ECCHK

Hanging Standard

Preset 237

FFAD000700EDCHK

Desktop Mirror

Preset 238

FFAD000700EECHK

Hanging Mirror

Preset 239

FFAD000700EFCHK

Set New Home Position

Set Home

Set Home

FFAD00490000CHK

Call Home Position

Call Home

Preset 230

FFAD000700E6CHK

Thermal Colour Palettes

Mono / White Hot

Preset 201

FFAD000700C9CHK

Mono / Black Hot

Preset 202

FFAD000700CACHK

Redscale / Red Hot

Preset 203

FFAD000700CBCHK

Redscale / Black Hot

Preset 204

FFAD000700CCCHK

Ironbow

Preset 205

FFAD000700CDCHK

Reverse Ironbow

Preset 206

FFAD000700CECHK

Greenscale / Green Hot

Preset 207

FFAD000700CFCHK

Greenscale / Black Hot

Preset 208

FFAD000700D0CHK

Rainbow

Preset 209

FFAD000700D1CHK

Reverse Rainbow

Preset 210

FFAD000700D2CHK

Hot Metal

Preset 211

FFAD000700D3CHK

Reverse Hot Metal

Preset 212

FFAD000700D4CHK

Isotherm

Preset 213

FFAD000700D5CHK

Reverse Isotherm

Preset 214

FFAD000700D6CHK

High Contrast

Preset 215

FFAD000700D7CHK

Reverse High Contrast

Preset 216

FFAD000700D8CHK

Bluescale / Blue Hot

Preset 217

FFAD000700D9CHK

Bluescale / Black Hot

Preset 218

FFAD000700DACHK

Non Uniformity Correction (NUC)

NUC

Preset 240

FFAD000700F0CHK

45˚ Auto Scan

Slow

Scan 45 Slow

FFAD00390401CHK

Medium

Scan 45 Med

FFAD00390401CHK

Fast

Scan 45 Fast

FFAD00390401CHK

Page 13

Function

Value

Command

H

AddC1C2D1D2

CHK

90˚ Auto Scan

Slow

Scan 90 Slow

FFAD00390101CHK

Medium

Scan 90 Med

FFAD00390101CHK

Fast

Scan 90 Fast

FFAD00390101CHK

180˚ Auto Scan

Slow

Scan 180 Slow

FFAD00390201CHK

Medium

Scan 180 Med

FFAD00390201CHK

Fast

Scan 180 Fast

FFAD00390201CHK

360˚ Auto Scan

Slow

Scan 360 Slow

FFAD00390301CHK

Medium

Scan 360 Med

FFAD00390301CHK

Fast

Scan 360 Fast

FFAD00390301CHK

Stop Scan

Stop Scan

Preset 97

FFAD00070061CHK

Set Camera Safe Position

Set Safe

Set Preset 232

FFAD000300E8CHK

Call Camera Safe Position

Call Safe

Preset 232

FFAD000700E8CHK

Freeze Image

Freeze

Preset 234

FFAD000700EACHK

Un-Freeze Image

Resume

Preset 235

FFAD000700EBCHK

Scene Mode

Off

Preset 220

FFAD000700DCCHK

Day

Preset 221

FFAD000700DDCHK

Night

Preset 222

FFAD000700DECHK

Fog

Preset 223

FFAD000700DFCHK

Man Over Board

Preset 224

FFAD000700E0CHK

Marina

Preset 225

FFAD000700E1CHK

Start Tour

Tour 1

Preset 84

FFAD00070054CHK

Tour 2

Preset 85

FFAD00070055CHK

Tour 3

Preset 86

FFAD00070056CHK

Tour 4

Preset 87

FFAD00070057CHK

Page 14

9.01 Camera Address Table

The cameras unique device address is set using DIP switch

Bank 1. The following table lists switch positions for each

address from 0~38. There are a total of 255 address positions

available. For address settings above 38 please contact Iris

Innovations technical support.

Do not use address 0 as this is rarely used by control

equipment.

ADDRESS

123456780

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF1ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF2OFFONOFF

OFF

OFF

OFF

OFF

OFF3ONONOFF

OFF

OFF

OFF

OFF

OFF4OFF

OFFONOFF

OFF

OFF

OFF

OFF5ON

OFFONOFF

OFF

OFF

OFF

OFF6OFFONON

OFF

OFF

OFF

OFF

OFF7ONONON

OFF

OFF

OFF

OFF

OFF8OFF

OFF

OFFONOFF

OFF

OFF

OFF9ON

OFF

OFFONOFF

OFF

OFF

OFF10OFFONOFFONOFF

OFF

OFF

OFF11ONONOFFONOFF

OFF

OFF

OFF12OFF

OFFONON

OFF

OFF

OFF

OFF13ON

OFFONON

OFF

OFF

OFF

OFF14OFFONONONOFF

OFF

OFF

OFF15ONONONONOFF

OFF

OFF

OFF16OFF

OFF

OFF

OFFONOFF

OFF

OFF17ON

OFF

OFF

OFFONOFF

OFF

OFF18OFFONOFF

OFFONOFF

OFF

OFF19ONONOFF

OFFONOFF

OFF

OFF20OFF

OFFONOFFONOFF

OFF

OFF21ON

OFFONOFFONOFF

OFF

OFF22OFFONON

OFFONOFF

OFF

OFF23ONONON

OFFONOFF

OFF

OFF24OFF

OFF

OFFONON

OFF

OFF

OFF25ON

OFF

OFFONON

OFF

OFF

OFF26OFFONOFFONON

OFF

OFF

OFF27ONONOFFONON

OFF

OFF

OFF28OFF

OFFONONONOFF

OFF

OFF29ON

OFFONONONOFF

OFF

OFF30OFFONONONON

OFF

OFF

OFF31ONONONONON

OFF

OFF

OFF32OFF

OFF

OFF

OFF

OFFONOFF

OFF33ON

OFF

OFF

OFF

OFFONOFF

OFF34OFFONOFF

OFF

OFFONOFF

OFF35ONONOFF

OFF

OFFONOFF

OFF36OFF

OFFONOFF

OFFONOFF

OFF37ON

OFFONOFF

OFFONOFF

OFF38OFFONON

OFF

OFFONOFF

OFF

Page 15

Specifications

IRIS216 - L

IRIS216 - H

IRIS316 - L

IRIS316 - H

Video System

PAL/NTSC Switchable

PAL/NTSC Switchable

Image Sensor

IRIS384 ASi Microbolometer

IRIS640 ASi Microbolometer

Resolution

384 x 288

640 x 480

TV Lines

-

-

Total Effective Pixels

110,592

307,200

Refresh Rate

8.3Hz PAL / 7.5Hz NTSC

25Hz PAL / 30Hz NTSC

8.3Hz PAL / 7.5Hz NTSC

25Hz PAL / 30Hz NTSC

Spectral Response

8~14µm

8~12µm

Pixel Size

25µm

17µm

Lens

Fixed 18.5mm

Fixed 35mm

Optical Zoom

NA

NA

Digital Zoom

Continuous ‘Smooth’ Zoom 1x ~ 36x

Continuous ‘Smooth’ Zoom 1x ~ 36x

Horizontal Field of View

28.0˚

17.4˚

Vertical Field of View

21.3˚

13.2˚

Diagonal Field of View

34˚

21.4˚

HIFOV

1.27mrad

0.474mrad

VIFOV

1.29mrad

0.479mrad

Detection on 2.3m Target

Detection: 870m / Recognition 290m

Detection: 2370m / Recognition 780m

Minimum Illumination

0.0 lux @ 100IRE - Illumination not required

0.0 lux @ 100IRE - Illumination not required

Thermal Sensitivity

<50mK @ f/1.0

<70mK @ f/1.0

Digital Image Stabilization

Yes

Yes

Video Output

1.0 Vp~p Composite Video

1.0 Vp~p Composite Video

Image Flip

Vertical / Horizontal

Vertical / Horizontal

Scene Modes

Selectable: Day Mode, Night Mode, Man Over Board Mode, Fog Mode, Marina Mode

Colour Modes

9 Reversible Colour Palettes (18 total)

9 Reversible Colour Palettes (18 total)

Positional Indicator

Yes

Yes

Heater

Yes. Operates below 20˚C

Yes. Operates below 20˚C

Safe Position

Yes. User Definable

Yes. User Definable

Target Tracking

MOB mode applies box around hottest object in scene.

Video Pause

Yes

Yes

Standby Mode

Yes

Yes

Communications Protocol

Serial Control RS485 / Pelco-D Protocol / Iris Variant

Serial Control RS485 / Pelco-D Protocol / Iris Variant

Dimensions

163mm x 130mmØ

163mm x 130mmØ

Power

6VDC ~ 36VDC

6VDC ~ 36VDC

Consumption

<700mA idle / Approx 1.5A under full motor drive / <2A full motor drive & heater on

Weight

1.132kg

1.322kg

Environmental

IP66

IP66

Operating Temperature

-30˚C ~ 60˚C

-30˚C ~ 60˚C

Pan / Tilt Coverage

Pan: 360˚ Continuous Rotation / Tilt -15 to 90˚ with Auto-Flip (210˚ Total)

Pan Speed (Normal)

0.05~70˚/sec

0.05~70˚/sec

Pan Speed (Full)

0.05~220˚/sec

0.05~220˚/sec

Tilt Speed (Normal)

0.03~38˚/sec

0.03~38˚/sec

Tilt Speed (Full)

0.03~140˚/sec

0.03~140˚/sec

User Presets

100 User Presets. Note: Certain presets have been assigned to camera features.

Tours

4 User Definable Tours of 10 presets each

4 User Definable Tours of 10 presets each

Scans

Narrow Scan / Wide Scan / Random Scan / Auto Scan

Shock & Vibe

EN60945 2002 MIL STD 810 E

EN60945 2002 MIL STD 810 E

Sand & Dust

MIL STD 810 E

MIL STD 810 E

Specifications and features subject to change without prior notice. E&OE

Page 16

Iris Innovations Limited (UK)

Units 8 & 9 Swanwick Business Centre

Bridge Road, Swanwick. Hampshire SO31 7GB

United Kingdom

Tel: +44(0)1489 570797

email: info@boat-cameras.com

web: www.boat-cameras.com

Iris Innovations Limited (USA)

Suite 130. 401 E. Las Olas Blvd.

Fort Lauderdale 33301. Flordida.

United States of America

email: info@boat-cameras.com

web: www.boat-cameras.com

Loading...

Loading...