Page 1

USE AND

MAINTENANCE

INSTRUCTIONS

REV No. REVISION DESCRIPTION REV. DATE PROOF READER

00 26/10/2015 L.B.

01 10/09/2017 D.N.

FIRST EMISSION

ADDED GAS R452A

Page 2

Dear Customer,

Thank you for having chosen IRINOX.

Please take the time to read this manual carefully to make the most of all the potential and benefits of your

new CP ONE.

We would like to remind you that the perfect operation of the machine also depends on its correct use.

Keep this manual close to the CP ONE so that it can be consulted easily by you and anyone else.

The graphic representations of the controls in the manual have been designed to make the machine easy

and intuitive to use.

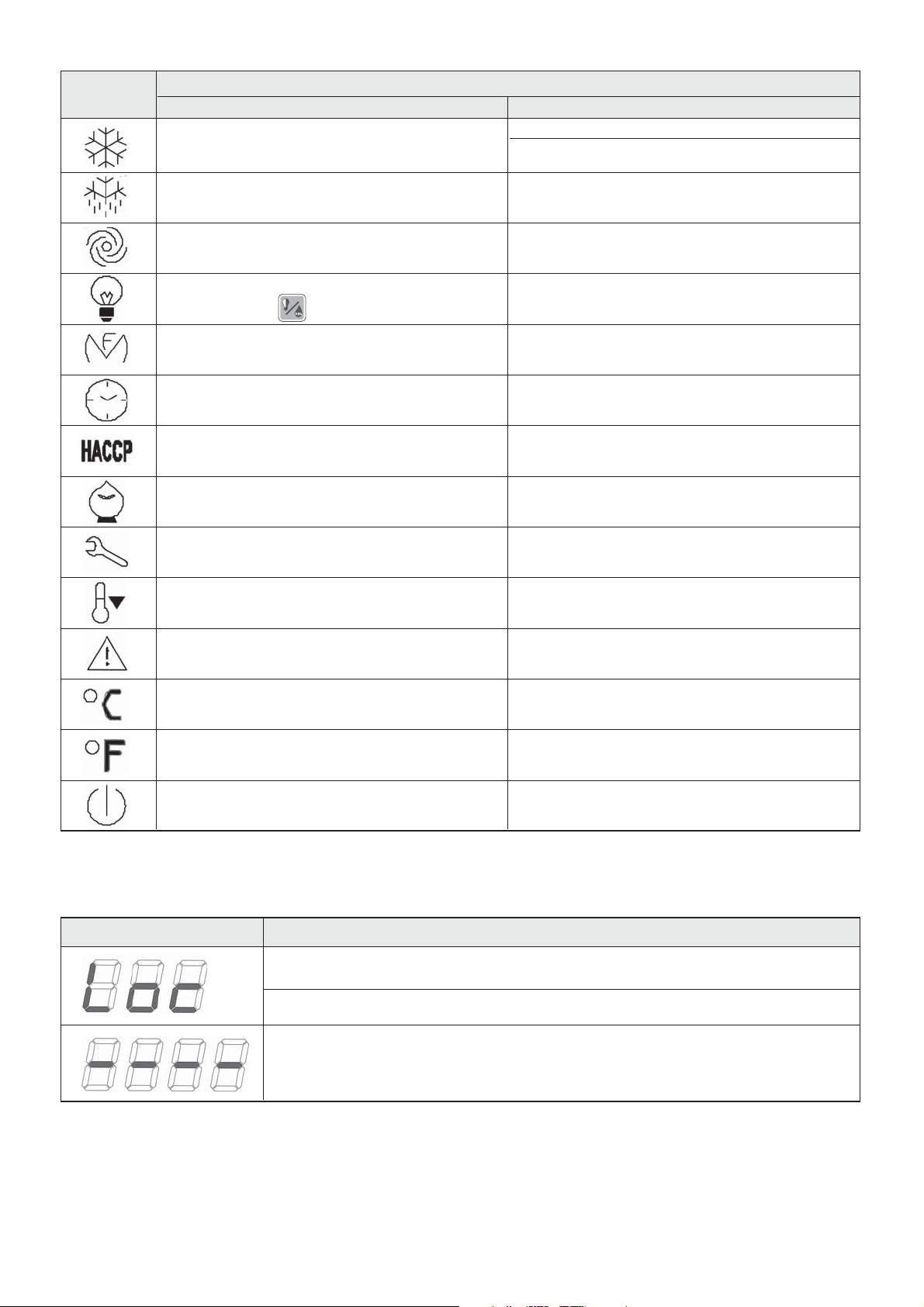

Symbols key

suggestions and details for correct use of the blast chiller

standards for your safety

additional information in the manual

Information regarding the warranty and assistance

Warranty validity: of the individual parts for 12 months from the date of invoicing, as stated in the price list in force.

Contacts:

Customer service: +39.0438.5844

User assistance +39.0438.5844

Technical - spare parts after-sales +39.0438.2020

Fax +39.0438.2023

E-mail service@irinox.com

Web site www.irinoxprofessional.com

For every request relative to your product, always indicate:

• The model

• The serial number

stated on the label on the machine.

Page 3

SAFETY INFORMATION

Below are the main general Safety

Standards:

do not touch the machine with humid or wet

•

hands or feet

do not work on the machine with bare feet

•

do not insert screwdrivers, kitchen tools or

•

any other object between the protections and

moving parts

before performing any cleaning or routine

•

maintenance operation, disconnect the

machine from the electrical power supply by

turning the main switch off and removing the

plug

do not pull the power supply cable to discon-

•

nect the machine from the power supply

mains.

If the power supply cable is damaged it

must be replaced by the manufacturer,

by a service centre, or by qualified staff in

order to avoid risks.

Non-mobile equipment, not equipped with

disconnection devices from the power supply

having a contact separation of all poles that

provides disconnection in category III overvoltage conditions, must be equipped with a

disconnection device incorporated in the fixed

connection in compliance with the connection

regulations.

Use gloves suitable for cold trays.

The responsibility of the operations

performed on the machine, ignoring

the indications stated in this manual, is implemented by the user.

Climatic class:

4 (environmental temperature 30°C with

relative humidity 55% non-condensing)

pursuant to Standards IEC EN 60335-1, IEC

EN 60335-2-89, ISO 23953-2:2005(E)

Do not store explosive substances such

as spray cans with flammable propellant

inside the appliance.

Children should be supervised to ensure

they do not play with the appliance.

Cleaning and maintenance by the user

should not be performed by children

without the supervision of an adult.

The machine is not intended for use in

a potentially explosive environment.

The manufacturer declines any liability

if this note is not complied with.

During cleaning operations, especially of

the condenser, always wear protective

gloves, glasses and masks for protection of

the respiratory tract.

It is prohibited to remove the protections

and safety devices in order to perform

routine maintenance.

Do not overload the machine beyond

that indicated by the manufacturer

(3.5.2. Loading the machine).

Maximum load per shelf: 10 kg

3

Page 4

INDEX

1. GENERAL DOCUMENTATION 5

1.1 GENERAL WARNINGS 5

1.2 INTRODUCTION 5

1.3 TRANSPORT AND HANDLING 5

1.4 UNPACKING AND DISPOSAL OF PACKAGING 6

2. INSTALLATION 7

2.1 PLATE DATA 7

2.2 POSITIONING 7

2.3 DIMENSIONAL DATA 8

2.4 ENVIRONMENTAL TEMPERATURES AND AIR EXCHANGE 9

2.5 COOLING CAPACITIES 9

2.6 ELECTRICAL CONNECTION 9

2.7 REFRIGERATOR CONNECTION 10

2.8 CONDENSATE DRAIN 11

2.9 WATER COOLING UNITS CONNECTION 11

2.10 NOTES FOR THE INSTALLER 12

2.11 SAFETY AND CONTROL SYSTEMS 12

2.12 R404A /R452A GAS SAFETY SHEET 13

2.13 DISPOSING OF THE MACHINE 14

3. OPERATION 15

3.1 USE 15

3.2 CONTROL PANEL 15

3.3 DESCRIPTION AND OPERATION 16

3.4 STOP MODES 19

3.5 RECOMMENDATIONS FOR USE 19

4. MAINTENANCE / ASSISTANCE 20

4.1 ROUTINE MAINTENANCE 20

4.2 CLEANING THE CELL 20

4.3 TROUBLESHOOTING 21

4.4 EXTRAORDINARY MAINTENANCE 23

4

Page 5

1. GENERAL DOCUMENTATION

1.1. GENERAL WARNINGS

This manual is an integral part of the product, it

•

supplies all of the indications necessary for correct

installation, correct use and maintenance of the

machine.

It is mandatory for the user to read this manual care-

•

fully and always make reference to it. Moreover, it

must be kept in a place that is known and accessible

to the authorised operators (installer, user, maintenance technician)

The holding cabinet is intended for professional use

•

and therefore only qualified staff can use it.

The holding cabinet is intended only for the use for

•

which it has been designed, i.e. for storage of food

products.

Products that require constant temperature control

•

and recording are excluded, such as:

1.2 INTRODUCTION

Installation must be carried out by authorised and

specialised staff, respecting the instructions in this

manual. The manufacturer declares and assigns to

each individual machine a Declaration of Conformity to

the 2006/42/EC Machinery Directive, to the 2006/95/EC

Low Voltage Directive and to the 2004/108/EC Electromagnetic Compatibility Directive.

Whenever the machine is supplied with the remote

condensing unit, it is the installer's responsibility to check

all connections and issue a declaration of perfect execution that is in compliance with the provisions of the abovementioned Directive. The joints made by IRINOX S.p.a.

are in compliance with Standard EN14276-2.

- heat reactive chemicals

- medicines

- blood products

The manufacturer declines any liability for any damage

•

caused by incorrect or unreasonable use, such as for

example:

- improper use by untrained staff.

- modifications or interventions that are not specific

for the model.

- use of non-original spare parts or that are not

specific for the model.

- failure to comply, even partial, with the instructions

in this manual.

IMPORTANT NOTE: IRINOX reminds you that all

machines must be subjected to periodic inspections in

compliance with the national standards in force.

In particular for the Italian market: a complete control of

the plant must be carried out and especially an inspection of the integrity of the cooling circuits under pressure after ten years of operation as a set, as required in

Italy by Annex B of the Italian Ministerial Decree no.

329 of 1 December 2004 for sets belonging to categories from I to IV containing group 2 fluids.

1.3 TRANSPORT AND HANDLING

All necessary precautions must be adopted when

•

handling the appliance in order not to damage it,

respecting the indications on the packaging.

Table 1

WEIGHT

Holding cabinet model

CP ONE

Condensing unit (if remote)

Condensing unit

NET

kg

240 840 2270 1190 2,27 275

38 690 450 720 0,22 58 700 450 780 0,25 76

(mm) H (mm) D (mm) m

L

CARDBOARD PACKAGING CRATE PACKAGING

3

kg

L (mm) H (mm) P (mm) m

930 2320 1230 2,65 410

5

3

kg

Page 6

1.4. UNPACKING

•

Remove the cardboard or wooden packaging or crate

from the wooden base on which the machine is

rested.

Lift the machine using suitable means (forklift truck),

remove the wooden base and position the machine in

the envisioned place (see par. 2.2).

•

After the packaging has been removed, check the

integrity of the holding cabinet.

•

Remove the protective PVC film from all sides (Fig.1).

•

•

When handling the packaging and the wooden

base, use protective gloves.

NOTE: all of the various packaging components must

be disposed of according to the Standards in force in

the Country where the appliance is used. In any case,

nothing must be dispersed into the environment.

Fig. 1

6

Page 7

2. INSTALLATION

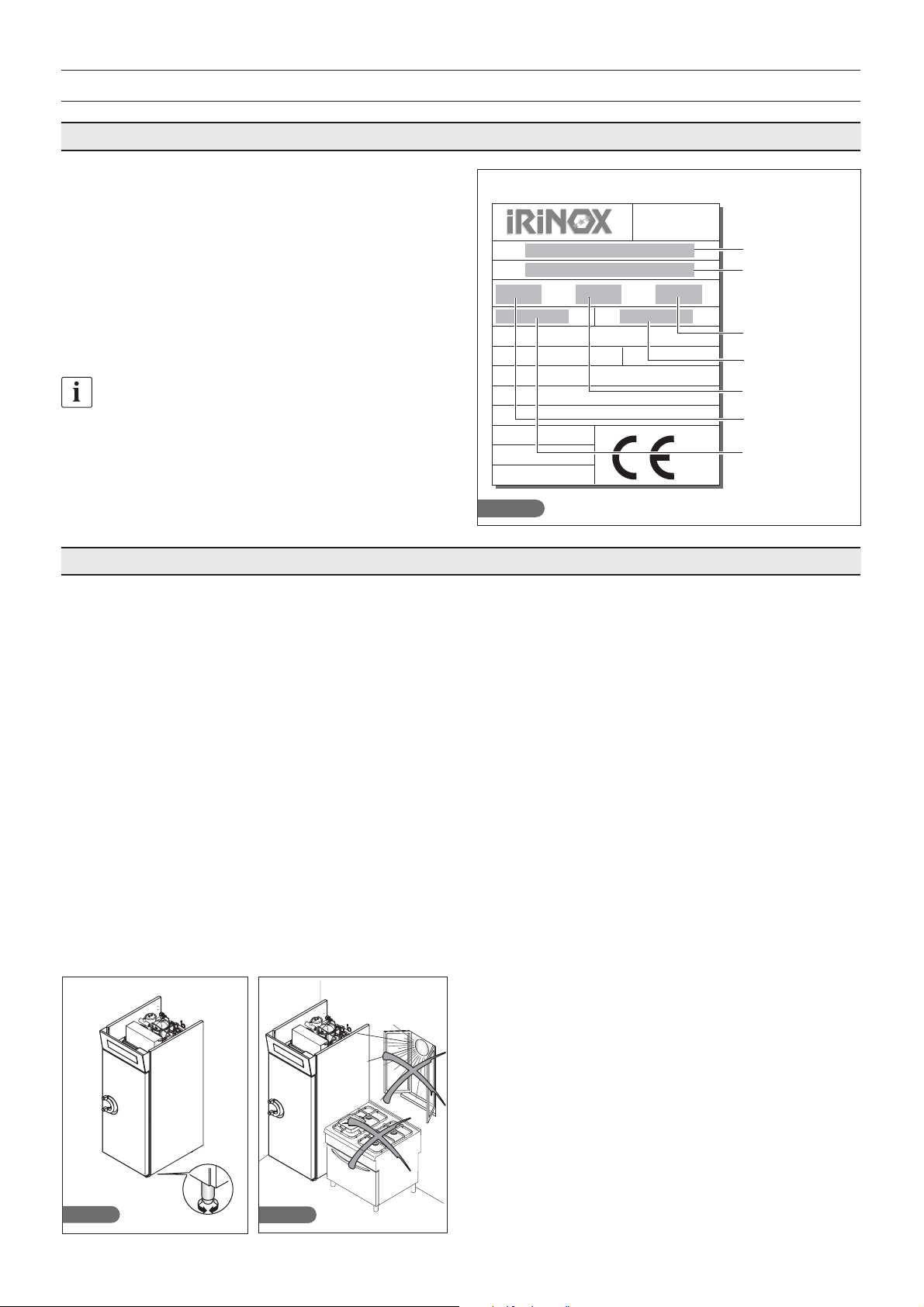

2.1. PLATE DATA

•

Check that the plate data and the characteristics of

the electrical line correspond (V, kW, Hz, no. phases

and power available).

•

The plate showing the appliance's characteristics is

affixed on the right side of the holding cabinet (fig.2)

and under the control panel.

The eventual preparation of machine rooms for positioning

the condensing units must follow the Standards in force

in the country of installation regarding fire prevention

(contact the local fire department for the due indications).

It must also be considered that any intervention of

the safety valve or fuse caps, currently in the refrigerator

circuit, leads to the immediate discharge of all coolant

used in the environment. Consequently, realise

appropriate means of disposal and first aid as indicated

in the coolant safety sheet (8see par. 2.12).

Mod.

s/n

V

A

Compressor HERMETIC

Refrigerant R404A / R452A Charge

Desing pressure (Low)

Desing pressure (High)

Class Volume

Rated Load

IP

PED Code

Ph Hz

Fig. 2

31010

CORBANESE (TV)

ITALY

KPa

KPa

Model

Serial no.

mm/yy/progres.

Kw

Frequency

Power

Phase

Volt

Absorption

2.2. POSITIONING

•

The machine must be installed and inspected with

complete respect of the accident-prevention legal Standards, traditional regulations and Standards in force.

•

The installer must check any provisions on the subject

of fire prevention (contact the local fire department for

the due indications).

•

Place the machine in the provided place.

•

Use the adjustment feet to level the appliance. Do not

use the forklift truck to straighten the machine as it

could damage the basin guides on the bottom of the

machine (Fig.3).

If the appliances are not levelled, their functioning and

•

the flow of condensate can be compromised.

To avoid (Fig.4):

•

Places exposed to direct sunlight

•

Enclosed places with high temperatures and poor air

exchange. (

•

Do not install the machine near to any heat source.

see Table 2).

•

The remote units are designed to be installed in

places protected from the weather. The plants must

be positioned on a level cement or steel base and

space for maintenance must be foreseen, as indicated in the technical data sheets. For installation on

the roof or on floors, weight distribution beams should

be arranged. The base must also be sufficiently

strong and suitable to support the weight of the entire

unit, as resulting from the technical data on the specific drawing. To avoid additional vibrations and noises

we recommend use of neoprene anti-vibration mats

placed under the corners of the unit's base.

•

If the operating cabinet holder is to be installed below

the floor level or underground, the installer will apply

the clauses required by the Standard EN3781:2008+A1:2010 ANNEX D to ensure that no person

can remain locked in the cell at the end of the work

shift.

•

The cabinet holder can be installed underground or on

a mezzanine as long as there are suitable emergency

exits as provided for by the Standard EN3781:2008+A1:2010 ANNEX C.

Fig. 3

Fig. 4

•

The need for forced ventilation in a room where the

cabinet holder is installed must be verified by the

installer, as required by the Standard EN3782:2008+A1:2009 in chapter 6.2.14.

7

Page 8

2.3. DIMENSIONAL DATA

810

B

1970

2085

Service Area

250

B

AA

56

670

1053,5

SECTION

A-A

1347

871,5

SECTION

8

B-B

Page 9

2.4. ENVIRONMENTAL TEMPERATURES AND AIR EXCHANGE

For air-cooled chiller units, the temperature of the

operating environment must not exceed 30°C. The

performance declared is not guaranteed above this

temperature.

The remote condensing units must be installed in opposite rooms or outdoors, in a place protected from direct

sunlight. If the circumstances should make it necessary, the installer must evaluate whether the use of a

cover or roof is required (in all cases sufficient air

exchange must be guaranteed).

For further details

see Table 2.

2.5. COOLING CAPACITIES

Table 4

Cooling capacity [W] Condensing power [W]

1458

Values declared at T.evap=-10°C and T.cond.=40°C.

Over-heating in compliance with EN12900

2248

2.6. ELECTRICAL CONNECTION

Table 2

MINIMUM AIR EXCHANGE

3

m

/h AIR 700

Table 3

MAXIMUM WATER USE (when foreseen)

Well water (l/h)

Values referring to the condensing power declared at -10/40°C

in compliance with EN12900

220

Install an automatic differential circuit breaker switch

upstream from every appliance, for omnipolar disconnection of the power supply, according to the Standards

in force in the country of installation.

The dimensions of the connection cables must be in

compliance with the information contained in the electrical data on the technical data sheets. The voltage of

the systems must be within the limit of +10% and the

voltage distortion of the phases must not exceed 3%.

The electrical power connection must be performed by

qualified staff, in compliance with the directives and

laws in the country of installation. The power supply is

to be taken to the electrical control panel of each single

appliance, according to the data in

The electrical power supply cables must be correctly

•

Table 5.

sized for the units installed;

•

The electrical cables must be laid and blocked in the

relevant cable gland and installed properly according

to the place of installation;

Every wire must be inserted into the corresponding

•

terminal;

•

The earth wire must be correctly connected to an

efficient earthing system.

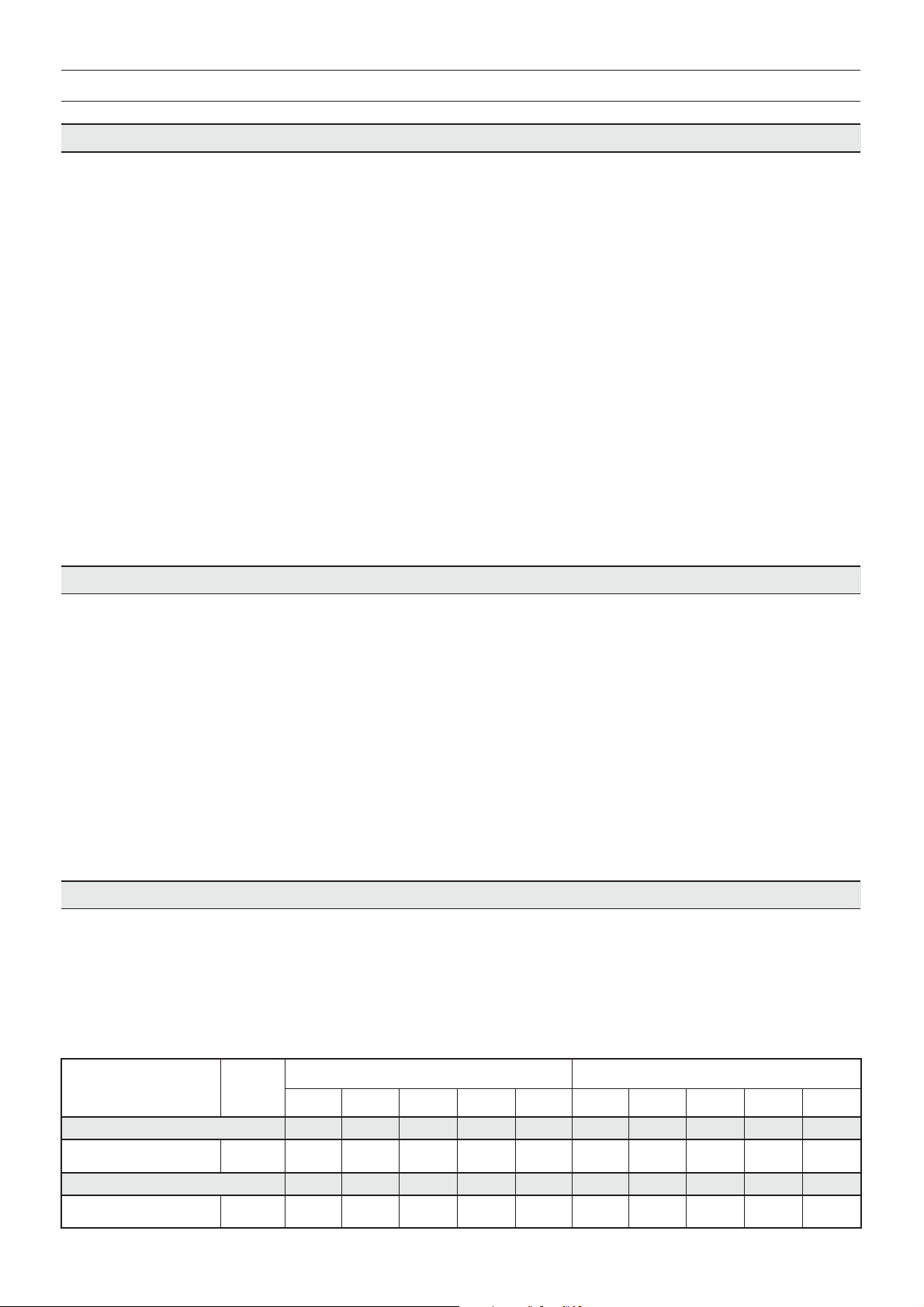

POWER SUPPLY

Voltage

220-240

Frequency

(V)

220

200

(Hz)

50

60

50/60

Poles

1P+N+PE

1P+N+PE

2P+PE

nominal

POWER SUPPLY

Power

(kW)

0,93

0,85

0,88

Power

(A)

5,2

4,5

5,6

defrosting

ABSORPTION

Potenza

(kW)

1,30

1,60

1,30

The manufacturer declines all liability and

every warranty obligation, whenever the appliance

or objects are damaged and persons are injured

due to incorrect installation and/or failure to

comply with the laws in force.

Fig. 6

Fig. 7

Table 5

POWER

SUPPLY CABLE

3G1,5mm2+3G2,5mm

3G1,5mm2+3G2,5mm

3G1,5mm2+3G2,5mm

Current

(A)

6,4

7,2

6,7

POWER

SUPPLY CABLE

Type Section Type Section

H07RN-F

H07RN-F

H07RN-F

3G1,5mm

3G1,5mm

3G1,5mm

2

H07RN-F

2

H07RN-F

2

H07RN-F

2

2

2

NOTES: cable sized for a length of 7m with an industrial voltage drop ∆V% ≤ 1%

9

Page 10

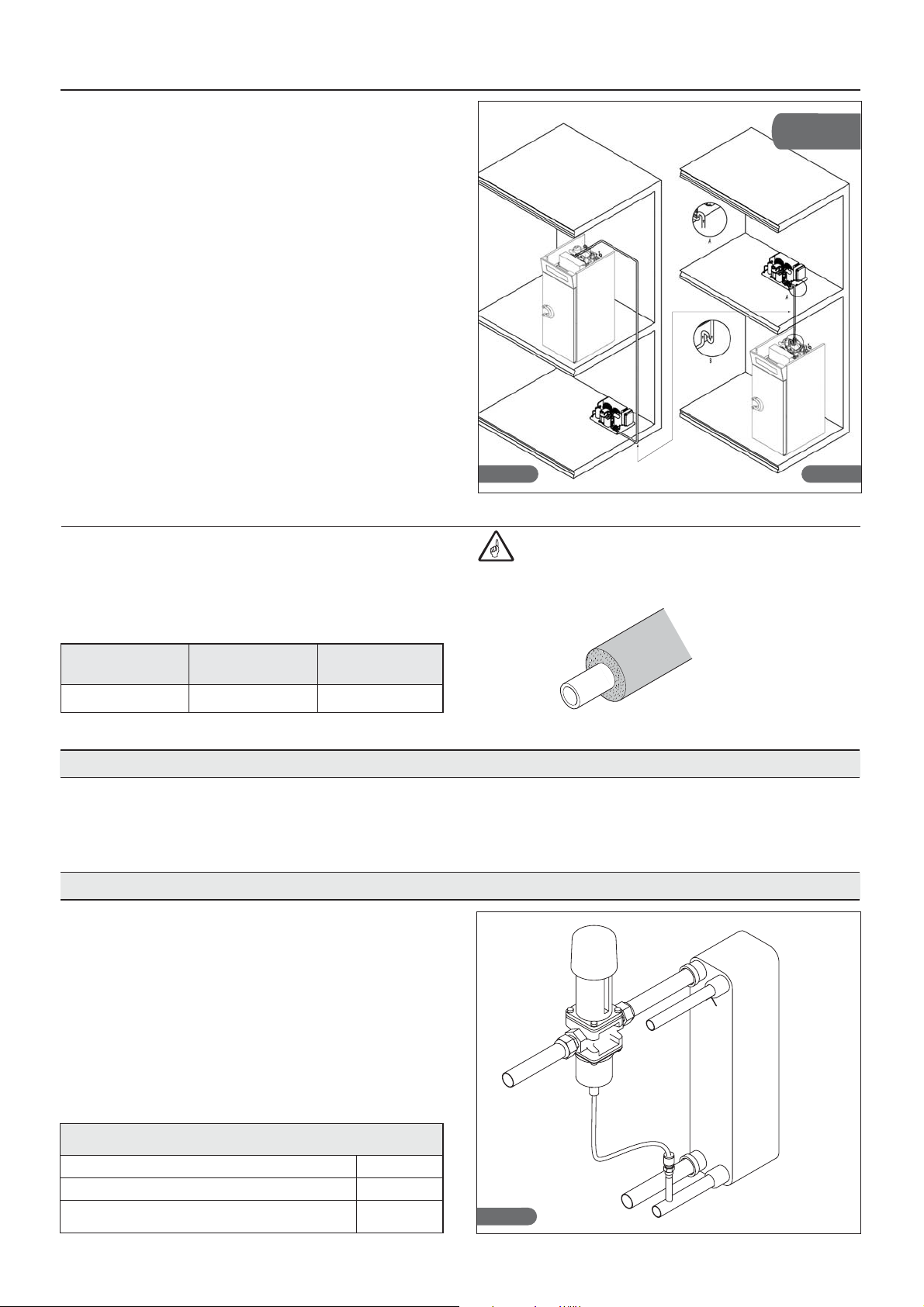

2.7. REFRIGERATOR CONNECTION

2.7.1. Equal level installation

General criteria that must be satisfied in the installation of

the remote units:

1)

Slope of the pipes (Fig.8)

Fastening brackets onto the insulated pipes.

2)

The number of brackets to be applied to the refrigerator connection line of the remote units

Table 6.

Hermetic sealing (Fig.10).

3)

Execution of the vacuum (0.03 mBar) in the connec-

4)

tion pipes (flow and intake).

5)

Check vacuum sealing of the pipes.

6)

Opening of the shut-off valves on the condensing

unit.

Leak check.

7)

8)

Check of the exact gas load via the liquid passage

indicator light on the condensing unit.

see

Fig. 8

Tabella 6

DISTANCE

Cell -> Remote unit

10 metres 3

15 metres 5

20 metres 7

25 metres 8

COMPRESSORE

2%

COMPRESSOR

NUMBER

OF BRACKETS

5 metres 2

Check of the circulation and pressure of the conden-

9)

sing water (systems with water cooling).

The criteria indicated above are sufficient for

installation at equal level (Fig.11).

The pipes must be installed so that their lengths may be

varied, using supports so they can slide and that provide sufficient space near to the walls and other obstructions.

If the cabinet holder's heat exchangers can be shut-off

from the rest of the plant via valves, these exchangers

must be protected by suitable safety devices as foreseen by the Standard EN378-2:2008+A1:2009 in chapter

6.2.6.8.

For water-cooled units or units with heat recovery: for

the choice and installation of the water pipes, the local

provisions and regulations regarding constructions and

the safety standards must be followed.

The installer must provide mechanical coupling of the

appropriately sized connections to the system and make

sure that the water inlet and outlet connections are

compliant with the dimensional drawing and with the

labels on the connections. The pipes must be supported

to reduce weight and strain on the connections. A filter

that can be inspected for filtering solid bodies must be

installed on the inlet pipe to the exchanger. If the noise

and vibrations are critical, anti-vibration joints must be

installed on the water inlet and outlet pipes from the

exchangers.

Fig. 9

Fig. 10

Equal level

installation

10

Fig. 11

Page 11

2.7.2. Different level installation

If the remote unit is installed higher with respect to the

appliance (fig.13), a siphon must be installed at every

branch or return (a), every 1.8 metres of difference in level

along the return pipe and at every delivery (b).

If the remote unit is installed lower compared to the appliance, no siphon is required (fig.12).

2.7.3. Refrigerator-remote units connection

The diameters of the appliance power supply pipes are

sized for installation distances up to 15 metres (see

Table 7).

For greater distances, contact IRINOX Spa.

Table 7

Flow line

Ø mm

61210

Pipes maximum length: 15 m

Intake line

Ø mm

Hot gas line

Ø mm

Dierent level

installation

Fig. 12 Fig. 13

L’isolamento della linea di aspirazione e del gas

Intake pipe

caldo dovrà essere fatto con isolante del tipo a cellule

chiuse di buona qualità, dello spessore minimo di 19

mm.

19 mm

2.8. CONDENSATE DRAIN

CP ONE has a basin for collecting the condensate.

The basin can be extracted from the bottom part of the

cabinet holder.

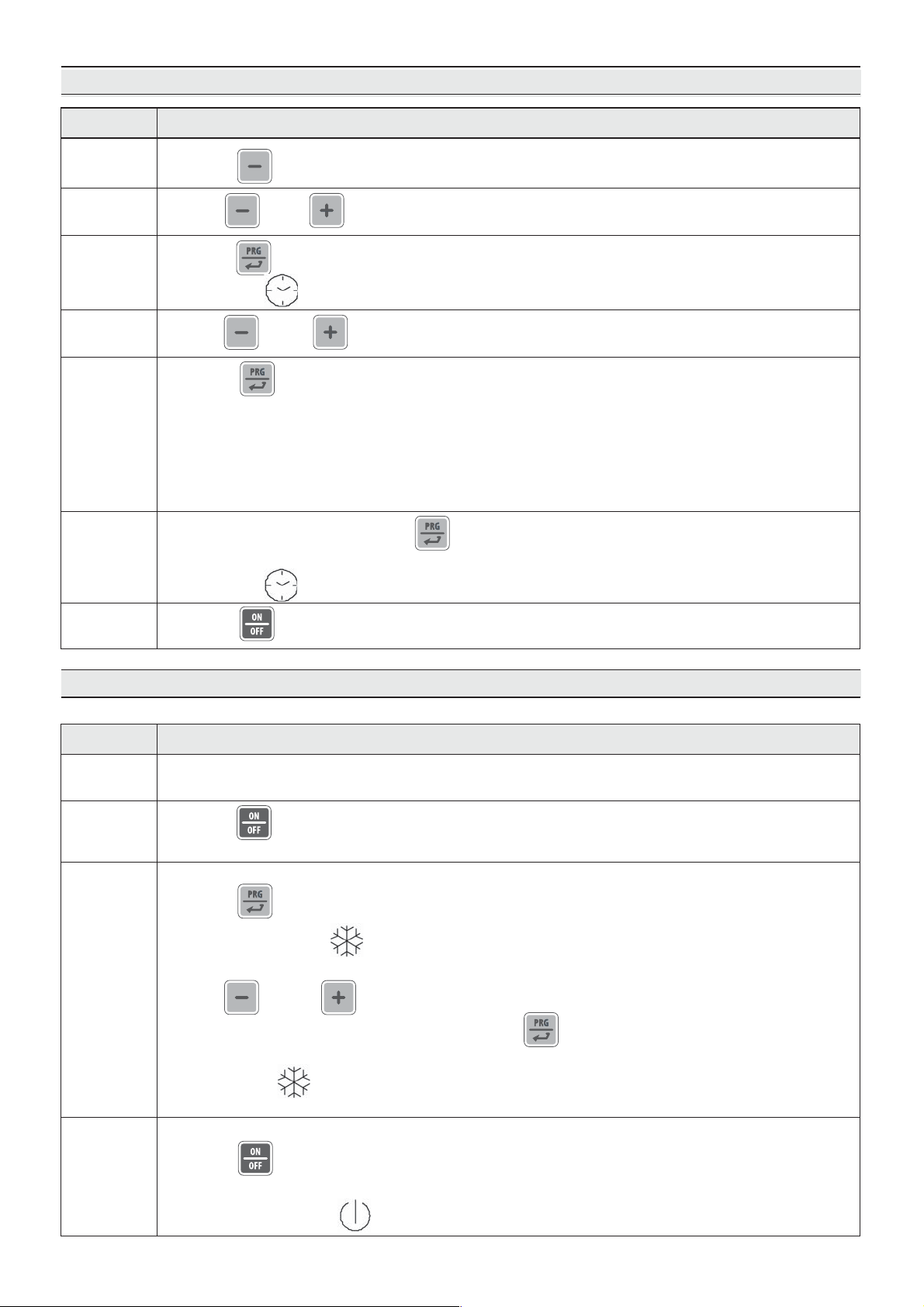

2.9. WATER COOLING UNITS CONNECTION

•

During testing (mains water), with the machine at a

standstill and water network ready, check that the

condenser drain pipe does not allow water to escape.

If this is not the case, regulate the pressure valve until

the leak stops (Fig.17).

•

It is recommended to supply a gate valve and an

inspectionable filter in the water flow line. The

condenser water flow and drain pipes are indicated by

relevant plates. Both connections are 3/8”F and threaded.

•

See Table 3 for maximum water consumption

FEATURES OF THE LINE FOR

WATER-COOLED CONDENSING UNITS

Maximum pressure of the inlet water

Minimum pressure of the inlet water

Maximum temperature of the inlet water in order to

guarantee normal functioning of the appliance

1600 KPa

50 KPa

25°C (well water)

Fig. 17

11

Page 12

2.10. NOTES FOR THE INSTALLER

Verification of correct installation and testing:

•

Check for any gas leaks from the seals or joints

made during the installation phase.

•

Check the good insulation of the connection pipes

between cabinet holder and remote condensing unit

(when foreseen).

•

Check the electrical connection.

•

Check absorption.

•

Check the standard pressures.

•

Check the water connection by regulating the pressure valve during operation and the good circulation of

the condensing water (when the holding cabinet is

water-cooled).

•

Perform at least one complete preservation cycle

(reach the set temperature), and one manual defrosting cycle.

Inform the customer regarding the exact use

of the appliance with specific reference to use and

the requirements of the customer him/herself.

Installation and the start-up must be performed by authorised staff.

2.11. SAFETY AND CONTROL SYSTEMS

•

Door micro switch (A): blocks operation of the fans in

the cell when the door is opened.

•

Protection fuses (B): protect the circuits from short

circuit and overloads.

•

Fuse holders (C): they contain the fuses and they

allow the opening and isolating of the circuits.

•

Electronic boards (D): depending on the parameters

acquired, they command and control the various

devices connected to the machine.

•

Temperature control in the cell and at defrosting end

(E): it is managed by the electronic board via NTC

probe.

Fig. A Fig. B

Fig. C

12

Fig. D

Fig. E

Fig. 19

Page 13

2.12. R404A / R452A GAS SAFETY SHEET

• Identification of dangers

High exposure to inhalation can have anaesthetic

effects. Very high exposure can cause anomalies of the

heart beat and cause sudden death. The neubulised or

sprayed product can cause cold burns to the eyes or

skin. Dangerous for the ozone layer.

• First aid measures

Inhalation

Move the accident victim away from exposure and keep

him/her warm and rested. Give oxygen if necessary.

Perform artificial respiration if breathing stops or gives

signs of stopping. In the case of cardiac arrest, perform

external cardiac compression.

Request immediate medical assistance.

Contact with the skin

Thaw the affected areas using water.

Remove contaminated clothing.

Attention: clothing can stick to the skin in the case of

cold burns. In the case of contact with the skin, wash

immediately with plenty of warm water. If symptoms

occur (irritation or the formation of blisters) request

medical assistance.

Contact with the skin

Sprays of liquid and the nebulised liquid can cause

cold burns.

It is improbable that it is dangerous due to cutaneous

absorption.

Repeated and prolonged contact can cause the removal

of sebaceous matter, with consequent dryness, cracking

and dermatitis.

• Ecological information

It decomposes relatively quickly in the lower atmosphere

(troposphere). The decomposition products are highly

dispersed and therefore have a very low concentration.

Does not affect photochemical smog (i.e. it does not lie

within the volatile organic compounds -VOC- according to

that established by the UN/ECE agreement).

The ozone destruction potential (ODP) is 0 for both R404A

and R452A measure in comparison with a standard ODP

equal to 1 for the cfc11 (according to uNeP definitions).

The Global Warming Potential of the gas is 3260 for

R404A and 2141 for R452A.

The substance is governed by the Montreal Protocol

(revision dated 1992).

The discharges of the product into the atmosphere do

not cause contamination of waters in the long term.

Contact with the eyes

Wash immediately with an eyewash or clean water,

keeping the eyelids open for at least 10 minutes.

Request immediate medical assistance.

Ingestion

Do not induce vomiting.

If the accident victim is conscious, rinse the mouth with

water and make him/her drink 200-300 ml of water.

Request immediate medical assistance.

Further medical care

Symptomatic treatment and support therapy when

indicated. Do not give adrenalin and similar

sympathomimetic drugs following exposure, due to the

risk of cardiac arrhythmia with possible cardiac arrest.

• Fire-prevention measures

Not inflammable.

The heat decomposition causes the emission of very

toxic and corrosive vapours (hydrogen chloride,

hydrogen fluoride). In the case of fire, use respiratory

aids and suitable protective clothing.

Extinguishers

Use extinguishing agents that are appropriate for the

fire.

• Use extinguishing agents that are appropriate for

the fire.

Inhalation

Higher atmospheric concentrations can cause anaesthetic

effects with possible loss of consciousness.

Very high exposure can cause anomalies of the heart

beat and cause sudden death.

Higher concentrations can cause asphyxia due to the

reduced content of oxygen in the atmosphere.

• Considerations regarding disposal

The best solution consists in recovery and recycling of

the product.

If this is not possible, destruction must take place in an

authorised plant equipped to absorb and neutralise the

acid gases and the other toxic products.

• Measures in the case of accidental leaks

Ensure adequate personal protection (with the use of

means of protection for the respiratory tract) during the

elimination of spills.

If the conditions are sufficiently safe, isolate the source

of the leak. In the presence of spills of modest size,

leave the material to evaporate on the condition that

there is suitable ventilation.

Large leaks

-ventilate the area;

-contain the leaking material with sand, earth or other

suitable absorbent material;

-prevent the liquid from penetrating drains, sewers,

basements and work holes, because the vapours can

create a suffocating atmosphere.

• Handling

Avoid the inhalation of high concentrations of vapours.

The atmospheric concentrations must be reduced to a

minimum and kept at the minimum level reasonably

possible, below the professional exposure limit.

The vapours are heavier than the air and therefore the

formation of high concentrations near to the ground is

possible, where ventilation is usually low. In these cases,

ensure adequate ventilation or wear suitable protection

devices for the respiratory tract with air reserve. Avoid

contact with naked flames and hot surfaces as irritant and

toxic decomposition products can be formed. Avoid

contact between the liquid and the eyes/skin.

13

Page 14

2.13 DISPOSING OF THE MACHINE

The machine must be demolished and disposed of in

compliance with the Standards in force in the country of

installation, especially regarding the compressor

coolant gas and lubricant oil.

Prevent coolant gas from leaking into the environment

by using suitable pressure containers and instruments

for pouring the fluid under pressure. This operation

must be entrusted to staff competent with refrigeration

plants.

INFORMATION FOR THE USERS

On implementation of the 2002/95/EC and

2002/96/EC Directives, relative to the

reduction of use of dangerous substances

in electrical and electronic appliances, as

well as disposal of waste.

The barred bin symbol on the appliance or package

indicates that at the end of the product's life it must be

collected separately from other waste.

The separate waste collection of this appliance at the

end of its life is organised and managed by the manufacturer. The user that wishes to dispose of this equipment must therefore contact the manufacturer and

follow the system that has been adopted to allow the

separate collection of the appliance at the end of its life

span. The suitable separate collection for successive

start-up of the appliance abandoned for recycling, treatment and compatible environmental disposal contributes to preventing possible negative effects on the

environment and favours the re-use and/or recycling of

the materials of which the appliance is made.

The abusive disposal of the product by the owner leads

to the application of administrative sanctions envisioned

by the Standard.

14

Page 15

3. OPERATION

3.1. USE

The CP ONE cabinet holder is designed for preservation of food products.

CP ONE can work at +15 / -25°C.

Especially:

• POSITIVE mode (3°C), suitable for the preservation of

fresh products, or for brief periods, of cooked food;

• NEGATIVE Mode (-20°C), suitable for the preserva-

tion of frozen products also for long periods of time;

• CHOCOLATE Mode (14°C), suitable for the preserva-

tion of chocolate based products (for example pralines).

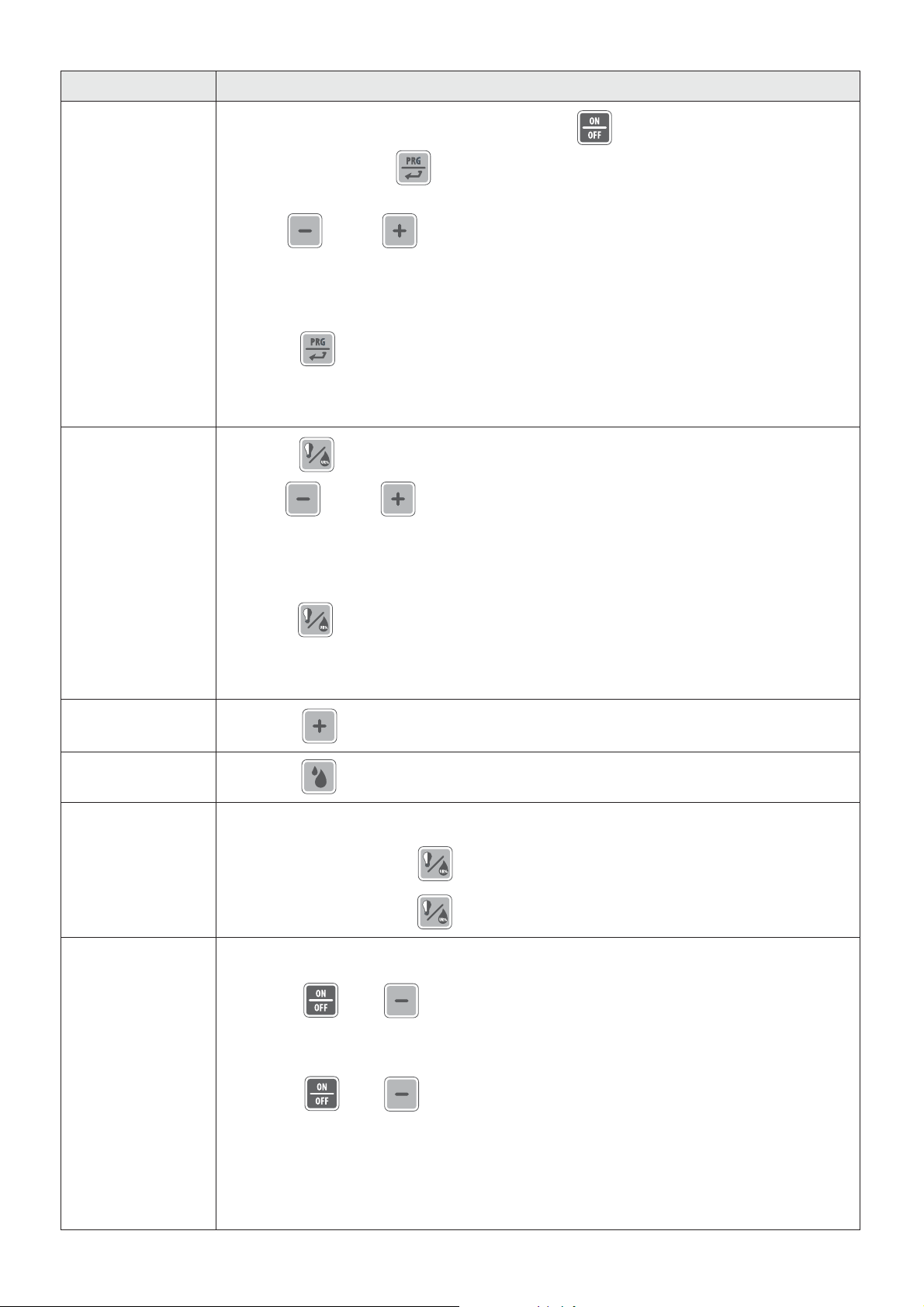

3.2. CONTROL PANEL

P1 P2 P3

Fig. 20

P4 P5 P6

P1: Light/humidity key

P2: Manual defrosting key

P3: ON/Stand By key

P4: Values decrease key

P5: Programming key

P6: Values increase key

15

Page 16

DATE AND TIME ADJUSTMENT

DescriptionPhase

1

2

3

4

5

6

Press P4 for 1 second

Use P4 or P6 to select “rtc” on the display

Press P5 to confirm and access the clock setting menu.

The indicator flashes

Use P4 or P6 to select the current year (last 2 digits e.g. 2011 = 11)

Press P5 to confirm and move on to the following setting.

In sequence:

- YEAR (display: “YY 01”)

- MONTH (display: “nn 01”)

- DAY (display: “dd 01”)

- HOUR (display: “hh 01”) in 24 hour format

- MINUTES (display: “nn 01”)

After setting the minutes, press P5 to confirm and save

the clock setting. "rtc" appears on the display.

The indicator goes off.

7

Press P3 to exit the menu.

3.3. DESCRIPTION AND OPERATION

Preservation cycle

1

2

3

With the cabinet holder in Stand-by, select the operating mode.

See paragraph Common functions ☞ Operating mode selection.

Press P3 for 2 seconds to start preserving.

– The display shows the detected cell temperature

Changing set temperature:

Press P5 :

– The indicator flashes

– The display shows the setpoint

Use P4 and P6 to change the setpoint

– Do not press any key for 15 seconds or press P5 to exit

and save the modification.

DescriptionPhase

– The indicator stops flashing

– The display shows the detected cell temperature

4

Finish preserving

Press P3 for 2 seconds

– The display turns off ☞ cabinet holder Stand-by

– The indicator turns on

16

Page 17

Common functions

DescriptionFunction

Operating mode

selection.

Humidity control

(for POSITIVE

or CHOCOLATE

mode)

Put the cabinet holder in Stand-by by pressing P3 .

Press P5 for 4 seconds .

The display shows the set operating mode.

Use P4 and P6 to set the desired operating mode

where:

POS = POSITIVE mode

NEG = NEGATIVE mode

CIOC = CHOCOLATE mode

Press P5 to confirm the data entered and exit the menu.

If no key is pressed, after a pre-set time

one automatically exits the menu and the entered data is saved.

Press P1 for 4 seconds.

Use P4 and P6 to set the relative humidity level

desired, where:

Ur1= low humidity

Ur2= average humidity

Ur3= high humidity

Overcooling

Manual defrost

Switching on

of cell light

Key locking

Press P1 to confirm the data entered and exit the menu.

If no key is pressed, after a pre-set time

one automatically exits the menu and the entered data is saved.

Press P6 for 4 seconds to start up the Overcooling cycle.

Press P2 for 4 seconds to start up the Manual defrost cycle.

Upon door opening, the light inside the cell is automatically switched on.

With the light off, press P1 to switch the light on inside the cell.

With the light on, press P1 to switch the light off inside the cell.

To lock operation of the keys:

Press P3 + P4 simultaneously for 1 second.

The display shows "Loc" for 1 second.

To unlock operation of the keys:

Press P3 + P4 simultaneously for 1 second.

The display shows "UnL" for 1 second.

17

Page 18

Signals

Indicator

Steady Flashing

Compressor command

Defrosting in progress

Evaporating fan command

Light inside cell manually switched on

by pressing P1

Liquid line solenoid valve command

NOT USED

All information regarding

the HACCP alarms

NOT USED

Meaning

Change temperature set point

Compressor run requested but pending

safety time end

Defrosting in progress but pending

compressor safety time end

During evaporating fan stop time

Internal cell light switched on for door opening

NOT USED

Date and time change in progress

At least one new HACCP alarm

was recorded.

NOT USED

Indications

NOT USED

OverCooling cycle in progress

Alarm or error is in progress

The temperature unit of measurement is °C

The temperature unit of measurement is °F

The instrument is in standby

Display

Key lock activated

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

Meaning

Running set point locked

Operation required not available

18

Page 19

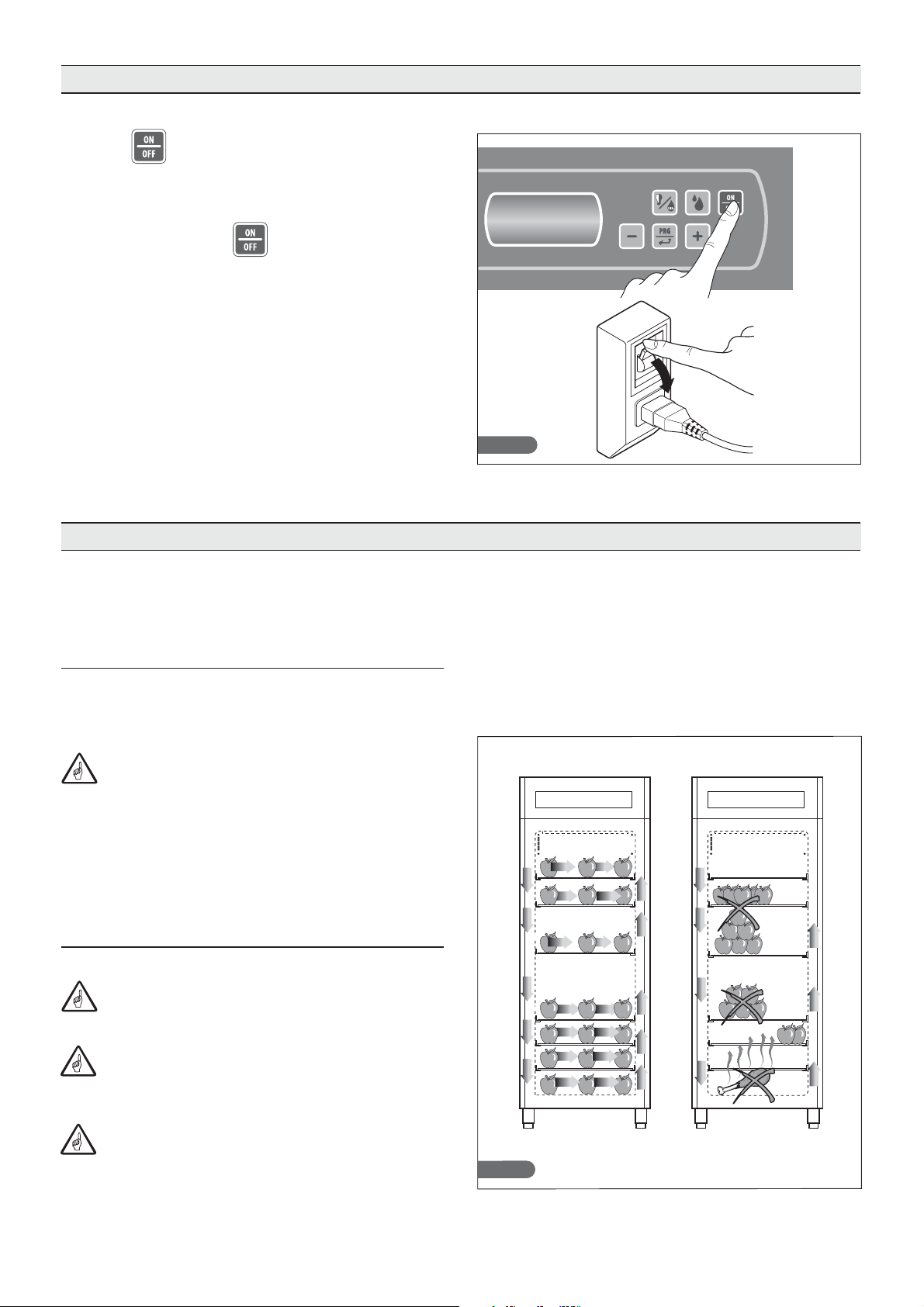

3.4. STOP MODES

In case of emergency, to switch off the cabinet holder,

press P3 for 2 seconds and disconnect power

supply.

ATTENTION! Press P3 with machine running to

place the cabinet holder in Stand-by: all the commands

are removed from the various components; the cabinet

holder IS NOT DISCONNECTED FROM THE POWER

SUPPLY.

3.5. RECOMMENDATIONS FOR USE

Before starting the machine, clean the inside of the cell

thoroughly ( see par. 4.2).

Fig. 20

Fig. 21

3.5.1. Pre-cooling

Before using the cabinet holder for the first time or after a

period of downtime, pre-cool the cell by running the

machine on empty until the operating temperature is set.

In order to have good machine performance and

not have deterioration of food, we recommend you:

•

do not put hot foods or liquids in containers without

lids into the cell.

•

arrange the products in order to favour cold air circulation throughout the cell.

•

avoid opening the door for a prolonged time and

frequently.

3.5.2. Loading the machine

Maximum load per shelf: 35 kg

Make sure that a sufficient space is left between

the trays for suitable air circulation.

If the machine is not completely loaded, distribute

the trays and the load over the entire useful height

avoiding accumulation.

OK! NO!

When the CP ONE is used in Positive mode

(20÷0°C), run the cabinet holder on empty for at least 4

hours in order to work at the desired relative humidity.

Fig. 22

19

Page 20

4. MAINTENANCE

4.1. ROUTINE MAINTENANCE:

The information and the instructions in this chapter are

intended for all staff operating the machine: the user, the

maintenance technician and the unskilled staff.

Elementary Safety Standards

To carry out routine cleaning and maintenance safely,

follow the safety regulations of (

•

do not touch and operate the machine with humid or

wet hands or feet,

•

do not insert screwdrivers, kitchen tools or any other

object between the protections and moving parts

•

before performing any cleaning or routine maintenance

operation, disconnect the machine from the electrical

power supply by turning the main switch off and removing the plug.

do not pull the power supply cable to disconnect the

•

machine from the power supply mains.

Fig.23) :

It is prohibited to remove the protections and safety

devices in order to perform routine maintenance. The

Manufacturer declines any liability for accidents caused by

failure to comply with the aforementioned obligation.

Before starting the machine, clean the inside of the

cell thoroughly, as indicated in paragraph 4.2.

4.2. CLEANING THE CELL

In order to guarantee hygiene and protection of the quality

of the foodstuffs treated, the internal cleaning of the cell

must be performed frequently, depending on the type of

food preserved.

Weekly cleaning is recommended.

The conformation of the cell and the internal components

can be washed using a cloth or sponge.

Clean using water and non-abrasive neutral detergents.

Rinsing can be done with a cloth or sponge soaked in

water, or with a

moderate jet of water (not exceeding the mains pressure).

Do not scrape the surfaces with sharp or abrasive

bodies.

Fig. 23

Fig. 24

Do not use abrasives or solvents and thinners.

Always wear protective gloves during the

cleaning operations.

Do not use cleaning agents containing acetic acid

and derivatives or ammonia;

Do not use the holding cabinet in direct contact with

products emanating acetic acid and derivatives or

ammonia

20

Page 21

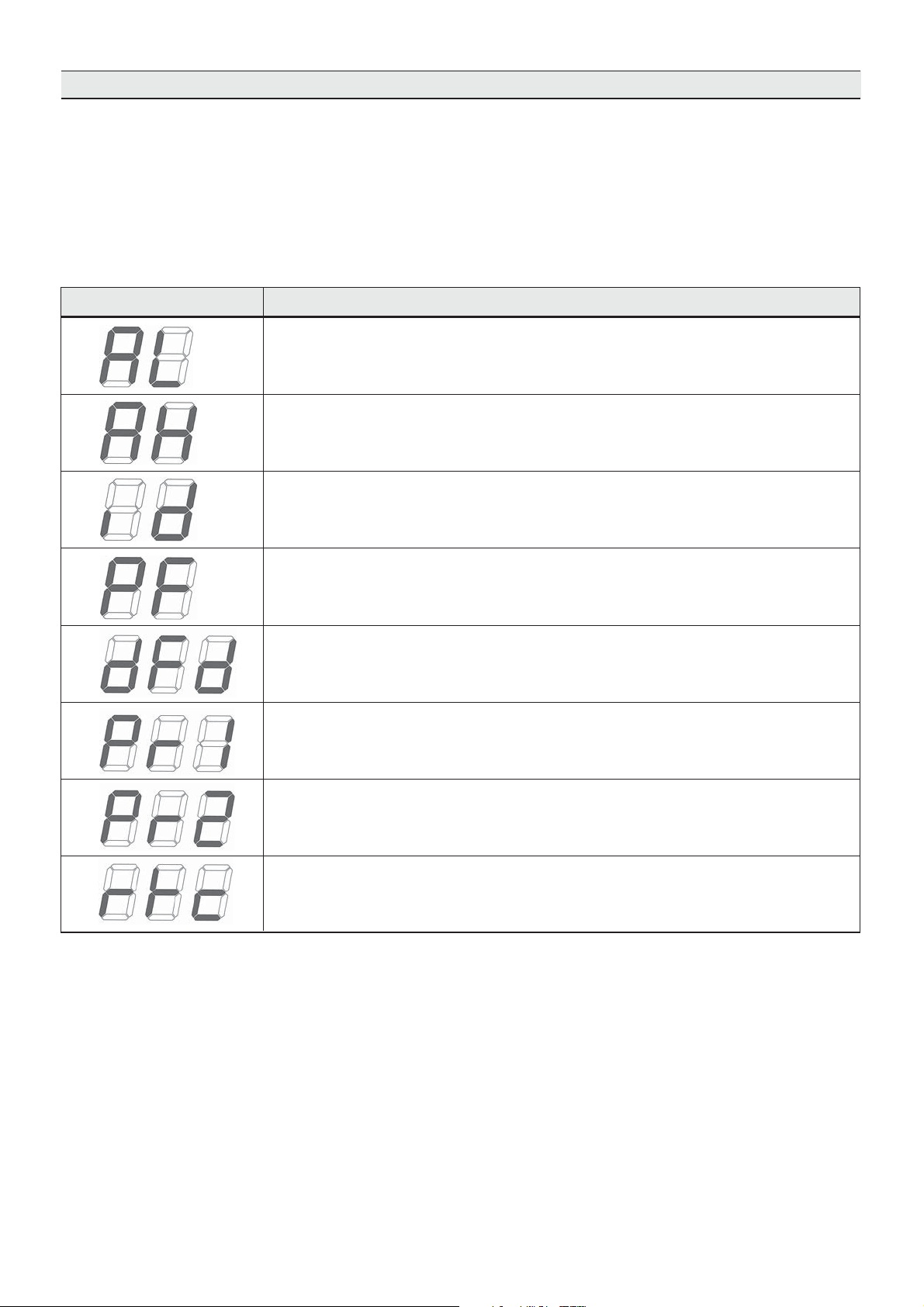

4.3. TROUBLESHOOTING

The machines' electronic control is supplied with a sound

and visual signal system which signals the presence of an

alarm; press a key to silence the sound alarm.

Diagnostics managed by the electronics:

Display

Meaning

Minimum temperature (HACCP alarm)

Maximum temperature (HACCP alarm)

Open door (HACCP alarm)

No voltage (HACCP alarm)

Defrosting ended due to maximum duration

Faulty chamber probe

Faulty evaporator probe

Clock error

21

Page 22

Diagnostics NOT managed by the electronics:

MALFUNCTION POSSIBLE CAUSE POSSIBLE SOLUTION

No power supply Check the connection to the electrical line

The cell front board does

not switch on

Protective fuses triggered Fuse replacement by an authorised

technician

The cell fans do not turn

The compressor does

not function

The compressor functions but

does not cool the cell

No power supply

Faulty fan

Faulty board

No power supply Verificare l'allacciamento alla linea elettrica

Intervention of the internal Klixson

due to overloads

No electronic board consent Check the connection to the electrical line

No coolant gas Technician intervention

Faulty solenoid valve Technician intervention

Dirty condenser Clean condensing battery

Faulty liquid line solenoid valve Intervention of a technician to replace

Faulty defrost line solenoid valve Intervention of a technician to replace

Check the connection to the electrical line

Technician intervention to replace

the board

Technician intervention to replace

the board

Intervento di un tecnico

the solenoid valve or coil

the solenoid valve or coil

The condenser fan does

not function

No evaporator

defrosting

No power supply Check the connection to the electrical line

Faulty fan Intervention of a technician

to replace the fan

No electronic board consent Technician intervention to replace

the electronic board

Defrosting cycle incorrect programming Control defrosting cycles programming

Faulty defrosting line coil or solenoid valve Intervention of a technician to replace

the solenoid valve or coil

22

Page 23

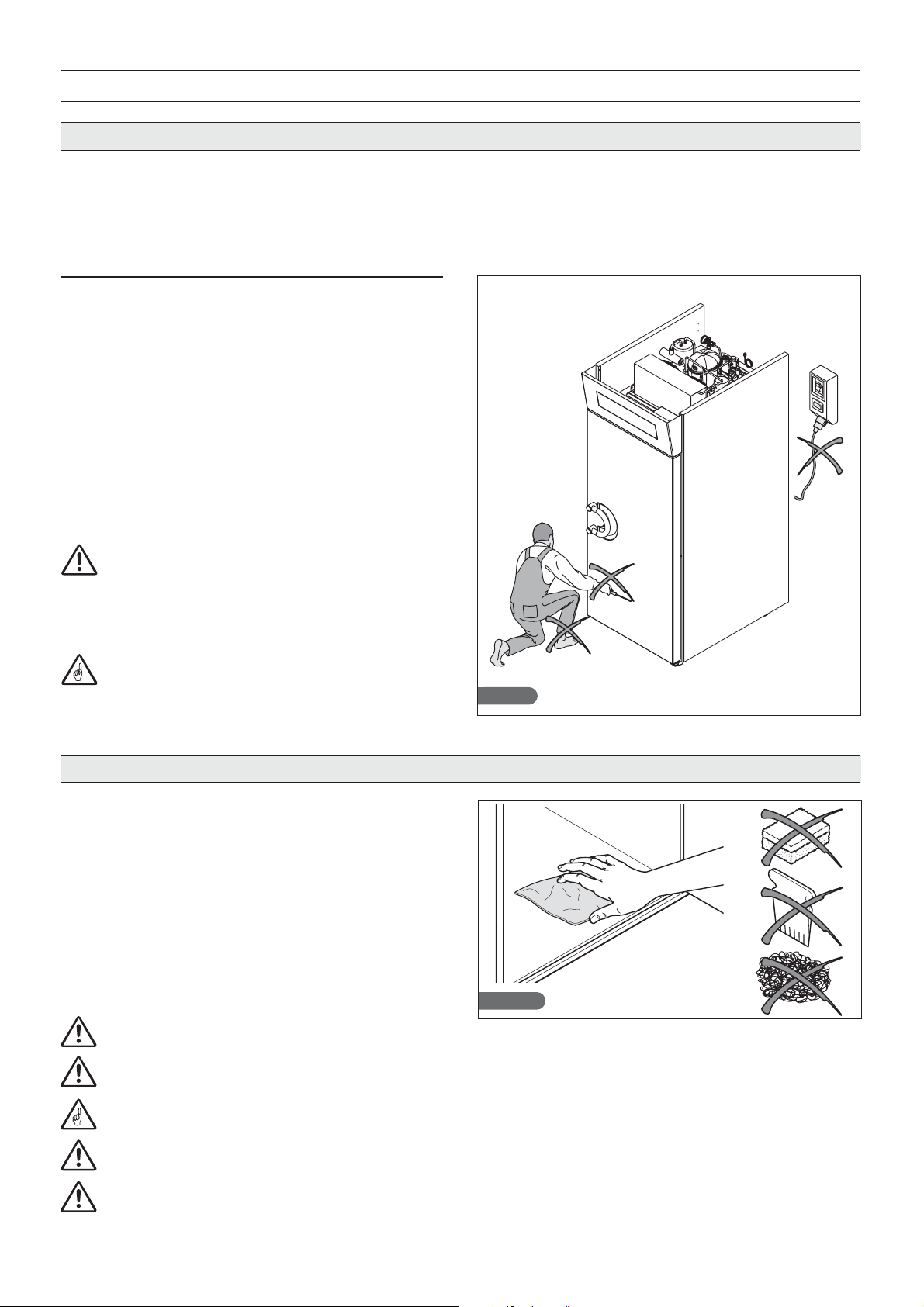

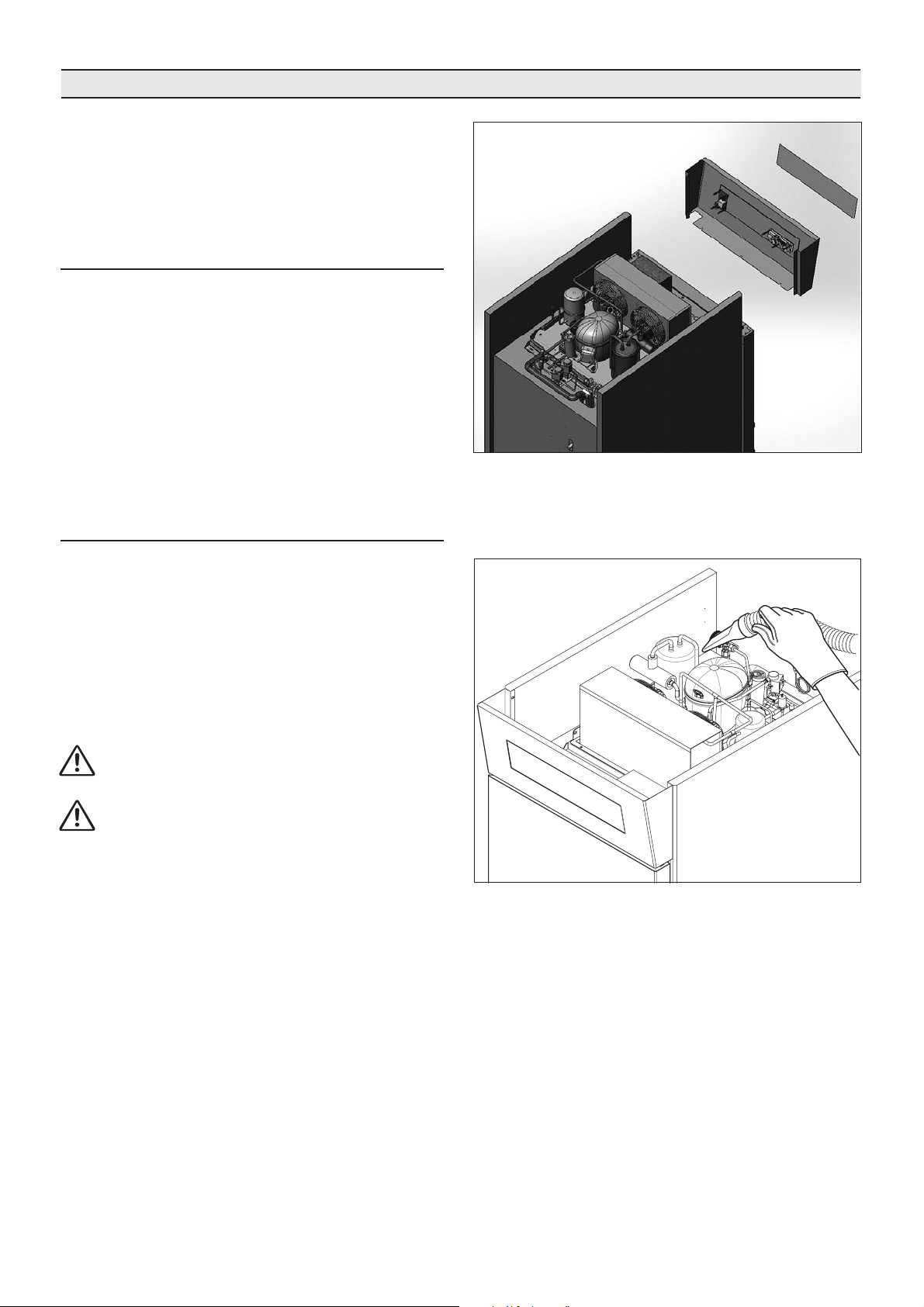

4.4. EXTRAORDINARY MAINTENANCE

The information and instructions in this paragraph are

destined exclusively to the specialised staff authorised

to intervene on the electrical and refrigerator components of the machine.

4.4.1. How to access the electronic boards and the

electrical control panels.

The electronic boards and the electrical control panels

are located on the top part of the machine, protected by

a metal sheet. Remove the electrical power supply

before intervening for maintenance. Then remove the

steel cover, unscrewing the locking screws.

At the end of maintenance operations, accurately reassemble the covers and tighten the locking screws.

4.4.2. Cleaning the condenser

For correct and efficient functioning of the cabinet

holder, the air condenser must be kept clean in order to

allow the free circulation of the air. This operation must

be performed every 30 days maximum. It can be carried

Fig. 29

out using non-metal brushes in order to remove all of

the dust and soot from the condenser fins themselves.

The use of a suction device is recommended in order to

prevent the dispersion of the dust removed into the

environment. Whenever there are greasy deposits, use

a brush soaked in alcohol.

Fig. 28

Do not scrape the surfaces with sharp or abrasive

bodies.

During the above-mentioned operations, always

wear protective gloves, glasses and masks for protection

of the respiratory tract.

23

Page 24

IRINOX

headquarter

via Madonna di Loreto, 6/B

31020 Corbanese di Tarzo (TV) - Italy

production site

via Caduti nei lager, 1

Z.I. Prealpi Trevigiane, loc. Scomigo

31015 Conegliano (TV) - Italy

P. +39 0438 2020

F. +39 0438 2023

irinox@irinox.com

www.irinoxprofessional.com

- Printed in Italy

Cod. 4430141 - n. rev. 01 - 09/2017

Loading...

Loading...