Bulletin PD-20744 rev. B 02/06

150EBU04

Ultrafast Soft Recovery Diode

Features

• Ultrafast Recovery

• 175°C Operating Junction Temperature

• Screw Mounting Only

• Lead-Free Plating

Benefits

• Reduced RFI and EMI

• Higher Frequency Operation

• Reduced Snubbing

• Reduced Parts Count

Description/ Applications

These diodes are optimized to reduce losses and EMI/ RFI in high frequency power conditioning systems.

The softness of the recovery eliminates the need for a snubber in most applications. These devices are ideally suited

for HF welding, power converters and other applications where switching losses are not significant portion of the total

losses.

t

= 60ns

rr

I

= 150Amp

F(AV)

VR = 400V

Absolute Maximum Ratings

Parameters Max Units

V

R

I

F(AV)

I

FSM

I

FRM

TJ, T

Square Wave, 20kHz

Cathode to Anode Voltage 400 V

Continuous Forward Current, TC = 104°C 150 A

Single Pulse Forward Current, TC = 25°C 1500

Maximum Repetitive Forward Current 300

Operating Junction and Storage Temperatures - 55 to 175 °C

STG

Case Styles

PowIRtab

www.irf.com

1

150EBU04

Bulletin PD-20744 rev. B 02/06

Electrical Characteristics @ T

= 25°C (unless otherwise specified)

J

Parameters Min Typ Max Units Test Conditions

VBR, VrBreakdown Voltage, 400 - - V IR = 200µA

Blocking Voltage

V

F

I

R

C

L

Forward Voltage - 1.07 1.3 V IF = 150A

- 0.9 1.1 V IF = 150A, TJ = 175°C

- 0.96 1.17 V IF = 150A, TJ = 125°C

Reverse Leakage Current - - 50 µA VR = VR Rated

--4mATJ = 150°C, VR = VR Rated

Junction Capacitance - 100 - pF VR = 400V

T

Series Inductance - 3.5 - nH Measured lead to lead 5mm from package body

S

Dynamic Recovery Characteristics @ TJ = 25°C (unless otherwise specified)

Parameters Min Typ Max Units Test Conditions

t

I

RRM

Q

rr

rr

Reverse Recovery Time --60 ns IF = 1.0A, diF/dt = 200A/µs, VR = 30V

I

-93- TJ = 25°C

- 172 - TJ = 125°C

Peak Recovery Current - 11 - A TJ = 25°C

-20- TJ = 125°C

Reverse Recovery Charge - 490 - nC TJ = 25°C

- 1740 - TJ = 125°C

= 150A

F

VR = 200V

diF /dt = 200A/µs

Thermal - Mechanical Characteristics

Parameters Min Typ Max Units

R

thJC

R

thCS

Wt Weight 5.02 g

T Mounting Torque 1.2 2.4 N * m

Mounting Surface, Flat, Smooth and Greased

2

Thermal Resistance, Junction to Case 0.35 K/W

Thermal Resistance, Case to Heatsink 0.2

0.18 (oz)

10 20 lbf.in

www.irf.com

0.001

0.01

0.1

1

10

100

1000

0 100 200 300 400

25˚C

T = 175˚C

J

125˚C

1000

(A)

F

100

10

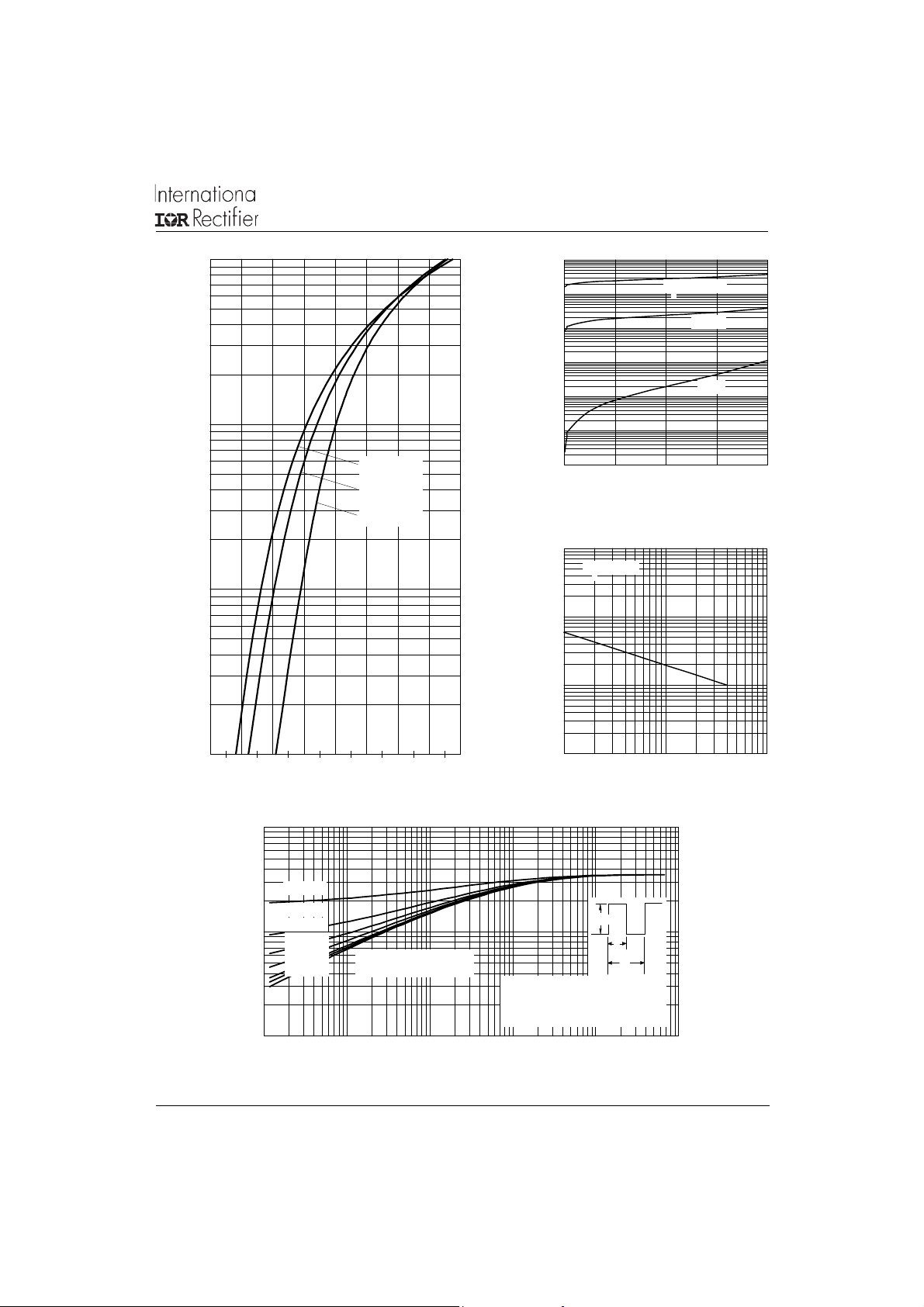

Instantaneous Forward Current - I

T = 175˚C

J

T = 125˚C

J

T = 25˚C

J

150EBU04

Bulletin PD-20744 rev. B 02/06

(µA)

R

Reverse Current - I

Reverse Voltage - VR (V)

Fig. 2 - Typical Values Of Reverse Current

10000

(pF)

T

1000

Vs. Reverse Voltage

T = 25˚C

J

www.irf.com

1

0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8

Fig. 1 - Typical Forward Voltage Drop Characteristics

Forward Voltage Drop - VFM (V)

1

(°C/W)

thJC

D = 0.50

D = 0.20

D = 0.10

0.1

D = 0.05

D = 0.02

D = 0.01

Thermal Impedance Z

Single Pulse

(Thermal Resistance)

0.01

0.00001 0.0001 0.001 0.01 0.1 1

t1, Rectangular Pulse Duration (Seconds)

Fig. 4 - Max. Thermal Impedance Z

100

Junction Capacitance - C

10

10 100 1000

Reverse Voltage - VR (V)

Fig. 3 - Typical Junction Capacitance

Vs. Reverse Voltage

P

DM

t

1

t

2

Notes:

1. Duty factor D = t1/ t 2

2. Peak Tj = Pdm x ZthJC + Tc

Characteristics

thJC

3

150EBU04

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

100 1000

IF = 150A

IF = 75A

Vr = 200V

Tj = 125˚C

Tj = 25˚C

Bulletin PD-20744 rev. B 02/06

180

160

140

DC

120

100

Square wave (D = 0.50)

Rated Vr applied

80

60

Allowable Case Temperature (°C)

see note (3)

40

0 50 100 150 200 250

Average Forward Current - IF

Fig. 5 - Max. Allowable Case Temperature

Vs. Average Forward Current

250

Vr = 200V

Tj = 125˚C

Tj = 25˚C

200

(A)

(AV)

IF = 150A

IF = 75A

300

250

200

150

100

RMS Limit

D = 0.01

D = 0.02

D = 0.05

D = 0.10

DC

50

Average Power Loss ( Watts )

0

0 50 100 150 200 250

Average Forward Current - IF

D = 0.20

D = 0.50

DC

(AV)

Fig. 6 - Forward Power Loss Characteristics

(A)

150

trr ( ns )

100

50

100 1000

di

Fig. 7 - Typical Reverse Recovery time vs. di

(3) Formula used: TC = TJ - (Pd + Pd

Pd = Forward Power Loss = I

Pd

= Inverse Power Loss = VR1 x IR (1 - D); IR @ V

REV

4

/dt (A/µs )

F

REV

x VFM @ (I

F(AV)

) x R

thJC

;

F(AV)

/dt

F

/ D) (see Fig. 6);

= rated V

R1

Qrr ( nC )

di F /dt (A/µs )

Fig. 8 - Typical Stored Charge vs. di

R

/dt

F

www.irf.com

Reverse Recovery Circuit

V = 200V

R

0.01

Ω

L = 70µH

D.U.T.

150EBU04

Bulletin PD-20744 rev. B 02/06

di F /dt

dif/dt

ADJUST

G

Fig. 9- Reverse Recovery Parameter Test Circuit

I

F

t

a

0

1

di F /dt

di /dt

f

1. diF/dt - Rate of change of current through zero

crossing

2. I

- Peak reverse recovery current

RRM

3. t

- Reverse recovery time measured from zero

rr

crossing point of negative going IF to point

where a line passing through 0.75 I

and 0.50 I

current

RRM

extrapolated to zero

Fig. 10 - Reverse Recovery Waveform and Definitions

RRM

3

2

D

IRFP250

S

t

rr

t

b

Q

I

RRM

0.5

di(rec)M/dt

0.75

I

RRM

4. Qrr - Area under curve defined by t

and I

RRM

Q

rr

5. di

/ dt - Peak rate of change of

(rec) M

current during t b portion of t

I

=

4

rr

RRM

t rr x I

2

5

rr

RRM

rr

www.irf.com

5

150EBU04

Bulletin PD-20744 rev. B 02/06

Outline Table

Dimensions in millimeters and (inches)

Ordering Information Table

Device Code

150 E B U 04

52

1

1 - Current Rating (150 = 150A)

2 - Single Diode

3 - PowIRtab (Ultrafast/ Hyperfast only)

4 - Ultrafast Recovery

5 - Voltage Rating (04 = 400V)

Data and specifications subject to change without notice.

This product has been designed and qualified for Industrial Level and Lead-Free.

IR WORLD HEADQUARTERS: 233 Kansas St., El Segundo, California 90245, USA Tel: (310) 252-7105

Visit us at www.irf.com for sales contact information. 02/06

4

3

Qualification Standards can be found on IR's Web site.

TAC Fax: (310) 252-7309

6

www.irf.com

Loading...

Loading...