Wireless Digital Flat Panel Detector

E

Mars1417V

User Manual

To Customer

Document Version: A1

Document ID: 085-201-02

Release Date: 2019-08-22

Before operating, please read this user manual and pay attention to all safety precautions.

Please ensure that this user's manual is properly maintained so that it can be accessed at any time

(reserve).

Please use it correctly on the basis of full understanding of the content.

iRay Technology Co. Ltd.………………………………………………………………………………………………………………………………….………..

1

Mars1417V Digital Flat Panel Detector User Manual

Congratulations on your purchase of iRay Mars1417V (configuration: Mars1417V3)

Digital Flat Panel. At iRay, we strive to not only make the world-class products that

Service Office

Tel: +86 21 50720560

Fax: +86 21 50720561

E-mail: service@iraygroup.com

Location: Rm. NO.33 Xinggang Road, Taicang Port Economic and

Technological Development Zone, Jiangsu, China, PC: 215434

deliver the best value to our users but also offer the highest quality of service and customer care. Please

take time to read user manual to utilize the product effectively. We hope you enjoy the experience with

Mars1417V (configuration: Mars1417V3).

If you have any questions or suggestions, please feel free to contact us.

Notes on usage and management of the equipment

1. Read all of the instructions in user manual before operation. Give particular attention

to all safety precautions.

2. Only a physician or a legally certified operator could use the product.

3. The product should be maintained in a safe and operable condition by maintenance

personnel.

4. Use computers and image display monitors complying with IEC 60601-1 or IEC

60950-1. For details, consult our sales representative or local iRay dealer.

5. Use dedicated cables. Do not use any cables other than those supplied with the

product.

6. Request your sales representative or local iRay dealer to install the product

2

..................................................................................................................................................iRay Technology Co. Ltd.

Caring for your environment

This symbol indicates that this product is not to be disposed of with your residential or

commercial waste

Recycling iRay Equipment

Please do not dispose of this product with your residential or commercial waste. Improper

handling of this type of waste could have a negative impact on health and on environment.

Some countries or regions, such as the European Union, have set up systems to collect and

recycle electrical or electronic waste. Contact your local authorities for information about

dropping off waste product for recycling. If collection systems are not available, call iRay

Customer Service for assistance.

Disclaimer

1. iRay shall not be liable to the purchaser of this product or third parties for any

damage, loss, or injury incurred by purchaser or third parties as a result of fire,

To Customer

Copyright

earthquake, any accident, misuse or abuse of the product.

2. iRay shall not be liable to any damage, loss, or injury arising from unauthorized

modifications, repairs, or alterations to the product or failure to strictly comply with

iRay’s operating and maintenance instructions.

3. iRay shall not be liable for any damage or loss arising from the use of any options or

consumable products other than those dedicated as Original products by iRay

Technology.

4. It is the responsibilities of user or physician to maintain the privacy of image data

and provid medical care services. iRay shall not be responsible for the legality of

image processing , reading and storage nor it shall be responsible for loss of image

data for any reason.

5. Information regarding specification, compositions, and appearance of this product is

subject to change without prior notice.

1. All rights reserved

2. No part of this publication may be reproduced in any form or by any means without

the written permission of iRay. The information contained herein is designed only

for use with iRay Mars1417V.

Trademarks

The iRay name and iRay logo are registered trademarks of Shanghai iRay Technology Ltd.

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

3

Mars1417V Digital Flat Panel Detector User Manual

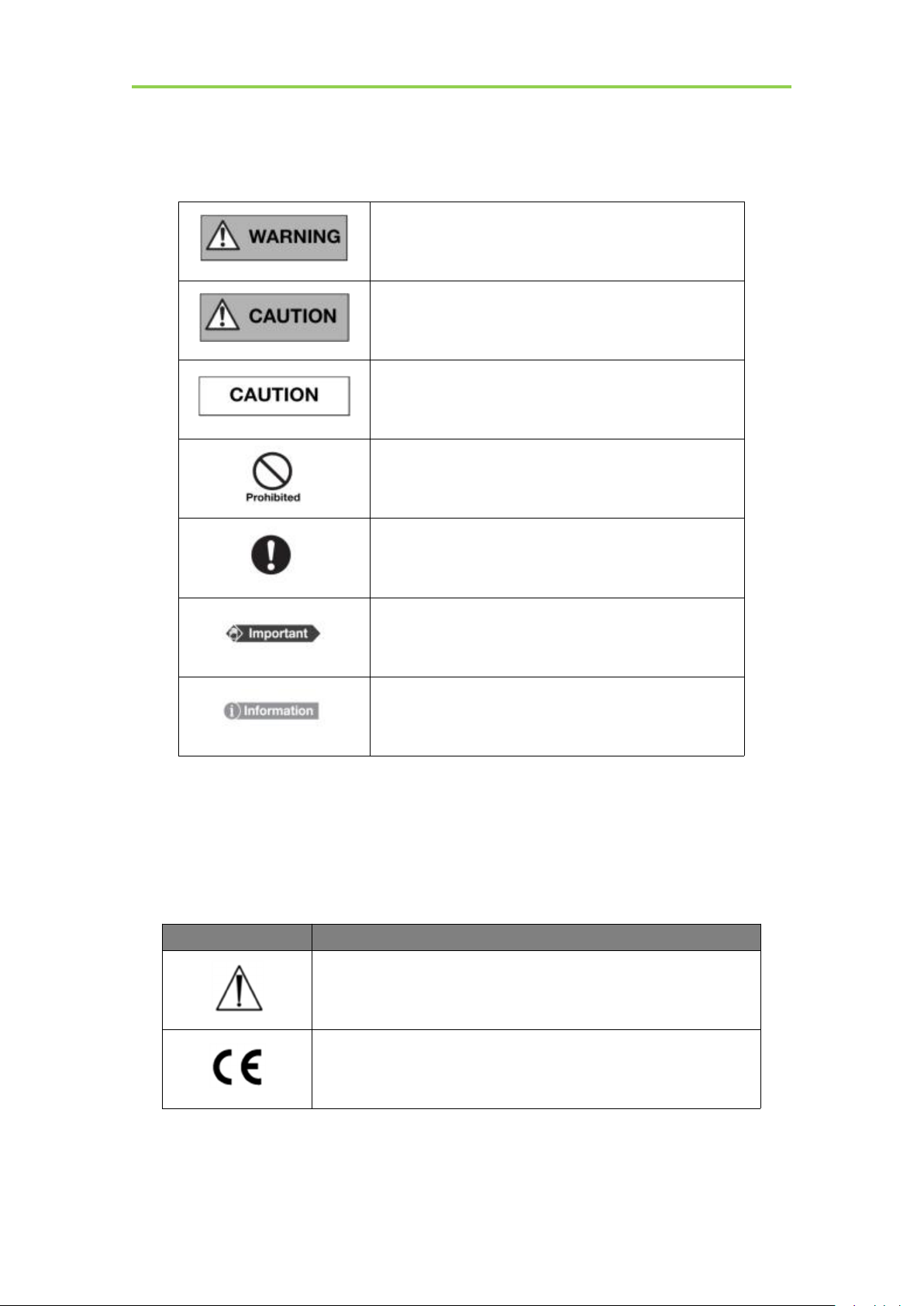

This symbol is used to identify conditions under which

improper use of the product may cause death or serious

personal injury.

This notice is used to identify conditions under which

improper use of the product may cause minor personal

injury.

This notice is used to identify conditions under which

improper use of the product may cause property damage.

This is used to indicate a prohibited operation.

This is used to indicate an action that must be performed.

This is used to indicate important operations and

restrictions.

This is used to indicate operations for reference and

complementary information.

ICON

MEANING

Caution: please refer to the instructions in user manual.

This symbol indicates that the product has passed CE certification

and followed by CE number.

Symbols and Conventions

The following symbols and conventions are used in user manual.

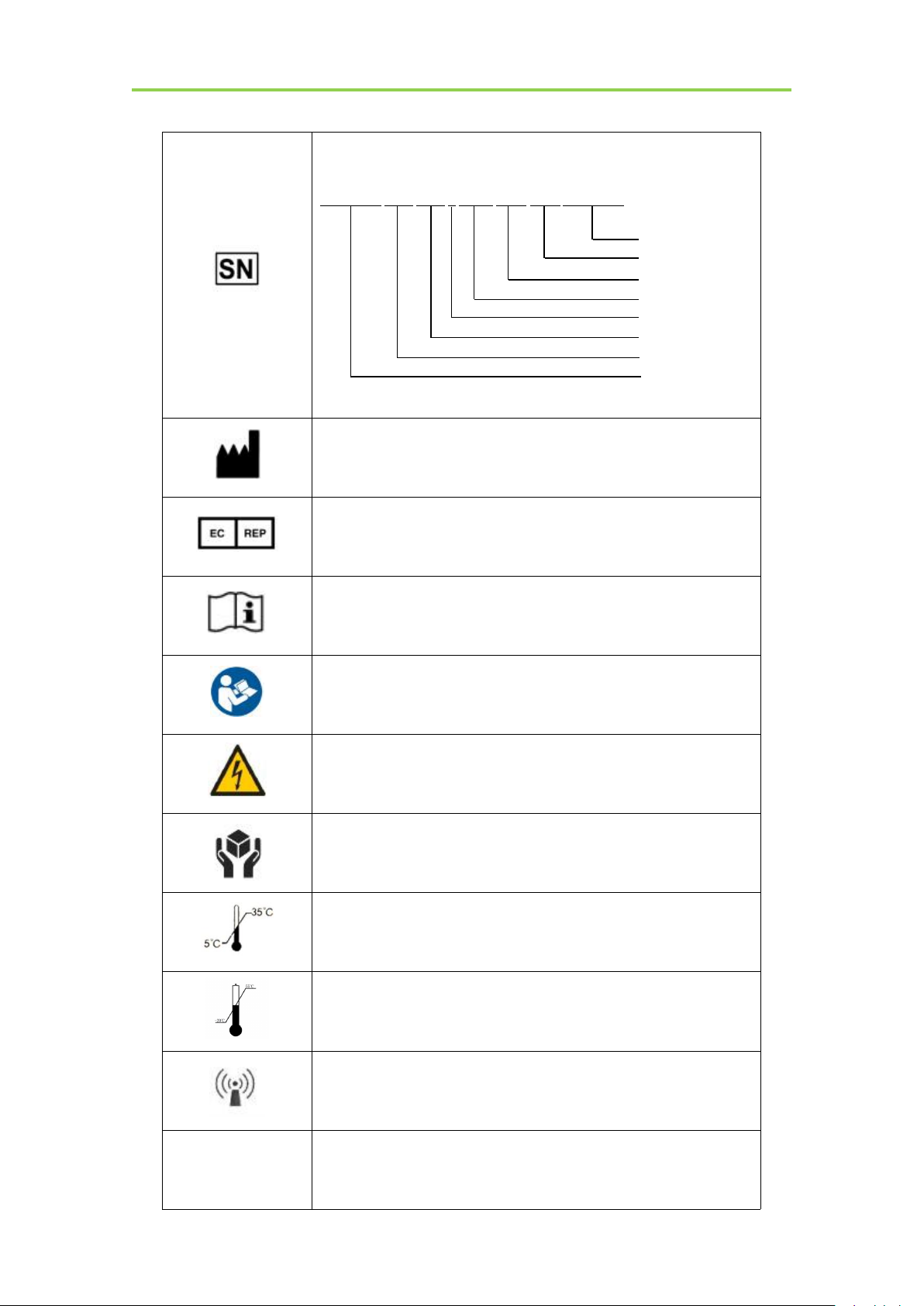

Labels and markings on the equipment

The contents of the labels and markings on Mars1417V (configuration: Mars1417V3) product are

indicated below:

4

..................................................................................................................................................iRay Technology Co. Ltd.

To Customer

This symbol is used to identify the manufacture series number which

is after, below or adjacent to the symbol. The series number of iRay

products is usually made of nineteen digits as shown below:

A1A2A3A4 B1B2 C1C2 L M1M2 D1D2 Y1Y2 X1X2X3X4

Numerical Order

Year

Date

Month

Production site

Version

Derived classes

Product Code

This symbol indicates the name and address of manufacturer.

This symbol indicates the name and address of iRay authorized

representative in the European region.

This symbol is used to indicate consultation of the user guide for

general information.

Safety Signs: please refer to user manual for safety instructions

Safety Signs: Dangerous Voltage

Handled with care

This symbol indicates operational temperature limits.

This symbol indicates storage temperature limits.

This symbol indicates the product radiates wireless signal.

FCC

This symbol indicates the product has passed FCC certification.

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

5

Mars1417V Digital Flat Panel Detector User Manual

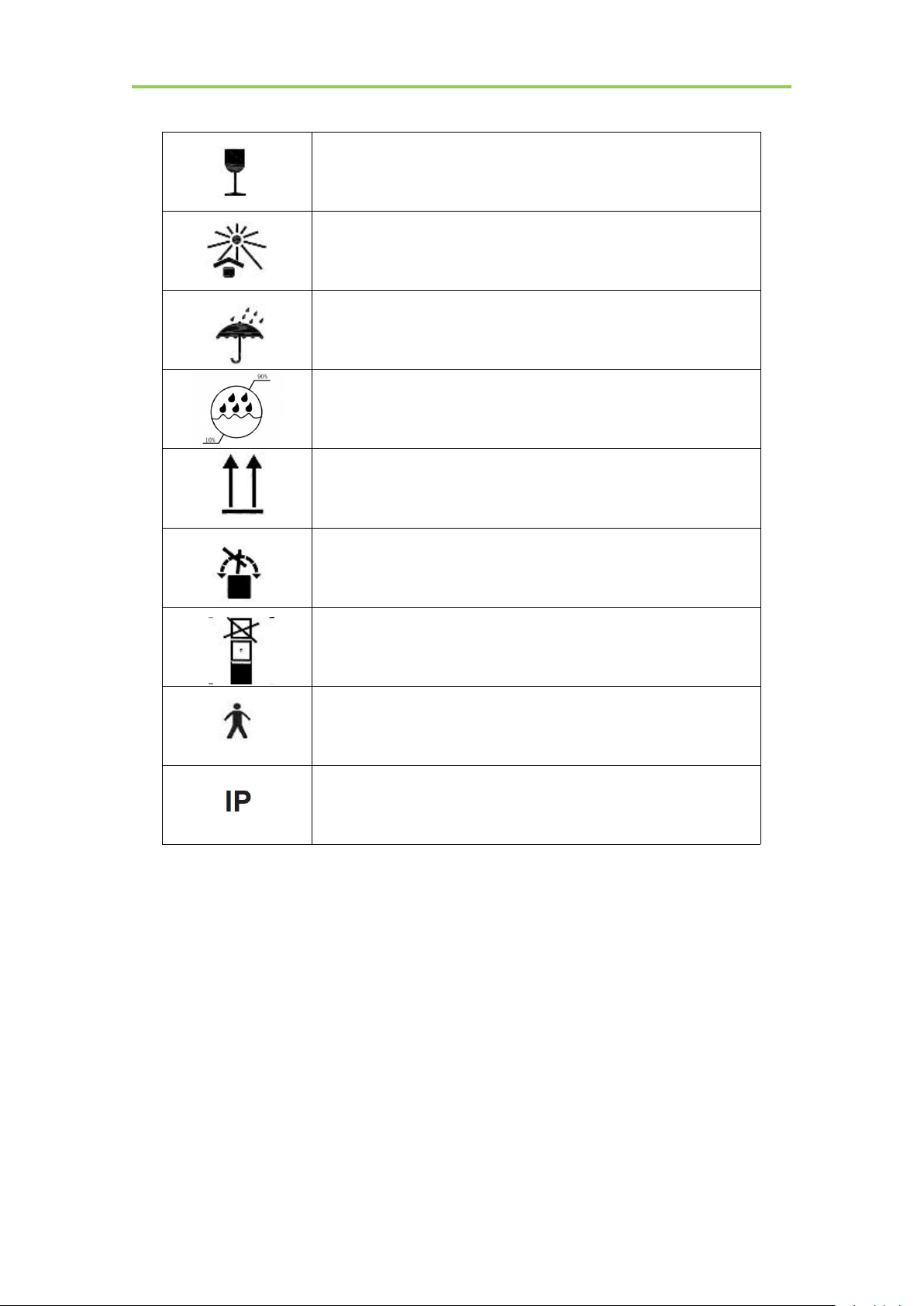

Package symbol, fragile.

Package symbol, keep away from sunlight.

Package symbol, keep dry.

This symbol indicates the humidity limits.

Keep the product up right

Do not roll the transportation package.

This symbol indicates stacking limit number.

Type-B applied part

IPX1 for working surface only

6

..................................................................................................................................................iRay Technology Co. Ltd.

Mars1417V Digital Flat Panel Detector User Manual

Contents

1. SAFETY

1.1. Safety precautions

1.2. Notes for Using

2. GENERAL DESCRIPTION

2.1. Scope

2.2. Model

2.3. Characteristic

2.4. Intended use/ essential performance/ application specification

2.4.1. Intended use.............................................................................................................................21

2.5. Essential performance

....................................................................................................................

..........................................................................................................................

................................................................................................................................

...........................................................................................

.................................................................................................................................................

..................................................................................................................................................

...................................................................................................................................

.......................................

..................................................................................................................

12

12

17

20

20

20

21

21

21

2.5.1. Application specification............................................................................................................21

2.6. The relative position between patient and detector

2.7. Product Components

2.8. Components Description

2.8.1. Detector......................................................................................................................................24

2.8.2. Battery........................................................................................................................................ 25

2.8.3. Battery Charger......................................................................................................................... 25

2.9. Product Specification

2.9.1. Detector......................................................................................................................................27

2.9.2. Battery........................................................................................................................................ 28

2.9.3. Battery Charger......................................................................................................................... 29

2.9.4. Power supply.............................................................................................................................. 29

2.9.5. AP Router...................................................................................................................................30

.....................................................................................................................

..............................................................................................................

....................................................................................................................

..............................................................

22

22

24

27

2.9.6. Wireless Communication........................................................................................................... 30

2.9.7. Recommended Application Condition........................................................................................30

2.9.8. Mechanical Outlines.................................................................................................................. 31

7

..................................................................................................................................................iRay Technology Co. Ltd.

Mars1417V Digital Flat Panel Detector User Manual

2.9.9. Use Environment........................................................................................................................31

2.10. IT network

2.10.1. Purpose for IT-network.............................................................................................................. 31

2.10.2. Required characteristics............................................................................................................ 32

2.10.3. Required configuration.............................................................................................................. 32

2.10.4. Technical specifications............................................................................................................. 32

2.10.5. Intended information flow.......................................................................................................... 32

2.10.6. Hazardous situations resulting from failure of the IT-network................................................. 32

2.10.7. Warning......................................................................................................................................33

2.10.8. Changes to the IT-network include............................................................................................ 33

3. INSTALLATION

3.1. Panel Installation

3.1.1. Attach Battery Pack....................................................................................................................35

3.1.2. Attach DC Power....................................................................................................................... 35

3.1.3. Booting Up................................................................................................................................. 36

....................................................................................................................................

..........................................................................................................

............................................................................................................................

31

35

35

3.1.4. Button function........................................................................................................................... 38

3.2. Battery Charger Installation

3.3. Software Installation

3.4. Panel Infrastructure

3.4.1. Wireless Client Mode................................................................................................................. 40

3.4.2. Wireless AP Mode...................................................................................................................... 44

4. OPERATION

4.1. Main Operation

4.1.1. Software Mode........................................................................................................................... 50

4.1.2. Inner2 Mode............................................................................................................................... 52

4.1.3. Freesync Mode...........................................................................................................................54

4.2. Connection Build

...............................................................................................................

......................................................................................................................

........................................................................................................................

................................................................................................................................

............................................................................................................................

.........................................................................................................

38

39

39

50

50

55

4.3. Panel Configuration

4.4. Correction and Calibration Template Generation

8

..................................................................................................................................................iRay Technology Co. Ltd.

.......................................................................................................................

..................................................................

56

57

Contents

4.4.1. Pre-offset Template Generation................................................................................................. 57

4.4.2. Gain Calibration Template Generation..................................................................................... 59

4.4.3. Defect Correction Template Generation....................................................................................60

4.5. Image Check and upload

4.5.1. Local Image Check.....................................................................................................................62

4.5.2. Panel Image Upload.................................................................................................................. 63

4.6. Defect Template Check and Modification

4.6.1. Defect Template Check.............................................................................................................. 64

4.6.2. Defect Template Modification.................................................................................................... 65

4.7. Correction and Calibration Management

4.7.1. Correction and Calibration template synchronization.............................................................. 66

4.7.2. Correction and Calibration management.................................................................................. 67

4.8. Firmware Update

4.8.1. MCU Update.............................................................................................................................. 68

4.8.2. FPGA Update............................................................................................................................. 71

4.8.3. ARM Update............................................................................................................................... 73

4.8.4. ALL FIRMWARE Update........................................................................................................... 75

.............................................................................................................................

..............................................................................................................

................................................................................

.................................................................................

62

63

66

68

4.9. Short cut

4.10. Software

4.10.1. Main GUI................................................................................................................................... 76

4.10.2. Message Box...............................................................................................................................77

4.10.3. Configuration GUI..................................................................................................................... 78

4.11. List of the HAZARDOUS SITUATIONS resulting from a failure of the IT-

NETWORK

5. REGULATORY INFORMATION

5.1. Medical equipment safety standards

5.2. The compliance for each EMISSIONS and IMMUNITY standard or test specified by

IEC60601-1-2 standard

5.3. Radio Frequency Compliance Information

............................................................................................................................................

.......................................................................................................................................

.........................................................................................................................................

...................................................................................

........................................................................................

..................................................................................................................

..............................................................................

75

76

81

83

83

84

87

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

9

Mars1417V Digital Flat Panel Detector User Manual

5.3.1. FCC Compliance........................................................................................................................87

5.4. Battery Safety Standards

6. TROUBLE SHOOTING

7. SERVICE INFORMATION

7.1. Product Lifetime

7.2. Regular Inspection and Maintenance

7.3. Repair

7.4. Replacement Parts Support

APPENDIX A INFORMATION OF MANUFACTURES

APPENDIX B INFORMATION OF MEDICAL DEVICE DIRECTIVE EUROPEAN

REPRESENTATIVE

.................................................................................................................................................

..............................................................................................................................

.....................................................................................................

..............................................................................................................

.................................................................................................

...........................................................................................

........................................................................................

.........................................................................................................

...........................................................

88

90

92

92

92

92

92

94

95

10

..................................................................................................................................................iRay Technology Co.

Ltd.

Mars1417V Digital Flat Panel Detector User Manual

1. SAFETY

1.1. Safety precautions

1.2. Notes for Using

......................................................................................................................

................................................................................................................................

..........................................................................................................................

12

12

17

11

................................................................................................................................................iRay Technology Co. Ltd.

1. Safety

WARNING

Installation and

environment of

use

Do not use or store the product near flammable

chemicals such as alcohol, thinner, benzene, etc.

If chemicals are spilled or evaporated, it may result in fire

or electric shock through contact with electric parts inside

the product. Also, some disinfectants are flammable. Be

sure to take care when using them.

Do not connect the equipment with anything other than

specified.

Doing so may result in fire or electric shock.

All patients with active implantable medical devices

should be kept away from the product.

Power supply

Do not operate the product with power supply other

than the one indicated on the rating label.

Otherwise, it may result in fire or electric shock.

Do not handle the product with wet hands.

You may experience electric shock that could result in

death or serious injury.

Do not place heavy object on cables and cords. Do not

pull, bend, bundle, or step on them to prevent their

sheath from being damaged, and do not alter them

neither.

Doing so may damage the cords which could result in fire

or electric shock.

Do not supply power to more than one piece of product

with the same AC outlet.

Doing so may result in fire or electric shock.

Do not turn on system power when condensation has

formed on the equipment.

Doing so may result in fire or electric shock.

Do not connect multiple portable socket-outlets or

extension cords to the system.

Doing so may result in fire or electric shock.

To avoid the risk of electric shock, this product must

only be connected to power supply with protective

earth.

Not doing so may result in fire or electric shock.

Do not connect the adapter cord when connect the

panel to patient.

1.1. Safety precautions

Follow these safeguards and properly use the product to prevent injury and damage to it.

Safety

iRay Technology Co. Ltd.………………………………………………………………………………………………….…………………………….………..

12

Safety

Securely plug the power cord into the AC outlet.

If contact failure occurs, or if metal objects come into

contact with exposed metal prongs of the plug, fire or

electric shock may result.

Be sure to turn off the power before connecting or

disconnecting the cords.

Otherwise, you may get an electric shock that could result

in death or serious injury.

Be sure to hold the plug or connector to disconnect the

cord.

If you pull the cord, the core wire may be damaged,

resulting in fire or electric shock.

WARNING

Handling

Never disassemble or modify the product. No

modification is allowed.

Doing so may result in fire or electric shock. Also, since

the product incorporates parts that may cause electric

shock as well as other hazardous parts, touching them may

cause death or serious injury.

Do not place anything on top of the product.

The object may fall and cause an injury. Also, if metal

objects such as needles or clips fall into the product, or if

liquid is spilled, it may result in fire or electric shock.

Do not hit or drop the product.

The product may be damaged if it receives a strong jolt,

which may result in fire or electric shock if it is used

without being repaired.

Do not put the product and pointed objects together.

The product may be damaged. If so, it should be used in

bucky.

Have the patient take a fixed posture and do not let the

patient touch parts unnecessarily.

If the patient touches connectors or switches, it may result

in electric shock or malfunction.

When a problem

occurs

Should any of the following occurs, immediately unplug

the power cord of adaptor or battery, and contact your

sales representative or local iRay dealer:

When there is smoke, an odd smell or abnormal sound.

When liquid has been spilled into the equipment or a metal

object has entered through an opening.

When the product has been dropped and damaged.

Maintenance and

inspection

Please turn off power of the product and unplug power

cord of adapter before cleaning.

Never use alcohol, ether and other flammable cleaning

agent for safety. Never use methanol, benzene and acid

because they would corrode the equipment.

Don’t dip the product into liquid.

Please make sure that surface & plugs are dry before

turning on.

Otherwise, it may result in fire or electric shock.

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

13

Mars1417V Digital Flat Panel Detector User Manual

Clean the plug of the power cord periodically by

unplugging it from the AC outlet and removing dust or

dirt from the plug, its periphery and AC outlet with a

dry cloth.

If the cord is kept plugged in for a long time in a dusty,

humid or sooty place, dust around the plug will attract

moisture; this could cause insulation failure that may result

in a fire.

For safety reasons, be sure to turn off the power when

performing inspections indicated in this manual.

Otherwise, electric shocks may occur.

CAUTION

Installation and

environment of

use

Do not install the product in any of the locations listed

below. Doing so may result in failure, malfunction,

falling, fire or injury.

Close to facilities where water is used

Where it will be exposed to direct sunlight

Close to the air outlet of an air-conditioner or ventilation

equipment

Close to heat source such as a heater

Where the power supply is unstable

In a dusty environment

In a saline or sulfurous environment

Where temperature or humidity is high

Where there is freezing or condensation

In areas prone to vibration

On an incline or in an unstable area

Take care that cables do not become tangled during

use. Also, be careful not to get your feet caught by

cable.

Otherwise, it may cause a malfunction of the product or

injury of the user due to tripping over the cable.

Non-medical equipment such as battery charger, access

point and infrared register tools cannot be used in

patient’s vicinity.

14

................................................................................................................................................iRay Technology Co. Ltd.

Safety

Power supply

Always connect three-core power cord plug to a

grounded AC power outlet.

To make it easy to disconnect the plug at any time,

avoid putting any obstacles near the outlet. Otherwise,

it may not be possible to disconnect the plug in an

emergency.

Be sure to ground the product to an indoor grounded

connector. Also, be sure to connect all the grounds of

system to common ground.

Do not use any power source other than the one

provided with the product.

Otherwise, fire or electric shock may be caused due to

leakage.

Handling

Do not spill liquid or chemicals onto the equipment. In

case the patient is injured, it is not allowed to contact

with blood or other body fluids.

Doing so may result in fire or electric shock.

In such a situation, protect the equipment with a disposable

cover as necessary.

Turn OFF the power and pull out the plug to each

piece of equipment for safety when not used.

CAUTION

Handling

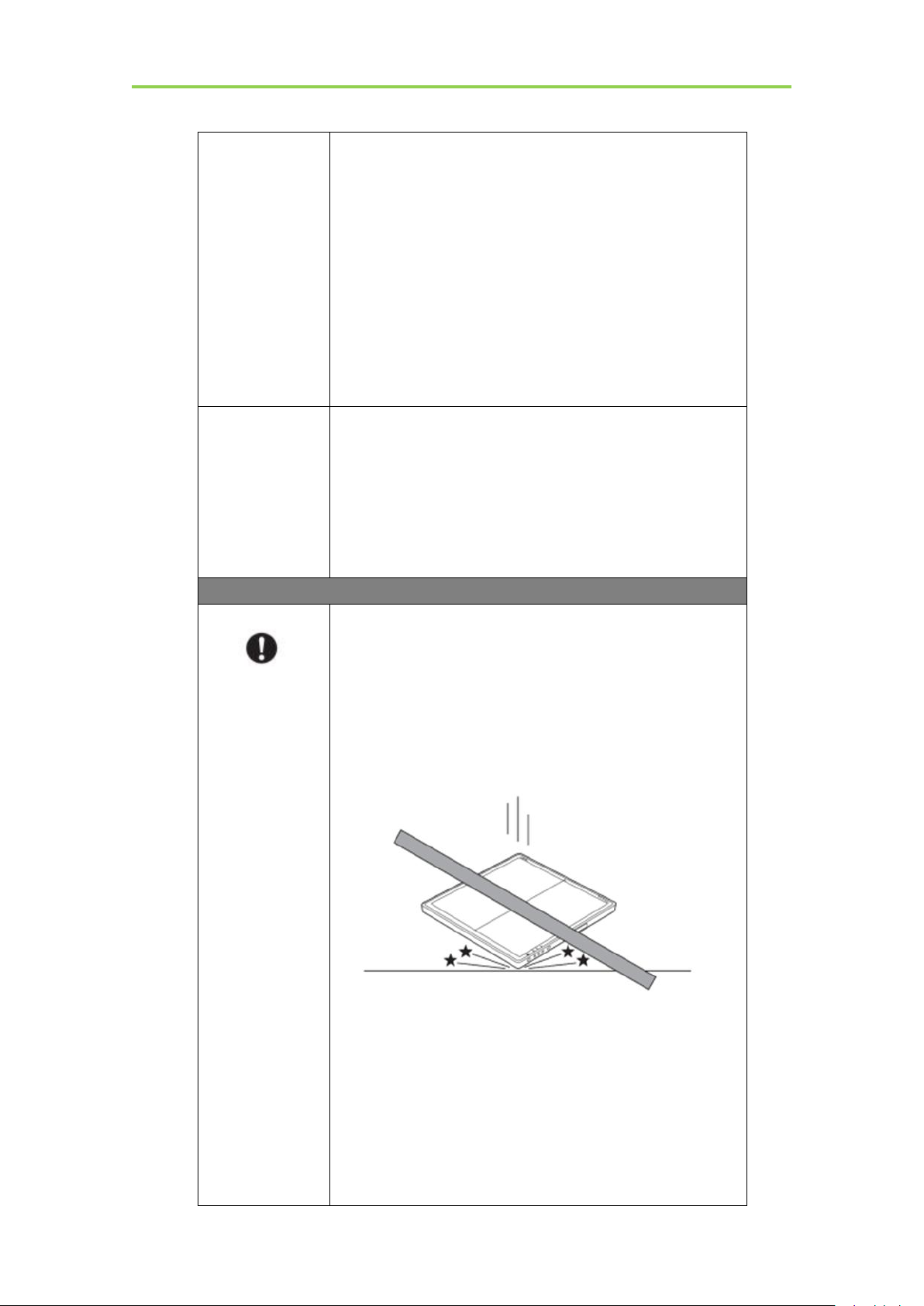

Handle the product carefully.

Do not submerge the product in water.

Only working surface meets IPX1

The internal image sensor may be damaged if

something hits against it or it is dropped. If the product

is dropped, the drop sensor inside would record and

the product would not be warranted by iRay.

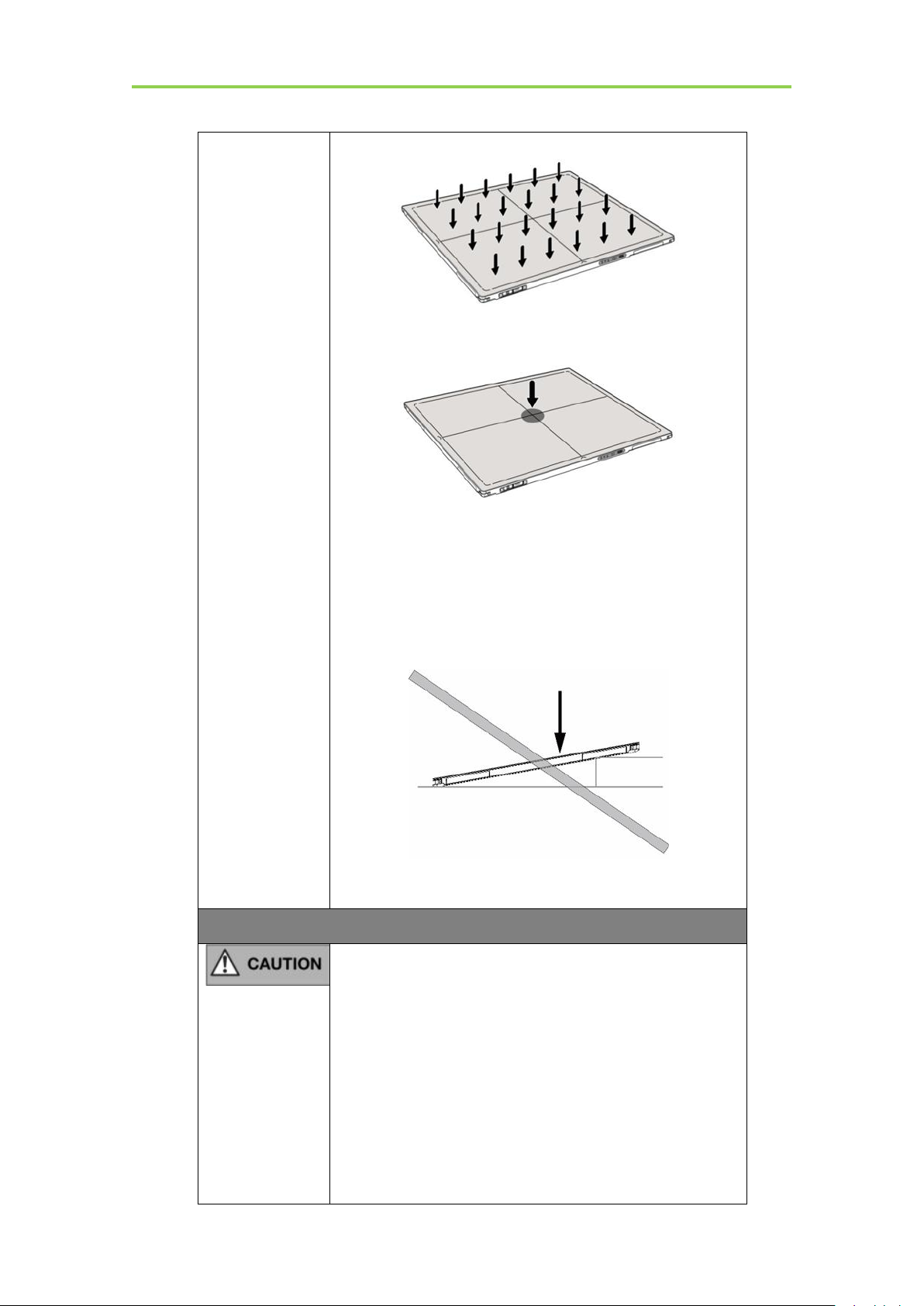

Do not place excessive weight on the panel.

Otherwise, the internal image sensor may be damaged and

image may be incorrect.

Patients stand on the product temporarily, and the intended

weight can be 135kg.

Based on the internal TFT character, cannot load the

dynamic forces due to loading from persons

<Load Limit>

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

15

Mars1417V Digital Flat Panel Detector User Manual

Uniform load:150 kg over the whole area of the surface.

Local load:100 kg on an area 4 cm diameter.

Be sure to use the product on flat surface so it would

not bend. Otherwise, the internal image sensor may be

damaged. Be sure to securely hold the product while

using it in upright positions. Otherwise, the product

may fall over, resulting in injury to user or patient, or

may flip over, resulting in damage to the inner device.

Keep the same load on the product when acquiring image.

The image will be incorrect.

CAUTION

Do not close to fire, do not use in high temperature

Do not invert positive and negative pole

Do not contact with metal in case of short circuit

Do not insert sharp objects into battery

Do not beat battery

Do not stand on battery

Do not use battery out of rules

Do not dispose of battery or change inner structure

Do not submerge battery in water, please keep dry in

storage and do not contact with water in use

Please charge battery with charger following GB

16

................................................................................................................................................iRay Technology Co. Ltd.

9706.1 Standards provided by us

Do not mix battery with ones not provided by our

company

Do not charge battery with broken charger.

Substitution of battery inside main unit must be

carried out by qualified people

Do not touch output connector for adaptor

Do not remove the battery when the panel is powered

on only with the battery.

1.2. Notes for Using

When using the product, take the following precautions. Otherwise, problems may

occur and the product may not function correctly.

Before exposure

Safety

Be sure to check the product daily and confirm it work properly.

Sudden heating of the room in cold areas will cause condensation on the

product. In this case, wait until the condensation evaporates before performing

an exposure. If it is used when condensation is formed, problems may occur in

the quality of captured images. When an air-conditioner is used, be sure to

raise/lower the temperature gradually to prevent condensation.

The product should be warmed up for 15 minutes before exposure or updating

the gain map and defect map.

Make sure exposure rate is over 900nGy/s @70KV.

Make sure wave form of the energy going to the X ray tube is square not pulse.

Be cautious with circumstance that someone has radio isotope recently injected

into them, it may cause that panel transmit image without x ray.

During exposure

Do not move Power Cable, or it may cause image noise or artifacts, even

incorrect images.

Do not use the product near the equipment generating a strong magnetic field.

Otherwise, it may cause image noise, artifacts or even incorrect images.

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

After usage

It’s strongly recommended to remove battery from panel if panel is not used

more than 5 days. If battery stores for a long time, it should be charged (30% to

50%) every 3 month or charged (50% to 70%) every 6 month.

17

Mars1417V Digital Flat Panel Detector User Manual

Contact with the patients parts cleaning, disinfection and sterilization

After every examination, wipe the patient contact surfaces with nonflammable

disinfectants to prevent the risk of infection, such as benzalkonium chloride,

benzalkonium bromide. For details on how to sterilize, consult a specialist.

Do not spray the product directly with disinfectants or detergents.

Wipe it with a cloth slightly damped with a neutral detergent. Do not use

solvents such as benzene and acid. Doing so may damage the surface of the

product.

It’s recommended to use a waterproof non-woven cover as the isolated layer

between product and the blooding patient.

Applied part

The front and back of detector is application part.

18

................................................................................................................................................iRay Technology Co. Ltd.

Mars1417V Digital Flat Panel Detector User Manual

2.GENERAL DESCRIPTION

2.1. Scope

2.2. Model

2.3. Characteristic

2.4. Intended use/ essential performance/ application specification

2.5. Essential performance

2.6. The relative position between patient and detector

2.7. Product Components

2.8. Components Description

2.9. Product Specification

............................................................................................................................................

.............................................................................................................................................

................................................................................................

.............................................................................................................................

.............................................................................................................

.........................................................

...............................................................................................................

.........................................................................................................

...............................................................................................................

..................................

20

20

20

21

21

21

22

22

24

27

2.10. IT network

....................................................................................................................................

31

19

................................................................................................................................................iRay Technology Co. Ltd.

Mars1417V Digital Flat Panel Detector User Manual

2. General Description

Mars1417V (configuration: Mars1417V3, hereinafter referred as Mars1417V) is a cassettesize wireless X ray flat panel detector based on amorphous silicon thin-film transistor

technologies. It is developed to provide the highest quality of radiographic image, which

contains an active matrix of 2304×2800 with 150um pixel pitch. The greatest feature is

Mars1417V supports wireless communication between panel and Workstation. Mars1417V’s

power supply includes battery. Mars1417V can be used as a real portable panel.

2.1. Scope

This manual contains information about the Mars1417V. Information in the manual, including

the illustrations, is based on prototype. If your configuration does not have any of these items,

information about these items does not apply to your panel.

2.2. Model

Mars □ □ □

TSI- CsI Model

Product Application: Cassette size portable detector

Product dimension: 1417, 14inch×17inch

Product series: Wireless digital flat panel detector series

Product Type: Battery-KV---------Rechargeable lithium battery

Product Type: Charger-KV--------Battery charger

20

................................................................................................................................................iRay Technology Co. Ltd.

Installation

2.3. Characteristic

Wireless static flat panel detector used for general radiography.

Cassette-size

Sync-shot exposure trigger

CsI scintillation screen.

Easy to change the cable and update firmware.

Battery recycling

2.4. Intended use/ essential performance/ application specification

2.4.1. Intended use

Mars1417V Wireless Digital Flat Panel Detector is indicated for digital imaging solution

designed for providing general radiographic diagnosis of human anatomy. It is intended to

replace radiographic film/screen systems in all general-purpose diagnostic procedures. This

panel provides digital X ray imaging for diagnosis of disease, injury, or any applicable health

problem. The image is obtained as the result of X ray passing through the human body and

detected by detector.

iRay would provide hardware and software support for integration of system.

This panel is not intended for mammography and extra-oral X-ray applications which are

covered by IEC60601-2-63.

2.5. Essential performance

According to the Mars1417V series intended use and the result of risk management, getting

imaging and function of data transmission is defined as essential performance.

Getting qualified dark image proves that essential performance does not influence intended

use. Method for getting dark image in detail refers to section “install” and “operation”.

2.5.1. Application specification

PATIENT population:

Age: except for children

Weight: not relevant

Health: not relevant

Nationality: multiple

Patient state: patient is not user

Gender: except for pregnant women

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

21

Mars1417V Digital Flat Panel Detector User Manual

Item

Description

Mars1417V Detector

1pcs

Main Unit

Intended OPERATOR:

All of use, maintenance and operation steps should be carried out by the operator who has

accepted the professional training offered by the company's customer service staff.

Life-time:

Life-time: 7 years without frequency limit

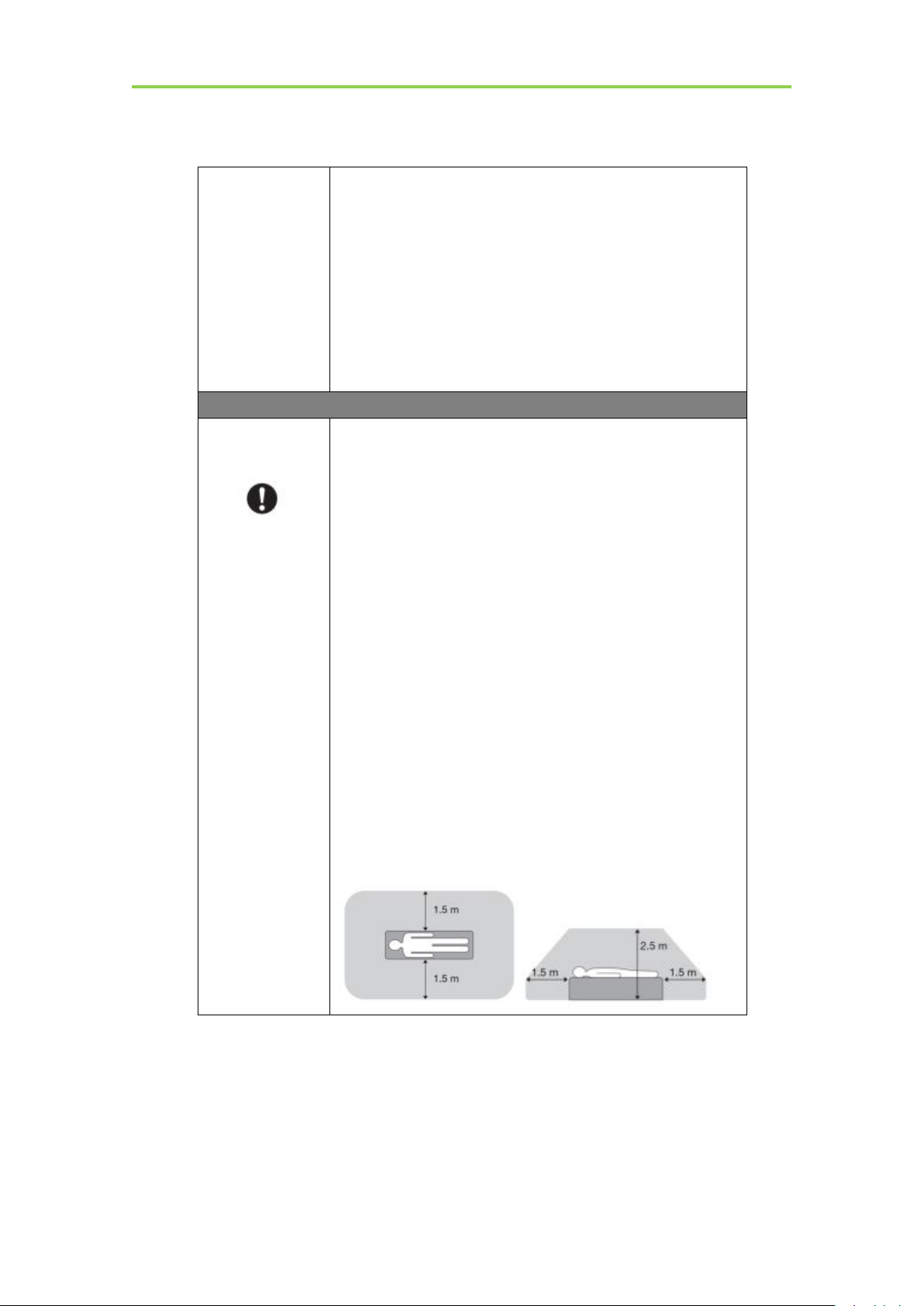

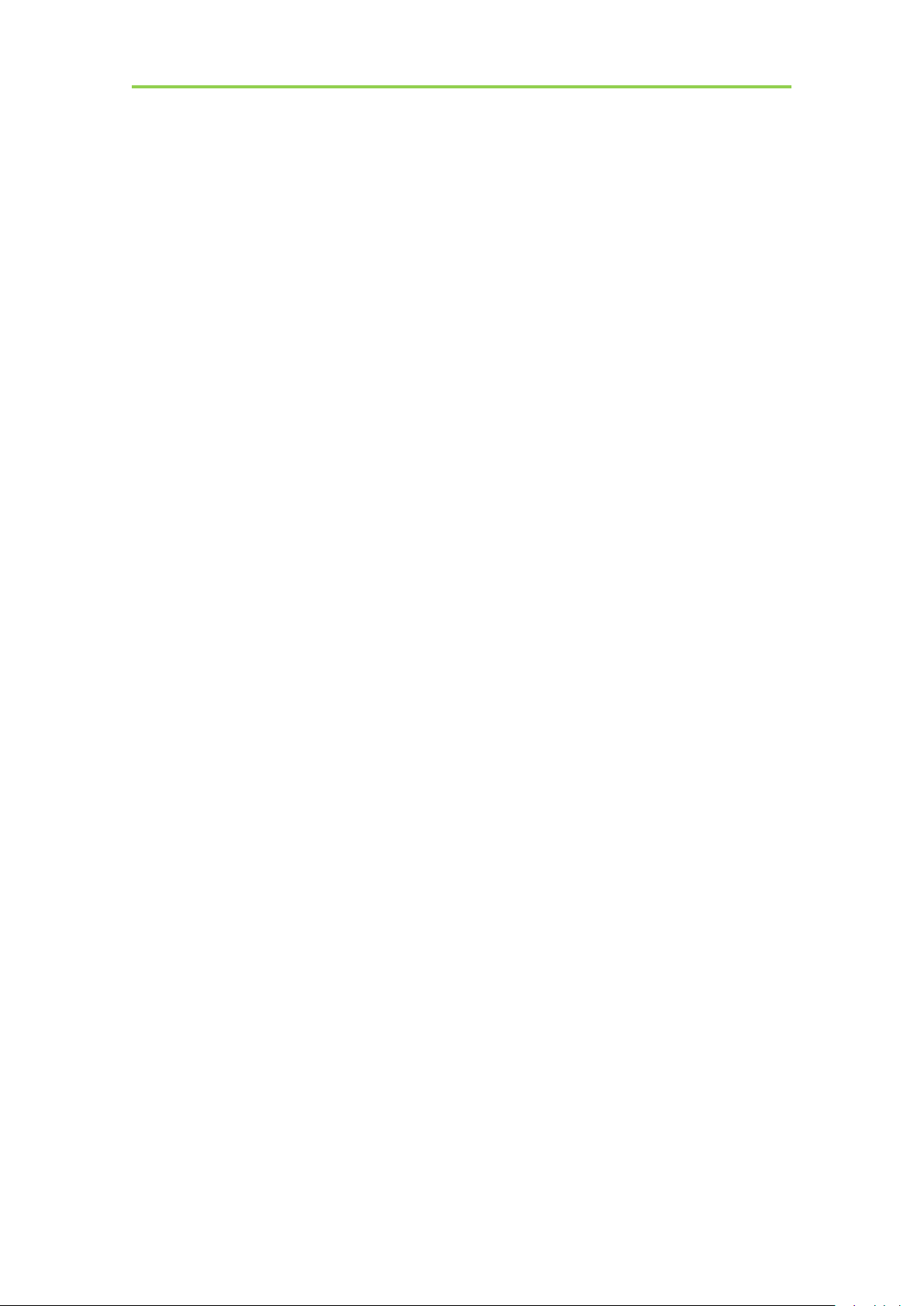

2.6. The relative position between patient and detector

Because of the crosstalk effect of Amorphous silicon flat-panel detector, Pay attention to the

relative position of patient and detector, the recommended position as shown below,

Otherwise, the image is prone to abnormal light lines.

2.7. Product Components

Mars1417V comes with both DC power supply and battery package. Once powered

on, it would build a connection with Workstation through Ethernet cable (only for

service) or Wireless connection.

22

................................................................................................................................................iRay Technology Co. Ltd.

Installation

Medical Adapter

1 pcs

DC 24V

Battery

2 pcs

Battery pack

Ethernet Cable

(Only for service)

1pcs

3.5 m

Gigabit Ethernet Cable

1pcs

3 m

AC Power Cable

1 pcs

DC Power Cable

1 pcs

3.5 m

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

23

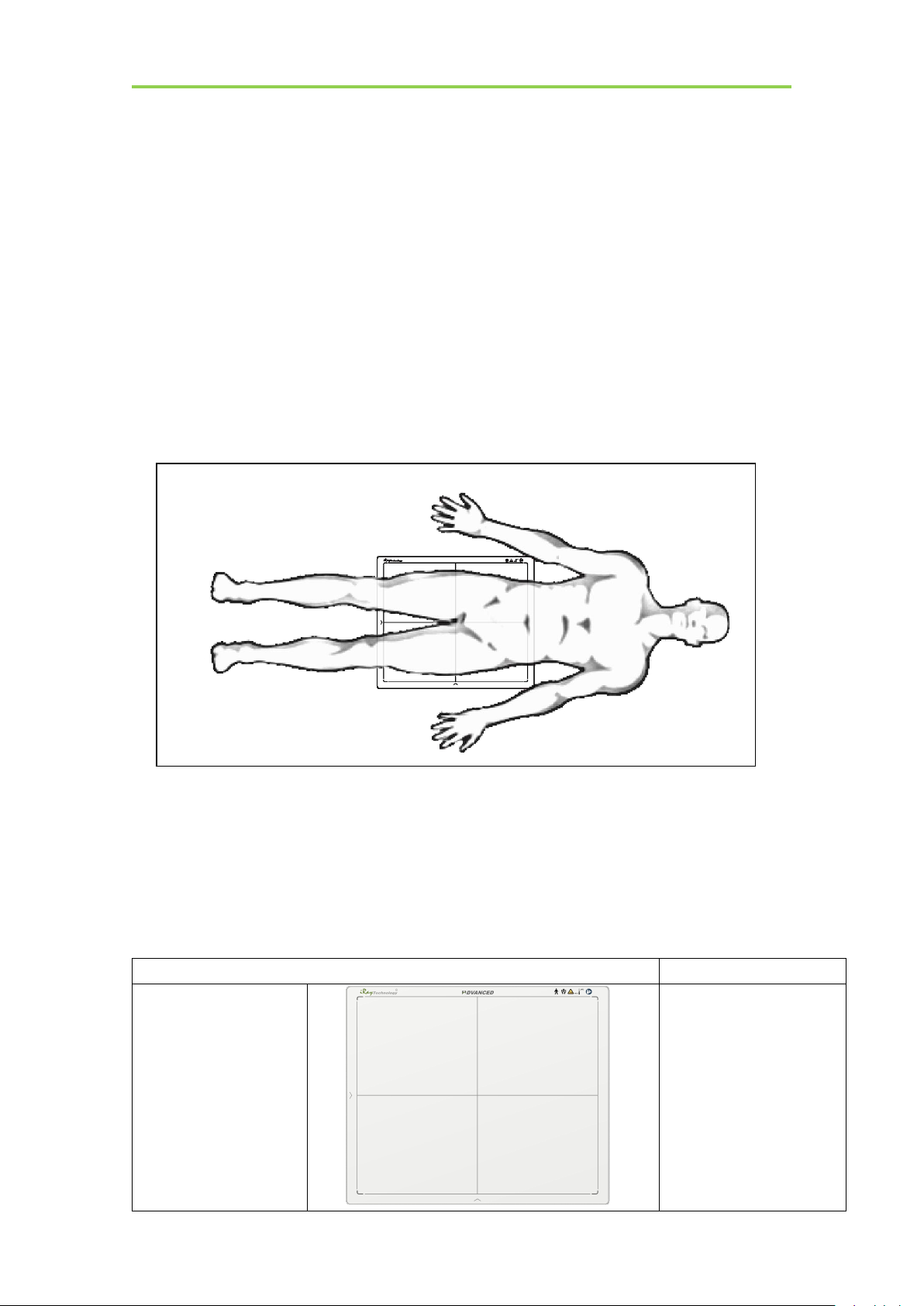

Mars1417V Digital Flat Panel Detector User Manual

Battery Charger

1pcs

CD-Rom

1pcs

Gain correction data

Defect correction map

SDK

Manual

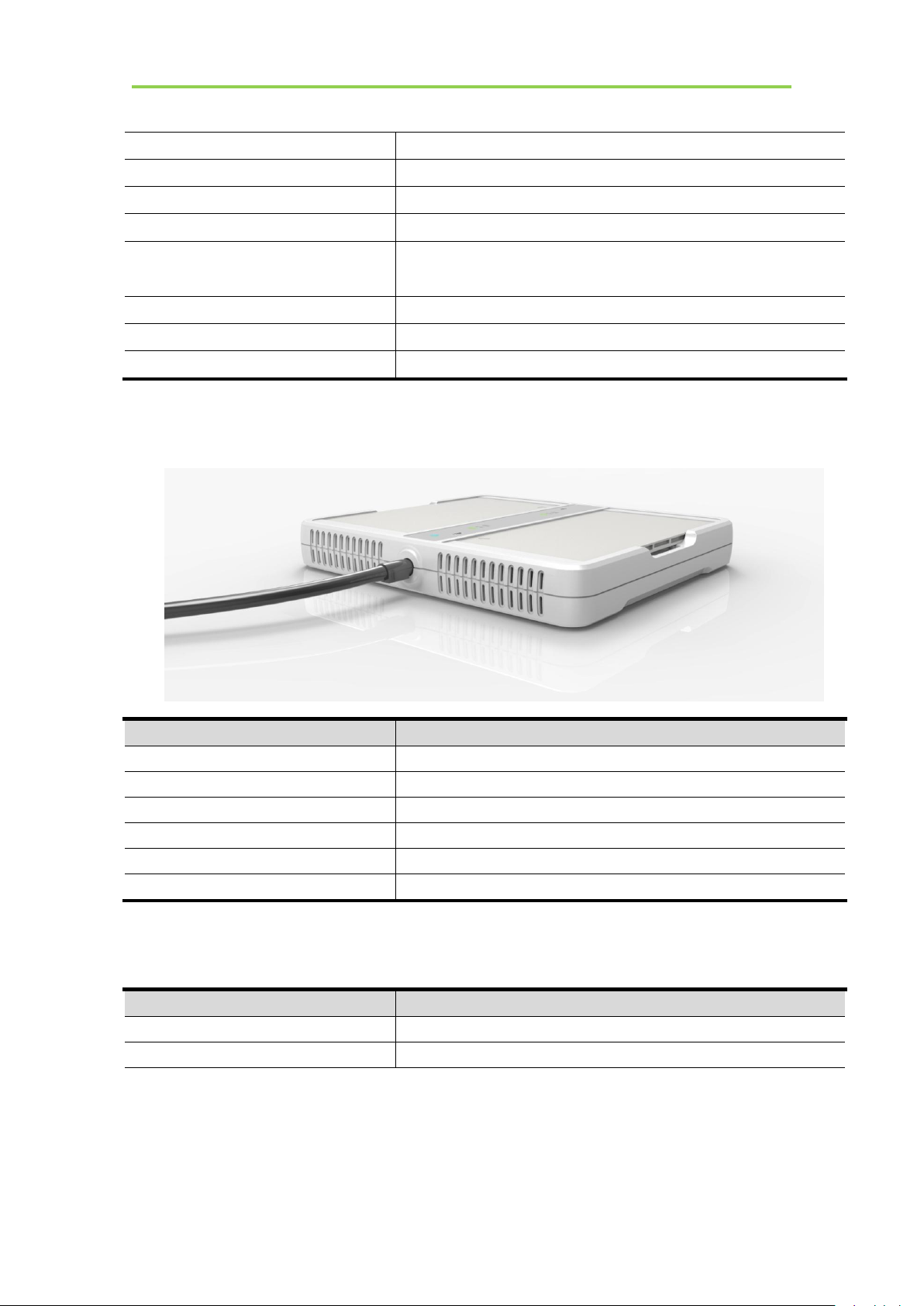

2.8. Components Description

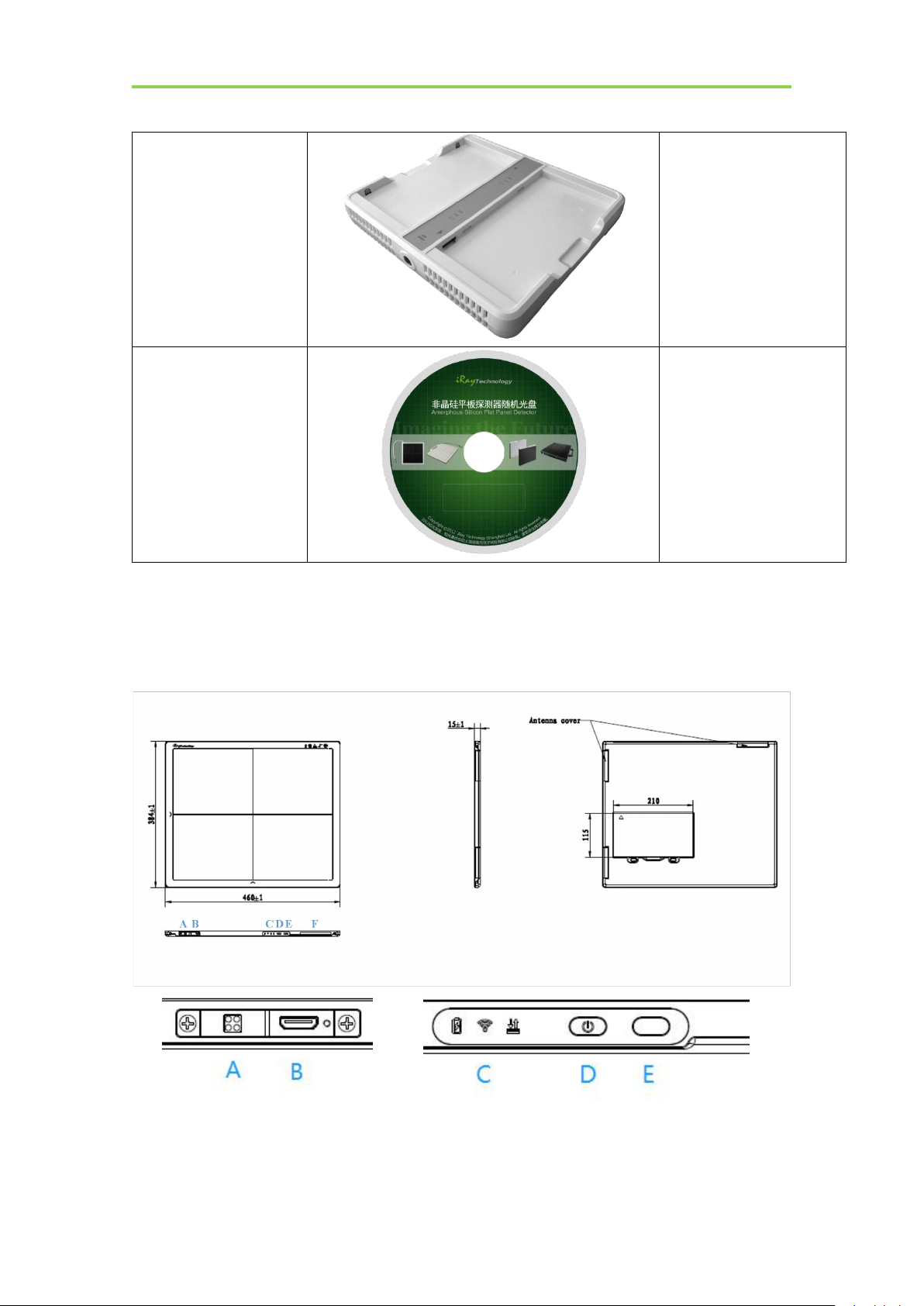

2.8.1. Detector

External Signals Input Control Panel

24

................................................................................................................................................iRay Technology Co. Ltd.

Item

Name

Description

A

DC Jack

24V DC input

B

Ethernet Port

Gigabit Ethernet port

C

Detector Indicator

Detector indicator of control panel

D

Power Button

Power button of control panel

E

reserved

/

F

Antenna

Antenna

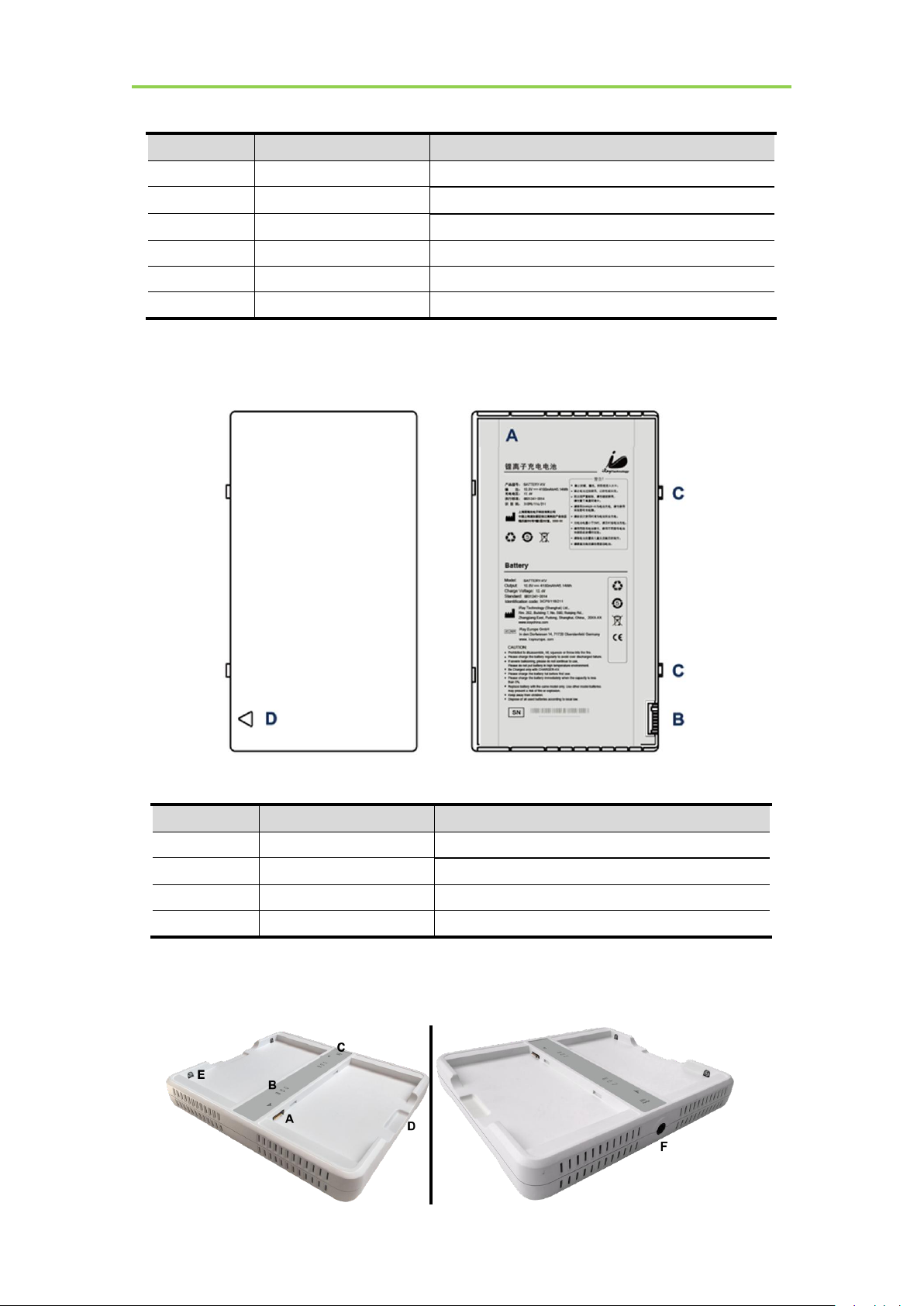

2.8.2. Battery

Item

Name

Description

A

Battery Label

/

B

Battery Interface

8 Pin Battery connector

C

Pilot Pin

/

D

Indicator

Installation direction indicator

Installation

2.8.3. Battery Charger

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

25

Mars1417V Digital Flat Panel Detector User Manual

Item

Name

Description

A

Battery Interface

8 Pin Battery connector

B

Capacity Indicator

The indicator definition is as follow

C

Power Indicator

The indicator definition is as follow

D

Hand Pull Position

/

E

The limit ball plug

/

F

DC Jack

24V DC input

Firmware versions

Lighting Status

Value range (BCD)

Major

00-11

Minor

0000-1111

Power Indicator

Lighting Status

Operating Status

OFF

No external DC adaptor input

GREEN

External DC adaptor input

Firmware major versions

Firmware minor versions

Power indicator

Firmware versions definition

Power indicator definition:

26

................................................................................................................................................iRay Technology Co. Ltd.

The battery charging capacity indicator definition:

X Group Indicator

Lighting Status

Operating Status

I, II and III grid off

No battery Insert

I grid blinking

II and III grid off

Battery Insert with capacity ≤30%,charging

II grid blinking

I and III grid off

Battery Insert with capacity >30% and ≤60%,

charging

III grid blinking

I and II grid off

Battery Insert with capacity >60% and ≤95%,

charging

I and II grid off

III grid on

Battery Insert with capacity >95% and

charging, when capacity = 100%, charging

stops

I, II and III blinking

Battery enter into 2nd level protection,

automatic unlock with safety condition

Item

Specification

Model

Mars1417V-TSI (CsI)

Image Sensor

a-Si (Amorphous Silicon) TFT

Installation

2.9. Product Specification

2.9.1. Detector

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

27

Mars1417V Digital Flat Panel Detector User Manual

Pixel Size

150 μm

Active Array

2304 x 2800

Active Area (H x V)

345.6mm x 420mm

Gray scales

16bit

Spatial Resolution

3.3 Lp/mm

Image Acquisition Time (Wireless)

Both AP mode and Client mode

Preview Acquisition Time: 3 sec.

Processed Acquisition Time : 5 sec.

Cycle Time

Min. 8s

Power Consumption

Max. 18W

Dimension (L × W × H)

460 x 384 x 15 mm

Weight (with one battery)

3.43 kg

Image Transfer

Wireless : IEEE802.11a/b/g/n/ac

Data Transmission Rate (Wireless)

802.11b: Max. 11Mbps

802.11a/g: Max. 54Mbps

802.11n: Max. 300Mbps (MIMO 2x2)

802.11ac: Max. 867Mbps(MIMO 2x2)

Item

Specifications

Model

Battery-KV

Rated Capacity

Typ. 4180mAh @ Discharge 0.2C

Nominal Voltage

10.8V

2.9.2. Battery

28

................................................................................................................................................iRay Technology Co. Ltd.

Charge Voltage

12.6±0.05V

Discharged End Voltage

9V

Charging Method

CC-CV

Operating Temperature

Charge 0℃-+60℃, Discharge-10℃-+60℃

Storage Temperature

≤3 month -20℃-+45℃

≤6 month -20℃-+35℃

Relative Humidity

5%~95%

Dimension (L × W × H)

210 x 115 x 7.5 mm

Weight

0.28kg

2.9.3. Battery Charger

Item

Specifications

Model

Charger-KV

Simultaneous Charging

2 battery packs

Full charging time

2.5 hours

Rated power supply

24V(DC)

Dimension (L × W × H)

300 x 263 x 42 mm

Weight

1.26 kg

Item

Specifications

DC Power

24V(DC), 0.75A

Battery Package

10.8V(DC),1.6A

Installation

2.9.4. Power supply

Mars1417V supports both DC Power and Battery package input.

The product must be used with the approved adaptor whose CB certificate number is SG PSB-MD-

00191.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

29

Mars1417V Digital Flat Panel Detector User Manual

Item

Specifications

Wireless Standard

IEEE 802.11 a/b/g/n/ac

Frequency Range

2.412 ~ 2.4835 GHz and 5.15 ~ 5.85 GHz

Wireless Data Rate

802.11b: Max. 11Mbps

802.11a/g: Max. 54Mbps

802.11n: Max. 300Mbps (MIMO 2x2)

802.11ac: Max. 867Mbps(MIMO 2x2)

Item

Description

Wireless Standard

IEEE 802.11a/b/g/n/ac

Frequency Range

2.412~2.472GHz: ch1~ch13

5.18~5.24GHz: ch36~ch48

5.745~5.85GHz: ch149~ch165

Data Transmission Rate

802.11b: Max. 11Mbps

802.11a/g: Max. 54Mbps

802.11n: Max. 300Mbps (MIMO 2x2)

802.11ac: Max. 867Mbps(MIMO 2x2)

Modulation

802.11b:

CCK, DQPSK, DBPSK

802.11a/g/n:

64 QAM, 16 QAM, QPSK, BPSK

802.11ac:

256 QAM, 64 QAM, 16 QAM, QPSK, BPSK

Transmission Power

Max.17dBm

Security

WPA, WPA-PSK, WPA2, WPA2-PSK, WEP 64bit & 128bit

Antenna

2 Dual Band inner antenna

Item

Description

Operating System

Windows 7 32/64bit

CPU

Intel Core i7 3.6G

Memory

4G DDR3

Hard Disk

640 G

LAN Card

Intel Pro EXP9301CT PRO

2.9.5. AP Router

Mars1417V do not include AP Router. Users can choose AP Router as they wish, however specification

below is a requirement.

2.9.6. Wireless Communication

2.9.7. Recommended Application Condition

30

................................................................................................................................................iRay Technology Co. Ltd.

2.9.8. Mechanical Outlines

Temperature

Temperature

change

Humidity

Atmospheric

Pressure

Pressure Change

Operating

5~35℃

<1k/min

10%~90% RH

700~1060hPa

<10kp/min

(1kp=1.0197E-5Pa)

Storage

-20~55℃

<1k/min

5%~95% RH

700~1060hPa

<10kp/min

(1kp=1.0197E-5Pa)

The Mars1417V serial detectors shall operate at an altitude specified not more than 3000m, the environment

is only for detector.

Installation

2.9.9. Use Environment

2.10. IT network

2.10.1. Purpose for IT-network

Transmission between the detector and the workstation is image data and command/status

communication.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

31

Mars1417V Digital Flat Panel Detector User Manual

Item

Description

Wireless Standard

IEEE 802.11a/b/g/n/ac

Frequency Range

2.412~2.472GHz: ch1~ch13

5.18~5.24GHz: ch36~ch48

5.745~5.85GHz: ch149~ch165

Data Transmission Rate

802.11b: Max. 11Mbps

802.11a/g: Max. 54Mbps

802.11n: Max. 300Mbps (MIMO 2x2)

802.11ac: Max. 867Mbps(MIMO 2x2)

Modulation

802.11b:

CCK, DQPSK, DBPSK

802.11a/g/n:

64 QAM, 16 QAM, QPSK, BPSK

802.11ac:

256 QAM, 64 QAM, 16 QAM, QPSK, BPSK

Security

WPA, WPA-PSK, WPA2, WPA2-PSK, WEP 64bit & 128bit

2.10.2. Required characteristics

Wireless communication follows IEEE 802.11a/b/g/n/ac protocol. It works on 2.4GHz and

5GHz.

It supports at least 2 routers.

2.10.3. Required configuration

The wireless card and the detector must work on the same IP segment such as 192.168.8.XXX

They must support IEEE 802.11a/b/g/n/ac.

2.10.4. Technical specifications

2.10.5. Intended information flow

The detector sends image data acquired to the workstation. The workstation sends users’

commands to the detector. Please refer to the operation manual of the Console for detail.

2.10.6. Hazardous situations resulting from failure of the IT-network

1. Failure of completing essential performance

2. Failure of finishing configuration of product

3. Operating system is not compatible

4. Change or update software failed

5. Compatibility of interface

6. Data transfer protocol error

32

7. Inconsistency of interface or format leads to data distortion;

8. Data output failed;

................................................................................................................................................iRay Technology Co. Ltd.

2.10.7. Warning

Connection of the main unit to an IT-network that includes other equipment could result in

previously unidentified risks

The manufacturer of x-ray machine should identify, analyze, evaluate and control these risks;

subsequent changes to the IT-network could introduce new risks and require additional

analysis

2.10.8. Changes to the IT-network include

1. Changes in the IT-network configuration;

2. Connection of additional items to the IT-network;

3. Disconnecting items from the IT-network;

4. Update of equipment connected to the IT-network;

Installation

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

33

Mars1417V Digital Flat Panel Detector User Manual

3. INSTALLATION

3.1. Panel Installation

3.1.1. Attach Battery Pack....................................................................................................................35

3.1.2. Attach DC Power....................................................................................................................... 35

3.1.3. Booting Up................................................................................................................................. 36

3.1.4. Button function........................................................................................................................... 38

3.2. Battery Charger Installation

3.3. Software Installation

3.4. Panel Infrastructure

3.4.1. Wireless Client Mode................................................................................................................. 40

3.4.2. Wireless AP Mode...................................................................................................................... 44

..........................................................................................................

............................................................................................................................

.........................................................................................................

......................................................................................................................

........................................................................................................................

35

35

38

39

39

34

................................................................................................................................................iRay Technology Co. Ltd.

3. Installation

Make sure that the connectors on the

battery package are pointed to the cave

in battery compartment.

Slide battery package into battery

compartment ( Make sure battery

capacity overpass 10%).

Slide the battery lock lever.

3.1. Panel Installation

3.1.1. Attach Battery Pack

Mars1417V can be powered by both battery package and DC power. Once battery package is

inserted or DC power is on, Panel would be activated immediately. If none of battery and DC

power is on, Mars1417V would power off. Please see below for battery installation.

Installation

3.1.2. Attach DC Power

Please see below for DC power installation.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

35

Mars1417V Digital Flat Panel Detector User Manual

Connect one end of DC Power Cable to

the Medical Adapter

As figure is power interface Ethernet

interface

Connect another end of DC Power Cable

to the DC input of the detector.

If panel is powered off, user can press the

button for 4 seconds to power on when

battery is inserted and battery capacitor is

no less than 10%, or DC power is

connected.

If panel is powered on, user can press the

button for 4 seconds to shut down. On the

other hand, it can also be used as reset

inner control IC when button is active for

7s.

3.1.3. Booting Up

On the control panel, user can press power button to power on/off.

36

................................................................................................................................................iRay Technology Co. Ltd.

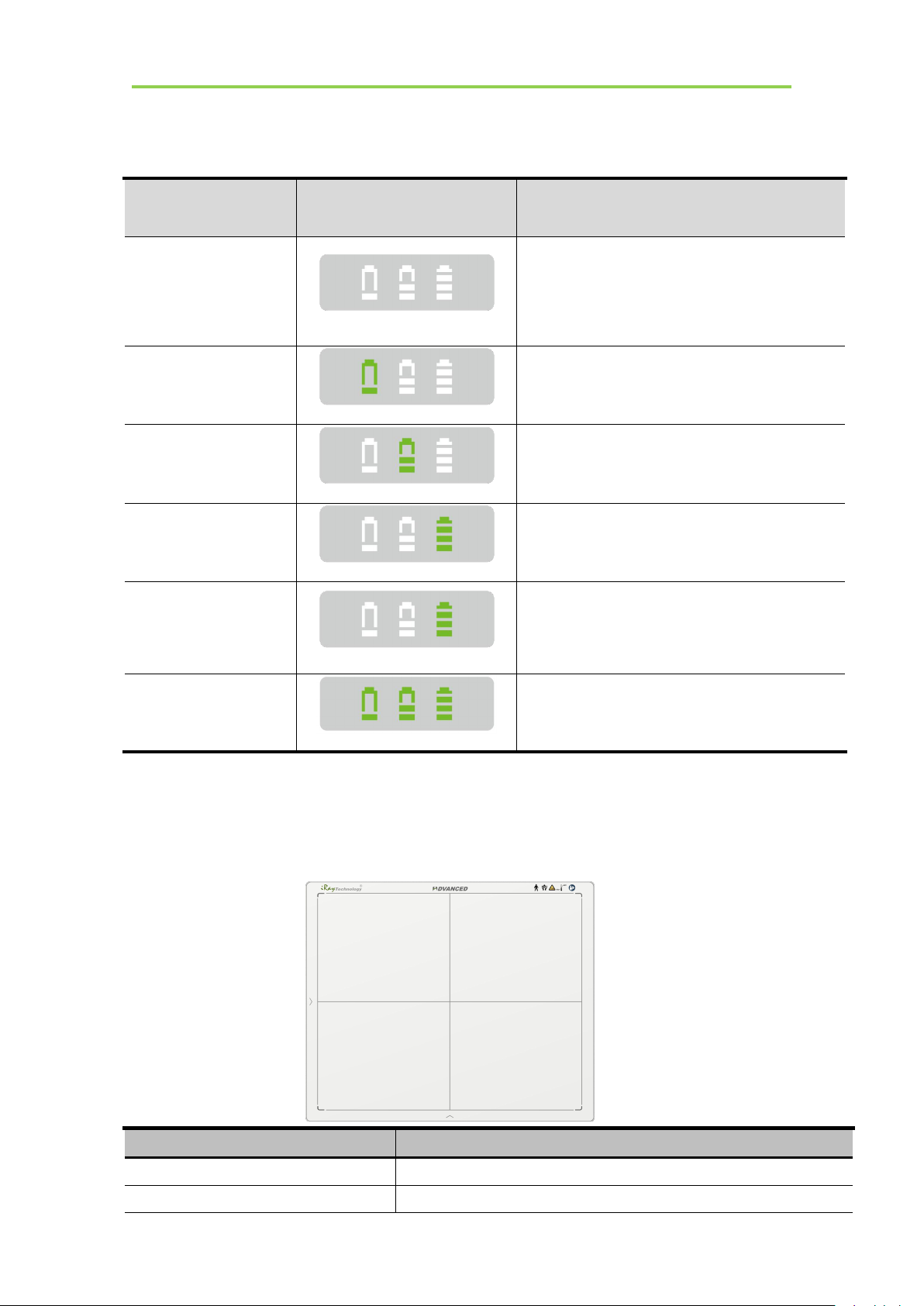

After booting up, user can check the status LED indicator.

Power Indicator

Lighting Status

Operating Status

Operating

Battery

Capacity

DC Input

OFF

Power OFF//

Orange ON

Power ON

≤20%

NO

Green ON

Power ON

Battery capacity ≥20%, no DC

input

DC input , no Battery

Orange Blinking

Power OFF

<20%

YES

Green and Orange

Blinking

Power OFF

≥20% and

<95%

YES

Green Fast Blinking

Power OFF

≥95% and

<100%

YES

OFF

Power OFF

=100%

YES

Link Indicator

Lighting Status

Description

OFF

Shut down

wired connection broken and wireless

connection not ready

Green ON

Wired Connection is built

Blue ON

Client mode, wireless connection is built

AP mode, wireless AP is ready

Blue Blinking

Client mode, no connection is built

Green and Blue

Blinking

Initialization

Status Indicator

Lighting Status

Description

OFF

Shut down

Exposure prohibit

Green ON

Exposure enable

Green Blinking

Image transmission

Installation

Link indicator is as table:

Status indicator is as table:

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

37

Mars1417V Digital Flat Panel Detector User Manual

Orange ON

Error

Orange Blinking

Safety mode

Action

FPD

Status

Power

Note

N.A.

/

No-Action

Power ON

Power

OFF

Short-Hold

Hold for 4 seconds.

Forced Restart

Long-Hold

Hold for more than 7 seconds, Release

Power Key when the POWER indicator is

ON.

Forced Restart

Power

ON

Long-Hold

Hold for more than 7 seconds, when the

POWER indicator is OFF and then ON,

Release Power Key.

Enter/Exit Sleep

Mode

Double-Click

Release after two short presses (interval <1s)

Power OFF

Short-Hold

Hold for 4 seconds, Release Power Key

when the POWER indicator is OFF.

Operation

Figure

Unload Battery from battery charger.

3.1.4. Button function

The Button function is shown as table below

3.2. Battery Charger Installation

38

................................................................................................................................................iRay Technology Co. Ltd.

Installation

Insert battery into battery charger.

Note the interface position as figure.

Press the battery to the bottom of battery

compartment.

3.3. Software Installation

In the case of iDetector not work, please install Microsoft .NET Framework 4.5 first, then install

vcredist_x86_2013(or vcredist_x64_vs2013). (iDetector should not be used for terminal hospital)

3.4. Panel Infrastructure

Mars1417V supports two connection modes as follows, the IP address and other information mentioned

below is as the example, user should configure the connection with the specific requirement.

1) Wireless Client Mode

2) Wireless AP Mode

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

39

Mars1417V Digital Flat Panel Detector User Manual

Connect one end of Gigabit Ethernet

Cable to Workstation,

Connect another end to LAN port of

External wireless AP

/

Open local network management

interface

Open local network configuration

To build connection between workstation and Panel, User should follow steps below.

3.4.1. Wireless Client Mode

To complete Wireless Client mode configuration, user has to finish actions listed below.

Configuration of External wireless AP

40

................................................................................................................................................iRay Technology Co. Ltd.

Installation

open IPV4 setting

IP and network mask setting

Select “Obtain an IP address automatically”

Open browser and type 192.168.1.1

Log into external wireless AP

Wireless setup

Configure 2.4GHz wireless network

SSID: NETGEAR_BIG_24

Security: WPA2-PSK

Password: 12345678

Channel: [Please check the current Wi-Fi environment, and choose a

relatively clean channel]

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

41

Mars1417V Digital Flat Panel Detector User Manual

Configure 5GHz wireless network

SSID: NETGEAR_BIG_50

Security: WPA2-PSK

Password: 12345678

Channel: [Please check the current Wi-Fi environment, and choose a

relatively clean channel]

LAN setup

Configure LAN IP address

IP address: 192.168.8.1

Subnet Mask: 255.255.255.0

External wireless AP reboot

Apply above settings and reboot your wireless router.

Recover local network IPv4 setting

IP setting

Network mask setting

IP address: 192.168.8.188

Subnet mask: 255.255.255.0

Configuration of detector

Either Wired Cable can be used to configure detector in wireless client mode. The wired connection

should be used by the service operator only.

To start configuration with wired cable. It is necessary to finish the configuration of external wireless

AP, then proceed to the steps below.

42

................................................................................................................................................iRay Technology Co. Ltd.

Installation

Connect panel to Workstation with

Ethernet Cable like 3.4.1

Click “Detector”

Click ”Wifi”

Click ”Read Config”

Choose “Client” mode

Click “Add”

Type SSID and Password

Click “Apply”

Choose SSID and select(There will be

√ occurred)”

Click “write config” to save

parameters.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

43

Mars1417V Digital Flat Panel Detector User Manual

Turn on wireless router.

Make sure there are wired connection

between router and work station and IP

192.168.8.188.

Click “Read wifi Status” to check

wireless transmission status, numericl

value occurred means the link is up

and available.

Connect panel to Workstation with

Ethernet Cable like 3.4.1

Since we have chosen default SSID and password, it would connect to wireless AP immediately after

powered on next time.

3.4.2. Wireless AP Mode

To complete wired connection configuration, user has to finish actions listed below.

Configuration of detector

Either Wired cable can be used to configure panel wireless AP mode. The wired connection should be

used by the service operator only.

To start wired cable configuration, users should finish the configuration of external wireless AP, then

proceed to the steps below.

44

................................................................................................................................................iRay Technology Co. Ltd.

Installation

Click “Detector”

Select “wifi”

Choose AP mode

Click “Read Config” to get default

setting. Change SSID and password

setting , make sure SSID is different

from other already exist;

Change channels and frequency

setting

Click “Country” and choose a country

setting

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

45

Mars1417V Digital Flat Panel Detector User Manual

Click ”Channel” and choose a clean

frequency and channel

Click ”write config”

Do not remove wired cable until FPD

status from Busy become Ready

Since we have chosen default SSID and password, it would connect to wireless AP immediately after

powered on next time.

Configuration of external wireless card

46

................................................................................................................................................iRay Technology Co. Ltd.

Installation

Open local wireless signal list

Select SSID which belongs to

detectors;

Input password and log into system

Open wireless card configuration

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

47

Mars1417V Digital Flat Panel Detector User Manual

open IPV4 setting

IP setting

Network mask setting

IP address: 192.168.8.188

Subnet mask: 255.255.255.0

Open SDK and choose product start

connection

48

................................................................................................................................................iRay Technology Co. Ltd.

Operation

4. OPERATION

4.1. Main Operation

4.2. Connection Build

4.3. Panel Configuration

4.4. Correction and Calibration Template Generation

4.5. Image Check and upload

4.6. Defect Template Check and Modification

4.7. Correction and Calibration Management

4.8. Firmware Update

4.9. Short cut

...............................................................................................................

................................................................................................................................

............................................................................................................................

.......................................................................................................................

..............................................................................................................

................................................................................

.................................................................................

.............................................................................................................................

............................................................................................................................................

..................................................................

50

50

55

56

57

62

63

66

68

75

4.10. Software

4.11. List of the HAZARDOUS SITUATIONS resulting from a failure of the IT-

NETWORK

.......................................................................................................................................

.........................................................................................................................................

76

81

iRay Technology Co. Ltd.……………………………………………………………………………………………………………………………….………..

49

Mars1417V Digital Flat Panel Detector User Manual

4. Operation

Mars1417V provides SDK for user to integrate panel into their DR system. Additionally, it also

provides an application for demonstration, i.e. iDetector. User can use iDetector to control panel

without DR system.

4.1. Main Operation

To Acquire X ray image is the main operation of Mars1417V. Most importantly, panel should

build synchronization with X ray generator.Mars1417V is born with three ways to acquire x

ray image, that is Software Mode, Inner2 Mode, and FreeSync Mode.

4.1.1. Software Mode

4.1.1.1. Block Diagram

Software mode is the basic way to acquire x ray image. Please see figure below for general feature.

Workstation is a host device installed with iDetector and SDK. Chapter 3 has described how to establish

connection between panels and workstation. In software mode, workstation does not control x ray

generator. Users would decide when to shoot x ray.

50

................................................................................................................................................iRay Technology Co. Ltd.

4.1.1.2. Work flow

Click “Prep”

Panel preparation, Wait until the warning message change from “Exposure

Prohibit” to “Exposure Enable”

Shoot X ray at any time. However the longer time you wait. The worse

image would be. So please shoot once x ray generator is ready.

After shooting, Click “Acquire”

Wait for image uploaded

Operation

4.1.1.3. Timing Setting

To set a clear scenario for programming, see diagram below for details

1. Workstation receives “prep” request, send command “Clear” to panel.

2. Panel receives “clear” from workstation, starts clearing leakage of panel. Meanwhile, panel send a

message to workstation “Exposure Prohibited”.

3. Panel finishes “Clear” and send a message to workstation “Exposure Enable”.

4. Workstation shows “Exposure Enable” on the iDetector’s message bar to tell user shoot X ray now.

5. User triggers x ray generator to initialize and do anode rotation to prepare for X ray shooting.

6. X ray generator finishes preparation for X ray shooting and reminds user to shoot.

7. X ray generator starts releasing x ray

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

51

Mars1417V Digital Flat Panel Detector User Manual

8. X ray generator finishes x ray shooting.

9. Workstation receives “Acquire” request, send command “Data Acquisition” to panel.

10. Panel receives “Data Acquisition” from workstation, start data acquisition operation.

11. Panel completes image acquisition and begins to send data to workstation.

12. Workstation receives all image data from panel which are after calibration if Hardware calibration

is on.

4.1.2. Inner2 Mode

4.1.2.1. Block Diagram

Workstation is a host PC device installed with iDetector and SDK. Chapter 3 has described how to

establish connection between panels and workstation. In inner2 mode, workstation does not control x

ray generator. Users would decide when to shoot x ray.

52

................................................................................................................................................iRay Technology Co. Ltd.

4.1.2.2. Work Flow

Click “Prep”

Panel preparation

Shoot X ray

X ray sensor in panel would trigger panel to start image acquisition.

Wait for image uploaded

Operation

4.1.2.3. Timing Setting

To set a clear scenario for program, see diagram below for details

1. Workstation receives “prep” request.

2. X ray generator is ready for X ray shooting and begins to release X ray.

3. Panel starts uploading Pre-dark image and Light image to Workstation for preview. If hardware

offset is selected, panel would do offset first, and then upload preview image.

4. Panel starts uploading Post-dark image to Workstation. If hardware offset is chosen, panel would

do correction and calibration first, then upload processed image to Workstation.

5. Workstation into exposure prohibit state.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

53

Mars1417V Digital Flat Panel Detector User Manual

Check SDK to make sure panel is ready

Shoot X ray

X ray sensor in panel triggers panel to stop flushing the panel

After fixed time, panel starts image acquisition

Wait for image uploaded

4.1.3. Freesync Mode

4.1.3.1. Block Diagram

Workstation is a host PC device installed with iDetector and SDK. Chapter 3 has described how to

establish connection between panel and Workstation. In FreeSync mode, User doesn’t interact with

Workstation. After shooting, images would be shown on screen immediately.

4.1.3.2. Work Flow

54

................................................................................................................................................iRay Technology Co. Ltd.

Operation

Open SDK and choose

product start connection

Confirm the IP address and

the Port are the same as the

value in config.ini.

The port should use the

default value of 28000

4.1.3.3. Timing Setting

1. X ray generator is ready for X ray shooting and begins to release X ray.

2. Workstation receives “Exposure Prohibited” from Panel.

3. Panel starts uploading Pre-dark image and Light image to Workstation for preview. If hardware

offset is selected, panel would do offset first, and then upload preview image.

4. Panel starts uploading Post-dark image to Workstation. If hardware offset is chosen, panel would

do correction and calibration first, then upload processed image to Workstation.

5. Workstation receives “Exposure Enable” from Panel.

4.2. Connection Build

Note: 1. once changing connection from different network card, user must re-connect panel with

different IP address.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

55

Mars1417V Digital Flat Panel Detector User Manual

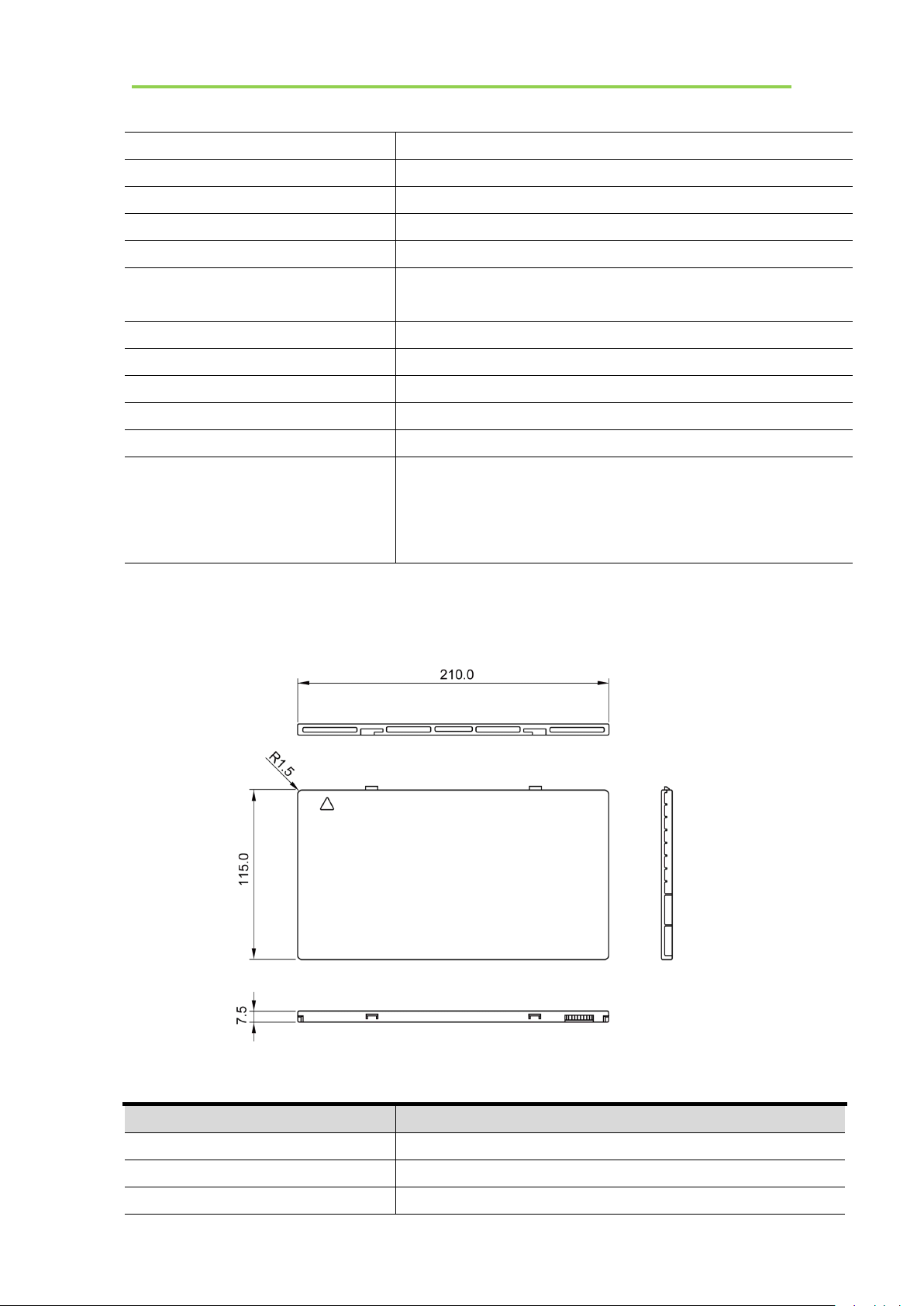

Choose iDetector menu

related modules

Acquire module related

setting, such as loading

correction and calibration

template, acquiring images

SDK module related setting,

such as IP address

Detector module related

setting, such as trigger

module, wireless signal

2. The rule of Multi-Share control is based on IP address. The second terminal with different IP address

is not allowed to operate panel after the first one connected. If there is no command transmission

between panel and Workstation over 5 minutes, panel releases access authority.

4.3. Panel Configuration

56

................................................................................................................................................iRay Technology Co. Ltd.

Operation

Calibrate module related

setting, such as making

correction and calibration

template, template in panel

could be uploaded to

workstation, and template in

workstation could also be

downloaded to panel.

Local File module related

setting, such as import Raw

or DCM image.

4.4. Correction and Calibration Template Generation

The correction and calibration should be performed after installation and it is recommended to perform

the new correction and calibration after any major change on the system settings and hardware

configuration. On the other hand, it is also recommended to do the correction and calibration in each 6

months.

4.4.1. Pre-offset Template Generation

If panel is configured to do Pre-offset correction, Pre-offset Template is necessary. See below

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

57

Mars1417V Digital Flat Panel Detector User Manual

Select “Calibrate”

Click “Start Generate

Templates”

Click “Create Offset”

Click “Start create offset

template file”

It will show ”Offset Map

Generating”

58

................................................................................................................................................iRay Technology Co. Ltd.

Operation

After “generating”, it would

show “Offset MAP

Genetated”

On Gain template generating

page, there are five images

that need to be got

Click “start” button

Click “PREP”, and start

exposure

4.4.2. Gain Calibration Template Generation

Before Gain template generating, make sure SID1.2m, no copper is required, the GUI of the software

maybe different with the below figures.

iRay Technology Co. Ltd.……………………………………………………………………………………….……………………………………….………..

59

Mars1417V Digital Flat Panel Detector User Manual

After exposure, click

“Acquire” to get the light

image

If the value meet the

expected value, click

“Accept”, then get the other

four images.

If the value does not meet the

expected value, please do not

click the “Accept”, and

adjust the exposure

dose ,then click the “PREP”

to get light image again

After getting five images,

click “Generate” to generate

gain template