3860+3860+

OPERATION MANUALOPERATION MANUAL

MRidium

MRI INFUSION/MONITOR SYSTEM

TM

REF 1138REF 1138

IRADIMEDIRADIMED

CORPORCORPORATIONTION

MRidiumTM 3860+ MRI Monitor/Infusion System

Operation Manual, Part Number 1138

Release 4B, 2015-10

PER ECN 000711

© 2010-2015 IRadimed Corporation

IRadimed Corporation

1025 Willa Springs Drive

Winter Springs, Florida 32708 U.S.A.

Tel 407-677-8022 Fax 407-677-5037

www.iradimed.com

European Authorized Representative

Medical Device Consultancy

7 Pinewood Drive

Ashley Heath, Market Drayton,

Shropshire, UK, TF9 4PA

www.medicaldeviceconsultancy.co.uk

CONTENTS

Paragraph Page

General Information.........................................................................vi

Equipment Classification .................................................................. vi

Intended Uses / About the Pump .................................................... v ii

Warnings / Precautions...................................................................viii

User Responsibility..........................................................................xiv

Definitions.......................................................................................xiv

Symbols .......................................................................................... xv

1.0 Introduction...................................................................................1-1

1.1 Product Description............................................................................1-1

1.1.1 Front of the Pump ....................................................................1-2

1.1.2 Pump Drive Mechanism .............................................................1-3

1.1.3 Back of the Pump .....................................................................1-4

1.1.4 1120 MRI Power Supply ............................................................ 1-5

1.1.5 Front of the Remote Display/Charger ..........................................1-6

1.1.6 Back of the Remote Display/Charger...........................................1-7

1.2 Controls...........................................................................................1-8

1.2.1 Front Panel Control Keys ...........................................................1-8

1.3 Pump Preparation for Use................................................................. 1-10

1.3.1 Administration Sets ................................................................1-11

1.3.2 Artifacts................................................................................1-11

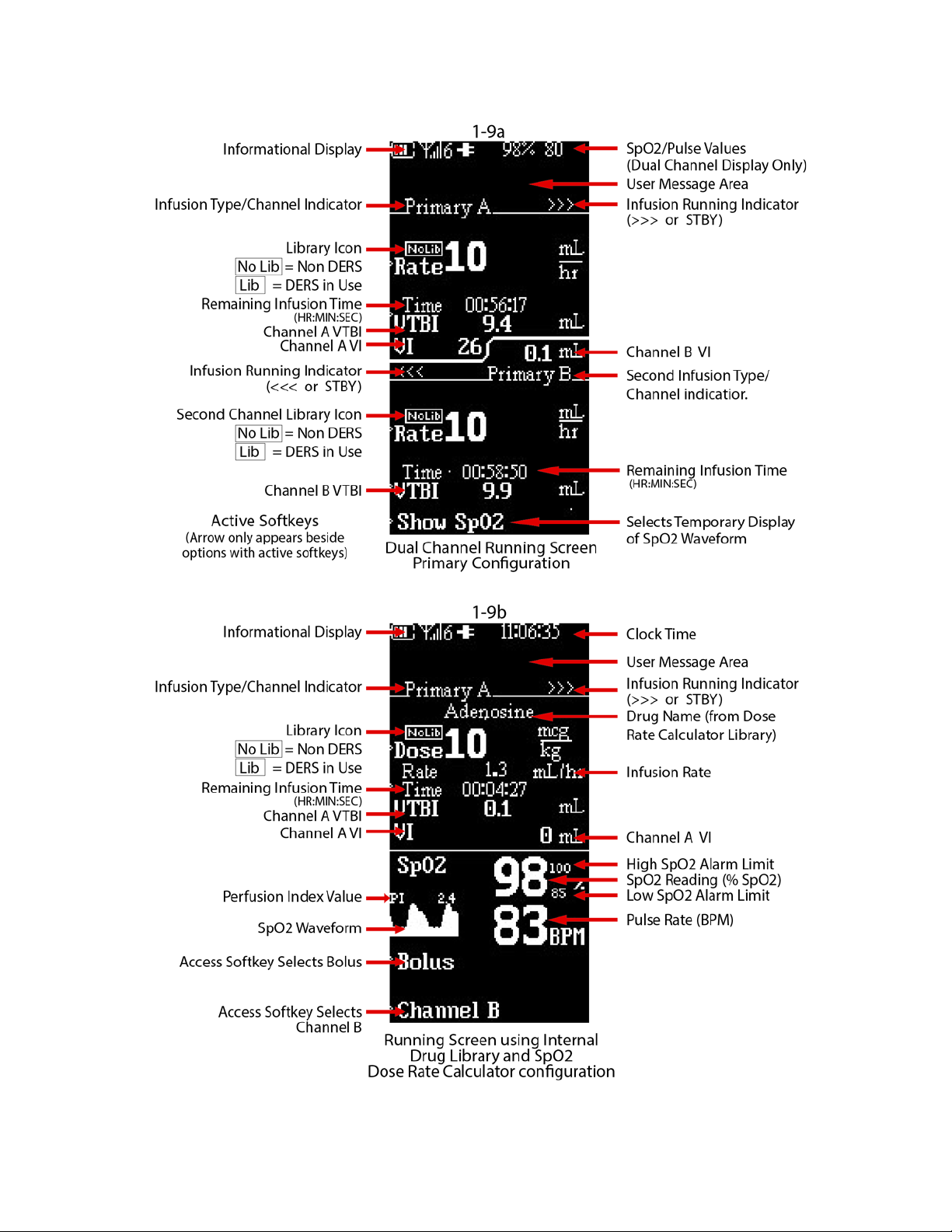

1.4 Display .......................................................................................... 1-13

1.4.1 Informational Display.............................................................. 1-17

1.4.2 User message area................................................................. 1-17

1.4.3 Infusion Parameter Setup Display.............................................1-17

1.4.4 Secondary.............................................................................1-18

1.4.5 Bolus....................................................................................1-18

1.4.6 Special Features Setup Menu ................................................... 1-19

1.5 User Interface.................................................................................1-19

1.6 System Self Test .............................................................................1-19

1.7 Maintenance and Operator Verification ...............................................1-19

1.8 Cleaning Instructions .......................................................................1-20

2.0 Installation.....................................................................................2-1

2.1 Introduction......................................................................................2-1

2.2 Unpacking the Pump..........................................................................2-1

2.3 Unpacking Remote Display/Charger .....................................................2-1

2.4 Unpacking 3861 Channel B SideCar .....................................................2-2

2.5 Preparing the Pump for Use ................................................................2-2

2.5.1 Installing Battery......................................................................2-2

2.5.2 Installing Optional Pulse Oximeter Sensor....................................2-2

2.5.3 Removing The Pulse Oximeter Sensor .........................................2-2

2.6 Mounting on I.V. Pole......................................................................... 2-2

2.7 Operational Checkout of the Pump.......................................................2-2

2.7.1 Determining the current IV Pump Software revision level:..............2-3

2.8 Pump Storage...................................................................................2-3

2.9 Remote Display Installation ................................................................2-3

2.9.1 Charging Battery with the Remote. .............................................2-4

2.10 Language Options..............................................................................2-5

2.11 Product Structure ..............................................................................2-5

i

3.0 I.V. Set Preparation for Use............................................................3-1

3.1 Precautions.......................................................................................3-1

3.2 I.V. Set Priming ................................................................................3-2

3.2.1 I.V. Administration Set 1056 Priming ..........................................3-2

3.2.2 I.V. ByPass Set 1055 Priming.....................................................3-2

3.2.3 I.V. Syringe Adapter Set 1057 Priming ........................................3-2

3.2.4 I.V. Extension Set 1058 Priming .................................................3-3

3.3 I.V. Set Insertion and Removal............................................................3-4

3.3.1 Administration Set Insertion ......................................................3-4

3.3.2 Administration Set Removal.......................................................3-4

4.0 Primary Configuration ....................................................................4-1

4.0.1 Programming a Basic Infusion....................................................4-1

4.0.2 Editing the Infusion Program......................................................4-2

4.0.3 Canceling/Pausing an Infusion....................................................4-2

4.0.4 KVO (Keep Vein Open) - Infusion Complete..................................4-3

4.0.5 Volume Infused........................................................................4-3

4.0.6 Pump Shut Down......................................................................4-3

4.0.7 Restoring an Infusion following Pump Power Down........................4-3

4.1 Dual Channel Infusion........................................................................4-4

4.1.1 Dual Channel Infusion Setup......................................................4-4

4.1.2 Single Channel/Dual Display Setup .............................................4-4

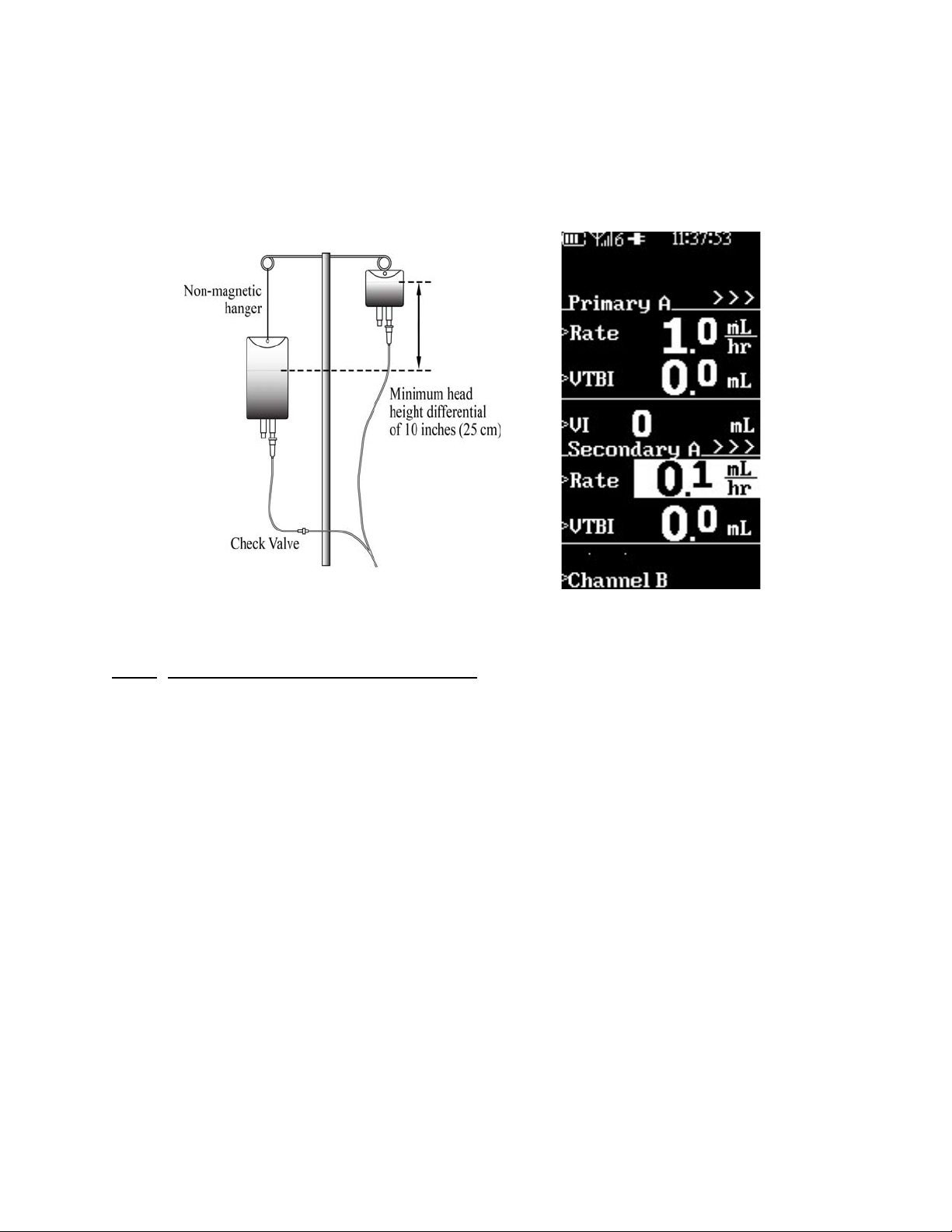

4.2 Secondary (“Piggyback”) Infusion Configuration ....................................4-5

4.2.1 Priming a Secondary Administration Set ......................................4-6

4.2.2 Secondary Infusion Setup..........................................................4-6

4.2.3 Programming a Secondary Infusion.............................................4-7

4.2.4 Viewing Primary Settings during a Secondary Infusion...................4-8

4.2.5 Changing Primary Settings during a Secondary Infusion.................4-8

4.2.6 Stopping a Secondary Infusion and Returning to Primary Infusion...4-8

4.2.7 Dual Channel Operation.............................................................4-8

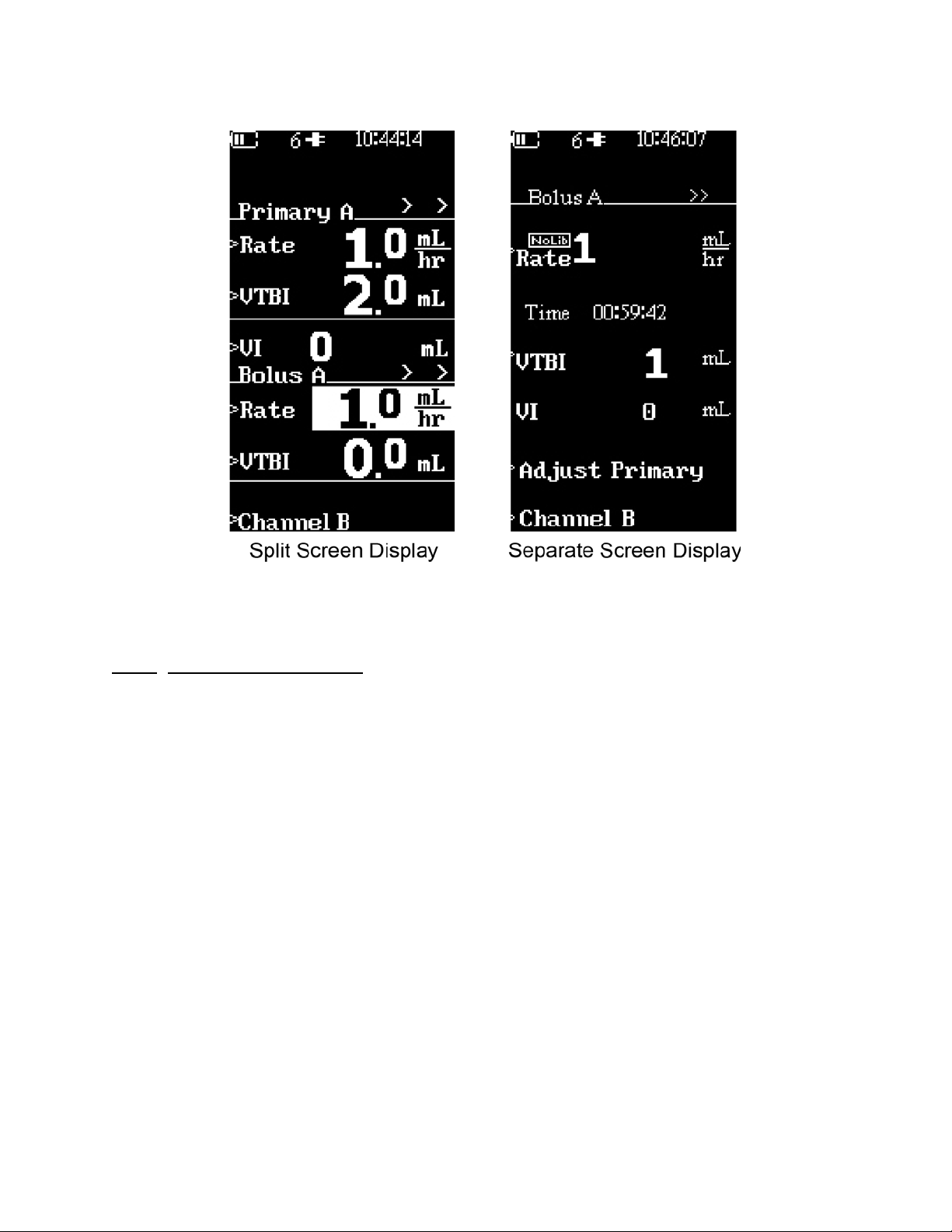

4.3 Bolus Delivery...................................................................................4-9

4.3.1 Bolus Setup and Start ...............................................................4-9

4.3.2 Stopping Bolus Rate Dose........................................................4-10

4.3.3 Restoring Bolus Dose. .............................................................4-10

4.4 Channel B ...................................................................................... 4-11

4.4.1 Attaching the Channel B SideCar .............................................. 4-11

4.4.2 Detaching the Channel B SideCar.............................................. 4-11

4.5 Special Features Menu .....................................................................4-12

4.5.1 Dose Rate Calculation .............................................................4-14

4.5.2 Alarm Volume........................................................................ 4-21

4.5.3 KVO Rate ..............................................................................4-22

4.5.4 Occlusion Limits ..................................................................... 4-23

4.5.5 Lock Keys..............................................................................4-24

4.5.6 NEXT MENU key .....................................................................4-24

4.5.7 Radio Channel menu...............................................................4-24

4.5.8 Exiting the Special Features Menu.............................................4-25

4.6 Air Bubble Detection and Reset. ........................................................4-25

4.7 Data Retention................................................................................4-25

5.0 Alarms............................................................................................5-1

5.1 Introduction......................................................................................5-1

5.2 User Messages..................................................................................5-1

5.3 Responding to an Alarm .....................................................................5-1

5.4 Remote Alarms .................................................................................5-2

ii

6.0 Battery Operation...........................................................................6-1

6.1 Introduction......................................................................................6-1

6.2 Inserting the Battery Pack ..................................................................6-1

6.3 Charging the Battery Pack ..................................................................6-1

6.4 Removing the Battery Pack.................................................................6-2

6.5 Testing the Battery Pack.....................................................................6-2

6.6 Battery Charge Indicator ....................................................................6-3

6.7 Battery Low Indication .......................................................................6-3

6.8 Battery Power Gauge .........................................................................6-4

6.9 Battery Care and Maintenance: ...........................................................6-4

6.9.1 Introduction.............................................................................6-4

6.9.2 1133 Battery Pack Maintenance Checkout Procedure .....................6-4

6.10 Battery Pack Replacement ..................................................................6-4

6.11 Battery Pack Related Precautions.........................................................6-5

7.0 Introduction, Pulse Oximeter, 3860+ .............................................7-1

7.0.1 User Warnings and Precautions ..................................................7-1

7.1 Installation.......................................................................................7-3

7.2 Symbols, Displays, and Controls..........................................................7-4

7.2.1 SpO2 Symbols .........................................................................7-4

7.2.2 Displays..................................................................................7-5

7.3 Operator Verification..........................................................................7-7

7.4 Operating the 3860+ Pulse Oximeter ...................................................7-7

7.4.1 Probe Set-up and Use ...............................................................7-8

7.4.2 Applying the Model 1170 Fiberoptic SpO2 Sensor..........................7-8

7.4.3 Verifying Operation of the Model 1170 Fiber Optic Sensor ............ 7-11

7.5 Probe Cleaning................................................................................7-11

7.5.1 Cleaning the Model 1170 Fiberoptic Sensor and 1171 Sensor Grips 7-11

7.6 SpO2 Alarms and Alerts ...................................................................7-11

7.6.1 Patient and Equipment-Related Alarms...................................... 7-11

7.6.2 Watchdog Alarms ...................................................................7-11

7.6.3 Reviewing, Setting, or Changing Volumes and Alarm Limits..........7-12

7.7 SpO2 Menu Choices .........................................................................7-12

7.8 SpO2 Troubleshooting...................................................................... 7-13

7.9 SpO2 Parts and Accessories .............................................................. 7-15

7.10 SpO2 Testing Summary.................................................................... 7-16

7.11 Specifications..................................................................................7-17

7.12 The Masimo Set® Principles of Operation............................................7-18

8.0 Dose Error Reduction System .........................................................8-1

8.1 Introduction: ....................................................................................8-1

8.2 DERS Installation ..............................................................................8-1

8.3 DERS FEATURES AND DEFINITIONS.....................................................8-2

8.4 DERS RELATED ALERT AND USER PROMPT MESSAGES ...........................8-3

8.4.1 ALERT / PROMPT - MESSAGES, TYPE, CAUSE AND RESOLUTION .....8-4

8.5 DERS Indicators / Status....................................................................8-6

8.6 SETTING UP A DERS PRIMARY INFUSION..............................................8-7

8.6.1 SETTING UP A DERS PRIMARY INFUSION.....................................8-7

8.6.2 Adjusting a Dose or the VTBI During an Infusion.........................8-14

8.6.3 SETTING UP A DERS BOLUS.....................................................8-15

8.6.4 REPEATING A BOLUS DOSE .....................................................8-19

8.6.5 Canceling Bolus Delivery .........................................................8-20

8.6.6 DUAL CHANNEL DERS INFUSION ..............................................8-21

8.6.7 DUAL CHANNEL BOLUS DELIVERY.............................................8-23

iii

Specifications..........................................................................................A-1

Repair .....................................................................................................B-1

Warranty information..............................................................................C-1

Manufacturers Technical declaration ...................................................... D-1

IV Sets and Accessories...........................................................................E-1

Troubleshooting ......................................................................................F-1

1119 I.V. Pole Assemblies and Parts descriptions..................................G-13

Trumpet and start up curves................................................................... H-1

Appendix A: Specifications ......................................................................A-1

Appendix B: Repair..................................................................................B-1

Appendix C: Warranty information...........................................................C-1

Appendix D: Manufacturers Technical Declaration .................................. D-1

Appendix E: Accessories..........................................................................E-1

Appendix F: Troubleshooting ...................................................................F-1

Appendix G: 1119 I.V. Pole Assemblies and Parts Descriptions............... G-1

Appendix H: Trumpet and start up curves............................................... H-1

Appendix I: 1145 Dose Error Reduction System....................................... I-1

iv

FIGURES

Figure Page

1-1 Front of Pump...................................................................................1-2

1-2 Pump Drive Door Open.......................................................................1-3

1-3 Bac k of Pump....................................................................................1-4

1-4 Model 1120 MRI Power Supply ............................................................1-5

1-5 Front of 3865 Remote Display/Charger.................................................1-6

1-6 Bac k of 38 65 Remote Display/Charger..................................................1-7

1-7 Front Panel Control Keys ....................................................................1-8

1-8 Setup Display Screens......................................................................1-13

1-9 Running Screens .............................................................................1-15

1-10 Special Features Setup Menu ............................................................ 1-18

3-1 Free Flow Preventer...........................................................................3-1

3-2 Roller and Slide Clamps......................................................................3-1

3-3 IV Set Installation .............................................................................3-5

4-1 Primary Pump Setup Screen................................................................4-1

4-2 Dual Infusion Display.........................................................................4-5

4-3 Secondary Infusion Set-up and Programming Screen .............................4-7

4-4 Bo lus Setup Displ a ys..........................................................................4-9

4-5 Attaching Channel B “SideCar” .......................................................... 4-11

4-6 Special Features Menu .....................................................................4-12

4-7 Dose Rate Calculation Menu..............................................................4-14

4-8 Primary Screen with Dose Rate Displayed...........................................4-17

4-9 Alarm Volume Adjustment Screen......................................................4-21

4-10 KVO Rate Screen.............................................................................4-23

4-11 Set Comm Channel Displays ............................................................. 4-25

5-1 Alarm Display in User Message Area.....................................................5-2

6-1 Battery Installation............................................................................6-1

6-2 Battery Removal ...............................................................................6-2

6-3 Battery Test......................................................................................6-3

7-1 3860+ Display w/SpO2 ......................................................................7-4

7-2 C onnecting the 117 0 Fibe roptic Probe ..................................................7-9

7-3 Applying the 1170 SpO2 Sensor ........................................................ 7-10

7-4 Saturation Charting. ........................................................................7-19

Table Page

5-1 Alarm , Alert and User Prompt Messages ...............................................5-3

7-1 SpO

Alarm Limits.............................................................................7-8

2

v

General Information

This document provides the following directions for use:

• Single channel pump that provides a full range of features in a compact,

easy to use, linear peristaltic pump.

• Dual channel pump offers the same features while providing two

independent infusion pumps in one instrument.

• The Remote Display/Charger Unit allows for remote ability to control the

Pump with a total of two channels from outside the MR Scanner.

The system is designed for use in the following patient care areas:

• MRI (0.2 to 3T systems).

• MRI/Recovery.

• Pump operable and safe in up to 1 Tesla (10,000 Gauss) magnetic field.

EMI Statement:

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to other devices in the vicinity. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to other devices, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures: 1. Reorient or relocate the receiving device.

2. Increase the separation between the equipment. 3. Connect the equipment into

an outlet on a circuit different from that which the other devices(s) are connected. 4.

Consult the manufacture or field service technician for help.

Mains Disconnection Method:

3860 Pump: Disconnect power cord (1121) from Appliance Inlet on the side of the

MRI power supply unit (1120).

3865 Remote/Charger Unit: Disconnect power cord (1128) from Appliance Inlet on

the rear of the Unit.

Alternate Voltage/Export:

For power cord plug types see local country distributor. Unit shipped in USA with US

3 pin power NEMA plug.

3860 EQUIPMENT CLASSIFICATION

Classification according to IEC 60601-1

According to the type of protection

against electrical shock:

According to the degree of protection

against electrical shock:

According to the type of protection

against harmful ingress of water:

According to the methods of sterilization

or disinfection:

According to the mode of operation Continuous operation

Equipment not suitable for use in the presence of flammable anesthetic mixture with air or

with oxygen or nitrous oxide

Class I equipment and internally powered

Type CF (defibrillator-proof) equipment

Ordinary Equipment. Complies with Section 44.4 of the

Infusion Pump standard, IEC 60601-2-24.

Non-sterilizable. Use of liquid surface disinfects only.

vi

About the Pump: Intended Uses

Indications for Use:

The Iradimed Corporation's MRidium 3860+ MRI Infusion Pump/Monitoring System

is intended for general hospital or clinical use by medical professionals whenever it is

required to infuse patients with subcutaneous, intra-venous or intra-arterial fluids

before, during, or after Magnetic Resonance Imaging (MRI) scans, functioning while

either in a stationary or mobile position. The system is useful in the administration of

fluids requiring precisely controlled infusion rates. The system can operate in either

continuous, intermittent, or bolus delivery mode. The Infusion Pump can be used

inside the MRI room mounted outside the 10,000 Gauss line (1 Tesla line), and with

shielded magnets of field strength of 3.0 Tesla or less. This device is available for

sale only upon the order of a physician or other related licensed medical

professional, and not intended for any home use applications.

The Pulse Oximeter is used to measure, display, and record functional oxygen

saturation of arterial hemoglobin (SpO2) and pulse rate of adult, pediatric, and

infant patients in an MR environment. Testing of the oximeter was performed in MR

conditional environments at 1.5T and 3T. It is indicated for spot checking and/or

continuous monitoring of patients who are well or poorly perfused in the MRI.

This infusion pump is contraindicated for use on the inlet side of Extra Corporeal

Membrane Oxygenation (ECMO) systems where the negative pressure is greater

than -100 mmHg as the high negative pressure can result in uncontrolled fluid flow.

TM

The MRidium

providing the non-magnetic motor power driving the MRidium

unit. This allows the MRidium

material and safely operable in high magnetic fields.

Features include:

• Non-magnetic ultrasonic drive motor.

• Special aluminum RF noise shielding enclosure.

The pump is equipped with a unique battery display that provides the clinician

continuous monitoring of battery capacity available. This information is displayed

when the instrument is turned on.

3860+ Infusion System incorporates a unique ultrasonic motor

TM

TM

3860+ to be constructed with minimal magnetic

3860+ pumping

The Dual Rate Feature allows the pump to administer both primary and secondary

solutions at separate flow rates and volumes. Using this feature the clinician can

select and start a program for secondary delivery. Upon completion of the secondary

dose, the pump can automatically switch over to a primary rate. Both channels of

TM

the MRidium

3860+ can be programmed for primary and secondary operation.

Optional modes are easily accessed with the press of one key.

The Dose Rate Calculator allows the clinician to calculate a dose rate for continuous

infusion given concentration and dosage orders.

The Bolus Dose feature allows the clinician to set up an initial infusion rate for a

specific Bolus volume, automatically followed by a maintenance rate from the same

container.

A 2.4 GHz wireless link allows communication between the infusion pump and

remote display.

Qualified service personnel can configure many features of the pump to meet

specialized needs.

Specific pump menu screens may vary depending on software release being used.

vii

This device is covered under one or more of the following U.S. Patents:

7,267,661 B2, 7,404,809 B2 and International Equivalents

7,553,295, 7,553,882, 8,105,282 B2 and International Equivalents

7,753,882; 8,150,493; 8,690,829; 8,262,642; 8,469,932; 8,105,282; 8,500,694

EP1530440; 1802362; 4597970; 5001845 International Patents

Other U.S. and International patents pending.

Possession or purchase of this device does not convey any express or implied license

to use the device with unauthorized infusion sets, sensors or cables which would,

alone, or in combination with this device, fall within the scope of one or more of the

patents relating to this device.

Masimo

®

, Masimo SET®, Signal Extraction Technology® and Signal IQTM are

trademarks or registered trademarks of Masimo Corporation.

Warnings/Precautions

Federal Law in the U.S.A. restricts this device to sale by or on the order of a

physician.

This device is intended for use by trained medical professionals only.

Refer all service to Iradimed Corporation Authorized Service R epresentatives.

The 3860 Pump has been specifically designed for operation inside an MRI Magnet

Room, and is designed to operate normally in the presence of most frequently

encountered electromagnetic interference in the MRI environment. Under extreme

levels of interference, such as in close proximity to an electrosurgical generator,

cellular telephone or a 2 way radio normal pump operation may be interrupted.

Avoid use of this pump under these conditions.

Use only MRI-compatible patient access devices (e.g. needles, luer-ports, etc.) to

prevent any possible RF current from reaching the patient's skin.

The Remote Display Charger is intended for use in the MRI control room. Do not

operate the 3865 Remote Display/Charger inside the MRI Magnet Room.

For safe operation, use only Iradimed Corporation recommended MRI-compatible or

MRI-safe accessories.

The MRI pump must be mounted securely when used in the MRI scan room. Always

securely mount the pump using it’s integral pole mount clamp or other mechanical

fixing means.

Always secure the I.V. Pole wheel locks after positioning within the MRI Magnet

Room.

Avoid placing the I.V. Set adjacent to any electrical conductor within the MRI bore,

which can become heated during MRI scans.

The Alarm Sound Volume is adjustable for various clinical environments. Ensure the

alarm sound level is appropriate for the use environment in the MRI so that it can be

heard above the ambient noise level, especially during scanning.

Product damage may occur unless proper care is exercised during unpacking and

installation. Do not use the pump if it appears damaged in any way. The battery

should be charged before use.

Battery may not be fully charged upon receipt. Connect pump to AC power for at

least nine (9) hours before placing the pump into use.

Always connect the infusion pump power supply or Remote Display/Charger to a

properly grounded 3-wire power receptacle. Never use power extension cords. If the

quality of the earth grounding is in question, use battery power for the infusion

pump.

This equipment is not suitable for use in the presence of flammable anesthetic or

other gases. Do not use this system in the presences of flammable gases.

viii

Precautions/Continued

Arrange tubing, cords and cables to minimize the risk of patient or other equipment

entanglement.

The pump is not intended for high pressure, high viscosity radiological contrast

agents.

To avoid patient injury, always respond to Pump or Remote Display/Charger alarms

immediately.

Never leave the patient with the Pump stopped if the infusion has not been

completed.

To prevent injury, avoid placement of an y NIBP cuff on the limb receiving the I.V.

therapy.

The Pump contains materials which must be recycled, or disposed of properly. For

proper disposal methods, contact your local sales representative or distributor.

Hospital personnel must ensure the compatibility of the drugs as well as the

performance of each pump as part of the overall infusion. Potential hazards such as

drug interactions, inaccurate delivery rates, inaccurate pressure alarms and

nuisance alarms may arise from other incompatibilities.

MRI pump uses medical grade silicone rubber and PVC tubing. Do not infuse

pharmaceuticals or solutions that are incompatible with these materials. Drugs not

compatible with silicone rubber or PVC plastics, or drugs not stable under infusion

conditions should not be used with this system.

Consult the drug labeling to confirm drug compatibility, concentr ation, delivery r ates

and volumes are suitable for concurrent delivery, or piggyback delivery (secondary

followed automatically by primary).

Simultaneously infusing with more than one pump into one patient line may

significantly affect the infusion rate of at least one of the pumps.

Hyberbaric Chamber Operation: The MRidium system is not certified for use in

oxygen enriched environments. It is not intended for use in this environment.

Equipment use outside it’s specified environmental conditions can affect infusion

accuracy.

WARNING: This product may contain a chemical known to the State of California

(U.S.A.) to cause cancer, or birth defects or other reproductive harm.

Pump Related Warnings/Precautions

This pump is designed to stop fluid flow under alarm conditions. Periodic patient

monitoring must be performed to ensure the infusion is proceeding as expected.

Immediately respond to a “Close Door” alarm due to imminent lapse in infusion

therapy.

Immediately respond to the “Check Door” alarm as this indicates possible Free-Flow

of IV Fluids.

Dropping, or a severe shock to the pump, could result in damage and resultant

pump inaccuracy. Refer the pump to qualified service personnel for proper checkout

if either of these conditions occur.

Do not place the pump into use if it fails any of the Power On Self Tests.

Always verify flow rate, VTBI (V olume to be Infused) and/or dose drug entries before

starting infusion.

When opening the door, always check that the free flow preventer (black slide

clamp) is fully pulled outward to the shut off position.

ix

Pump Related Warnings/Precautions (Continued)

If questionable Pump operation is observed, or if a System Failure occurs (i.e. an

unexplained continuous audible alarm with no displayed values), discontinue use of

the Pump and refer it to qualified service personnel.

Although unlikely, failure of certain rugged mechanical components, such as the

free-flow prevention mechanism could cause fluid delivery limited to the contents of

the fluid container. The maximum volume that may be infused under a single fault

condition is 0.1 mL. Single fault failure of any electronic or motor control component

would result in less than 0.3 mL of unexpected fluid delivery.

A small amount of fluid is expelled from the set (less than 0.05 mL) under worse

case conditions when the mechanical drive advances to Index each time the pump

latch is opened and closed with a set loaded. If potent drugs are being used, take

appropriate action to guard against overmedication of the patient.

Always set the occlusion pressure alarm limit at the minimum level required for the

prescribed fluid therapy.

Whenever closing the Pump Door, check to make sure that nothing interferes with

the pumping mechanism.

During a running infusion, each interruption and re-start of the infusion can add

approximately 0.05 mL of delivered fluid to the indicated Volume Infused.

There are dangerous voltages present on internal components that may cause

severe shock or death upon contact. Never open the pump casing, it’s power supply ,

or the Remote/Charger when connected to AC Mains power. Disconnect from AC

power and remove battery pack prior to servicing or cleaning.

Do not operate the pump on patients with the battery removed (pump will stop and

not alarm during AC power loss without battery installed). Use of a properly

maintained and charged battery will allow proper operation. Do not touch battery

connector pins and patient simultaneously.

If the Low Battery alarm sounds, connect the pump with its power supply to AC

power immediately.

Replace blown fuses on the 1120 Pump MRI power supply or Remote Display/

Charger with fuses of the same type and rating only, or a fire hazard could exist.

Never use sharp objects (paper clips, needles, etc.) to clean any part of the pump.

Keep the pump door latch securely closed when the pump is not in use. This will

avoid door latch damage.

Do not sterilize the pump or any component by heat, steam, ethylene oxide (ETO),

or radiation.

The screen displays the VTBI (Volume to be Infused) in whole integers above 99.9.

Any fraction of a milliliter delivered is not displayed, but is retained in memory.

To avoid damage to the I.V. Pump and Pole, always move the I.V. Pole separately

from the patient trolley to prevent accidental entanglement.

The pump body is made of aluminum and is non-magnetic. However, when moving

the pump within high magnetic fields (>2000 gauss) one might notice Eddy Current

effects. These are forces generated in the aluminum which resists motion through

the intense magnetic field. Such effects are normal and present no risk of free

magnetic movement of the unit.

Sensors detect open or poorly shut door clamp and incompletely closed IV Set free

flow preventer clamp, generating a “Check Door” alert. Immediate attention should

be given to possible free flow.

x

Set Related Warnings/Precautions

Always use aseptic techniques. Patient infection could result from mishandled or

non-sterile assemblies.

Use only Iradimed Corporation MRidium

of other sets will cause improper pump operation resulting in inaccurate fluid

TM

delivery. MRidium

with the MRidium

1000 Series administration sets are only intended to be used

TM

Pump.

All infusion administration sets are supplied sterile and are single use only. Do not

sterilize or re-use. Patient infection or inaccurate flowrate could result.

Prior to use of any Infusion Set, examine the pouch and inspect for damage that

could compromise sterility. If the pouch or Set is damaged, discard and use another

Set.

Administration sets should be changed per the Center for Disease Control (CDC)

guidelines or healthcare provider policy . Disc ard after use. Design use life of I.V. sets

is six (6) hours maximum.

Disconnect the I.V. line from the patient before starting the priming procedure.

Prepare the primary solution container in accordance with the manufacturer’s

instructions.

The use of positive displacement infusion devices ported together with gravity flow

infusion systems into a common I.V. site may impede the flow of the gravity flow

system and affect their performance. Hospital personnel must ensure that the

performance of the common I.V. site is satisfactory under these conditions.

Interconnection with I.V. sets with small inner diameter may affect pump accuracy at

high flow rates. Avoid interconnection with small bore diameter I.V. sets (less than

0.050 inch (1.25mm) I.V. tubing) if high flow rates are used.

A kinked or occluded I.V. line could cause the pump to operate abnormally and affect

the accuracy of the infusion. Before operating this system, verify that the I.V. line is

not kinked or occluded.

To avoid nuisance alarms, confirm that the fluid source is positioned higher than the

pump.

Setting the primary rate greater than the secondary rate will result in a more rapid

infusion of any residual secondary drug remaining in the line, the administration set,

and fluid container.

When performing a secondary infusion:

• Secondary solution container must be higher than the primary

solution container.

• The Secondary VTBI (Volume to be Infused) setting must be

equal to the volume in the secondary container. This requires

consideration of such variables as factory overfill, medication

additions, etc. Underestimating the volume will cause the

remaining secondary solution to be infused at the primary rate;

overestimating will result in the primary solution being infused at

the secondary rate. Multiple doses from a single container are

not possible.

Air bubbles may form distal to the pump as a result of normal out-gassing of

dissolved air in the fluid. This may occur if a chilled solution is being used, if the

pump is mounted significantly above the patient, or with certain fluids known to

routinely outgas. In these cases, an air eliminating filter may be required.

During a prolonged infusion, routinely inspect I.V. Set, access device and patient line

assemblies for proper attachment and orientation.

TM

1000 Series administration sets. The use

xi

Set Related Warnings/Precautions (Continued)

Variations of head height, back pressure, selected catheter type, or any combination

of these may affect rate accuracy. Factors that can influence back pressure are: I.V.

set configuration, I.V. solution viscosity and I.V. solution temperature. Back pressure

may also be affected by catheter type.

The use of pumping infusion devices ported together with gravity flow infusion

systems into a common IV site (primary IV set with secondary IV lines) can affect

the accuracy of the gravity flow systems, and result in unintended flow rates from

these gravity systems. Always ensure the common IV site is acceptable for use

under these conditions.

Reference to specific drugs and default parameters are provided for the user’s

convenience. Always refer to the specific drug product labeling for information

concerning appropriate administration techniques and dosages.

Battery Pack Related Warnings/Precautions

The 1133 Battery Pack contains several lithium-polymer cells and an integral safety

circuit. As these cells age, they can expand due to internal gas release, which is

anticipated for this type of cell. However, if excessive expansion occurs, this can

result in the battery case expanding (swelling), and possibly cause failure of the

battery case, cells, or safety circuit. If this is observed, remove the Battery Pack

from use and replace it as soon as possible.

The 1133 Battery Pack contains protective circuitry to prevent catastrophic battery

failure. If the Battery pack is damaged, this protective circuitry may not prevent

battery failure. Remove the Battery P ack fr om use if the Pack becomes damaged, or

the potential for Battery Pack damage is suspected.

Do not use a damaged or swollen 1133 Battery Pack.

Avoid damage to the 1133 Battery Pack by impact, dropping, overheating, or

mechanical abuse. Never compress, drop, shock, or strike the 1133 Battery Pa ck.

Never use objects that could puncture the internal battery cells. Any of these

actions can cause the battery cells to heat, smoke, or cause catastrophic battery

failure, which could result in fire.

Do not attempt to disassemble the 1133 Battery Pack. Damage caused by

disassembly or tool use can result in catastrophic battery failure, which could result

in fire.

If the 1133 Battery Pack case begins to expand and/or swell, discontinue battery

charging and use immediately, and replace the Battery Pack. Continued charging

will cause further Battery Pack case expansion, with possible battery case fracture,

and potential electrolyte leakage.

If the 1133 Battery Pack becomes damaged, avoid contact with the battery cell

electrolyte. If the electrolyte contacts the skin or eyes, seek medical attention

immediately.

If the 1133 Battery Pack shows sign of the battery case expanding (swelling),

remove the Battery Pack from use and replace it as soon as possible. In extreme

conditions, this swelling can cause the 1133 Battery Pack to become jammed or

stuck within the 3860 Pump or 3865 Remote Display, and/or cause the Battery Pack

plastic case to burst open. If this occurs, do not use tools that could cause damage

to the internal battery cells. Refer to the 1125 Service Manual for removal under

these conditions.

Under no circumstances should Battery Packs or the internal cells be incinerated as

this can cause an explosion.

xii

Pulse Oximeter Related Warnings/Precautions

USE ONLY Recommended SpO2 Fiberoptic Sensors (Sensors containing electrical

conductors will cause patient burns). Do not use cables or sensors that contain

conductive wires.

This device is intended only as an adjunct device in patient assessment. It must be

used in conjunction with other methods of assessing clinical signs and symptoms.

Iradimed SpO

cable / male connector on pump) than that found with other non-MRI pulse

oximeters. This is done to help prevent improper sensor connection to the pump.

Use only recommended pulse oximeter sensors. These sensors are manufactured to

meet the accuracy specifications for Iradimed Corporation’s pulse oximeters. Using

other manufacturers’ sensors can result in improper pulse oximeter performance.

The fiberoptic cable for this device is extremely sensitive and must be handled with

caution at all times. DO NOT use a damaged sensor.

Refer to the User Warnings and Precautions area in Section 7 (Pulse Oximeter) for

additional Pulse Oximeter related warnings and precautions.

sensors are reverse gender connectors (female connector on sensor

2

xiii

User Responsibility

This product will perform in conformity with the description contained in this users

manual and accompanying labels, inserts, etc., when assembled, operated,

maintained and repaired in accordance with the instructions provided. This product

must be checked and calibrated periodically. A malfunctioning product should not be

used. Parts that are broken, missing, plainly worn, distorted or contaminated should

be replaced immediately. Should such repair or replacement become necessary,

refer unit to Iradimed Corporation qualified service personnel. This product or any of

its parts should not be repaired other than in accordance with written instructions

provided by the manufacturer, or altered without written approval of Iradimed

Corporation. The user of the product has the sole responsibility for any malfunction

which results from improper use, faulty maintenance, improper repair, damage or

alteration by anyone other than Iradimed Corporation or Iradimed Corporation

authorized service personnel.

Using This Manual

Read this manual completely before attempting to use the pump.

Warning, Cautions and Notes. This manual contains three levels of precautionary

information.

•A Warning alerts the user that there is a possibility of injury or death to a

human being.

•A Caution alerts the user that there is a possibility of damage to

equipment.

•A Note contains essential information deemed especially important by

Iradimed Corporation.

Definitions

Channel A The designation for the first infusion channel. All pumps contain at

least one linear peristaltic pump head for one infusion line.

Channel B The designation for the second infusion channel. The second infusion

pump module is optional and some pumps may not contain it.

hr. hour.

KVO Keep-Vein-Open.

mL milliliter.

Primary Main Infusant for the prescribed I.V. therapy. The infusion settings

that are implemented after any secondary infusion sequence is

complete.

Rate Infusion rate in mL / hr.

Secondary The first infusion settings to be implemented in an infusion sequence

when more than one infusion is delivered with the same pump

channel, sometimes referred to as “piggyback.”

VI Volume Infused in mL.

VTBI Volume To Be Infused in mL.

%SpO

2

Percent of Oxygen (pulse) Saturation.

xiv

Symbols

ISO 8536-8-IS-P

Attention: Consult Accompanying

Documents, or alternately, Caution

Defibrillator proof

Type CF Applied Part

Date of Manufacture

Indicates that the device conforms

to the Medical Device Directive

Direct Current

Indicates Infusion Sets comply with

requirements specified in ISO 85368 (Infusion Equipment with pressure

infusion apparatus up to a maximum

of 200 kPa).

Drops per milliliter specification for

I.V. Set is identified on Drop Symbol

Appropriate for use in MR

environment

MR Conditional. Only appropriate

for use in MR environment with

manufacturer’s defined

restrictions.

MR Unsafe. Not appropriate for

use in MR environment (i.e. inside

the MR magnet room)

Single Use Only

Product Serial Number

Alternating Current

Do not Resterilize

Lot or batch code for I.V. Set will be

identified near Lot Symbol

Approximate Set priming volume

Main Battery Capacity . (X inside Icon

denotes no battery installed.)

AC Power is connected to 100-240

VAC

Product Part Number

Expiration date for I.V set will be

identified near hour glass symbol

Denotes I.V. Set was sterilized

with Irradiation

Contains Lithium. Requires proper

disposal/recycling of this material.

Secondary Infusion Mode

Volume to be Infused

Caution: Federal (U.S.A.) law

restricts this device to sale by or on

the order of a physician

Maximum rated load is 20 Kg.

Power On, or On

Power Off, or Off

Volume Infused

Both Input/output connection.

Allows data communication.

xv

Do not discard. Contact recycler for

proper disposal

Input Connection Only

Output Connection Only

EC Authorized Representative

Percent of Oxygen (pulse)

Saturation

Radio-Frequency transmission

source

Storage Temperature Range

BPM

2.4 GHz Radio is communicating.

Pulse Rate in Beats/Minute

Pulse Detected

Telecommunications Alert Symbol

- Class 2 (European Union

Countries Only)

This product has been certified to

UL60601-1 and applicable Particular

Standard IEC 60601-2-24, for which

the product has been found to

comply by Intertek.

Spare Battery Capacity. (X inside

Icon denotes no battery installed.)

Refer to operating instructions

for important safety information.

STBY

2.4 GHz Radio Antenna

Infusion has been paused.

Press start to resume infusion

xvi

>>>

Alternating symbols indicate

Channel A is infusing

Sterile Fluid Path Do not use if package is

Keep equipment below this line

on the 1119 IV Pole.

<<<

Alternating symbols indicate

Channel B is infusing

damaged

Replace fuse with 1 Amp, 3AG,

250V time delay (Slow Blow)

fuse.

xvii

xviii

SECTION 1

INTRODUCTION

1.0 Introduction. The MRidiumTM 3860/3860+ MRI Infusion/Monitor System is

intended for patients that require medications and/or fluids during an MRI scan. This

pump is designed to provide infusion therapy at all stages of the MRI procedure. This

system is for use by trained medical personnel only and is not intended for long term

patient care outside of an MRI environment.

This system provides the following features:

• Continuous Infusion, Dose Rate Calculation Program and Automatic Bolus.

• Automatic free-flow protection for the I.V. line.

• Up to two channel fluid delivery, each with separate primary/secondary

programmable rate and VTBI, into single or separate IV lines.

• Rechargeable long life battery. Lasts up to 12 hours at 125 mL/hr.

• Status indicator light above door (Red for Alarm, Green for Infusing).

• Soft keys to program various functions.

• Large LCD display screen.

• Up and Down arrow control keys and 10 Key numeric Keypad to change

numeric values quickly and easily.

• Handle for easy portability, weighs less than 11.5 pounds.

• I/O port for Service related functions.

• Optional second channel with the addition of the 3861 SideCar

• Optional remote control with the additional 3865 Remote Display/Charger.

• Optional Dose Error Reduction System with dedicated drug library card.

• Memory card slot for easy upgrades.

• On-Board Masimo SpO

Monitor (3860+ only).

2

• Expanded Infusion Rate Range from 0.1 to 1400 ML/Hr.

TM

.

CAUTION: Handle the MRidium

additional accessories with care. If it should be dropped or severely jarred, it

should be immediately taken out of service and inspected by a qualified biomedical

technician.

1.1 Product Description.

designed for operation in the MRI environment and may be used on the patient near

the MRI magnet (up to the 1.0 Tesla or 10,000 Gauss Line). Operating on battery

power, when fully charged this system will provide up to 12 hours of operation at an

infusion rate of up to 125 mL/hr and at least four (4) hours at r ates up to 999 mL/hr.

The MRidium Wireless Remote Display allows for remote ability to control the Model

3860 MRidium MRI Infusion/Monitor Pump with a total of two channels from outside

the MR Scanner. It utilizes the same user interface as the 3860 infusion pump and

will allow adjustment of all pump parameters, rates, titration, volume to be infused,

starts, stops, and resetting alarms. The large clear display shows all pump

information at your desk top from the control room. The Wireless remote also acts

as a charger for a backup or spare battery pack for the 3860 MRidium MRI Infusion/

Monitor Pump. It utilizes a wireless link at 2.4 GHz for easy installation with no

image artifacts.

NOTE: The 3860/3860+ pumps will only communicate with 3865 wireless

Remote/Display units.

NOTE: The Remote Display/Charger only operates on AC Mains Power. This unit

does not operate on battery power. This unit does not sound a Low Battery alarm

for the Spare Battery being charged.

The MRidium

TM

3860/3860+ MRI Infusion/Monitor Pump and

TM

3860 MRI Infusion/Monitor System is

1-1

1.1.1 Front of the Pump. See Figure 1-1 for the location of the major components

on the front of the pump.

a. Handle. Located on the top of the pump, the handle provides for easy

transportation of the pump from location to another.

b. Main Display. Provides a visual display of all the parameters and

features of the pump.

c. Run/Alarm Lamp. Provides a visual display of the pumps operating

condition.

d. Battery. Located behind a door on the back of the pump, the battery

provides for power in the absence of a hospital grade AC Mains outlet.

e. Pump Area EZ-Latch Door. Pressing down on this button and lifting

this handle unlatches the door protecting the pumping mechanism and

infusion line.

f. Main Control Keypad. Provides control of the various features of the

pump including 10 key numeric keypad for entering parameter values

quickly and easily.

g. Soft keys. Provides a way to adjust the configuration of the pump.

h. AC Power/Battery Charge LED. Provides indication that MRI power

supply is connected and AC power is applied to Charge the pump

battery.

Figure 1-1. Front of Pump

1-2

1.1.2 Pump Drive Mechanism. See Figure 1-2 for location of the major

components of the infusion system pump drive mechanism.

Figure 1-2. Pump Drive Door Open

a. Upper and Lower I.V. Set Snap-In Port. Provides for a secure

mounting of the I.V. set for infusion.

b. Linear Peristaltic Pump Drive Mechanism. Provides for the positive

movement of fluids through the infusion line.

c. Bubble Detector. Provides for the detection of air bubbles in the

infusion line.

d. Free-Flow Detector Switch. Located internally in the pump’s lower

snap-in port the IV Set Free-Flow Detector Switch detects when IV set

is properly installed and functioning.

e. Inlet and Outlet Pressure Sensors. Provide infusion line pressure

measurements for pressure monitoring and alarms.

TM

NOTE: After attachment of the 3861 Sidecar

TM

the operation of Channel B Sidecar

pump drive mechanism is identical to the

module (Refer to Section 4.6),

main pump drive. The only difference is that the Channel B door opens to the left

side, which is opposite that of the main pump door.

1-3

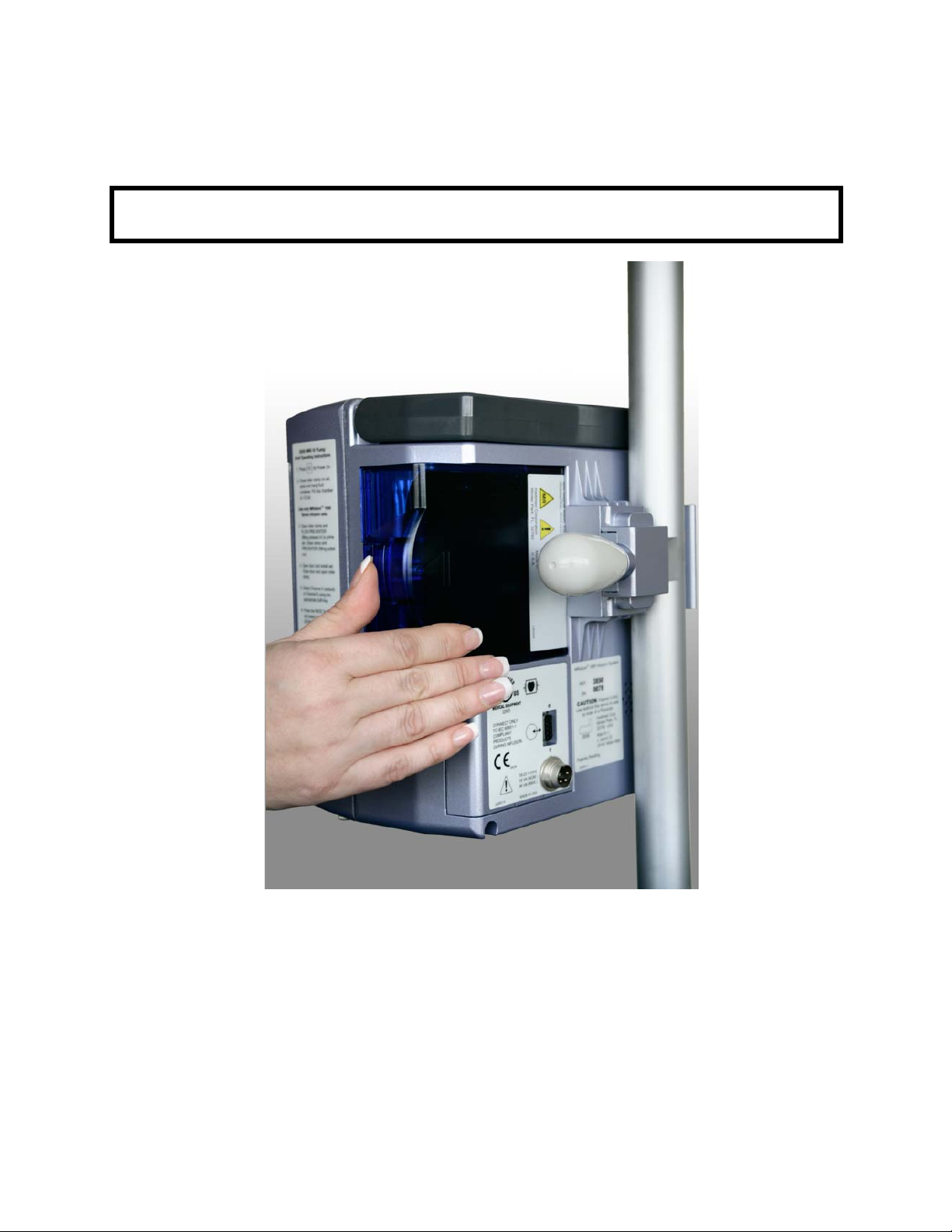

1.1.3 Back of the Pump. See Figure 1-3 for the location of the major components

on the back of the pump.

a. Handle. Provides for easy transportation of the pump from location to

another.

b. Optional Secondary Pump Drive Electrical Connector. Provides for

the addition of a Channel B pump mechanism.

c. I.V. Pole Clamp. Provides a secure mounting of the pump to the IV

pole. Rotate knob clockwise to secure pump to the IV pole.

d. Audible Speaker. Provides the audible sounds for alarms and alerts.

e. 2.4 GHz Antenna and Connector. Used to connect Antenna for

Remote Display/Charger 2.4 GHz wireless interface.

f. Power Input. Provides for connection to the AC Power Adapter to run

the pump on hospital grade AC Mains power. Connect only model

1120 MRI Power Supply.

Figure 1-3. Back of Pump

1-4

g. I/O Port. Provides a connection for retrieving the pump’s infusion data

from memory. Connect only 60601-1 compliant computer for

History Log download.

WARNING: Serial I/O Port is not PC-compatible computer format (Pin # 8 is

connected to the +5 volt supply). Refer to the Service Manual for History Log data

download instructions. Do not communicate through this port during patient use.

h. Memory Port. Provides for field update of system software or

receptacle for retaining the optional DERS Drug Library Card (Refer to

Section 8). Use only AM04 update card, AM04DERS update or

Iradimed Corporation recommended Media/Memory cards.

i. SpO

Iradimed SpO

Series SpO

j. Battery Compartment. Provides a safe and secure location for the

pump’s battery. Use only Iradimed model 1133 Battery Pack.

Sensor Port. (3860+ only) Provides the connection for the

2

Fiber Optic Sensor. Use only Iradimed model 1170

2

Fiberoptic Sensors.

2

CAUTION: Battery pack is slightly magnetic. Use caution when removing from

pump near strong magnetic fields.

1.1.4

Power Supply.

1120 MRI Power Supply. See Figure 1-4 for information on the pump’s MRI

WARNING: AC Adapter is magnetic. Keep outside the 1,000 Gauss line, or at

least 10 feet (3 meter) from the MRI magnet. Secure with velcro straps provided

to the floor. NEVER Velcro or secure the AC Adapter directly to the pump or I.V.

pole.

Figure 1-4. Model 1120 MRI Power Supply

1-5

1.1.5 Front of the Remote Display/Charger. See Figure 1-5 for the location of the

major components on the front of the 3865 Remote Display/Charger.

a. Antenna. Provides 2.4 GHz bidirectional communication to MRidium

TM

3860 MRI Infusion/Monitor Pump.

b. Main Display. Provides a visual display of all the parameters and

features of the pump.

c. Run/Alarm Lamp. Provides a visual display of the pumps operating

condition.

d. Battery Charger Compartment. Located at the top rear of the

Remote, allows charging of an 1133 Pump Battery when battery is

installed and Remote is connected to AC Mains outlet as indicated by AC

Power/Battery Charge LED (located below the power On/Off keys).

e. Main Control Keypad. Provides control of the various features of the

pump.

f. Soft keys. Provides a way to adjust the configuration of the pump.

g. AC Power/Battery Charge LED. Provides indication that AC power is

applied (Green) or Charging a spare battery (Amber).

h. Memory Port. Located underneath the front panel provides for field

update of system software. Use only AM04 Software Card.

Important: 3865 Remote Display/Charger will only communicate with 3860 or

3860+ pumps. These can be recognized by the 10 digit main control

keypad.

Figure 1-5. Front of 3865 Remote Display/Charger

1-6

1.1.6 Back of the Remote Display/Charger. See Figure 1-6 for the location of the

major components on the back of the 3865 Remote Display/Charger.

a. Audible Speaker. Provides the audible sounds for alarms and alerts.

b. 2.4 GHz Antenna / Connector. Used to connect 2.4 GHz Antenna for

wireless communication with the 3860/3860+ MR IV pump.

c. Power Input. Provides for connection to hospital grade AC Mains

power.

d. Fuse Holder. Provides replaceable 1A 3AG, 250V fuse for the AC Mains

power.

e. Ground Terminal. Used for grounding lug during electrical testing.

f. Battery Charger Compartment. Located at the top rear of the

Remote, allows charging of an 1133 Pump Battery when battery is

installed and Remote is connected to AC Mains outlet as indicated by AC

Power/Battery Charge LED (located below the power On/Off keys).

Remote/Charger is AC powered only and will not run on battery power.

CAUTION: Battery pack is slightly magnetic. Use caution when transferring

battery pack from pump to Remote/Charger near strong magnetic fields.

CAUTION: Gently position 1133 battery pack into charger compartment until

battery pack snaps into position. Do not drop or force the battery pack into the

charger compartment, as this could cause battery pack damage or failure.

Figure 1-6. Back of 3865 Remote Display/Charger

1-7

1.2 Controls. The MRidiumTM 3860 MRI Infusion/Monitor System is controlled

with the use of “soft-touch” control keys. These control k eys are located on the front

panel of both the Pump and Remote Display. These control keys provide for turning

the Pump and Remote Display ON or OFF, starting/stopping Channel’s A and B

infusion sequences, accessing and navigating in operational menus, review of data

and setups, and for silencing any active alarms that may occur.

1.2.1

Front Panel Control Keys. See Figure 1-7 for location of the control keys.

Figure 1-7. Front Panel Control Keys

1-8

START/STOP CHANNEL A. Pressing this control key starts, or

stops, the Channel A infusion sequence.

CANCEL. Pressing the control key returns function to the

previous menu or display with no action.

Up and Down Arrows. Pressing this control key will increase

or decrease the value of the currently selected option. It is also

used for on-screen menu navigation.

MENU. Pressing this control key activates the Main Menu

Display.

ENTER. Pressing this control key will activate, or select, a

menu choice, proceed from one prompt to the next and accept/

store changes.

START/STOP CHANNEL B. If the Channel B option

(SideCar

key starts, or stops, the Channel B infusion sequence.

ALARM SILENCE. Pressing this control key temporarily

silences audible alarms for two (2) minutes and clears alarms

that have been resolved.

TM

Pump mechanism) is installed, pressing this control

( l ) Pressing this control key turns the unit on. When the unit

is on this control key is inactive.

O Pressing and holding this control key for longer than one

(1) second turns the unit off.

Special Function Soft Keys. The six (6) Soft Keys, located to

the left of the pump’s display screen, are used to perform

variable functions depending on the current state of the device.

When active there is a small arrow present to the right of the

key on the pump’s display.

Numeric Key Pad. The numeric keypad can be used to input

values for flow rates or clear a recent entry (“C” key). After

using keys to input correct values, pressing the “ENTER” key

will lock value in place.

1-9

1.3 Pump Preparation for Use.

There are several configurations for starting an infusion with the MRidium

3860+ Infusion Pump. These include the following:

a. Primary Configuration – Refer to Section 4.0. This mode enables an

infusion to be set up with Rate and VTBI only, and is the main screen if the

pump has been turned off for more than one (1) hour. This mode is the

most basic mode of use, as there are no saved infusion settings available

through the “Same Patient” soft key. This mode does not use the DERS

Library Card or the Dose Rate Calculator.

b. Restore Last Infusion settings – Refer to Section 4.0. This mode

restores the last infusion settings after the pump has been powered off for

less than 1 hour. When the pump is powered on, a repeat of the previously

run infusion can be set up quickly. The infusion can be set up to use the

previous infusion’s settings (“Same Patient”) or can be programmed for

new dose information (“New Patient”). This mode requires the setting of

Rate and VTBI only, and does not use the Dose Error Reduction System

(DERS) Library Card or the Dose Rate Calculator.

c. Dual Channel Infusion – Refer to Section 4.1. This mode enables two

infusions to be performed simultaneously on both Channel A and Channel

B (if the optional SideCar is installed – refer to Section 4.4). This would be

used for patients who require two different medications to be delivered,

and a secondary infusion (piggyback) is not used. Both channels are set up

with Rate and VTBI.

d. Secondary Infusion (“piggyback”) – Refer to Section 4.2. This mode

enables two infusions to be performed on one channel (either Channel A or

Channel B). This will have the secondary infusion (piggyback) to deliver

fluid to the patient only. Once the secondary infusion has been delivered,

the primary infusion will resume. Therefore, only delivering one medication

to the patient at a time (which is different than the Dual Channel Infusion,

where both medications are delivered simultaneously).

e. Bolus Delivery – Refer to Section 4.3. This mode enables a bolus of fluid

to be delivered and can be programmed at the start of an infusion, or

added to an infusion in progress on either Channel A or Channel B.

f. Dose Rate Calculator – Refer to Section 4.5.1. This mode is accessed

through the Special Features Menu and is used to calculate the pump

parameters (e.g. flow rate, volume, and/or time) for either Channel A or

Channel B for a dose to be delivered to the patient by entering the Dose

amount, Patient Weight, and Concentration of medication.

g. Dose Rate Calculator with Drug Library – Refer to Section 4.7.1.2.

This mode is accessed through the Special Features Menu and is used to

calculate the volumetric rate for either Channel A or B, and has five (5)

drug options to select from. One of these options, “Drug ?” can be

customized by the user to any name when in the Service Mode and has

user-defined values that serve as a “starting point” for programming the

infusion and can be modified at any time.

1-10

h. Dose Error Reduction System (DERS) Library (optional) – Refer to

Section 8. This mode is optional and is only accessible if a DERS Library

Card has been programmed with the customer’s drug library and installed

into the pump. If a DERS Library Card has been installed, the display will

show “Lib” indicator (refer to Section 8.3.3). If there is not a DERS Library

Card installed, it will show “No Lib” indicator (refer to Section 1.3.1), which

is the normally presented indicator. This mode provides user-programmed

infusion protocols with hard and/or soft entry limits that can be set by the

customer.

WARNING: This pump will stop fluid flow during Alarm Conditions, however,

SpO

related alarms will not stop fluid flow. Periodic patient monitoring must be

2

performed to ensure that the infusion is operating normally.

WARNING: It is the responsibility of hospital personnel to ensure that drugs

used in this system are compatible as well as ensuring the performance of each

pump as part of the overall infusion. Potential hazards include, but are not limited

to, drug interactions, inaccurate delivery rates, inaccur ate pressure alarms and

nuisance alarms.

WARNING: The use of positive displacement infusion devices connected

together with gravity flow infusion systems into a common I.V. site may impede

the flow of common “gravity only” systems and affect their performance. It is the

responsibility of hospital personnel to ensure that the performance of the common

I.V. site is acceptable under the circumstances in which it is being used.

1.3.1 Administration Sets. Use only Iradimed Corporation approved MRidiumTM 1000

series infusion sets. The use of any other set will cause improper pump operation

and will result in inaccurate fluid delivery and risk to the patient.

Before beginning any infusion cycle, verify that the infusion lines are free from kinks

and are loaded correctly on the pump.

Do not reuse any component that is labeled for single use. Discard these items

immediately after use. Patient infection or inaccurate flow rates could result if reused.

1.3.2

being used for the infusion of electrolytes. These currents will vary proportional to

the pump’s infusion rate. Therefore, when an ECG monitoring system is not

functioning under optimal conditions, these currents may appear on the ECG display

screen as artifacts and simulate actual ECG readings. To determine if the ECG

abnormalities are caused by patient condition or the ECG equipment receiving

artifact from the pump, place the infusion pump on HOLD and observe the ECG

signal. If the ECG signal becomes normal, the ECG monitor requires attention as

proper setup of the ECG equipment should remove the pump caused artifact.

Reference the appropriate ECG monitoring system documentation for instructions on

setup and maintenance of the ECG device.

Artifacts. It is normal for this pump to produce non-hazardous currents when

1-11

NOTE: Operating parameters (Power, VTBI, etc.) are retained in memory for one

(1) hour unless all power is lost (no AC and a depleted battery). A “Settings Lost”

message at power up indicates existing operating parameters have been erased,

and the system has reverted back to initial default parameter settings.

The operator may choose “New Patient” or “Same Patient.” Same patient will preset primary pump setup display with the prior Rate and VTBI. New patient will

clear the Rate, VTBI and VI.

If the Primary Pump Setup screen does not appear as shown in Figure 4-1, it may

indicate improper functioning of the display. Although the Pump may appear to

function properly, return it to qualified service personnel for examination and/or

repair.

CAUTION: Each time the Pump is turned on, verify and/or set the pressure

alarm limit. If the pressure alarm limit is not verified, the Pump may not be

operating with the desired occlusion detection parameter(s).

1-12

1.4 Display. The display screen provides the operator with the information and

prompts necessary to operate this pump. See Figure 1-8 and 1-9 for examples of

the Primary and secondary displays. In general, the display screen functions as

follows:

• Highlighting. As the different settings are “scrolled” through (using the

Up or Down arrow control key), the selected item will become

highlighted to distinguish it from the unselected items.

• Visual indicating of Soft key status. Active Soft keys have a “arrow”

beside them pointing toward the menu item or setting that the Soft key

controls. When Soft keys are inactive, the “arrow” is not displayed.

• Split Screen. The pump displays different types of information in the

same area of the screen no matter what particular display is active.

The general layout of the various Screen Configurations, Information and Icons

displayed is provided below:

Figure 1-8. Setup Display Screens

1-13

Figure 1-8. Setup Display Screens (Continued)

1-14

Figure 1-9. Running Screens

1-15

FIGURE 1-9. Running Screens (Continued)

1-16

Additional information (i.e. Dose value, remaining Time, and the Indicator

denoting Drug Library card use) can be displayed on the running screens with

software revision 3.0.XXXX and higher.

1.4.1

display screen. This portion of the display provides the operator with operational

information such as the battery status, AC power status and the current time. (Refer

to Section 7 for MRI-SpO

Informational Display.The Informational Display is located at the top of the

related symbols and icons).

2

Provides a visual indication of the charge level of the

Pump main battery. When full, the battery is charged

fully. The level drops in increments of 25% on both the

Pump and Remote as the battery discharges. If the

symbol has an X through it no battery is installed.

Provides a visual indication of connection with Remote

Display and receive level as indicated by vertical bars.

Only displayed when internal radio has linked with

Remote Display. Current channel is displayed to the

right of the bars (1-6). No bars indicates no

communication.

Provides a visual indication of the spare battery charge

level in the Remote Display unit Informational Display.

When full, the battery is charged fully. Level shows

increments of 25% as the battery is charged, if symbol

has an X through it no battery is installed.

Provides a visual indication that AC Main Power is

98% 80

1.4.2

Alarms, Alerts and user prompts during use. Refer to Section 5 for a complete list of

these messages.

1.4.3

Infusion Display provides windows into which the Volume to be Infused (VTBI) and

the Infusion Rate are entered.VI Display.

the Volume Infused for the connected patient.

User message area. Area below Informational Display provides messages for

Infusion Parameter Setup Display. Below the informational display, the

Primary,

Secondary or

Bolus

Channel

being Displayed

<<< OR >>>

connected on the Pump Informational Display.

Provides the current time in a 24 hour time format.

Displays SpO2 and Pulse Rate values (only seen in dual

channel configurations when using SpO

The VI Display provides the operator with

Denotes Infusion Type being delivered.

Enter Channel A or B.

Denotes Channel is infusing.

sensor).

2

1-17

STBY

Denotes Channel is paused / in standby.

Name of Drug

(Example: Adenosine)

DOSE

RATE

TIME

VTBI

VI

SpO

related

2

display

Identifies selected Drug from either the Dose Rate

Calculator or Dose Error Reduction System (DERS)

Library.

Denotes infusion dose value and corresponding units.

Denotes infusion flow rate value in mL/hr.

Denotes remaining infusion time until completion with

the current infusion parameters.

Denotes Dose Error Reduction (DERS) library is not

active.

Denotes Dose Error Reduction (DERS) library is active.

(Refer to Section 8 for operating information)

Volume to be Infused for the infusion.

The VI display provides the operator with the Channels

volume infused for the connected patient.

Refer to Section 7.2 for optional SpO

information.

related

2

1.4.4 Secondary. Pressing this soft key brings up the Secondary Infusion Setup

Display to provide the operator with the ability to configure a secondary infusion.

1.4.5 Bolus. Pressing this soft key brings up the Bolus Setup Display to provide the

operator with the ability to configure a Bolus infusion.

Figure 1-10. Special Features Setup Menu

1-18

1.4.6 Special Features Setup Menu. Pressing the MENU button brings up the Special

Features Setup Menu (See Figure 1-10) to provide the operator with the ability to

set the Dose Rate Calculation, adjust the Alarm Volume, set the KVO Rate, adjust

the Occlusion Limit, and Lock Keys and Next Menu if additional options are installed

(Refer to Section 4.7 for more information). The Lock Keys Feature will not be

displayed unless it has been enabled in the Service Mode. (Refer to 1125 Service

Manual for additional details on the Service Mode.)

1.5 User Interface. The user communicates with the unit by pressing the

appropriate control and/or soft key and then using the up or down arrows and enter

control keys to set and verify the setting being made.

1.6 System Self Test. The unit performs a series of power on Self-T ests on star t -

up to confirm readiness for use. Failure during any of these Self -Tests will result in a

fault message and inability to use the pump. Verify successful completion of self -test

prior to each use.

1.7 Maintenance and Operator Verification. (Using IVP1056 IV Set). Verify