• Do not place the NIB P cuff over a wound, as this can cause further injury.

• Do not place the NIBP cuff on the same or adjacent arm to a mastectomy, or where the

lymph nodes we r e r emoved, or if a shunt is on that arm. This can lea d to bruising,

inaccurate readings, or negatively impact the drainage of fluids because of temporary

interference to blood flow.

! CAUTION

• Only use recommended MRI NIBP cuffs and tubing identified in section 9.2.

• In AUTO Mode, th e monitor displays results of the last measurement until another

measurement starts. If a patient's condition changes during the time interval between

measurements, the monitor will not detect it.

• Excessive patient motion may cause inaccurate measurements. Minimize motion to

improve blood pressure measurements.

• Avoid crimping or undue bending, twisting, or entanglement of the NIBP hose.

6.4.1.1. Limitations

The following factors may affect the accuracy of measurement:

• Heart rate extremes of less than 40 bpm or greater than 240 bpm

• A regular arterial pressure pulse is hard to detect

• Cardiac arrhythmias

• Physical movement (patient or imposed)

• Rapid blood pressure changes

• Severe shock or hypothermia that reduces blood flow to the peripheries

• Obesity, wh ere a thick layer of fat surrounding a limb dampens the oscillations coming

from the artery

• Edematous extremity

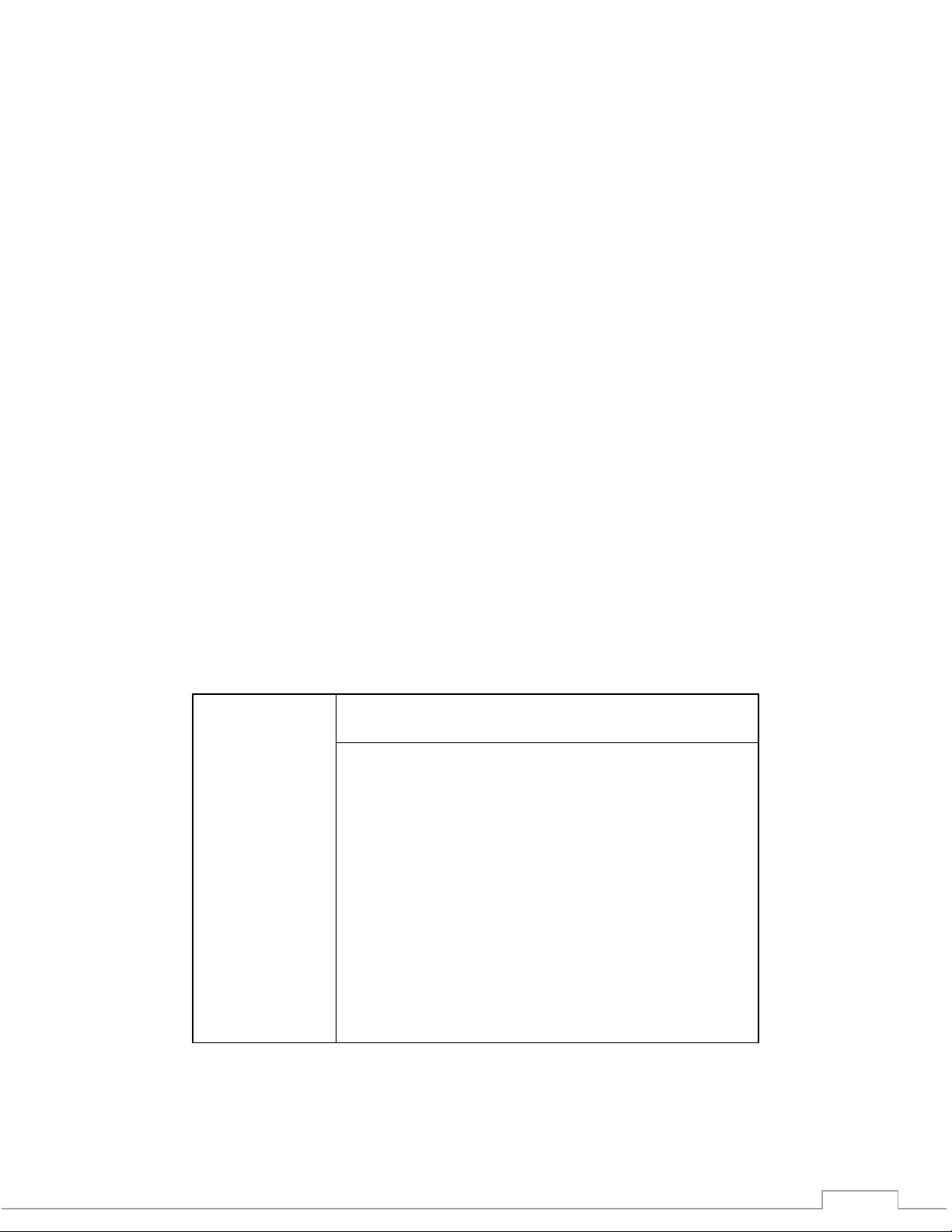

6.4.2. Understanding the Display

1. Measurement Unit (mmHg or kPa)

2. Current Mean Pressure upper and lower alarm lim its

3. NIBP cuff pr essure when inflat ing

4. Time until nex t NI BP Measurement (m inutes : seconds or manual)

5. Current Systolic Pressure upper and lower alarm li mits

6. Most recent NIBP reading

7. Current Diastoli c P re ss ure upper and lower alarm limits

6-25

6.4.3. NIBP Patient Application

When positioning the patient, routine NIBP measurements (including for the condition

hypertension) require the patient to remain silent, still and relaxed, with legs uncrossed and

arms supported. Note that during MRI procedures, patients are typically lying down with their

legs uncrossed and arms supported as needed for the MRI scan. A five minute waiting period

is recommended before starting readings. Ensure that the cuff is at the level of the right atrium

of the heart.

1. Verify that the patient type is corr ec t . Change it if necessary.

2. Ensure tubing is connected to the 3880 monitor

3. Select a correct sized cuff and then apply it as follows:

a. Determine the patient’s limb circumference.

b. Select an appropriate cuff by referring to the limb circumference marked on the

cuff. The width of the cuff should be 40% (50% for neonates) of the limb

circumference, or 2/3 of the uppe r arm’s length. The i nflatable part of the cuff

should be long enough to encircle at least 50% to 80% of the limb.

c. Apply the cuff to an upper arm or leg of the patient and make sure the marking

on the cuff matches the artery location. Do not wrap the cuff too tightly around

the limb. It may cause discoloration, and ischemia of the extremities. Make sure

that the cuff edge falls within the marked range. If it does not, use a larger or

smaller cuff that will fit better.

4. Connect the cuff to the air tubing and make sure that the bladder inside the cover is not

folded and twisted

5. Press the START/STOP button to initiate a blood pressure reading. Hold TART/STOP

button down for three seconds to initiate a STAT burst of three successive NIBP

readings.

NOTE

• Automatic NIBP readings will n ot cy cle when the monit or is i n St andby

6.4.3.1. Setup Checklist

• The hose is correct.

• The connector is fi r mly pushed inside the cuff tube.

• The NIBP hose is pr operly connected to the module and will not detach if pulled.

• The NIBP cuff is correct for the patient’s limb size.

6-26

• There are no hol es or cracks in the cuff bladder or cuff tube.

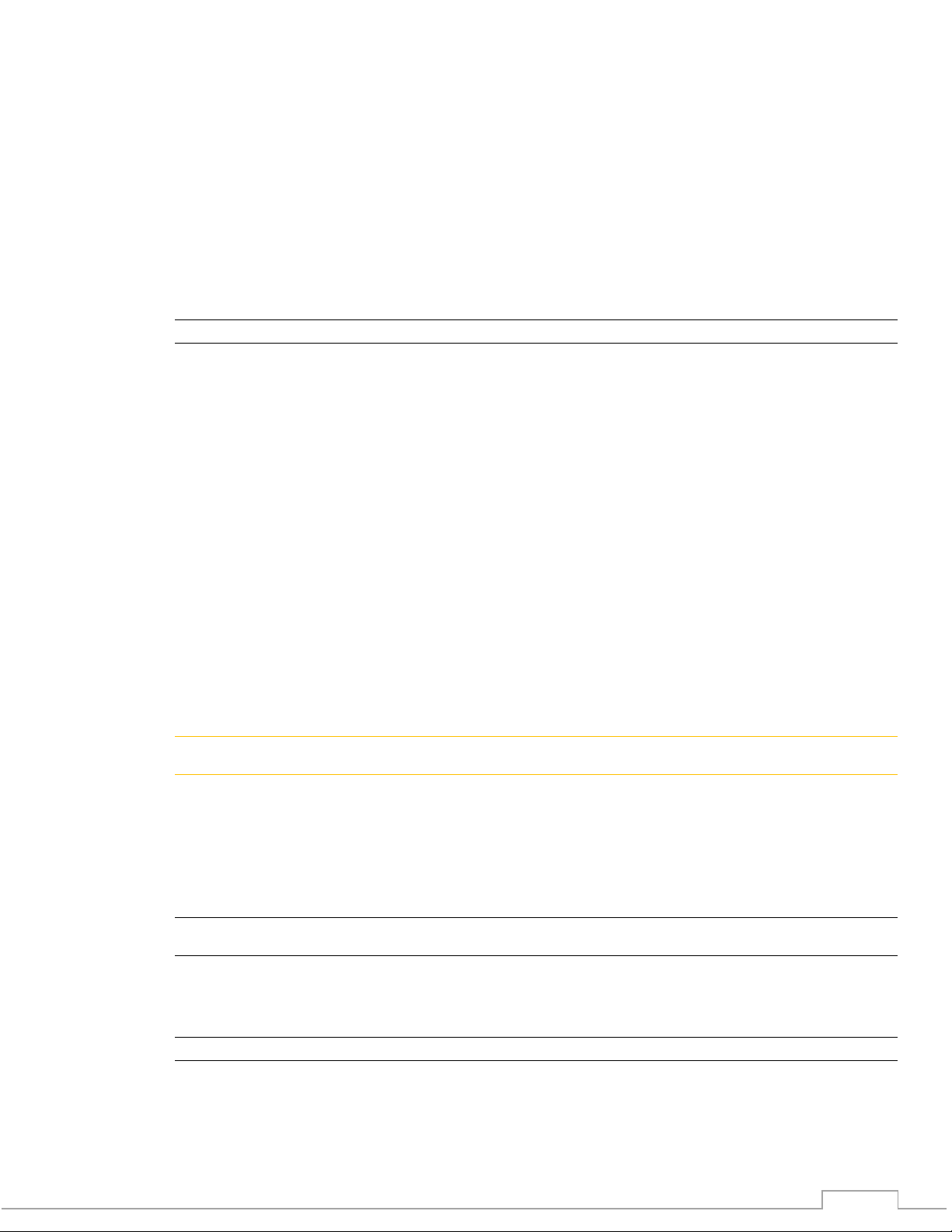

Range

Low

High

Range

Adult

systolic

Off, 30-270

90

160

30-270, Off

diastolic

Off, 10-245

50

90

10-245, Off

mean

Off, 20-255

60

110

20-255, Off

Pediatric /Infant

systolic

Off, 30-270

70

120

30-270, Off

diastolic

Off, 10-245

40

70

10-245, Off

mean

Off, 20-255

50

90

20-255, Off

Neonatal

systolic

Off, 30-130

40

90

30-130, Off

diastolic

Off, 10-100

20

60

10-100, Off

mean

Off, 20-120

25

70

20-120, Off

• All residua l air is squeezed out of the cuff before wrapping it around the arm.

• The symbol indicating the center of the bladder is over the artery.

• The cuff is not loose.

• The cuff is at hear t level.

• The cuff tubes or NIBP tube are not kinked or squeezed together.

• Non-invasive blood pressure is selected to be displayed through Monitor Setup patient

parameters menu.

6.4.4. Changing Frequently Use d NIBP Settings

6.4.4.1. Manual NIBP Mode

To adjust the NIBP mode between manual and automatic follow these steps:

1. Touch the NIBP vital sign numerical box to bring up the NIBP menu

2. For manual mode set the “Auto Cycle Time” to OFF

3. Touch Back button to close the menu

6.4.4.2. Automatic NIBP Int e rval Mode

To adjust the NIBP intervals for the Automatic settings follow these steps.

1. Touch the NIBP vital sign numerical box to bring up the NIBP menu

2. Select “Auto Cycle Time” to show drop down: OFF, 3 min, 5 min, 8 min, 10 min, 15 min,

30 min

3. Make your sel ection

4. Touch Back button to close the menu

6.4.5. NIBP Alarm Limits

Low Limit

Default

Default

High Limit

6-27

Message

Trigger Condition

NIBP Inop

Hardware or software failure detected

NIBP Over Press

Pressure exceeds 300 mmHg for Adult / Ped or 150 mmHg for Neonatal patients

15 mmHg remains in the line for Adult / Ped or 5mmHg for Neo for greater than 90 seconds

NIBP Time Out

Pressure remains the same for more than 30 seconds or if measurement exceeds 180 seconds

NIBP Leak

Air leak is detected

Wrong Cuff

Displayed if the NIBP system detects an incorrect cuff size for the selected patient mode

NIBP Occlusion

Occlusion is detected

NIBP Cal Error

Calibration error detected

NIBP Delayed

NIBP reading start has been delayed to allow blood flow to resume

6.4.6. NIBP Messages

-or-

6.5. Temperature Monitoring

6.5.1. Temperature Overv i e w

The 3880 system f eatures a unique and in novative temper ature measureme nt system

supporting surface temperature readings.

6.5.1.1. Temperature Sensor

The fiber-optic temperature sensor is used for the measurement of patient body temperature

using axillary sensing tip placement.

! WARNING

• Frequent medical attention to the sensor axilla site for possible pressure tissue necrosis

should be given during longer term monitoring sessions (4 hours or more), especially on

tender skin of neonatal patients.

! CAUTION

• The fiber-optic temperature sensors are constructed of fiber-optic glass and must

always be handled with care to prevent damage. Improper handling can result in

inaccurate readings.

6.5.1.2. Limitations

The following factors may influence the accuracy of measurement:

• Sensors access to ambient tem perature or drafts

• Do not bend the fiber optic sensor in a radius of less than 15 mm

• Do not expose to temperature above 50

• Do not pull or apply tension to the fiber-optic cable

• Do not alter or modify the accessories

○

C

6.5.2. Underst an d ing the Display

6-28

1. Measurement Unit

2. Curren t Vital Sigh

3. Alarm Limits

4. OVR/UND for Temp extended range <30.0 °C or >44.0 °C(<86.0°F or >111.2°F ),

accuracy ± 0.4 °C

6.5.3. Temperature Patie nt Application

6.5.3.1. Surface T e m p erature A pp l ication

Perform the following procedure to apply the fiber-optic temperature sensor to a patient:

1. Carefully uncoil the sensor, avoid knotting or kinking the fiber optic cable

2. Inspect sensor for damage, including tears or deformations

3. Thoroughly clean and dry the axilla or groin application site

4. Position the sensor tip at the application site

5. Secure sensor with some medical tape

6. Cover application site to block air drafts

! WARNING

• Avoid the use of any metalized foil temperature probe covers, or hydrogel backed probe

covers, as excessive RF heating could occur resulting in inaccurate temperature

measurements and/or burns.

NOTE

• There is a temperature difference between surface temperature and patient body (core)

temperature.

• When monitoring temperature during MRI procedures, the radio frequency (RF) energy

may normally increase the patient’s body temperature.

6.5.3.2. Setup Checklist

• Temperat ur e c able is properly in s er ted into the 3880 system

• Temperat ur e sensor is applied and positioned correctly

• Temperat ur e sensor is not damaged in any way

6.5.4. Changin g the Temperat ur e Settings

6.5.4.1. Units

The temperature format can be in Celsius or Fahrenheit. To adjust the units follow these steps:

1. Touch the Temperature vital sign box

2. Select “Unit”

3. Make your sel ection

4. Touch Back button to close menu

6-29

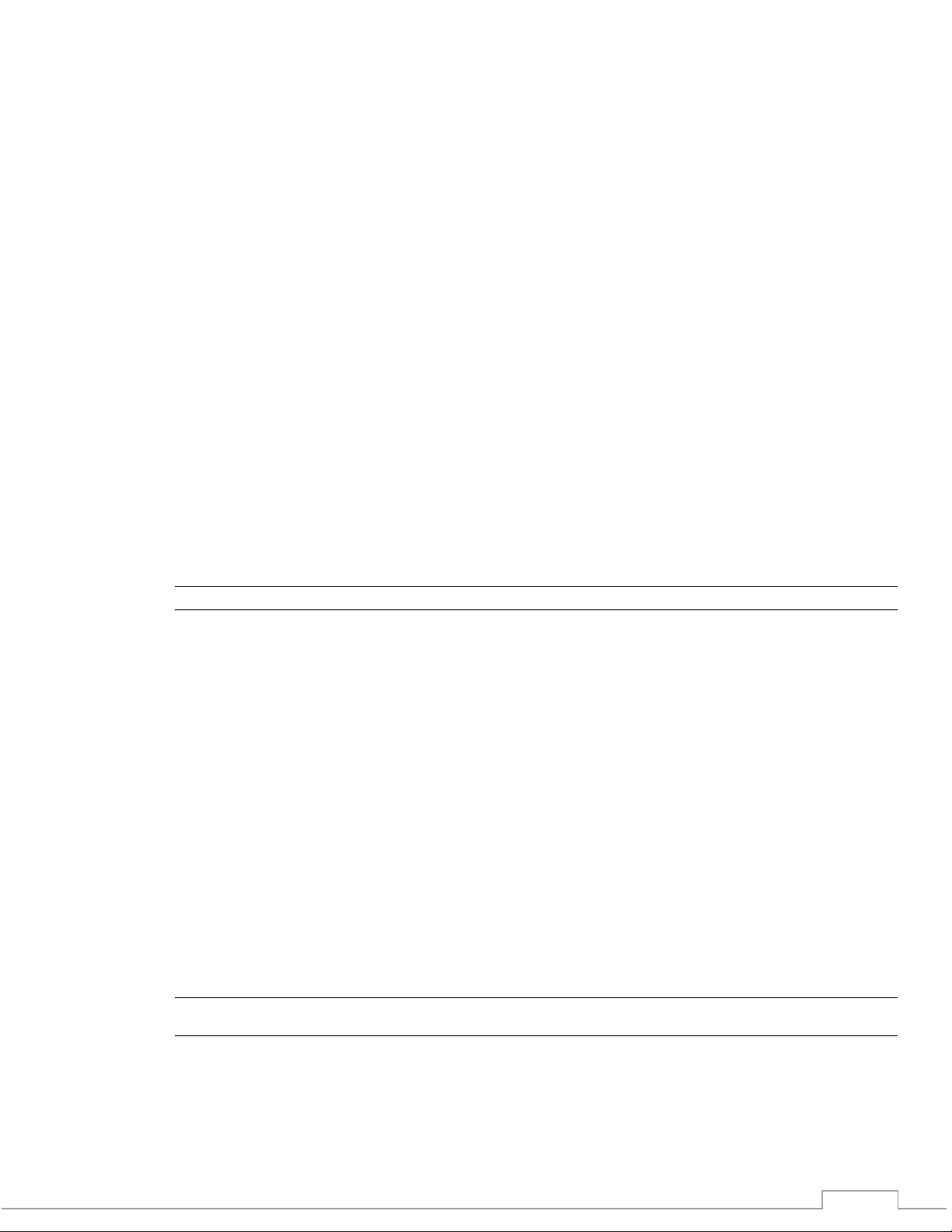

6.5.5. Temperature Alarm Limits, Celsius

Range

Default Low

High

Range

Adult Temp

Off, 25-40

36

39

25-40, Off

Pediatric Temp

Off, 25-40

36

39

25-40, Off

Neonatal Temp

Off, 25-40

36

39

25-40, Off

Message

Trigger Condition

Temp Inop

Hardware or software failure detected

Temp Probe Fail

Broken sensor detected or a sensor is not attached properly

OVR / UND

Indicating Temp extended range < 30.0 °C or > 44 C°(<86.0°F or

accuracy ± 0.4 °C

Low Limit

Default

High Limit

6.5.6. Temperature Messaging

>111.2°F )

6.5.7. Connecting the Sensor

The fiber optic temperature sensor utilizes a keyed twist locking connector to securely mate to the

temper a ture c o nne c tion port on the right s ide of the 3 8 8 0 M onitor unit. Ro tate the sensor

co nne c tion while ge ntly pushing i nto the ma ting co nnec tion on the monitor. O nc e the ke y wa y

h a s s lid e in t o th e m a t in g s lo t , t u r n t h e o u t e r s h e ll ≈3 0 ° t o lo c k in t o p la c e .

6.5.8. Temperature refer en ce measurement

A baseline temperature meas urement sho uld be made once the fi ber o ptic temperat ure s ensor is

appl ied and befo re s t arting the MR i mage scan , which s ho uld be used as a reference for t he

temperature measured duri ng t he scan.

6-30

7. Using the Recorder

The optional 3885-B Base Station recorder provides hard copies of up to two waveforms and

trend information.

NOTE

• The 3880 MRI Patient monitor does not have an internal recorder. Printing can only be

done if the system is communicating with the optional 3885-B Base Station. The Base

station unit houses and drives the strip chart recorder in response to Record or Print

requests from the 3880 Monitor or 3885-T Remote Tablet hard ( Record) and soft (Print)

keys.

7.1. Loading Paper

To load paper into the recorder review section 2.2.9 for details.

7.2. Recorder Setup Menu

7.2.1. Trace 1

The optional recorder can print one or two waveforms of ECG, SpO2, CO2 waveforms. When

Trace 1 and 2 are selected to print, Trace 1 will appear on the top of the paper. To adjust which

waveform yo u want to print when the Print button is pressed follow these steps:

1. Press the SETTINGS button

2. Select “Recorder Setup”

3. Select “Trace 1”

4. Select desired waveform to print

5. Touch Back button to close the menu

7.2.2. Trace 2

The optional recorder can print one or two waveforms of ECG, SpO2, CO2 waveforms. When

trace 1 and 2 are selected to print, T r ace 2 will appear on the bottom of the paper. To adjust

which wavefor m you want to print when the Print button is pressed follow the se steps:

1. Press the SETTINGS button

2. Select “Recorder Setup”

3. Select “Trace 2”

4. Select desired waveform to print or select OFF to print a single waveform

5. Touch Back button to close the menu

NOTE : Each vital sign parameter must be set ‘ON’ to allow recording of its trace. Also,

with ECG, two leads must be on displa y (d isplay Trace A and B) and set for recording,

to record ECG Trace 2.

7.2.3. Waveform Trace delay

Trace delay allows users to set a time delay before the waveform data is sent to the recorder.

This can account for the time delay between when a user decides to print and when they

actually depress the button. The delay options are 0, 4, 8 and 16 seconds.

To adjust the trace delay foll ow these steps:

1. Press the SETTINGS button

2. Select “Recorder Setup”

7-31

3. Select “Trace Delay”

4. Select des ired delay

5. Touch Back button to close the menu

7.2.4. Auto Strip

Auto strip allows the automatic report feature of the recorder to be switched ON and OFF. The

auto strip will automatica ll y print when a clinic al alarm is detected.

To enable the Aut o St rip follow thes e st eps:

1. Press the SETTINGS button

2. Select “Recorder Setup”

3. Toggle “Auto Strip” ON and OFF

4. Touch Back button to close the menu

7.2.5. Run Time

Recorder Run Time allows users to adjust the length of time the recorder prints when activated.

The options ar e 8, 1 2, 16, 20 and 30 seconds.

To adjust the waveform Record Run Time follow these steps:

1. Press the SETTINGS button

2. Select” Recorder Setup”

3. Select “Run Time“

4. Select desired time

5. Touch Back button to close the menu

7.2.6. Recorder Sweep Speed

The Sweep Speed sw itches the recorder speed between 25 and 50 mm/second.

To adjust recorder Sweep Speed follow these steps:

1. Press the SETTINGS button

2. Select “Recorder Setup”

3. Select “Speed”

4. Select des ired speed

5. Touch Back button to close the menu

7.2.7. To manually start a strip chart recording

Press the front panel “Record” hard key at either the 3880 Monitor or 3885-T Remote Tablet.

7.2.8. Rec order O utput

The strip chart recorder output will be the waveform Trace or Traces selected in the Record

Setup along with the selected delay and run time, with the text printout of all active vital signs

values. The vital signs, such as HR, SpO2, Blood Pressure, GAS measurements, and

Temperature print on the paper in a table at conclusion of the strip run time.

7.3. Printing

7-32

The term “Printing” is used herein to refer to using the strip chart recorder as a printer of text

and numeric information, such as the Tabular Trend table. Strip “Recording” is a specialized

print out of waveform data as described in 7.2.7 and 7.2.8 above. See section 5.5 for instruction

to print Trends.

7-33

8. Pre-Use Operator Verification, Troubleshooting and User

Maintenance

8.1. Overview

Check the following items prior to monitoring to ensure completion of all essential preparations.

Items that are broken, missing, plainly worn, distorted, or contaminated must be replaced

immediately. The 3880 system must not be repaired other than in accordance with written

instructions provided by IRadimed. The device shall not be altered without written approval of

IRadimed. The user has the sole responsibility for any malfu nc ti on which results fro m imp r oper

use, faulty maintenance, improper repair, damage or alteration by anyone other than IRadimed

authorized personnel.

! WARNING

• For proper equipment performance, maintenance and service procedures should be

performed at the recommended intervals as described in the monitor’s service manual.

NOTE

• The IRadimed software design controls include performance of a risk analysis using

methods consistent with ISO 14971 Medical devices - Application of risk management to

medical dev i ces. The 3880 system employs watchdog timers, self-monitoring activities

(memory, c om m unication and sensor checks and so on), and power-on self-diagnostics

(for example, memory checksums).

8.1.1. Battery Life Expectancy

Life expectancy of a battery depends on how frequent and how long it is used. For properly

maintain ed and stored batter i es , the life expectancy is about 2 or 3 years res pectively. For more

aggressi v e and non-traditional use mo dels, the life expectancy maybe less.

recommend s re placing batteries every 2 to 3 years or wh en signs of wear or operation are

noticeably different.

To get the most out of your batteries observe the following guidelines:

• The batter y performance test must be performed ever y year, before monitor repairs, or

whenever the battery is suspected as being the source of the problems.

• Take out the battery before the monitor is shipped or will not be used for more than 3

months.

• The shelf-life of a Lithium Polymer battery is about 6 months when the battery is stored

with the battery power being 50% of the total power.

IRadimed

8-1

8.1.2. Checking a Battery

The user replaceable battery packs utilized in the 3880 patient monitor can be checked outside

of the monitor. Thi s feature allows facilities with multiple batteries to proac t ively select a battery

that has a desired charge level prior to inserting it into the system. To che c k a batteries charg e

follows these steps :

1. Locate the button on the rear corner of the battery (1)

2. Depress the button and the LED indicators will momentarily show the charge status. (2)

8.2. Performance Checks

8.2.1. Daily in between tasks

• Check that s ystem components and ac cessories do not have any visual defects such as

cracks or loo se parts.

• Check that the system components as described in the Care and Cleaning 8.4 part of

this section were cleaned properly after the previous use.

• All supplies and accessories are not passed their expired date.

• Check that batteries are properly inserted and charged.

• Ensure all system components are wir elessly communicated

• Wipe the monitor, PODs and accessory surfaces

• Change all airway patient accessories.

• Ensure that you are using correct accessory sizes for each patient and that they are

properly connected.

• Check that all accessories, cables and monitor parts are clean and working properly.

• Check that you have selected desired parameters to be displayed in digit and waveform

fields.

• Check that the trends of the previous patient are erased.

• Monitor patient type mode and alarm limits are suitable fo r the patient.

• Check the compatibility of the 3880 monitor, sen sors and cables before use

8.2.2. Regular Inspection and Verification

Wireless Communication

• Place the PODs and 3880 Monitor inside the MRI room suite with the door shut. Place

the 3885-T Remote Ta ble t in the control room i n it s desired locat io n and check that the

communication performance is acceptab le.

ECG

• Check that the message 'Leads Off' disa ppears and the waveforms are displayed when

the lead wires are connected to the patient.

Pulse Oximetry

• Check that the R ed Light is visible in t he s ensor

• Check that the SpO

the sensor is connected to the patient

CO

(CO2 only or 3886 Multi-Gas system)

2

value is display ed and the message “P ro be O f f” disappears when

2

8-2

• Occlude the sampling line and check that the message “Occlusion” appears within 30

seconds

NIBP

• Check that the pressure values are displayed for all cuff sizes

Temperature

• Check that the temperature value is displayed when the cable is connected

Recorder

• Check that the strip chart recorder is functional

Alarms

• Turn the monitoring system on and check that the Red, Amber and blue Tri-Color TriColor Alarm D om e Light are lit momentarily

• Check that the speaker gives and audible tones at the desired level

• Use a conventional patient simulator and / or test gasses to verify alarm functionality.

When a problem with the alarm system is suspected, always refer the monitor to a

qualified service personnel.

Battery

• The battery pack should be inspected anytime the battery pack is removed. Look for

signs of physical damage, shock and swelling. Che c k that the battery pack is holding

sufficient operating capacity.

• Check that the battery is communicating with the monitor by observing the battery icon

on the display.

! CAUTION

• Any failure of the inspection of the battery pack will require discontinuance of use and

replacement will be needed.

• If any cells swollen greater than 8 mm thi ck or cause the plas tic case to bulge

discontinue use and contact your support personnel for proper disposal.

8.2.3. Every Twelve Months

Preventative Maintenance Check

• Calibration check of temperature, NIBP and CO

NOTE

• The annual check a c co rd i n g to detailed instruction s of the Service Manual requires

trained service personnel and appropriate testing tools and equipment.

• Verify all calibration / test gas mixture containers are empty before disposal.

• Use only MRI compliant calibration / test gas mixture containers suitable for use in the

MRI enviro nm ent for verification of gas reading s inside of zone IV.

8.3. Service Setup Menu

8.3.1. Software Version

To check the current revision of software in the 3880 system, P OD s and Tablet follow these

steps:

1. Press the SETTINGS Button

2. Select “Service Mode”

3. Enter password

4. Select “Device Information”

5. Check software version

6. Touch Back button to close the menu

/ Multi-Gas Agents Unit

2

8-3

8.4. Care and Cleaning

8.4.1. Introduction

For safe and reliable function and operation of the monitor, regular care has to be carried out in

accordance with manufactures guidelines. Use only manufactures approved substances and

methods to clean and disinfect y our equipment. The warranty does not cover damage caused

by unappro v ed substances or methods.

IRadimed makes no claims regarding the efficacy of the listed chemicals or methods as a

means for controlling infection.

NOTE

• If the monitoring system does not function as it should and troubleshooting cannot solve

the problem, contact your service representative.

• Detailed cleaning instructions provided with any accessory should be followed.

8.4.2. General Guidelines

Keep your equipment and accessories free of dust, dirt and contaminants. To avoid damage to

the 3880 monitor follow these rules:

• Always dilute liquid cleaning agents according the manufacturer’s instructions or use

lowest possible concentration.

• Do not immerse part of the 3880 monitor into liquid.

• Do not pour or use pressurized spray liq uid onto the 3880 monitor or accessories.

• Do not allow liquid to enter the case.

• Never use abrasive materials, solvent or corrosive cleaners.

• Clean the 3880 monitor in a well-ventilated area before and after each patient use.

• Allow components to dry completely prior to use.

• A soft bristled brush may be used to clean narrow areas.

• Do not use hard or pointed objects to clean any part of the monitor.

! WARNING

• Be sure to shut down the system and disconnect all power cables from the outlets

before cleaning the 3880 monitor.

• Do not use unspecified cleaners, materials or methods as they may damage the device,

labels or cause failures.

• Do not use conductive solutions or materials to clean the system.

• Do not reuse sensors intended for single patient use.

! CAUTION

• If liquid is sp illed on the 3880 monitor or accessories and may have entered the system

immediately contact your service personnel.

• Do not use solvent based cleaning agents as damage to the plastic parts could occur.

NOTE

• Before cleaning any equipment, consult your hospital’s regulations for cleaning

• Refer to any superseding instr uc tions accompan y i ng any accessori es or options.

8-4

8.4.3. Cleaning & Disinfecting

The 3880 system should be cleaned on a regular basis. If there is heavy pollution and/or lots of

dust and sand at/in your facility, the 3880 monito r should be cleaned more frequently.

Recommended cleaning agents are:

• Mild Soap (diluted)

• Ammonia (diluted )

• Isopropanol (70% )

• Chloramine (5%)

• Glutaraldehyde (2%)

• Ethyl Alcohol Based (60-95%)

• Chlorine/Bleach Based (4-6%)

• Iodine Based (0.5-5%)

• Phenols (0.2-3%)

• Quaternary Ammonium Compounds (2%)

• Hydrogen Peroxide (<3%)

To clean the 3880 monitor, follow these rules:

1. Shut down the pati ent monitor and disconnect it from power .

2. Clean the displays using a soft, clean clo th da m pened with glass clea ne r .

3. Clean the exterior surface of the 3880 monitor using a soft cloth dampened with an

approved cleaner .

4. Wipe the cleaning solution off the 3880 monitor with a dry cloth.

NOTE

• Disinfection may cause damage to the 3880 monitor and is therefore not recommended

unless otherwise indicat ed in your hospital’s policy. Cleaning the 3880 monitor prior to

disinfecting is recommended.

8.4.4. Sterilizing

Sterilization may cause damage to the 3880 monitor and is therefore not recommended. The

decision to sterilize components must be made per your institution’s requirements with an

awareness of the effects on the integrity of the cables and potential hazards that it may cause.

8.4.5. Cleaning the Recorder Printhead

After the recorder has been used for a long time, deposits of paper debris may collect on the

printhead compromising the print quality and shortening the lifetime of the roller. Follow this

procedure to clean the printhead:

1. Open the Recorder door

2. Gently wipe around the printhead using cotton swa ps dampened with alcohol.

3. After the alcohol has complete dried, reload the paper and close the door.

! CAUTION

• Do not use anythin g t ha t may destroy the thermal print head.

• Do not add unnecessary force to the thermal print head.

8-5

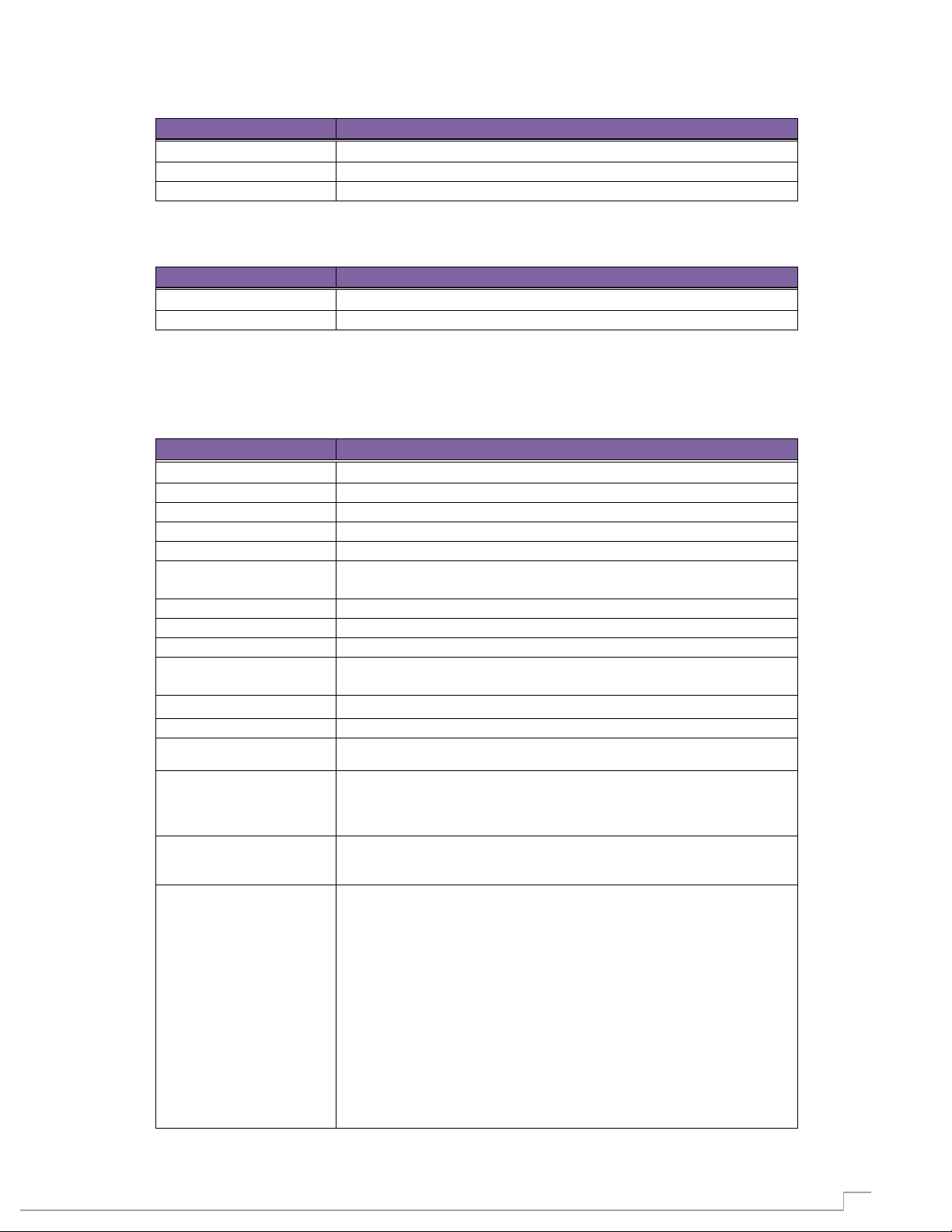

8.5. User Maintenance

Problem

Possible Cause

Solution

1

3880 will not turn on.

Power dial is not in the

1) Turn 3880 ON by

position.

No AC power/battery

1) Plug AC Adapter

charged battery.

8.5.1. Overview

Before every use, a thorough inspection sho uld be performed.

Follow these guidelines when inspecting the 3880 monitor:

• Make sure that the environment and power supply meet the requirements.

• Inspect th e 3880 system and its accessories fo r mechanical dama ge .

• Inspect all power cords for damage, and make sure that their insulation is in good

condition.

• Make sure that only specified accessories are applied.

• Inspect if the alarm system functions correctl y .

• Make sure that the recorder functions correctly and the recorder paper meets the

requirements.

• Make sure that the patient monitor is in good working condition, and batteries have

sufficient charge.

In case of any damage or abnormity, do not use the patient monitor. Contact the hospital’s

biomedical engineers or your authorized

8.5.2. Updating Software

As revisio ns of the software become available, the 3880 can be updated, see service manual

for detail procedure.

IRadimed service personne l imm ediately.

8.6. Troubleshooting Probl ems With No Ons cr e en Mes sag e

The following section is for troubleshooting the 3880 system when there is no corresponding

message displayed on the screen. If a message is displayed on the screen please review Exhibit B of

the operators manual. Please contact IRadimed Technical support at (407) 677-8022 if you need

assistance troubleshooting or are unable to resolve any issues.

8.6.1. Troubleshooting Power Related Problems

correct position

depleted.

rotating the power

dial to the ON

power cord into a

working AC outlet

immediately.

2) Plug AC Adapter

into the circular

power receptacle on

the rear of the

device.

3) Optional Swap low

battery with a fully

8-6

Problem

Possible Cause

Solution

Blown Fuse(s).

1) Replace the fuse in

the power supply

type and procedure.

AC power source has

1) Switch AC power

requirements.

Screen Damaged.

If an audible alarm is

technical support.

2

3885-T will not turn on.

Power ON [ I] key not

1) Turn 3885-T ON by

pressed.

Battery depleted.

1) Plug AC Adapter

charged battery.

box (P/N 1120).

Refer to the service

manual for proper fuse

incorrect voltage.

pressed.

cord to a power

receptacle with

sufficient voltage.

Refer to the service

manual for voltage

heard and the alarm

dome light changes

when the power ON

button is pressed.

1) Investigate the LCD

display screen for

failure.

2) Contact IRadimed

firmly pressing the

ON button firmly.

Listen and feel for

the tactile feedback

to confirm the button

has been properly

power cord into an

AC outlet

immediately.

2) Plug AC Adapter

into the circular

power receptacle on

the rear of the

device.

3) Optional: Swap low

battery with a fully

8-7

Problem

Possible Cause

Solution

3

3885-B will not turn on.

Power ON key not

pressed.

1) Toggle the power

pressed.

Blown Fuse(s).

1) Replace the fuse in

type and procedure.

No AC power

1) Plug AC Adapter

immediately.

AC power source has

1) Switch AC power

requirements.

4

3886 will not turn on.

Power ON key not

1) Toggle the power

pressed.

Blown Fuse(s).

1) Replace the fuse in

type and procedure.

No AC power

1) Plug AC Adapter

immediately.

switch to the ON

position.

Listen and feel for

the tactile feedback

to confirm the button

has been properly

the rear of the 3885T

Refer to the service

manual for proper fuse

power cord into a

working AC outlet

incorrect voltage.

pressed.

cord to a power

receptacle with

sufficient voltage.

Refer to the service

manual for voltage

switch to the ON

position.

Listen and feel for

the tactile feedback

to confirm the button

has been properly

the rear of the 3885T

Refer to the service

manual for proper fuse

power cord into a

working AC outlet

8-8

Problem

Possible Cause

Solution

AC power source has

incorrect voltage.

1) Switch AC power

requirements.

5

ePOD or oPOD will not

Power ON key not

1) Toggle the power

pressed.

Insufficient battery life

1) Plug 3880 system

Technical Support

6

3880 will not operate

Battery not properly

1) Plug AC Adapter

pack before use.

cord to a power

receptacle with

sufficient voltage.

Refer to the service

manual for voltage

turn on

on battery.

pressed.

charged.

switch to the ON

position.

Listen and feel for

the tactile feedback

to confirm the button

has been properly

into AC power.

2) Ensure the POD is

correctly docked and

seated into a

charging bay on the

3880 monitor.

3) Allow to charge a

minimum of 4 hours.

4) Contact IRadimed

power cord into an

AC outlet

immediately.

2) Plug AC Adapter

into the circular

power receptacle on

the rear of the

device.

3) Wait until battery is

fully charged.

4) Press the button on

the exterior of the

battery pack. If no

LED’s illuminate

replace the battery

8-9

Problem

Possible Cause

Solution

Aged battery won't hold

charge.

1) Plug AC Adapter

pack before use.

Battery is in sleep

When the battery test

3880 back in use.

7

Short battery run time.

Battery not charged

1) Plug AC Adapter

off.

power cord into an

AC outlet

immediately.

2) Plug AC Adapter

into the circular

power receptacle on

the rear of the

device.

3) Wait until battery is

fully charged.

4) Press the button on

the exterior of the

battery pack. If no

LED’s illuminate

replace the battery

mode.

long enough.

button is pressed and

no lights illuminate.

1) Insert the dead

battery into a 3880

or 3885-B that is

already turned on

and connected to

AC power.

2) If battery doesn’t

wake up after 1 hour

of charge dispose of

it according to

policy.

3) Replace the battery

prior to putting the

power cord into an

AC outlet

immediately.

2) Plug AC Adapter

into the circular

power receptacle on

the rear of the

device.

3) Check battery by

pressing the test

button on the battery

(1133 battery only).

Note: The batteries will

charge at a faster rate

when the 3880 is turned

8-10

Problem

Possible Cause

Solution

Aged battery will not

hold charge.

1) Plug AC Adapter

technical support.

8

Battery is hard to

Swollen Battery Cells.

Return the device to

removal.

Problem

Possible Cause

Solution

1

No Audible alarm tone

Alarm volume set too low

1) Press the Settings

environment.

Faulty alarm speaker.

1) Contact IRadimed

Technical Support.

2

Continuous alarm tone

Faulty hardware.

1) Note any onscreen

technical support.

power cord into an

AC outlet

immediately.

2) Plug AC Adapter

into the circular

power receptacle on

the rear of the

device.

3) For 1133 batteries

only. After a few

hours of charge

check battery by

pressing the test

button on the

battery.

4) If problem persists

dispose of the

battery according to

policy.

5) Replace battery or

POD with a new

one.

6) If problem persists,

contact IRadimed

remove.

8.6.2. Troubleshooting Alarm Related Problems

heard.

after alarm silence is

pushed.

for the use environment.

IRadimed for battery

Button.

2) Select Alarms

Function

3) Adjust alarm volume

for the intended use

messages.

2) Contact IRadimed

8-11

Problem

Possible Cause

Solution

3

The unit is in Alarm mode

with lights flashing but

The 2 minute Alarm

1) Press the

re-engage.

Audible volume set too

1) Press the Settings

environment.

Problem

Possible Cause

Solution

1

Buttons will not function.

Key not pressed firmly.

1) Repeat key press

been properly pressed.

Faulty key panel.

If the above 2 solutions

Service.

2

Programmed settings are

3880 turned off for

1) Train appropriate

settings.

Volatile memory may not

1) Replace CR2032

Technical Service.

3

Clock is not correct.

Clock not properly

after receipt.

1) Adjust clock time as

Internal coin cell battery

1) Replace CR2032

Technical Service.

Summer/Winter time

1) Adjust clock as

manual.

no audible alarms can be

heard.

Silence button is

activated.

ALARMSILENCE

button to re-engage

alarm volume.

2) Or wait for two

minutes.

After two minutes, alarm

tones will automatically

low to be heard.

2) Select Alarms

3) Adjust alarm volume

8.6.3. Troubles hooting Operation Related Probl em s

Listen for audible and feel

for the tactile feedback to

confirm the button has

are acceptable contact

IRadimed Technical

Button.

Function

for the intended use

more firmly.

restored to default on

power up.

longer than 30 seconds

between uses.

store due to internal Coin

cell battery problem.

adjusted to local time

has become depleted.

change.

personnel that

turning off the 3880

for more than 30

seconds resets

coin cell battery.

2) Contact IRadimed

described in manual.

coin cell battery.

2) Contact IRadimed

described in service

8-12

Problem

Possible Cause

Solution

4 3885-T Remote will not

3880 is not turned ON.

1) Ensure the 3880 is

operational.

3880 is not within

1) Verify 3880 and

needed.

Software incompatibility.

1) Ensure the software

equal.

Incorrect Channel.

1) Ensure that both the

3885-B.

Multiple system

1) Ensure that each

simultaneously).

Loose or damaged

1) Ensure that the

are attached tightly.

Local radio interference

1) Ensure other

system components.

1) Try using a different

communicate on.

communicate to a

selected 3880 or drops

out.

wireless range.

turned on and is

3885-T within 90 ft

(30 m) of 3885-B

and that no other

devices are blocking

the wireless signal.

2) Reposition 3880 to

establish

communication as

revisions for the

3880 and 3885-T are

3885-T, 3885-B and

3880 are operating

on the same

wireless network

channel.

2) Record wireless

network from the

3880.

3) Select matching

wireless channel on

3885-T

4) Select matching

wireless channel on

components on the same

wireless network

channel.

antenna.

prevents communication.

3880 in your facility

are on separate,

unique channels (or

not used

antennas on the

3885-B are in good

working order and

wireless equipment

is greater than 3 feet

away from the 3880

wireless network

channel for the 3880

system to

8-13

Problem

Possible Cause

Solution

MRI Room Attenuation.

1) Ensure the high gain

antenna is attached

Technical Service.

5

ePOD or oPOD will not

3880 is not turned ON.

1) Ensure the 3880 is

operational.

3880 is not within

1) Verify PODS are

needed

Incorrect Channel.

1) Ensure that the

3882 oPOD.

Multiple system

1) Ensure that each

simultaneously).

6

Printer will not print

Wireless communication

1) Ensure wireless

with a recorder

to the correct

receptacle on the

3885-B

2) Position the high

gain antenna so it

has a direct line of

sight to the 3880.

3) Try a different

wireless channel

4) Contact IRadimed

communicate with a

3880

wireless range.

turned on and is

within 9 ft (3 m) of

3880 and that no

other devices, walls

or doors are blocking

the wireless signal.

2) Reposition 3880 to

have a line of sight

to the PODS as

ePOD, oPOD and

3880 are operating

on the same wireless

network channel.

2) Record wireless

network from the

3880.

3) Select matching

wireless channel on

3881 ePOD

4) Select matching

wireless channel on

components on the same

wireless network

channel.

to the 3885-B

3881 and 3882 in

your facility are on

separate, unique

channels that match

a corresponding

3880 (or not used

connection is

established to a

3885-B equipped

8-14

Problem

Possible Cause

Solution

Printer out of paper or

paper jam

1) Review section 7 of

manual

Problem

Possible Cause

Solution

1

Artifact on MR images.

Loose connection to cord

Tighten AC cord connection

Faulty Hardware.

1) Switch to battery

technica l service.

Problem

Possible Cause

Solution

1

ECG Vital Signs are not

1) Ensure the ePOD is

applications training.

8.6.4. Troubleshooting MRI Related Problems

the operators

when running on AC

power.

to Monitor and power

supply.

power.

2) Disconnect the power

cable from the 3880

monitor.

3) Disconnect AC power

cord from the AC

outlet in the MRI r oom.

4) Inspect components

damage.

5) Remove all power

cables from the room.

6) If artifact disappears

then replace faulty

hardware.

7) If artifact is still present

repeat steps for the

3886.

8) If artifact still appears

contact IRadimed

8.6.5. Troubleshooting Vital Sign Related Problems

performing as expected

2) Ensure the ECG

3) Inspect all ECG

4) Review section 6.1

5) Contact your local

on the same

wireless network

channel as the 3880.

parameter is

enabled.

components for

damage and replace

as necessary.

of the operators

manual

representative to

schedule

8-15

Problem

Possible Cause

Solution

Incompatible lead view

for the MRI scan and/or

Change the ECG lead view

sequence.

Poor skin preparation

Re-prep the patient

section 6.

Poor electrode

Reposition/replace

found in section 6.

Poor electrode quality

Replace the electrode with

electrode.

Weak radio link

Verify radio channel

improved reception.

QRS amplitude is less

Change the lead view and

the electrodes.

Faulty ECG ePOD

Replace ECG module, or

service representative.

Incorrect ECG Mode

Select the appropriate

manual.

Patient motion

Ensure that the patient is

not shivering or moving.

ECG lead not properly

Ensure each ECG leadwire

the ePOD.

Damaged ECG lead

Replace ECG lead with an

lead.

electrode placement

to select the best

performing view for the

according the application

procedure found in

placement

than 10 mm/mv

selected

electrodes according to

the application procedure

an IRadimed approved

setting and signal level.

Reposition antenna for

/ or reprep and reposition

refer to qualified technical

ECG filter mode for the

application. Refer to

section 6 of the operators

inserted into the ePOD

is inserted completely into

IRadimed approved ECG

8-16

Problem

Possible Cause

Solution

All other issues

1) Ensure the ePOD is

on the same

applications training.

2

SpO2 not functioning

SpO2 sensor is not

attached to the patient.

Ensure SpO2 sensor is

securely attached.

Poor SpO2 sensor

Reposition/replace SpO2

section 6.

Weak radio link

Verify radio channel

improved reception.

Faulty SpO2 oPOD

Replace SpO2 oPOD, or

service representative.

SPO2 readings are

Sensor positioning

Check the P.I. value and

section 6.

Ensure the SpO2 cable is

SpO2 applicator / grip.

Averaging time

Try adjusting the SpO2

averaging time.

Patients specific anatomy

Skin pigment and certain

readings.

Check that there is no nail

impeding the readings.

Cool temperature is

Check the P.I. value and

touch.

wireless network

channel as the 3880.

2) Ensure the ECG

parameter is

enabled.

3) Inspect all ECG

components for

damage and replace

as necessary.

4) Review section 6.1

of the operators

manual

5) Contact your local

representative to

schedule

unstable or poor

placement

sensor according to

setting and signal level.

Reposition antenna for

refer to qualified technical

try repositioning the

sensor correctly on the

patient according to

correctly inserted into the

anatomy ailments can

cause inconsistent SpO2

affecting patients

perfusion

polish on the patients digit

ensure the patient is not

shivering and that their

digits are warm to the

8-17

Problem

Possible Cause

Solution

interference from NIBP

cuff or arterial catheter.

Move the SpO2 sensor to

functions.

Excessive ambient light

Limit the amount of

as needed.

Excessive patient motion

Ensure that the patient is

not shivering or moving.

Circulation is reduced

Position the sensor at a

the patients digit.

Finger was removed from

Check that the

according to section 6.

SpO2 Vital Signs are not

All other issues

1) Ensure the SpO2

applications training.

3

CO2 not functioning

Sampling line hose is not

connected

Attach sampling line hose.

Leaking sampling line

Re-check fittings to ensure

sampling line hose.

Sampling line filter is wet

Verify proper drying

line hose filter.

Monitor has an internal

leak

Refer to qualified technical

service representative.

Values are too low or

unstable

Monitor has an internal

failure

Refer to qualified technical

service representative.

an application site and

limb that is not being

utilized for other medical

ambient light entering the

sensors. Cover with a cloth

performing as expected

because of excess

pressure

the sensor

different site and ensure it

is not applied to tightly to

appropriate sized sensor is

being used and reapply

parameter is

enabled.

2) Inspect all SpO2

components for

damage and replace

as necessary.

3) Review section 6.2

of the operators

manual.

4) Contact your local

representative to

schedule

hose

or clogged

they are tight. Replace

tubing is in position. Recheck filter to ensure it is

clear. Replace sampling

8-18

Problem

Possible Cause

Solution

EtCO2 Vital Signs are not

performing as expected

All other issues

1) Ensure the EtCO2

applications training.

4

NIBP values seem

Compromised hose or

Check that tubing is not

compressed or loose.

Ensure the patient is not

shivering or moving.

Ensure the correct sized

applied correctly.

Replace Hose or cuff if a

leak is suspected.

Monitor has an internal

leak

Refer to qualified technical

service representative.

Patients Arm Position

Ensure that the patients

arm is at heart level.

Cuff comes off patient

Inappropriate sized cuff

Determine correct cuff

according to section 6.

Cuff applied inside out

Reapply cuff according to

section 6.

NIBP not functioning

NIBP hose or cuff is

disconnected

Ensure NIBP hose is

securely connected.

Monitor has an internal

failure

Refer to qualified technical

service representative.

NIBP Vital Signs are not

All other issues

1) Ensure the NIBP

applications training.

parameter is

enabled.

2) Inspect all EtCO2

components for

damage and leaks

and replace as

necessary.

3) Review section 6.3

of the operators

manual.

4) Contact your local

representative to

schedule

unstable

limb

cuff

stretched, bent,

cuff is being used and

size and apply to patient

performing as expected

parameter is

enabled.

2) Inspect all NIBP

components for

damage and leaks

and replace as

necessary.

3) Review section 6.4

of the operators

manual.

4) Contact your local

representative to

schedule

8-19

Problem

Possible Cause

Solution

5

Temperature error or

intermittent function

Temperature sensor is

the patient.

Re-attach Temperature

Poor Temperature sensor

placement

Reposition/replace

Temperature sensor.

Faulty Temperature

Replace Temperature

representative.

Temperature Vital Signs

All other issues

1) Ensure the

applications training.

6

Respiration and Gases

1) Ensure the 3886 is

applications training.

not securely attached to

sensor.

are not performing as

expected

from 3886 are not

performing as expected

sensor

sensor, or refer to

qualified technical service

Temperature

parameter is

enabled.

2) Inspect all

Temperature cable

for damage or

kinking and replace

as necessary.

3) Review section 6.4

of the operators

manual.

4) Contact your local

representative to

schedule

turned ON

2) Ensure the Gas

parameter is

enabled on the

3880.

3) Inspect all EtCO2

components for

damage and leaks

and replace as

necessary.

4) Review section 6.3.8

of the operators

manual.

5) Contact your local

representative to

schedule

8-20

8.7. Repair

8.7.1. Overview

All repairs on c omponents under war ranty must be performed by authorized IRadimed service

personnel. If the 3880 system fails to function properly or requires maintenance, contact your

IRadimed representative.

! CAUTION

• Decontaminate all equipment prior to performing any repair or before sending to

IRadimed.

• No repair should ever be attempted by anyone not having a thorough knowledge of the

3880 system.

• Only replace damaged components with parts manufactured and authorized by

IRadimed.

NOTE

• Unauthorized repairs will void the w arranty.

• The user of this product shall have sole responsibility for any m alfunction which r esults

from improper use, faulty maintenance, improper repair, damage, or alterations by

anyone other than authorized

IRadimed service personnel.

8.7.2. Changing Fuses

1. Remove the power cord if used.

2. Remove the fuse holder by pulling the holder out with screwdriver.

3. If a fuse is blown, replace it with the IRadimed HE14 fuse which is the correct type an d

rating.

8.7.3. Removing a Paper Jam

If the recorder works incor rectly or produces unusual sounds, check if there is a paper jam. If a

jam is detected follow these steps to remove it:

1. Open the Recorder Door

2. Remove the paper and tear off any damaged paper

3. Reload the paper and close the recorder door.

8-21

8.8. Warranty

IRadimed Corporation warrants the major components of the 3880 system (e.g. 3880, 3885-T

Remote Tablet and 3885-B Base Station) to be free from defects in materials and workmanship

for a period of twelve (12) months from t he date of original de livery to the buyer or to buyer's

order, prov i ded that same is properly operated under conditions of normal use, and that periodic

maintenance and service is per formed. A ninety (90 ) day warranty applies to limited-life parts

and accessories (e.g.1 133 MRI Compatible Bat tery Pack, gating cable, SpO

, ECG, NIBP, CO2,

2

Temperature patient accessories). A thirty (30) day warranty applies to all parts and

accessories not listed above .

This warranty will become null and void if p r od uct has been repaired ot her than by IRadimed

Corporation, or its authorized representative, or if the product has been subject to misuse,

accident, negligence, or abuse.

IRadimed Corporation's sole obligation under this warranty is limited to repairing a product

which has been reported to IRadimed Corporation's Technical Servic e Center during norm al

business hours and shipped transportation prepaid. IRadimed Corporation is not liable for any

damages including, but not limited to, incidental damages, consequential damages or special

damages.

This warranty is in lieu of any other warranties, guar antees or conditions, includi ng

merchantability or fitness for a particular purpose. The remedies under this warranty are

exclusive and IRadimed Corporation neither assumes nor authorizes anyon e t o as sume for it

any other obligation in connection with the sale or repair of its products.

A purchased Maintenance Extension agreement provides for an additional 1, 2, or 3 years of

authorized repair for major products. The maintenance extension period will begin at the end of

the standard warranty period, and continue until the end of the maintenance extension period

purchased. The extended maintenance does not apply to equipment which has been subject to

abuse or neglect.

Maintenance Extensions purchased after the standard warranty has expired shall require a

physical inspec tion by IRadimed Corporation prior to purchase of any Maintenance Extension.

An additional service fee may also be required to bring the out of warranty product(s) within

specifications before any maintenance extension can be activated. (Cost of such inspection and

possible repair to the product will be communicated to customer at that time). We reserve the

right to refuse the sale of Maintenance Extension to any Product.

IRadimed Corporation warrants any such product subject to a Maintenance Extension

agreement shall, other than its expendable parts, provided that same is properly operated under

conditions of normal use, and th at periodic maint enance and servic e is performed; be repaired

by IRadimed and restored to full operational specification as where applicable at the time of

original manufacture. Any Ma intenance Ext ension will become null and void if product has been

repaired other than by IRad imed Corporatio n, or its authorized representative, or if the product

has been subject to misuse, accident, negligence or abuse.

Should a unit perform outside of IRadimed specifications and cannot be corrected by on site

technicians with instruction and support from IRadimed and unit must be returned to IRadimed

for repair, a loaner unit, if available, may be provided.

IRADIME D CORPORAT ION PRODUCT S CONTAIN PRO PRIETARY COPY WRITTEN

MATERIAL; ALL RIGHTS ARE RESERVED BY IRADIMED CORPORATION

8-22

9. Accessories

Part Number

Description

Image

Use Type

1171

Reusable Sensor Grip Kit (Pack of 3)

1821

Fiber Optic oPOD SpO2 Cable

3882

8 Channel Wireless oPOD

technology. For use with the IRadimed 3880.

Part Number

Description

Image

Use Type

1832LA

Large Adult Reusable Cuff (34-44cm)

patient use.

1832A

Adult Reusable Cuff (27-35cm)

patient use.

1832SA

Small Adult Reusable Cuff (20.5-28.5cm)

patient use.

The packaging of the accessories is color coded to help identify which access ories are most

likely appropriate for your par ticular pati ent.

• Gray – All patient sizes

• Neonatal (Birth to one month of age) – Purple

• Infant (One month to two years of age) – Orange

• Child (Two to Twelve years of age) – Green

• Adult (Above twelv e years of age) – Blue

NOTE

• All materials that come in contact with patients and users comply with ISO 10993-1.

To order replacement parts contact your IRadimed representative or call 1-866-677-8022

9.1. SpO

9.2. NIBP

2

Reusable Sensors Grip come in 3 sizes (Grips only)

Fiber optic SpO2 cable for use with IRadimed oPODs.

Wireless MRI SpO2 module featuring Masimo

Multiple Use

Multiple Use

Multiple Use

Reusable Non-Invasive blood pressure cuff are

constructed of an extremely soft, easy to clean material

to provide a long usable life and support multiple

Multiple Use

Reusable Non-Invasive blood pressure cuff are

constructed of an extremely soft, easy to clean material

to provide a long usable life and support multiple

Reusable Non-Invasive blood pressure cuff are

constructed of an extremely soft, easy to clean material

to provide a long usable life and support multiple

Multiple Use

Multiple Use

9-1

Part Number

Description

Image

Use Type

1832P

Pediatric Reusable Cuff (14-21.5cm)

patient use.

1832I

Infant Reusable Cuff (9-15cm)

patient use.

1833N4-10

Neonatal Size 4 Cuff (7-13cm) (Box of 10)

1833N3-10

Neonatal Size 3 Cuff (6-11cm) (Box of 10)

1833N2-10

Neonatal Size 2 Cuff (4-8cm) (Box of 10)

1833N1-10

Neonatal Size 1 Cuff (3-6cm) (Box of 10)

1831

NIBP Swift Connect NIBP Hose

Part Number

Description

Image

Use Type

1813-3

ECG Skin Prep Gel (Box of 3)

skin for MRI ECG electrodes.

1811

9” Five Lead ePOD MRI Leadwire (AAMI)

AAMI color coding. For Use with IRadimed ePOD only.

1811E

9” Five Lead ePOD MRI Leadwire (IEC)

IEC color coding. For Use with IRadimed ePOD only.

3881

8 Channel Wireless ePOD

Reusable Non-Invasive blood pressure cuff are

constructed of an extremely soft, easy to clean material

to provide a long usable life and support multiple

Reusable Non-Invasive blood pressure cuff are

constructed of an extremely soft, easy to clean material

to provide a long usable life and support multiple

Single Use Non-Invasive blood pressure cuffs are

constructed of soft fabric material that conform to the

tiniest of patients.

Single Use Non-Invasive blood pressure cuffs are

constructed of soft fabric material that conform to the

tiniest of patients.

Single Use Non-Invasive blood pressure cuffs are

constructed of soft fabric material that conform to the

tiniest of patients.

Multiple Use

Multiple Use

Single Use

Single Use

Single Use

9.3. ECG

Single Use Non-Invasive blood pressure cuffs are

constructed of soft fabric material that conform to the

tiniest of patients.

Single lumen non-invasive blood pressure hose

featuring simple connections

Package of 3 tubes of skin prep gel to prepare patients

ECG leadwire for 3 and 5 lead ECG applications with

ECG leadwire for 3 and 5 lead ECG applications with

Single Use

Multiple Use

Multiple Use

Multiple Use

Multiple Use

Wireless MRI ECG module for use with the IRadimed

3880

Multiple Use

9-2

Part Number

Description

Image

Use Type

1842A-25

Adult Nasal Cannula (Pack of 25)

1842P-25

Pediatric Nasal Cannula (Pack of 25)

1842I-25

Infant Nasal Cannula (Pack of 25)

1841-25

Coextruded Sample Line (Pack of 25)

Part Number

Description

Image

Use Type

1849-25

Nomoline Agent Sample Line (2m) (Pack of 25)

Module only

1846-25

Scavenge Hose (Pack of 25)

1848

Verification Check Gas

Part Number

Description

Image

Use Type

1851

Optical Temperature Sensor

9.4. CO2/Respiration Mo nitoring

Single use standard nasal cannula

Single use standard nasal cannula

Single use standard nasal cannula

Sample line for use with capnography and anesthetic

agent gas monitoring. For use with P/N 1849.

9.5. Multi-Gas (Agents) Monitoring

For use with IRadimed’s 3886 Wireless Multigas

Single Use

Single Use

Single Use

Single Use

Single Use

For use with IRadimed’s 3886 Wireless Multigas

Module only

For use with IRadimed’s 3886 Wireless Multigas

Module only

9.6. Temperature

Multiple use Fiber Optic temperature sensor

Single Use

Multiple Use

Multiple Use

9-3

Part Number

Description

Image

Use Type

1881

Universal Gating Interface

Systems equipped with cardiac gating leads

Part Number

Description

Image

Use Type

1133

3880 Battery

Non-Magnetic battery used with the 3880

1188

3885T Battery

Non-Magnetic battery used with the 3885T

1122

DC Power Cable, 10 feet (3m)

with the 1120 power supply

1120

Power Supply / Charger

Replacement power cable us ed with the 1122 cable

1128

North America AC Power Cord, 10 feet (3m)

1121

North America AC Power Cord, 3 feet (1m)

with the 1120 power supply

Part

Number

Description

Image

Use Type

1882-3

3885B Recorder Paper (Pack of 3)

9.7. Gating

Non-Magnetic gating interface cable for use with MRI

9.8. Power Supply

Replacement power cable used to interface the 3880

Replacement power cable us ed with 3885 and 3886

Multiple Use

Multiple Use

Multiple Use

Multiple Use

Multiple Use

Multiple Use

Replacement power cable used to interface the 3880

9.9. Recorder

3 Rolls of printer paper for the 3885B recorder

Multiple Use

Multiple Use

9-4

10-1

10. Exhibits

Technical Parameters

Technical Detail

Type:

Color TFT resistive touchscreen

Screen Size:

25.7 cm (10.1 inches) diagonal

Pixels:

800 by 480

Backlight:

LED

Screen Update Rate

2 Hz

Waveform Display Mode:

Moving Waveform

Waveform Display Width:

~145 mm

Waveform Display Height:

ECG Single Waveform:

~48mm max

ECG Dual Waveform:

~20mm max

All other Waveforms:

~25mm max

A. Specifications

10.1. Overview

Standard S ystem Components

• 3880 MRI Patient Monitor

• Wireless ECG POD

• Wireless SpO

• Non- Invasive Blood Pressure

• Accessories

Optional System Components

• 3885-T Remote Tablet ‘ Extended Range’ Control Room Display

• 3885-B Base Station with recorder

• CO

• Temperat ur e v i tal sign

• 3886 Multi-Gas Anesthetic Agent , 3886 Unit

Clinical Parameters

• Dual Channel, 5 Lead ECG

• Pulse Oximetry

• Perfusion Index

• Non – Invasive Blood Pressure

• Sidestream Capnography, Et CO

• Respirat ion Rate

• Fiber Optic Temperature

• Dual Anesthetic Agents

• Inspired N

• Inspired O

• MAC

POD

2

and Respiration vital signs

2

0

2

2

and CO2

2

10.1.1. Technical Specifications

10.1.1.1. Display

10-2

Technical Parameters

Technical Detail

Power:

Rotary On, Off

Feature Hard Keys:

Trends, Print, NIBP Start/Stop and Alarm Silence

Setup Hard Keys:

Setup and Standby

Soft Keys:

Touchscreen

Technical Parameters

Technical Detail

Power:

Push Button On, Off

Feature Hard Keys:

Trends, Print, NIBP Start/Stop and Alarm Silence

Setup Hard Keys:

Setup and Standby

Soft Keys:

Touchscreen

Technical Parameters

Technical Detail

Power:

Push Button On, Off

Hard Keys:

Channel Selection

Technical Parameters

Technical Detail

Power:

Toggle

Channel Select:

Button

Technical Parameters

Technical Detail

Types:

Tabular

Trend Memory:

50 readings

Tabular Intervals:

3, 5, 8, 10, 15, 30, Auto NIBP

Data Types:

HR, SpO2, NIBP, EtCO2, Resp, Temp, MAC, O2

Technical Parameters

Technical Detail

Indication:

Audible & Visual

Levels:

High, Medium, Low and Information Messages

Volume:

User Adjustable, 50 to 85 dba, or OFF

Silence:

Permanent or 2 minutes timed hold

10.1.1.2. User Interface

10.1.1.2.1. Monitor

10.1.1.2.2. Tablet

10.1.1.2.3. PODS

10.1.1.2.4. Base Station

10.1.1.3. Application Features

10.1.1.3.1 Trend Reports

10.1.1.3.2 Alarms

10-3

Technical Parameters

Technical Detail

IEC:

60601-1, 60601-1-2, 60601-1-8, 60601-2-27, 60601-2-49, 80601-2-30,

80601-2-55, 80601-2-56, 80601-2-61

Med Device Directive:

93/42/EEC, 2007/47/EEC

Defibrillator Protection:

Up to 5 KV

Defibrillator Recovery

Time:

During a defibrillation procedure, the ECG waveform will saturate then

recover in less than 5 seconds

Technical Parameters

Technical Detail

3880 Monitor:

23 cm (8.8 inches)

3885-T Remote Tablet:

19.6 cm (7.7 inches)

3885-B Base Station:

18.8 cm (7.4 inches)

3881/3882 Wireless

9.5 cm (3.8 inches)

3886 Multi-Gas Unit

8 cm (3.13 inches)

Technical Parameters

Technical Detail

3880 Monitor:

29 cm (11.4 inches)

3885-T Remote Tablet:

26.7 cm (10.5 inches)

3885-B Base Station:

38 cm (15 inches)

3881/3882 Wireless

PODS:

2.0 cm (0.8 inches)

3886 Multi-Gas Unit

14.7 cm (5.8 inches)

Technical Parameters

Technical Detail

3880 Monitor:

12.7 cm (5 inches)

3885-T Remote Tablet:

4.5 cm (1.8 inches)

3885-B Base Station:

12 cm (4.8 inches)

3881/3882 Wireless

PODS:

5.7 cm (2.3 inches)

3886 Multi-Gas Unit

10.2 cm (4.1 inches)

Technical Parameters

Technical Detail

3880 Monitor:

4 kg (8.9 lbs)

3885-T Remote Tablet:

1.6 kg (3.6 lbs)

3885-B Base Station:

2.1 kg (4.6 lbs)

3881/3882 Wireless

PODS:

73 g (0.16 lbs) (without sensors/leads)

3886 Multi-Gas Unit

1.04 kg (2.3 lbs)

PODS:

10.1.1.4. Safety Standards

10.1.1.5. Physical Specifications

10.1.1.5.1. Height

10.1.1.5.2.

Width

10.1.1.5.3. Depth

10.1.1.5.4. Weight

10-4

10.1.1.6. Electrical Specifications

Technical Parameters

Technical Detail

Power

Requirements

Voltage Range:

(All 3880 system components)

85 - 264 VAC

Frequency Range:

50 - 60 Hz

Max Consumption:

3885-B Base Station

< 65 VA during charging, 388 5 -B

3886 Multi-Gas Unit

< 10 VA

Battery Capacity

3880 Monitor:

14.8 V at 6 Ah Lithium Polymer

3885-T Remote Tablet:

7.4 V at 6 Ah Lithium Polymer

3881/3882 W ireless PODS:

3.7 V at 1200 mAh Lithium Polymer

Battery Operation

Time

3880 Monitor:

>8 hours with NIBP readings every 5 minutes

3885-T Remote Tablet:

>10 hours

3881/3882 Wireless PODS:

>12 hours

Battery Charge Time

3880 Monitor:

< 5 hours to 90% capacity

3885-T Remote Tablet:

< 5 hours to 90% capacity

3881/3882 Wireless PODS:

< 3 hours to 90% capacity

Power On

Boot Time:

< 4 seconds

Technical Parameters

Technical Detail

Operating

All 3880 system components

Temperature Range:

+10○ to + 40○ C (+50○ to + 104○ F)

Humidity Range:

5% to 85% RH, non-condensing

Altitude Range:

0 – 5000 meters, Pressure: 1010hPa – 540hPa

Storage

All 3880 system components

Temperature Range:

-20○ to + 50○ C (-4○ to + 122○ F)

Humidity Range:

5% to 95% RH, non-condensing

Altitude Range:

0 – 5000 meters, Pressure 1010hPa – 540hPa

Technical Parameters

Technical Detail

3880 Monitor

MR Environment Safety:

MRI Conditional

Magnetic Field Limit:

30,000 Gauss

MRI System:

0.5 to 3.0 Tesla MRI Systems

3881/3882 Wireless PODS

MR Environment Safety:

MRI Conditional

SAR:

≤4 W/kg whole body average SAR

Magnetic Field Limit:

30,000 Gauss

MRI System:

0.5 to 3.0 Tesla MRI Systems

3885-T Remote Tablet

MR Environment Safety:

MRI Conditional

Magnetic Field Limit:

15,000 Gauss

3885-B Base Station

MR Environment Safety:

MRI Unsafe

Accessories

MR Environment Safety:

MRI Safe as listed in Section 9.1-9.7

3886 Multi-Gas Unit

Magnetic Field Limit:

MR conditional 600 gauss

3880 Monitor

< 40 VA during charging

10.1.1.7. Environmental Specifications

10.1.1.8. MRI Conditions

10-5

10.1.1.9. Recorder

Technical Parameters

Technical Detail

Technique:

Thermal line recorder at 3885-B Base Station

Data Type:

Single or Dual Waveform; Tabular

Paper Speed:

12.5 or 25mm/sec continuous

Technical Parameters

Technical Detail

Technique:

Cardiac or Peripheral

Digital Pulses:

3.3 p-p signal with a pulse duration of 10ms ± 3ms

Technical Parameters

Technical Detail

Lead Set Configuration:

3 and 5 lead

Lead Color:

AAMI/AHA and IEC

Lead Configurations:

I, II, III, V, AVF, AVR, AVL

Lead Fail:

Passive, sensing signal imbalance

Input Impedance:

> 2.5MΩ (according to IEC 60601‐2‐27, 50.102.3)

Electrode Contact

≤ 20K ohms @ 10 Hz

Heart Rate:

30 - 250 bpm

Heart Rate Accuracy:

± 1% or ± 5 BPM, whichever is greater

Heart Rate Resolution:

1 beat per minute (BPM)

Heart Rate T-Wave

1.3 mV with a 1mV QRS amplitude

Cardiotach Sensitivity:

200 μV minimum

Cardiotach Bandwidth:

0.5 - 40 Hz

Heart Rate (HR)

Averaging Method:

Five point Mean filter

Heart Rate Meter

Irregular Rhythm:

A1: Ventricular bigeminy: 40 BPM

A4: Bidirectional systoles 90 – 110 BPM

Response Time of Heart

in Heart Rate:

HR change from 80 to 120 BPM: 5 sec

Time to Alarm for

B1 ‐ Vent Tachycardia

Gain 2.0 (9.7, 12.6, 8.9, 11.8, 8.3) Average: 4.01 seconds

10.1.1.10. Gating

10.1.1.11. Vital Signs

10.1.1.11.1. ECG

Impedance:

Rejection:

Accuracy and Response

to

Rate Meter to Change

Tachycardia:

A2: Slow alternating ventricular bigeminy: 30 BPM

A3: Rapid alternating ventricular bigeminy: 59 BPM

HR change from 80 to 40 BPM: 9 sec

1 mVpp, 206 BPM:

Gain 0.5 (12.03, 11.04, 14.1, 11.8, 11.4) Average: 6.25 sec (The

monitoring system may temporarily exit the alarm condition

during the arrhythmia waveform duration.)

Gain 1.0 (11.9, 11.6, 9.2, 9.6, 10.9) Average: 2.59 seconds

Gain 2.0 (8.8, 9.1, 10.3, 9.4, 12.1) Average: 3.93 seconds

B2 ‐ Vent Tachycardia

2 mVpp, 195 BPM:

Gain 0.5 (9.0, 10.4, 12.3, 8.1, 10.4) Average: 3.99 seconds

Gain 1.0 (8.4, 7.7, 12.5, 7.7, 8.3) Average: 1.82 seconds

10-6

10.1.1.11.2. SpO2

Technical Parameters

Technical Detail

Technique:

Masimo SET®

Saturation Range:

1% - 100%

Saturation Accuracy:

± 2.1% at 70% - 99% (full scale)

< 70% oxygen saturation is unspecified

Saturation Resolution:

1%

Pulse Rate Range:

30 - 240 ppm

Pulse Rate Accuracy:

± 3 ppm

Pulse Rate Resolution:

1 pulse per minute (PPM)

Wavelength Range:

660 nm / 905 nm Note: Wavelength range can be especially useful to

clinicians

Emitted Light Energy

< 1.2mW maximum average at 905nm

Calibration Range:

70 - 100%

Minimum sensor Bend

Radius

4 cm (1.6 inches)

SpO2 averaging time:

6 seconds

Technical Parameters

Technical Detail

Technique:

Oscillometric

Modes:

Manual, Automatic and STAT

Measurement Time:

< 60 seconds typical; standard adult cuff

Systolic Measureable

Adult/Pediatric: 40 - 270 mmHg (5.3 - 36 kPa)

Diastolic Measureable

Adult/Pediatric: 25 - 245 mmHg (3.3 - 32 kPa)

Mean Measureable

Adult/Pediatric: 30 - 255 mmHg (4 - 34 kPa)

Pressure Accuracy:

Max. Std. Deviation: <8 mmHg (1.1 kPa)

Pressure Resolution:

1 mmHg (0.1 kPa)

Pulse Rate Range:

30-240 ppm

Pulse Rate Accuracy:

± 1% or ± 5 BPM, whichever is greater

Max Cuff Inflation

Adult/Pediatric: 270 mmHg

Pressure Transducer

0 - 300 mmHg (0 - 40 kPa)

Transducer Accuracy:

The greater of ± 2 mmHg or 2% of the reading

Overpressure Protection:

Adult: 300 mmHg (40 kPa) < 2 seconds

Initial Pressure:

Adult: 165 mmHg (22 kPa)

STAT Mode:

3 consecutive NIBP Readings

Minimum Time Between

Auto: 30 seconds (non STAT)

10.1.1.11.3. NIBP

Pressure Range:

Pressure Range:

Pressure Range:

Pressure:

Range:

Neonatal: 30 - 130 mmHg (4 - 17 kPa)

Neonatal: 10 - 100 mmHg (1.3 - 13 kPa)

Neonatal: 15 - 120 mmHg (2 - 16 kPa)

Max. Mean Error: within ± 5mmHg (±0.7 kPa)

Neonatal: 140 mmHg

Pediatric: 300 mmHg (40 kPa) < 2 seconds

Neonatal: 150 mmHg (20 kPa) < 2 seconds

Pediatric: 165 mmHg (22 kPa)

Neonatal: 100 mmHg (13.3 kPa)

All initial pressures ± 15 mmHg (2 kPa)

Readings:

Manual: 5 seconds

10-7

10.1.1.11.4. CO2 Only, Internal System

Technical Parameters

Technical Detail

Technique:

Sidestream, Non-dispersive infrared absorption technique

Range:

0-15% CO2, or partial pressures at STP: 0-115 mmHg, or 0 - 16 kPa,

Accuracy:

± 0.43 Vol% +8%, or ± 3.75 mmHg +8%, or ±0.5kPa +8%

Resolution:

1 mmHg, 0.1%, 0.1 kPa

Warmup Ti me:

< 10 seconds (concentrations reported and full accuracy)

Response Time:

< 5 seconds for sample, 150mS waveform response

Flow Rate:

80 ± 20 ml/min

Calibration:

Automatic

Technical Parameters

Technical Detail

Source:

Capnogram

Range:

3 - 120 breaths per minute

Accuracy:

1 bpm

Resolution:

1 bpm

Technical Parameters

Technical Detail

Technique:

Sidestream, Non-dispersive infrared (NDIR) absorption

technique

Warmup Ti me:

< 20 seconds (concentrations reported and full accuracy)

Response Time:

≤ 5 seconds