IQ Design Joule Installation & Operating Instructions Manual

Multifuel Stove

Installation & Operating

Instructions for the Joule Inset Model

Important

This product MUST be installed by a suitably qualied installer .

Combustion fumes entering a home from an incorrectly installed or operated appliance

are DANGEROUS. For safety reasons, it is essential that the stove is correctly

installed and operated and that the chimney is regularly swept.

IQ Design cannot accept responsibility for any fault or consequential

problems arising through incorrect installation or operation

Date of installation: Serial No.

IQ Design Limited,

Whilst in operation, this appliance will be hot. For the safety and the protection of the

young, elderly and infirm, it is recommended that a suitable guard be placed around the

stove.

This appliance is NOT an incinerator - DO NOT BURN RUBBISH IN IT!

Only burn wood, processed peat or smokeless mineral fuels. DO NOT Burn Bituminous

Coal or Petroleum Coke. Use of incorrect fuels will invalidate the guarantee.

Please read this handbook prior to installation and operation.

Please ensure that the commissioning sheet on Page 15 is completed by your

installer and returned for registration and guarantee records.

Conditional on correct installation and use, Joule Stoves are Guaranteed for a period of two years

from date of purchase. An additional three year warranty is available subject to the form at the back

of this hand book being fully completed and returned to IQ Design.

The Guarantee and Warranty does not cover consumable spare parts. This Guarantee does not

aect your statutory rights.

Unit 20, Millennium Business Park,

Cappagh Road, Dublin 11, Ireland.

Phone: +353 1 8649004 | Email: info@iqdesign.ie

Contents

1. List of Components 3

2. Component Identification and Assembly 3

3. General Information and Instructions 4

Warnings and important safety information

Chimney Sweeping

Ventilation - Combustion Air

Health & Safety

Maintenance

4 Installation Information 5 & 6

Fixing and Sealing

Flue & Chimney

Flue Draught Requirement

Connection to the Chimney

Clearances from Combustibles

Hearths

Commissioning & Handover

Useful Information

5. Operating Instructions 7 & 8

Air controls

Multifuel Grate

Door

Ash Pan

Baffle

Fuels

Notes on Wood Burning

Lighting the Stove

Re-fuelling

Shutting Down

6. Safety Notes 9

7. Carbon Monoxide Information 10

8. Wood as a Fuel 11

9. Chimney Draught 12

10. Spare Parts & Accessories 13

11. Commissioning Check list & Guarantee Registration 14

Section Page No.

Page 2

1. List of Components

Assembled Stove

Ash Pan Handle

Ash Pan

Ash Pan

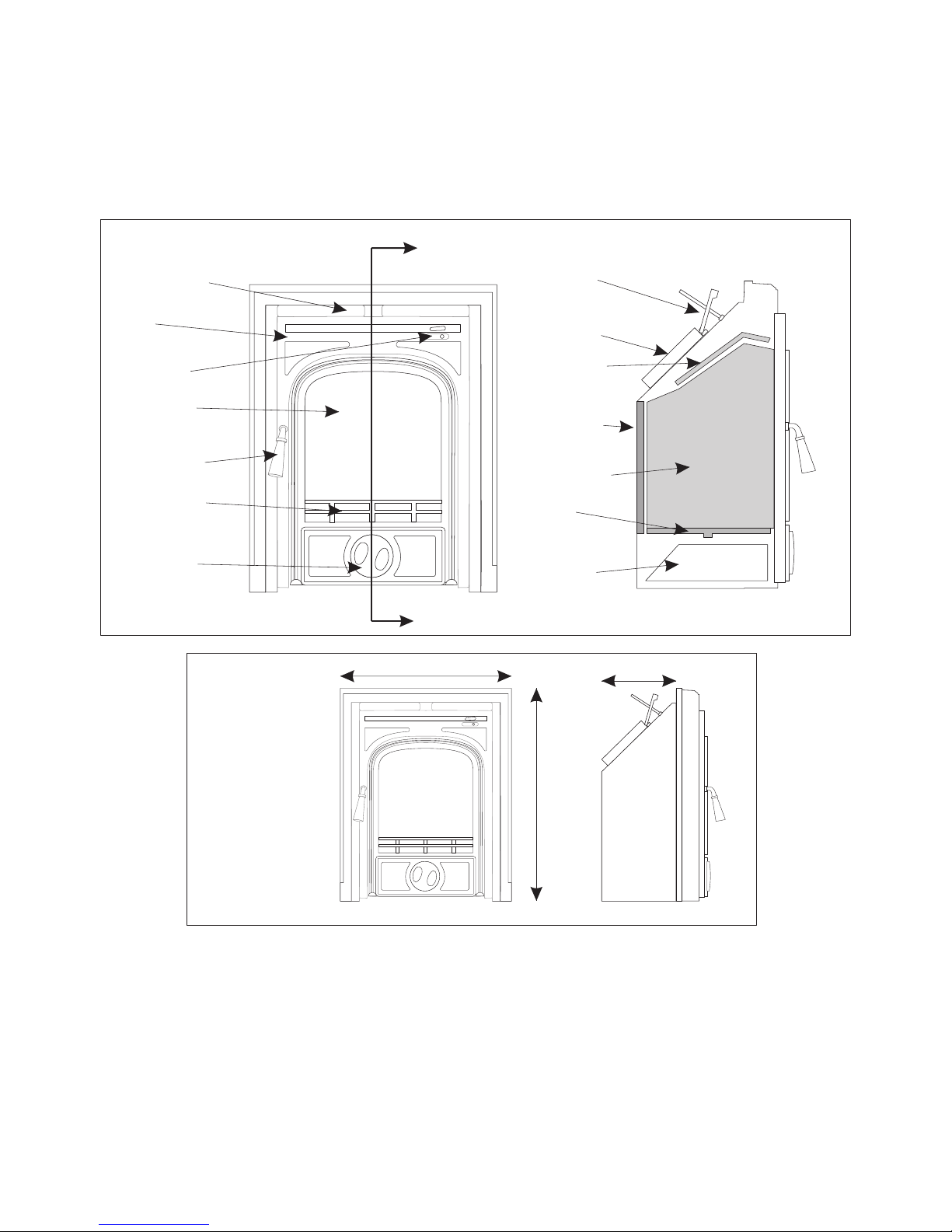

2. Component Identification and Assembly

The Joule Inset Stove is packed in a re-useable wooden box which may be suitable as a

fuel store. Carefully remove the Stove from the box and check contents carefully.

The Stove is supplied in a fully assembled state. The stove features a collar on the flue outlet. If

any connection is made to the collar, it should be fitted so that the connection sits INSIDE the

collar so as to ensure that any by-products of combustion can only enter, and not fall around the

outside of the appliance.

Some of the components identified in the drawing above are considered “consumables”, and as

such will require replacement from time to time. These would include: Glass, Ash Pan, Grate,

Baffle Plate and Back and Side Plates.

Page 3

See page 13 for a

comprehensive list of

spare parts & accessories

Assembly & Controls

Grate

Back Plate

Side Plates

Baffle Plate

Fixing &

Securing

Bracket

Flue Collar

Secondary

Air Control

Door

Fuel Catcher

or Fret

Door Handle

Primary Air

Control

A

A

Section A - A

Door Glass

Convected Air

Outlet

Stove Operating Glove

Adhesive Backed Fibre Rope

Manual / Hand Book

484mm

600mm

385mm

Stove

Dimensions

Page 4

3. General Information and Instructions

These instructions are intended to provide for a safe and satisfactory installation of the

Stove. In all cases the installation must comply with current local regulations including

Building Regulations, Local Authority Bye Laws and other specifications or regulations

including Ireland, UK or EU Standards. Approved Document J is particularly important for

England and Wales and can be downloaded for no cost at:

http://www.planningportal.gov.uk/england/professionals/en/4000000000503.html

Important Chimney Warning

This stove must not be installed into a chimney that serves any other heating appliance.

Extractor Fan Warning

There must not be an extractor fan fitted in the same room as the Stove. As extractor fans create

a negative pressure in any room; it would have the effect of sucking fumes down the chimney and

into the room.

Cleaning and Chimney Sweeping

The appliance, flue & chimney must be regularly cleaned and checked internally and

externally whilst the stove is in use and especially after a period of disuse (e.g. after

summer).

Lift down the baffle at least weekly to check for build up of soot, fly ash or debris on the top. Also

check that the flue spigot and connector is fully clear while the Baffle is removed. The chimney

and flue connector must be swept at least annually, more often when used with sooty fuels or

damp wood. Any loose, broken or leaking joints or flue ways MUST be repaired immediately.

Ventilation

ALL combustion processes need an air supply and whilst the requirement for combustion air can

be met within the dictates of Building Regulations, it should not be assumed that because this

appliance is rated at just 5kW, no combustion air opening requirements are needed. Adequate

ventilation is ESSENTIAL for the safe and efficient operation of any solid fuel or wood burning

appliance and the initial installation process of checking operation and draught readings may well

result in the need for the provision of a permanent combustion air opening into the room.

Ventilation in the form of fixed non-adjustable and non-mechanical grills should be provided.

Keep all ventilation clear and free of blockage.

Health And Safety Precautions

Fire Cement

Some types of fire cement are caustic and should not be allowed to come into contact with the

skin. In case of skin contact, wash immediately with plenty of water. We recommend the use of

SmartCare FlueSeal.

Asbestos

This Stove contains no asbestos. If there is a possibility of disturbing any asbestos in the course

of installation then please seek specialist guidance and use appropriate protective equipment.

Maintenance

Glass: Despite the advanced air wash system provided, the glass will still occasionally need to be

cleaned. Frequency will depend on the fuel quality and rate of burning. Never clean glass when

the Stove is hot. We recommend the use of SmartCare Stove and Boiler Glass Cleaner.

Outer body: The outer body simply needs to be dusted from time to time. DO NOT use any kind of

furniture polish or cleaning agent. For touching up purposes, we recommend the use of

SmartCare Heat Resistant Paint.

Inner firebox: Brush or vacuum the inside of the firebox from time to time and check the integrity

of the cast iron firebox components. If replacement items become needed, contact IQDesign.

Page 5

4. Installation Information

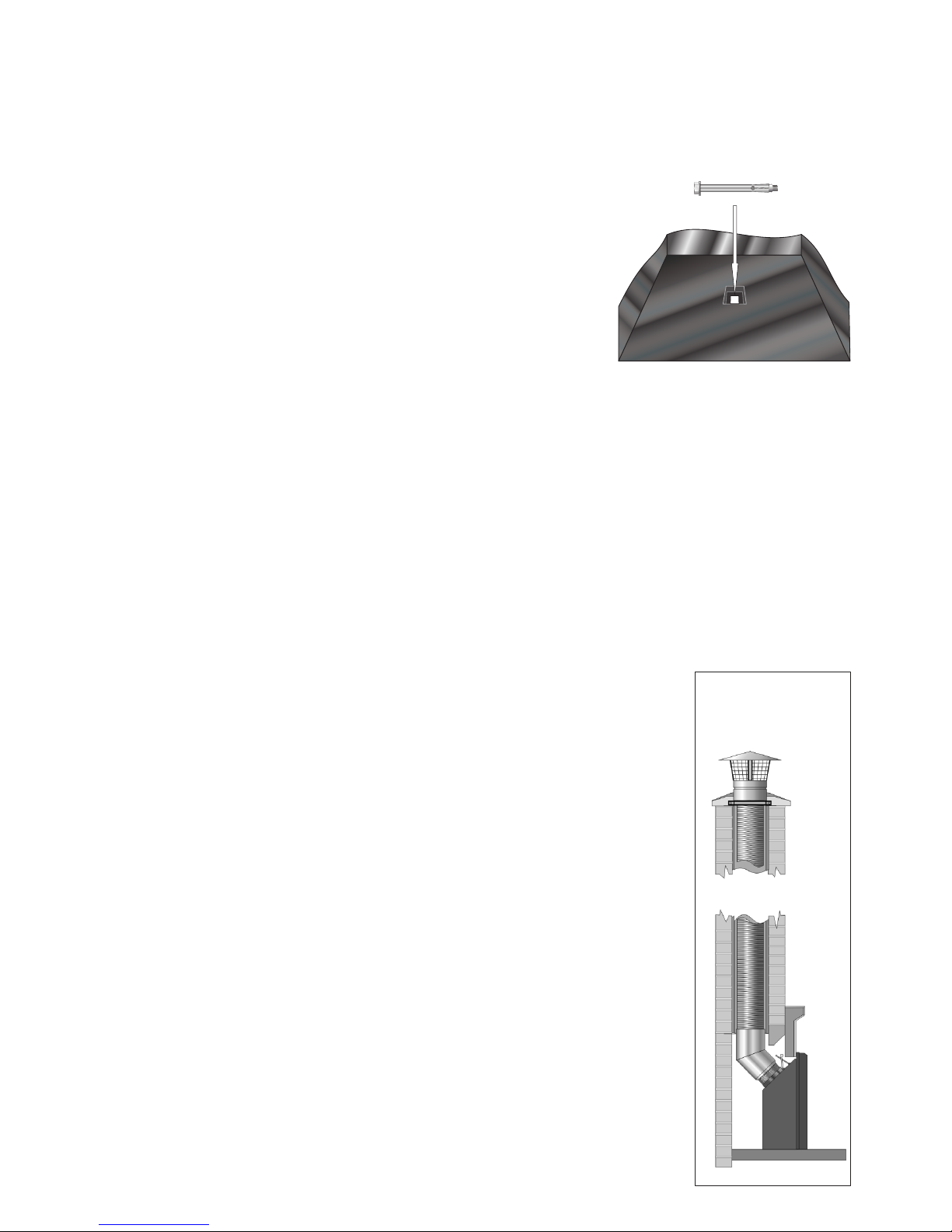

Flue and Chimney

The chimney height and the position of the chimney terminal should conform to Building

Regulations. Minimum chimney height is 4.5m. Check that the chimney is in good condition, dry,

free from cracks and obstructions. Whilst the flue pipe connecting collar on the appliance accepts

a 5" (125mm) flue pipe, the diameter of the chimney flue should never be less than 150mm and

not more than 200mm. If any of these requirements are not met, the chimney should be lined

using a suitable method. In any case we recommend that the chimney is lined with a 6" (150mm)

twin ply stainless steel flexible liner which will ensure that the chimney will heat up quickly and

provide the optimum draught for good appliance operation. It is imperative to use a robust

stainless steel angled connecting adaptor between the appliance and the

chimney liner. Where the chimney has previously served an open fire, it

must be thoroughly swept before connection to the Stove and the

installation of a chimney liner.

The retention of a high flue gas temperature is more beneficial for some

combustion equipment than others. Heating appliances burning solid fuel

or wood produce flue gas temperature levels depending on combustion

rate, which are in turn dictated by draught.

Flue Draught Requirement

A flue draught of minimum 1.2mm to a maximum 2.5mm water gauge (12

to 25 Pascals) is required for satisfactory appliance performance.

Connection to the Chimney

This appliance must not be used in a shared flue. It is essential that all

connections between the Stove, the adaptor and flue liner are sealed with

fire cement, (FlueSeal recommended). The chimney must be accessible

for cleaning which can normally be achieved through the appliance when

the Baffle Plate is removed.

It will be noticed that the illustration to the right does not feature a fire back

in the builders opening. It might be possible on occasion to use the

existing opening with a fire back in situ; individual circumstances will

dictate the actual installation requirements.

Typical

Application

Fixing and Sealing

1. Before offering the appliance into the fireplace opening, apply the self adhesive ceramic rope

to the rear face of the three surfaces of the appliance edges which locate against the fire

surround.

2. Locate the appliance in the builder’s opening so that the

surround seal is a good tight fit. Use the concrete anchor bolt

supplied to firmly secure the Stove to the hearth.

3. It will normally be necessary to provide an opening in the

chimney breast over the surround in order to locate and fit the

appliance flue adaptor and subsequently the flue liner, lowered

from above. Circumstances will vary, and in any event it is

important that all flue joints are adequately made with fire

cement.

4. An optional fixing and securing bracket is located on top of the appliance which can be

accessed from above and be used to provided additional fixing security if required. It is intended

to bear against the back of the fire surround and no drilling or additional fixings are required.

Loading...

Loading...