IQAir CleanZone 3020 series, CleanZone 3030 series Installation Manual & Owner's Manual

Installation Guide & Owner’s Manual

CleanZone® 3020 & 3030 Series

for HVAC Integration

Swiss Made

HB_CZ_0407_208 04 01 00

Important Safety

Instructions

IQAir welcomes any suggestions

you may have concerning this

manual and/or the product, or

ways to better serve you. Please

contact us at:

• TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE

THE FOLLOWING:

• This manual covers use in residential installations only. Contact IQAir for information on commercial and other uses.

• Installations must be done in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

• The unit is not designed to provide combustion and/or dilution air for fuel-burning

appliances.

• Do not install in a cooking area or connect directly to an appliance.

IQAir North America, Inc.

CleanZone Assistance

10440 Ontiveros Place

Santa Fe Springs, CA 90670

Email: feedback@iqair.com

WARNING:

The installation of the CleanZone

air cleaning system needs to be

performed by a qualified HVAC

contractor.

WARNING:

This installation guide is designed

to assist in the installation. Since

no installation is alike,the installer

needs to take into account all

factors pertaining to the installation.

• Always disconnect the power cord from electrical outlet before replacing filters,

adding or removing parts and before cleaning.

• When cutting or drilling into wall or ceiling, do not damage electrical wiring or

other hidden utilities.

• This unit must be grounded.The power supply cord has a 3-prong grounding plug

for your personal safety. It must be plugged into a mating 3-prong grounding

receptacle,grounded in accordancewith the national electricalcode and localcodes

and ordinances.Do not remove the ground prong. Do not use an extension cord.

• This unit must be installed in a weatherized location out of direct sunlight and

protected by the elements.

• When the ambient temperature for the unit location is below freezing

(32°F – 0°C), the unit must run continuously to prevent condensation.

• Do not attempt to recover in any way the exhaust air from a dryer or a range hood.

This would cause clogging of the filters and constitute a fire hazard. This will also

void the warranty.

• Do not operate this appliance if it has a damaged cord or plug,if the motor fan fails

to rotate, if it is not working properly, if it has been dropped or damaged. Contact

IQAir for repair or replacement part service.

• Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer at the address or telephone number listed in

this document.

• Do not use this appliance in areas with very high concentrations of dusts or

powder to prevent the danger of dust explosions.

• Do not use this appliance in explosive areas.

• Only use original IQAir® filters and accessories.

• Do not run any air ducts directly above or closer than 2 ft (0.6 m) to any furnace or

its supply plenum, boiler or other heat producing appliance.

• The ductwork must be be installed in compliance with all local and national codes

that are applicable.

• Keep the power cord away from heated surfaces.

• If the unit is used during construction or renovation, regularly check filters for

prematurely clogged filters.

• Save these instructions for future reference.

2

Table of Contents

Important Safety Instructions 2

Modular Housing Concept 4

Tool & Materials Checklist 4

Planning Your Installation 5

Chapter 1 Installation Diagrams 6

Model 3030 6

Model 3020 7

Chapter 2 System Components 8

Model 3030 8

Model 3020 10

How the System Works 12

Chapter 3 CleanZone Assembly 14

Unpacking the Modules 14

Preparing the HyperHEPA Module 15

Connecting the HyperHEPA and Motor Module 16

Placing the HyperHEPA Filter 17

Finishing the Module Assembly 17

Attachment of the Air Inlet and Outlet Panels 18

Chapter 4 Electrical Connections 19

Power Cord 19

EAC TerminalWire 19

Control Panel 19

Chapter 5 Mounting of the Control Panel 20

Mounting for Wall Surface Wiring 20

Mounting for Through Wall Wiring 21

Chapter 6 Control Panel Functions 22

Description of the Control Panel Elements 22

Menu Items 23

Filter Life Monitor 24

New Filter Reset 25

Initial Installer Set-Up of the Control Panel 26

Setting the System Airflow 27

Filter Configuration 28

Password Menu 30

Chapter 7 Replacing Filters 31

Replacing the Micro-Particle Filters 32

Replacing the HyperHEPA Filter 33

New Filter Reset 34

3

Modular Housing

Concept

The IQAir CleanZone air cleaning system is based on a modular architecture that allows

for easy system customization and regular non-palletized shipment.

Each CleanZone system is made up of a motor module and at least one filter module.

Each of these modules is supplied in a separate transport box.

Tool & Materials

Checklist

To assemble the CleanZone system components the following tools are necessary:

Hand tools:

Torx-30 Screwdriver

4mm Hex Ballpoint Screwdriver (supplied in CleanZone Basic Tool Kit)

Crimping tool for quick connect terminals

PowerTools (optional):

Cordless Driver-Drill

Torx-30 Ballpoint Power Bit (supplied in CleanZone Basic Tool Kit)

Torx-30 Power Bit (supplied in CleanZone Basic Tool Kit)

Materials Checklist

The CleanZone components are shipped with all necessary materials to be assembled.The

following list is designed as guide to the other materials that may be required for the installation:

Ducting

• Flex duct (18” recommended) or other ducting from return grille to CleanZone

• Return plenums

• T-wyes and elbows

• Return platform

• Miscellaneous items: cable ties,sheet metal screws, duct mastic,approved duct

tape, plumbers tape

• Insulation for T-wyes, elbows and return plenums when installed in unconditioned spaces

Electrical

• Two

• Rigid wire to fish control panel wire through wall Mounting

• Chains, straps, threaded bars

1

⁄4-in female quick connect terminals (for 16–14 wire) for the EAC IN wire

connection to the air handling control board.

4

Planning your

Installation

When planning the installation of

the CleanZone® system, keep the

following considerations in mind:

Installation Principle

Single speed 2-3 ton HVAC systems

The CleanZone system is designed to go inline to the residential HVAC return duct in

installations up to airflow rates of 1200 cfm. If the airflow is lower than 1000 cfm, the

CleanZone fan speed should be reduced also. The CleanZone is designed to replace all

existing furnace filters or similar.

Single speed 4-5 ton HVAC systems

In installations, with airflow rates of over 1200 cfm, a filtered bypass (additional Perfect 16)

needs to be installed to make up for the additional HVAC system airflow.The CleanZone is

designed to replace all existing furnace filters or similar.

Multiple speed 2-3 ton HVAC systems

In installations with 2-3 ton multiple speed air handling systems,the CleanZone is designed

to go inline to the residential HVAC return duct. Integration of a excess air bypass duct into

the duct design is necessary to allow excess air to be circulated back to the air cleaning

system on speed setting of less than 1000 cfm. If the maximum airflow of the HVAC

system is lower than 1000 cfm, the CleanZone fan speed should be reduced also.

Multiple speed 4-5 ton HVAC systems

In installations, with airflow rates of over 1200 cfm, a filtered bypass needs to be installed

to make up for the system airflow and the maximum of 1200 cfm supplied by the

CleanZone air cleaning system. This filtered bypass will also serve as a excess air bypass

duct, as it allows recirculation of excess air when HVAC airflow capacity is reduced to

less than 1000 cfm.

LOCATION

• The CleanZone should be located on the return side (upstream) of the air handling

system. Please note that locating the CleanZone on the supply side (down stream)

may cause the motor and/or electronics in the CleanZone to fail due to overheating

or condensation.

• For best performance, the CleanZone should be connected as close to the air

handling system as possible. Duct runs to and from the CleanZone should be held

as short as possible.

• Choose a location that is readily accessible for checking and replacing the filter(s).Allow

at least 24

• Note that the micro-particle V-bank filters can only be replaced through the square

panels.The HyperHEPA filter can be replaced from all four sides of the unit.

MOUNTING

• If positioned on the floor or a platform, anti-vibration pads (supplied with the unit)

should be used to reduce vibration.

• If the unit is suspended,screws must not penetrate through the cabinet. Make sure that

you have the proper equipment to keep the unit secure.

DUCTING

• Installed duct runs should be as straight as possible.

• If flex duct is used, the preferred duct diameter is 18”.

• For best indoor air quality, fiberglass ductboard or fiberglass lined ducts are not

recommended.

• To reduce the possibility of noise from the CleanZone system travelling down to the

return grille, a minimum return duct length of 6 feet is recommended.

ELECTRICITY

• The CleanZone requires a 120 Vac grounded electrical outlet.If an outlet is not available,

have a qualified electrician install one.

1

⁄2in. (622 mm) clearance in front of the unit.

5

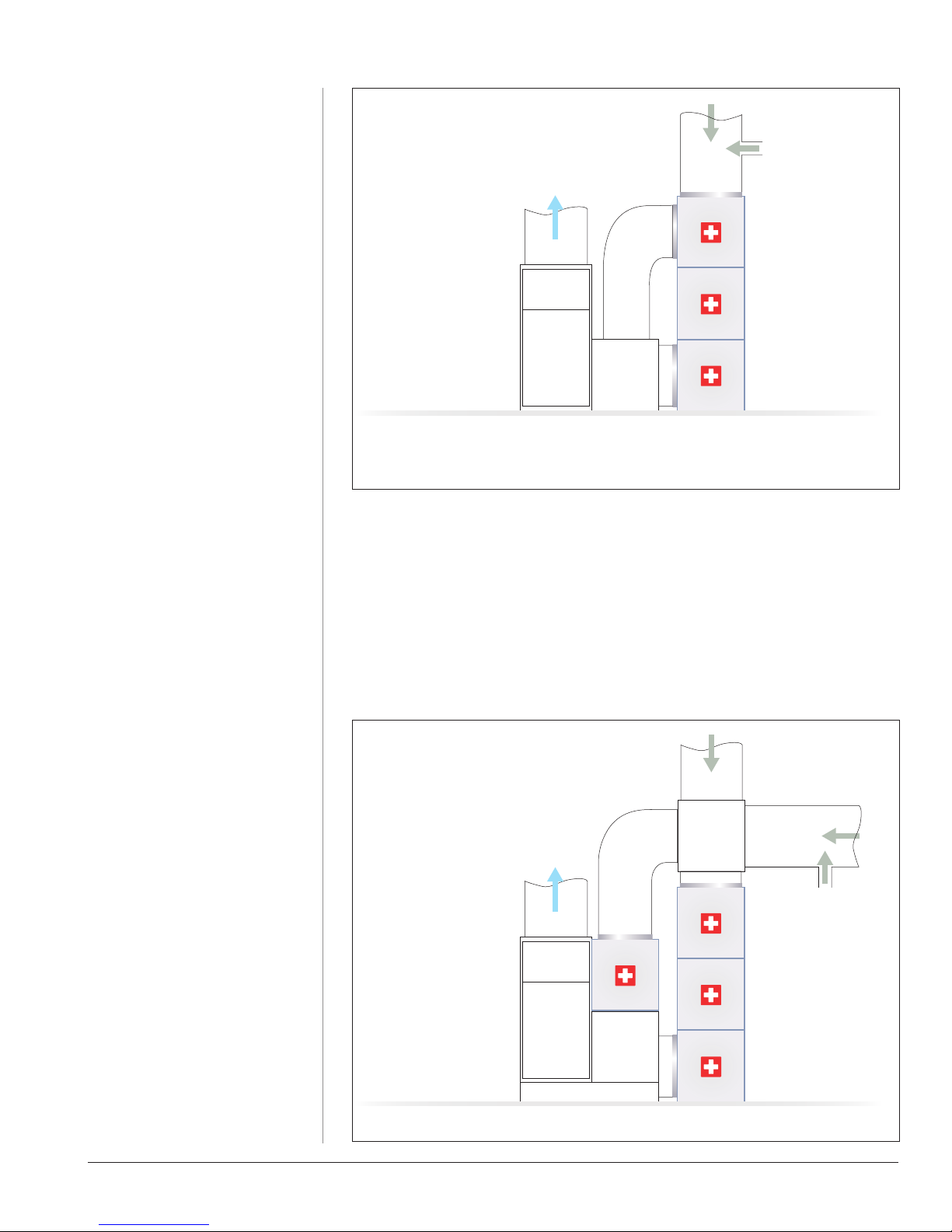

Chapter 1

Supply Duct

Furnace

Fresh Air

(Optional)

Return Plenum

Return Air

Return Air

CleanZone

®

MERV16

Micro-Particle

Filter Module

Return Plenum

CleanZone

®

HyperHEPA

®

Nano-Particle

Filter Module

CleanZone

®

Motor Module

Perfect16

®

ID-Series

Micro-Particle

Filter Module

Supply Duct

Furnace

Fresh Air

(Optional)

Return Plenum

Multiple

Speed

Bypass

Return Air

CleanZone

®

MERV16

Micro-Particle

Filter Module

CleanZone

®

HyperHEPA

®

Nano-Particle

Filter Module

CleanZone

®

Motor Module

Installation Diagrams

MODEL 3030

Preferred Basement Installation

*

2–3 ton installation (side view).

* Multiple Speed Bypass is required for multiple speed HVAC systems.

For 2–3 ton basement

installations the following CleanZone

items are recommended:

1 CleanZone 3030

(incl. 2 connection panels)

1 additional connection panel if

multiple speed bypass connection

For 4–5 ton basement

installations the following combination

is recommended:

1 CleanZone 3030

(incl. 2 connection panels)

1 Perfect 16 ID-2225

(incl. 2 connection panels)

4–5 ton installation with multiple returns (side view)

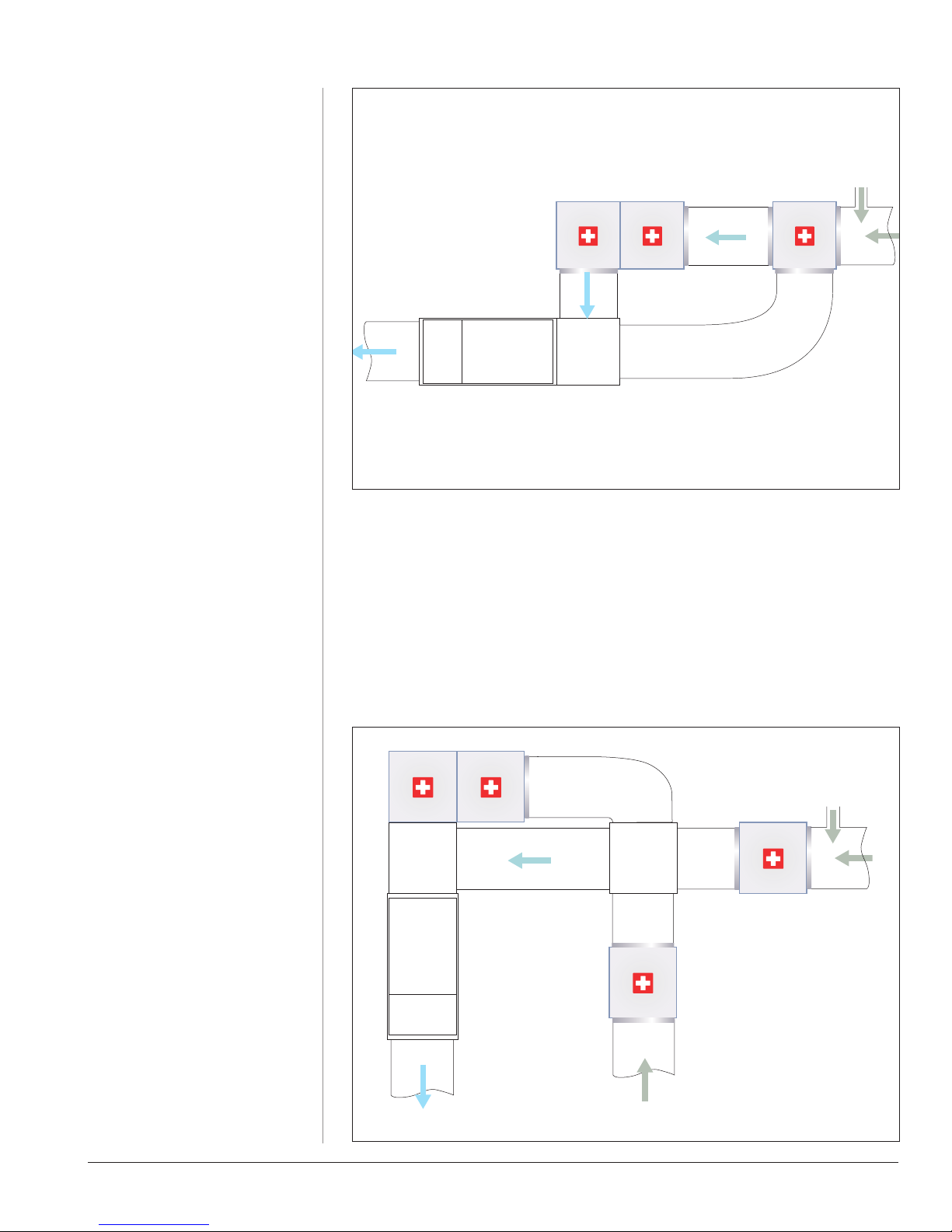

6Chapter 1

Perfect16

®

ID-Series

Micro-Particle

Filter Module

Supply Duct Furnace

Fresh Air

(Optional)

Return Plenum

Return Air

CleanZone

®

HyperHEPA

®

Nano-Particle

Filter Module

CleanZone

®

Motor Module

Multiple

Speed

Bypass

Perfect16

®

ID-Series

Micro-Particle

Filter Module

Supply Duct

Furnace

Fresh Air

(Optional)

Return Plenum

Return Air

Perfect16

®

ID-Series

Micro-Particle

Filter Module

Return Plenum

Return Plenum

CleanZone

®

HyperHEPA

®

Nano-Particle

Filter Module

CleanZone

®

Motor Module

Installation Diagrams

MODEL 3020

Preferred Attic Installation

2–3 ton installation (bird’s eye view).

* Multiple Speed Bypass is required for multiple speed HVAC systems.

For 2–3 ton basement

installations the following combination is

recommended:

1 CleanZone 3020

(incl. 2 connection panels)

1 Perfect 16 ID-2225

(incl. 2 connection panels)

1 additional connection panel if

multiple speed bypass connection

For 4–5 ton basement

installations the following combination

is recommended:

1 CleanZone 3020

(incl. 2 connection panels)

2 Perfect 16 ID-2225

(incl. 2 connection panels each)

4–5 ton single or multiple speed installation (bird’s eye view)

7Chapter 1

Chapter 2

System Components

MODEL 3030

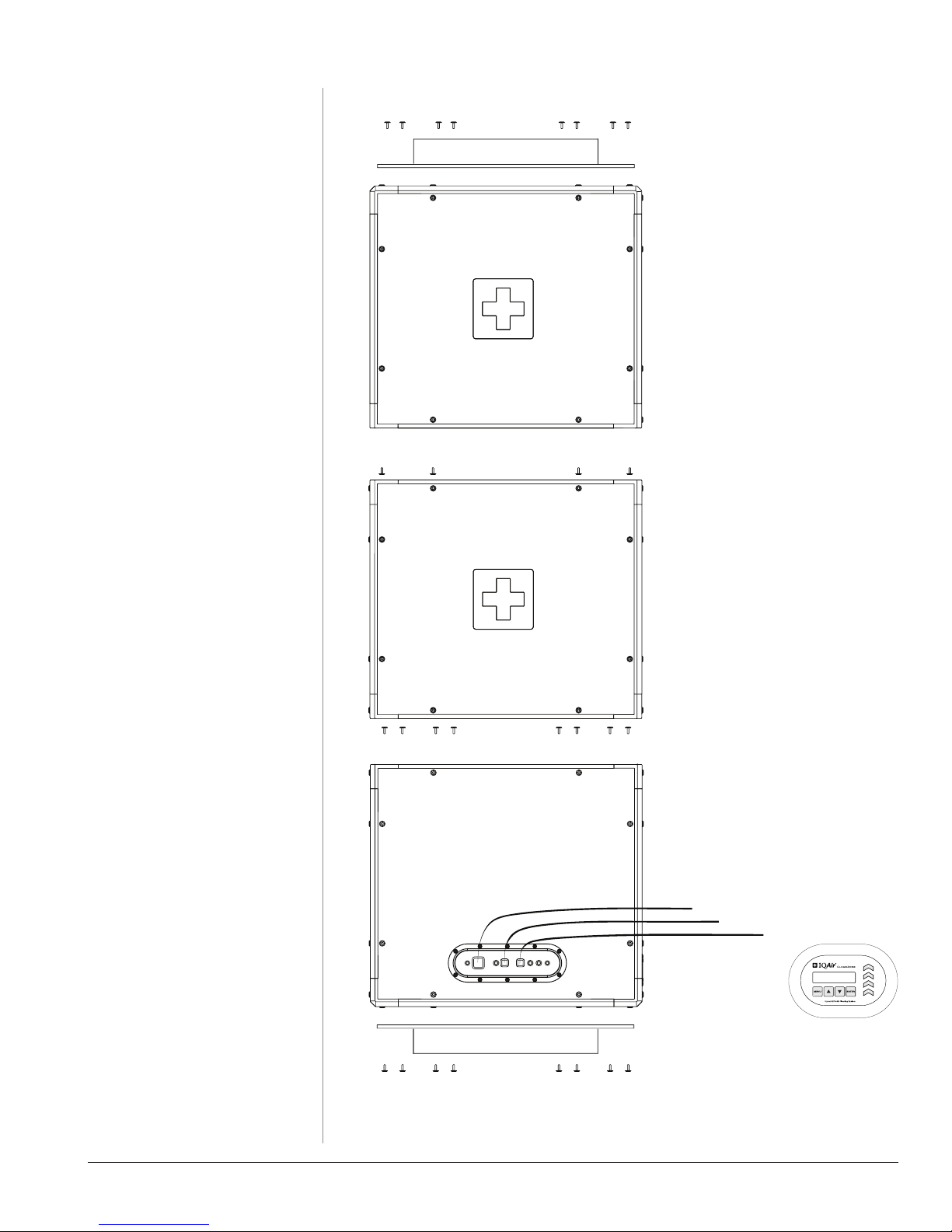

Eight Torx-30 screws

Rectangular Connection Panel

Micro-Particle Filter

End Module (MERV 16)

Four 4 mm Hex screws

HyperHEPA Middle Module

(Nano-Particle Filtration)

Eight 4 mm Hex screws

Motor End Module

Power cord with 3-prong 120 Vac

connector plug with ground

EAC terminal connection cord

Rectangular Connection Panel

Wall control panel cord

Eight Torx-30 screws

8Chapter 2

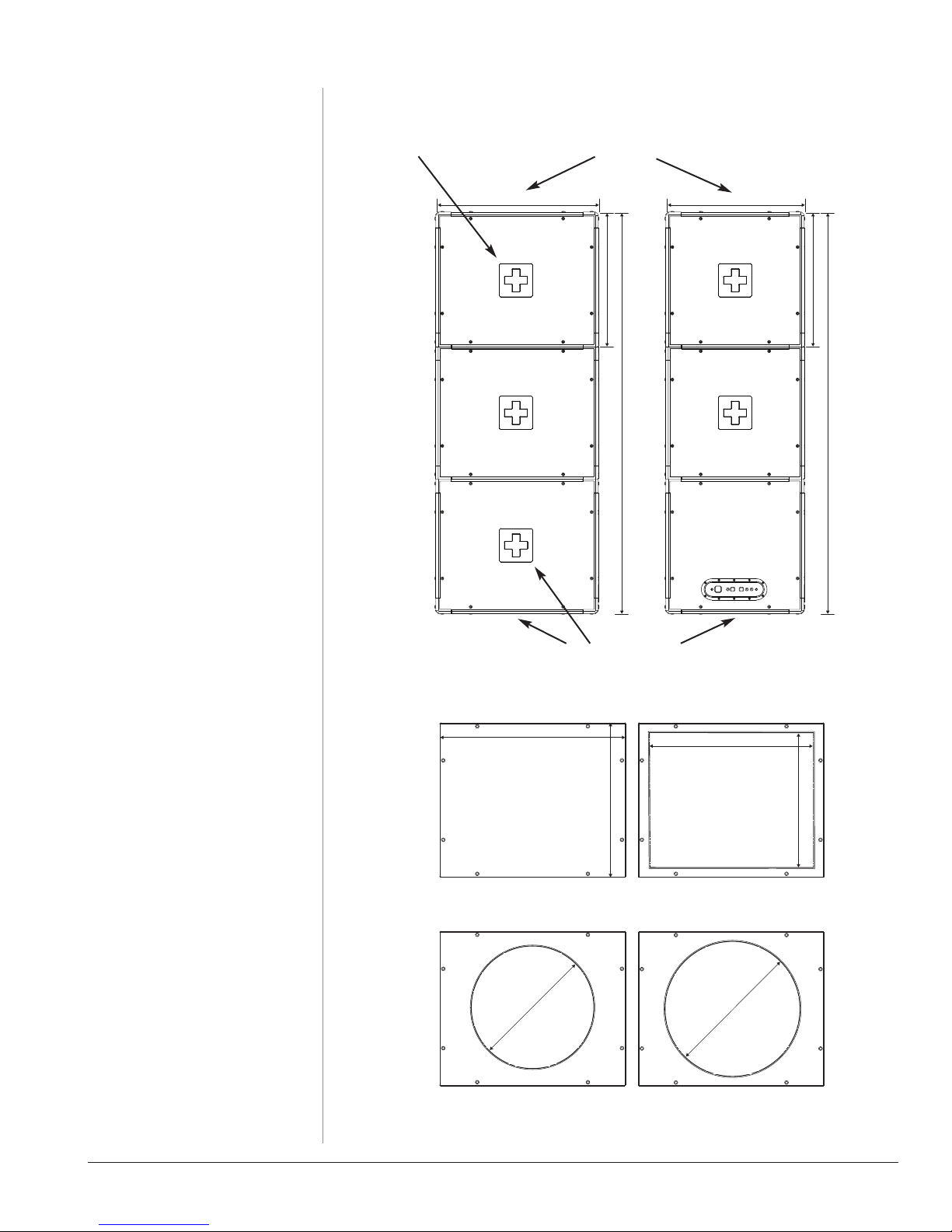

16 (400)

18 (450)

20 (500)

16 (400)

23.69 (601)

19.63 (499)

can be cut and adapted

61.75 (1568)

25.25 (642)

20.75 (527)

61.75 (1568)

21.25 (540)

20.75 (527)

Dimensions

Connection panel for optional

multiple speed bypass

Connection panel for air inlet

attaches to face of system

Connection Panels

Four different connection panels are

available:

• Panel without opening

(to be cut and adapted as neces-

sary by installer)

Order No. 207 30 05 04

• Panel with16” x 20” connection

Order No. 207 30 09 04

• Panel with 16”round connection

Order No. 207 30 06 04

• Panel with 18”round connection

Order No. 207 30 07 04

Connection panel for air outlet attaches

to face or long side of system

All measurements in inch (mm)

9Chapter 2

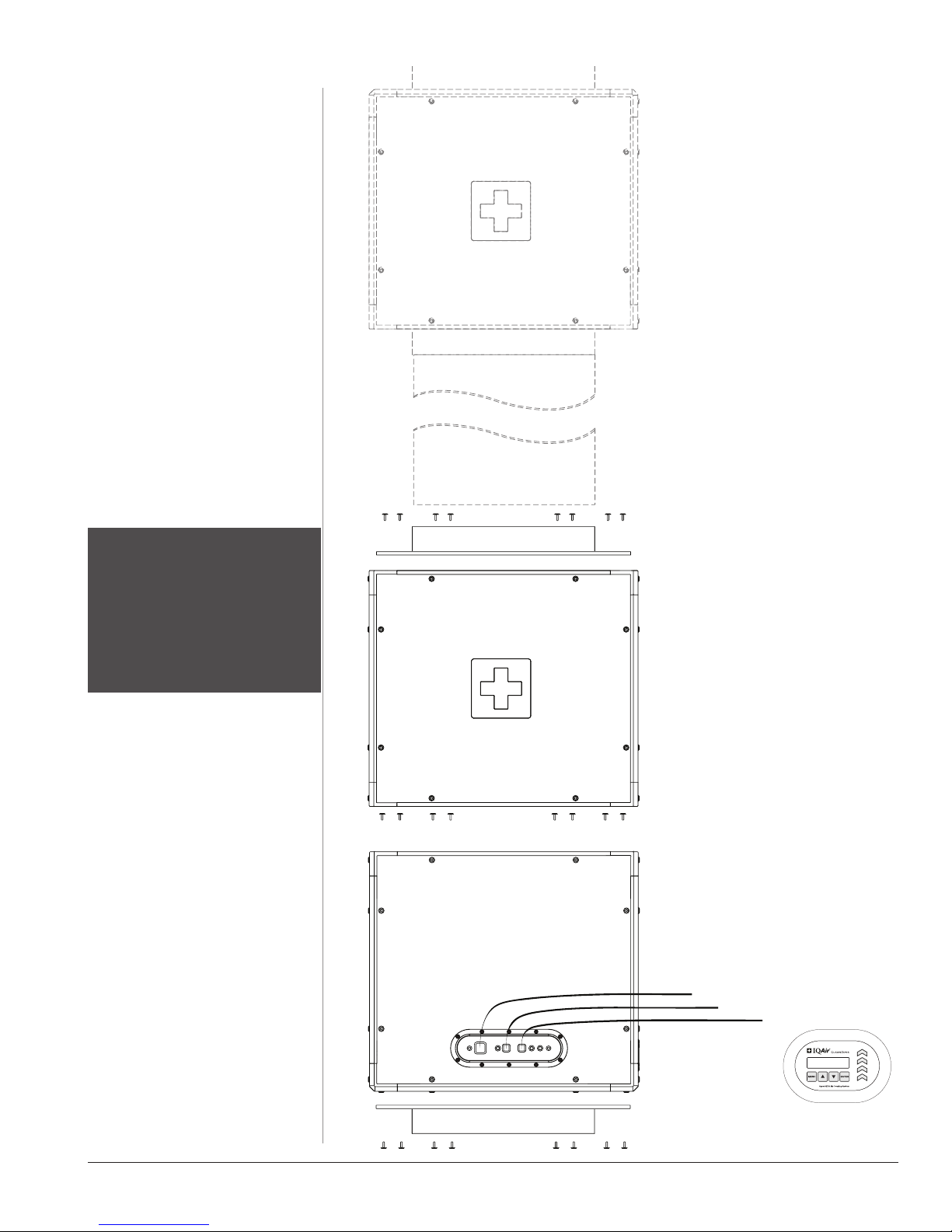

SystemComponents

MODEL 3020

TheCleanZone 3020wasdesigned to

allow more installation flexibility in

tight spaces.For the CleanZone 3020

to function properly it requires a

Perfect 16 filter for pre-filtration.The

Perfect 16 can be connected to the

CleanZone withas muchas 20 feetof

duct distance between the two.

If flex duct is used, 18” diameter is

recommended.

Perfect 16

Micro-Particle Filter

(to be ordered separately)

Eight Torx-30 screws

ATTENTION

Failure to use a Perfect 16 for prefiltration of a CleanZone 3020 will

cause the HyperHEPA filter to

become pre-maturely loaded and

can lead to a drastic reduction of

airflow.

Rectangular Connection Panel

HyperHEPA End Module

(Nano-Particle Filtration)

Eight 4 mm Hex screws

Motor End Module

Power cord with 3-prong 120 Vac

connector plug with ground

EAC terminal connection cord

Wall control panel cord

Rectangular Connection Panel

Eight Torx-30 screws

10Chapter 2

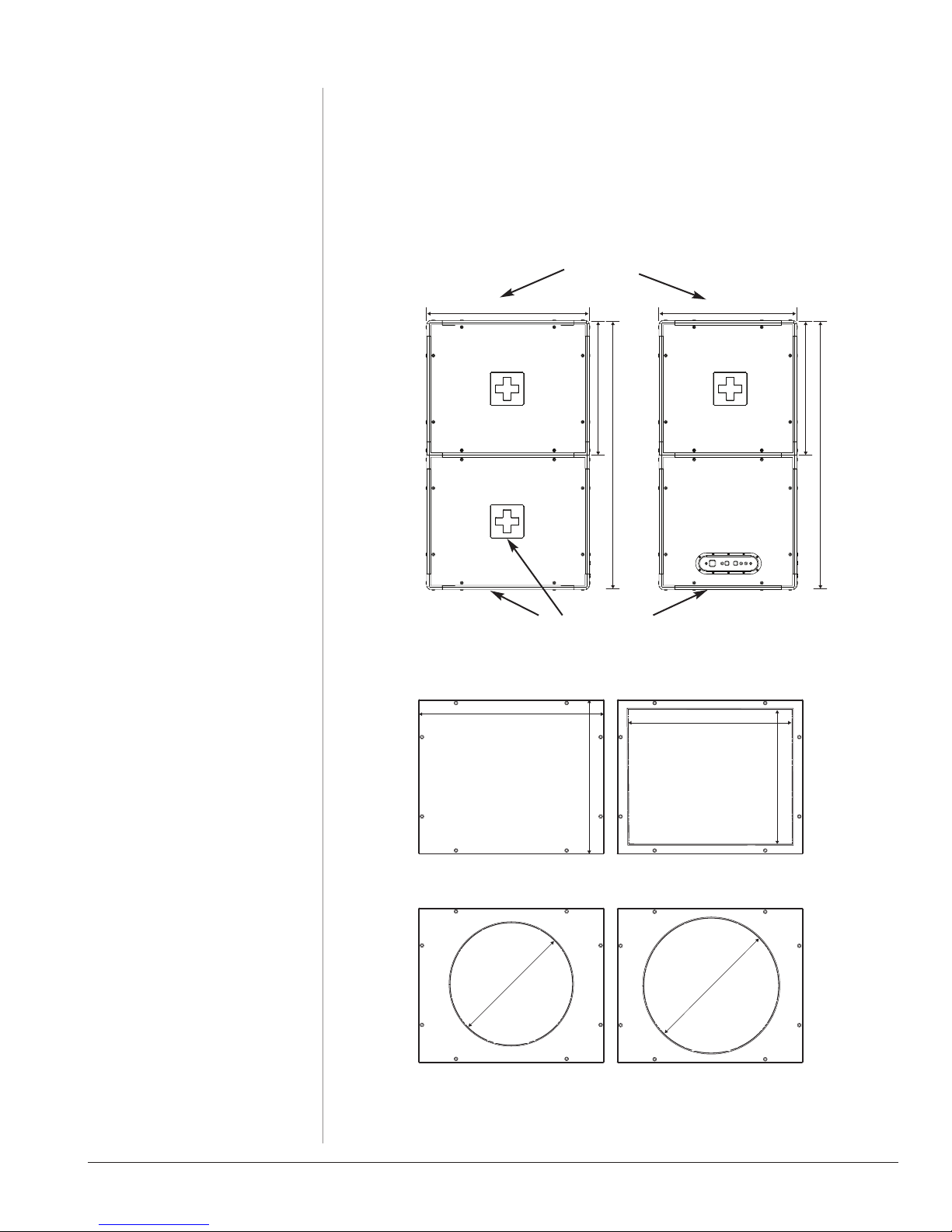

16 (400)

18 (450)

20 (500)

16 (400)

23.69 (601)

19.63 (499)

can be cut and adapted

41.5 (1055)

25.25 (642)

20.75 (527)

41.5 (1055)

25.25 (642)

20.75 (527)

Dimensions

Connection panel for air inlet

attaches to face of system

Connection Panels

Four different connection panels are

available:

• Panel without opening

(to be cut and adapted as neces-

sary by installer)

Order No. 207 30 05 04

• Panel with16” x 20” connection

Order No. 207 30 09 04

• Panel with 16”round connection

Order No. 207 30 06 04

• Panel with 18”round connection

Order No. 207 30 07 04

Connection panel for air outlet attaches

to face or long side of system

All measurements in inch (mm)

11Chapter 2

Loading...

Loading...