Page 1

M

440000 -- 551122 M

Hzz

H

Baassee SSttaattiioonn

B

Daattaa

D

Raaddiioo

R

Owner’s Manual

Date Prepared:

March 1, 2000

16842 Von Karman Avenue, Suite 200 Irvine, CA 92606

Voice: (949) 417-4590 Fax: (949) 417-4591

Document Control #: DC-95

Version: C-1 (Special Release)

Copyright 2000-2002 IP MobileNet, Inc.

Page 2

TABLE OF CONTENTS

SECTION 1: THEORY OF OPERATION .................................................................................. 3

General Block Diagram ........................................................................................................... 3

General Block Diagram Definitions

DR4B Base Station Data Radio Circuitry

System Controller ................................................................................................ 5

Input/Output ......................................................................................................... 5

Modem Switching................................................................................................. 6

Modem .................................................................................................................6

Diversity Reception Controller .............................................................................6

Receive Signal Strength Indication Comparator .................................................. 7

Baseband............................................................................................................. 8

Receiver Board .................................................................................................... 8

IF Amplifier........................................................................................................... 9

Receiver Injection ................................................................................................ 9

Exciter ................................................................................................................10

Analog Modulation ............................................................................................. 10

Phase Locked Loop ........................................................................................... 11

Power Amplifier.................................................................................................. 11

SECTION 2: FACTORY TEST PROCEDURE ........................................................................12

Equipment List ........................................................................................................... 12

Programming and Configuring the Base Station Data Radio ................................ 13

Adjustment / Alignment Procedure .......................................................................... 14

Receiver Injection

Receiver 1

........................................................................................................ 14

............................................................................................. 14

Diversity Reception Controller

Receive Data

Exciter

............................................................................................................ 16

Power Amplifier

.................................................................................................... 15

................................................................................................ 16

SECTION 3: FCC LABEL ....................................................................................................... 17

DR4B Base Station Data Radio FCC Label Placement ........................................... 17

DR4B Base Station Data Radio FCC Label .............................................................. 17

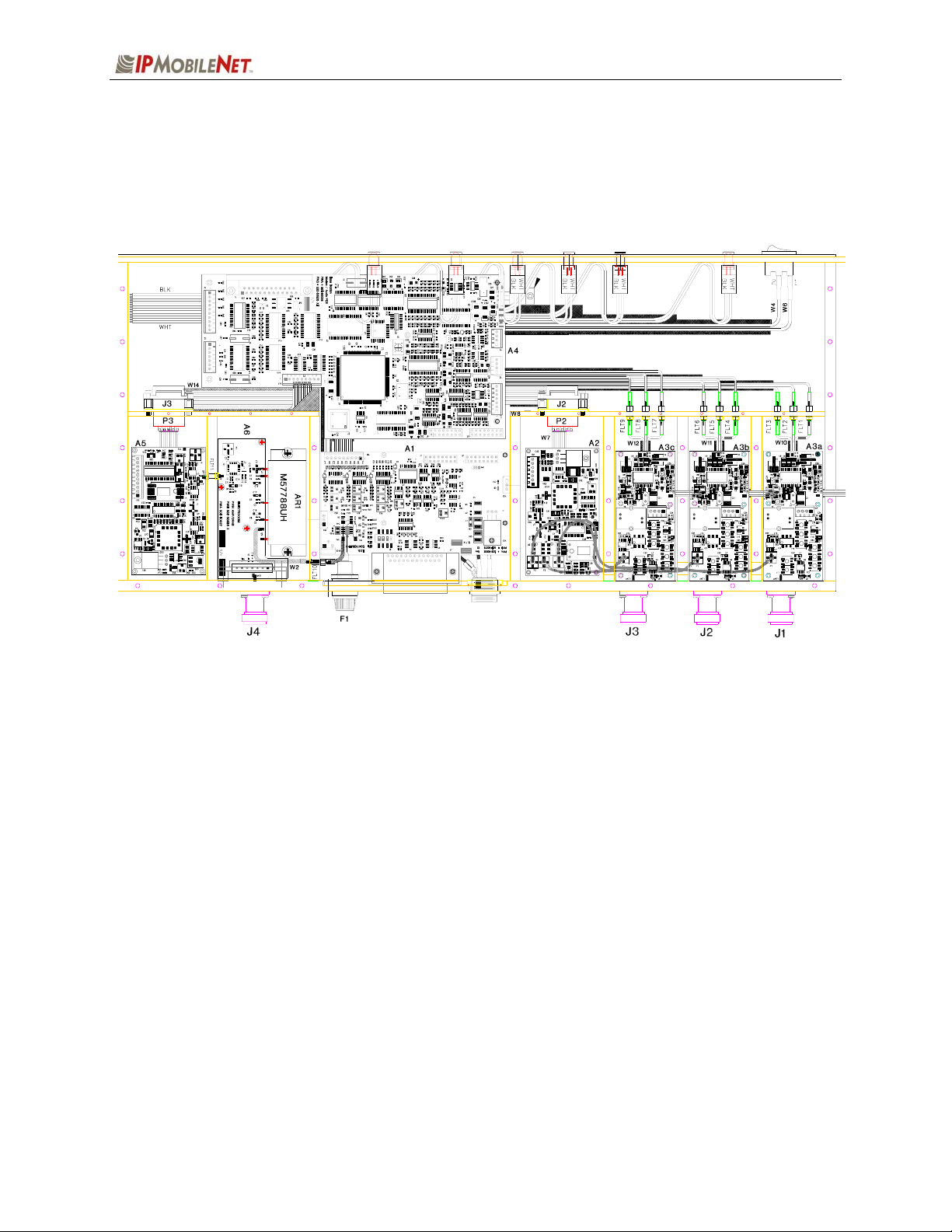

APPENDIX A: DR4B BASE STATION DATA RADIO CIRCUIT BOARD DIAGRAM ............ 18

................................................................................ 3

....................................................................... 5

.......................................................................... 14

~\Technical Documentation\System Manuals\FCC-Reports\IP1B-FCCRpt.doc Page 2

Page 3

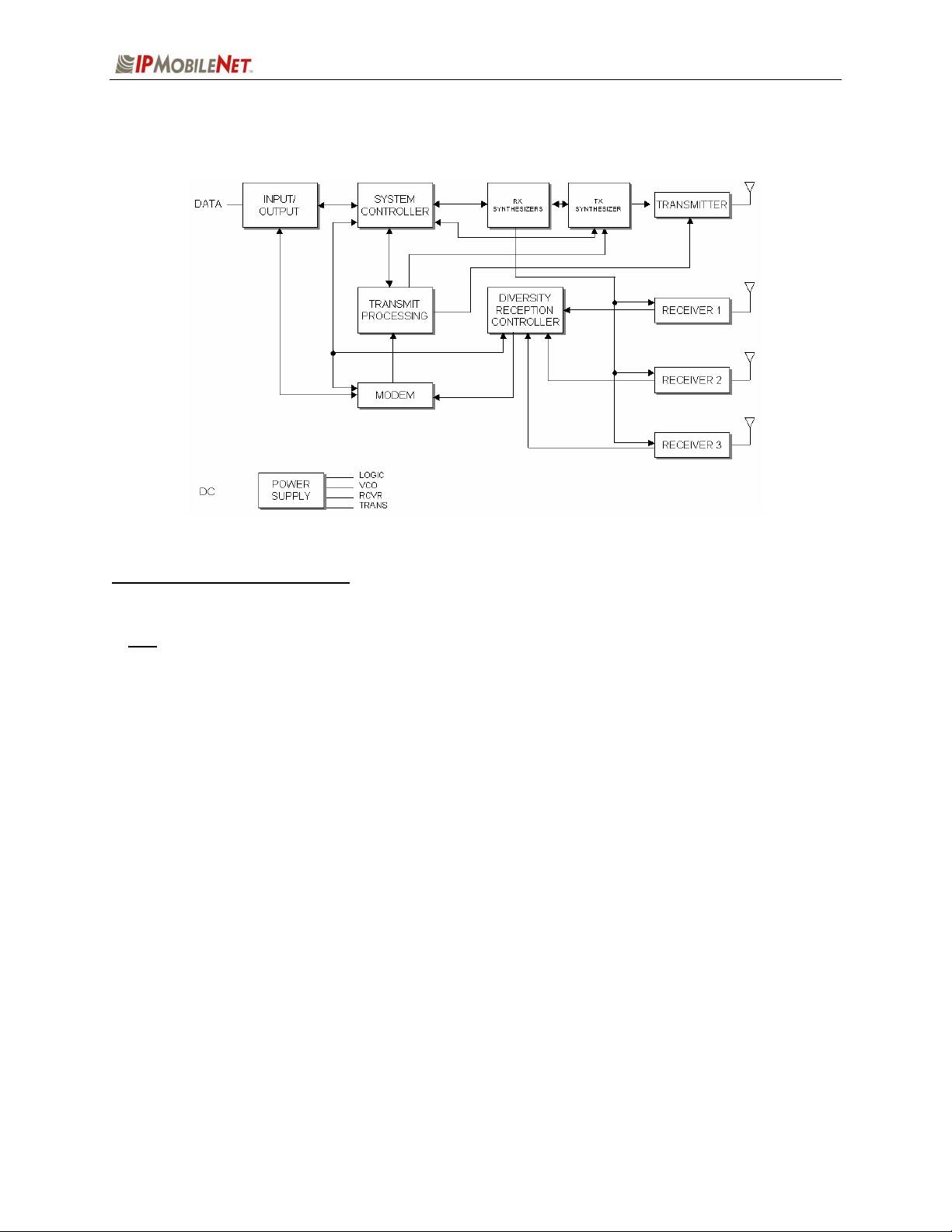

SECTION 1: THEORY OF OPERATION

General Block Diagram

General Block Diagram Definitions

For increased data security, the modem supports the U.S. Government developed Digital Encryption

Standard (DES) data encryption and decryption protocols.

The standard Base Station Data Radio circuit board contains eight (8) sections defined below:

Input/Output Circuitry associated with the base station’s DB25 data connector

System Controller Manages the operation of the base station loading selected transmit/

Includes memory for storage of base station operating parameters.

Transmit Processing Circuitry, which amplifies the analog audio signal from the modem

providing all of the RS232 data and handshake functions, including

the necessary RS232 to logic level changes.

receive frequencies into the injection synthesizer, controls the

operation of the modem and provides transmit timeout protection in

the event a fault causes the radio to become stuck in the transmit

mode.

Electrically erasable programmable read only memory (EEPROM) is

used to store parameters entered by the technician such as channel

numbers and RX/TX frequencies. This information is retained after

power is removed from the base station.

and uses it to modulate a voltage-controlled oscillator (VCO) and

reference oscillator in the transmitter synthesizer section.

Modulating the VCO and reference oscillator simultaneously results

in a higher quality FM signal.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 3

Page 4

SECTION 1: THEORY OF OPERATION

Modem Converts parallel data into an analog audio waveform for

transmission and analog audio from the receiver to serial data.

Serial data appears on the base station’s DB25 serial port.

The radio supports a 115.2 KBPS data transmission rate on the

serial port, SLIP protocol, and a 19.2 KBPS OR 9.6 KBPS over-theair data transmission rate.

Within a single chip the modem provides forward error correction and

detection, bit interleaving for more robust data communications, and

third generation collision detection and correction capabilities.

Synthesizers Provides ultra stable signals for the three (3) receivers and the

transmitter. Two (2) independent synthesizers are used in the base

station to obtain full duplex (simultaneous receive and transmit)

operations. Both synthesizers incorporate phase lock loop (PLL)

technology and use separate reference oscillators.

RX Synthesizer The receive synthesizer provides a local oscillator signal 45 MHz

above or below the desired receive channel frequency. This is called

high side injection or low side injection.

TX Synthesizer The transmit synthesizer produces the desired frequency by

controlling a VCO. The VCO and the reference oscillator are both

frequency modulated by the modem output.

Diversity Reception Controller Circuitry selects one of three diversity receiver audio outputs for

processing by the modem by comparing the Received Signal

Strength Indication (RSSI) output from each receiver. Essentially,

audio from the receiver with the highest RSSI value is passed on to

the modem.

Transmitter Consists of an exciter and a power amplifier module covering various

frequency bands in segments. A different power amplifier module is

required for each segment. The transmitter power control is included

with the power supply circuitry on the same board.

Receiver 1/Receiver 2/ Uses three (3) discrete receivers tuned to the same frequency.

Receiver 3 The three (3) receivers are required to support IPMN’s base station

DRS.

NOTE

The receivers are double-conversion superhetrodynes with an

Power Supply Power supply circuitry derives the various operating voltages

: Some installations use only two (2) receivers.

Intermediate Frequency (IF) of 45 MHz. Each receiver consist of

bandpass filters, RF amplifiers, a mixer, 45 MHz crystal filter, and a

one-chip IF system. The injection synthesizer provides the first local

oscillator signal and outputs from each receiver including RSSI and

analog audio for the diversity reception controller.

required by the base station. Fixed voltage regulators are employed

through the radio for this purpose.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 4

Page 5

SECTION 1: THEORY OF OPERATION

DR4B Base Station Data Radio Circuitry

The DR4B Base Station Data Radio works within the frequency range of 400-512 MHz.

The following section provides detail views, descriptions, and key areas on the DR4B Base Station Data

Radio circuit board especially useful during troubleshooting.

System Controller

This section displays the Central Processing Unit (CPU)(U1), clock, and power-on reset circuitry. It

provides more processing power than required for future capabilities to be incorporated into the radio

without changing processors. Such capabilities include data encryption/decryption (DES), remote fault

monitoring, etc. U1 features a 16-bit address bus and 128K of internal flash random access memory

(RAM). To enter the programming mode it is necessary to reset the switch (S1) and power up again.

CPU operations are controlled by Y2 an 4.9152 MHz clock module. Capacitor (C1) and an internal

Schmidt trigger circuit inside of U1 generates the power on reset signal. The RESET* output from U1

drives a latch and decoder found elsewhere on the board.

This section displays the RAM, decoder, EEPROM, and programming power supply circuitry. U2 is a

512K x 8 bit static RAM chip, which provides temporary storage of radio configuration data while the

power is on. This is necessary in order to program the radio configuration. U2 is controlled directly by the

address, data, and control busses from the CPU.

Chip U5 decodes the A11-A14 address bus to provide chip selects for the modem and EEPROM

memory. Chip U6 is an 8-bit latch. It latches inputs from the D0-D7 bus and lights the front panel status

indicators (

Chip U3 is a serial EEPROM, which provides 2K bits of pre-programmed data storage for the CPU. Data

is clocked out of U3 by EECLK, and back into the CPU via EEDATA.

A programming power supply is required for the flash RAM inside of the CPU, and this function is

performed by U4. This chip is an adjustable voltage regulator with a shutdown control. Resistors R8 and

R9 set the output voltage. When the radio configuration data is to be stored in flash RAM, the CPU

makes VPP_ENABLE high. This turns on the regulator, producing a 12-volt output via VPP for the flash

RAM.

This section displays a dedicated processor and voltage regulator. Chip U7 is an optional processor,

which permits manual keyboard operation of the radio. It is not used, and may not be installed on the

board. Regulator U10 provides 5 volts DC power for all logic circuitry on the System Controller Board.

Input/Output

This section displays the CPU input/output circuitry. Chip U11 is an RS232 transmitter/receiver, which

interfaces the CPU to the Diversity Reception Board via J6. From there, the RS232 data goes directly to

a rear panel DB25 connector. U11 converts 5-volt logic-level data to +/-12 volt data in RS232C form, and

vice-versa. A charge pump power supply on the chip converts the +5 volt DC power to the +/-12 volt

levels required. The charge pump uses capacitors (C28 to C31) to generate voltages.

The RS232 serial port data transmission rate of the base station is 115.2 KBPS.

TX, CD, RX1, RX2, and RX3).

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 5

Page 6

SECTION 1: THEORY OF OPERATION

Modem Switching

This section displays the connector wiring and modem switching circuitry. Connector J2 is routed to the

front-panel TX, CD, and RX1-RX3 LED indicators. The radio will also accept modulation from an external

source (modem or amplified microphone audio).

Modem

This base station uses separate modems for receive and transmit functions so that full-duplex operation

may be obtained. The A0-A1 address bus in addition to the individual read (RD*), write (WR*), and chip

select (MODEMTXCS*) lines control all three (3) modems. Modem operations are timed by Y2, a 4.9152

MHZ clock module.

Modem chip U14 is dedicated to the transmit operation. Data from the D0-D7 bus is read by the chip,

and then converted to a 4-level FSK analog signal, which appears on the TXOUT pin. Op amp U21B

buffers the signal, which becomes the MODEM_TXMOD output. From this point, the signal is routed to

the modulation circuitry on the Exciter Board.

Chip U14 has the ability to demodulate receiver audio, although this capability is not used in most

systems. Incoming data-bearing audio from the Diversity Reception Controller Board (and selected

receiver) appears at DISC_AUDIO. The signal passes through resistor R54 and into the modem chip.

Resistor R52 and capacitor C41 serve as feedback elements, limiting both the gain and bandwidth of an

amplifier within U14. The modem chip demodulates the audio into 8 bits of data, which exit U14 on the

D0-D7 bus.

Chip U14 also provides a bias voltage for the analog circuitry on the Exciter Board. This voltage is about

2.5 volts DC, and it appears on the VBIAS line. The purpose of VBIAS is to bias the Exciter Board analog

circuitry for proper operation. Please note that if this voltage is low or missing, the Exciter Board circuitry

may not work.

Modem chip U15 is dedicated to the receive operation. Incoming data-bearing audio from the Diversity

Reception Controller Board (and selected receiver) appears at DISC_ AUDIO. The signal passes through

resistor R56 and into the modem chip. Resistor R55 and capacitor C46 serve as feedback elements,

limiting both the gain and bandwidth of an amplifier within U15. The modem chip breaks down the audio

into 8 bits of data, which exit U15 on the D0-D7 bus.

Modem chip U16 is also dedicated to the receive operation, although it may not be used in this

application. The operation of U16 is exactly the same as U15.

Diversity Reception Controller Board

This section displays the power supply circuitry and input/output connector wiring. The power supply

consists of a diode (CR1), metal oxide varistor (MOV) (CR2), a fuse (F1), and voltage regulators (VR2

and VR3). 13.8 volts DC from the radio’s power connector appears on the anode of CR1. CR1 provides

reverse polarity protection, while CR2 absorbs any damaging transient spikes, which appear on the

unregulated supply line. F1 provides over-current protection. The SWB+ output powers the remaining

boards in the radio, with the exception of the power amplifier module. VR2 provides a 5-volt DC source

for all of the circuitry on the Diversity Reception Controller Board. VR3 provides 5 volts DC for the three

receiver boards via a connector (TB1).

Two (2) 16-pin DIP headers connect this board to the System Controller Board. One header (J2)

provides power and control signals for the System Controller Board. The ALARMA and ALARMC lines

are of particular interest because the base station has optional external fault monitoring capabilities. For

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 6

Page 7

SECTION 1: THEORY OF OPERATION

example, if a fault in the base station site produces a contact closure on one of the alarm inputs, the radio

transmits a fault message to the Communication Center. Examples of faults include site door open, high

temperature, high VSWR, etc. Upon receipt of the fault message, a technician is dispatched to the base

station site to correct the fault. In order to obtain these capabilities, monitoring software must be loaded

into the System Controller Board CPU and the Internet Protocol Network Controller (IPNC).

Another header (J1) routes RS232 data, clock, and handshake signals from the System Controller Board

to DB25 interface connector (J3). This connector is physically mounted on the rear panel of the base

station.

This section displays the level shifters for the three (3) receivers. Each receiver provides a DC voltage

received signal strength indication (RSSI) corresponds to the signal strength of an incoming signal. The

RSSI output from receiver 1 appears at RSSI1. It passes through low pass filter R13 and C16. The low

pass filter capacitor (C16) minimizes RF pickup by the op amp. An op amp (U11B) provides amplification

and a DC level shift. An additional op amp (U11C) provides additional amplification. Resistors (R3 and

R4) and a pot (R11) set gain of the op amp. The DC offset is injected into U11C via a pot (R12) and a

resistor (R5). The amplified and level shifted output leaves the op amp as SHIFT_ RSSI1 and goes to a

comparator circuit.

The remaining level shifters work in the same manner.

Individual gain and DC offset pots are provided so that minor RSSI performance differences between the

Receive Signal Strength Indication Comparator

This section displays the RSSI comparator circuitry. It uses a two-step selection process to determine

which receiver has the strongest signal, as follows:

The receiver 1 and receiver 2 RSSIs are compared, and the strongest receiver is selected.

The selected receiver’s RSSI and receiver 3 RSSI are compared, and the strongest is selected. The

A comparator (U5) looks at the RSSI1 and RSSI2 inputs. When RSSI1 is greater than RSSI2, the

comparator output goes high, and a LED (D1) lights to indicate receiver 1 was selected. At the same

time, the RX1/RX2_SELECT line goes high, which activates the solid-state switch (U8). This causes the

receiver 1 RSSI signal to be routed to a second comparator. Otherwise, if the receiver 2 RSSI is greater

than receiver 1, the RX1/RX2_SELECT line goes low, and another LED (D2) lights to indicate receiver 2

was selected. U8 simply routes receiver 2 RSSI to a second comparator (U10). The digital

RX1/RX2_SELECT output controls a switch.

U10 looks at the selected receiver (RSSI1/RSSI2) and RSSI3 inputs. Should RSSI3 be greater than the

other input, the comparator output goes high, and LED (D3) lights to show receiver 3 is selected. At the

same time, another switch (U6) connects RSSI3 to the analog SEL_RSSI output. The digital

RX3_SELECT output controls a switch. Otherwise, if the selected receiver’s RSSI is greater than RSSI3,

the comparator output remains low making the RX3_SELECT output low. U6 simply connects the

selected receiver’s analog RSSI signal to the SELRSSI output.

A chip (U3) forms a comparator circuit. When the RSSI voltage exceeds a threshold, a LED (D4) lights.

Like the other three (3) LEDs, this circuit is intended as a diagnostic tool. It provides a go/no go indication

that an RF signal has been received. A pot (R74) sets the turn-on voltage.

three receivers can be trimmed out.

circuitry provides two (2) digital outputs and an analog RSSI voltage from the selected receiver.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 7

Page 8

SECTION 1: THEORY OF OPERATION

Baseband

This circuitry amplifies the audio from each receiver, routes it through solid-state switches, and selects the

audio from the receiver with the highest quality value. The comparator circuit on the previous sheet

controls it.

There are three (3) channels of audio, with separate gain and DC offset adjustments to compensate for

performance differences in the receivers. For example, incoming audio from receiver 1 appears at

AUDIO 1. An op amp (U12D) is then amplifies the audio. A pot (R72) adjusts the gain. The amplifier

output drives a switch (U4).

The remaining audio circuits work in the same manner.

Two (2) solid-state switches route audio from the selected receiver. U4 selects audio from either

Receiver 1 or 2. When the RX1/RX2_SELECT input from the comparator circuitry is high, Receiver 1

audio is passed through the device. Another switch (U7) selects audio from either a selected Receiver (1

or 2) or receiver 3. When the RX3_SELECT input from the comparator circuitry is high, Receiver 3’s

audio is passed through the device. The output from U7 appears on DISC_AUD, which goes to a header

(J2). From there the audio is demodulated by the modems on the System Controller Board.

The radio also offers a voice grade audio output via the rear panel DB25 connector. DISC_AUD also

drives low pass filter (U14), and buffer (U9D). The AUDIO OUT line from the buffer goes to pin 12 of a

connector (J3).

This section displays manual receiver switching and DC power distribution. Manual receiver switching is

primarily intended as a diagnostic tool. By closing various switches on S1, the RX1/RX2_SELECT or

RX3_SELECT LINES may be forced high or low, as appropriate. This overrides the operation of the

comparator circuitry, forcing one receiver to operate at all times. Resistors (R98 and R97) provide power

supply short circuit protection in the event the wrong switches are closed.

Pads (TP4 and TP5) represent the power distribution bus (TP4 and TP5). Incoming power from the rear

panel fuse holder appears on pad TP4. The B+ output goes to the power supply circuitry. TP5 connects

to the transmitter power amplifier.

Receiver Board

Please be aware that the radio uses three (3) identical receiver boards. As a result, the circuitry will be

Front end. Incoming signals pass through a filter (FT1). The filter (FT1) is a double-tuned device, which

provides a high degree of selectivity. The desired signals are amplified by U4, a low noise amplifier.

Additional selectivity is provided by triple-tuned filter (FT2). An RF amplifier (Q1) amplifies the signal.

The output from Q1 passes through triple-tuned filter (FT3), and then to mixer (U5). U5 is a doublebalanced mixer, which heterodynes a local oscillator signal from the Injection Synthesizer Board. The IF

output leaves the mixer as the 45 MHz line. It goes to an IF filter on the following sheet.

There are five (5) filter sets (FT1, FT2, and FT3) available, and each covers a 20-30 MHz

described only once.

portion of the UHF band. Should replacement of the filters be required, exact replacement

parts must be used.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 8

Page 9

SECTION 1: THEORY OF OPERATION

IF Amplifier

The incoming 45 MHz signal passes through Y5, a highly selective monolithic bandpass filter. From there

the IF signal passes through an LC matching network. C17, C18, C24, and L5 provide impedance

matching to the IF amplifier input. U6 is a super heterodyne IF subsystem. Inside the chip, the signal is

applied to a mixer. The mixer also accepts a 44.545 MHz local oscillator input. The local oscillator

consists of an internal amplifier, plus crystal (Y4) and associated components. The mixer output passes

through Y3, a 455 KHz ceramic IF filter. It is amplified, passed through ceramic filter (Y2), and on to a

second IF stage. The IF output drives a quadrature detector. The recovered audio appears at pin 9,

while RSSI appears at pin 7.

Within the RSSI circuitry, chip U6 uses a detector, which converts if the current is generated inside the

chip into a DC level corresponding logarithmically to signal strength. RSSI is used by the Diversity

Reception Controller to select the receiver with the highest quality signal.

The audio is buffered by op amp U3A. From there the AUDIO output line goes to a connector, for hookup

to the Diversity Reception Controller Board.

The RSSI is buffered by op amp U3B. From there the RSSI output line goes to a connector, for hookup

to the Diversity Reception Controller Board.

Several sets of 455 KHz IF filters (Y3 and Y2) are available to suit receiver selectivity requirements.

Should replacement of these filters be required, exact replacement parts must be used.

Receiver Injection

The Injection Synthesizer Board provides a highly stable local oscillator signal for the three receivers. A

synthesizer on the board develops the signal.

This displays a serial data input/output interface, synthesizer, and VCO. The I/O interface circuitry

accepts clock, serial data, and enable signals from the System Controller Board via terminal block TB1. A

lock detect (LD) status output is returned to the System Controller Board from the synthesizer. U3 is a

hex Schmidt Trigger inverter, which squares up incoming signals for reliable operation of the synthesizer

chip. This is necessary because of a cable run between the two (2) boards.

The main section of this board is synthesizer chip (U2). The device contains the key components of a

phase locked loop (PLL), including a 1.1 GHz prescaler, programmable divider, and phase detector. In

operation, the desired frequency is loaded into U2 as a clocked serial bit stream via the CLK and DATA/I

inputs. The lock detection circuitry consists of inverters U3E/U3F, diode CR3, and resistor R5. When the

synthesizer is in lock, the LD pin on U2 is high, making the LD output on terminal block TB1 high. The

EXC LD input on TB1 routes the lock detect output from the Exciter Board through diode CR3, and out

through LD. This configuration tells the CPU on the System Controller Board that it is acceptable to

process received data, or to key the transmitter when LD is high. Otherwise, if a fault in either synthesizer

prevents a lock, receive and transmit operation will be inhibited.

The UHF injection signal is generated by module VCO1. This device is a wide-range voltage controlled

oscillator (VCO). A voltage on the VT input determines the VCO frequency. The voltage is generated by

the phase detector output (PD/O) of U2, which drives a loop filter consisting of R4, C19, C20, R21 and

C10. The filter integrates the pulses, which normally appear on PD/O into a smooth DC control signal for

the VCO. The output of VCO1 is attenuated by module AT1, resulting in improved VCO stability.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 9

Page 10

SECTION 1: THEORY OF OPERATION

This section displays the DC power supplies, frequency reference, and RF output circuitry. Regulator

VR1 provides 9 volts DC for VCO module VCO1, and RF amplifier (U7). Regulator (VR2) provides a low

noise 5-volt DC output for inverter (U3), synthesizer (U2), and reference (Y1).

Reference module (Y1) provides a high-stability 10 MHz reference frequency. Y1 is a voltage controlled,

temperature controlled crystal oscillator (VCTCXO). This device also has a VC input which accepts a

control voltage from pot R23. The pot permits a slight shift in the reference frequency which enables the

three (3) receivers to be tuned precisely to the assigned receive frequency. A diode (CR2) provides

additional voltage regulation, improving the frequency stability of reference Y1.

The RF output circuitry consists of RF amplifier (U7), and power splitters (U5 and U6). U7 increases the

signal level to correct for losses in the splitters. One output drives splitter U5, which provides local

oscillator injection for Receivers 2 and 3. The other output drives splitter (U6), which drives receiver 1

and the PLL_FEEDBACK input on chip U2.

Exciter Board

This section displays the input/output interface, transmitter keying, and power supply circuitry. The

input/output interface is built around terminal block (TB1) and Schmidt Trigger inverters (U7). Incoming

clock, serial data, and chip select signals on block TB1 are squared up by U7. Then they are sent to the

appropriate inputs on the transmitter synthesizer (U2). The EXCDATA source comes from the receive

synthesizer on the Injection Synthesizer Board. A Schmidt Trigger chip is used here because of a cable

ran to the System Controller Board. The synthesizer returns a lock detect output to the Injection

Synthesizer Board via U6 and EXCLD.

A regulator (VR2) powers the T/R switch circuitry. When the System Controller Board makes TXKEY*

low, inverter U6D goes high, turning on transistor Q2 and FET Q1. This applies 5-volt power to the

TXENABLE output, turning on the T/R switch on the Power Amplifier Board. At the same time, transistor

Q3 conducts, grounding the KEY* input of the Power Amplifier Board. Finally, inverter U6C goes high

and turns on RF switch U1, connecting the VCO output to the Power Amplifier Board for transmission.

The power supply consists of two (2) voltage regulators. A regulator (VR1) provides 5-volt power for the

VCO.

Analog Modulation

This section displays the analog modulation circuitry. Incoming modem audio from the System Controller

Board appears at TXMOD, and is buffered by op amp U5C. If an external modulation source (modem or

amplified microphone) is connected to the base station’s DB25 connector, audio appears at EXTMOD.

From there the audio passes through low pass filters U10, U4DCBA, and on to the input of op amp U5B.

The audio is inverted and amplified by an op amp (U5B). It then passes on to the VCO module via

VCOMOD.

The 10 MHz reference is also modulated in order to counteract the corrective effects of the synthesizer

loop circuitry. For example, if only the VCO were modulated, the synthesizer would try to compensate for

the frequency “error,” caused by the modulation. This effectively reduces the amount of modulation

available. Modulating the reference and the VCO simultaneously effectively cancels this effect when the

reference frequency goes high, the VCO frequency goes high, and vice-versa.

An op amp (U9A) amplifies the AUDIO output from another op amp (U5D) and applies it to jumper block

JMP1. Pot R30 adjusts the gain of U9A. Op amp (U9B) inverts the phase of the audio and applies it to

the other side of jumper block JMP1. The purpose of the jumper block is to select the proper phase of the

audio. If the wrong phase is used, on modulation peaks the reference will swing in the same direction as

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 10

Page 11

SECTION 1: THEORY OF OPERATION

the VCO, canceling out most of the modulation. The output from the jumper block goes to the 10 MHz

reference via REFMOD.

The VBIAS input is a 2.5-volt DC source, which biases the op amps to the correct operating point. It is

generated by modem chip (U14) on the System Controller Board.

Phase Locked Loop

This section displays phase locked loop (PLL) circuitry. The 10-MHz reference (Y1), runs synthesizer

(U2), which in turn controls VCO1. The main section of this board is the synthesizer chip (U2). The

device contains the key components of a PLL, including a 1.1 GHz prescaler, programmable divider, and

phase detector.

In operation, the desired frequency is loaded into U2 as a clocked serial bit stream via the CLK and

DATA/I inputs. The lock detection circuitry consists of inverters U6A and U6B, diode CR1, and resistor

R1. When the synthesizer is in lock, the LD pin on U2 is high, making the EXCLD output on terminal

block (TB1) high. The EXCLD output on TB1 routes the lock detect output from the Exciter Board. This

configuration tells the CPU on the System Controller Board that it is acceptable to process received data,

or to key the transmitter when LD is high. Otherwise, if a fault in either synthesizer prevents a lock,

receive and transmit operation will be inhibited.

The switch (JMP1) is used to select the supply voltage to chip U2. The UHF injection signal is generated

by module VCO1. This device is a wide-range voltage controlled oscillator (VCO). A voltage on the VT

input determines the VCO frequency. The voltage is generated by the phase detector output (PD/O) of

U2, which drives a loop filter consisting of R19, C16, C17, and C47. The filter integrates the pulses,

which normally appear on PD/O into a smooth DC control signal for the VCO. The output of VCO1 is

attenuated by module AT2, resulting in improved VCO stability.

Amplifier U8 amplifies the signal and applies it to a splitter (U3). One output of U3 is connected to a

switch (U1). U1 is enabled by signal TX when the transmitter is enabled. The other output of the splitter

is connected through AT1 and provides feedback to U2.

Power Amplifier

The transmit injection signal from the RF injection section is applied to the high-powered linear amplifier

(U1) one (1) watt amplifier. The signal is then routed to the final power amplifier boosting the output

signal to 40 watts. The output of the amplifier is routed to transmit antenna port ANT1 (via SW1).

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 11

Page 12

SECTION 2: FACTORY TEST PROCEDURE

Equipment List

The following table lists the equipment required to perform the DT450 Mobile Data Radio Factory Test Procedure:

QTY DESCRIPTION MANUFACTURER MODEL

PC’s

2

1

1 Digital multi-meter

1

1 4-Channel Scope Tektronix TDS 460A

1 DR4B Calibrated Base Station

1

1 100 watt dummy load/attenuator Pasternack

2 UHF Antennas (generic mag mount)

1

1 DT power cable

One for Mobile

One for Base

Service Monitor – Communication Test

Set

DC power supply w/ ammeter, 13.8V,

12 Amps or more

Internet Protocol Network Controller

(IPNC)

Serial cable DB25M-DB25F

connectors

Windows 9X w/

IPMessage

AVR

HP

Tektronix

Fluke

Astron

HP890 or

equivalent

77 or

equivalent

VS12M or

equivalent

PE7021-40 or

equivalent

1

1

1 Ceramic tuning tool

1 ea

3-foot RF jumper cable with type N

connectors (generic)

Scope test probe (generic, X1

attenuation)

#0, #1, and #2 Phillips screwdrivers

(generic)

IPMN p/n:

44010006

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 12

Page 13

SECTION 2: FACTORY TEST PROCEDURE

Programming and Configuring the Base Station Data Radio

Once the appropriate equipment for performing the factory test are gathered, perform the following steps

to rpgoram and configure the DR4B Base Station Data Radio:

Step 1 Enter the following information on the Base Station Data Radio Performance Test Data

Sheet:

Base Station Serial number

Date test being performed

Tester’s name

Step 2 At the HyperTerminal window, type in the appropriate password and press [ENTER].

Step 3 Type ? and press [ENTER]. The following example displays in the HyperTerminal

window:

Host serial = 115200,N,8,1, timeout=200

Host framing = SLIP, no split frames no status messages

tunnel = 0

TX format = new

Injection = LOW SIDE, 45MHz

channel spacing = 25000

Channel = 0

Channel Tx freq Rx freq Inj freq

Frequency=0 , 481.000000, 486.000000, 441.000000

Serial number: yyyyyyyyy

RIM address = 1

Frequency group = 1

TX quiet time = 5

Symbol sync time = 12 milliseconds, 0 extra inter-split-frame count

TX tail time = 5

Radio data rate = 19200

Max data tx time = 60 seconds

Carrier detect delay time = 1 millisecond

Station ID = ABC123

Station ID time =10 minutes

Polarity = TX+, RX+

Allow crc errors = 0

Suppress keep alive = 0

Allow base to base = 0

Timeslot status = 0

Duplicate time = 10 milliseconds

Control head grant delay = 50 milliseconds

RIM DD delay = 0 milliseconds

Retry interval = 0 milliseconds

Retry time limit = 0 milliseconds

RSSI step = 25 (=19dBm)

IPNC = 192.168.3.3

SLIP Address = 192.168.4.6

RF IP Address = 192.168.3.1

SNTP interval = 60 seconds

num timeslots = 16

timeslot period = 992ms

timeslots per voice packet = 4

noise = -128dBm

Fixed TX Delay = 0 milliseconds

Scale TX Delay = 0 microseconds

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 13

Page 14

SECTION 2: FACTORY TEST PROCEDURE

Adjustment / Alignment Procedures

Receiver Injection

Perform the following steps to adjust the receiver injection and injection frequency:

Step 1 Using the HP high frequency probe, verify that the receiver injection frequency is

Step 2 Adjust R7 on the receiver injection circuit board to set the injection frequency within 10

Receiver 1

Step 1 Using the high frequency probe, monitor the 44.545 MHz second injection frequency

Step 2 Inject an on-frequency signal at a level of –80 dBm, modulated with a 1 KHz test tone at

Step 4 While monitoring RSSI at TB1-4 with the digital multi-meter, adjust the trimmer capacitor

Step 5 Check the receiver’s distortion and verify that it is less than 3%.

Step 6 Adjust C1 slightly if necessary for minimum distortion.

Step 7 Check the receiver’s sensitivity, verifying that the SINAD is 12 dB or better at a maximum

Step 8 Repeat procedure for Receivers 2 and 3.

Diversity Reception Controller

Step 1 Inject an on-frequency signal at a level equal to Receiver 1 12dB SINAD level, modulated

Step 2 While monitoring TP1 with the digital multi-meter, adjust RSSI1 low adjust potentiometer

Step 3 Increase the amplitude of the signal by 50 dBm.

Step 4 While monitoring TP1 with the digital multi-meter, adjust RSSI1 high adjust potentiometer

Adjustments R11 and R12 are interactive adjustments, therefore continue adjustments until the DC voltage

at TP1 is 0.750 VDC for the receiver’s 12 dB SINAD level and 2.75 VDC for a 50 dBm increase from the

receiver’s 12 dB SINAD level.

present at each of the three (3) receivers by monitoring the receivers’ R12 surface mount

pad which lies on the 50 ohm track between L3 and U3.6.

Hz of the exact injection frequency. The amplitude of the injection frequency should read

approximately +5 dBm ±1 dBm.

at U2 pin 3, adjust trimmer capacitor (C5) to the center of the oscillator’s oscillation

range. The amplitude level of pin 3 of U2 should read between +5 and +10 dBm.

±5.0 KHz deviation into the receiver under test.

(C1) for maximum RSSI. The RSSI properly tuned receiver should be approximately 2.8

to 3.4 VDC.

level of –119 dBm (-120 is typical).

with a 1 KHz test tone at ±5.0 KHz deviation into Receiver 1.

(R12) for a reading of 0.750 VDC ±10 mV.

(R11) for a reading of 2.75 VDC ±10 mV.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 14

Page 15

SECTION 2: FACTORY TEST PROCEDURE

Step 5 Inject an on-frequency signal at a level equal to Receiver 2 12dB SINAD level, modulated

with a 1 KHz test tone at ±5.0 KHz deviation into Receiver 2.

Step 6 While monitoring TP2 with the digital multi-meter, adjust RSSI2 low adjust potentiometer

(R10) for a reading of 0.750 VDC ±10 mV.

Step 7 Increase the amplitude of the signal by 50 dBm.

Step 8 While monitoring TP2 with the digital multi-meter, adjust RSSI2 high adjust potentiometer

(R9) for a reading of 2.75 VDC ±10 mV.

Adjustments R9 and R10 are interactive adjustments, therefore continue adjustments until the DC voltage

at TP2 is 0.750 VDC for the receiver’s 12 dB SINAD level and 2.75 VDC for a 50 dBm increase from the

Step 9 Inject an on-frequency signal at a level equal to Receiver 3 12dB SINAD level, modulated

Step 10 While monitoring TP3 with the digital multi-meter, adjust RSSI3 low adjust potentiometer

Step 11 Increase the amplitude of the signal by 50 dBm.

Step 12 While monitoring TP3 with the digital multi-meter, adjust RSSI3 high adjust potentiometer

Adjustments R33 and R35 are interactive adjustments, therefore continue adjustments until the DC voltage

Step 13 Adjust the carrier detect potentiometer (R74) to illuminate a level of –116 dBm.

Receive Data

Step 1 Using a calibrated mobile radio, generate uplink data messages using the X=2000,19

Step 2 Attach an antenna to one of the base station’s receiver ports and verify on the base

receiver’s 12 dB SINAD level.

with a 1 KHz test tone at ±5.0 KHz deviation into Receiver 3.

(R33) for a reading of 0.750 VDC ±10 mV.

(R35) for a reading of 2.75 VDC ±10 mV.

at TP3 is 0.750 VDC for the receiver’s 12 dB SINAD level and 2.75 VDC for a 50 dBm increase from the

receiver’s 12 dB SINAD level.

command in the IP Message Utility program (see the Internet Protocol (IP) Data

Transceiver IP4/IP8 System Manual for instructions).

station monitor screen (HyperTerminal) that the received message data quality are

consistently 240 and higher for 2000 character messages. Repeat test for each receiver.

Constant fluctuations in the data quality are indicative of group delay programs. The data

quality readings should always be at or above 240.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 15

Page 16

SECTION 2: FACTORY TEST PROCEDURE

Exciter

Step 1 Using the X=2000,19 command, generate data messages so the transmit power and

frequency can be checked.

Step 2 Connect the base stations' transmit port to the HP communication test set. Note the

power level prior to adjusting.

Step 3 On the power amplifier circuit board adjust the potentiometer (RV1) fully clockwise (this

will enable low power transmit operation).

Step 4 While transmitting data messages using the X=2000,19 command, adjust the following:

TCXO Y1 and R14 for minimum frequency error

R11 for ±5.0 KHz deviation

Transmit output power should be approximately 1mWatt. The REFMOD adjustment needs to be made

Step 5 Connect the base station to the IPNC.

Step 6 Using a calibrated mobile radio operating on the base station’s channel, adjust R4 for

This command will ping the IPNC continuously with a 500-character test message. Press [Ctrl]+C to

Power Amplifier

Step 1 Connect the base stations' transmit port to the communication test set.

Step 2 Using the X=2000,19 command, generate data messages.

Step 3 Slowly increase the base station output power by turning the power control potentiometer

Do not exceed 20 watts output power as this will reduce the life of the amplifier module.

Step 4 Perform a close visual inspection of the radio paying close attention to manufacturing

while the base station is transmitting real data messages to and from a mobile radio. This is most easily

done using the ping command to ping the IPNC from a mobile radio. This will cause the base station to

repeatedly send data messages and will facilitate the REFMOD adjustment.

consistent data quality readings of 248 (as observed on the mobile radio’s attached PC

IP Message window). Access the MSDOS prompt and ping using the following

command:

>;ping 192.168.3.3 –t -l 500 –w 2000

stop the ping.

counterclockwise until the power noted previously or 40 Watts of output power is

obtained or to the level.

related problems such as loose screws, solder practices, etc.

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 16

Page 17

DR4B Base Station Data Radio FCC Label Placement

DR4B Base Station Data Radio FCC Label Placement

SECTION 3: FCC LABEL

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 17

Page 18

APPENDIX B: DR4B CIRCUIT BOARD DIAGRAM

~\Technical Documentation\System Manuals\FCC-Reports\DR4B-FCCRpt.doc Page 18

Loading...

Loading...