Page 1

CHAPTER 3: PROGRAMMING INSTRUCTIONS

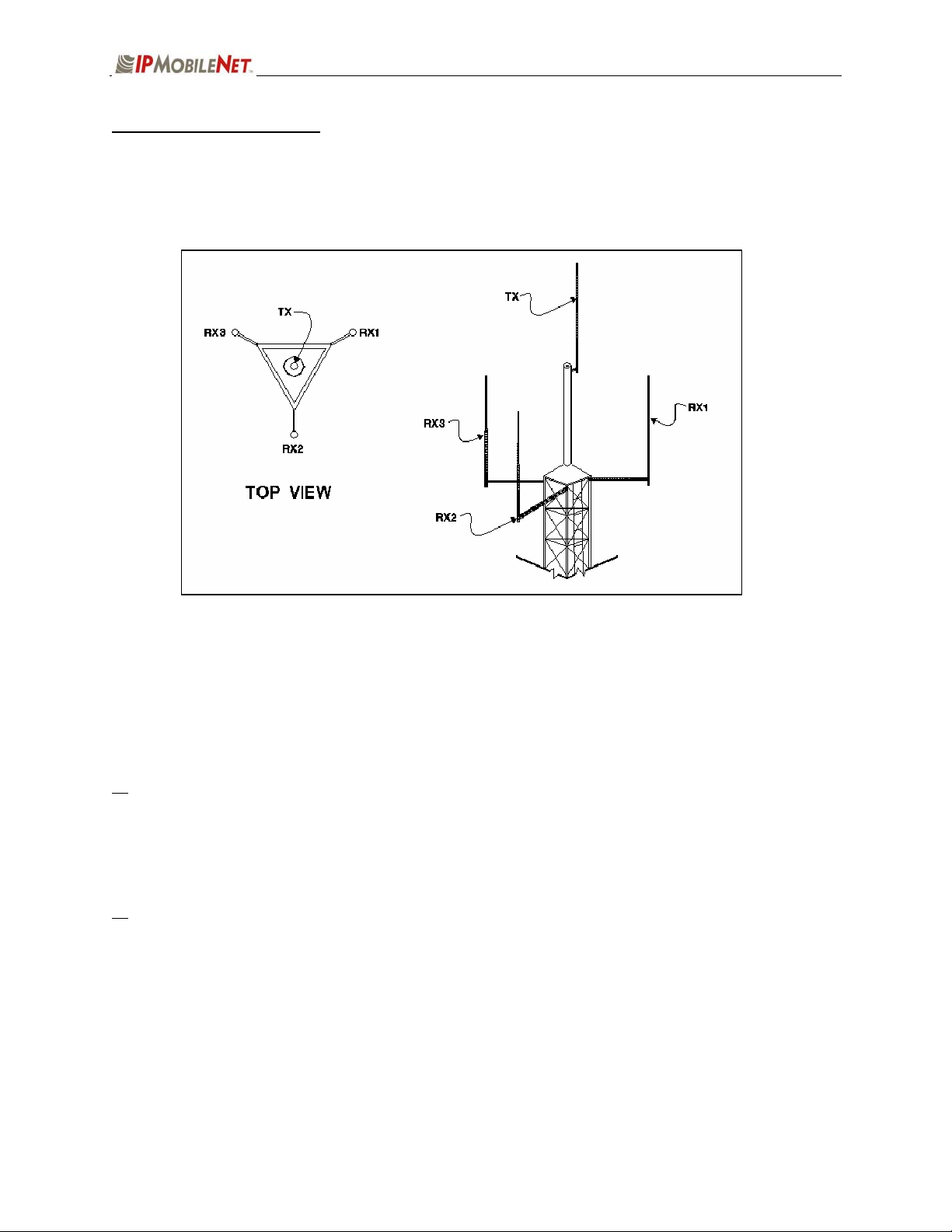

Typical Antenna Configuration

Base station antenna configurations may vary from site to site depending on the type of mounting

structure, the presence of existing antennas, mounting structure loading limitations, etc. The following

information is provided as a guideline for a typical scenario.

Figure 6: Typical Antenna Configuration

An otpimal antenna mounting configuration is shown in the figure above. The transmit antenna and

receive antennas are located at different elevations. This vertical separation provides the greatest degree

of isolation between transmit and receive antennas. The three (3) receive antennas are mounted at the

same elevation and are oriented in a 120 degree triangular pattern. A triangular orientation of the receive

antennas provides optimal diversity performance in an omnidirectional pattern.

The greater the separation between receive antennas, the greater the diversity gain; therefore,

the distance between antennas should be made as great as is practical.

In the event only two (2) receive antennas are used (i.e. a dual receiver diversity reception system), the

receive antennas should be mounted in a broadside orientation with respect to the radio coverage area.

To prevent the antenna’s radiation pattern from becoming distorted, the immediate area

surrounding each antenna should be kept free from conductive objects (i.e. other antennas, guy

wires, or the tower structure itself). The amount of clear area required to prevent pattern distorion

is equal to the antenna’s near-field exclusion.

Page 2

CHAPTER 3: PROGRAMMING INSTRUCTIONS

Near-Field Exclusion Zone

The near-field exclusion zone (NFEZ) is the required distance between antennas to any other surfaces to

improve transmit and receive performance. The large radio frequency field that builts up around the

antenna upon transmitting is essential for proper data transmission. It can be severely corrupted by metal

objects in the NFEZ. As seen in the previous figure, the transmitting antenna is placed at the very top of

the tower especially if the base station will be required to transmit in all directions (omni-directional).

If the transmitting antenna cannot be positioned on the top of the tower and must be placed

on a tower arm, then it is important to realize that coverage will be shaded in the area behind

the tower from the anetnna. The installer must be certain that the area of desired coverage is

away from the tower and not behind it.

Receiving and transmitting antennas should not be on the same plane, especially VHF and

UHF systems where the frequency splits are relatiely small. An antenna in the near-field

exclusion zone that is tuned for the same frequency as the transmitting antenna will reradiate

the signal and create unwanted effects on the transmittal signal. The receivers will be

inundated by high levels of radio frequency energy from the transmitting antenna. This is

why it is important to include vertical separation in the plan for the base station installation.

The isolation provided by 30 feet of vertical spearation can dramatically improve the

performance of the base station.

An antenna’s NFEZ can be calculated as follows:

D = 2d2

λ

Where: D is the distance to the anenna’s near field boundary

d is the antenna’s longest linear dimension (in the same units as D)

Maximizing the distance between the receive antennas will provide maximum diversity gain and

will minimize antenna radiation pattern distortion.

λ is the wavelength (in the same units as D)

Page 3

CHAPTER 3: PROGRAMMING INSTRUCTIONS

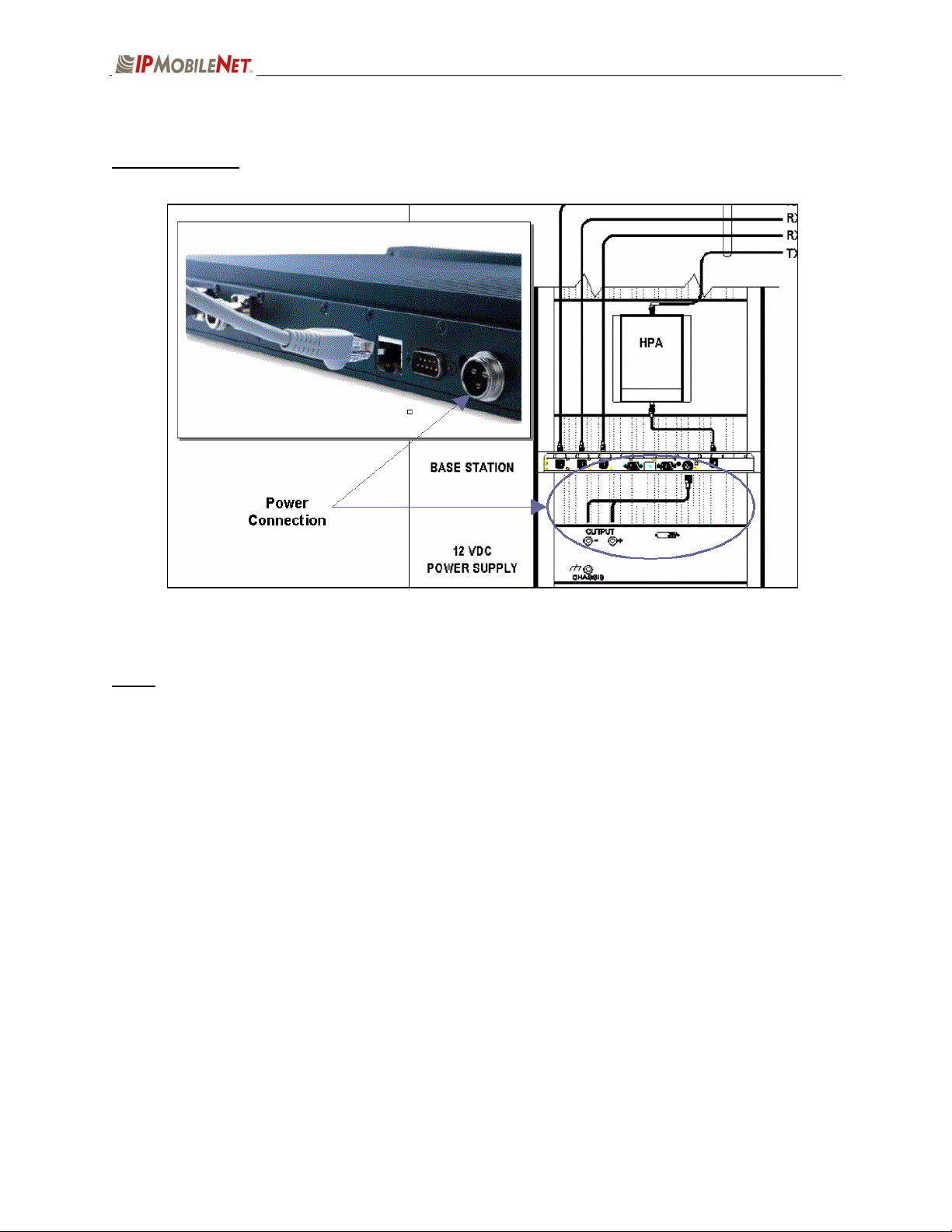

Power Connection

Figure 7: Base Station Power Connection

NOTE

: The base station shown in the figure only displays Ethernet connectivity and is not display the

actual 700 MHz base station.

To connect the base station power connector, perform the following steps:

Step 1 Connect the power cable to the base station power supply connection (as shown in the figure

Step 2 Connect the wires to the appropriate output (+ and -) output posts on the power supply (as

above).

shown in the figure above).

Page 4

CHAPTER 3: PROGRAMMING INSTRUCTIONS

Post Installation Checklist

The following table lists the tasks that should be performed upon completing installation.

TABLE 4: POST INSTALLATION CHECKLIST

NO. CHECKLIST ITEM

1 Scope out the entire area setup to locate any obvious problem areas.

2 Check antenna routing for safety concerns and near-field boundary setup.

Use tie wraps, where possible to ensure that all cables routed in parallel are

3

bundled together.

4 Perform appropriate testing to ensure base station works properly.

Once installation is complete make sure the area is clear of debris that would prevent proper

airflow and ventilation.

Overview

This section applies to all frequency ranges of the IPSeries Base Stations. Important! The base

station’s IP address must be known prior to performing the procedures in this section.

The programming procedure should be performed when it is necessary to upgrade a base station’s

Firmware or to change the operating parameters to suit the customer’s needs before putting into

complete operation.

HyperTerminal Setup

To communicate and access parameters from the base station, the base station must be connected to a

HyperTerminal session setup on a personal computer.

Perform the following steps to setup the base station for communication with HyperTerminal:

Step 1 Connect the base station and the PC as shown in the figure below.

;

Page 5

CHAPTER 3: PROGRAMMING INSTRUCTIONS

Figure 8: Base Station-to-HyperTerminal Connection Diagram

NOTE

: The base station shown in the figure only displays Ethernet connectivity and is not display the

actual 700 MHz base station.

Step 2 Power on the PC.

Step 3 Power on the base station using the front panel power switch.

Step 4 On the PC’s desktop, click on the Start button and select Accessories,

Communications, and HyperTerminal.

Step 5 At the Connection Description window enter IPMNBS and click on the OK button.

Step 6 At the Connect To window, under Con

available on the computer) and click on the OK button.

nect using: select COM1 or COM2 (whichever is

Page 6

CHAPTER 3: PROGRAMMING INSTRUCTIONS

Step 7 At the COM Properties window make sure the properties selected are as follows:

B

its per second: 9600

D

ata bits: 8

arity: None

P

Stop bits: 1

F

low control: None

Step 8 Click on the OK button.

Step 9 Open HyperTerminal.

Step 10 Recycle the base power and HyperTerminal displays the base’s Firmware revision.

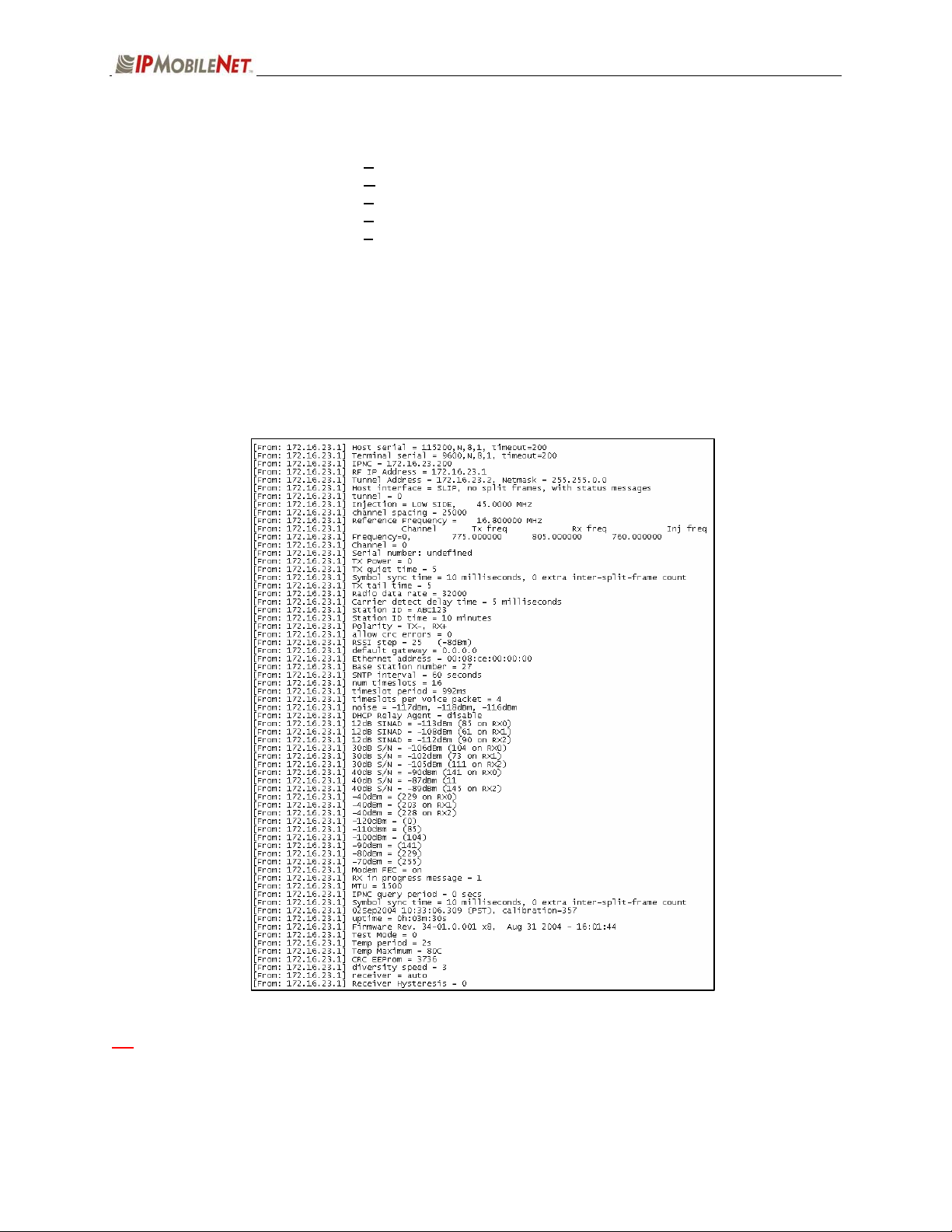

Step 11 Type in a ? in the HyperTerminal screen and press [ENTER]. This will list the Base

Station parameters, as shown in the sample below. If the cursor is not responsive, check

the cables for proper connection.

a Ensure that the calibrated base station and the mobile radio antennas are separated by

at least 10 feet. If the antennas are too close, the mobile radio receivers may overload

by the transmitters resulting in intermittent communication and high data errors.

Page 7

CHAPTER 3: PROGRAMMING INSTRUCTIONS

Additional Programming Needs

Refer to the following technical notes and programming instructions and select the appropriate document

for additional functionality, programming, and setup information.

TABLE 5: ADDITIONAL PROGRAMMING DOCUMENTS

Remote Firmware Updates for the IPNC and Base Station

TN01-0020

516.80489.UM

This technical note provides instructions on how to perform remote Firmware

updates for the IPNetwork Controller and IPSeries base stations.

Internet Protocol Network Controller

Refer to the section on Fault-Tolerance for information on how the base station

operates within a fault-tolerant setup.

Page 8

SECTION 4: FACTORY TEST PROCEDURE

Equipment List

The following table lists the equipment required to perform the 700 MHZ Base Station Factory Test

Procedure.

CHECKLIST OF REQUIRED MATERIAL FOR

PRELIMINARY TESTING OF THE IPSeries BASE STATION

NO. REQUIRED TOOLS

Calibrated Base Station System – Consisting of the following components:

(1) Appropriate version IPSeries Base Station to be tested

(2) Desktop or laptop computer configured as an Internet Protocol Network Controller (IPNC)

1

(3) Corresponding IPSeries Mobile radio (If an 700 MHZ base station, use IP8 mobile radio)

(4) Desktop or laptop computer with two (2) available serial ports and Microsoft Windows 95 or

greater and IPMobileNet Dial-Up Networking, IPMessage software (SLIP2IPMN.exe), and

HyperTerminal for base station installed

2

Comm Test Set (HP 8920A or B)

3

High Frequency Probe (85024A)

4

Power Supply for 85024A Probe (HP1122A)

5

Four (4) Channel Scope (Tektronix TDS 460A)

6

General Purpose Scope Probe

7

Digital multi-meter Tektronix Fluke (DMM912 77)

8

DC power supply with ammeter, 13.8V, 12 amps or more (Astron VS12M or equivalent)

9

100-watt dummy load/attenuator (Pasternack PE7021-40 or equivalent)

10

Four (4) antennas (generic mag mounts) tuned to frequency or transceiver

;

11

Serial cable DB9M – DB9F connectors (generic)

12

Input/Output (I/O) Board (IPMN p/n: 502-80081)

13

IPSeries Base Station power cable specified for use with the specific base station being used

14

Three (3) serial DB9F-DB9M Null Modem cables

489288.DOC Page 8

Page 9

SECTION 4: FACTORY TEST PROCEDURE

Programming and Configuring the Base Station

Important! The base station’s IP address must be known prior to performing the procedures in this

The programming procedure should be performed when it is necessary to upgrade a base station’s

Firmware or to change the operating parameters to suit client needs.

Viewing the Base Station’s Configuration Data

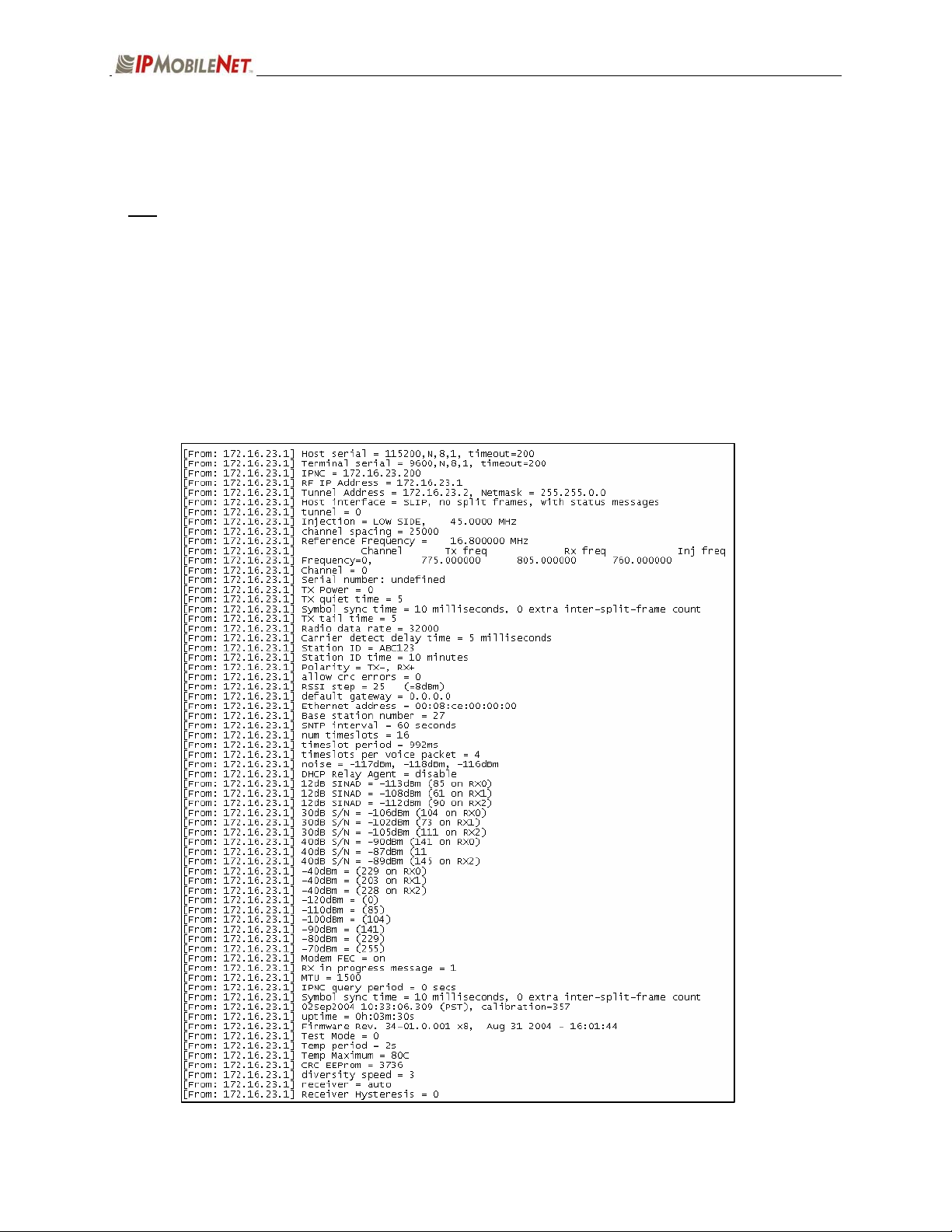

Step 1 At the HyperTerminal window, type in the appropriate password and press [ENTER].

Step 2 Type ? and press [ENTER]. The following example displays in the HyperTerminal

section.

window:

489288.DOC Page 9

Page 10

SECTION 4: FACTORY TEST PROCEDURE

Adjustment / Alignment Procedures

Make appropriate notations of any items that require attention during this procedure. This information is

needed later during the repair process.

Startup

Step 1 Remove the base station cover placing the screws in a location where they will not be

Step 2 Connect the base station to the appropriate components.

Step 3 Power up the base station and computer. The power supply ammeter must read 1.2

Receiver Injection

Step 1 Connect the base station to gps antenna and wait until the frequencies of OCXO and

Step 2 Using the high frequency prob,at AL7 check the amplitude of the signal. The amplitude

Receiver

Step 1 Using the high frequency probe, monitor the 44.545 MHz second injection frequency

Step 2 Inject an on-frequency signal at a level of –80 dBm, modulated with a 1 KHz test tone at

Step 3 Check the receiver’s sensitivity, verifying that the SINAD is 12 dB or better at a maximum

misplaced.

amps or less with a 13.8 VDC input.

VCTCXOs are corrected and the error is below 0.1 ppm. You can check the error by

typing gpsstatus.

of the injection frequency should read approximately 0 dBm ±1 dBm.

at AU4 pin 3, adjust trimmer capacitor (C22) to the center of the oscillator’s oscillation

range. The amplitude level of pin 3 of AU4 should read between +5 and +10 dBm.

±5.0 KHz deviation into the receiver under test.

level of –119 dBm (-120 is typical).

489288.DOC Page 10

Page 11

SECTION 4: FACTORY TEST PROCEDURE

Diversity Reception

Step 1 Inject an on-frequency signal at a level equal to Receiver 1 12dB SINAD level, modulated

with a 1 KHz test tone at ±5.0 KHz deviation into Receiver 1.

Step 2 While monitoring TP1 with the digital multi-meter, adjust RSSI1 low adjust potentiometer

(R12) for a reading of 0.750 VDC ±10 mV.

Step 3 Increase the amplitude of the signal by 50 dBm.

Step 4 While monitoring TP1 with the digital multi-meter, adjust RSSI1 high adjust potentiometer

(R11) for a reading of 2.75 VDC ±10 mV.

Adjustments R11 and R12 are interactive adjustments, therefore continue adjustments until the DC voltage

Step 5 Inject an on-frequency signal at a level equal to Receiver 2 12dB SINAD level, modulated

Step 6 While monitoring TP2 with the digital multi-meter, adjust RSSI1 low adjust potentiometer

Step 7 Increase the amplitude of the signal by 50 dBm.

Step 8 While monitoring TP2 with the digital multi-meter, adjust RSSI1 high adjust potentiometer

Adjustments R9 and R10 are interactive adjustments, therefore continue adjustments until the DC voltage

Step 9 Inject an on-frequency signal at a level equal to Receiver 3 12dB SINAD level, modulated

Step 10 While monitoring TP3 with the digital multi-meter, adjust RSSI1 low adjust potentiometer

Step 11 Increase the amplitude of the signal by 50 dBm.

Step 12 While monitoring TP3 with the digital multi-meter, adjust RSSI1 high adjust potentiometer

Adjustments R33 and R35 are interactive adjustments, therefore continue adjustments until the DC voltage

at TP1 is 0.750 VDC for the receiver’s 12 dB SINAD level and 2.75 VDC for a 50 dBm increase from the

receiver’s 12 dB SINAD level.

with a 1 KHz test tone at ±5.0 KHz deviation into Receiver 2.

(R10) for a reading of 0.750 VDC ±10 mV.

(R9) for a reading of 2.75 VDC ±10 mV.

at TP2 is 0.750 VDC for the receiver’s 12 dB SINAD level and 2.75 VDC for a 50 dBm increase from the

receiver’s 12 dB SINAD level.

with a 1 KHz test tone at ±5.0 KHz deviation into Receiver 3.

(R33) for a reading of 0.750 VDC ±10 mV.

(R35) for a reading of 2.75 VDC ±10 mV.

at TP3 is 0.750 VDC for the receiver’s 12 dB SINAD level and 2.75 VDC for a 50 dBm increase from the

receiver’s 12 dB SINAD level.

489288.DOC Page 11

Page 12

SECTION 4: FACTORY TEST PROCEDURE

Step 13 Inject on-frequency signal at a level of –80 dBm, modulated with a 1 KHz test tone at

±5.0 KHz deviation into Receiver 1.

Step 14 While monitoring the AC voltage at RXMOD1,pin 4 of AU6C adjust audio 1 AC

adjustment potentiometer (R72) for 350 mVRMS (±1 mV).

Step 15 While monitoring the DC voltage at RXMOD1,pin4 of AU6C adjust audio 1 DC

adjustment potentiometer (R57) for 2.500 VDC (±1 mV).

The audio AC and DC adjustments are interactive, therefore continue adjusting ARV1 for 350 mVRMS and

Step 16 Inject on-frequency signal at a level of –80 dBm, modulated with a 1 KHz test tone at

Step 17 While monitoring the AC voltage at RXMOD2, pin4 of BU6C adjust audio 1 AC

Step 18 While monitoring the DC voltage at RXMOD2, pin4 of BU6C adjust audio 1 DC

The audio AC and DC adjustments are interactive, therefore continue adjusting BRV1 for 350 mVRMS and

Step 19 Inject on-frequency signal at a level of –80 dBm, modulated with a 1 KHz test tone at

Step 20 While monitoring the AC voltage at RXMOD3, pin4 of CU6C adjust audio 1 AC

Step 21 While monitoring the DC voltage at RXMOD3, pin4 of CU6Cadjust audio 1 DC

The audio AC and DC adjustments are interactive, therefore continue adjusting CRV1 for 350 mVRMS and

Step 22 Adjust the carrier detect potentiometer (R74) to illuminate a level of –116 dBm.?

Receive Data

Step 1 Using a calibrated mobile radio, generate uplink data messages using the X=1400,19

Step 2 Attach an antenna to one of the base station’s receiver ports and verify on the base

ARV2 for 2.500 VDC until further adjustments are no longer required.

±5.0 KHz deviation into Receiver 2.

adjustment potentiometer BRV1) for 350 mVRMS (±1 mV).

adjustment potentiometer (BRV2) for 2.500 VDC (±1 mV).

BRV2 for 2.500 VDC until further adjustments are no longer required.

±5.0 KHz deviation into Receiver 3.

adjustment potentiometer (CRV1) for 350 mVRMS (±1 mV).

adjustment potentiometer (CRV2) for 2.500 VDC (±1 mV).

CRV2 for 2.500 VDC until further adjustments are no longer required.

command in the IPMessage Utility program.

station monitor screen (HyperTerminal) that the received message data quality are

consistently 240 and higher for 1400 character messages. Repeat test for each receiver.

489288.DOC Page 12

Page 13

SECTION 4: FACTORY TEST PROCEDURE

Exciter

Step 1 Using the X=1400,19 command, generate data messages so the transmit power and

frequency can be checked.

Step 2 Step 3 Connect the base stations’ transmit port to the HP communication test set.

Step 4 While transmitting data messages using the X=1400,19 command, adjust the following:

RV2 for ±5 KHz deviation

Transmit output power should be approximately 1mWatt. The REFMOD adjustment needs to be made

Step 5 Connect the base station to the IPNC.

Step 6 Using a calibrated mobile radio operating on the base station’s channel, adjust RV1 for

This command will ping the IPNC continuously with a 500-character test message. Press [Ctrl]+C to

Power Amplifier

Step 1 Connect the base station’s transmit port to the communication test set.

Step 2 Using the X=1400,19 command, generate data messages.

Step 3 Slowly increase the base station output power by turning the power control potentiometer

Do not exceed 40 watts output power, as this will reduce the life of the amplifier module. If the base

Step 4 Perform a close visual inspection of the base station paying close attention to

while the base station is transmitting real data messages to and from a mobile radio. This is most easily

done using the ping command to ping the IPNC from a mobile radio. This will cause the base station to

repeatedly send data messages and will facilitate the REFMOD adjustment.

consistent data quality readings of 248 (as observed on the mobile radio’s attached PC

IPMessage window). Access the MSDOS prompt and ping using the following command:

>;ping 192.168.3.3 –t –l 500 –w 2000

stop the ping.

clockwise until the power noted in Step 2.

station uses a power amplifier, output power must be set to achieve power output specified for the

specific base station installation.

manufacturing related problems such as loose screws, solder practices, etc.

489288.DOC Page 13

Page 14

700 MHZ Base Station FCC Label Placement

SECTION 5: FCC LABEL

16842 Von Karman Ave S uite 200, CA 92606

Model

SNMAC ID

700 MHZ Base Station FCC Label

U.S. PATENT Nos.

5,640,695

6,018,647

6,243,393

Made in U.S.A

489288.DOC Page 14

Page 15

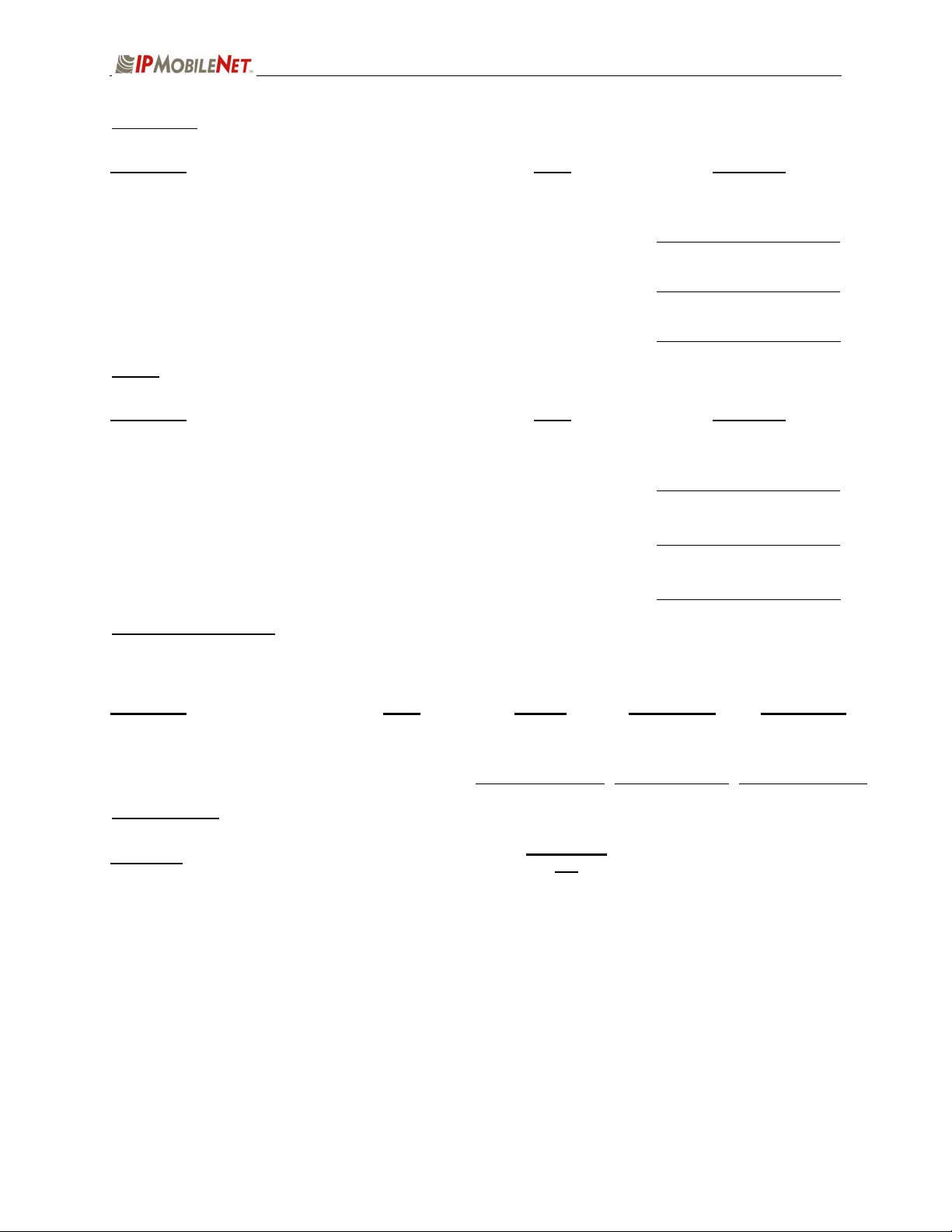

Program and Configure the Base Station

Date

Serial Number

Firmware Revision

End User

Tester

Adjustment / Alignment Procedures

Receiver Injection

Parameter

Spec Measured

Injection Frequency Error at RXINJ1(within +/- 10

Hz of exact injection frequency)

SECTION 6: 700 MHZ TEST DATA SHEET

+/- 100 Hz

P1 & C39

Receiver Diversity Reception Controller 1, 2 & 3

Parameter

U2 Pin 4

RSSI Test Point TB1-4

Distortion

(1 kHz Test Tone @ 5.0 kHz)

SINAD 12 dB

(1 kHz Test Tone @ 5 kHz)

Spec

+10 to +5 dBm

2.8 to 3.0 VDC

3%<

-119dBm >

Audio AC Amplitude

(1 kHz Test Tone @ 5 kHz

350 mVRMS

+/- 1mV

Deviation)

Audio DC Amplitude

(1 kHz Test Tone @ 5 kHz

2.5 VDC

+/1 1mV

Deviation)

Carrier Detect Light Set

-116 dBm

5 +/- 1 dBm

Receiver 1

Measured

Receiver 2

Measured

Receiver 3

Measured

489288.DOC Page 15

Page 16

Data Quality

Parameter

Spec Measured

Receiver 1 Data Quality

(x=1400, 19 Command IPMessage Utility)

SECTION 6: 700 MHZ TEST DATA SHEET

240>

Receiver 2 Data Quality

(x=1400, 19 Command IPMessage Utility)

Receiver 3 Data Quality

(x=1400, 19 Command IPMessage Utility)

240>

240>

Exciter

Parameter

Transmit Frequency Error

(Transmitting 1400 character test message)

Spec Measured

+/- 500 Hz

Transmit Modulation Deviation

(5.3 kHz while transmitting 1400 character test

5.1 kHz to 5.3 kHz

message)

Transmit Data Quality

(While transmitting 1400 character test message to

240>

the base station)

Transmit Power Control

Warning: Do Not exceed 40 Watts RF output power during this test

Parameter

Output Power

(Use x=1400,19 command)

Spec RF Out RF Out Max Level set to

40 +/- 1 Watt

Test Check List

Test Task

Attached copy of Base Station’s Firmware Settings

Visual Inspection

Completed

(9)

Copy Base Station Settings Below:

489288.DOC Page 16

Loading...

Loading...