Page 1

Volume XI:

Thermoplastic

Valves

Industrial Technical

Manual Series

FIRST EDITION

IPEX THERMOPLASTIC VALVES

• Ball Valves

• Butterfly Valves

• Diaphragm Valves

• Check and Vent Valves

• Specialty Valves

Page 2

Thermoplastic Valves

Industrial Technical Manual Series

Vol. XI, 1st Edition

© 2008 by IPEX. All rights reserved. No part of this book may

be used or reproduced in any manner whatsoever without prior

written permission. For information contact: IPEX, Marketing, 2441

Royal Windsor Drive, Mississauga, Ontario, Canada, L5J 4C7.

The information contained here within is based on current

information and product design at the time of publication and is

subject to change without notification. IPEX does not guarantee or

warranty the accuracy, suitability for particular applications, or

results to be obtained therefrom.

Page 3

ABOUT IPEX

At IPEX, we have been manufacturing non-metallic pipe and fittings since 1951. We formulate our own compounds and

maintain strict quality control during production. Our products are made available for customers thanks to a network of

regional stocking locations throughout North America. We offer a wide variety of systems including complete lines of piping,

fittings, valves and custom-fabricated items.

More importantly, we are committed to meeting our customers’ needs. As a leader in the plastic piping industry, IPEX

continually develops new products, modernizes manufacturing facilities and acquires innovative process technology. In addition,

our staff take pride in their work, making available to customers their extensive thermoplastic knowledge and field experience.

IPEX personnel are committed to improving the safety, reliability and performance of thermoplastic materials. We are involved in

several standards committees and are members of and/or comply with the organizations listed on this page.

For specific details about any IPEX product, contact our customer service department.

Page 4

SAFETY ALERTS

Engineered thermoplastics are safe inert materials that do not pose any significant safety or environmental hazards during

handling or installation. However, improper installation or use can result in personal injury and/or property damage. It is

important to be aware of and recognize safety alert messages as they appear in this manual.

The types of safety alert messages are described below.

This safety alert symbol indicates important safety messages in

this manual. When you see this symbol be alert to the possibility

of personal injury and carefully read and fully understand the

message that follows.

WARNING

“WARNING” identifies hazards or unsafe practices that

can result in severe personal injury or death if

instructions, including recommended precautions, are

not followed.

Note: The use of the word “NOTE” signifies special instructions which are

important but are not related to hazards.

For the materials described in this manual, the following warming applies.

“CAUTION” identifies hazards or unsafe practices that

can result in minor personal injury or product or

property damage if instructions, including

recommended precautions, are not followed.

WARNING

• NEVER use compressed air or gas in PVC/CPVC/PP/PVDF

pipe and fittings.

• NEVER test PVC/CPVC/PP/PVDF pipe and fittings with

compressed air or gas, or air-over-water boosters.

• ONLY use PVC/CPVC/PP/PVDF pipe for water and

approved chemicals.

CAUTION

Use of compressed air or gas in PVC/CPVC/PP/PVDF pipe

and fittings can result in explosive failures and cause severe

injury or death.

IPEX Thermoplastic Valves

i

Page 5

NOTES

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

ii

IPEX Thermoplastic Valves

Page 6

CONTENTS

Thermoplastic Valves Manual

About IPEX

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Section One: General Information

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Material Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Valve Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Valve Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Further Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Section Two: Ball Valves

VKD Series Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

VX Series Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

VE Series Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

MP Series Compact Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

TK Series 3-Way Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

TKD Series 3-Way Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

VT Series 3-Way Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Section Three: Butterfly Valves

FK Series Butterfly Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

FE Series Butterfly Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Section Four: Diaphragm Valves

VM Series Manual Diaphragm Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

VM Series Pneumatic Diaphragm Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

DV Series Diaphragm Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

CM Series Compact Diaphragm Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

DM Series Diaphragm Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

IPEX Thermoplastic Valves

iii

Page 7

Section Five: Check and Vent Valves

VB Series Ball Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

VR Series Piston Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

SC Series Swing Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

VA Series Air Release Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Section Six: Specialty Valves

RV Series Sediment Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

SF Series Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

LV Series Lab Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Section Seven: Standards

Standards Organizations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Applicable Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Valve Application Assistance Form

iv

IPEX Thermoplastic Valves

Page 8

SECTION ONE: GENERAL INFORMATION

OVERVIEW

This manual provides the most up-to-date and comprehensive information about IPEX valves. Written with the needs of the

engineer and contractor in mind, all aspects of our valves are covered. This includes material properties, specifications, valve

types and selection, installation, as well as testing and operating considerations.

With more than 50 years of design and manufacturing experience, these lightweight, long life and maintenance free valves

save both time and money. Our high-tech automated manufacturing and testing facility ensures unparalleled reliability for

each and every valve.

IPEX quality engineered products include many unique characteristics ranging from important safety features, to simple

ergonomic and aesthetic benefits. Material options such as PVC, CPVC, PP, PVDF, and ABS make our corrosion resistant

valves ideal for use in a wide variety of demanding applications.

IPEX thermoplastic valves are part of our complete systems of pipe, valves, and fittings, engineered and manufactured to our

strict quality, performance, and dimensional standards. Our network of manufacturing and customer service facilities across

North America ensures fast, reliable service, and expert technical support.

INFORMATION

GENERAL

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

1

Page 9

GENERAL

INFORMATION

FEATURES AND BENEFITS

IPEX valves have extensive features and benefits unrivalled

by the competition. The compact and double blocking design

of our ball valves makes them easy to install, yet safe while

conducting line maintenance. Machined components and

anti-frictions rings result in reduced seal wear and minimal

breakaway torque on all our quarter turn valves. Ergonomic

handles with incorporated safety lockouts can be removed to

reveal integrated ISO pads for direct mount actuation. Many

of our valves feature deep square style threads for improved

strength and reliability as well as thick o-rings and deep

grooves for maximum sealing. For a complete list of features

and benefits, please consult the Thermoplastic Valve

Multimedia CD or the specific valve literature.

2

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 10

APPLICATIONS

Industrial and Process Piping

• Plant Water Supply and Distribution Lines

• Cooling Water Systems

• Chemical and Washwater Systems for Photographic Laboratories

• Acid Products Handling for Refineries, Metal Works and Plating Plants

• Bleach, Dye and Acid Lines in Textile Mills

• Deionized Water

• Tailing and Slurry Lines in Mines, Smelters and Fertilizer Plants

• Vacuum Piping

• Pure Chemicals for Semiconductor & Pharmaceutical Industries

• Piping in Fish Hatcheries, Aquariums, Zoological and Biological Buildings

• Well Casings and Dewatering Lines

• Drainage and Effluent Piping

• Swimming Pool Piping

• Rainwater Leaders for Buildings

Pulp and Paper

INFORMATION

GENERAL

• Pulp/Chemical Recovery Systems

• Bleach Plant Piping Systems

• Washwater Piping and Lagoon Systems

Food Processing

• Brine and Seawater Distribution in Fish Plants

• Brine Systems in Meat Packaging Plants

• Piping for the Dairy, Canning and Beverage Industries

Water and Sewage Treatment

• Alum and Ferric Chloride Handling

• Chlorine Injection Systems

• Piping in Lagoons and Settling Ponds

• Rainwater Lines

Irrigation

• Golf Courses

• Greenhouses

• Agriculture

• Residential Turf

• Commercial Turf

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

3

Page 11

MATERIAL DESCRIPTION

GENERAL

INFORMATION

PVC (Polyvinyl Chloride)

PVC is the most frequently specified of all thermoplastic

materials and has been used successfully for over 60 years.

PVC is characterized by distinctive physical properties, and is

resistant to corrosion and chemical attack by acids, alkalis,

salt solutions and many other chemicals. It is attacked,

however, by polar solvents such as ketones and aromatics. Of

the various types and grades of PVC used in plastic piping

systems, Type 1, Grade 1 PVC (Cell Classification 12454)

conforming to ASTM D1784 is the most common.

CPVC (Chlorinated Polyvinyl Chloride)

CPVC (Cell Classification 23447) conforming to

ASTM D1784 has physical properties at 73°F (23ºC) similar

to those of PVC and chemical resistance similar to or

generally better than that of PVC. With a design stress of

2,000psi and maximum service temperature of 210°F

(99ºC), CPVC has proved to be an excellent material for hot

corrosive liquids, hot and cold water distribution and similar

applications above the temperature range of PVC.

PP (Polypropylene)

Polypropylene is a lightweight polyolefin that is generally high

in chemical resistance. Although Type 1 Polypropylene

conforming to ASTM D2146 is slightly lower in physical

properties than PVC, it is chemically resistant to organic

solvents as well as acids and alkalies. Generally, polypropylene

should not be used in contact with strong oxidizing acids,

chlorinated hydrocarbons and aromatics. Polypropylene has a

design stress of 1,000psi at 73°F (23ºC).

ABS (Acrylonitrile-Butadiene-Styrene)

ABS identifies a broad family of engineering thermoplastics

with a range of performance characteristics. The copolymeric

system can be blended to yield the optimum balance of

properties suited to a selected end use. Acrylonitrile imparts

chemical resistance and rigidity. Butadiene endows the

product with impact strength and toughness, while Styrene

contributes to ease of processing.

EPDM (Ethylene propylene diene monomer)

EPDM is the abbreviation, issued by ASTM, for elastomers

derived from the propylene and ethylene copolymer. The

absence of unsaturation groups at the molecular level gives

EPDM excellent resistance to oxidation products but will

show a certain swelling when in contact with mineral and

petroleum oils, diester base lubricants and organic solvents.

Its operating temperature ranges from -65ºF to 284°F

(-54ºC to 140°C).

FPM (Vinylidene fluorine rubber)

FPM is the abbreviation, issued by ASTM, for fluorocarbon

elastomers derived from vinylidene fluorine copolymers.

Trade names include Viton A&B

Characterized by excellent resistance to heat and chemical

agents, FPM is virtually inert to oil and most solvents and

exhibits good chemical resistance to many aromatic and

aliphatic hydrocarbons. Its working temperature range is

considered to be from -13°F to 392°F (-25°C to 200°C)

although it has been known to seal at very low

temperatures such as -58°F (-50°C).

TM

or TecnoflonTM.

PVDF (Polyvinylidene Fluoride)

Polyvinylidene Fluoride is a strong, abrasion-resistant

thermoplastic with excellent heat stability and chemical

resistance typical of fluorocarbon polymers. It can be used in

temperatures up to 300°F (149ºC) with a wide variety of

acids, bases and organic solvents, and is ideally suited for

handling wet or dry chlorine, bromine and other halogens. No

other thermoplastic piping material can approach the

combination of strength, chemical resistance and operating

temperature that PVDF piping systems can offer.

PTFE (Polytetrafluorethylene)

PTFE or polytetrafluorethylene is a fluorinated polymer

characterized by a high molecular weight and a nearly

complete chemical resistance to reactives and solvents.

Thanks to its characteristics of self-lubrication, shock

resistance and extraordinary chemical inertness,

polytetrafluorethylene polymers, under trade names such as

TeflonTM, FluonTMand ArgoflonTM, have been successfully used

in the manufacture of sealing components. Among

thermoplastic resins, PTFE allows the highest working

temperatures. It can be used at constant temperatures of up

to 500°F (260°C).

4

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 12

VALVE TYPES

By definition, a valve is any device that regulates the flow of gases, liquids, or loose materials through piping or through

apertures by opening, closing, or obstructing ports or passageways. Some main categories of valve types are as follows:

Ball Valves

Ball valves are generally used for on/off service, but can range from simple

molded-in-place construction to high-end industrial designs with many

features and benefits. Multi-port ball valves allow for mixing, diverting, and

bypassing flow. Their name is derived from the modified ball in the center of

the valve which allows flow to enter and exit through two or more ports. This

ball is tightly held between multiple seats, and is cycled via a stem-handle

connection. They are typically categorized as "quarter turn" or 90° valves, and

can be easily automated. Many ball valves feature full port flow, blocking true

union ends, and compact ergonomic designs allowing for simple installation

and maintenance.

Butterfly Valves

These highly versatile valves can be used for simple on/off service but also

for processes requiring precise throttling. They get their name from the stemdisc assembly that controls the flow. Cycling the valve just 90° allows full

travel from the closed position (disc perpendicular to the pipeline) to the

open position (disc parallel to the pipeline) or vice versa. A continuous flow

profile between fully closed and fully open makes these valves ideal for use

in modulating service. While typically connected to the system between two

flanges, end-of-line installation is possible while maintaining pressure

upstream. An extensive size range and direct mount actuation make them

suitable for a wide range of applications.

INFORMATION

GENERAL

Diaphragm Valves

These valves are the perfect solution when precise flow throttling is required.

Their design employs a flexible "diaphragm" component which is compressed

against the body of the valve to provide a bubble tight seal. The weir style

design is extremely good for abrasive slurries as there is no "dead space" for

particles to become trapped. They are widely used in high purity applications

because their design prevents friction and subsequent particle creation when

cycling. Only the body and diaphragm are in contact with the process media.

Due to the modular nature of the design, many body styles, diaphragm and

seal materials, and actuation options are available.

Check and Vent Valves

Check valves are unidirectional and should be used whenever there is a need

to prevent back-flow of process media. This may be when two incompatible

fluids cannot be allowed to mix, or when reverse flow would cause

undesirable drainage of a system line or tank. Many styles exist including:

simple ball checks, heavy duty swing checks, and highly efficient piston

checks. These valves are typically gravity operated and require very little back

pressure seal. Air release or vent valves safely allow any entrapped air or gas

to escape, avoiding potential damage to the piping system.

Specialty Valves

IPEX offers a few specialized valves for a variety of process requirements.

Sediment strainers trap suspended particles flowing in the process line,

ensuring that downstream components are protected. Solenoid valves are

ideal for high-cycle applications where remote operation and precise control

are important. Lab valves are an economical solution for small scale on/off

requirements.

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

5

Page 13

The following table should be used as a guide only as some valves only offer certain combinations of sizes, materials,

connections, and pressure capabilities.

Always consult the specific valve style section for complete information regarding

availability and technical performance.

IPEX Thermoplastic Valves

GENERAL

INFORMATION

Valve

Series

VKD Ball 1/2 to 4 PVC, CPVC, PP, ABS TU (S, T), Sm 232

VX Ball 1/2 to 6 PVC, CPVC TU (S, T), F

VE Ball 1/2 to 2 PVC TU (S, T) 232

MP Compact Ball 1/2 to 2 PVC S, T 150

TK 3-Way Ball 1/2 to 2 PVC TU (S, T) 232

VT/VL 3-Way Ball 1/2 to 2 PVC, PP TU (S, T), F, Sm 150

FK Butterfly 1-1/2 to 12 PP, PVC, CPVC, PVDF F (W, L)

FE Butterfly 1-1/2 to 12 PVC F (W)

VM Diaphragm

DV Diaphragm 1/2 to 6 PVC F 150

Valve Type

Sizes

(in)

1/2 to 4

20 to 110 (mm)

Materials End Connections

PVC, CPVC, PP, PVDF TU (S, T), F, Sp, Sm 150

Pressure Rating

(PSI)

232 (1/2" to 2")

150 (2-1/2" to 4")

150 (1-1/2" to 10")

120 (12")

232 (1/2" to 2")

150 (2-1/2" to 8")

75 (10" to 12")

CM Compact Diaphragm

DM Diaphragm 1/2 to 2 PVC TU (S, T), F, Sp 120

VB Ball Check 1/2 to 4 PVC, CPVC TU (S, T), F 150

VR Piston Check 1/2 to 4 PVC TU (S, T), S, T, F

SC Swing Check 3 to 8 PVC F

VA Air Release 3/4, 1-1/4, 2 PVC SU (S, T) 232

RV Strainer 1/2 to 4 PVC, CPVC TU (S, T), S, T, F

SF Solenoid 1/4, 1/2 PVC TU (T)

LV Lab 1/4 PVC T 150

TU = True Union, SU = Single Union, S = Socket (IPS), T = Threaded (NPT), F = Flanged (ANSI 150),

W = Wafer, L = Lugged, Si = Spigot (IPS), Sm = Socket (Metric), Sp = Spigot (Metric)

1/2

16 to 20 (mm)

PVC, CPVC, PP, PVDF TU (S, T), Sp, Sm 90

232 (1/2" to 1")

150 (1-1/4" to 2")

90 (3" to 4")

100 (3")

70 (4" to 8")

232 (1/2" to 1")

150 (1-1/4" to 2")

60 (3" to 4")

30 (1/4)

60 (1/2)

6

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 14

VALVE SELECTION

As is the case with other thermoplastic components in a

processing system, valves must be selected based on the

characteristics of the fluid medium, the system's operating

parameters, and its intended function for a particular

application. Certain valve types are more suitable than others

for on/off service, throttling or modulating, automation, back

flow prevention, etc.

Fluid Properties

Like other system components, the material that is used in

valve construction should be chosen depending on the

chemistry of the fluid. Different plastics have varying abilities to

handle certain chemical types. In a given piping system, the

material selected for a valve is typically the same as what is

specified for the pipe and fittings. However, since valves

contain other components such as seats and seals, particular

attention should be paid to their material selection. Please

consult IPEX's Chemical Resistance Guide for specific materialfluid compatibilities. Abrasiveness, viscosity, and other fluid

properties are sometimes important to consider as well.

Temperature and Pressure

As with pipe and fittings, the strength of a valve is limited by

the operating temperature and pressure of the system.

However, the type of failure that can be expected in valves is

different than that of other piping components as valves

typically contain seats, seals, and moving components. These

critical points can be potentially displaced if the seat or seal

housing softens or distorts due to excessive prolonged heat.

This can result in a loss of pressure capacity if these contact

points lose competence. During the design, manufacture, and

assembly of IPEX valves, careful attention is given to these

vital connections in order to compensate for reduced

performance under extreme conditions.

Valves are typically pressure rated by style; however size,

material type, and temperature play significant roles in

determining the pressure capabilities of a specific valve.

Since they are often constructed of more than one material

type, it is important to review the pressure-temperature

relationship. General pressure ratings are given assuming an

ambient operating temperature of 73°F (23ºC), above which

the maximum pressure capability decreases. To account for

this, detailed pressure-temperature graphs are included in

this manual for each valve type.

Flow rate

An important consideration in valve selection is the intended

flow rate of the system. The flow rate of a particular valve is

expressed as a CV coefficient. This value represents the

number of gallons per minute (GPM) that will flow through a

fully open valve with a 1psi pressure drop at 68°F (20ºC).

These values are determined from an industry standard

testing procedure which uses water as the flowing media

(specific gravity of 1.0). Tables showing acceptable flow rates

for different size valves are included in this manual for each

valve type.

Vacuum Service

Many of our valves have been tested to determine their

ability to withstand service under vacuum conditions. Our

ball, butterfly, and diaphragm valves have been tested to hold

a vacuum in excess of 29 inches of mercury. Please contact

the IPEX technical services department for specific vacuum

service applications.

Other Considerations

Occasionally it may be important to select a particular valve

based on spatial constraints or weight limitations. Some

compact light weight valves are better suited to applications

where space is limited and/or pipe support is not possible.

Requirements such as automation or remote operation may

also demand the selection of a particular valve. For details

regarding actuated ball and butterfly valves, please refer to

the IPEX Industrial technical manual entitled "Quarter Turn

Automation".

INFORMATION

GENERAL

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

7

Page 15

FURTHER INFORMATION

GENERAL

INFORMATION

System Design

The necessity and selection of valves for use in a piping

system is largely a function of the overall process

requirements. For detailed information regarding the design

process and associated considerations, please refer to the

IPEX Industrial technical manual entitled "Vinyl Process

Piping Systems".

Installation Considerations

For detailed information regarding piping installation and

associated considerations, please refer to the IPEX Industrial

technical manual entitled "Vinyl Process Piping Systems". For

particular valve installation instructions, please refer to the

specific valve type section in this manual.

Testing and Operating

The purpose of system testing is to assess the quality of all

joints and fittings to ensure that they will withstand the

design working pressure, plus a safety margin, without loss of

pressure or fluid. Typically, the system will be tested and

assessed in sub-sections as this allows for improved isolation

and remediation of potential problems. With this in mind, the

testing of a specific installed valve is achieved while carrying

out a test of the overall system.

An onsite pressure test procedure is outlined in the IPEX

Industrial technical manual entitled "Vinyl Process Piping

Systems" under the section entitled, "Testing". The use of this

procedure should be sufficient to assess the quality of a valve

installation. In any test or operating condition, it is important

to never exceed the pressure rating of the lowest rated

appurtenance in the system.

Important points

• Never test thermoplastic piping systems with

compressed air or other gases including air-over-water

boosters.

• When testing, do not exceed the rated maximum

operating pressure of the valve.

• Avoid the rapid closure of valves to eliminate the

possibility of water hammer which may cause damage to

the pipeline or the valve.

There are certain applications where proper standard

procedure for valve selection may still result in operating

problems. For example, when conveying volatile liquids such

as hydrogen peroxide (H

(NaClO) through ball valves, these liquids may vaporize

causing a potentially dangerous pressure increase in the dead

space between the ball and the valve body. If left unchecked,

this pressure buildup can result in catastrophic failure of the

valve. IPEX offers specially modified ball valves for these

types of critical applications.

) and sodium hypochlorite

2O2

Maintenance

IPEX valves are designed and manufactured to high quality

standards with long service life expectancy. However, if

maintenance is required, please refer to the specific valve

type section in this manual for instructions.

8

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 16

SECTION TWO: BALL VALVES

VKD SERIES BALL VALVES

IPEX VKD Series Ball Valves offer a variety of advanced

features such as the patented seat stop carrier, a high quality

stem and ball support system, and a multifunctional locking

handle. Deep grooves, thick o-rings, and cushioned Teflon

seats contribute to strong seals at pressures up to 232psi

while an integral ISO mounting flange and support bracketing

combine for simple actuation and anchoring. VKD Series Ball

Valves are part of our complete Xirtec®140, Corzan®, SFPP and

Duraplus®systems of pipe, valves, and fittings, engineered and

manufactured to our strict quality, performance, and

dimensional standards.

Valve Availability

Body Material: PVC, CPVC, PP, ABS

®

Size Range: 1/2" through 4"

Pressure: 232psi

150psi (PP)

Seats: Teflon

Seals: EPDM or Viton

End Connections: Socket (IPS)

®

Threaded (FNPT)

Socket (Metric)

(PTFE)

®

(FPM)

BALL VALVES

ASTM D1784

ASTM D2464

ASTM D2466

ASTM D2467

ASTM D4101

ASTM F437

ASTM F439

ASTM F1498

ANSI B1.20.1

ISO 11922-1

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

9

Page 17

BALL VALVES

VKD SERIES BALL VALVES

Sample Specification

1.0 Ball Valves - VKD

1.1 Material

• The valve body, stem, ball and unions shall be made of

PVC compound which shall meet or exceed the

requirements of cell classification 12454 according to

ASTM D1784.

or The valve body, stem, ball and unions shall be made of

or The valve body, stem, ball and unions shall be made of

or The valve body, stem, ball and unions shall be made of

1.2 Seats

• The ball seats shall be made of Teflon

1.3 Seals

• The o-ring seals shall be made of EPDM.

or The o-ring seals shall be made of Viton

1.4 All wetted parts of the valves shall comply with

2.0 Connections

2.1 Socket style

• The IPS socket PVC end connectors shall conform to

or The IPS socket CPVC end connectors shall conform to

or The Metric socket PP end connectors shall conform to

2.2 Threaded style

• The female NPT threaded PVC end connectors shall

or The female NPT threaded CPVC end connectors shall

or The female NPT threaded PP end connectors shall

®

Corzan

CPVC compound which shall meet or exceed

the requirements of cell classification 23447 according

to ASTM D1784.

stabilized PP homopolymer compound, also containing

a RAL 7032 pigment, which shall meet or exceed the

requirements of Type I Polypropylene according to

ASTM D4101.

Duraplus

®

ABS compound which shall meet or exceed

the requirements of cell classification 43234 according

to ASTM D3965.

®

(PTFE).

®

(FPM).

standards that are equivalent to NSF Standard 61 for

potable water.

the dimensional standards ASTM D2466 and ASTM

D2467.

the dimensional standard ASTM F439.

the dimensional standard ISO 11922-1.

conform to the dimensional standards ASTM D2464,

ASTM F1498, and ANSI B1.20.1.

conform to the dimensional standards ASTM F437,

ASTM F1498, and ANSI B1.20.1.

conform to the dimensional standards ASTM F1498,

and ANSI B1.20.1.

3.0 Design Features

• The valve shall be double blocking with union ends.

• All valves shall be full port.

• All valves shall allow for bi-directional flow.

• The valve body shall be single end entry with a

threaded carrier (ball seat support).

• The threaded carrier shall be adjustable with the valve

installed.

• The valve body shall have an expansion and contraction

compensating groove on the molded end.

• The valve body, union nuts, and carrier shall have deep

square style threads for increased strength.

• The ball and stem shall be machined smooth to

minimize wear on valve seats and seals.

• All valve seats shall have o-ring backing cushions to

compensate for wear and prevent seizure of the ball.

• The stem design shall feature double o-ring seals as

well as a safety shear point above the o-rings.

• All valves shall have integrally molded mounting

features for actuation.

• All valves shall have integrally molded support

bracketing for anchoring.

• The valve shall include the Dual Block

®

union nut

locking mechanism.

3.1 Pressure Tested

• All valves shall have been pressure tested in both the

open and closed positions by the manufacturer.

3.2 Pressure Rating

• All PVC, CPVC and ABS valves shall be rated at

232psi at 73°F (23ºC).

• All PP valves shall be rated at 150psi at 73°F (23ºC).

3.3 Markings

• All valves shall be marked to indicate size, material

designation, and manufacturers name or trade mark.

3.4 Color Coding

• All PVC valves shall be color-coded dark gray.

or All CPVC valves shall be color-coded light gray.

or All PP valves shall be color-coded beige gray.

or All ABS valves shall be color-coded light gray.

4.0 All valves shall be Xirtec

Duraplus

®

by IPEX or approved equal.

®

140, Corzan®, SFPP or

10

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 18

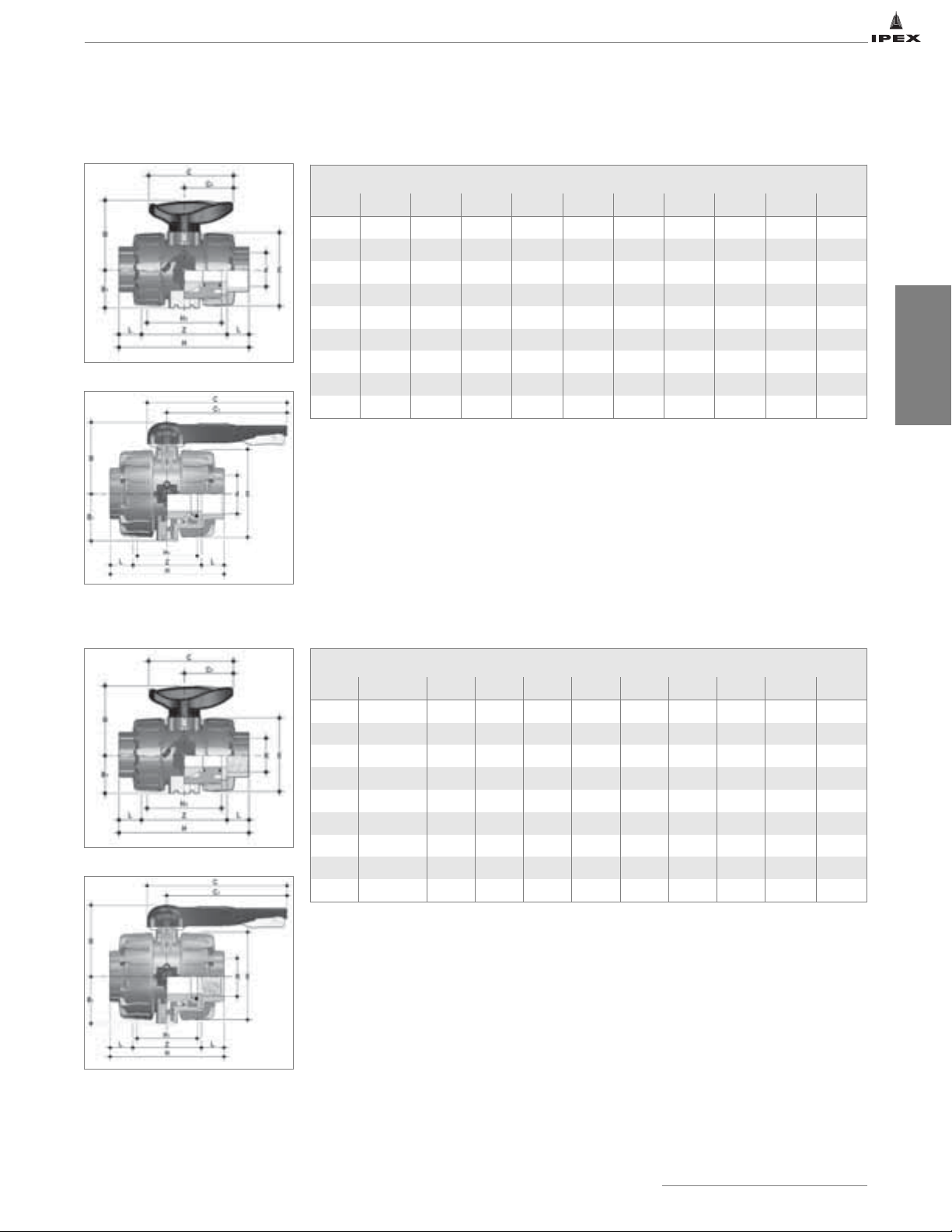

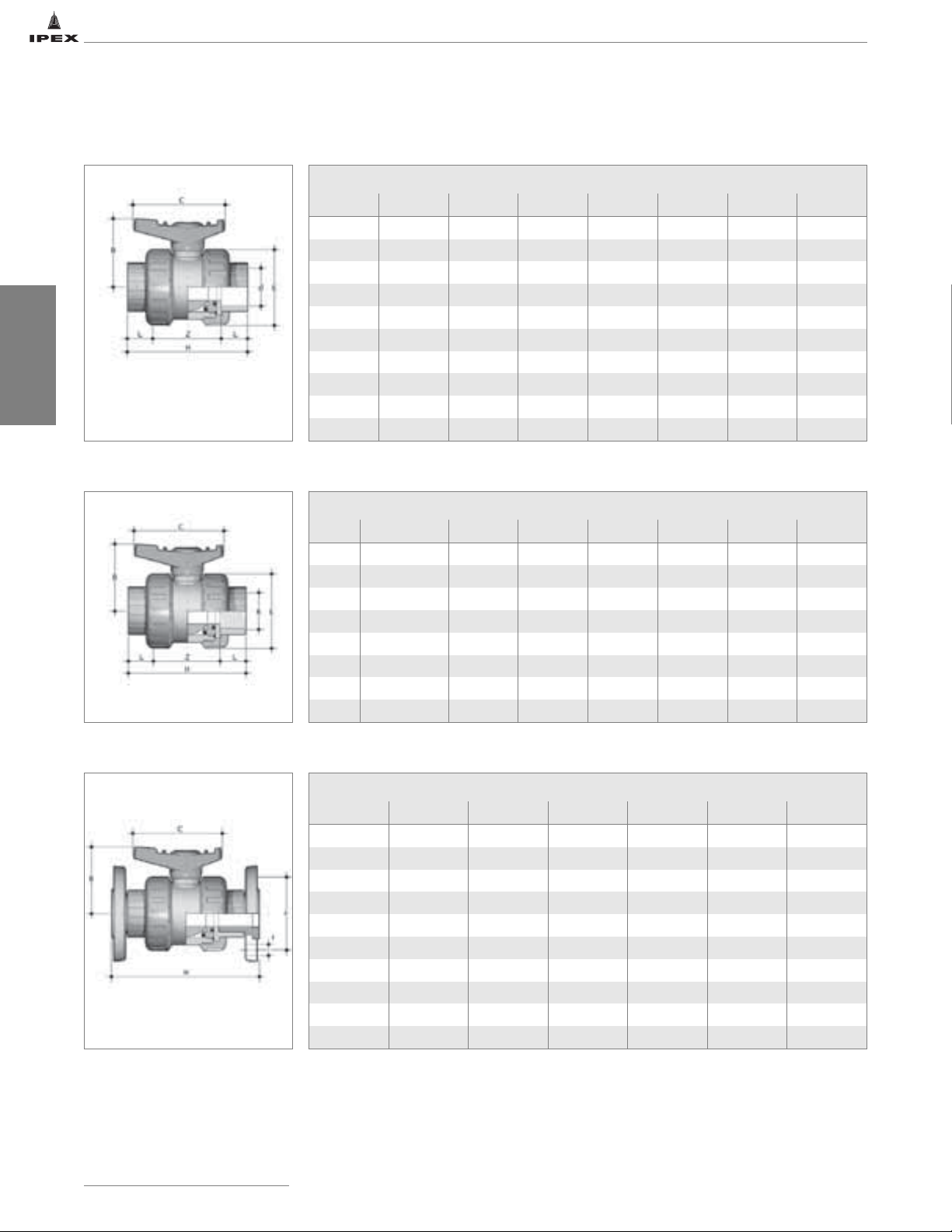

Dimensions

Sizes 1/2" to 2"

VKD SERIES BALL VALVES

IPS Socket Connections - Dimension (inches)

Size d H L Z H1 E B1 B C1 C

1/2 0.84 4.61 0.89 2.83 2.56 2.13 1.14 2.13 1.57 2.64

3/4 1.05 5.08 1.00 3.07 2.76 2.56 1.36 2.56 1.93 3.35

1 1.32 5.59 1.13 3.33 3.07 2.87 1.54 2.74 1.93 3.35

1-1/4 1.66 6.38 1.26 3.86 3.46 3.39 1.81 3.25 2.52 4.25

1-1/2 1.90 6.77 1.38 4.02 3.66 3.86 2.05 3.50 2.52 4.25

2 2.38 7.83 1.50 4.83 4.37 4.80 2.44 4.25 2.99 5.28

2-1/2 2.88 9.25 1.75 5.75 5.24 6.46 3.43 6.46 6.89 8.86

3 3.50 10.63 1.89 6.85 5.87 7.99 4.13 6.97 10.71 12.87

4 4.50 12.13 2.26 7.60 6.57 9.37 5.08 7.68 12.99 15.16

BALL VALVES

Sizes 2-1/2" to 4"

Sizes 1/2" to 2"

Female NPT Threaded Connections - Dimension (inches)

Size R H L Z H1 E B1 B C1 C

1/2 1/2-NPT 4.37 0.70 2.97 2.56 2.13 1.14 2.13 1.57 2.64

3/4 3/4-NPT 4.61 0.71 3.19 2.76 2.56 1.36 2.56 1.93 3.35

1 1-NPT 5.31 0.89 3.54 3.07 2.87 1.54 2.74 1.93 3.35

1-1/4 1-1/4-NPT 6.02 0.99 4.05 3.46 3.39 1.81 3.25 2.52 4.25

1-1/2 1-1/2-NPT 6.14 0.97 4.20 3.66 3.86 2.05 3.50 2.52 4.25

2 2-NPT 7.32 1.17 4.99 4.37 4.80 2.44 4.25 2.99 5.28

2-1/2 2-1/2-NPT 9.25 1.31 6.64 5.24 6.46 3.43 6.46 6.89 8.86

3 3-NPT 10.63 1.40 7.83 5.87 7.99 4.13 6.97 10.71 12.87

4 4-NPT 12.13 1.48 9.17 6.57 9.37 5.08 7.68 12.99 15.16

Sizes 2-1/2" to 4"

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

11

Page 19

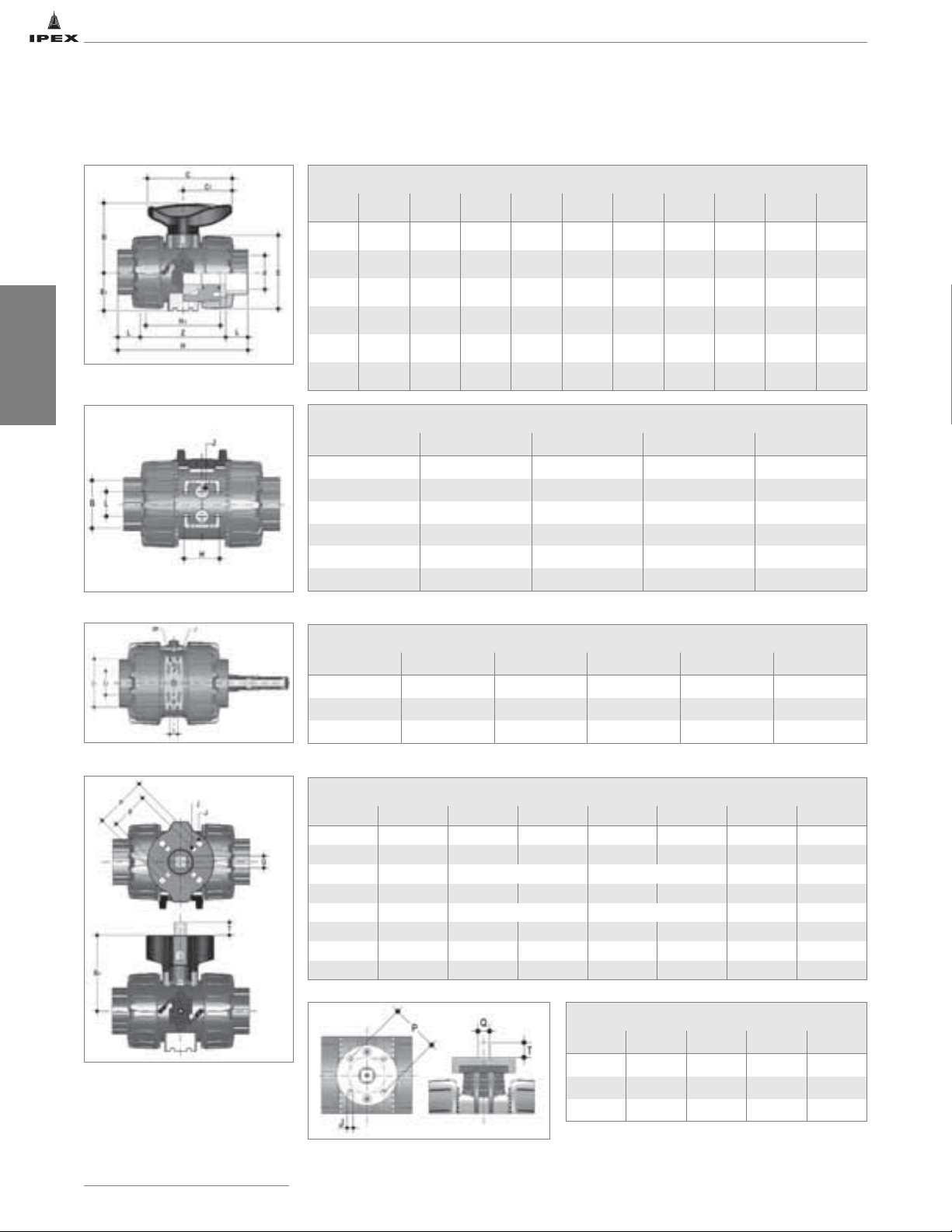

Dimensions

VKD SERIES BALL VALVES

Metric Socket Connections - Dimension (inches)

Size d H L Z H1 E B1 B C1 C

20mm 0.79 4.02 0.57 2.87 2.56 2.13 1.14 2.13 1.57 2.64

25mm 0.98 4.49 0.63 3.23 2.76 2.56 1.36 2.56 1.93 3.35

32mm 1.26 4.96 0.71 3.54 3.07 2.87 1.54 2.74 1.93 3.35

40mm 1.57 5.55 0.81 3.94 3.35 3.39 1.81 3.25 2.52 4.25

50mm 1.97 6.46 0.93 4.61 3.66 3.86 2.05 3.50 2.52 4.25

BALL VALVES

Sizes 20mm to 63mm

Sizes 1/2" to 2"

Sizes 2-1/2" to 4"

63mm 2.48 7.83 1.08 5.67 4.37 4.80 2.44 4.25 2.99 5.28

Support Bracket - Dimension (inches)

Size J B L H

1/2 M4 1.24 0.79 1.06

3/4 M4 1.57 0.79 1.18

1 M4 1.57 0.79 1.18

1-1/4 M6 1.97 1.18 1.38

1-1/2 M6 1.97 1.18 1.38

2" M6 2.36 1.18 1.57

Support Bracket - Dimension (inches)

Size J f I I1 I2

2-1/2 M6 0.25 0.69 3.54 2.04

3 M8 0.33 0.83 4.43 2.48

4 M8 0.33 0.83 5.39 2.64

Actuation Pad - Dimension (inches)

Size B2 p P j J T Q

1/2 2.28 F03 F04 0.22 0.22 0.47 0.43

3/4 2.89 F03 F05 0.22 0.26 0.47 0.43

*3/4 2.89 F04 0.22 0.47 0.43

1 2.91 F03 F05 0.22 0.26 0.47 0.43

*1 2.91 F04 0.22 0.43 0.43

1-1/4 3.82 F05 F07 0.26 0.33 0.63 0.55

1-1/2 4.09 F05 F07 0.26 0.33 0.63 0.55

2 4.49 F05 F07 0.26 0.33 0.63 0.55

12

Actuation Pad - Dimension (inches)

Size P J T Q

Sizes 1/2" to 2"

Sizes 2-1/2" to 4"

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

2-1/2 F07 0.35 0.63 0.55

3 F07 0.35 0.63 0.55

4 F07 0.35 0.75 0.67

Page 20

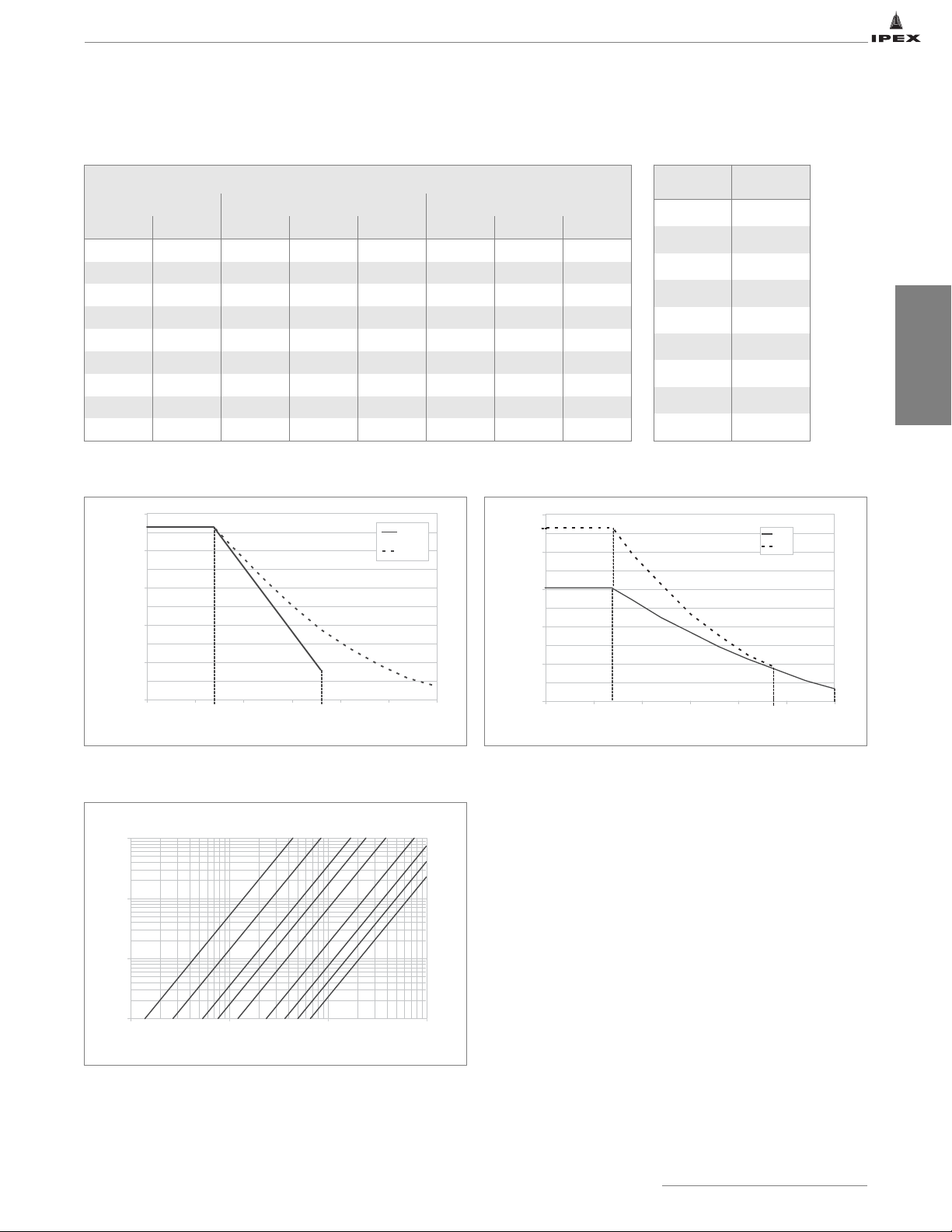

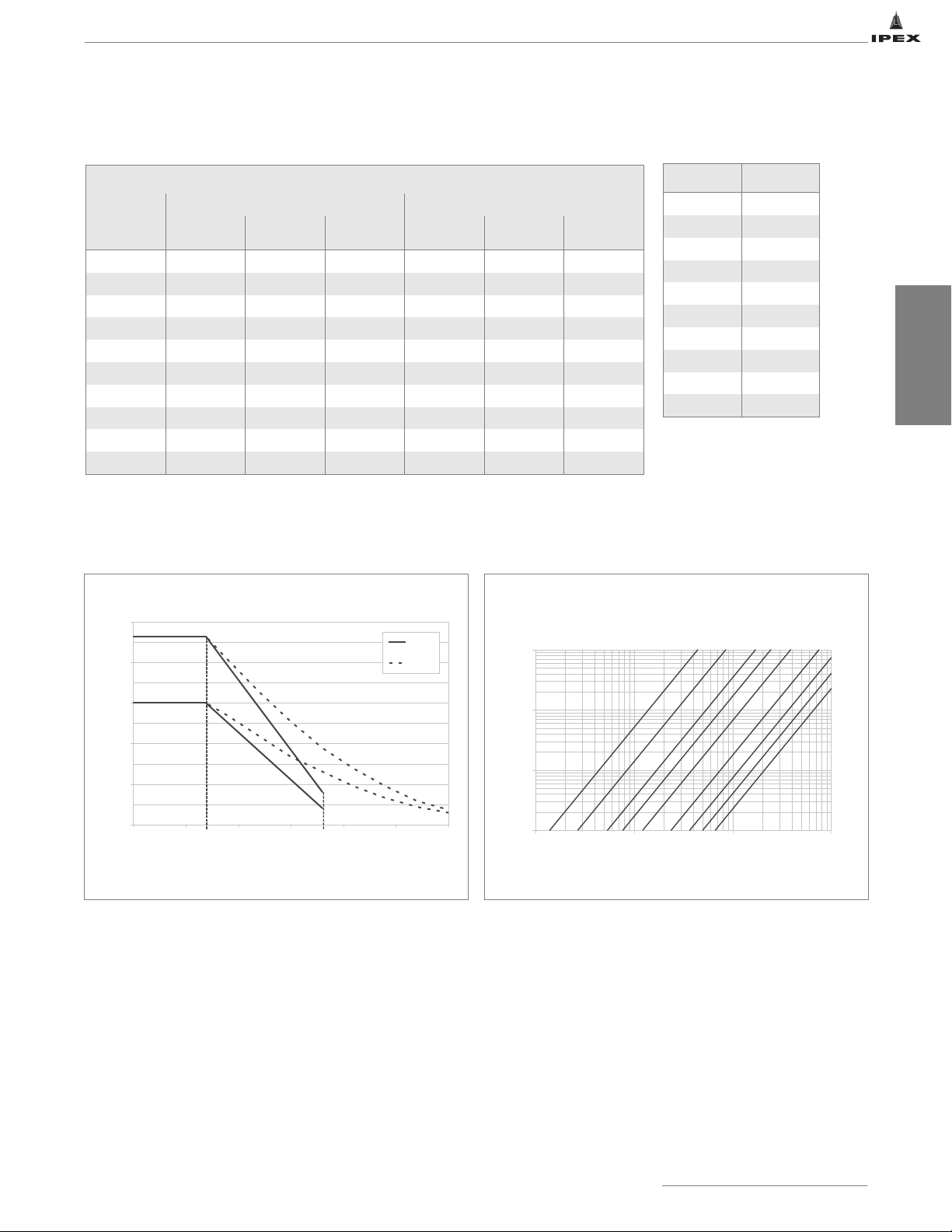

VKD SERIES BALL VALVES

0

50

100

150

200

250

32 62 92 122 152 182 212

Working Temperature (˚F)

Working Pressure (psi)

PVC

CPVC

73 140

232

232

176

1/2"

3/4"1"1-1/4"

1-1/2"2"2-1/2"

3"

4"

Flowrate (GPM)

Pressure loss (psi)

Weights

Approximate Weight (lbs)

Size (inches) IPS / Metric Socket FNPT Threaded

IPS Metric PVC CPVC PP PVC CPVC PP

1/2 20mm 0.47 0.51 0.32 0.46 0.50 0.31

3/4 25mm 0.76 0.82 0.48 0.74 0.79 0.50

1 32mm 0.99 1.06 0.66 0.99 1.06 0.67

1-1/4 40mm 1.58 1.70 1.06 1.49 1.61 1.01

1-1/2 50mm 2.15 2.31 1.50 2.11 2.26 1.43

2 63mm 3.77 4.06 2.57 3.68 3.95 2.50

2-1/2 - 9.68 10.50 - 9.69 10.50 -

3 - 15.90 17.30 - 16.00 17.40 -

4 - 24.40 26.90 - 24.50 27.00 -

Pressure – Temperature Ratings

250

200

150

Flow Coefficients

Size

1/2 14.0

3/4 27.0

1 53.9

1-1/4 77.0

1-1/2 123

2 238

2-1/2 368

3 497

4 665

C

V

BALL VALVES

PP

ABS

Pressure Loss Chart

10

0.1

0.01

1

1 10 100 1000

100

Working Pressure (psi)

50

0

32 62 92 122 152 182 212

73 140

Working Temperature (˚F)

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

IPEX Thermoplastic Valves

13

Page 21

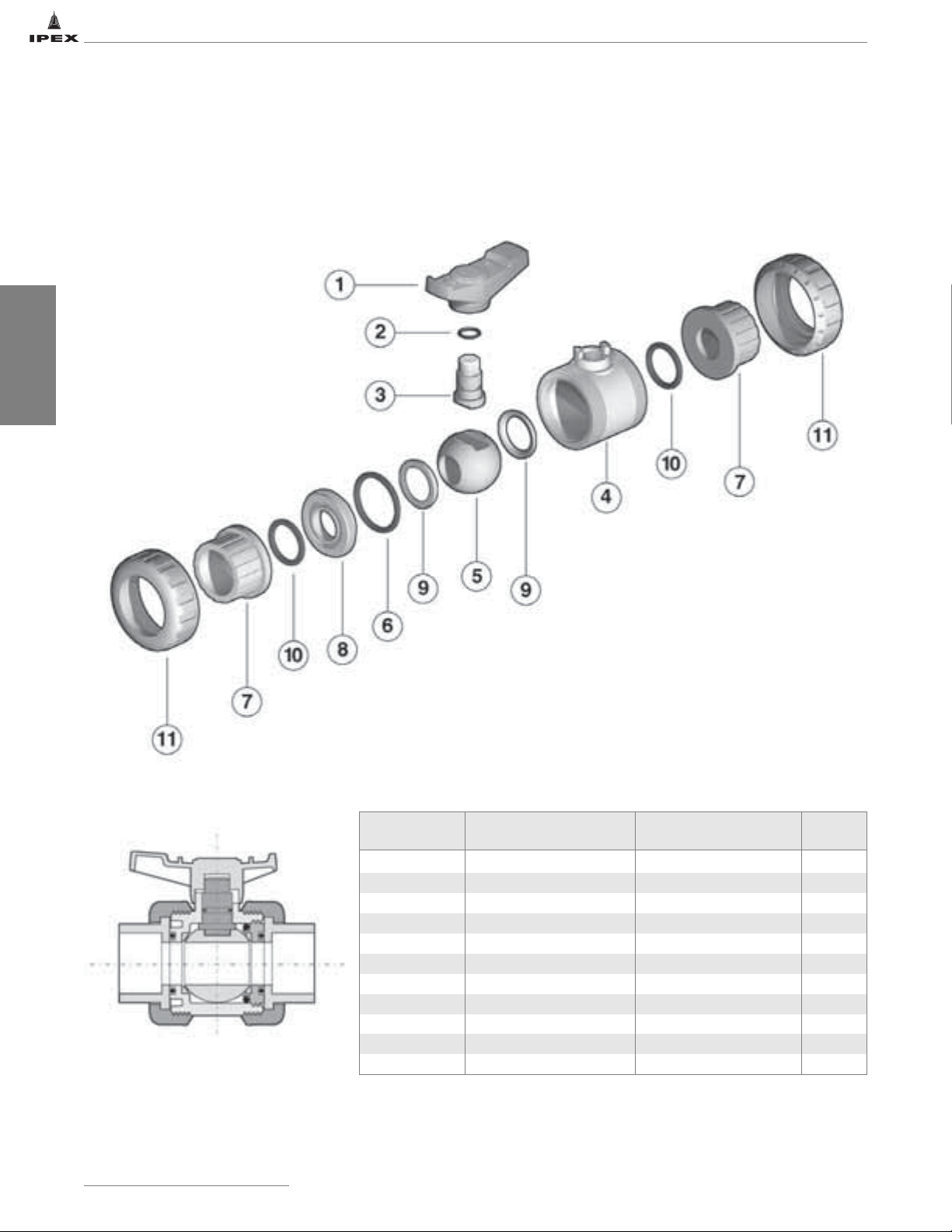

BALL VALVES

VKD SERIES BALL VALVES

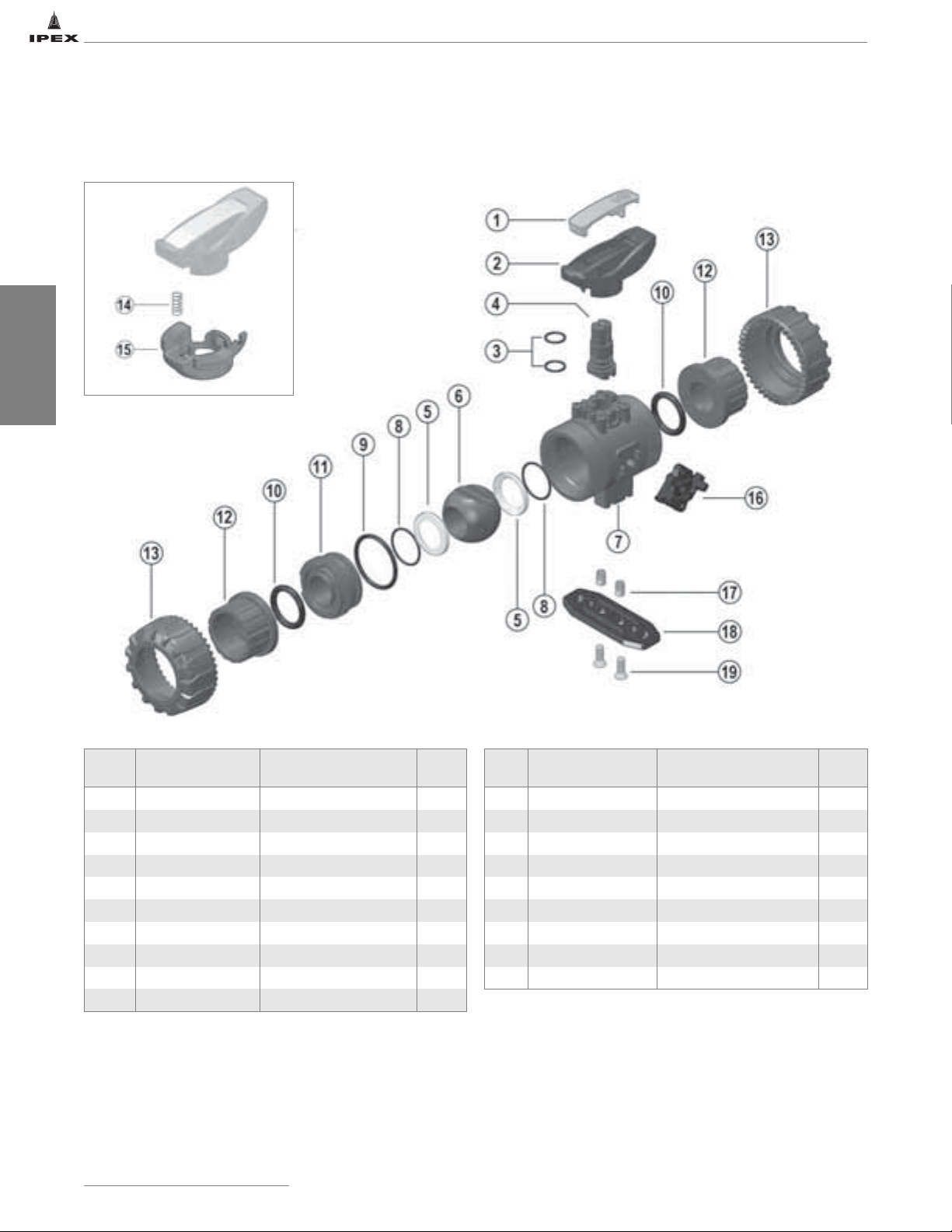

Components

Sizes 1/2" to 2"

# Component Material Qty

1 insert PVC / CPVC / PP / ABS 1

2 handle PVC / CPVC / PP / ABS 1

3 stem o-ring EPDM / Viton

®

4 stem PVC / CPVC / PP / ABS 1

5 ball seat PTFE 2

6 ball PVC / CPVC / PP / ABS 1

7 body PVC / CPVC / PP / ABS 1

8 ball seat o-ring EPDM / Viton

9 body o-ring EPDM / Viton

10 socket o-ring EPDM / Viton

14

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

®

®

®

# Component Material Qty

11 carrier PVC / CPVC / PP / ABS 1

12 end connector PVC / CPVC / PP / ABS 2

2

13 union nut PVC / CPVC / PP / ABS 2

14* spring SS 1

15* handle lock GRPP 1

16 DUAL BLOCK

®

POM 1

17* bracket bushing SS / brass 2

2

1

2

18* mounting plate GRPP 1

19* screw SS 2

*Accessories

Page 22

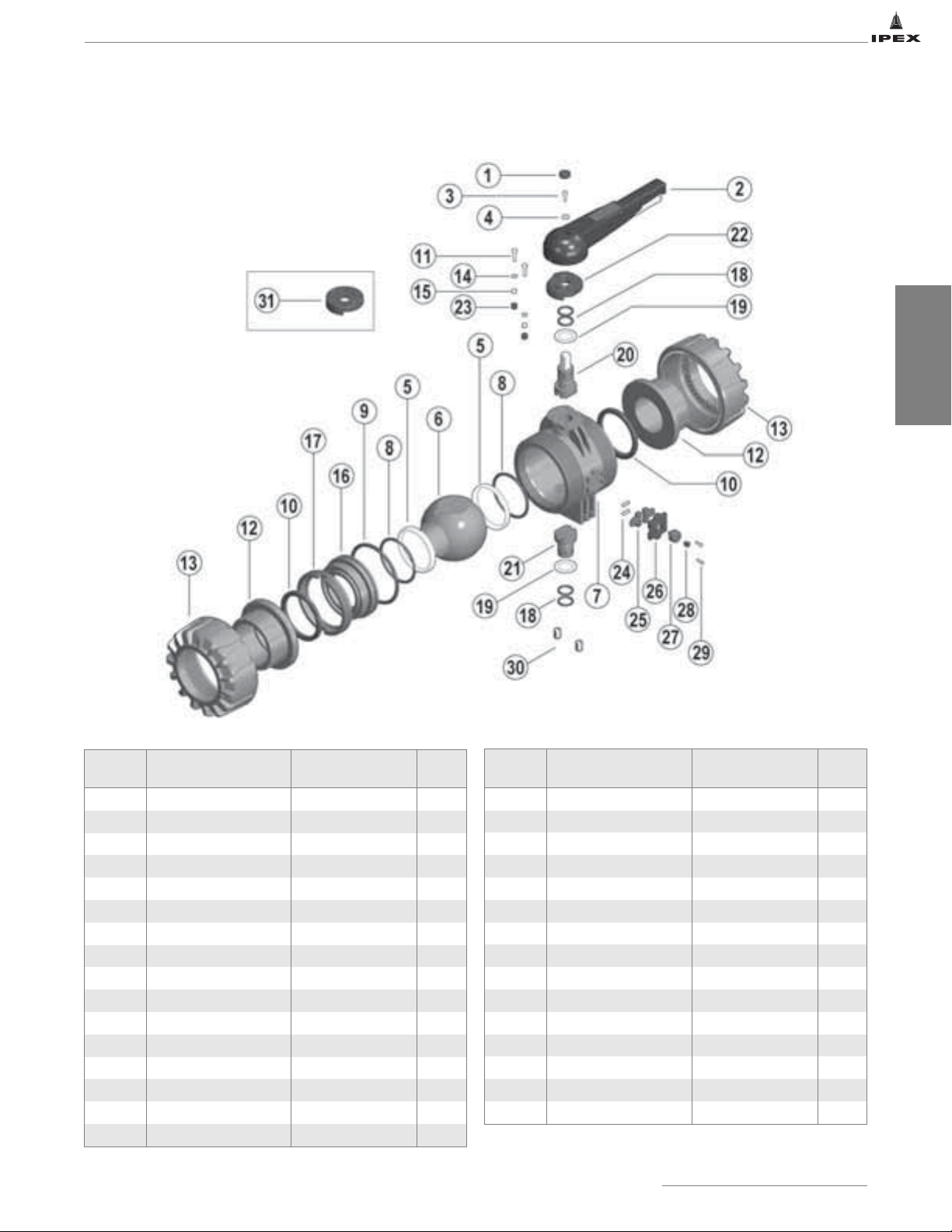

Components (cont’d)

VKD SERIES BALL VALVES

Sizes 2-1/2" to 4"

BALL VALVES

# Component Material Qty

1 protective cap PE

2 handle PVC 1

3 bolt SS

4 washer SS 1

5 ball seat PTFE

6 ball PVC / CPVC 1

7 body PVC / CPVC 1

8 ball seat o-ring EPDM / Viton

9 body o-ring EPDM / Viton

10 socket seal EPDM / Viton

®

®

®

11 bolt SS 2

12 end connector PVC / CPVC 2

13 union nut PVC / CPVC 2

14 washer SS 2

15 nut SS 2

1

1

2

2

1

2

# Component Material Qty

17 stop ring PVC / CPVC

18 stem o-ring EPDM / Viton

19 bushing PTFE

20 upper stem PVC / CPVC & SS 1

21 lower stem PVC / CPVC 1

22 pad GRPP 1

23 protective cap PE

24 spring SS 2

25 nut block GRPP 2

26 cover PP 1

27 nut block button GRPP 1

28 protective cap PE 1

29 screw nylon 2

30 bracket bushing brass 2

31 actuation pad GRPP 1

16 carrier PVC / CPVC 1

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

1

®

4

2

2

15

Page 23

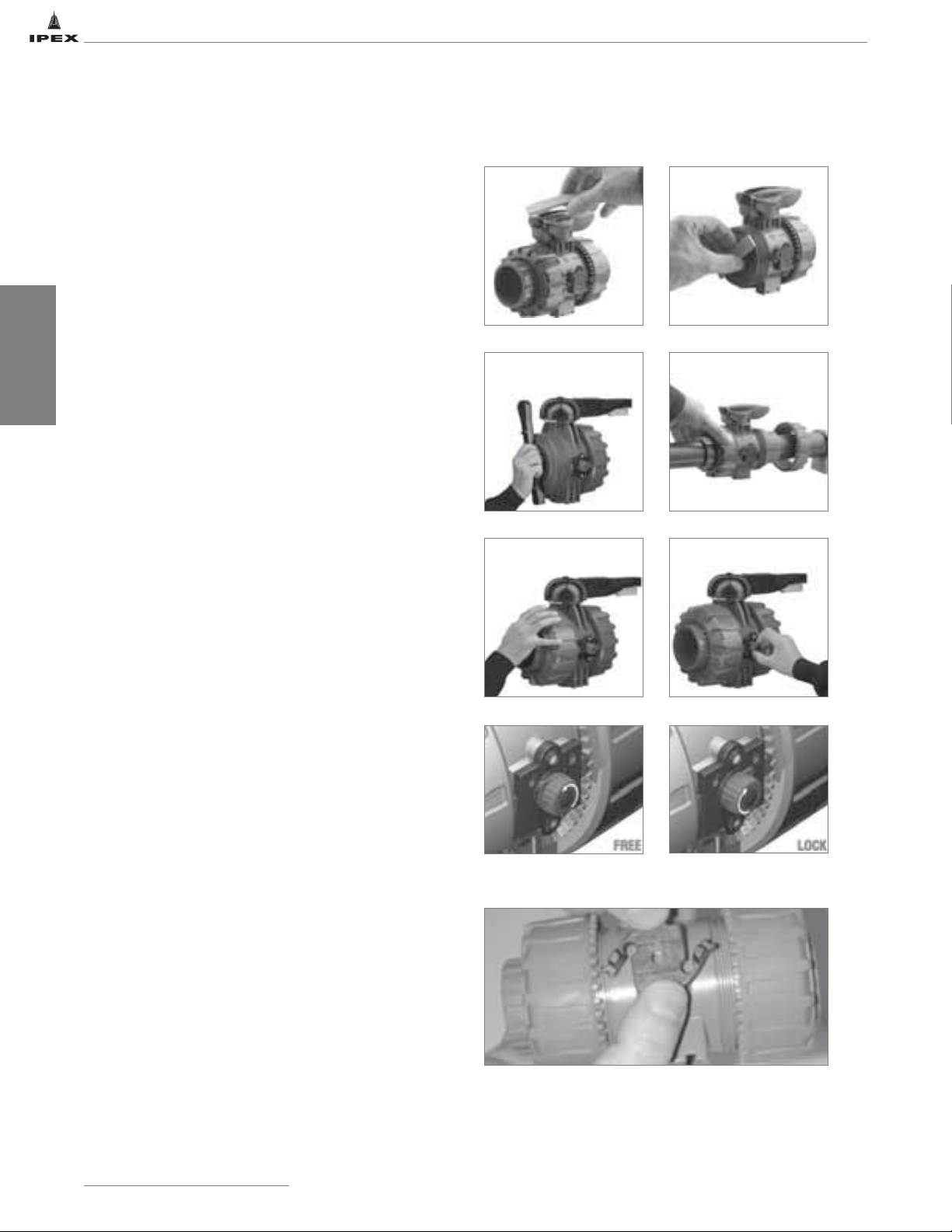

VKD SERIES BALL VALVES

Installation Procedures

1. Remove the union nuts (part #13 on previous page) and

slide them onto the pipe.

2. Please refer to the appropriate connection style sub-section:

a. For socket style, solvent cement or fuse the end

connectors (12) onto the pipe ends. For correct

solvent cementing procedure, please refer to the

section entitled,

Cementing”

Series,

“Volume I: Vinyl Process Piping Systems”

Be sure to allow sufficient cure time before

continuing with the valve installation.

“Joining Methods - Solvent

in the IPEX Industrial Technical Manual

.

BALL VALVES

b. For threaded style, thread the end connectors (12)

onto the pipe ends. For correct joining procedure,

please refer to the section entitled,

Methods - Threading”

Technical Manual Series,

Piping Systems”

3. Open and close the valve to ensure that the carrier (11

or 16) is at the desired adjustment. If adjustment is

required, ensure that the valve is in the closed position

then remove the insert tool (1) from the handle (2). For

sizes 2-1/2" to 4", use the tool that accompanies the

valve. Line up the moldings on the tool with the slots in

the carrier. Tighten or loosen to the desired position then

replace the tool on the handle.

4. Ensure that the valve is in the closed position, and that

the socket o-rings (10) are properly fitted in their

grooves. If anchoring is required, insert the bracket

bushings (17) into the bottom of the valve (sizes 1/2" to

2" only). Carefully place the valve in the system between

the two end connections and fix if necessary.

5. Tighten the union nut on the side opposite to that which

is marked "ADJUST". Hand tightening is typically

sufficient to maintain a seal for the maximum working

pressure. Over-tightening may damage the threads on

the valve body and/or the union nut, and may even

cause the union nut to crack.

in the IPEX Industrial

“Volume I: Vinyl Process

.

“Joining

6. Tighten the union nut on the side marked "ADJUST".

Tightening the union nuts in this order results in the best

possible valve performance due to optimum positioning

and sealing of the ball and seat support system.

7. Open and close the valve to again ensure that the

cycling performance is adequate. If adjustment is

required, place the valve in the closed position, loosen

the union nuts, remove the valve from the system, and

then continue from Step 3.

®

8. Engage the Dual Block

piece (16, sizes 1/2" to 2") to the side of the valve body

or by turning the red knob (27, sizes 2-1/2" to 4") to the

locked position. This feature will prevent back-off of the

union nuts during operation.

16

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

system by affixing the molded

2-1/2" - 4" Dual Block®Mechanism

1/2" - 2" Dual Block®Mechanism

Page 24

VKD SERIES BALL VALVES

Valve Maintenance

Disassembly Assembly

1. If removing the valve from an operating system, isolate

the valve from the rest of the line. Be sure to

depressurize and drain the valve and isolated branch.

2. If necessary, detach the valve from the support structure

by disassembling the connections to the bracket on the

optional bottom of the valve body (7).

®

3. Unlock the Dual Block

system by compressing the two

ends of the molded piece (16, sizes 1/2" to 2") or by

turning the red knob (27, sizes 2-1/2" to 4") to the

unlocked position. Loosen both union nuts (13) and drop

the valve out of the line. If retaining the socket o-rings

(10), take care that they are not lost when removing the

valve from the line.

4. Place the valve in the open position then line up the

moldings on the wrench tool (1, sizes 1/2" to 2") with the

slots in the carrier (found on the side marked “ADJUST”).

Loosen and remove the carrier (11 or 16).

5. Carefully press the ball (6) out of the valve body, taking

care not to score or damage the outer surface.

6. Remove the handle (2) by pulling upwards (sizes 1/2" to

2") or by removing the protective cap (1), bolt (3) and

washer (4) (sizes 2-1/2" to 4").

7. On sizes 2-1/2" to 4", remove the throttling pad (22) by

loosening and removing the bolts (11), washers (14),

nuts (15), and caps (23).

8. Press the stem (4 or 20) into the valve body from above

On sizes 2-1/2" to 4", remove the lower stem (21) by

pushing it into the valve body from below.

9. The stem o-rings (3 or 18), body o-ring (9), ball seats

(5), ball seat o-rings (8), and bushings (19, sizes 2-1/2"

to 4") can now be removed and/or replaced.

Note: It is not typically necessary to disassemble the Dual

®

components (sizes 2-1/2" to 4").

Block

Note: Before assembling the valve components, it is advisable

to lubricate the o-rings with a water soluble lubricant. Be sure

to consult the

trusted resources to determine specific lubricant-rubber

compatibilities.

1. Replace the stem o-rings (3 or 18), body o-ring (9), ball

seat o-rings (8), ball seats (5), and bushings (19, sizes

2-1/2" to 4") in their proper positions.

2. Insert the stem (4 or 20) into position from inside the

valve body (7). On sizes 2-1/2" to 4", insert the lower

stem (21) as well.

3. On sizes 2-1/2" to 4", replace the throttling pad (22) and

affix in position using the bolts (11), washers (14), and

nuts (15). Replace the caps (23) over the nuts.

4. Replace the handle (2). On sizes 2-1/2" to 4", affix using

the bolt (3) and washer (4), then replace the protective

cap (1).

5. Carefully insert the ball (6) into the valve body, taking

care not to score or damage the outer surface. Ensure

that the valve handle and ball position correspond to the

same operating position.

6. Insert the threaded carrier (11 or 16) and tighten into

the valve body. Use the wrench tool to sufficiently

tighten.

7. Place the end connectors (12) into the union nuts (13),

then thread onto the valve body taking care that the

socket o-rings remain properly fitted in their grooves.

8. Engage the Dual Block

piece (16, sizes 1/2" to 2") to the side of the valve body

or by turning the red knob (27, sizes 2-1/2" to 4") to the

locked position.

“IPEX Chemical Resistance Guide”

®

system by affixing the molded

and/or other

BALL VALVES

Operating Notes

The VKD handle incorporates a locking mechanism that

prevents unintentional rotation. When engaged, the springloaded handle release is locked and the valve cannot be

cycled. A padlock can be installed through this portion of

the handle as an additional safety precaution.

Sizes 2-1/2"

Sizes 3" & 4"

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

17

Page 25

VX SERIES BALL VALVES

IPEX VX Series Ball Valves are ideal for general purpose and

O.E.M. applications. These valves feature an ultra-compact

double block design, and full port bi-directional operation.

The true union design allows the valve to be easily removed

from the piping system and fully serviced. A threaded seat

stop carrier provides improved seal integrity under tough

service conditions while the removable handle also

functions as a tool for ball seat adjustment. VX Series Ball

Valves are part of our complete Xirtec

®

140 and Corzan

systems of pipe, valves, and fittings, engineered and

manufactured to our strict quality, performance, and

dimensional standards.

BALL VALVES

ASTM D1784

ASTM D2464

ASTM D2466

ASTM D2467

ASTM F437

ASTM F439

ASTM F1498

ANSI B1.20.1

ANSI B16.5

Valve Availability

Body Material: PVC, CPVC

Size Range: 1/2" through 6"

Pressure: 232psi (1/2" to 2")

150psi (2-1/2" to 6")

®

Seats: Teflon

Seals: EPDM or Viton®(FPM)

End Connections: Socket (IPS)

®

Threaded (FNPT)

Flanged (ANSI 150)

(PTFE)

18

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 26

VX SERIES BALL VALVES

Sample Specification

1.0 Ball Valves - VX

1.1 Material

• The valve body, stem, ball and unions shall be made of

PVC compound which shall meet or exceed the

requirements of cell classification 12454 according to

ASTM D1784.

or The valve body, stem, ball and unions shall be made of

1.2 Seats

• The ball seats shall be made of Teflon

1.3 Seals

• The o-ring seals shall be made of EPDM.

or The o-ring seals shall be made of Viton

1.4 All wetted parts of the valves shall comply with

2.0 Connections

2.1 Socket style

• The IPS socket PVC end connectors shall conform to

or The IPS socket CPVC end connectors shall conform to

2.2 Threaded style

• The female NPT threaded PVC end connectors shall

or The female NPT threaded CPVC end connectors shall

2.3 Flanged style

• The ANSI 150 flanged PVC end connectors shall

or The ANSI 150 flanged CPVC end connectors shall

®

Corzan

CPVC compound which shall meet or exceed

the requirements of cell classification 23447

according to ASTM D1784.

®

(PTFE).

®

(FPM).

standards that are equivalent to NSF Standard 61 for

potable water.

the dimensional standards ASTM D2466 and ASTM

D2467.

the dimensional standard ASTM F439.

conform to the dimensional standards ASTM D2464,

ASTM F1498, and ANSI B1.20.1.

conform to the dimensional standards ASTM F437,

ASTM F1498, and ANSI B1.20.1.

conform to the dimensional standard ANSI B16.5.

conform to the dimensional standard ANSI B16.5.

3.0 Design Features

• The valve shall be double blocking with union ends.

• All sizes ½" through 4" shall be full port.

• All sizes shall allow for bi-directional flow.

• The valve body shall be single end entry with a

threaded carrier (ball seat support).

3.0 Design Features

• The valve body shall have an expansion and contraction

compensating groove on the molded end.

• The valve body, union nuts, and carrier shall have deep

square style threads for increased strength.

• The ball shall be machined smooth to minimize wear

on valve seats.

• The stem design shall feature a shear point above the

o-ring to maintain system integrity in the unlikely event

of a stem breakage.

• The handle shall incorporate a tool for adjustment of

the threaded carrier.

• The handle shall be reversible to allow for operation in

tight places.

3.1 Pressure Tested

• All valves shall have been pressure tested in both the

open and closed positions by the manufacturer.

3.2 Pressure Rating

• Valve sizes ½" through 2" shall be rated at 232psi

at 73°F (23ºC).

• Valve sizes 2½" through 6" shall be rated at 150psi

at 73°F (23ºC).

• All sizes of flanged valves shall be rated at 150psi

at 73°F (23ºC).

3.3 Markings

• All valves shall be marked to indicate size, material

designation, and manufacturers name or trade mark.

3.4 Color Coding

• All PVC valves shall be color-coded dark gray.

or All CPVC valves shall be color-coded light gray.

®

4.0 All valves shall be Xirtec

140 or Corzan®by IPEX or

approved equal.

BALL VALVES

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

19

Page 27

BALL VALVES

VX SERIES BALL VALVES

Dimensions

IPS Socket Connections - Dimension (inches)

Size d L Z H E B C

1/2 0.84 0.89 2.01 3.78 2.09 1.97 2.56

3/4 1.05 1.00 2.13 4.13 2.44 2.28 2.99

1 1.32 1.13 2.34 4.61 2.80 2.56 3.35

1-1/4 1.66 1.26 2.83 5.35 3.31 2.99 3.94

1-1/2 1.90 1.38 3.03 5.79 3.86 3.35 4.41

2 2.38 1.50 3.84 6.85 4.61 4.06 5.39

2-1/2 2.88 1.75 5.00 8.50 6.06 5.24 8.74

3 3.50 1.89 5.47 9.25 7.44 6.06 10.63

4 4.50 2.26 7.64 12.17 8.70 6.89 10.63

*6 6.63 3.03 19.59 25.65 8.70 6.89 10.63

*The 6" valve is a 4" with venturied ends.

Female NPT Threaded Connections - Dimension (inches)

Size R L Z H E B C

1/2 1/2-NPT 0.70 2.14 3.54 2.09 1.97 2.56

3/4 3/4-NPT 0.71 2.24 3.66 2.44 2.28 2.99

1 1-NPT 0.89 2.55 4.33 2.80 2.56 3.35

1-1/4 1-1/4-NPT 0.99 3.02 5.00 3.31 2.99 3.94

1-1/2 1-1/2-NPT 0.97 3.21 5.16 3.86 3.35 4.41

2 2-NPT 1.17 4.01 6.34 4.61 4.06 5.39

3 3-NPT 1.40 6.81 9.61 7.44 6.06 10.63

4 4-NPT 1.48 9.20 12.17 8.70 6.89 10.63

20

ANSI 150 Flanged (Vanstone) Connections - Dimension (inches)

Size # holes f F H B C

1/2 4 5/8 2-3/8 5.59 1.97 2.56

3/4 4 5/8 2-3/4 6.07 2.28 2.99

1 4 5/8 3-1/8 6.74 2.56 3.35

1-1/4 4 5/8 3-1/2 7.54 2.99 3.94

1-1/2 4 5/8 3-7/8 8.29 3.35 4.41

2 4 3/4 4-3/4 9.60 4.06 5.39

2-1/2 4 3/4 5-1/2 11.13 5.24 8.74

3 4 3/4 6 11.74 6.06 10.63

4 8 3/4 7-1/2 14.99 6.89 10.63

*6 8 7/8 9-1/2 28.55 6.89 10.63

*The 6" valve is a 4" with venturied ends.

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 28

VX SERIES BALL VALVES

Working Temperature (˚F)

Working Pressure (psi)

PVC

CPVC

1/2" to 2"

73

140

232

1/2"

3/4"1"1-1/4"

1-1/2"2"2-1/2"

3"

4" & 6"

Flowrate (GPM)

Pressure loss (psi)

Weights Flow Coefficients

Approximate Weight (lbs)

Size

(inches)

IPS Socket

PVC CPVC

FNPT

Threaded

ANSI

Flanged

IPS

Socket

Threaded

FNPT

ANSI

Flanged

1/2 0.32 0.32 0.72 0.34 0.34 0.76

3/4 0.49 0.49 1.07 0.53 0.53 1.13

1 0.69 0.69 1.48 0.76 0.76 1.58

1-1/4 1.11 1.11 2.11 1.22 1.22 2.22

1-1/2 1.60 1.60 2.80 1.75 1.75 3.02

2 2.74 2.74 4.62 3.02 3.02 5.02

2-1/2 5.73 N/A 8.31 6.27 N/A 9.35

3 9.55 9.55 13.29 10.45 10.45 14.40

4 16.42 16.42 22.42 17.97 17.97 24.30

*6 25.02 N/A 35.04 27.14 N/A 37.73

*The 6" valve is a 4" with venturied ends.

Pressure – Temperature Ratings Pressure Loss Chart

250

Size

C

V

1/2 14.0

3/4 27.0

1 53.9

1-1/4 77.0

1-1/2 123

2 238

2-1/2 368

3 497

4 665

6 665*

*Not including venturied ends.

BALL VALVES

200

2-1/2" to 6"

150

100

50

0

32 62 92 122 152 182 212

10

1

0.1

0.01

1 10 100 1000

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

21

Page 29

BALL VALVES

VX SERIES BALL VALVES

Components

22

# Component Material Qty

1* handle High Impact PVC

2* stem o-ring EPDM or Viton

®

3* stem PVC / CPVC 1

4 body PVC / CPVC 1

5 ball PVC / CPVC 1

6* body o-ring EPDM or Viton

®

7* end connector PVC / CPVC 2

8 support for ball seat PVC / CPVC 1

9* ball seat PTFE 2

10* socket o-ring EPDM or Viton

®

11* union nut PVC / CPVC 2

* Spare parts available.

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

1

1

1

2

Page 30

VX SERIES BALL VALVES

Installation Procedures

1. For socket and threaded style connections, remove the

union nuts (part #11 on previous page) and slide them

onto the pipe. For flanged connections, remove the union

nut / flange assemblies from the valve.

6. Tighten the union nut on the side marked “ADJUST”.

Tightening the union nuts in this order results in the best

possible valve performance due to optimum positioning

and sealing of the ball and seat support system.

2. Please refer to the appropriate connection style subsection:

a. For socket style, solvent cement the end connectors

(7) onto the pipe ends. For correct joining

procedure, please refer to the section entitled,

“Joining Methods – Solvent Cementing”

Industrial Technical Manual Series,

Process Piping Systems”

sufficient cure time before continuing with the

valve installation.

b. For threaded style, thread the end connectors (7)

onto the pipe ends. For correct joining procedure,

please refer to the section entitled,

Methods – Threading”

Technical Manual Series,

Piping Systems”

c. For flanged style, join the union nut / flange

assemblies to the pipe flanges. For correct joining

procedure, please refer to the section entitled,

.

“Joining Methods – Flanging”

Technical Manual Series,

Piping Systems”

3. Open and close the valve to ensure that the ball seat

support (8) is at the desired adjustment. If adjustment is

required, ensure that the valve is in the closed position

then remove the handle (1) from the valve stem. Line up

the moldings on the handle with the slots in the ball seat

support. Tighten or loosen to the desired position then

replace the handle on the valve stem.

.

. Be sure to allow

in the IPEX Industrial

“Volume I: Vinyl Process

in the IPEX Industrial

“Volume I: Vinyl Process

in the IPEX

“Volume I: Vinyl

“Joining

7. Open and close the valve to again ensure that the cycling

performance is adequate. If adjustment is required,

place the valve in the closed position, loosen the union

nuts, remove the valve from system and then continue

from Step 3.

BALL VALVES

4. Ensure that the valve is in the closed position, and that

the socket o-rings (10) are properly fitted in their

grooves. Carefully place the valve in the system between

the two end connections.

5. Tighten the union nut on the side opposite to that which

is marked “ADJUST”. Hand tightening is typically

sufficient to maintain a seal for the maximum working

pressure. Over-tightening may damage the threads on the

valve body and/or the union nut and may even cause the

union nut to crack.

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

23

Page 31

Valve Maintenance

VX SERIES BALL VALVES

Disassembly

1. If removing the valve from an operating system, isolate

the valve from the rest of the system. Be sure to

depressurize and drain the isolated branch and valve

before continuing.

2. Loosen both union nuts (11) and drop the valve out of

the line. If retaining the socket o-rings (10), take care

that they are not lost when removing the valve from

the line.

3. To disassemble, place the valve in the closed position

BALL VALVES

then remove the handle (1) from the valve stem.

4. Line up the moldings on the handle with the slots in the

ball seat support (found on the side marked "ADJUST").

Loosen and remove the ball seat support (8) by turning

in a counterclockwise direction.

5. Carefully press the ball (5) out of the valve body, taking

care not to score or damage the outer surface.

6. To remove the stem (3), press it into the valve body (4)

from above.

7. The stem o-ring (2), body o-ring (6), and ball seats (9)

can now be removed and/or replaced.

Assembly

Note: Before assembling the valve components, it is advisable

to lubricate the o-rings with a water soluble lubricant. Be

sure to consult the

and/or other trusted resources to determine specific

lubricant-rubber compatibilities.

1. Firmly place the ball seat (9) in the groove on the

opposite end inside the valve body (4).

2. Properly fit the stem o-ring (2) in the groove on the stem

(3), then insert the stem from the inside of the valve

body.

3. Ensure that the valve stem is in the closed position then

insert the ball (5) into the valve body taking care not to

score or damage the outer surface.

4. Check that the ball seat (9) and body o-ring (6) are

properly fitted on the ball seat support (8), then slightly

hand tighten into the valve body. Line up the moldings

on the handle (1) with the slots in the ball seat support

then tighten by turning in a clockwise direction.

5. Replace the handle on the valve stem then cycle the

valve open and closed to determine whether or not the

performance is adequate. If so desired, the handle can

be removed and used to make further adjustments.

“IPEX Chemical Resistance Guide”

6. Properly fit the socket o-rings (10) in their respective

grooves.

7. Place the end connectors (7) into the union nuts (11),

then thread onto the valve body taking care that the

socket o-rings remain properly fitted

in their grooves.

24

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 32

VE SERIES BALL VALVES

IPEX VE Series Ball Valves are ideal for light industrial and

water applications. These valves feature an ultra-compact

double block design, and full port bi-directional operation. The

true union design allows the valve to be easily removed from

the piping system and fully serviced. A threaded seat stop

carrier provides improved seal integrity under tough service

conditions while the removable handle also functions as a tool

for ball seat adjustment. VE Series Ball Valves are part of our

complete Xirtec

®

140 systems of pipe, valves, and fittings,

engineered and manufactured to our strict quality,

performance, and dimensional standards.

ASTM D1784

ASTM D2464

ASTM D2466

ASTM D2467

ASTM F1498

ANSI B1.20.1

Valve Availability

Body Material: PVC

Size Range: 1/2" through 2"

Pressure: 232psi

Seats: Teflon

Seals: EPDM

End Connections: Socket (IPS)

®

(PTFE) – HDPE blend

Threaded (FNPT)

BALL VALVES

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

25

Page 33

BALL VALVES

VE SERIES BALL VALVES

Sample Specification

1.0 Ball Valves - VE

1.1 Material

• The valve body, stem, ball and unions shall be made of

PVC compound which shall meet or exceed the

requirements of cell classification 12454 according to

ASTM D1784.

1.2 Seats

®

• The ball seats shall be made of a Teflon

HDPE blend.

1.3 Seals

• The o-ring seals shall be made of EPDM.

1.4 All wetted parts of the valves shall comply with

standards that are equivalent to NSF Standard 61 for

potable water.

2.0 Connections

2.1 Socket style

• The IPS socket PVC end connectors shall conform to

the dimensional standards ASTM D2466 and ASTM

D2467.

2.2 Threaded style

• The female NPT threaded PVC end connectors shall

conform to the dimensional standards ASTM D2464,

ASTM F1498, and ANSI B1.20.1.

(PTFE) –

3.0 Design Features

• The valve shall be double blocking with union ends.

• All sizes shall be full port.

• All sizes shall allow for bi-directional flow.

• The valve body shall be single end entry with a

threaded carrier (ball seat support).

• The valve body shall have an expansion and contraction

compensating groove on the molded end.

• The valve body, union nuts, and carrier shall have deep

square style threads for increased strength.

• The ball shall be machined smooth to minimize wear

on valve seats.

• The stem design shall feature a shear point above the

o-ring to maintain system integrity in the unlikely event

of a stem breakage.

• The handle shall incorporate a tool for adjustment of

the threaded carrier.

• The handle shall be reversible to allow for operation in

tight places.

3.1 Pressure Tested

• All valves shall have been pressure tested in both the

open and closed positions by the manufacturer.

3.2 Pressure Rating

• All sizes shall be rated at 232psi at 73°F (23ºC).

3.3 Markings

• All valves shall be marked to indicate size, material

designation, and manufacturers name or trade mark.

3.4 Color Coding

• All PVC valves shall be color-coded dark gray with a

blue handle.

®

4.0 All valves shall be Xirtec

140 by IPEX or approved equal.

26

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 34

Working Temperature (˚F)

Working Pressure (psi)

PVC

73

140

232

3/4"

1"

1-1/4"

1-1/2"

2"

Flowrate (GPM)

Pressure loss (psi)

Dimensions

VE SERIES BALL VALVES

IPS Socket Connections - Dimension (inches)

Size d L Z H E B C

1/2 0.84 0.89 2.01 3.78 2.09 1.97 2.56

3/4 1.05 1.00 2.13 4.13 2.44 2.28 2.99

1 1.32 1.13 2.34 4.61 2.80 2.56 3.35

1-1/4 1.66 1.26 2.83 5.35 3.31 2.99 3.94

1-1/2 1.90 1.38 3.03 5.79 3.86 3.35 4.41

2 2.38 1.50 3.84 6.85 4.61 4.06 5.39

Female NPT Threaded Connections - Dimension (inches)

Size R L Z H E B C

1/2 1/2-NPT 0.70 2.14 3.54 2.09 1.97 2.56

3/4 3/4-NPT 0.71 2.24 3.66 2.44 2.28 2.99

1 1-NPT 0.89 2.55 4.33 2.80 2.56 3.35

1-1/4 1-1/4-NPT 0.99 3.02 5.00 3.31 2.99 3.94

1-1/2 1-1/2-NPT 0.97 3.21 5.16 3.86 3.35 4.41

2 2-NPT 1.17 4.01 6.34 4.61 4.06 5.39

BALL VALVES

Weights

Approximate Weight (lbs)

Size

(inches)

IPS Socket FNPT Threaded

1/2 0.32 0.32

3/4 0.49 0.49

1 0.69 0.69

1-1/4 1.11 1.11

1-1/2 1.60 1.60

2 2.74 2.74

Pressure – Temperature Ratings

250

200

150

100

50

PVC

Flow Coefficients

Size

1/2 14.0

3/4 27.0

1 53.9

1-1/4 77.0

1-1/2 123

2 238

Pressure Loss Chart

10

1

0.1

C

V

1/2"

0

32 62 92 122 152 182 212

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

0.01

1 10 100 1000

IPEX Thermoplastic Valves

27

Page 35

BALL VALVES

VE SERIES BALL VALVES

Components

28

# Component Material Qty

1 handle High Impact PVC 1

2 stem o-ring EPDM 1

3 stem PVC 1

4 body PVC 1

5 ball PVC 1

6 body o-ring EPDM 1

7* end connector PVC 2

8 support for ball seat PVC 1

9 ball seat PTFE – HDPE blend 2

10 socket o-ring EPDM 2

11* union nut PVC 2

* Spare parts available

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

Page 36

VE SERIES BALL VALVES

Installation Procedures

1. Remove the union nuts (part #11 on previous page) and

slide them onto the pipe.

2. Please refer to the appropriate connection style subsection:

a. For socket style, solvent cement the end connectors

(7) onto the pipe ends. For correct joining

procedure, please refer to the section entitled,

“Joining Methods – Solvent Cementing”

Industrial Technical Manual Series,

Process Piping Systems”

sufficient cure time before continuing with the

valve installation.

b. For threaded style, thread the end connectors (7)

onto the pipe ends. For correct joining procedure,

please refer to the section entitled,

Methods – Threading”

Technical Manual Series, “Volume I: Vinyl Process

Piping Systems”.

3. Open and close the valve to ensure that the ball seat

support (8) is at the desired adjustment. If adjustment is

required, ensure that the valve is in the closed position

then remove the handle (1) from the valve stem. Line up

the moldings on the handle wit the slots in the ball seat

support. Tighten or loosen to the desired position then

replace the handle on the valve stem.

. Be sure to allow

in the IPEX Industrial

in the IPEX

“Volume I: Vinyl

“Joining

BALL VALVES

4. Ensure that the valve is in the closed position, and that

the socket o-rings (10) are properly fitted in their

grooves. Carefully place the valve in the system between

the two end connections.

5. Tighten the union nut on the side opposite to that which

is marked “ADJUST”. Hand tightening is typically

sufficient to maintain a seal for the maximum working

pressure. Over-tightening may damage the threads on the

valve body and/or the union nut and may even cause the

union nut to crack.

6. Tighten the union nut on the side marked “ADJUST”.

Tightening the union nuts in this order results in the best

possible valve performance due to optimum positioning

and sealing of the ball and seat support system.

7. Open and close the valve to again ensure that the cycling

performance is adequate. If adjustment is required,

place the valve in the closed position, loosen the union

nuts, remove the valve from system and then continue

from Step 3.

IPEX Thermoplastic Valves

CAUTION: Do not use or test the products in this manual with compressed air or other gases including air-over-water-boosters.

29

Page 37

Valve Maintenance

VE SERIES BALL VALVES

Disassembly

1. If removing the valve from an operating system, isolate

the valve from the rest of the system. Be sure to

depressurize and drain the isolated branch and valve

before continuing.

2. Loosen both union nuts (11) and drop the valve out of

the line. If retaining the socket o-rings (10), take care

that they are not lost when removing the valve from the

line.

3. To disassemble, place the valve in the closed position

then remove the handle (1) from the valve stem.

BALL VALVES

4. Line up the moldings on the handle with the slots in the

ball seat support (found on the side marked “ADJUST”).

Loosen and remove the ball seat support (8) by turning

in a counterclockwise direction.

5. Carefully press the ball (5) out of the valve body, taking

care not to score or damage the outer surface.

6. To remove the stem (3), press it into the valve body (4)

from above.

7. The stem o-ring (2), body o-ring (6), and ball seats (9)

can now be removed and/or replaced.

Assembly

Note: Before assembling the valve components, it is advisable

to lubricate the o-rings with a water soluble lubricant. Be

sure to consult the