Page 1

Installation Methods for IPEX System 636

®

Type BH Class IIA (PVC) and Class IIB (CPVC)

Gas Venting Systems

A. Examine all components for possible shipping damage prior to installation.

B. Proper joint construction is essential for a safe installation. Follow these instructions exactly as written.

C. This venting system must be free to expand and contract. This venting system must be supported in

accordance with these instructions.

D. Check for proper joint construction when joining pipe to fittings.

E. Check for unrestricted vent movement through walls, ceilings, and roof penetrations.

F. Different manufacturers have different joint systems and adhesives. Do NOT mix pipe, fittings

or joining methods from different manufacturers.

System 636 Pipe, Fittings and Cements are certified as a system and must be installed as such.

Page 2

Page 3

Table of Contents

Product Application .........................................................1

Limits of Use and Application............................................1

Termination Requirements .................................................3

Support and Restraint Spacing ..........................................7

Expansion and Contraction...............................................8

Firestops .......................................................................11

Appliance Testing ..........................................................11

Vent Connection to the Appliance....................................11

Solvent Welding ............................................................11

Basic Principles ......................................................12

Priming .................................................................14

Set and Cure Times ................................................16

Required Quantities ................................................17

Safety Precautions ..................................................18

Handling and Storage....................................................19

Cement and Primer.................................................19

Pipe and Fittings ....................................................20

System 636 Statement of the Basis for Acceptance............22

Maintenance.................................................................23

Training........................................................................23

Accessory Installation Instructions ....................................24

Access Tee.............................................................24

Low Profile Side Wall Termination Kit........................25

Concentric Vent Termination Kit................................28

System 636 Installation Methods

i

Page 4

Introduction

System 636®PVC and CPVC Type BH Gas Venting Systems are third party certified to ULC S636, latest edition.

The following installation methods have been prepared in conformity with the requirements of section 4 of ULC Standard S636.

1. Product Application

IPEX System 636 PVC and CPVC Gas Venting Systems are intended for positive and negative pressure venting of gas fired appliances

producing exhaust gases having temperatures limited to the range specified in 1(a) and 1(b).

(a) System 636 PVC venting systems are suitable for temperatures up to and including 65°C (149ºF); ULC S636 Class IIA.

(b) System 636 CPVC venting systems are suitable for temperatures up to and including 90°C (194ºF); ULC S636 Class IIB.

System 636 PVC and CPVC have a zero clearance to combustible construction.

2. Limits of Use and Application

(a) Improper installation of System 636 PVC or CPVC systems may result in personal injury or death. Only qualified personnel should

attempt the installation of gas burning equipment, following the gas appliance manufacturers directions.

(b) All System 636 gas venting pipe and fittings must be carefully inspected before use to ensure no damage has occurred during

transportation. Any damaged product must be replaced. No attempt at repairs are to be made at the job site.

(c) The common temperature changes in a gas venting application will cause the system to expand and contract accordingly, proper care

must be taken to allow for this movement through walls, ceilings, and roof penetrations. The venting system must be supported in

accordance with these instructions.

1

System 636 Installation Methods

Page 5

(d) Only certified System 636 PVC or CPVC primer and cement shall be used to assemble System 636 PVC or CPVC venting systems.

* All IPEX System 636 cements contain special additives to aid in identification during warranty claims.

NOTE: Follow IPEX solvent welding procedures as shown in this manual, and check for proper joint construction when joining pipe

to fittings.

(e) Venting should be as direct as possible with a minimum number of fittings. The maximum vertical rise or horizontal run of vent pipe

plus the total number of fittings in a single vent installation shall not exceed the requirements outlined in the appliance manufacturer’s

installation instructions.

(f) All framing requirements for floor and ceiling penetrations shall be in accordance with the local building code and/or the local

regulatory authority.

(g) All penetrations of fire rated floors and walls shall be firestopped as described in Section 7 of this manual.

(h) Roof penetrations should be sealed with a plumbing roof boot or equivalent flashing as per the local building code, or as

permitted by the local regulatory authority.

(i) Chemical attack can cause product failure. Only use PVC/CPVC chemically compatible sealants, gaskets and adhesives.

(j) If spray foam insulation comes in contact with System 636, it is recommended that foam be applied in a maximum layer thickness

of 2 inches (50mm) until the required thickness of insulation is achieved.

(k) All horizontal sections of the venting system must be installed with a slope not less than 20mm/m (0.25 in./ft.) down towards the

appliance in order to collect condensate and remove condensate generated inside the line. The removal of condensate will help

reduce the possibility of ice buildup and blockage. Refer to the appliance manufacturers' installation instructions for further details

regarding the installation of necessary condensate drains.

System 636 Installation Methods

2

Page 6

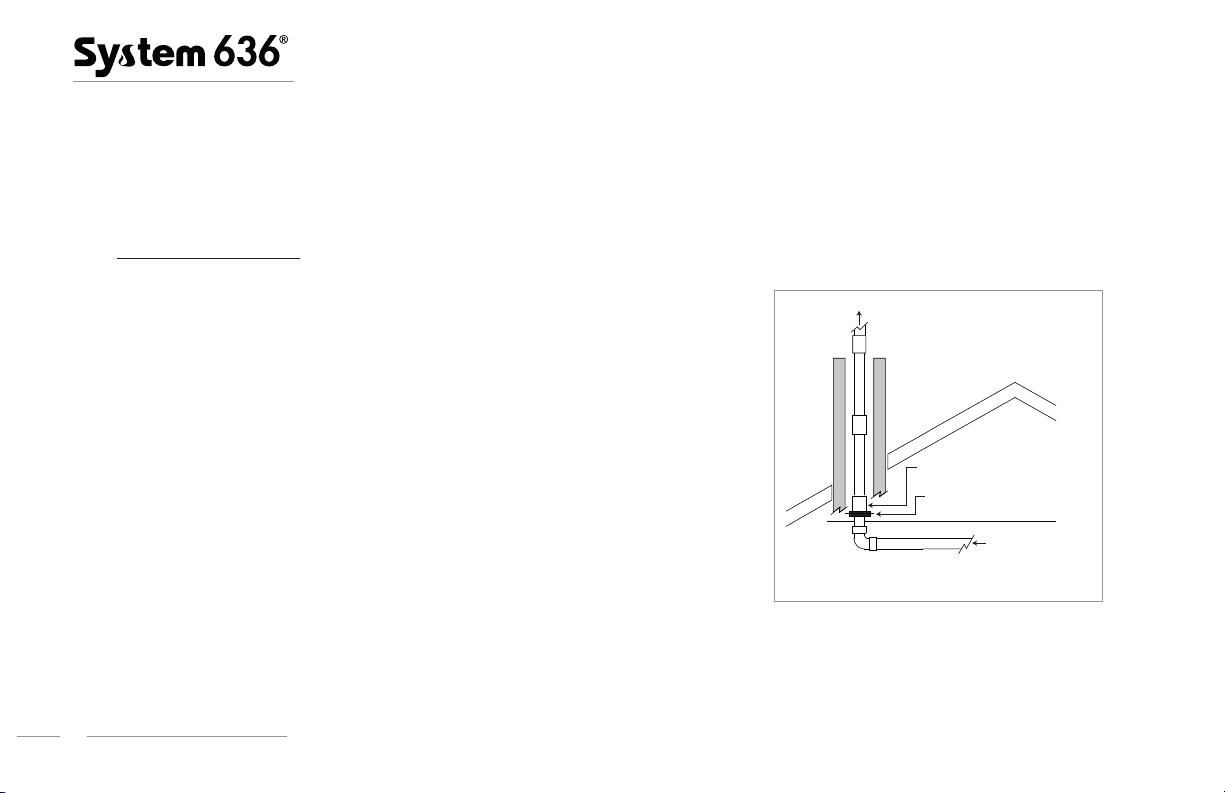

3. Termination Requirements (positive pressure venting)

yp

8" MIN.

Separation

Typical Roof Termination

3" MAX separation

Insulation in

unconditioned

space

Reducer Coupling

Approved Penetration

and Flashing as per

Building Code

Unconditioned

Attic Space

12" Above avg.

snow accumulation

Provide support for

intake and vent lines

Install condensate drain

as per appliance

manufacturer’s

recommendations

VentIntake

(a) Installation and location of terminations must be in accordance with the latest edition of

appliance manufacturer’s installation instructions, local building code requirements and

CSA B149.1 Natural Gas and Propane Installation Code.

Figure 1

Vent

Insulation in

unconditioned

space

12" MAXIMUM

Reducer coupling

3

System 636 Installation Methods

(b) Intake and vent pipes may be routed either horizontally through an outside wall

(see Figure 1) or vertically though the roof (see Figure 2).

(c) To avoid recirculation of exhaust gas on roof terminations, the end of the vent pipe must be

higher than the intake pipe. The minimum vertical separation between the end of the vent pipe

and the end of the intake pipe is 8 inches (see Figure 2).

(d) The runs of intake and vent pipes for terminations in general should be installed as close

together as possible. Specific spacing limits are 3" maximum separation for roof

Figure 2

penetrations and 6" maximum separation for wall penetrations (see Figures 1, 2 & 3).

(e) Terminate the vent piping straight up when through a chimney or fortified

penetrations (see Figure 2). For wall penetrations, the vent should be straight out or

elevated (see Figure 3).

(f) Intake piping terminating through the roof must terminate straight down through the

use of two 90° elbows (see Figure 2). On wall terminations intake piping should

point straight down through the use of one 90º elbow. (see Figure 1).

Insulation

Intake

Outside Wall

ical Wall Termination

T

Top View

6" MAX

separation

2" 90º Elbow

8" MINIMUM

Page 7

(g) A reducer may be used on the vent termination to increase the velocities of the exiting

12" MAXIMUM

Side View

Typical Wall Termination Restricted Grade

Insulation in

unconditioned space

Reducer Coupling

Provide support for

intake and vent

lines every 5 feet

Unconditioned space

Outside wall

Insulation

8" MINIMUM

12" Above expected

snow accumulation

Vent

Intake

gases away from the intake (see Figures 1 & 3). Do not direct exhaust to window wells,

alcoves or stairwells.

(h) The exit points of gas venting pipe must not be less than 3 ft. from an opening into

another building.

Figure 3

(i) Domestic Type Clothes Dryers

A moisture-exhaust duct from a domestic type clothes dryer shall not terminate within 3 ft (1m) in

any direction of any System 636 pressure regulator vent termination or fresh air intake.

Commercial Type Clothes Dryers

A dryer shall be connected to a metal moisture-exhaust duct that terminates outdoors

and shall not be less than 3 ft (1m) from any System 636 pressure regulator vent

terminations and not less than 10 ft (3m) from a fresh-air intake.

(j) The termination of the fresh air intake through the wall should be such that the bottom of the 90º elbow must be at a level of at

least 12 inches above the expected height of snow accumulation (see Figure 3).

(k) Except for: 1) appliances certified to ANSI Z21.10.3 / CSA 4.3 (Gas-fired Water Heaters,

ratings above 75,000 Btu per hour, circulating and instantaneous)

pressure steam and hot water boilers) insulating in unconditioned space is required for all vent piping. Insulation should also be considered

for inlet piping near the outside wall to prevent pipe condensation (See Figure 1). Insulation must have an R value sufficient to prevent

freezing of condensate. Consult with the insulation manufacturer for compatibility of insulation with System 636 pipe and fittings.

(Type 1):

(Type 2):

Volume III, Storage water heaters with input

and 2) appliances certified to ANSI Z21.13 / CSA 4.9 (Gas-fired low

System 636 Installation Methods

4

Page 8

(l) Follow appliance manufacturer's instructions regarding vent to appliance connections. Refer to ULC Standards Bulletin 2009-18.

(Interpretation: Clause 4.7 F, ULC - S636-08, Standard for Type BH Gas Venting Systems).

(m) For concentric vent installations see Concentric Vent Termination Kit section.

4. Chimney Installations

IPEX considers it acceptable to install System 636 piping through an existing unused

chimney space. It is suggested that installers adhere to the following guidelines when

doing such installations:

(a) Vent pipe sizing to be as per appliance manufacturers’ instructions or technical

manual.

Figure 4

To Te rmination

(b) Any existing non-certified vent piping cannot be re-used for venting and should be

(c) It is recommended that the chimney space be cleaned prior to installation to remove

(d) All recommended practices for solvent welding must be observed in the same

(e) Multiple vent pipes are permitted in one chimney space as limited by the interior available cross-sectional area. Zero clearance is

5

System 636 Installation Methods

replaced with System 636 Class IIA or IIB as required.

any debris, creosote, or other material.

manner as regular System 636 installations.

permitted between multiples runs of System 636 piping or other combustibles. (refer to Figure 4).

Coupling to sit on riser clamp to

support weight or section above

Clamp to be snugly fit but allowing

pipe travel due to expansion

From Appliance

Chimney Installations

Page 9

(f) Fresh air intakes may also be installed within existing unused chimney spaces providing acceptable spacing and clearance is obtained

at the termination as per appliance manufacturer requirements.

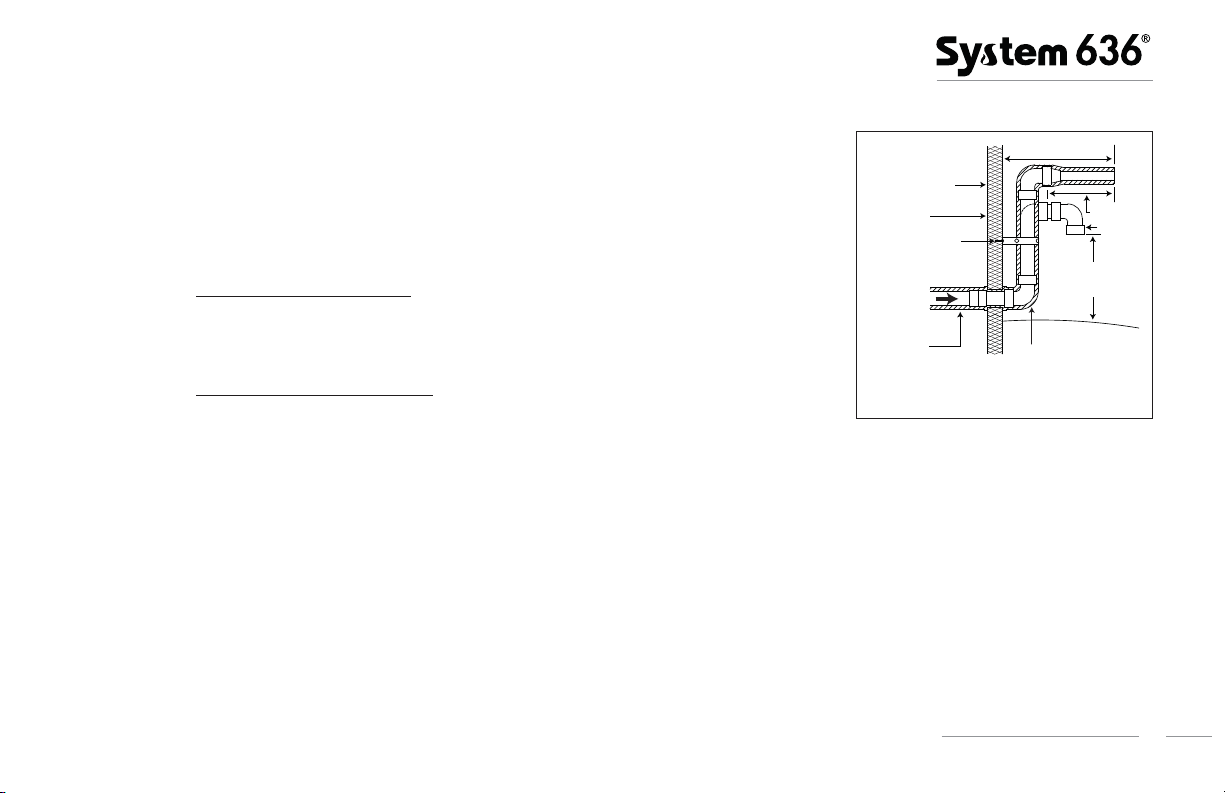

(g) Vertical piping through the chimney space or any other vertical spaces exceeding 20 ft (6m) is to be structurally supported by use of a

pipe coupling installed immediately above and sitting upon a snugly fit pipe clamp. One of these pipe coupling and pipe clamp

combinations is to be installed at the entrance of the chimney space to support the pipe weight. The clamp at the entrance of the

chimney is to be rigidly fixed against the wall or floor (see Figure 4). Should the pipe run exceed 60 feet (18 meters) inside the

chimney space, please contact IPEX for further guidance.

(h) It is recommended that consideration be given to obtaining an air-tight or water-tight seal as required at the chimney exit to prevent

entry of water, snow, moisture or cold air.

(i) The use of System 636 Deep Socket Couplings is recommended when available for added joint strength for chimney installations.

System 636 Installation Methods

6

Page 10

5. Support and Restraint Spacing

(a) System 636 PVC and CPVC systems must be supported horizontally at a maximum of every 5 ft (1.5 m).

(b) Supports to be used on System 636 pipe shall be suitable for use on plastic pipe and shall not be tightly clamped onto the pipe to

allow for possible expansion/contraction movement. Pipe clamps or hangers shall not have sharp edges or fulcrum points which might

damage the System 636 pipe over time.

(c) Changes in direction (e.g. 90° elbows) should be supported as close as practical to the fitting to avoid introducing excessive torsional

stresses into the system. This is especially important for vertical 90º bends. If support is being applied to the fitting, then the fitting must

be free to move during expansion and contraction of the venting system.

(d) System 636 horizontal venting shall be supported with steel strapping or equivalent. Strapping shall meet the following requirements.

• 1/2" strapping - 22 gauge steel • 3/4" strapping - 28 gauge steel

Strapping shall be fixed to supporting structure (e.g. floor joists or cross members) using typical framing nails or screws.

(e) In order to adequately support the weight of vertical vent pipe, a pipe anchor or support shall be installed at the first floor penetration

and every second floor thereafter with a System 636 coupling installed immediately above it. Securely fasten pipe anchors or supports

to the building structure. Pipe anchors or supports used for this purpose shall be suitable for use with plastic pipe. These anchors or

supports shall be snugly fastened to the vent in order to support the weight of the vent, but shall not be allowed to deform or damage

the vent. Anchors or supports supporting the weight of the vertical vent shall be in addition to the required pipe straps which are

intended only to maintain the position of the vertical vent while allowing for expansion and contraction. Make certain that allowance for

expansion and contraction is provided in all venting installations.

7

System 636 Installation Methods

Page 11

6. Expansion and Contraction

To accommodate expansion/contraction movement and stresses that may occur, IPEX suggests the following guidelines during installation:

1. Leave adequate clearance between any System 636 elbows and walls or the underside of floor boards or joists.

2. Use loose fitting clamps and hangers to allow free pipe movement if required.

3. For critical areas such as near the appliance outlet, two 45º elbows is recommended for use in lieu of one 90º elbows for more

structural flexibility.

System 636 Installation Methods

8

Page 12

TABLE 1 – PVC / CPVC Linear Expansion (ΔL) in inches

9

System 636 Installation Methods

Temp.

change

(°F) 10 20 30 40 50 10 20 30 40 50

10 0.04 0.07 0.11 0.14 0.18 0.05 0.09 0.14 0.18 0.23

20 0.07 0.14 0.22 0.29 0.36 0.09 0.18 0.27 0.36 0.46

30 0.11 0.22 0.32 0.43 0.54 0.14 0.27 0.41 0.55 0.68

40 0.14 0.29 0.43 0.58 0.72 0.18 0.36 0.55 0.73 0.91

50 0.18 0.36 0.54 0.72 0.90 0.23 0.46 0.68 0.91 1.14

60 0.22 0.43 0.65 0.86 1.08 0.27 0.55 0.82 1.09 1.37

70 0.25 0.50 0.76 1.01 1.26 0.32 0.64 0.96 1.28 1.60

80 0.29 0.58 0.86 1.15 1.44 0.37 0.73 1.09 1.46 1.82

90 0.32 0.65 0.97 1.30 1.62 0.41 0.82 1.23 1.64 2.05

100 0.36 0.72 1.08 1.44 1.80 0.46 0.91 1.37 1.82 2.28

PVC CPVC

Length of Run (ft)

Page 13

TABLE 2 – PVC / CPVC Linear Expansion (ΔL) in mm

Temp.

Change

(°C) 3 6 9 12 15 3 6 9 12 15

5 0.8 1.6 2.4 3.2 4.1 1.0 2.0 3.1 4.1 5.1

10 1.6 3.2 4.9 6.5 8.1 2.0 4.1 6.1 8.2 10.2

15 2.4 4.9 7.3 9.7 12.2 3.1 6.1 9.2 12.2 15.3

20 3.2 6.5 9.7 13.0 16.2 4.1 8.0 12.2 16.3 20.4

25 4.1 8.1 12.2 16.2 20.3 5.1 10.2 15.3 20.4 25.5

30 4.9 9.7 14.6 19.4 24.3 6.1 12.2 18.4 24.5 30.6

35 5.7 11.3 17.0 22.7 28.4 7.1 14.3 21.4 28.6 35.7

40 6.5 13.0 19.4 25.9 32.4 8.2 16.3 24.5 32.6 40.8

45 7.3 14.6 21.9 29.7 36.5 9.2 18.4 27.5 36.7 45.9

50 8.1 16.2 24.3 32.4 40.5 10.2 20.4 30.6 40.8 51.0

PVC CPVC

Length of Run (m)

System 636 Installation Methods

10

Page 14

7. Firestops

Should System 636 pass through a fire rated floor or wall, the penetration shall be firestopped with a device or system listed to

CAN/ULC-S115 for an F and/or FT Rating equivalent to the hour rating of the floor or wall.

8. Appliance Testing

Should the appliance not be equipped with an access port for flue gas testing, IPEX recommends the use of a System 636 Access Tee during

installation to allow access for flue gas testing. The Access Tee has a 1/2" female thread outlet with a removable 1/2" male thread plug.

Each time the plug is assembled into place, it shall have two wraps of PTFE (Teflon®) tape applied to the bare male threads. The Access Tee

shall be installed as close to the appliance as possible. Drilling holes in piping is NOT permitted.

9. Vent Connection to the Appliance

Please refer to the appliance installation manual for instructions to connect System 636 to the appliance exhaust and intake collar. The use of

screws to join System 636 to the appliance is NOT permitted.

10. Solvent Welding

(a) Installation of System 636 for the application of flue gas venting requires a certain degree of skill to avoid joint failures which could be

life threatening. On-site training is available from IPEX for proper solvent welding procedures as well as other important installation

points. Contact IPEX for details.

(b) Do not use solvents or cements other than what is required by this guide.

(c) For assembly of System 636 PVC piping, installers may use either System 636 PVC (gray) or CPVC (orange) cements.

11

System 636 Installation Methods

Page 15

(d) For assembly of System 636 CPVC piping, only System 636 CPVC cement may be used.

(e) Where primer is required (see Basic Principles of Solvent Welding), System 636 brand primer must be used (either purple or clear).

(f) For transitions between PVC and CPVC, only System 636 CPVC cement shall be used. In instances where transitions to ABS are

necessary, only System 636 Transition Cement shall be used. Note – some appliance manufacturers furnish adapter fittings which

are PVC but black in color. Check with the appliance manufacturer as to whether these fittings are ABS or PVC before selecting a

solvent cement.

(g) CPVC solvent cements must not be used more than 2 years beyond the date of manufacture printed on the container. PVC solvent

cements and all primers must not be used more than 3 years beyond the date of manufacture printed on the container.

Basic Principles of Solvent Welding

To make consistently good joints, the following points should be clearly understood.

1. Before the use of cement and or primer, shake the can thoroughly to ensure complete mixture of container contents.

2. Sufficient cement must be applied to fill the gap between pipe and fitting.

3. Assembly of pipe and fittings must be made while the surfaces are still wet and cement is still fluid.

4. Joint strength develops as the cement dries. In the tight part of the joint the surfaces will tend to fuse together; in the loose part,

the cement will bond to both surfaces.

Penetration and softening will be achieved by the solvent content in System 636 Cement, and additionally by using System 636 Primer

which is essentially 100% solvent. Where indicated in this manual, there are circumstances where IPEX feels that the penetration

achieved by System 636 Cement will be adequate and that the additional step of primer application may not be required.

System 636 Installation Methods

12

Page 16

Surface Interaction in Solvent Weld Joint

3/32" (2.5mm)

Approx

Chamfer

pipe ends

10-15°

Cement Coatings of Sufficient Thickness

Surfaces must be assembled

while they are wet and soft

Bonded Surfaces

Fused Surfaces

(Primer is always required for 6" and 8" piping systems and for all installations performed at temperatures of 0ºC or less.)

Note: Some jurisdictions have mandated the use of primer regardless of temperature. Verify with your local Regulatory Authority.

1. Obtain proper materials for job (proper cement and applicator for the size of piping system to be assembled).

2. Pipe must be cut as square as possible since a diagonal cut would reduce the fusing area in the most critical area of the joint.

3. A PVC wheel tube cutter or chop saw shall be used to cut the pipe. Tube cutters will produce a raised edge on the pipe end after

cutting which must be removed by a reamer. When cutting with a chop saw, a sharp and fine tooth blade must be used. Chop

saws will produce shavings which may remain inside the pipe. Failure to remove these shavings may compromise the

performance of the appliance and venting system.

4. After cutting, remove all burrs from both the inside and outside of the pipe and also chamfer the pipe end using a Reed DEB4

deburring tool. Failure to remove burrs can scrape channels into pre-softened surfaces, create hang-ups inside surface walls, or

inadvertently plow cement out of the joint during assembly.

5. Remove dirt, grease and moisture from surfaces to be welded. A thorough wipe with a clean dry rag is usually sufficient.

Moisture will increase cure times and dirt or grease can prevent adhesion.

13

System 636 Installation Methods

Page 17

6. Check pipe and fittings for dry fit before welding. For proper interference fit, the pipe must go easily into the fitting 1/3 to 2/3 of

the way. Should the dry fit be outside this range, do not proceed. Contact the System 636 supplier for further instruction.

7. Check for penetration and softening of the pipe’s surface. Take a scrap piece of System 636 pipe you will be using and make a

normal application of the cement. Then immediately, using a knife or other sharp object, try to scratch or scrape a few

thousandths of an inch of the surface away. If you are able to do so, proceed with installation. If not, try making a more

aggressive application of the cement on the scrap piece of pipe and check for penetration as noted above. If still unable to

achieve penetration or softening of the pipe surface, a primer should be used prior to solvent cement.

8. Use the right applicator for the size of pipe or fittings being joined. As a general guide, the applicator size should be equal to 1/2 the

pipe diameter. It is important that a satisfactory size applicator be used to help ensure that sufficient layers of cement are applied.

Priming (When Required)

9. The use of System 636 primer in the solvent welding process is beneficial as it allows for deeper penetration of the weld after

assembly. System 636 primer is mandatory for installation temperatures at or below 0ºC, and for all installations of 6" and 8"

System 636 pipe and fittings.

10. Using the correct applicator (as outlined in step #7), aggressively work the primer into fitting socket, keeping the surface and applicator

wet until the surface has been softened. More applications may be needed for hard surfaces and cold weather conditions. Re-dip the

applicator in primer as required. When the surface is primed, remove any puddles of primer from the socket.

11. Next, aggressively work the primer on to the end of the pipe to a point 1/2" beyond the depth of the fitting socket.

12. A second application of primer in the fitting socket is recommended.

13. Immediately and while the surfaces are still wet, apply the appropriate System 636 cement.

System 636 Installation Methods

14

Page 18

Solvent Welding

14. Stir the System 636 cement or shake can before using. Using the proper size applicator for the pipe size, aggressively work a full

even layer of cement on to the pipe end equal to the depth of the fitting socket - do not brush it out to a thin paint type layer, as

this will dry within a few seconds.

15. Aggressively work a medium layer of cement into the fitting socket; avoid puddling cement in the socket.

16. Apply a second full, even layer of cement on the pipe.

17. Without delay, while cement is still wet, assemble the pipe and fittings. Use sufficient force to ensure that the pipe bottoms in the

fitting socket. If possible, twist the pipe a 1/4 turn as it is inserted.

18. Hold the pipe and fitting together for a minimum of 15 seconds to resist buoyancy forces from disturbing the joint (push-out).

Higher potential for push-out exists with joint sizes larger than 4" and or in colder weather installations. If push-out does occur,

the joint will need to be redone.

19. A well-assembled joint should have a ring or bead of cement completely around the juncture of pipe.

20. Using a rag or dry cloth, remove all excess wet cement outside of the pipe-fitting joint.

21. Handle newly assembled joints carefully until initial set has taken place. Follow IPEX set and cure times before handling or testing

pipe system.

15

System 636 Installation Methods

Page 19

Solvent Weld Set and Cure Times (PVC or CPVC)

Set and Cure time for flue gas venting applications only.

Average Initial Set Schedule **

Temperature Range Joint Size

˚C (Celsius) ˚F (Fahrenheit) 1.5" to 2" 2.5" to 8"

15 to 40 60 - 105 5 min 30 min

5 to 15 40 - 60 10 min 2 hr

–16 to 4 3 - 40 15 min 12 hr

Note - Initial set schedule is the necessary time to allow before

the joint can be carefully handled.

In damp or humid conditions above 60% relative humidity

allow 50% more set time.

** These figures are estimates based on testing done under laboratory conditions. Field working conditions can vary significantly. This chart

should be used as a general reference only.

˚C (Celsius) ˚F (Fahrenheit) 1.5" to 2" 2.5" to 8"

15 to 40 60 - 105 30 min 1.5 hr

5 to 15 40 - 60 45 min 4 hr

–16 to 4 3 - 40 1 hr 72 hr

Note - Joint cure schedule is the necessary time before

commissioning System 636 piping for flue gas venting.

In damp or humid conditions above 60% relative humidity

allow 50% more cure time.

Average Joint Cure Schedule **

Temperature Range Joint Size

Cement Shelf Life

To determine the age of System 636 cement and primer, refer to the bottom of the container where the Date of Manufacture, Expiry Date, or

both will be displayed.

System 636 Installation Methods

16

Page 20

Required Quantities of Solvent Cement

Average Number of Joints/Qt. of IPEX System 636 Cement*

Pipe Diameter (inches) 1-1/2 2 3 4 6 8

Number of Joints 90 60 40 30 10 5

For the same number of joints where primer is used, one pint will be required for each quart of cement used.

*These figures are estimates based on our laboratory tests. Due to the many variables in the field, these figures should be used as a

general guide only.

17

System 636 Installation Methods

Page 21

Safety Precautions

All solvent cements and primers for plastic pipe are flammable and shall not be used or stored near heat, spark, open flames and other

sources of ignition. Vapors may ignite explosively. Keep containers closed when not in use and covered as much as possible when in use.

Use in well ventilated area. If confined or partially enclosed, use forced ventilation or NIOSH-approved respirator. Avoid breathing vapors.

Atmospheric levels should be maintained below established exposure limits contained in the product’s Material Safety Data Sheet. If airborne

concentrations exceed those limits, use of NIOSH-approved organic vapor cartridge with full face piece is recommended. The effectiveness of

an air purifying respirator is limited. Use it only for a single, short term exposure. For emergency and other conditions where short-term

exposure guidelines may be exceeded, use an approved positive pressure self-contained breathing apparatus. Do not smoke, eat or drink

while using these products. Avoid contact with skin, eyes and clothing. Wash clothing if contaminated before re-use. May cause eye injury.

Protective equipment such as gloves, goggles and an impervious apron shall be used. Keep out of reach of children. Carefully read our

Material Safety Data Sheets and follow all precautions.

First Aid

Inhalation: If feeling illness from inhalation, person should be moved to a source of fresh air. If not breathing, give artificial respiration. If

breathing is difficult, give oxygen. Call a physician.

Eye Contact: Flush with plenty of water for 15 minutes and call a physician.

Skin Contact: Wash skin with plenty of soap and water for at least 15 minutes. If irritation develops, get medical attention.

Ingestion: If swallowed, consume 1 to 2 glasses of water or milk, DO NOT INDUCE VOMITING. Contact physician immediately.

System 636 Installation Methods

18

Page 22

Use Caution with Welding Torches

At construction sites where System 636 is being installed or has recently been solvent welded, extreme caution should be taken when using

welding torches or other equipment where sparks may be involved. Flammable vapors from welded joints sometimes linger within or around a

piping system for some time.

Special care must be taken when using a welding torch around System 636 systems in industrial plant areas with little or no air circulation. In

all cases, solvent vapors must be removed by air circulation, purging, or other means prior to the use of welding torches, or other spark or

flame generating equipment or procedures. This includes electronic sources of ignition such as, electronic vapour cigarettes.

11. Handling and Storage of System 636 Cement and Primer

Store System 636 cement and primer in the shade between 4ºC (40ºF) and 43ºC (110ºF) or as specified on label. Keep away from heat,

spark, open flame and other sources of ignition such as, electronic vapour cigarettes. Secure container lid tightly when not in use to prevent

escape of solvent vapours. If the unopened container is subjected to freezing, it may become extremely thick or gelled. This cement can be

placed in a warm area, where after a period of time, it will return to its original, usable condition. But such is not the case when gelatin has

taken place because of actual solvent loss—for example, when the container was left open too long during use or not properly sealed after

use. Cement in this condition should not be used and should be properly discarded.

IPEX solvent cements are formulated to be used “as received” in original containers. Adding thinners or primers to change viscosity is strictly

prohibited. If the cement is found to be jelly-like and not free flowing, it should not be used.

19

System 636 Installation Methods

Page 23

12. Handling and Storage of System 636 Pipe and Fittings

(a) The PVC and CPVC materials used in System 636 piping are strong and lightweight materials. Care should be taken in handling and

storage to prevent damage to the pipe.

System 636 pipe should be given adequate support at all times. It should not be stacked in large piles, especially in warm temperature

conditions, as bottom pipe may become distorted and joining will become difficult.

For long-term storage, pipe racks should be used, providing continuous support along the length. If this is not possible, timber supports

of at least 3" bearing width, at spacings not greater than 3 ft centers, should be placed beneath the piping. If the stacks are

rectangular, twice the spacing at the sides is required. Pipe should not be stored more than seven layers high in racks. If different

classes of pipe are kept in the same rack, pipe with the thickest walls should always be at the bottom. Sharp corners on metal racks

should be avoided.

For temporary storage in the field when racks are not provided, care should be taken that the ground is level and free of sharp objects

(i.e. loose stones, etc.). Pipe should be stacked to reduce movement, but should not exceed three to four layers high.

Since the soundness of any joint depends on the condition of the pipe end, care should be taken in transit, handling and storage to

avoid damage to these ends. The impact resistance and flexibility of System 636 piping are reduced as temperatures approach 0ºC

(32ºF) and below. Care should be taken when unloading and handling pipe in cold weather. Dropping pipe from a truck or forklift may

cause damage. Methods and techniques normally used in warm weather may not be acceptable at the lower temperature range.

When loading pipe onto vehicles, care should be taken to avoid contact with any sharp corners (i.e. angle irons, nail heads, etc.),

as the pipe may be damaged.

System 636 Installation Methods

20

Page 24

While in transit, pipe should be well secured and supported over the entire length and should never project unsecured

from the back of a trailer.

b) Prolonged Outdoor Exposure

Prolonged exposure of System 636 pipe to the direct rays of the sun will not damage the pipe. However, some mild discoloration may

take place in the form of a milky film on the exposed surfaces. This change in color merely indicates that there has been a harmless

chemical transformation at the surface of the pipe. A small reduction in impact strength could occur at the discolored surfaces but they

are of a very small order and are not enough to cause problems in field installation.

(c) Protection – Covering

System 636 PVC and CPVC pipes are packaged in crates and wrapped in protective plastic film, which protects from UV and keeps the

pipe clean. Discoloration of exposed pipe can be avoided by shading it from the direct rays of the sun. This can be accomplished by

covering the stockpile or the crated pipe with a light colored opaque material such as canvas. If the pipe is covered, always allow for

the circulation of air through the pipe to avoid heat buildup in hot summer weather. Make sure that the pipe is not stored close to

sources of heat such as boilers, steam lines, engine exhaust outlets, etc.

(d) System 636 gas venting systems should not be painted. However if painted, only latex/waterbase paint shall be used and all product

markings must be either visible or accessible for visual inspection. Example, apply masking tape over product markings prior to

painting. The ability to pull-back on the masking tape will allow for future inspection.

21

System 636 Installation Methods

Page 25

13. System 636 Statement of the Bases for Acceptance

The acceptance of any appliance using IPEX System 636 PVC or CPVC Gas Venting Systems is strictly predicated on the following conditions:

Condition No. 1 Only System 636 PVC or CPVC components supplied for the job have been used in the installation, with no

unauthorized substitutions.

Condition No. 2 The system has been installed in accordance with CSA B149 Gas and Propane Installation Code.

Condition No. 3 The appliance manufacturer’s instructions have been followed .

Condition No. 4 IPEX's System 636 installation recommendations have been observed.

Condition No. 5 All installations must be done in full compliance of local Building and Fire Codes; especially with respect to Plenums

and High Buildings.

System 636 Installation Methods

22

Page 26

14. Maintenance

IPEX recommends that the System 636 gas venting system be checked once per year by a qualified System 636 service technician during any

regular maintenance activities as required for the heating appliance.

15. Training

The following is an excerpt from CSA B149.1-15 for

Natural Gas and Propane Installation Code:

4.4.2:

Personnel performing installation,

operation, and maintenance work shall be

properly trained in such functions.

IPEX recommends that installers receive formal training on

System 636 every 3 years to ensure proper installation

methods are utilized at all times.

AIR/GAS

• NEVER use compressed air or gas in PVC/CPVC

• NEVER test PVC/CPVC pipe and fittings with

Use of compressed air or gas in PVC/CPVC

pipe and fittings can result in explosive

failures and cause severe injury or death.

WARNING

pipe and fittings.

compressed air or gas, or air-over-water boosters.

23

System 636 Installation Methods

Page 27

16. Accessory Installation Instructions

Access Tee

1. The Access Tee shall be installed in such a manner as to prevent the collection of condensate,

preferably on a vertical run of pipe.

2. PVC Access Tees shall only be used on PVC venting systems. CPVC access tees shall only be used

on CPVC venting systems.

3. Solvent cement the access tee into the piping system. Allow for the proper set and cure times before

proceeding to next step.

4. Apply two full turns of Teflon

®

Tape to the threaded portion of the 1/2” plug.

5. Hand thread and hand tighten the plug into the bushing. Take care not to cross-thread the fittings.

6. Once hand tight, slowly turn the plug an additional one and a half (1.5) turns.

7. If the fittings appear to be damaged during threading then the entire assembly should be replaced. If the Teflon Tape was unraveled

during threading the plug will need to be re-installed with new tape.

8. Repeat steps 4-7 every time the plug is removed ensuring to use new Teflon Tape each time.

System 636 Installation Methods

24

Page 28

Low Profile Side Wall Termination Kit

Termination kits must be tested and certified for

use with whatever brand of heating appliance

and pipe-fitting-cement system is used. IPEX

termination kits such as the Low Profile are fully

certified for use with IPEX product only.

System 636 PVC Low Profile vent kits are made

from certified compound and are rated to 65ºC

maximum.

The vent termination must maintain all termination clearances and be installed

in accordance with local building code and CSA B149.1 Natural Gas and

Propane Installation Code. (see Figure 5)

Installation Procedure

1. Once the proper location has been determined, cut 2 holes in the wall

large enough to accommodate the pipe. Pipe diameters and distance

between hole centers can be found in Table 3.

2. Slide both the intake and vent pipes through the holes. Solvent weld both pipes to the base of the vent termination kit, following the

solvent welding procedures outlined in this guide. (see Figure 7)

TABLE 3 – Low Profile Termination Kits Dimensions

Item # Description Pipe O.D.

196984 2" Flush Mount Vent Kit 2.375" 5.6"

196985 3" Flush Mount Vent Kit 3.5" 5.6"

196986 4" Flush Mount Vent Kit 4.5" 5.6"

Hole Spacing

(ctr to ctr)

TABLE 4 – Each Kit Contains:

Qty Item Description

1 Base (two holes)

1 Cap (one hole)

8 Stainless Steel Screws

4 Plastic Anchors

25

System 636 Installation Methods

Page 29

To appliance intake

air connection

From appliance vent

pipe connection

Vent/Air

termination

Grade or snow line

12"

MIN

12"

MIN

to overhang

3. To fasten the Base to the wall, use the supplied screws and anchors. A

3/16" (5mm) diameter, 1-3/16" (30mm) deep, will need to be drilled

for the anchors. Locate the anchor hole using the base as a template.

4. Screw the Cap to the Base using the supplied screws.

5. Once the vent termination and pipes are secured, the wall

penetrations will need to be sealed from the interior using a PVC-

compatible sealant material.

Figure 6

Possibl

e Orientation

Figure 5

*

*

s

* confirm minimum clearance for

termination with local building code.

System 636 Installation Methods

26

Page 30

6. When locating the penetration of the vent and air pipes, ensure the

r

V

Figure 7

termination is properly oriented as shown in Figure 6. For multiple vent

Vent Piping

Air Piping

Vent Base

Vent Cap

terminations ensure that a minimum clearance of 12 inches be

maintained between edge of air inlet and adjacent vent outlet and that

all vent pipes and air inlets terminate at the same height to avoid

possibility of severe personal injury, death, or substantial property

damage. (see Figure 8)

7. When installing the vent termination in a vertical configuration, ensure

the vent piping is located above the air inlet piping. This will avoid the

risk of flue gas products recirculating into the air inlet and building. (see

Figure 6).

Figure 8

ent

12" MIN. between edge of ai

inlet and adjacent vent outlet

Vent/Air Termination

Air

27

System 636 Installation Methods

Page 31

Concentric Vent Termination Kit

A

B

D

D

C

E

G

1

2

3

4

5

F

System 636 Pipe, Fittings, Termination Kits and Cements are

certified as a system and must be installed as such. Different

manufacturers have different materials, joining systems and

adhesives. Do NOT mix pipe, fittings, cements, or joining

methods from different BH Vent manufacturers, this can result in

unsafe conditions and will void the certification.

System 636 PVC/CPVC concentric vent kits are made from

certified compounds. PVC kits are rated to 65ºC maximum and

CPVC kits are rated to 90ºC maximum.

All termination kits must be located and installed in accordance

with local building code and CSA B149.1 Natural Gas and

Propane Installation Code.

Figure 9

Table 5

Concentric Vent

Termination Kits Include:

AB*C=

Dimension (Inches)

Nominal Pipe

Size

FG

Material Concentric Kit Item # D E

PVC 2" x 16" 196005 29.0 16.5 3.5 2 2 7.38 1.75

CPVC 2" x 16" 197040 29.0 16.5 3.5 2 2 7.38 1.75

PVC 2" x 28" 196105 41.0 28.0 3.5 2 2 7.38 1.75

CPVC 2" x 28" 197033 41.0 28.0 3.5 2 2 7.38 1.75

PVC 2" x 40" 196125 53.0 40.0 3.5 2 2 7.38 1.75

PVC 3" x 20" 196006 36.1 20.0 4.5 3 3 8.75 2.25

CPVC 3" x 20" 197009 36.1 20.0 4.5 3 3 8.75 2.25

PVC 3" x 32" 196106 48.1 32.0 4.5 3 3 8.75 2.25

CPVC 3" x 32" 197107 48.1 32.0 4.5 3 3 8.75 2.25

PVC 3" x 44" 196116 60.1 44.0 4.5 3 3 8.75 2.25

CPVC 3" x 44" 197117 60.1 44.0 4.5 3 3 8.75 2.25

PVC 4" x 36" 196021 56.0 37.3 6.62 4 4 10.00 3.50

CPVC 4" x 36" 197021 56.0 37.3 6.62 4 4 10.00 3.50

1 Wye - (Concentric)

2 Rain Cap

4 Fresh Air Intake Pipe (Outer)

5 Stainless Steel Bolt & Nut

3 Exhaust Vent Pipe (Inner)

45º

B* Dimension be may be shortened to a minimum of 12". Inner pipe (item 3)

must remain "F" inches longer than the outer pipe (item 4). Cut pipe ends

square and solvent weld as outlined in the System 636 installation manual.

C= Installation cutout should be at least 1/2" larger than dimension “C”.

Lengthening the units is not permitted.

System 636 Installation Methods

28

Page 32

Concentric Vent Kit Assembly

1. Once the proper location has been determined, cut a hole in the roof or wall large enough to accommodate the outer pipe. The size of

the hole can vary greatly depending on the roof pitch.

2. As per the procedures outlined in the System 636 Installation Guide, solvent weld the inner pipe to the concentric wye fitting.

3. Solvent weld the outer pipe to the concentric wye fitting.

4. Slide the assembly through the roof or wall penetration. (Install flashing if needed).

5. To permanently affix the rain cap, it should be solvent welded to the inner pipe. For installations where removal of the cap may be

required for service or cleaning the cap, it can be fastened mechanically (drill location reference 5 in Figure 9). For either installation

method, the outer pipe is only a friction fit with the cap.

6. Once the rain cap is installed, and the kit secured as outlined below, the kit can be connected to the venting system.

29

System 636 Installation Methods

Page 33

Installation / Support Procedures

1. Kits must be securely fastened to structure, to ensure dimensions shown on Table 5 and

Figure 9 are maintained.

Figure 10: Wall Termination

1” Min

2” Max

(From wall

or Face Plate)

Exhaust

Clamp or Strap

(Field Supplied)

Exhaust

2. Straps are field supplied. Use straps, clamps or equivalent that will not score or damage the

pipe. Expansion and contraction should be addressed between appliance and termination point.

3. All penetrations must be sealed according to local building codes. Caulking for side wall

terminations and flashing for roof penetrations are typical. Use only PVC/CPVC compatible

sealing material, contact IPEX for a complete list.

4. The weight of the concentric kits must be supported by the clamps/straps and not by the vent

system it connects to.

Air Intake

Exterior wall

Figure 11: Roof Termination

Exhaust

Air Intake

Flashing

(Field Supplied)

Air Intake

Distance above avg.

snow fall or grade

Ref: CSA B149.1

Distance above avg.

snow fall or grade

Ref: CSA B149.1

Clamp or Strap

(Field Supplied)

Roof

5. Insulating exhaust piping in unconditioned space to prevent freezing may be required by code.

Air Intake

6. The pipe length of the concentric vent kit can be shortened; providing that the cutting and welding

Exhaust

procedures adhere to the System 636 guidelines.

7. Pipe lengths and/or fittings can be solvent welded to the socket of the rain cap in order to divert or extend the exhaust gas; providing

that the appliance manufacture confirms that the extra length or changing in direction will not adversely impact the flow of flue gas.

System 636 Installation Methods

30

Page 34

Typical Concentric Vent Kit Spacing

For multiple horizontal installations, keep Concentric Vent Kit gaps

Figure 12: Typical CVK Spacing

Sidewall Termination for Multiple Horizontal

Concentric Vent

close (up to 4" apart) or over 24" apart.

These guidelines are not appliance specific; OEM manufacturers may

supply spacing dimension specific to each appliance. In this case the

manufacturer’s recommendations shall supersede those described

herein.

4”

MAX

24” MIN

4”

MAX

To prevent flue gas from recirculating, IPEX recommends installing

multiple concentric kits as follows:

• 2 concentric vent kits: either maintain a 24" minimum distance apart, or have the rain caps no more than 4" apart

• 3 concentric vent kits:

Option 1 – keep all 3 kits at least 24" apart.

Option 2 – group 2 kits close together up to a maximum of 4" apart and the third kit over 24" apart.

• 4 or more concentric vent kits:

Option 1 – keep all concentric kits at least 24" apart.

Option 2 – group the CVK’s in pairs, having 2 kits close together to a maximum of 4" apart, keeping the next grouping of 2 kits over

24" away as per Figure 12.

The dimensions shown in Figure 12, are distances between the edges of the rain caps.

24” MIN

to next CVK

31

System 636 Installation Methods

Page 35

Mechanically Fastened Rain Cap

A

B

D

D

C

E

G

1

2

3

4

5

F

The Rain Cap must be installed with the supplied Stainless Steel bolt and lock nut, and in accordance with the following instructions and

diagram (Figure 9).

1. Locate the drill location dimple on the outside of the

rain cap. (drill location reference 5 in Figure 9)

Figure 9

2. At this location, drill through the cap and the inner pipe

wall. Ensure that the path of the hole is perpendicular to

the inner pipe NOT the outside of the cap. For the 2" &

3" kit, drill a 3/16" hole, for the 4" kit, a 1/4" hole.

45º

3. Insert the bolt and tighten the lock nut supplied with the

Concentric Vent Kit. Do not over tighten (do NOT use

field supplied screws).

System 636 Installation Methods

32

Page 36

System 636 Pipe, Fittings and Cements are certified as a system and must be installed as such.

Different manufacturers have different materials, joining systems and adhesives.

Do NOT mix pipe, fittings, solvents, or joining methods from different BH Vent manufacturers, as

this can result in unsafe conditions.

These recommendations were issued in February 2018 and supercedes manual dated November 2016. These

recommendations are subject to periodic review and updates may occur without notice.

IPEX Inc. 1425 North Service Rd. E., Unit 3, Oakville, Ontario, Canada, L6H 1A7

Website: ipexna.com

IPEX System 636 Installation Methods - Cdn Customers call IPEX Inc. 866.473.9462 - U.S. customers call IPEX USA, LLC 800.463.9572

Products manufactured by IPEX Inc. and distributed in the United States. by IPEX USA LLC. | System 636

®

is a trademark of IPEX Branding Inc.

IGMESTIP161003 © 2018 IPEX MS0035UC

Loading...

Loading...