Page 1

ELECTROFUSION SYSTEMS

PE ELECTROFUSION SYSTEMS

For Gas and Water Applications

PE Electrofusion

Systems for Gas

and Water

Catalog

Page 2

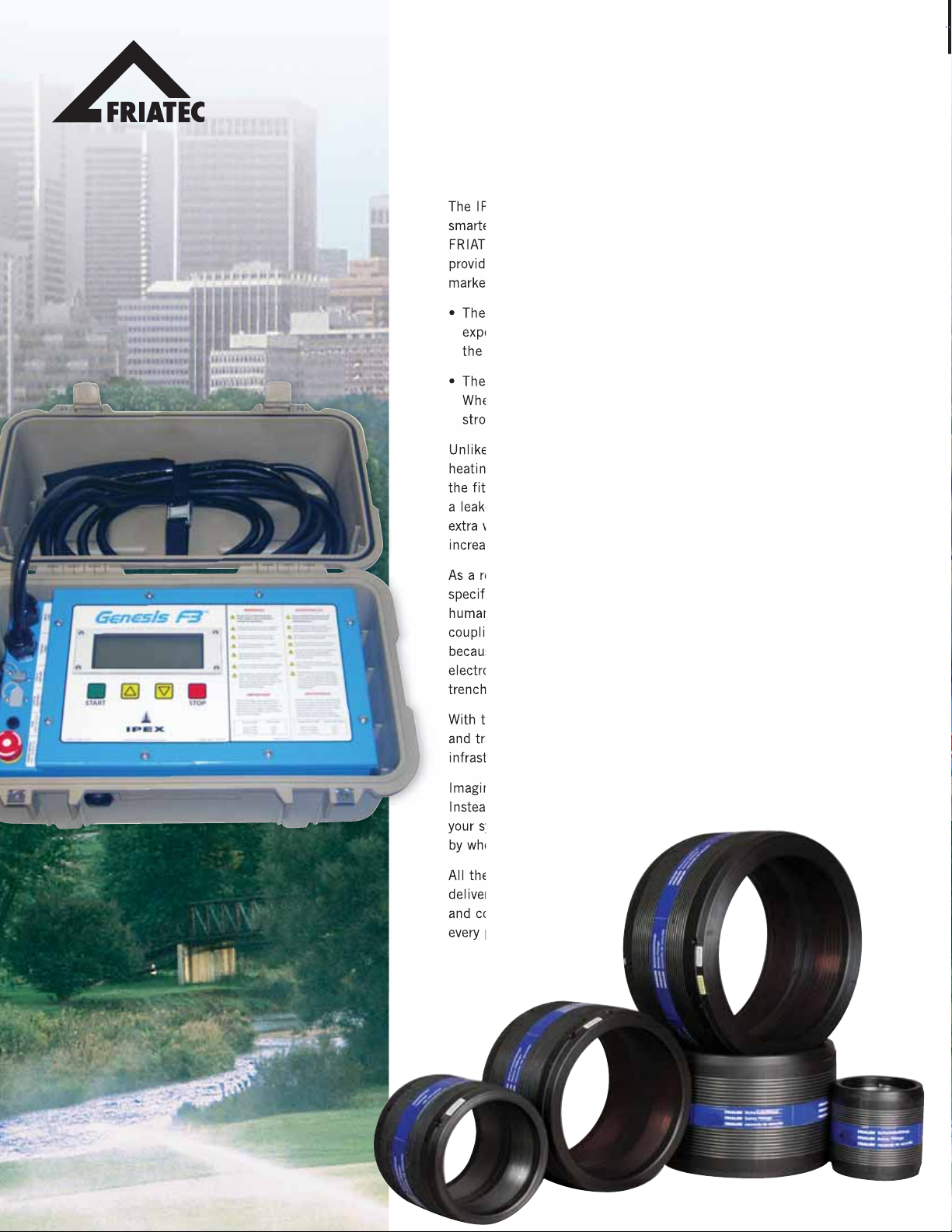

The IPEX FRIATEC brand of electrofusion products are engineered

smarter than traditional fusion systems. Manufactured in the USA,

FRIATEC couplings feature a unique, exposed coil design that

provides a seal stronger than any other electrofusion system on the

market. This is achieved for two reasons:

• The heat, created by the electrical current passing through the

exposed coil of the FRIATEC coupling, is transferred directly to

the PE pipe, and

• The coil protrudes from the interior surface of the coupling.

When the pipe is heated, the coil sinks into it creating a much

stronger bond.

Unlike competing embedded coil technology fittings which require

heating the entire coupling, FRIATEC’s unique “exposed coil” melts

the fitting and pipe surfaces directly, sinking into the pipe to form

a leak-proof bond. FRIATEC electrofusion fittings are designed with

extra wide fusion zones that provide greater contact area, further

increasing the integrity of the bond between coupling and pipe.

As a result of this process, every joint will be fused precisely to

specification, automatically, every time, minimizing the risk of

human error. This unique fusion technology has earned FRIATEC

couplings the highest pressure rating in the industry. What’s more,

because every joint is as strong as the pipe itself, the FRIATEC

electrofusion system is ideal for directional drilling and other

trenchless applications.

With the industry’s most advanced barcode monitoring, recording

and tracking technology, FRIATEC makes managing your

infrastructure easier than ever before.

Imagine, no more hidden costs or surprises on future dig ups.

Instead, you will know when, where and how every coupling in

your system was installed, and

by whom.

All these benefits add up to

deliver substantial time

and cost savings on

every project.

FRIATEC®PE Electrofusion

Systems for Gas & Water

Page 3

Genesis F3 Electrofusion Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Reducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tapping Tees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Scraper Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Re-Round Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Saddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Repair Patches and Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table of Contents

GENESIS F3

TM

ELECTROFUSION

PROCESSOR

COUPLINGS

& REDUCER

TAPPING TEES

SCRAPER TOOLS

RE-ROUND CLAMPS

REPAIR PATCHES

& CLAMPS

SADDLES

Page 4

2

Notes:

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

Page 5

3

GENESIS F3

TM

ELECTROFUSION

PROCESSOR

GENESIS F3

Electrofusion Processor

• 120 Volt

• Processor permanently mounted in a hard shell Pelican

TM

case

• USB download port

• Standard machine supplied with a barcode pen scanner.

• Options include SmartScanTMand SmartScanTMwith GPS

• Can be operated in Manual, Barcode ID or Resistor ID modes

Description Product Code

Processor with barcode pen scanner 328244

Processor with SmartScan 328243

Processor with SmartScan with GPS 328242

Stores information on up to 1000 fusions

Windows®7 Compatible

Calibration Window 3 years

Operator ID readable

Barcode readable without leads attached

AutoCal

TM

system allows processor to be recalibrated at

customer’s facility

3 handles so the processor can be carried easily by 2 people

Cable storage in lid

Lid opens 180 degrees

Weight 48 lbs meets Corporate Health and Safety limits of under

50 pounds

Page 6

4

GENESIS F3

TM

ELECTROFUSION

PROCESSOR

GENESIS F3 CONT’D

GENESIS F3 Specifications

Technical Data

Parameter Value

Supply Voltage 97 VAC to 150 VAC

Supply Frequency 47 Hz to 70 Hz

Supply Waveform Sine Wave or Square Wave

Maximum Supply Current 30 Amps at 60 Amps Output (120 VAC)

Output Voltage 8 VAC to 48 VAC +/- 1.5%

Output Current 4 AAC to 60 AAC +/- 1.5% (80 AAC @ 42 VAC output)

Operating Temperature Range 0°F to 140°F

Operating Modes Barcode, Manual, Manual Barcode, Resistor ID

Barcode Readability without Leads Attached YES

Output Cable Length 12 feet

Input Cable Length 12 feet

Fusion Information Storage 1000 Fusions

Type A USB Port

USB A type connector for attaching a USB flash drive to download fusion

data.

Type B USB Port USB B type connector for attaching the AutoCal®field calibration system.

Languages English/Spanish

Fitting Adapters 90 degree non-rotating

Weight 48 pounds

Environmental Protection IP54 Splash-Proof

Calibration Interval 3 Years

Warranty 1 Year

Scanning interchangeable Smart Scan/Smart Scan with GPS

GPS Optional

IEC Protection Class Class 1 Grounded

Calibration/Service Field calibration capable

Weight 48 pounds

This device is fully compatible with the AutoCal®field calibration system.

Page 7

5

GENESIS F3

TM

ELECTROFUSION

PROCESSOR

Accessories for Genesis F3 Electrofusion Processor

Accessories for Universal Electrofusion Processor

Description Product Code

Marinco Adapter, Plug 30A to 15A 328000

Frialen®Silver Pipe Markers 328002

FRIATOOL Complete Software Kit

includes: 328208, 328012 & 328013

328206

CD-ROM Software (only) 328208

Memory Box (only) 328012

Connection Cable: PC to Memory Box 328013

Connection Cable: PC to Friamat 328173

UPONOR / New Style Central Connectors (pair) 4.7mm 328015

Central Connectors (pair) 2.3mm 328016

Reader Wand Replacement 328063

Friafit®Adapter (pair) 328014

Aluminum Fusion Processor Carrying Case 328143

Fusion Lead End (pair) 328119

Replacement Parts

Item Part Number

Pen Scanner, Threaded Connector 328224

SMART Scanner, Genesis F3 328225

SMART Scanner with GPS, Genesis F3 328226

Display Shield 328230

Fitting Adapter, 4.0mm 90º 328231

Fitting Adapter, 4.7mm 90º w/White Pin 328232

Fitting Adapter, 4.7mm 90º w/Red ID Pin 328233

Smart Scanner Holster 328227

Barcode Pen Holster 328228

Accessory bag 328229

Genesis F3 Information Card 328234

Fuse, 2 Amp 250 Volt Slow-Blow, 5x20mm 328235

Page 8

6

COUPLINGS

& REDUCER

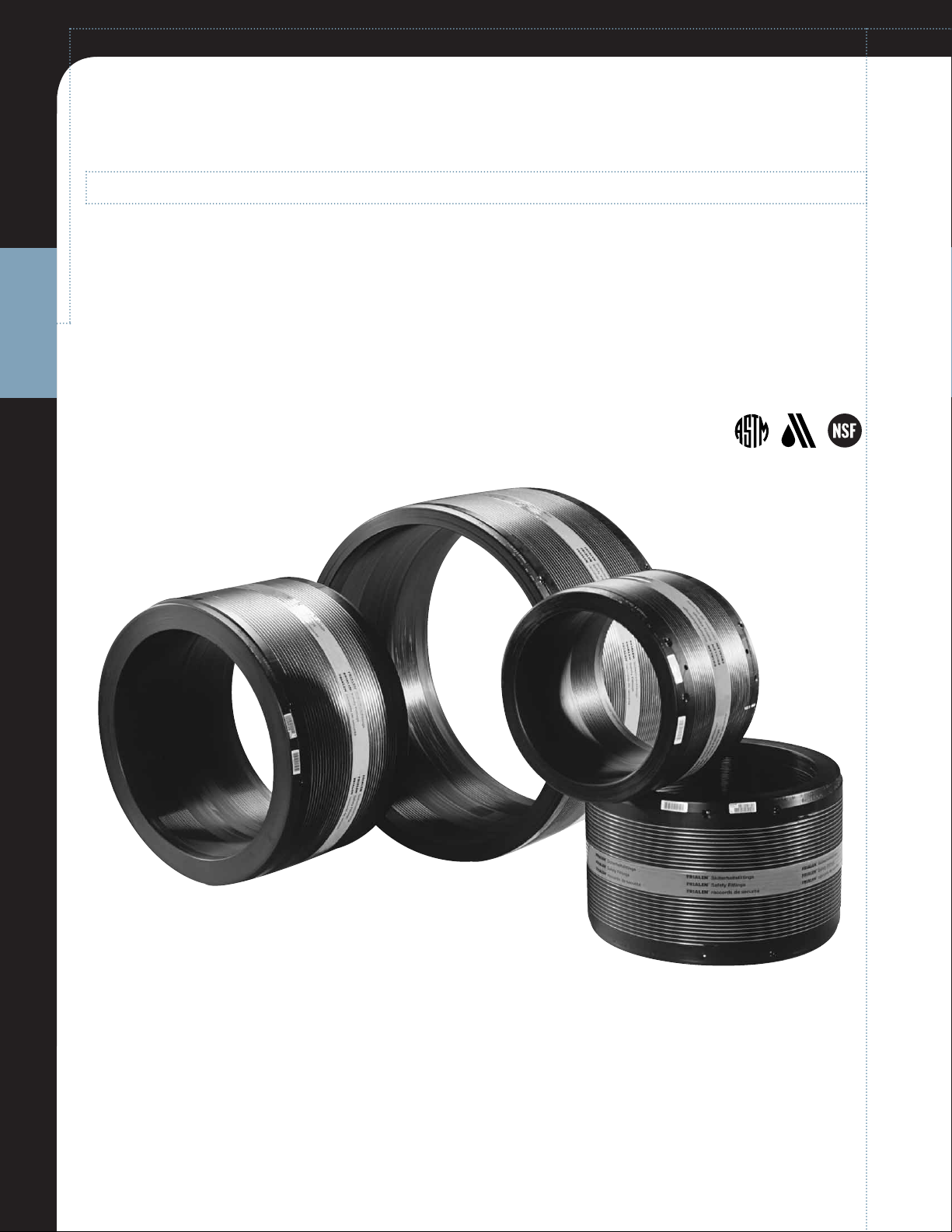

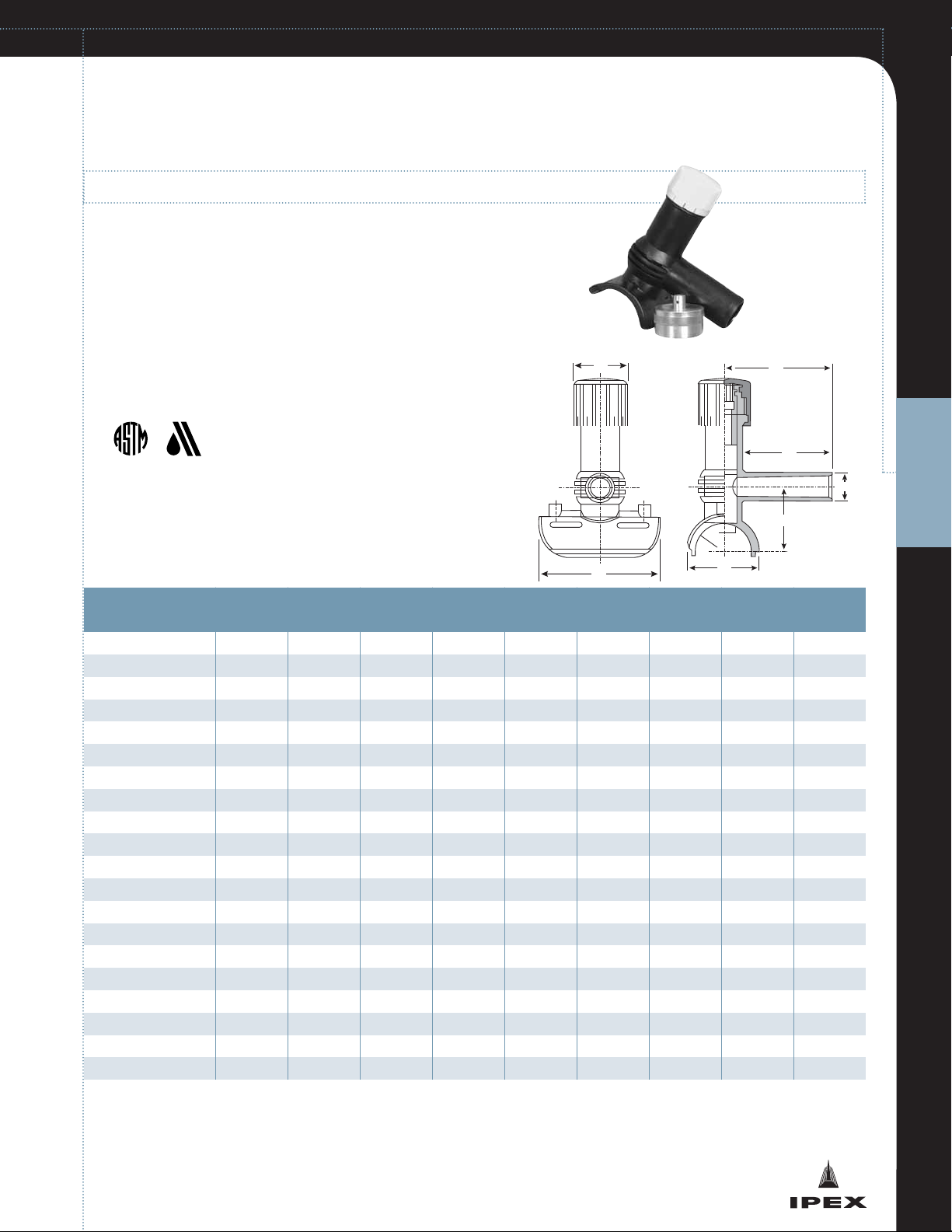

Couplings

1/2" CTS through 28" IPS

Our Couplings and Fittings deliver flexibility and reliability.

No one offers a wider range of coupling sizes and every FRIATEC

fitting is ASTM approved.

Short Designation MBI/UBI. . . OD

Field of Application Connections of PE Pipes 2406 and

3408/4710

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

Page 9

7

COUPLINGS

& REDUCER

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and pipe SDR range 9.33 through 17.6.

* Pipe can be moved after indicated cooling time (handling)

** Pipe can be pressurized after indicated cooling time (pressure <90 psi)

*** Pipe can be pressurized after indicated cooling time (pressure >90 psi)

✝ FM 200 psi, Short Designation: MBI...OD

1/2" - 6"

8" - 28"

✝

✝

✝

✝

✝

✝

✝

✝

✝

✝

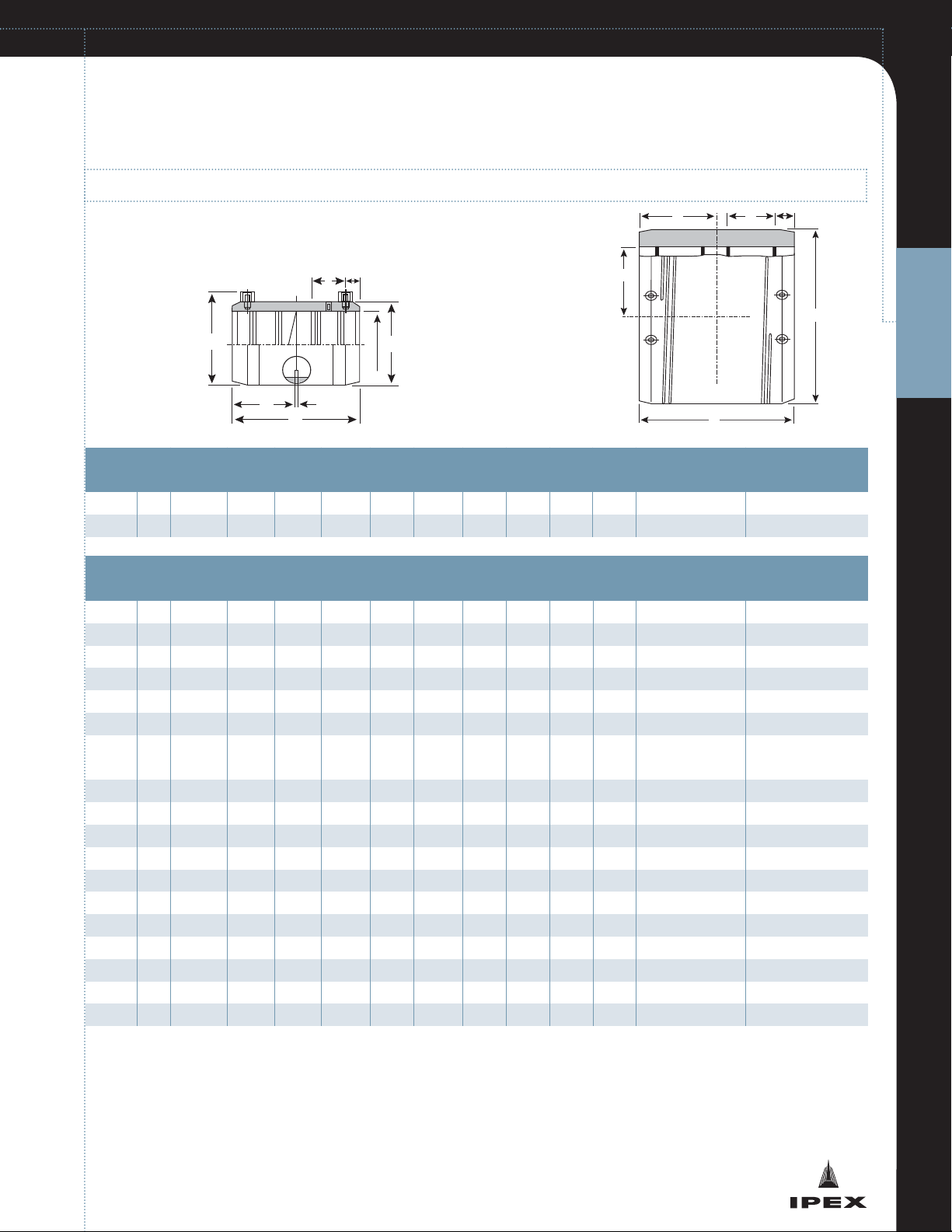

Nominal Pipe Product ID ID

D B L t z h x

Fusion Cooling

OD CTS SDR Code min max Time/Sec @ 73ºF Time/Min */**/***

1/2" 11 128031 0.622 0.634 1.102 1.732 2.283 1.142 0.079 0.591 0.23 27 05/08/10

1" 11 128027 1.122 1.134 1.654 2.244 3.071 1.535 0.079 0.787 0.31 28 05/08/10

Nominal Pipe Product ID ID

D B L t z h x

Fusion Cooling

OD IPS SDR Code min max Time/Sec @ 73ºF Time/Min */**/***

3/4" 11 128026 1.047 1.059 1.575 2.165 2.598 1.260 0.079 0.728 0.27 28 05/08/10

1" 11 128024 1.311 1.323 1.850 2.460 3.071 1.496 0.079 0.787 0.31 28 05/08/10

1-1/4" 11 128025 1.654 1.679 2.244 2.835 3.346 1.634 0.079 0.945 0.39 34 10/15/25

1-1/2" 11 128033 1.902 1.917 2.480 3.130 3.858 1.870 0.079 1.060 0.46 34 10/15/25

2" 11 128028 2.374 2.390 3.142 3.657 4.449 2.205 0.079 1.205 0.51 54 10/15/25

3" 11 128029 3.496 3.516 4.606 4.980 5.472 2.717 0.079 1.417 0.59 100 10/30/40

4" 11 128030 4.492 4.516 5.827 6.173 6.260 3.110 0.079 1.689 0.67 151 10/30/40

6" 11 128032 6.610 6.634 8.543 8.740 7.992 3.976 0.079 2.295 0.79 440 20/60/75

8"

monofilar

11 128060 8.626 8.665 11.029 - 9.448 4.724 - 2.953 1.063 540 20/60/75

8"

bifilar

11 128023 8.626 8.665 11.022 - 9.448 4.724 - 2.953 1.063 554 ea side 20/60/75

10" 11 128061 10.748 10.787 13.975 - 11.811 5.275 - 3.149 1.063 500 ea side 30/75/100

12" 11 128062 12.748 12.787 15.746 - 11.219 5.610 - 2.679 1.142 550 ea side 30/75/100

14" 11 128064 13.976 14.016 17.716 - 11.811 5.905 - 3.500 1.260 580 ea side 30/75/100

16" 11 128063 15.969 16.008 19.685 - 12.598 6.299 - 3.748 1.260 870/730 ea side 45/95/120

18" 11 128065 17.969 18.008 22.047 - 13.386 6.693 - 3.346 1.260 870/870 ea side 45/95/120

20" 11 128176 19.961 20.016 24.803 - 14.173 7.086 - 3.622 1.260 870/720 ea side 45/95/120

22" 17 128066 21.961 22.016 24.803 - 14.566 7.283 - 3.291 1.260 870/720 ea side 45/95/120

24" 13.5 128067 24.000 24.039 27.952 - 15.748 7.874 - 4.095 1.420 870/850 ea side 45/95/120

28" 17 128068 27.992 28.031 31.496 - 15.748 7.874 - 6.062 1.614 850/850 ea side 60/80/120

1/2" CTS through 28" IPS cont’d

x

t

h

x

h

B

t

z

L

D

Pipe OD

ID

D

L

Page 10

8

COUPLINGS

& REDUCER

4" through 24" DIPS

Short Designation UBI. . . OD

Field of Application Connections of PE Pipes 2406 and

3408/4710

Range of Application Water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

Nominal Pipe Product ID ID

D L t h x

Fusion Cooling

OD DIPS SDR Code min max Time/Sec @ 73ºF Time/Min */**/***

4" 13.5 128183 4.799 4.819 5.669 6.354 3.177 1.765 0.827 100 15/20/30

6" 11 128134 6.889 6.929 8.825 8.268 4.134 2.535 0.827 486 20/60/75

8" 11 128131 9.039 9.078 11.022 9.448 4.724 2.953 0.827 540 30/75/100

10" 11 128136 11.082 11.122 13.976 11.023 5.511 3.291 0.827 550 ea side 30/75/100

12" 11 128132 13.182 13.224 15.746 11.023 5.511 2.582 0.827 550 ea side 30/75/100

14" 11 128158 15.272 15.311 18.000 11.417 5.708 3.500 0.827 730 ea side 40/95/120

16" 11 128135 17.385 17.444 22.047 11.417 5.708 3.392 0.827 870/720 ea side 40/95/120

18" 13.5 128138 19.472 19.531 22.047 11.417 5.708 3.392 0.827 870/720 ea side 40/95/120

20" 13.5 128133 21.582 21.641 24.803 11.417 5.708 2.460 0.827 870/720 ea side 40/95/120

24" 11 128207 25.732 25.791 32.000 16.535 8.268 4.764 0.827 870/1080 ea side 45/95/120

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and pipe SDR range 9.33 through 17.6.

* Pipe can be moved after indicated cooling time (handling)

** Pipe can be pressurized after indicated cooling time (pressure <90 psi)

*** Pipe can be pressurized after indicated cooling time (pressure >90 psi)

Please note 4", 18" or 20" DIP are rated SDR 13.5 and can be pressurized up to 150 psi (water)

6" - 20"

4"

Couplings cont’d

x

t

h

x

h

B

t

z

L

D

Pipe OD

ID

D

L

Page 11

9

COUPLINGS

& REDUCER

Low Pressure Safety Electrofusion Couplings

The low pressure coupling can be fused to pipes of SDR stages 11 - 32

in accordance with ASTM F1055.

Pipes made of raw material types PE2406 and PE3408/4710,

PE63, PE80 and P100 in melt index groups 005 - 050 can be fused.

It is possible to work with these couplings at ambient temperatures of

between –4ºF up to 122ºF. It is always necessary to use a Friafit

adapter for the fusion.

The thinwall safety coupling (AM) is made of PE3408 and can be

pressurized up to a maximum of 80 psi if the pipe is of suitable

design.

With exposed heating coils for optimal heat transfer, large insertion

depth, extra wide fusion zones plus cold zones at the end and in the

middle to prevent the flow of molten material for use without a

holding device.

(formally called Friafit)

Size OD IPS Product Code Order No. VE PE ID (in) L (in) t (in) Weight lb/ea

8" 128139 190008-A 48 PE - HD 8.626 7.874 3.937 9

10" 128140 190010-A 32 PE - HD 10.748 8.268 4.134 11

12" 128141 190012-A 32 PE - HD 12.748 8.661 4.330 8

16" 128142 190016-A 16 PE - HD 16.008 8.661 4.330 16

t

ID

L

Page 12

10

COUPLINGS

& REDUCER

Reducer CTS x CTS & IPS x CTS

Field of Application Connections of PE Pipes 2406 and

3408/4710

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

• Increased coupler depth (no holding clamps required)

• Extra wide fusion zones

• Increased wall thickness providing maximum stability

• Front and middle cold zones

• Exposed heating coil with direct contact to pipe

• Contacts are safe to touch

• Visual fusion indicator

• Batch marking

• Individually wrapped

L

D2

d2

B

D1

d1

t1

t2

Reducer

Nominal Pipe

d1 (in)

Main Size d2

(in)

D1

(in)

D2

(in)

B

(in)

L

(in)

t1

(in)

t2

(in)

Weight lbs/ea

1 CTS 1/2 CTS 1.661 1.110 2.289 3.465 1.516 1.181 0.112

1 IPS 1/2 CTS 1.858 1.110 2.482 3.465 1.516 1.181 0.122

1-1/4 IPS 1 CTS 2.213 1.661 2.835 3.858 1.673 1.535 0.178

2 IPS 1 CTS 3.118 1.661 3.652 4.921 2.165 1.535 0.382

Page 13

11

TAPPING TEES

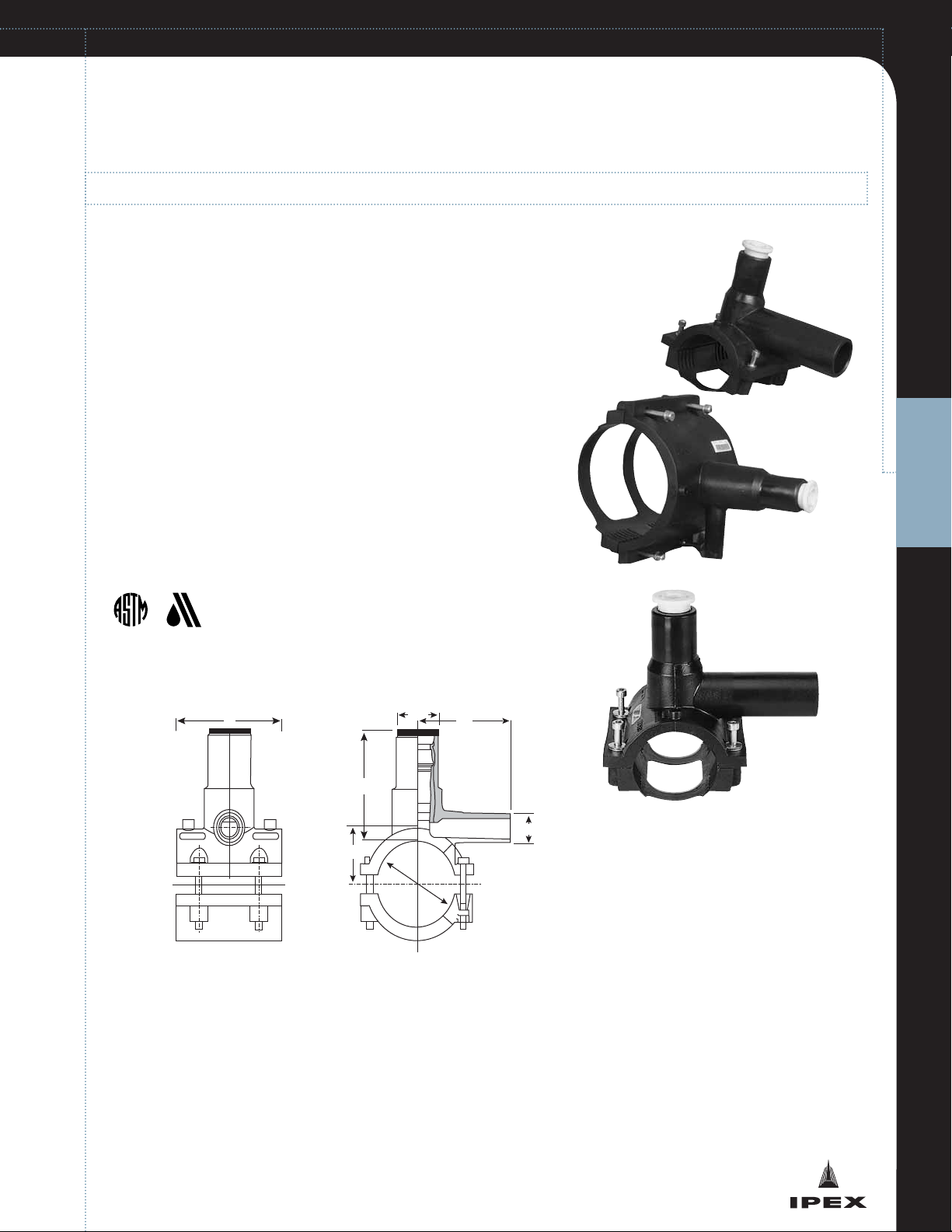

DAA High Pressure Tapping Tees - IPS

The industry-leading design of FRIATEC Tapping Tees makes for fast

and safe installation of service and branch pipe.

Short Designation DAA d1./d2...

Field of Application Installation of service and branch pipes

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

• Hot tapping tee designed for leakproof installation under pressure

up to 160 psi for water and 100 psi for gas

• Ease of assembly–no rounding clamps or special tools

• Cutter and sleeve made of brass

• Brass guide allows easy cutting of thick wall pipe

• Lower and upper “cutter stops” prevent overcutting as well as

accidental removal of cutter

• Threaded plug with o-ring seal

• Corrosion-proof construction

Tapping Tees

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and Pipe SDR Range 9.33 through 17.6.

For Pipe SDR Range 21+, contact IPEX for reduced fusion times.

Allow electrofusion joints to cool prior to handling, pressurizing or tapping.

B

L

Z1

OD2

ID

Z2

OD1

Page 14

12

TAPPING TEES

Tapping Tees con’t

4" 1/2" CTS 228045 4.512 0.626 1.969 1.180 4.764 2.905 4.016 4.785

4" 3/4" IPS 228034 4.512 1.051 1.969 1.180 4.764 2.846 4.409 4.764

4" 1" CTS 228035 4.512 1.126 1.969 1.180 4.764 2.846 4.527 4.785

4" 1" IPS 228046 4.512 1.315 1.969 1.180 4.764 2.913 4.527 4.785

4" 2" IPS 228025 4.512 2.378 1.969 1.180 4.780 2.913 7.086 4.905

6" 1/2" CTS 228047 6.638 0.626 1.969 1.180 6.575 4.500 4.586 7.677

6" 3/4" IPS 228036 6.638 1.051 1.969 1.180 6.575 4.528 4.331 7.677

6" 1" CTS 228038 6.638 1.126 1.969 1.180 6.575 4.528 4.331 7.677

6" 1" IPS 228049 6.638 1.315 1.969 1.180 6.575 4.528 4.331 7.677

6" 2" IPS 228027 6.638 2.378 1.969 1.180 6.575 4.803 6.811 7.677

8" 1/2" CTS 228048 8.605 0.626 1.969 1.180 6.575 5.483 4.586 7.677

8" 3/4" IPS 228037 8.605 1.051 1.969 1.180 6.575 5.315 4.331 7.677

8" 1" CTS 228041 8.605 1.126 1.969 1.180 6.575 5.315 4.331 7.677

8" 1" IPS 228040 8.605 1.315 1.969 1.180 6.575 5.315 4.331 7.677

8" 2" IPS 228039 8.605 2.378 1.969 1.180 6.575 5.827 6.811 7.677

10" - 16" * 2" IPS 228056 10.75 - 16.00 -- 1.969 1.180 6.575 -- 7.087 7.677

* Friatop pneumatic top-loading tool required

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and Pipe SDR Range 9.33 through 17.6.

For Pipe SDR Range 21+, contact IPEX for reduced fusion times.

Allow electrofusion joints to cool prior to handling, pressurizing or tapping.

For 12” and 14" IPS applications, maximum SDR for full coupon cut is SDR 11.

For 16" IPS applications, maximum SDR for full coupon cut is SDR 13.5.

For 12" DIP applications, maximum SDR for full coupon cut is SDR 11.

For 14" and 16" DIP applications, maximum SDR for full coupon cut is SDR 17.

Nominal Nominal Product

ID OD 1 OD 2 Cutter L Z1 Z2 B

Pipe OD IPS Outlet Code

1-1/4" 1/2" CTS 228020 1.575 0.626 1.259 0.630 2.913 1.102 9.624 2.756

1-1/4" 3/4" IPS 228021 1.575 1.051 1.259 0.630 2.913 1.102 9.624 2.756

1-1/4" 1" CTS 228022 1.575 1.126 1.259 0.630 2.913 1.102 9.624 2.756

1-1/4" 1" IPS 228023 1.575 1.315 1.259 0.630 2.913 1.102 9.624 2.756

2" 1/2" CTS 228042 2.378 0.626 1.575 0.846 3.878 1.780 3.937 4.094

2" 3/4" IPS 228029 2.378 1.051 1.575 0.846 3.878 1.780 3.701 4.094

2" 1" CTS 228033 2.378 1.126 1.575 0.846 3.860 1.780 3.701 4.094

2" 1" IPS 228032 2.378 1.315 1.575 0.846 3.860 1.780 3.701 4.094

2" 2" IPS 228274 2.378 2.378 1.575 1.180 5.000 2.170 5.952 6.060

3" 1/2" CTS 228043 3.504 0.626 1.969 1.180 4.764 2.343 4.410 4.803

3" 3/4" IPS 228030 3.504 1.051 1.969 1.180 4.764 2.343 3.937 4.803

3" 1" CTS 228031 3.504 1.126 1.969 1.180 4.764 2.343 4.255 4.803

3" 1" IPS 228044 3.504 1.315 1.969 1.180 4.764 2.343 4.255 4.803

3" 2" IPS 228028 3.504 2.378 1.969 1.180 4.780 2.350 6.890 5.905

DAA High Pressure Tapping Tees - IPS

Page 15

13

TAPPING TEES

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and Pipe SDR Range 9.33 through 17.6.

For Pipe SDR Range 21+, contact IPEX for reduced fusion times.

Allow electrofusion joints to cool prior to handling, pressurizing or tapping.

Nominal Nominal Product

ID OD 1 OD 2 Cutter L Z1 Z2 B

Pipe OD DIP Outlet (in) Code

4" 1/2" CTS 228251 4.512 0.626 1.969 1.201 4.764 2.905 4.016 4.785

4" 3/4" IPS 228252 4.512 1.051 1.969 1.201 4.764 2.846 4.409 4.764

4" 1" CTS 228250 4.512 1.126 1.969 1.201 4.764 2.846 4.527 4.785

4" 2" IPS 228253 4.512 2.378 1.969 1.201 4.780 2.913 7.086 4.905

6" 1/2" CTS 228254 6.638 0.626 1.969 1.201 6.575 4.500 4.586 7.677

6" 3/4" IPS 228255 6.638 1.051 1.969 1.201 6.575 4.528 4.331 7.677

6" 1" CTS 228256 6.638 1.126 1.969 1.201 6.575 4.528 4.331 7.677

6" 2" IPS 228257 6.638 2.378 1.969 1.201 6.575 4.803 6.811 7.677

8" 1/2" CTS 228258 8.605 0.626 1.969 1.201 6.575 5.483 4.586 7.677

8" 3/4" IPS 228259 8.605 1.051 1.969 1.201 6.575 5.315 4.331 7.677

8" 1" CTS 228260 8.605 1.126 1.969 1.201 6.575 5.315 4.331 7.677

8" 2" IPS 228261 8.605 2.378 1.969 1.201 6.575 5.827 6.811 7.677

DAA High Pressure Tapping Tees - DIP

The DAA is easy to assemble and delivers a high quality design for the

gas and water industry.

Short Designation DAA d1./d2...

Field of Application Installation of service and branch pipes

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

• Hot tapping tee designed for leakproof installation under pressure

up to 160 psi for water and 100 psi for gas

• Ease of assembly–no rounding clamps or special tools

• Cutter and sleeve made of brass

• Brass guide allows easy cutting of thick wall pipe

• Lower and upper “cutter stops” prevent overcutting as well as

accidental removal of cutter

• Threaded plug with o-ring seal

• Corrosion-proof construction

Page 16

14

TAPPING TEES

Description Product Code

10mm Hex Wrench for 1-1/4" Main DAA Tees 228050

17 mm Hex Wrench for 2" Main DAA Tees 228051

19mm Hex Wrench for 2" x 2" and 3" - 16" Main DAA Tees 228052

Friatop Pneumatic Top Loading Tool

for 10" - 16" DAA-TL and all TL fittings

228053

Pressure Test Cap Adapter (optional)

for DAA style 1-1/4" Tees

228024

Pressure Test Cap Adapter (optional)

for DAA style 2" - 16" Tees

228055

DAA Tapping Tee Accessories

Tapping Tees con’t

Page 17

15

TAPPING TEES

Nominal Pipe Product

d3 L z1 z2 t1 B1 B2 d4

Main Outlet Code

2" IPS x 1/2" CTS 228110 2.165 5.748 2.559 3.449 2.717 2.795 4.724 1.016

2" IPS x 3/4" IPS 228111 2.165 5.748 2.559 3.843 3.110 2.795 4.724 1.016

2" IPS x 1" CTS 228112 2.165 5.748 2.559 4.236 3.504 2.795 4.724 1.016

2" IPS x 1-1/4" IPS 228123 2.402 5.000 2.157 4.677 3.740 2.795 4.724 1.214

2" IPS x 2" IPS 228124 2.402 5.000 2.319 6.496 5.559 2.795 4.724 1.214

4" IPS x 1/2" CTS 228113 2.165 5.827 3.524 3.449 2.717 4.528 5.906 1.016

4" IPS x 3/4" IPS

228114 2.165 5.827 3.524 3.843 3.110 4.528 5.906 1.016

4" IPS x 1" CTS 228115 2.165 5.827 3.524 4.236 3.504 4.528 5.906 1.016

4" IPS x 1-1/4" IPS 228126 3.268 8.386 4.114 5.512 4.114 4.528 5.906 1.798

4" IPS x 2" IPS 228127 3.268 8.386 4.449 5.512 4.114 5.039 5.906 1.798

6" IPS x 1/2" CTS 228116 2.165 5.827 4.449 3.449 2.717 5.039 5.906 1.016

6" IPS x 3/4" IPS 228117 2.165 5.827 4.449 3.843 3.110 5.039 5.906 1.016

6" IPS x 1" CTS 228118 2.165 5.827 4.449 4.236 3.110 5.039 5.906 1.016

6" IPS x 1-1/4" IPS 228128 3.268 8.386 4.449 5.512 4.114 5.039 5.906 1.798

6" IPS x 2" IPS 228129 3.268 8.386 4.449 6.299 4.902 5.039 5.906 1.798

8" IPS x 1/2" CTS 228120 2.165 6.457 4.921 3.449 2.717 5.827 5.906 1.016

8" IPS x 3/4" IPS 228121 2.165 6.457 4.921 3.843 3.110 5.827 5.906 1.016

8" IPS x 1" CTS 228122 2.165 6.457 4.921 4.236 3.504 5.827 5.906 1.016

8" IPS x 1-1/4" IPS 228130 3.268 8.976 4.921 5.512 4.114 5.827 5.906 1.798

8" IPS x 2" IPS 228131 3.268 8.976 4.921 6.299 4.902 5.827 5.906 1.798

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and Pipe SDR Range 9.33 through 17.6.

For Pipe SDR Range 21+, contact IPEX for reduced fusion times.

Allow electrofusion joints to cool prior to handling, pressurizing or tapping.

DAS II Top Loading Tapping Tees

Short Designation DAS II d1./d2...

Field of Application Installation of service and branch pipes

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

• Top loading • High volume • Self-tapping tee

• Internal cutter blade that is the largest on the market

d3

z2

t1

d2

z1

d4

d1

B2

B1

Page 18

16

TAPPING TEES

DAS II Top Loading Tapping Tee Accessories

Description Product Code

Top Loading Tool and Tapping Tools (complete set)

Includes: 228065, 228066, 228072, 228073, 228074,

228075, 228077, 228078, 228079 and 228080

228067

Top Loading Tool (only)

Includes: Top Bar and Ratchet

228075

25mm Top Loading Cap (adapter only) 228072

33mm Top Loading Cap (adapter only) 228073

50mm Top Loading Cap (adapter only) 228074

15mm DAS II Tap Tool (only) 228065

24mm DAS II Tap Tool (only) 228066

DAS Lock Pin 228077

DAS Short Strap 228078

DAS Long Strap 228079

DAS Standard Case 228080

25mm Aluminum Test Cap 228057

33mm Aluminum Test Cap 228058

50mm Aluminum Test Cap 228059

Tapping Tees con’t

Page 19

17

SCRAPER TOOLS

Scraper Tools

Scraper Tools with Accessories

Scraper Tools

Product

Code

Pipe Size

Compatibility

FWZ Hand Scraper 328018 all

GBZ Pocket Scraper 128020 1/2" CTS - 1-1/4" CTS

FWSG 63 Scraper Tool w/ Case 128034 1/2" IPS - 2" IPS

FWSG 315 Scraper Tool w/ Case 128036

3" IPS - 8" IPS

4" DIP - 6" DIP

Scraper Tools w/ Case (complete set)

Includes: FWSG 63 & FWSG 315

128039

1/2" IPS - 2" IPS

3" IPS - 10" IPS

4" DIP - 6" DIP

FWSG 710 Scraper Tool w/ Case 128190

6" IPS - 28" IPS

6" DIP - 20" DIP

FRIATEC scraper tools are designed to assist the

installer in producing a quality electrofusion joint.

With our Scraper Tools a quality electrofusion joint

can be achieved every time.

Accessories

Product

Code

Spare Blades for FWZ Hand Scraper

(set of 5 blades)

328017

Spare Blade Kit for FWSG 63

3 blades, 2 screws, 1 driver

128041

Spare Blade Kit for FWSG 315

3 blades, 2 screws, 1 driver

128040

Spare Blade Kit for FWSG 630/710

3 blades, 2 screws, 1 driver

128042

Aluminum Carrying Case

for FWSG 630-710 Scraper Tool

128198

Aluminum Carrying Case

for FWSG 63-315 Scraper Tool

128035

Page 20

18

RE-ROUND CLAMPS

Hydraulic Re-Round Clamps

Re-Round Clamps

Description - IPS

Product

Code

14" IPS Master Re-Round Clamp 228152

16" IPS Re-Round Insert 228158

18" IPS Master Re-Round Clamp 228154

20" IPS Master Re-Round Clamp 228161

d 630mm Large Master Re-Round Clamp 22" - 24" 228156

22" IPS Re-Round Insert 228159

24" IPS Re-Round Insert 228160

28" IPS Master Re-Round Clamp 228217

If the end of a PE pipe is not perfectly round, the coupling will

not fit over the end of the pipe. Our Re-Round Clamps solve

this problem.

The clamping unit is comprised of:

1 – Hydraulic clamping unit

2 – Component inserts

Description - DIP

Product

Code

8" DIP Re-Round Insert 228162

10" DIP Master Re-Round Insert 228151

12" DIP Master Re-Round Clamp 228153

12" DIP Re-Round Insert 228163

16" DIP Master Re-Round Clamp 228155

16" DIP Re-Round Insert 228164

18" DIP Master Re-Round Clamp (20" IPS master) 228161

20" DIP Re-Round Insert

(requires 228156 d 630mm Master Re-Round Clamp)

228165

Page 21

19

RE-ROUND CLAMPS

Alignment Clamps - IPS / DIP

Description - Single Product Code

1-1/4" IPS 228244

2" IPS 228137

3" IPS 228248

4" IPS 228138

4" DIP 228263

6" IPS 228139

6" DIP 228264

8" IPS 228246

Description - Double Product Code

1-1/4" IPS 228245

2" IPS 228140

3" IPS 228249

4" IPS 228141

6" IPS 228142

8" IPS 228247

Description Product Code

6" IPS/DIP - 12" IPS/DIP Re-Round Tool 228271

12" IPS/DIP - 20" IPS/DIP Re-Round Tool 228278

20" IPS - 28" IPS & 20" - 24" DIP Re-Round Tool 228275

Our industrial-quality re-rounding tools for the gas and

water industries has a reputation of being the bestquality tools on the market.

Each alignment clamp listed in the table aligns only

one size pipe. Select tool according to pipe size to be

aligned.

Manual Re-Rounding Tools

Page 22

20

SADDLES

VA Electrofusion Service Saddles

Short Designation VA, VA-TL d1./d2...

Field of Application Installation of service and branch pipes

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

FRIATEC Molded Saddle Fittings may be clamped onto pipes up to

SDR 9 and sealed using electrofusion. In addition to house connection

fittings, FRIATEC Molded Saddle Fittings can also be used as branch

saddles for polyethylene relining pipes (U-liners, C-liners, Roll-down)

Benefits include:

• universal compatibility with various diameters of polyethylene pipe

from 3" up to 22"

• quick, easy and safe assembly

FRIATEC Safety fittings can be fused to all PE pipes within melt index groups 003-050 and SDR range 9.33 through 17.6.

Assemble nipple, bushing or corporation stop into saddle using red LOCTITE #262

(SSPT) = Straight Standard Pipe Thread. The use of tapered fittings for the outlet is not permitted

Saddles

Nominal Main Nominal Product

B1 B2 H L t e

Pipe d1 (in) Size d2 Outlet Code

3" IPS 2" SSPT 228262 6.102 5.906 7.835 3.740 1.063 3.189

4" IPS 2" SSPT 228170 6.890 7.087 8.228 3.740 1.063 3.189

4" DIP 2" SSPT 228298 6.890 7.087 8.228 3.740 1.063 3.189

6" IPS 2" SSPT 228171 8.858 7.677 10.197 3.740 1.063 3.189

6" DIP 2" SSPT 228302 8.858 7.677 10.197 3.740 1.063 3.189

8" - TL* IPS 2" SSPT 228218 9.843 7.677 11.693 3.740 1.063 3.189

8" - TL* DIP 2" SSPT 228173 10.039 7.677 12.283 3.740 1.063 3.189

10" - 22" TL* IPS

2" SSPT 228174 7.874 -- -- 3.543 -- --

10" - 20" TL* DIP

* FRIATEC Pneumatic Top-loading tool required

SW

L

e

L

H

B2

SW

t

B1

B1

Page 23

21

SADDLES

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and Pipe SDR Range 9.33 through 17.6.

For Pipe SDR Range 21+, contact IPEX for reduced fusion times.

PE pipes of different melt index groups can be joined.

Short Designation SA, SA-TL d1./d2...

Field of Application Installation of service and branch pipes

Range of Application Gas up to 100 psi and water up to 160 psi

SA Branch Saddles are available with either a 2" or 3" outlet

For higher pressure ranges, contact IPEX at 800-463-9572

Nominal Main Nominal Product

d3 L h t B1 B2

Pipe d1 (in) Size d2 Outlet Code

3" IPS 2 IPS 228184 1.969 4.055 8.150 2.756 6.102 5.906

4" IPS 2 IPS 228185 1.929 4.291 9.173 2.205 6.890 7.087

4" DIP 2 IPS 228296 1.929 4.291 9.173 2.205 6.890 7.087

4" IPS 3 IPS 228186 2.756 4.528 8.976 3.543 6.496 7.480

4" DIP 3 IPS 228297 2.756 4.528 8.976 3.543 6.496 7.480

6" IPS 2 IPS 228144 1.850 4.291 11.142 2.205 8.858 7.677

6" DIP 2 IPS 228305 1.850 4.291 11.142 2.205 8.858 7.677

6" IPS 3 IPS 228180 2.717 5.079 11.496 3.937 8.543 9.646

6" DIP 3 IPS 228306 2.717 5.079 11.496 3.937 8.543 9.646

6" IPS 4 IPS 228277 3.543 5.512 12.256 4.291 9.055 10.433

8" - TL * IPS 2 IPS 228146 1.850 4.291 12.244 2.205 9.843 7.677

8" - TL * DIP 2 IPS 228311 1.850 4.291 13.228 2.205 10.039 7.677

8" - TL * IPS 3 IPS

288181 2.402 4.567 13.780 3.150 10.039 7.677

8" - TL * DIP 3 IPS 228312 2.402 4.567 13.780 3.150 10.039 7.677

8" IPS 4 IPS 228276 3.543 5.512 14.256 4.370

11.220 11.024

10" - 22" - TL * IPS

2 IPS 228182 1.850 4.291 -- 2.205 -- 7.874

10" - 20" - TL * DIP

10" - 22" - TL * IPS

3 IPS 228187 2.402 4.567 -- 3.150

-- 7.874

10" - 20" - TL * DIP

* FRIATEC Pneumatic Top-loading tool required

SA Branch Saddles

d2

d3

d2

d3

t

L

h

d1

B2

B1

t

L

d1

B

Page 24

22

SADDLES

SPA Ballon Saddles

Short Designation VA, VA-TL d1./d2...

Field of Application Installation of service and branch pipes

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

FRIATEC Molded Saddle Fittings may be clamped onto pipes up

to SDR 9 and sealed using electrofusion. In addition to house

connection fittings, FRIATEC Molded Saddle Fittings can also be

used as branch saddles for polyethylene relining pipes (U-liners,

C-liners, Roll-down)

Benefits include:

• universal compatibility with various diameters of polyethylene pipe

from 3" up to 28"

• quick, easy and safe assembly

Saddles con’t

Description Product Code

Electrofusion Cap for SPA Saddles 228242

SPA Dust Cap

FRIATEC Safety fittings can be fused to all PE pipes within melt index groups 003-050 and SDR range 9.33 through 17.6.

Assemble nipple, bushing or corporation stop into saddle using red LOCTITE #262

(SSPT) = Straight Standard Pipe Thread. The use of tapered fittings for the outlet is not permitted

SPA Dust Cap protects against dirt and debris from entering the top

portion of the SPA saddle.

Nominal Main Product

Pipe d1 (in) Size d2 Code

3" IPS 228236

4" IPS 228237

4" DIP 228301

6" IPS 228238

6" DIP 228308

8" - TL* IPS 228239

10" - 12" TL* IPS 228241

* FRIATEC Pneumatic Top-loading tool required

Page 25

23

REPAIR PATCHES

& CLAMPS

Repair Patches and Clamps

For Pipe Repairs up to 28"

Short Designation VVS / VSC-TL d...

Field of Application Repair of small damage leakage

Reinforcement of “squeeze off” areas and

areas with surface damage

Range of Application Gas up to 100 psi and water up to 160 psi

For higher pressure ranges, contact IPEX at 800-463-9572

If a pipe is damaged, FRIATEC Repair Patches and Clamps are the

quick reliable way to make the repair.

FRIATEC pipe repair systems are both simple to use and effective

for pipe repair up to 28". Our repair systems make use of existing

FRIATEC technology to seal a pipe puncture.

Nominal Main Product

d1 d2 H t

Cold Zone Width

Pipe Size Code (Center)

3" IPS 228175 3.500 1.969 5.827 0.827 2.953"/75mm

4" IPS 228176 4.500 1.969 6.614 0.827 3.071"/78mm

4" DIP 228295 4.500 1.969 6.614 0.827 3.071"/78mm

6" IPS 228177 6.625 1.969 8.583 0.827 3.346"/85mm

6" DIP 228307 6.625 1.969 8.583 0.827 3.346"/85mm

Nominal

Main Product

d1 d2 t B

Cold Zone Width

Pipe (in) Size Code (Center)

8" IPS * 228178 8.625 1.969 0.827 10.157 3.268"/85mm

8" DIP * 228310 9.050 1.969 0.827 11.142 3.268"/85mm

10" - 22" IPS *

228179

10.750 - 28.000

1.969 0.787 7.874 3.307"/83mm

10" - 20" DIP * 11.100 - 21.600

* FRIATEC Pneumatic Top-loading tool required (restriction on 28")

B

FRIATEC Safety Fittings can be fused to all PE pipes within melt index groups 003-050 and Pipe SDR Range 9.33 through 17.6.

For Pipe SDR Range 21+, contact IPEX for reduced fusion times.

Repair Clamps - Under saddle

Repair Patches - Top Loading

t

d2

H

d1

d2

d1

t

Page 26

24

Notes:

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

____________________________________________

Page 27

Reference materials from IPEX

FRIATEC PE Electrofusion

Water Brochure and

Gas Brochure

Contact your IPEX representative for more information

or visit our websites.

FRIATEC PE Electrofusion

Multimedia Presentation

Ads for FRIATEC

PE Electrofusion

Water and Gas

FRIATEC PE Electrofusion

Price List

Page 28

CTMNPFIP130404 © 2013 IPEX MN004C

SALES AND CUSTOMER SERVICE

Canadian Customers call IPEX Inc.

Toll free: (866) 473-9462

www.ipexinc.com

U.S. Customers call IPEX USA LLC

Toll free: (800) 463-9572

www.ipexamerica.com

About the IPEX Group of Companies

As leading suppliers of thermoplastic piping systems, the IPEX Group of

Companies provides our customers with some of the largest and most

comprehensive product lines. All IPEX products are backed by more than

50 years of experience. With state-of-the-art manufacturing facilities and

distribution centers across North America, we have established a reputation for

product innovation, quality, end-user focus and performance.

Markets served by IPEX group products are:

• Electrical systems

• Telecommunications and utility piping systems

• PVC, CPVC, PVCO, PP, ABS, PEX, FR-PVDF and PE pipe and fittings

(1/4" to 48")

• Industrial process piping systems

• Municipal pressure and gravity piping systems

• Plumbing and mechanical piping systems

• PE Electrofusion systems for gas and water

• Industrial, plumbing and electrical cements

• Irrigation systems

This literature is published in good faith and is believed to be reliable.

However it does not represent and/or warrant in any manner the information

and suggestions contained in this brochure. Data presented is the result of

laboratory tests and field experience.

A policy of ongoing product improvement is maintained. This may result in

modifications of features and/or specifications without notice.

Friatec

®

is manufactured by IPEX Inc. and FRIATEC AG is distributed in the

United States by IPEX USA LLC.

Friatec

®

is a trademark of FRIATEC AG.

Loading...

Loading...