IPEX MUNICIPAL SYSTEMS Installation Manual

PVCO CIOD PRESSURE PIPE

4" (100mm) to 12" (300mm)

PVC CIOD PRESSURE PIPE & FITTINGS

4" (100mm) to 48" (1200mm)

PVC IPS PRESSURE PIPE & FITTINGS

1-1/2" (40mm) to 24" (600mm)

PVC PIPING SYSTEMS FOR HDD & OTHER TRENCHLESS APPLICATIONS

4" (100mm) to 12" (300mm)

MUNICIPAL SYSTEMS

We build tough products for tough environments

®

Installation Guide

PVC Pressure Pipe & Ftgs Installation Guide

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Pressure Pipe & Fittings Meet These Standards . . . . . . . .4

Receiving & Handling Pipe Shipments . . . . . . . . . . . . . . . .5

Before Accepting the Shipment . . . . . . . . . . . . . . . . . . . . .5

Handling the Pipe and Fittings . . . . . . . . . . . . . . . . . . . . .5

Storage at the Job Site . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Cold Weather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Stockpiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Outdoor Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Trench Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Excavating and Preparing the Trench . . . . . . . . . . . . . . . . .8

Depth of Trench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Flotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

The Bottom of the Trench . . . . . . . . . . . . . . . . . . . . . . . . .9

Lowering Pipe & Fittings into the Trench . . . . . . . . . . . . .10

Assembling IPEX Joints . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

For Sizes over 36 inches (900mm) . . . . . . . . . . . . . . . . .13

Curvature of the Pipeline . . . . . . . . . . . . . . . . . . . . . . . . . .14

Using PVC Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Deflecting the Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Bending the Pipe Barrel . . . . . . . . . . . . . . . . . . . . . . . . .16

Assembling to Iron Appurtenances . . . . . . . . . . . . . . . . . .17

Assembling to Cast Iron Fittings . . . . . . . . . . . . . . . . . . .17

Assembling to Butterfly Valves . . . . . . . . . . . . . . . . . . . . .17

Cutting and Chamfering the Pipe . . . . . . . . . . . . . . . . . . .18

Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Chamfering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Blue Brute®/IPEX Centurion® . . . . . . . . . . . . . . . . . . . . . .20

Cycle Tough

®

Series . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Bionax PVCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Outside Diameter Considerations . . . . . . . . . . . . . . . . . . .22

Blue Brute and Centurion PVC Pipe: CIOD . . . . . . . . . . . .22

Cycle Tough PVC Pipe: IPS OD . . . . . . . . . . . . . . . . . . . .23

Bionax PVCO Pipe: CIOD . . . . . . . . . . . . . . . . . . . . . . . .23

CIOD Injection-Molded PVC Fittings . . . . . . . . . . . . . . . . .24

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1

PVC Pressure Pipe & Ftgs Installation Guide

RECOMMENDED PRACTICES FOR

THE INSTALLATION OF IPEX

PVC PRESSURE PIPE & FITTINGS

Introduction

This booklet will answer the needs of pipe installers looking for

general recommendations on how to lay IPEX gasketed PVC

pressure pipes and fittings. Out-of-the-ordinary conditions not

covered here should be referred to the Engineer or field

inspectors to provide on-site solutions. In such cases IPEX's

advice is always available. Our objective is to encourage the

use of methods that lead to a professional installation that will

ensure the maximum service life for the pipe.

The Engineer who designs the pipeline will determine how it is

to be installed. It is not our intention that the Guide should

assume that responsibility unless the Engineer so directs.

This booklet sets out the preferred methods of installation

based on IPEX's experience and on a number of published

reports from other industry sources. Users will find additional

helpful advice in "Recommended Practice for the Installation

of PVC Pressure Pipe", AWWA C605, published by the

American Water Works

Association.

Readers are invited to order a

copy of the "Uni-Bell Handbook

of PVC Pipe - Design and

Construction". This comprehensive

reference manual covers all

aspects of design and installation

for PVC pipe & fittings. Call UniBell at (972) 243-3902 to order.

3

PVC Pressure Pipe & Ftgs Installation Guide

IPS Injection-Molded PVC Fittings . . . . . . . . . . . . . . . . . .31

Engineered Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Fabricated PVC Pressure Fittings . . . . . . . . . . . . . . . . . . .38

TerraBrute

®

CR Trenchless Applications . . . . . . . . . . . . . .39

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Minimum Bending Radius . . . . . . . . . . . . . . . . . . . . . . . .40

Joint Deflection Radius . . . . . . . . . . . . . . . . . . . . . . . . . .40

Maximum Allowable Pull Forces . . . . . . . . . . . . . . . . . . .40

Joint Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . .39

General Recommendations . . . . . . . . . . . . . . . . . . . . . . .41

Resisting Thrust at Fittings & Valves . . . . . . . . . . . . . . . . .45

Bearing Strength of Undisturbed Soils . . . . . . . . . . . . . . .46

Resisting Thrust in Very Poor Soils . . . . . . . . . . . . . . . . .46

Resisting Vertical Thrust . . . . . . . . . . . . . . . . . . . . . . . . .48

Holding Pipe to Steep Slopes . . . . . . . . . . . . . . . . . . . . .49

Mechanical Thrust Restraints . . . . . . . . . . . . . . . . . . . . .49

Flanged Joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Tapping and Service Connections . . . . . . . . . . . . . . . . . . .50

Direct Tapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Service Saddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Tapping Sleeve and Valve . . . . . . . . . . . . . . . . . . . . . . . .51

Tapped Couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

The Two Backfills and Haunching . . . . . . . . . . . . . . . . . . .53

Initial Backfill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Final Backfill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Compacting the Backfill . . . . . . . . . . . . . . . . . . . . . . . . .54

Shallow Bury Considerations . . . . . . . . . . . . . . . . . . . . . .55

Percent Deflections Charts . . . . . . . . . . . . . . . . . . . . . . .56

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Filling the Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

How Much Water is Needed . . . . . . . . . . . . . . . . . . . . . .65

Pressure and Leakage Tests . . . . . . . . . . . . . . . . . . . . . . .65

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Installing the Pipe Through Casings . . . . . . . . . . . . . . . . .70

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Casing Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Skids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Mechanical Casing Spacers . . . . . . . . . . . . . . . . . . . . . . .71

Casing Spacer Installation . . . . . . . . . . . . . . . . . . . . . . . .72

Sealing the Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Lubricant Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

2

PVC Pressure Pipe & Ftgs Installation Guide

RECEIVING AND HANDLING

PIPE SHIPMENTS

Before Accepting the Shipment

IPEX pipe and fittings are manufactured to a number of

standards, none of which are more demanding than IPEX's

own Standard Product Specifications. Quality Control

inspection of the products before they leave our plants ensures

that only the highest quality products are shipped. Damage to

the pipe, or shortages, are possible and must be checked

before the shipment is signed for by the contractor.

1. Walk around the vehicle to make sure there has been no

shifting of the load during transport. If there is some

indication of shifting in transit, the contractor should

inspect each piece as it is unloaded.

2. Check the quantity shipped against the tally sheet.

The contractor must note any shortages on the trucker's

bill of lading.

3. Carefully note any sign of damage to the pipe in the form

of cracks, chips or other damage. Damage depth is

considered significant if it is more than 10% of the

thickness of the pipe wall.

4. DO NOT THROW AWAY ANY DAMAGED MATERIAL.

Mark it carefully for further inspection by the carrier or

his representative.

5. Re-order any material that is needed to make up for

missing or damaged items.

6. Notify the carrier immediately and enter a claim for

damaged or missing parts in accordance with their

instructions.

Handling the Pipe and Fittings

Pipe arrives at the job site in standard pallet size units. The

preferred method of unloading is to keep the pipe in the units

as shipped and use mechanical equipment such as fork lifts,

cherry pickers or front end loaders with forks. Do not slide the

equipment forks against the underside of pipe in a pallet. This

may damage the pipe by abrasion.

When the pipe is unloaded in full units they should be stored

on level ground and they should not be stacked more than

2 units high. The units should be supported by dunnage in the

5

PVC Pressure Pipe & Ftgs Installation Guide

Pressure Pipe and Fittings Meet These Standards

Canadian Standards Association

B137.2 “Polyvinylchloride (PVC) injection-molded gasketed

fittings for pressure applications”

B137.3 “Rigid polyvinylchloride (PVC) pipe and fittings for

pressure applications”

B137.3.1 “Molecularly oriented polyvinylchloride (PVCO) pipe

for pressure applications”

ASTM

D2241 “Poly (Vinyl Chloride) (PVC) Pressure-Rated Pipe

(SDR Series)”

F1483 “Oriented Polyvinyl Chloride, PVCO, Pressure Pipe”

American Water Works Association

AWWA C900 “Polyvinyl Chloride (PVC) Pressure Pipe

and Fabricated Fittings, 4" through 12", for

Water Transmission and Distribution”

AWWA C905 “Polyvinyl Chloride (PVC) Pressure Pipe and

Fabricated Fittings, 14" through 48"”

AWWA C907 “Polyvinyl Chloride (PVC) Pressure Fittings for

Water – 4" through 12" (100 mm through 300 mm)”

AWWA C909 “Molecularly Oriented Polyvinyl Chloride (PVCO)

Pressure Pipe, 4" through 24" (100 mm through 600 mm) for

Potable Water, Wastewater, and Reclaimed Water Service”

BNQ

NQ 3624-250 “Unplasticized Poly(Vinyl Chloride) [PVC-U]

Pipe and Fittings - Rigid Pipe for Pressurized Water Supply

and Distribution - Characteristics and Test Methods”

4

PVC Pressure Pipe & Ftgs Installation Guide

In Very Cold Weather

Although PVC pipe has very good impact resistance, it

becomes stiffer and offers reduced impact resistance at very

low temperatures. Recommended handling as described above

is all that is required under these conditions. Do not allow the

pipe to fall off the truck or into the trench. Individual lengths

of pipe should not impact on each other as they are unloaded

or stockpiled.

Stockpiling

Where it is necessary to remove pipe from their crates for

storage, individual lengths should be placed on level ground

and secured to prevent them from rolling.

Prolonged Outdoor Storage

Prolonged exposure of PVC pipe to the direct rays of the sun

has no practical effects on the performance of the pipe.

However some discoloration may take place in the form of a

milky film on the exposed surfaces. This change in color

merely indicates that there has been a chemical transformation

at the surface of the pipe. A small reduction in impact

strength could occur at the discolored surfaces. Other strength

properties such as pressure capacity and structural strength

are completely unaffected by this discoloration.

Discoloration of the pipe can be avoided by shading it from

the direct rays of the sun. This can be accomplished by

covering the stockpile or the crated pipe with an opaque

material such as canvas. If the pipe is covered, always allow

for the circulation of air through the pipe to avoid heat buildup

in hot summer weather. Make sure that the pipe is not stored

close to sources of heat such as boilers, steam lines, engine

exhaust outlets, etc.

7

PVC Pressure Pipe & Ftgs Installation Guide

same way they were protected while on the transport. The

weight of the unit should be borne by the dunnage rather than

the pipe.

Units of pipe should not be lifted with single cables or chains.

The wooden frames around the units should not be used as

lifting points. Use straps and spreaders about 12 feet (3.7m)

apart looped under the load.

Should mechanical equipment not be available, caution should

be exercised when the pipe is unloaded by hand. Each unit or

crate of pipe will be approximately 4 feet (1.2m) wide and will

vary in height depending on the size of pipe in the unit. Where

several tiers of pipe are in the unit they will be held in place

with steel straps. By undoing the outer strap the top tier of

pipe may be unloaded by individual lengths. The length

behind the one being unloaded should be held in place with

wooden chocks. Lighter pipes may be carefully handed down

from the top of the load, but heavier pipes will require the use

of ropes and skids. As each tier is unloaded, the interlacing

straps are broken to provide access to the lower tier.

Storage at the Job Site

The preferred method of storage at the job site is in units or

crates as shipped.

When the pipe is strung along the trench, place it as close as

possible to the line of the trench, to the side opposite the area

reserved for the storage of spoil. Locate the pipes where they

can be lowered into the trench with the least amount of

additional handling.

6

PVC Pressure Pipe & Ftgs Installation Guide

Depth of Trench

For water distribution and transmission lines, pipe should be

buried so that the top of the pipe is at least 6" (150mm)

below the deepest recorded penetration of frost. Where surface

loads will be encountered and where frost is not a problem,

the minimum height of cover over the crown of the pipe is 12"

(300mm). Before vehicles pass over the line of the pipe under

shallow cover, make sure embedment material has been

completed and compacted to at least 95% standard proctor

density and has a minimum modulus of soil reaction (E’) of

1000psi.

Flotation

Where it is not possible to remove standing water from the

trench and the pipe will be in a flooded condition, it should be

held at grade with a soil cover of at least twice the pipe

diameter.

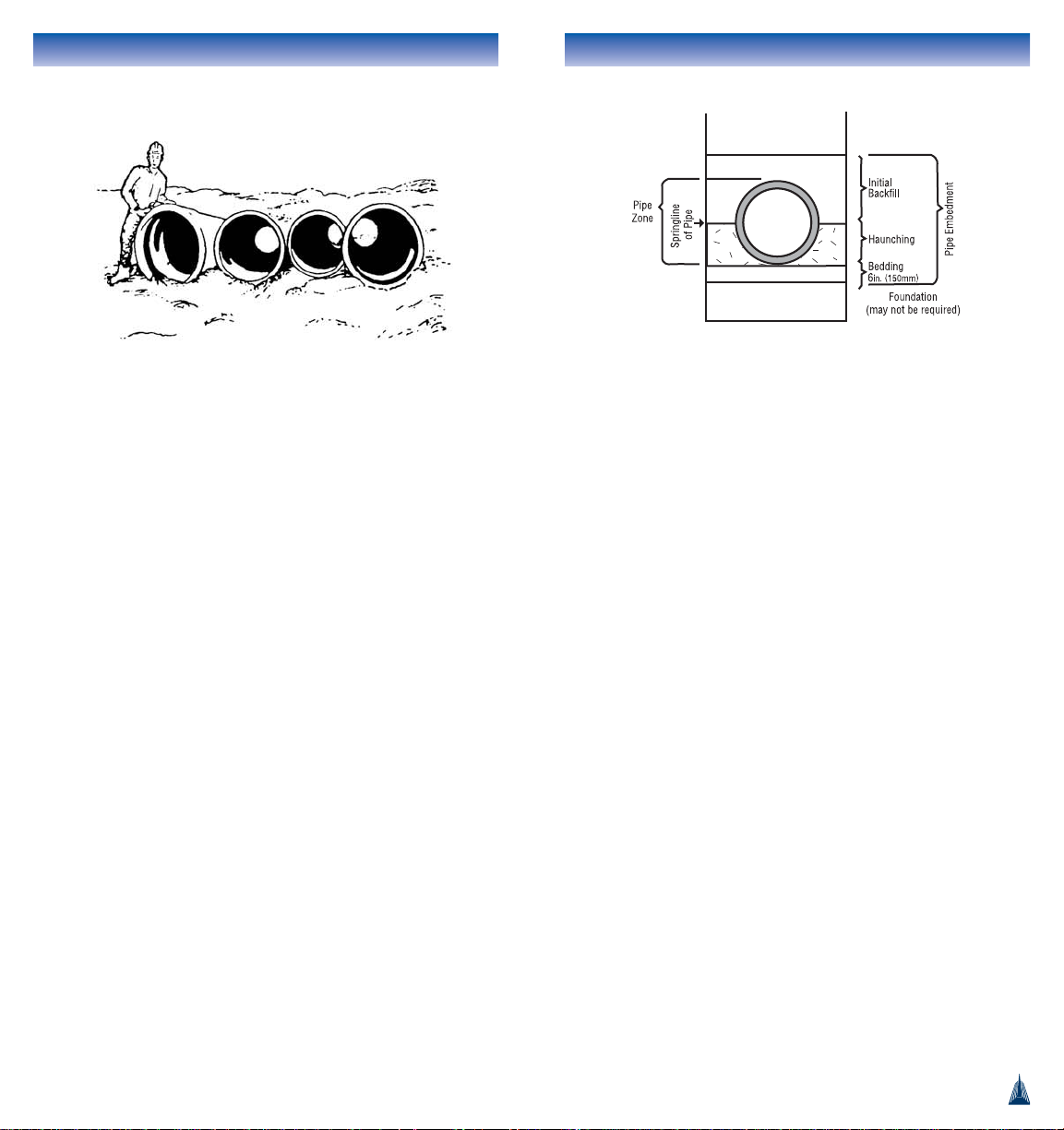

The Bottom of the Trench

The objective of bedding is to provide a continuous support for

the pipe at the required line and grade. Frozen material should

not be used to support or bed the pipe. At least 4" (100mm)

of bedding material should be placed under the pipe if rocky

conditions exist. The bedding may or may not be compacted,

but in any event the projecting bells of the pipe should be

properly relieved in the trench bottom so that the entire pipe

is evenly supported by the bedding. Where the trench bottom

is unstable (organic material, or "quick" sand or similar

material) the trench bottom should be over-excavated and

brought back to grade with approved material.

Often today, local labor codes require the use of a trench box

or sheeting to support the walls of an open trench. Removal of

9

PVC Pressure Pipe & Ftgs Installation Guide

TRENCH PREPARATION

Safety

Trenches can be dangerous places. The contractor is

responsible for ensuring that all applicable regulations have

been observed and that the protection of the workers and the

general public is provided.

Excavating and Preparing the Trench

The drawings and bid documents will specify the correct line

and grade to be established by the trenching operation. Aside

from these engineering considerations, good bedding practices

make sense for all types of pipes, including PVC.

The width of the top of the trench will be determined by local

conditions. But in the pipe zone the trench width should be

kept to a practical minimum.

The general rule is that the maximum width at the top of the

pipe should not be more than the outside diameter of the pipe

plus 24" (600mm). If trench width cannot be controlled and

will exceed the maximum then compacted backfill must be

provided for a distance of 2-1/2 pipe diameters to either side

of the pipe or to the trench wall, for pipe sizes up to 10"

(250mm). For larger sizes the compacted haunching material

should be placed one pipe diameter or 24" (600mm),

(whichever is greater) to either side of the pipe. This lateral

spacing will facilitate easy placement and shovel-slicing of

bedding material in the haunch zone of the trench. The

minimum distance required is 8" (200mm) on either side of

the pipe.

Keep the three basic operations close together: digging, pipe

laying and backfilling. The shortest practical stretch of open

trench reduces the possibility of problems associated with

water, frozen ground, impact damage, flotation, and traffic.

8

PVC Pressure Pipe & Ftgs Installation Guide

ASSEMBLING IPEX JOINTS

Preparation

All IPEX PVC pipe and fittings are prepared for assembly

as follows:

Keep both the spigot and the bell clean. It is good practice to

lay PVC pressure pipe with bells forward so that the assembly

operation will consist of pushing the spigot into the bell. This

will minimize the possibility of contaminating the surfaces

with foreign material. All assemblies should be concentric.

Use only IPEX PVC pipe lubricant. The use of substitute

lubricants may affect water quality or damage the gaskets.

For most pipes, gaskets are factory-installed.

If the gasket is not pre-installed: before inserting the gasket,

make sure that it is clean and that the bell groove is free of

any debris or dirt. Then carefully position the gasket in the

groove. Gaskets are not interchangeable – USE ONLY THE

GASKETS SUPPLIED BY IPEX.

If the gasket is already installed: it is usually not necessary to

remove the gasket for cleaning.

Clean the inside of the bell (including the face of the gasket),

and the outside of the spigot with a rag, brush, or paper towel

to remove any dirt or foreign material before assembling.

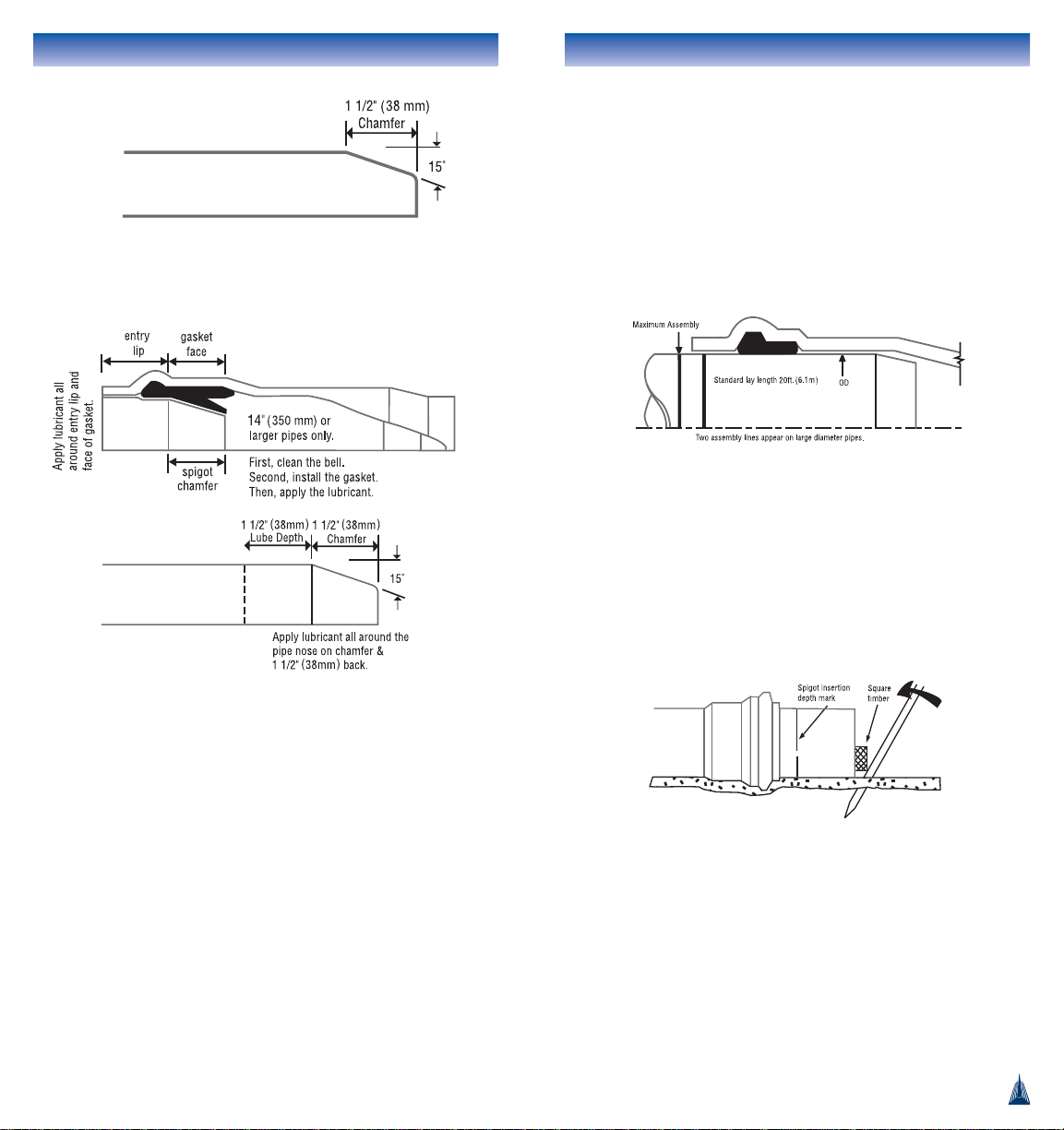

The pipe is shipped with

a chamfer on the end of

the spigot. If there is no

chamfer, follow the

example of a factorymade spigot and

machine a suitable

chamfer.

11

PVC Pressure Pipe & Ftgs Installation Guide

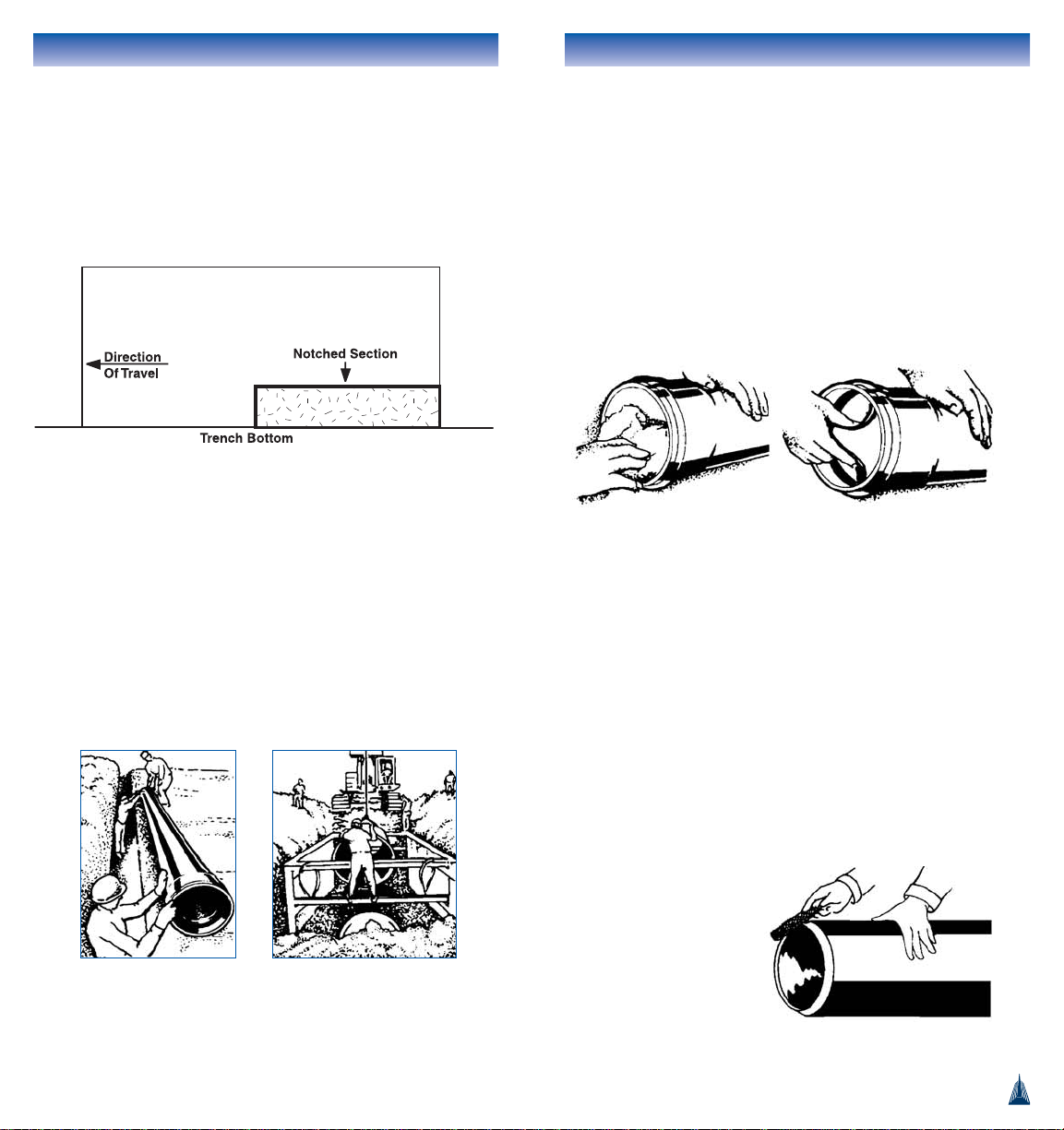

these supports after pipe installation may leave gaps in the

pipe zone of the trench. These voids should be filled in with

additional embedment material after sheeting removal. In

some cases, it may be desirable to leave the sheeting in place

as part of the pipe embedment, or to use a 'notched' trench

box as shown below.

LOWERING THE PIPE AND FITTINGS INTO THE

TRENCH

Place the pipe and fittings into the trench using ropes and

skids, slings on the backhoe bucket, or by hand. Do not throw

the pipe or fittings into the trench or allow any part of the pipe

to take an unrestrained fall onto the trench bottom. At this

point the pipe and other accessories are in a good position for

final inspection. Ensure there are no damaged materials before

assembly begins.

10

Form the chamfer using a beveling

tool, hand rasp or disk cutter.

PVC Pressure Pipe & Ftgs Installation Guide

the pipe. A two by four or a plank should be placed between

the backhoe bucket and the edge of the pipe. The use of a

backhoe bucket has the disadvantage that the backhoe

operator is unable to see clearly when the assembly is

complete. Thus, a helper should be located near the joint to

signal when the assembly is complete.

NOTE:

Factory-made assembly lines on the pipe do not indicate

correct assembly to fittings.

OVER-ASSEMBLY OF THE JOINT COULD DAMAGE THE BELL

OF THIS OR ADJACENT PIPE LENGTHS. MAKE SURE THAT

PREVIOUSLY ASSEMBLED JOINTS REMAIN UNDISTURBED.

If resistance is felt to the assembly, it may mean that the

sealing gasket has somehow become dislodged. If so, the joint

should be disassembled, cleaned, and reconstructed in

accordance with the methods given above.

NOTE:

If there are no assembly lines visible on the pipe, the

minimum and maximum insertion depths shown on pgs. 19,

20, 21 & 22 should be marked on the pipe by hand.

For Sizes Over 36 inches (900mm)

Consideration should be given to the use of come-along

devices for assembly of the gasketed joint in these sizes. A

minimum of 1/2" (13mm) thickness of chain should be used.

IPEX also has available a motorized come-along apparatus

known as a Pipe Puller. Contact IPEX for details.

13

PVC Pressure Pipe & Ftgs Installation Guide

Lubrication

Apply a thin coating of lubricant (equivalent to a brushed

coating) using a glove, a rag, or a paint brush. The area to be

covered is as follows:

Assembly

Keeping the spigot out of the dirt, position it so that the

chamfer is resting against the gasket in the bell. Push the

spigot into the bell until the assembly line on the spigot is

even with the edge of the bell. If there are two assembly lines

the edge of the bell should line up between them.

The assembly effort can be delivered by hand in small

diameters with the aid of a twist as the spigot enters the bell,

or by using a bar and block. Other assembly methods include

lever pullers, hydraulic jacks, and for large diameter pipes the

IPEX Pipe Puller.

Where mechanical means, such as a backhoe, are used, the

assembly effort should not be applied directly to the edge of

12

*For proper lubricant usage refer to page 74.

NOTE: Gasket drawings are for information only.

Actual gaskets may vary.

PVC Pressure Pipe & Ftgs Installation Guide

Deflecting the Joint

The procedure for offsetting the IPEX gasketed joint is shown

below.

Do not combine this method with bending the pipe barrel.

1. Make a concentric assembly, but push the spigot into the

bell only to a point about 1/2 inch (13mm) short of the

reference line (the first reference line if there are two).

This incomplete assembly permits more movement of the

end of the pipe at the bottom of the bell.

2. Without delay, shift the loose bell end of the assembled

length by not more than the following recommended

maximum offsets. Use only manual effort.

MAXIMUM RECOMMENDED OFFSETS, TO ACHIEVE

MINIMUM CURVE RADIUS BY DEFLECTING A STRAIGHT

LENGTH OF PIPE AT THE JOINT (FOR ALL PRODUCTS)

** Bell-by-Bell fittings such as tees and couplings offer a

total of 2º deflection per fitting.

15

PVC Pressure Pipe & Ftgs Installation Guide

CURVATURE OF THE PIPELINE

There are three common methods used to achieve changes in

direction with IPEX Pressure Pipe. They are 1) using PVC

fittings, 2) deflecting the joint, 3) bending the pipe barrel.

Using PVC Fittings

Pipeline curvatures can be achieved by using IPEX PVC

fittings. Standard elbows for molded fittings include 22 1/2,

45 and 90 degrees. Blue Brute

TM

or Cycle ToughTMfittings

offer an additional 1º of offset capacity at each bell. To

achieve greater changes in direction, IPEX offers 5° CIOD

bends in DR18 up to 24 inches (600 mm). The cut lengths

and radii are as follows:

14

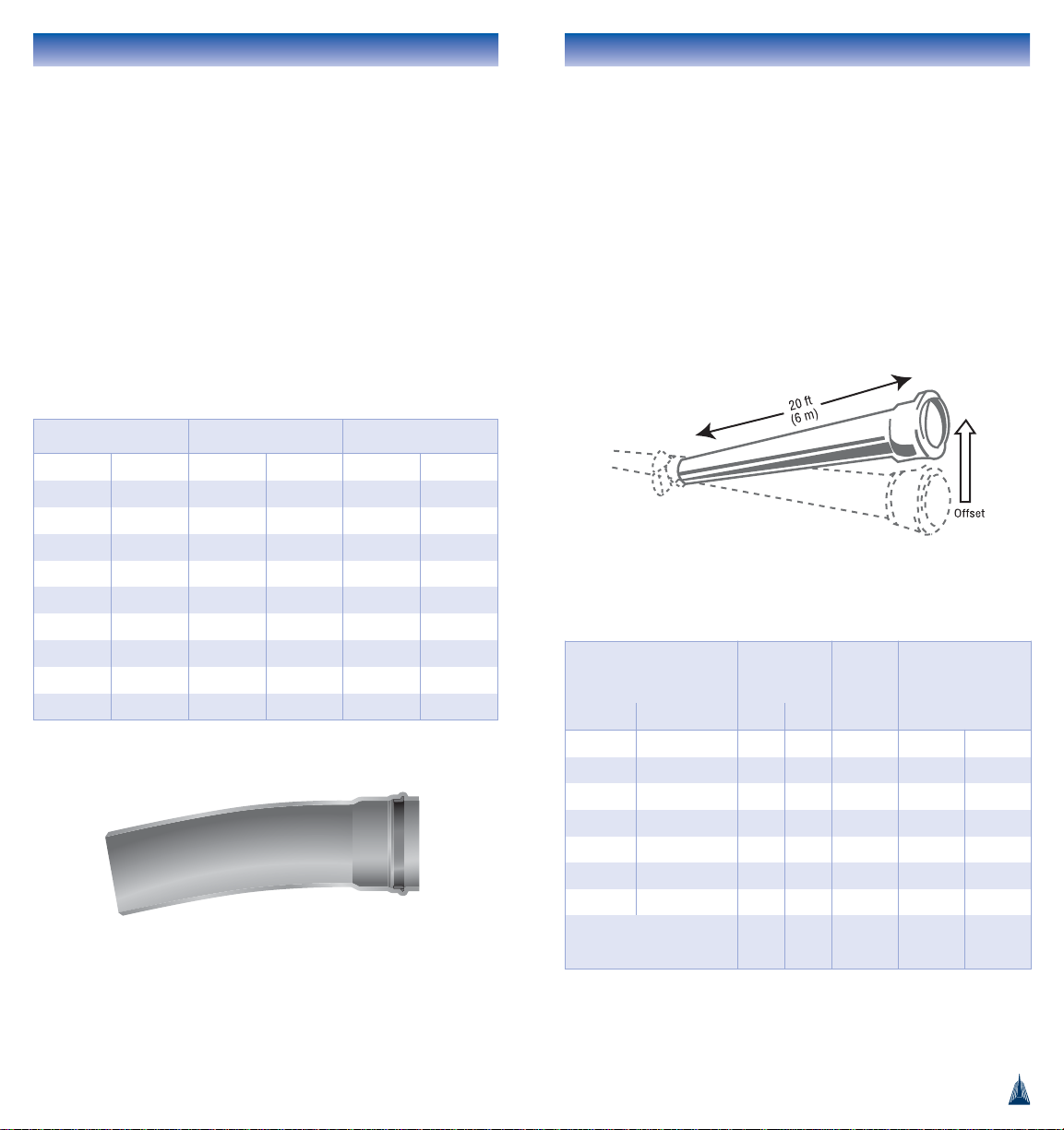

Pipe Size Max Offset

Angle at

One Bell

Resulting Radius of

Curvature Using

20ft (6m) Lengths

in mm in mm

4 100 121/2 320 3º 382 ft 116 m

6 150 121/2 320 3º 382 ft 116 m

8 200 121/2 320 3º 382 ft 116 m

10 250 121/2 320 3º 382 ft 116 m

12 300 101/2 270 2.5º 458 ft 140 m

14 - 24 350 - 600 61/4 160 1.5º 764 ft 233 m

30 - 48 750 - 1200 4 100 1.0º 1146 ft 349 m

At Molded PVC Fittings

(all sizes)

4 100 1.0º** 1146 ft 349 m

Size Cut Length Radius

in mm in mm ft m

6 150 36 910 22 6.7

8 200 36 910 21 6.3

10 250 42 1070 26 7.9

12 300 48 1220 30 9.2

14 350 60 1520 40 12.2

16 400 72 1830 48 14.6

18 450 74 1870 49 14.8

20 500 82 2080 54 16.5

24 600 98 2480 67 20.3

PVC Pressure Pipe & Ftgs Installation Guide

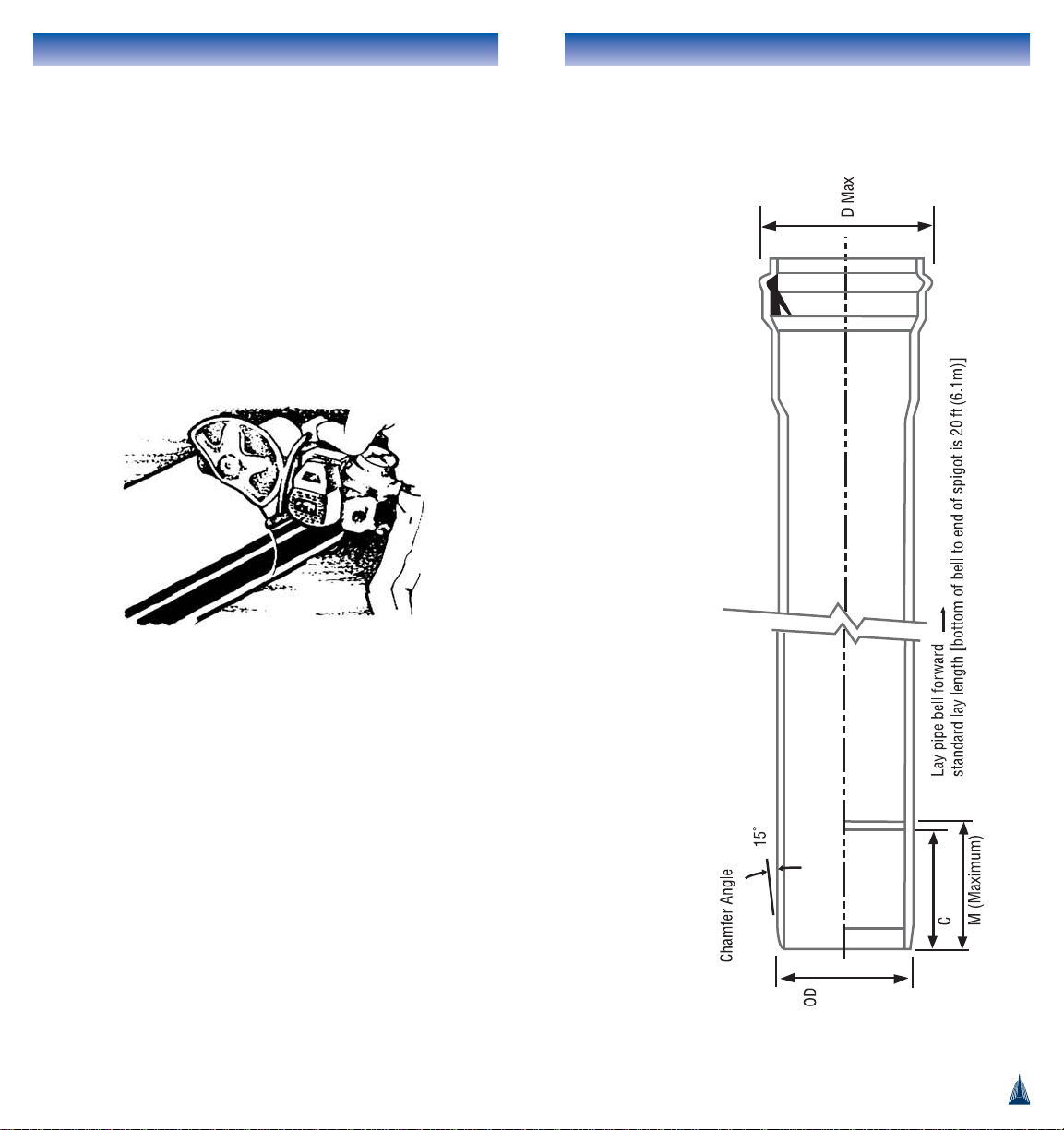

ASSEMBLING TO IRON APPURTENANCES

Assembling to Cast Iron Fittings

The bells of both mechanical joint and push-fit iron fittings

are much shallower than the bells of IPEX pipe. For this

reason, the assembly line on the pipe spigot is of no value as

an indicator of proper assembly to cast iron fittings. In order to

fully engage the gasket of the iron push-fit bell, the chamfer of

the PVC pipe spigot should be essentially removed. Leave only

an eighth of an inch of chamfer when assembling to push-fit

joints. When completing the mechanical joint, remove all the

pipe chamfer and reduce the torque requirements quoted for

iron assemblies. The gasket used in mechanical joint fittings

should be duck tipped. Do not attempt to deflect joints made

to iron fittings.

Assembling to Butterfly Valves

When heavy-wall PVC pipes, such as DR14, are assembled to

butterfly valves there is a possibility that the inside edge of

the pipe may interfere with the swing of the disc. In this case,

a 1/2" (13mm) 45° chamfer on the inside edge of the pipe

spigot will provide the needed clearance.

17

PVC Pressure Pipe & Ftgs Installation Guide

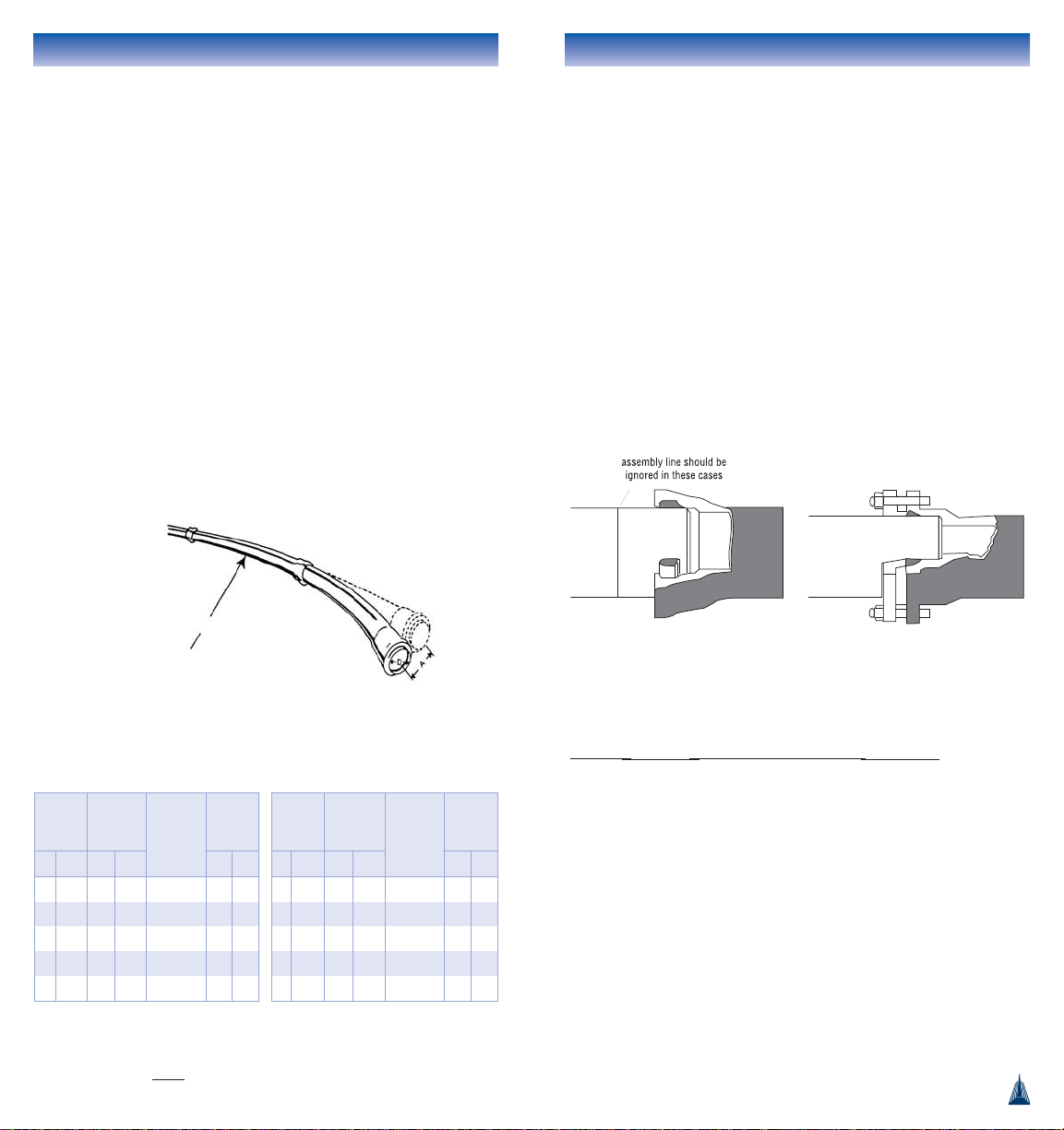

Bending the Pipe Barrel

Smaller diameters of IPEX PVC pressure pipes can be laid to

the line of curved trench by bending the pipe barrel into a

curved shape. The procedure is as follows:

1. Make a concentric assembly in the usual way. Keep the

spigot in straight alignment with the bell.

2. Place compacted backfill around the assembled joint to

restrict its movement while the curvature is being made.

3. Place compacted backfill at the inside of the curve, at the

mid-point of the pipe length, to form a fulcrum.

4. Using only manual effort, move the leading bell of the pipe

length to be curved by no more than the offset distance

shown in the following table.

5. Do not cut service taps into bent PVC pipe. Tapping bent

PVCO pipe is permitted.

NOTE: Bent pipes should be clearly marked along their length

to avoid the possibility that they will be tapped in the future.

MAXIMUM RECOMMENDED OFFSET, A, TO ACHIEVE

MINIMUM RADII OF CURVATURE BY BENDING THE BARREL

OF 20 ft (6 m) LENGTHS

16

Radius of Curvature

A = Offset (Varies

according to size.

See table.)

* SDR and DR both refer to the outside diameter of the pipe divided

by pipe thickness:

O.D.

t

Pipe SizeDMax Offset

A

Resulting

Angle of

Deflection

Resulting

Radius of

Curvature

in mm in mm ft m

4 100 32 813 7.6º 75 23

6 150 22 560 5.2º 111 34

8 200 17 430 4.0º 144 44

10 250 13 330 3.2º 179 55

12 300 11 280 2.7º 213 65

Pipe SizeDMax

Offset

Resulting

Angle of

Deflection

Resulting

Radius of

Curvature

in mm in mm ft m

4 100 24 600 5.7º 100 30

6 150 17 430 4.0º 144 44

8 200 13 300 3.0º 188 58

10 250 10 254 2.5º 232 71

12 300 8.7 221 2.1º 275 84

CIOD Pipe – Blue Brute

TM

& Bionax®C909 Pipe

NOTE: Minimum radius is

approximately 250 times nominal OD

IPS OD Pipe – Cycle Tough

TM

F1483 Pipe

NOTE: Minimum radius is

approximately 200 times nominal OD

Leave a slight chamfer on CIOD

PVC pipe assembled to push-fit

cast iron fittings. Bottom the pipe

in the iron bells.

Square-cut the edge of PVC

pipes assembled to M-J cast

iron fittings.

Pipe Size Bolt Torque

4"-24" (100 - 600mm) 70 - 80 ft lbs (95-108N-m)

30"-36" (750 - 900mm) 90 - 100 ft lbs (122-136N-m)

42"-48" (1050 - 1200mm) 125 - 150 ft lbs (170-200N-m)

PVC Pressure Pipe & Ftgs Installation Guide

19

PVC Pressure Pipe & Ftgs Installation Guide

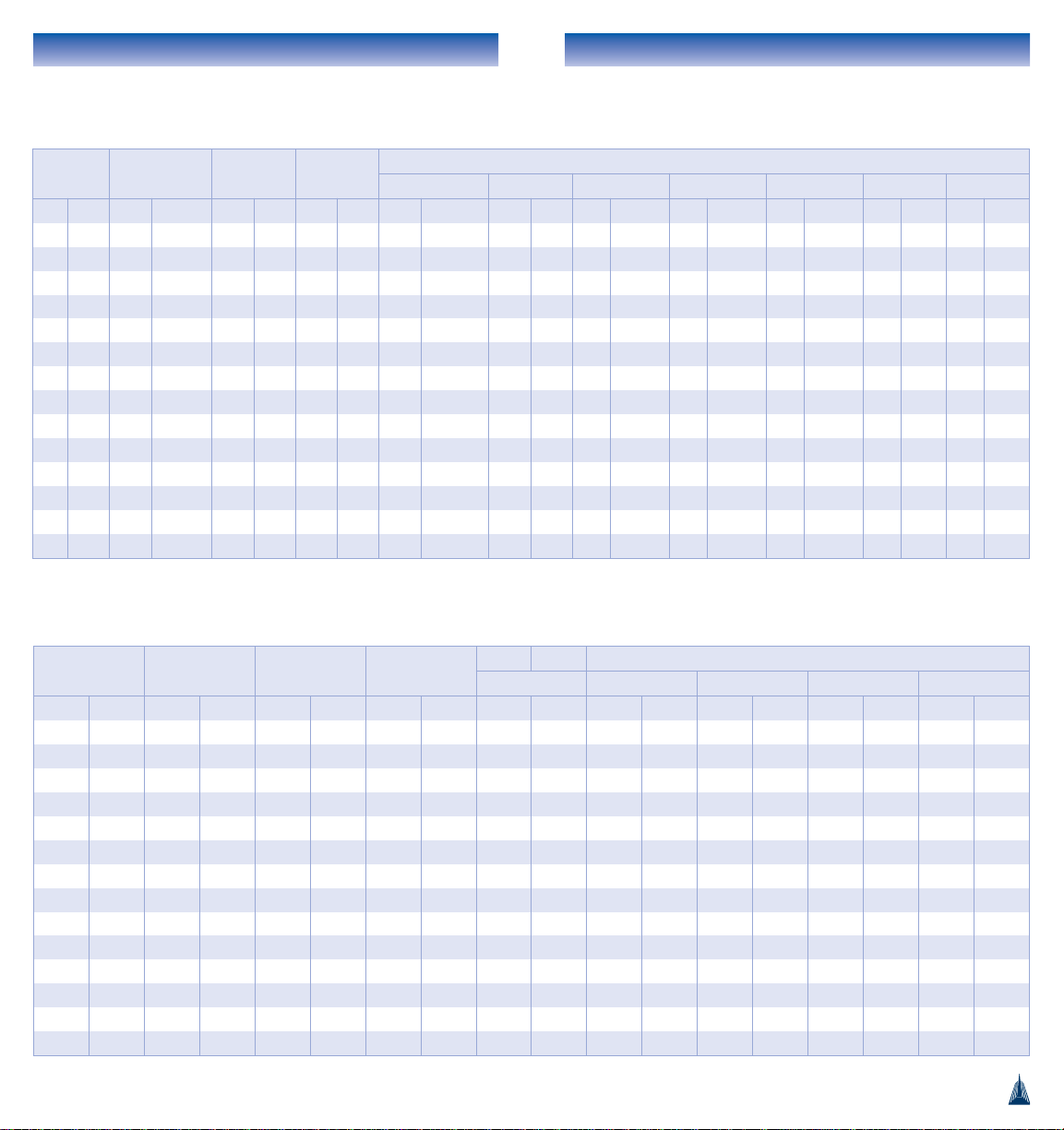

CUTTING AND CHAMFERING

THE PIPE

Cutting

A square cut is important. With smaller diameter pipes a

mitre-box can be used with a hand saw to complete the cut.

With large diameter pipes, which are difficult to lift, select a

flat piece of ground and roll the pipe across the ground while

scribing a cutting line on the pipe wall with a felt pen. This

line should be placed carefully to ensure a square cut. The

rolling action may also be used to feed a power tool along the

cutting line. Use an abrasive disc or steel saw blade while not

force-feeding the tool in a manner that causes burns.

Chamfering

The chamfer on pipe supplied from the factory is about 15°.

Using the factory pipe as a guide, the cut length should be

chamfered to approximately the same angle and distance

back. There are a number of ways of chamfering pipe: A power

sander or abrasive disc, a router, and a rasp or file, may be

used. When assembling to iron fittings, only a short bevel of

about 1/8" (3mm) or so should be made to the cut edge.

To ensure correct assembly of cut pipe to IPEX joints, mark an

assembly line on the spigot end with a felt pen. Use other

pipe lengths as a guide, or use the dimensions in the tables

on the next pages.

18

DIMENSIONS

Pipe Dimensions

(Minimum)

PVC Pressure Pipe & Ftgs Installation Guide

21

PVC Pressure Pipe & Ftgs Installation Guide

20

Nominal

Size

Average OD

Minimum

Insertion C

Maximum

Insertion M

D max

DR 51 DR 41 DR 32.5 DR 25 DR 18 DR 14

in mm in mm in mm in mm in mm in mm in mm in mm in mm in mm

4 100 4.8 122 5.8 148 - - - - - - - - 6.0 152.35 6.1 156.18 6.3 160.08

6 150 6.9 175 6.4 163 - - - - - - - - 8.3 210.04 8.5 215.55 8.7 221.16

8 200 9.1 230 7.1 181 - - - - - - - - 10.8 273.07 11.0 280.29 11.3 287.66

10 250 11.1 282 7.6 192 - - - - - - - - 13.3 338.61 13.7 347.47 14.0 356.50

12 300 13.2 335 8.1 207 - - - - - - - - 15.6 395.63 16.0 406.15 16.4 416.90

14 350 15.3 388.6 8.0 203 9.0 229 - - 17.7 449.84 18.0 456.34 18.2 462.08 18.7 474.28 19.2 486.73

16 400 17.4 442.0 10.0 254 11.0 279 - - 20.0 508.80 20.3 516.20 20.6 522.72 21.1 536.59 21.7 550.75

18 450 19.5 495.3 10.5 267 11.5 292 22.0 558.5 22.3 567.56 22.7 575.85 23.0 583.16 23.6 598.71 - 20 500 21.6 548.6 11.5 292 12.5 318 22.2 562.78 24.9 632.41 25.3 641.60 25.6 649.70 26.3 666.92 - 24 600 25.8 655.3 13.0 330 14.0 356 29.3 745.41 29.6 751.74 29.9 760.17 30.4 772.38 31.2 792.96 - 30 750 32.0 812.8 14.5 368 15.5 394 35.8 908.98 36.1 916.83 36.5 927.29 37.1 942.43 ---36 900 38.3 972.8 15.5 393 16.5 419 42.5 1079.90 42.9 1089.29 43.4 1101.82 44.1 1119.94 - - - 42 1050 44.5 1130.3 16.0 406 17.0 432 48.8 1240.00 49.4 1255.00 50.0 1270.00 50.9 1293.00 ---48 1200 50.8 1290.3 17.0 432 18.0 457 55.5 1409.00 56.1 1424.00 56.7 1441.00 57.8 1467.00 - - - -

Dimensions of Blue Brute and IPEX Centurion

Pressure Pipes with CIOD's

Nominal Size Average OD

Minimum

Insertion C

Maximum

Insertion M

D max

DR 41 DR 32.5 DR 26 DR 21

in mm in mm in mm in mm in mm in mm in mm in mm

1-1/2 40 1.900 48.3 3.3 83 - - ----2.75 70.00 2.75 70.00

1 50 2.375 60.4 3.7 93 - - - - - - 3.32 84.00 3.37 85.00

2-1/2 65 2.875 73.0 4.2 106 - - ----3.82 97.00 3.87 98.00

3 75 3.500 88.9 4.8 121 - - - - - - 4.54 115.00 4.60 117.00

4 100 4.500 114.3 4.8 123 - - 5.5 139.36 5.5 140.83 5.60 142.61 5.70 144.72

6 150 6.625 168.3 4.8 123 - - 7.8 198.16 7.9 200.33 8.00 202.94 8.10 206.05

8 200 8.625 219.1 5.4 138 - - 10.1 255.39 10.2 258.21 10.30 261.61 10.50 265.66

10 250 10.750 273.1 6.3 161 - - 12.6 319.25 12.7 322.77 12.90 372.01 13.10 332.06

12 300 12.750 323.9 6.5 165 - - 14.7 372.81 14.8 376.98 15.00 382.01 15.30 388.00

14 350 14.000 355.6 7.0 178 8.0 203 16.2 411.33 16.4 415.91 16.60 421.43 46.90 428.00

16 400 16.000 406.4 8.9 227 9.9 252 18.5 469.84 18.7 475.07 19.00 481.38 19.20 488.89

18 450 18.000 457.2 9.9 252 10.9 276 20.7 526.06 20.9 531.95 21.20 539.05 21.60 547.50

20 500 20.000 508.0 10.7 272 11.7 297 23.1 585.84 23.3 592.38 23.60 600.26 24.00 609.65

24 600 24.000 609.6 11.7 296 12.7 322 27.5 697.78 27.8 705.63 28.20 715.10 28.60 726.37

Dimensions of Cycle Tough Pressure Pipes

with IPS OD's

PVC Pressure Pipe & Ftgs Installation Guide

Cycle Tough PVC Pipe:

Iron Pipe Size (IPS) Outside Diameter

IPEX Series gasketed pipes with IPS O.D. (equivalent to steel

pipe outside diameters) are available in sizes ranging from

1-1/2" (40mm) through 24" (600mm). All IPEX Series pipe is

certified to CSA B137.3 and conforms fully to ASTM D 2241.

These pressure rated pipes fit directly into IPS Cycle Tough

injection molded fittings. They also fit into Blue Brute or iron

fittings by using transition gaskets or adapters. These adapters

are available with either spigot or bell ends and are

approximately 24" (600mm) long.

Bionax PVCO Pipe: Cast Iron Outside

Diameter (CIOD)

This is pipe associated with the American Water Works

Association Standard C909. IPEX offers CIOD sizes 4, 6, 8,

10, and 12" (100, 150, 200, 250, and 300 mm) in Pressure

Class 235. Bionax CIOD pressure pipes are third-party

certified to the AWWA C909 standard.

This pipe also is associated with Canadian Standards

Association B137.3.1. IPEX offers CIOD sizes 4, 6, 8, 10, and

12" (100, 150, 200, 250 mm, and 300 mm) in Pressure

Rated 1620 kPa. Bionax CIOD pressure pipes are third-party

certified to the CSA B137.3.1 standard.

Pipes having CIOD are adaptable directly to molded or

fabricated PVC fittings, cast iron fittings, valves, and other

appurtenances. For the iron fittings and valves, preparation of

the Bionax pipe end must reflect the reduced insertion depth

of these fittings.

23

PVC Pressure Pipe & Ftgs Installation Guide

OUTSIDE DIAMETER CONSIDERATIONS

IPEX pressure pipes are available in two different outside

diameter regimes in most nominal sizes. These are Cast Iron

(CIOD) and Iron Pipe Size (IPS) Outside Diameters. The

dimensions for each configuration are shown in the tables on

pages 20, 21, and 22.

Blue Brute & Centurion PVC Pipe:

Cast Iron Outside Diameter (CIOD)

These are the pipe and fittings normally associated with the

American Water Works Association Standards C900, C905 and

C907. IPEX offers sizes of 4, 6, 8, 10 and 12" (100, 150,

200, 250 and 300mm) with CIOD's in Pressure Class (PC)

165 (DR25), PC 235 (DR18) and PC 305 (DR14). Also

available are pipe sizes 14" (350mm) through 48" (1200mm)

with CIOD's in PC 80 (DR51), PC100 (DR41), PC125

(DR32.5), PC165 (DR25) and PC235 (DR18, to 24" only). All

CIOD PVC Pressure Pipes by IPEX are certified to CSA B137.3

and meet AWWA standards.

Pipes having CIOD are adaptable directly to molded or

fabricated PVC fittings, cast iron fittings, valves and other

appurtenances. For the iron fittings and valves, preparation of

the PVC pipe end must reflect the reduced insertion depth of

these fittings.

22

Nominal Size Average OD Insertion D max Average ID

in mm in mm in mm in mm in mm

4 100 4.80 122 5.43 138 6.10 155 4.48 114

6 150 6.90 175 5.94 151 8.49 216 6.44 164

8 200 9.05 230 6.57 167 10.83 275 8.45 215

10 250 11.10 282 7.05 179 13.33 339 10.37 263

12 300 13.20 335 7.76 197 15.60 396 12.33 313

Dimensions of Bionax PVCO Pressure Pipes with

CIODs

PC/PR 1620 kPa (235 psi)

Loading...

Loading...