IPC Eagle Integra-D ORB20, Integra-D ORB20V, Integra-D ORB28, Integra-D ORB28V Operation Manual

Parts & Operations Manual

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Orbital Floor Machine Model: ORB20, ORB20V/ ORB28, ORB28V

Serial Number:

____________________________________

28”

20”

Integra-D

Date of Purchase:

____________________________________

More info: www.ipceagle.com

Integra-D - Orbital Floor Machines

https://harrissupplyind.com - To Order Parts Call 608-268-8080

IPC Eagle

About the Integra-D Floor Machine

Our Integra-D orbital scrubbing machine has been designed from the ground up to oer the most time saving ecient features for

the user. A 1.5 hp motor spinning at 3450 rpm sits on a new, heavy duty vacuum system that signicantly reduces airborne dust.

Removable, ¼ inch weights and a removable handle oer an unprecedented ease of transportation and customization to your

unique application. The same pads, paper or screens can be used to their full potential in a cleaner, more ecient environment.

Please visit our website at www.ipceagle.com

Introduction

Thank you for choosing the Integra-D machine. It will faithfully provide many years of excellent service if properly cared for and

maintained according to this manual. Please fully read the entire manual before using this machine.

This product is for industrial/institutional/commercial use only.

WARNING: Potential risk of injury!

This product contains moving parts. To reduce the risk of injury, unplug before servicing.

General Safety

This machine is electrically grounded in accordance with United States regulations and must be operated with the supplied three

conductor cord with a grounding wire. This cord must only be used in the proper grounded receptacle. The ground pin must not be

removed or connected to any other device or receptacle.

This machine is for use on a nominal 120-volt circuit and has a grounding plug that

resembles the plug in gure 1. Make sure that the machine is connected to an outlet

having the same conguration as the plug. No adapter should be used with this machine.

Fig.1

WARNING: Improper connection of the equipment grounding conductor can result in a risk of electric shock. Check with a qualied electrician

or service person if you are in doubt as to whether the outlet is properly grounded. Do not modify the plug provided with the appliance - if it will

not t the outlet, have a proper outlet installed by a qualied electrician. RATED LESS THAN 15 AMPERES AND INTENDED FOR USE ON A NOMINAL

120-VOLT SUPPLY CIRCUIT: the Integra-D have a grounding attachment plug that looks like the plug illustrated. Make sure that the vacuum is

connected to an outlet having the same conguration as the plug. No adaptor should be used with these vacuums.

2

2

Maintenance Schedule

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Daily - Before Use

• Tighten knobs holding weights down

• Check AC power cord. Do NOT operate equipment if AC power cord is cut, frayed or if ground is missing

• Check to see if the quick release cam is still tight, the quick release bolt is housed in a slot on the handle support,

locating pins are in place and, locking handle is tight. Adjust all if needed

• Check vacuum hose and connections (if equipped).

• Check grip face and driver pad: inspect for wear/debris. Replace as needed. After use (daily).

Daily - After Use

• Clean pad and base plate assembly : remove/replace pad as needed.

• Inspect grip face for wear. Remove debris between grip face and base plate.

• Wipe base plate and motor assembly with damp cloth to remove dust build up.

• Make certain a pad is placed on grip face.

Weekly

• Check grip face for wear.

• Use vacuum to clean away debris build-up around motor assembly, weights and base plate.

Annually

• All isolators must be replaced

• Bearing Assembly Replacement*

* The bearings must be replaced every year under typical usage and are considered consumable parts. Heavier

usage places heavier demand on the bearings and will need to be replaced accordingly. A three month life

can be expected under heavy use.

N.B. Bearings and isolators should be replaced at the same time.

IPC Eagle

Manual Conventions

DANGER: Indicates an imminently hazardous situation which, if not avoided, may result in death or serious injury.

CAUTION: Indicates that machine or property damage could result if instructions are not followed.

Note: Provides helpful information.

Please read and observe all labels posted on the machine and in this manual. Serious injury or death may occur if safety instructions

are ignored.

Who to call for assistance

If you work with an authorized distributor, contact them for assistance. If any contents of the box are missing, contact your

authorized dealer, distributor or re-seller. Make sure you have the machine’s serial number, located on the back of the machine,

when you call.

Liability statement

This product has been built to the highest industry standards. Please note and heed the WARNING and CAUTION labels that have

been placed on the equipment and in this manual for your safety. PLEASE DO NOT ATTEMPT TO OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT ADEQUATE TRAINING. ANY USE, OPERATION OR REPAIR IN CONTRAVENTION OF THIS DOCUMENT IS AT YOUR OWN RISK.

BY ACCEPTANCE OF THIS SYSTEM YOU HEREBY ASSUME ALL LIABILITY CONSEQUENT TO YOUR USE OR MISUSE OF THIS EQUIPMENT.

SHALL NOT BE LIABLE FOR ANY INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGE OF ANY KIND.

Equipment specications, applications and options are subject to change at the sole discretion of the manufacturer without notice.

3

Safety

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Our products are built to strict safety and reliability specications in accordance with industry standards. Therefore, safety issues

pertaining to operation and repair of Integra-D equipment are primarily environmental and human interface. The following basic

IPC Eagle

safety tips are given to ensure safe installation, operation and maintenance of the Integra-D.

Transport of Machine

To transport this machine, the following procedure is advised:

• Unplug machine from power source.

• Unplug the motor from the handle.

• Leave the buer pad attached to the face grip as to not prematurely wear the machine.

• Wrap cord using cord wrap and handle.

• Unscrew the weight locking knobs and slide the weights out.

• Unlock the locking cam by raising the handle to the vertical position.

• Remove the two safety pins.

• Remove the handle from the handle support and place aside.

• The axle may be used as a carry handle.

• The handle, base assembly and weights may be transported separately.

CAUTION: This machine is very heavy. Please disassemble machine prior to transportation o site.

Get assistance when lifting the base assembly. Do not attempt to lift alone.

General Operating Instructions

1. Move machine to work location. Never operate, transport, or store the machine without a pad to protect the grip face.

2. Plug machine into grounded power outlet.

3. Stand behind the Integra-D and place your hands on the padded handle grips.

4. Push the safety lever away from you with your thumbs and squeeze the trigger with remaining nger. The machine naturally and

gently rotates in a clockwise motion if left un-managed. Please use both hands to operate the machine.

5. Begin moving forward in straight lines.

6. Best results are found when the handle is used in an upright position. However the handle may be tilted to suit your application.

Open the quick release cam handle and slide the pin into the desired stop. Always use the machine with the pin rmly in a stop.

Firmly close the cam with your hand. The cam lever must not be rotated to achieve tightness. Instead open and close the lever. A

tightness adjustment may be made on the locking nut opposite to the lever.

7. Continue moving in straight lines, checking your pad every 15 to 30 minutes (depending on pad in use) to maintain optimum

performance.

Important

To reduce the risk of re, electric shock or injury:

• Never leave the machine unattended while power cord is connected.

• Always wear personal protective equipment (PPE) when operating this machine.

• Never inhale dust created by the use of this machine. Any modications to this machine may result in damage

to the machine or injury to the operator or others nearby. Alterations to the machine will also void any and all

warranty and liabilities.

4

• Sanding wood decks is not recommended by the manufacturer due to uneven surfaces which could lead to

https://harrissupplyind.com - To Order Parts Call 608-268-8080

damage to the machine. Some pressure treated wood found in decking contains arsenic that, when sanded,

will create hazardous dust. The manufacturer assumes no liability if the machine is used on decks, and damage

caused from sanding pressure treated wood will not be warranted.

• Do not operate this machine around fuels, solvents, ammable oor nishes, thinners, wood particulate or any

ammable materials. Cigarette lighters, pilot lights, electrical sparks and all other sources of ignition should be

extinguished or avoided. Work areas should be well ventilated.

• Keep the power cord clear of the pad. Always lift the cord over the machine. Do not pull on the power cord in an

attempt to move the machine. This could result in electrocution.

• Do not use machine if it has been sprayed with water or left out in the rain. This could result in a shock, injury or

electrocution.

• Keep feet, hands, and loose clothing away from any moving parts on the machine to avoid injury. Disconnect

power cord before changing the pad or when servicing. Damage can occur to the machine or to other property

if instructions in the owner’s manual are not followed.

• Do not operate this machine while under the inuence of alcohol or other drugs.

• Never allow children under age 18 to operate this machine.

• Unplug machine from power source before adjusting height of handle or changing pad.

• Servicing this machine while still connected to a power source could lead to electrocution or re. Before

performing machine service or maintenance, disconnect the machine from its power source. Operating this

machine with a damaged power cord could lead to electrocution or re. Cord should remain clear of moving

parts during operation. Never use the cord to navigate the machine.

IPC Eagle

Integra-D Troubleshooting Guide

CAUTION: Always disconnect power cord before servicing.

WARNING: Repairs should only be performed by an authorized service center.

PROBLEM:

Machine won’t start

CAUSE SOLUTION

1. Machine is not plugged 1. Check wall outlet and motor connection

2. Socket breaker has been tripped 2. Reactivate breaker

3. Motor breaker has been tripped 3. Press manual reset on motor box

4. Faulty receptacle 4. Move to new receptacle

5. Defective switch / wiring 5. Contact your dealer

PROBLEM:

Runs unpredictably

CAUSE SOLUTION

1. Faulty receptacle 1. Move to new receptacle

2. Faulty extension cord 2. Use new 10 gauge extension cord less than 25 feet

3. Defective switch

4. Defective motor

3. Contact your dealer

CAUSE SOLUTION

1. Excessive weight for application 1. Reduce machine weight

2. Faulty Breaker 2. Breakers in electrical panel need replacement by electrician

3. Extension cord too long 3. Move machine to new receptacle closer to work site

PROBLEM:

Fuse / Breaker Trips

5

PROBLEM:

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Machine pulls hard to the right

IPC Eagle

1. Worn pad 1. Replace pad

2. Worn isolators 2. Replace isolators

CAUSE SOLUTION

PROBLEM:

Machine is unusually loud

CAUSE SOLUTION

1. Isolators worn 1. Replace isolators

2. Component has come loose 2. Tighten all screws, bolts, knobs

3. Replace foam pads where weights sit

Fast Track Vac Troubleshooting Guide

CAUTION: Always disconnect power cord before servicing.

WARNING: Repairs should only be performed by an authorized service center.

PROBLEM:

Loss of suction

CAUSE SOLUTION

1. Cap is damaged 1. Inspect and replace if needed

2. Faulty vacuum motor 2. Contact or a service center

3. Micro-Ply lter bag is full 3. Replace Micro-Ply lter bag

4. Clogged hose or wand 4. Remove obstruction

5. Loose or broken fan 5. Contact a service center

PROBLEM:

Motor is not running

CAUSE SOLUTION

1. Faulty ON/OFF switch 1. Contact a service center

2. Power cord defective 2. Contact a service center

3. Loose connection or wiring 3. Contact a service center

4. Motor defective 4. Contact a service center

5. Blown fuse or tripped circuit breaker 5. Replace fuse or reset circuit breaker

PROBLEM:

Dust blowing from vacuum when running

CAUSE SOLUTION

1. Micro-Ply lter bag is full 1. Replace Micro-Ply lter bag

2. Micro-Ply lter bag not installed properly 2. Reinstall or replace

3. Cloth lter bag dirty 3. Clean cloth lter bag

4. Cloth or Micro-Ply lter bag is torn 4. Replace

6

Handle

https://harrissupplyind.com - To Order Parts Call 608-268-8080

1

3

4

8

2

5

6

7

IPC Eagle

9

10

Integra-D 20’’ and 28’’

11

Item N. Part N. Description Quantity

1 IT-04248 Bolt 1/4-20 Nyloc 2

2 IT-20002 Nut 1/4-20 Nyloc 2

3 IT-04142 Cam Lever Assembly 1

4 IT-04158 Bushing 2

5 IT-22305 Acorn Nut 3/8-16 1

6 IT-27412 Handle with Cord Hook Brace Painted 1

7 IT-01745 Pigtail 42” SJT 105C 1

8 IT-04148 Extension Rod Welded 1

9 IT-04151 Tapered Sleeve 1

10 IT-04152 Wedge Handle Lock 1

11 IT-04159 Nyloc Nut 5/16-18 2

7

7

Switch Box

https://harrissupplyind.com - To Order Parts Call 608-268-8080

IPC Eagle

2

14

15

8

9

11

3

1

4

5

6

10

7

16

17

12

13

5

5

Item N. Part N. Description Quantity

1 IT-03789 Foam Handle Grip

2 IT-04909 Trigger 1

3 IT-04131 Switch Box 1

4 IT-04910 Safety Switch Lever 1

5 IT-04199 8-32 X 1/4” Phillips Screw 6

6 IT-03949 Safety Switch Knob 2

7 IT-03951 Safety Switch Spring 1

8 IT-20484 Cord Grip 2

9 IT-04190 Safety Switch Lever 1

10 IT-14717 Strain Relief

11 IT-03699 1 1/2 HP Micro Switch 1

12 IT-04169 6-32 X 7/8” Phillips Screw 2

13 IT-04333 Power Cord 75’ / 22.86M 1

14 IT-24713 Switch Board Cover 1

15 IT-04214 Insert Switch 1

16 IT-20031 Washer 3

17 IT-27558 6-32 Nut 3

2

Integra-D 20’’ and 28’’

8

8

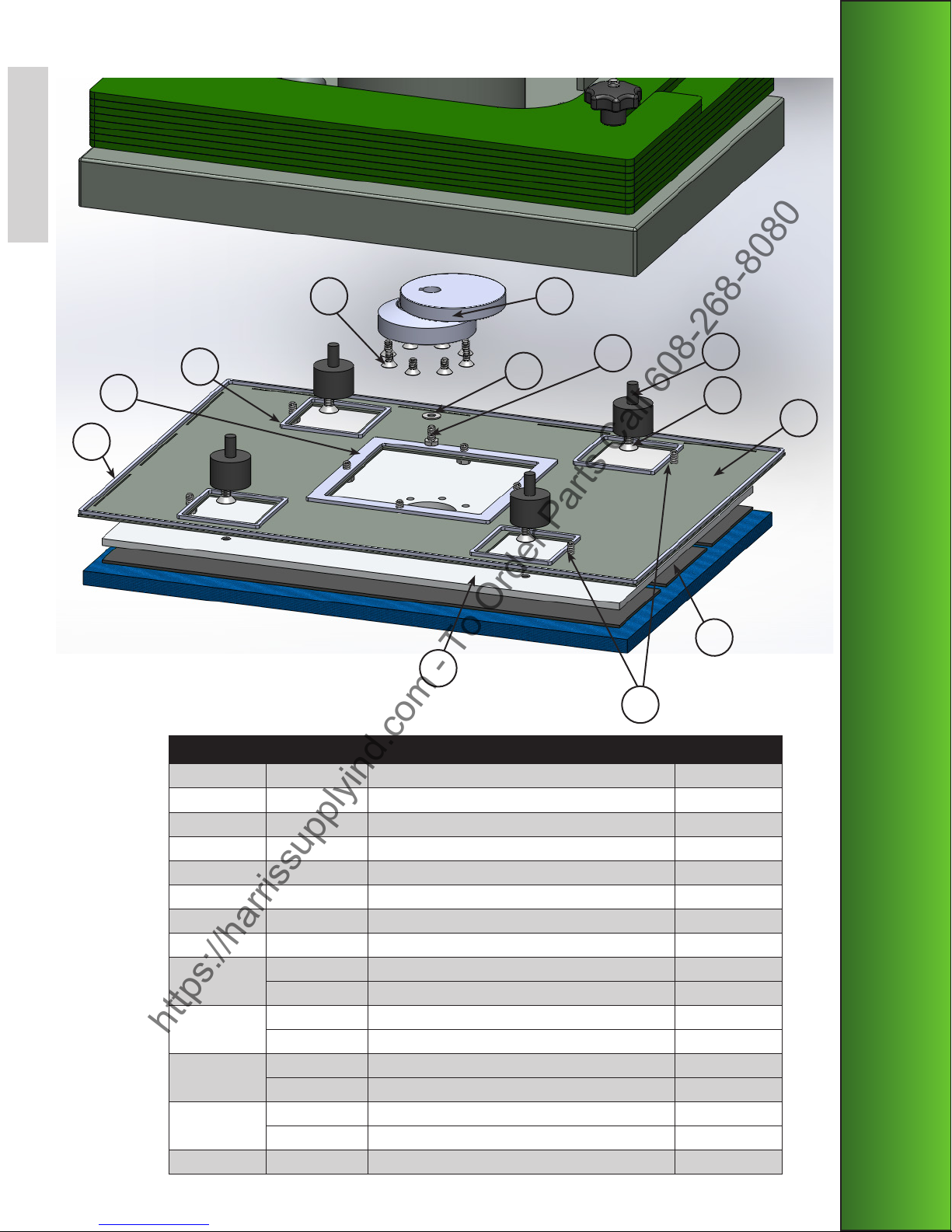

Base Assembly

https://harrissupplyind.com - To Order Parts Call 608-268-8080

1

IPC Eagle

3

2

5

6

4

7

8

9

15

16

13

12

10

11

17

14

18

19

Item N. Part N. Description Quantity

1 IT-70302 Motor 1.5 hp 3450 rpm 1

2 IT-27552 T-Handle Support with Tab Painted 1

3 IT-27536 Star Grip Knob 2

Integra-D 20’’ and 28’’

4 IT-27541 Fast Pin 2

5 IT-27523 Cam Lever 1

6 IT-27551 1/4 Washer for Cam Lever 1

7 IT-20002 1/4-20 Nyloc Nut 1

8 IT-27520 Wishbone 2

9 IT-27522 Wheel 2

10 IT-20060 Washer - 1/2” Tension 4

11 IT-04112 Axle End Cap 4

12 IT-03063 Washer - 1/2” Nyloc 4

13 IT-27543 Anxle Zinc Plated 7-5/8” 1

14

15 IT-27548 Bolt 3/8-16 X 4” Tap 2

16 IT-27549 Jam Nut 3/8-16 for Weights 2

17 IT-27557 3/8-16 X 5/8 Cap Screw 4

18

19

IT-27510 Base Top 20” 1

IT-27512 Base Top 28” 1

IT-27542A Bottom Weight 20” Painted Blue 6

IT-27531A Bottom Weight 28” Painted Blue 6

IT-27542B Top Weight 20” Painted Blue 2

IT-27531B Top Weight 28” Painted Blue 2

9

Base Assembly

https://harrissupplyind.com - To Order Parts Call 608-268-8080

IPC Eagle

2

5

8

1

4

6

3

7

10

9

12

11

13

10

Item N. Part N. Description Quantity

1 IT-27562 Bearing Kit

2 IT-27545 Screw 1/4-20 X 3/4” Countersunk for Drive Pad 8

3 IT-27551 1/4 Washer for Cam Lever 1

4 IT-27559 1/4-20 X 3/4 Cap Screw 1

5 IT-275IT-27 Base Gasket Small 1

6 IT-27517 Isolator 4 (20”)/8 (28”)

7 IT-27546 Screw 5/16-18 X 5/8” 4 (20”)/8 (28”)

8 IT-27528 Base Gasket Large 1

9

10

11

12

13 IT-27547 Screw 1/4-20 X 3/8” Hex Head for Base Cover 8 (20”)/12 (28”)

IT-27526 Perimeter Gasket 14 X 20 1

IT-27524 Perimeter Gasket 14 X 28 1

IT-27511 Base Cover 20” 1

IT-27513 Base Cover 28” 1

IT-27518 Aluminum Drive Pad 20” 1

IT-27530 Aluminum Drive Pad 28” 1

IT-27519 Face Grip 20” 1

IT-27532 Face Grip 28” 1

1

Integra-D 20’’ and 28’’

10

Skirt & Accessories

https://harrissupplyind.com - To Order Parts Call 608-268-8080

IPC Eagle

1

2

3

Integra-D 20’’ and 28’’

Item N. Part N. Description Quantity

1

2 IT-27525 Y Connector 1

3 IT-27540 Vacuum Hose Assembly 1

IT-27538 Grey Skirt for 20” 1

IT-27539 Grey Skirt for 28” 1

11

11

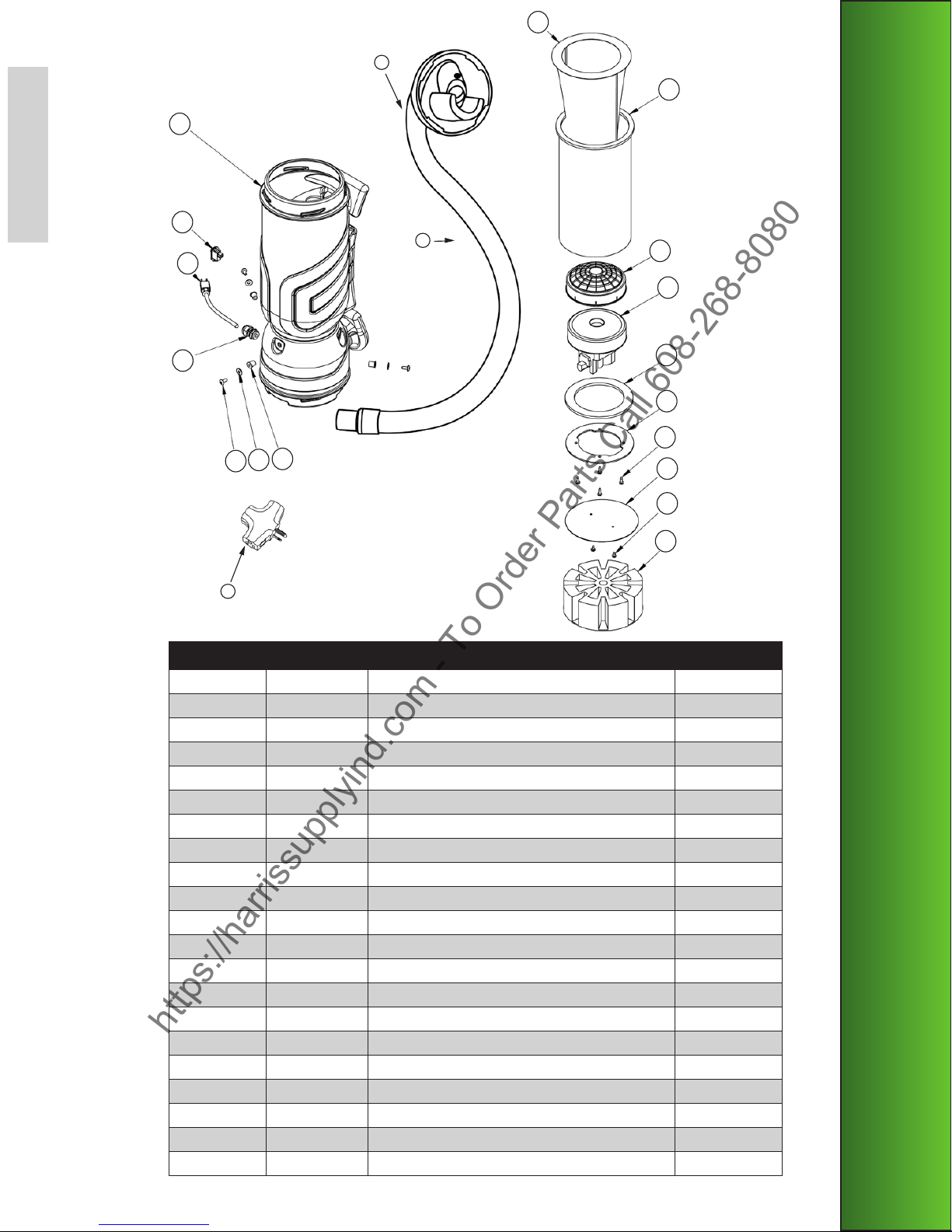

HEPA Dry Vac Kit Vacuum Schematic

3

4

5

15

17

18

19

19

20

8

2

9

10

12

13

14

16

1

17

18

18

11

6

7

21

3b

Fast Track Vac

https://harrissupplyind.com - To Order Parts Call 608-268-8080

IPC Eagle

Item N. Part N. Description Quantity

1 IT-27112 Vacuum Housing (Body) 1

2 IT-27108 Vacuum Motor 1

3 IT-27113 Lid, Vacuum Hose and Hose Cu Swivel 1

3b IT-27130 Hose and Hose Cu Swivel 1

4 IT-27132 3 Way Power Adapter 1

6 IT-27103 Cloth Bag w/Gasket 1

7 IT-27102 6 qt HEPA Micro-Ply Filter Bag 1

8 IT-27119 Gasket (Motor to Housing) 1

9 IT-27120 Mounting Ring for Motor 1

10 IT-27121 Well Nut Washer 3

11 IT-27122 Well Nut 3

12 IT-27123 Screw for Well Nut 3

13 IT-27124 Motor Finger Guard 1

14 IT-27125 #10 x 5/8” Hex Tapping Screw 2

16 IT-27110 On/O Rocker Switch 1

17 IT-27104 Pigtail Cord w/Connectors (Sold with 18 & 18b) 1

18 IT-27104 Strain Relief (Sold with 17 & 18b) 1

18b IT-27104 Nut for Strain Relief (Sold with 17 & 18) 1

19 IT-27128 Dual Cell Exhaust Filter 1

20 IT-27106 HEPA Dome Motor Filter 1

21 IT-27129 Screw - Motor to Mounting Plate 4

12

Fast Track Vac

12

Filter Use

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Disposable lter bag required

Please read the important information below regarding the proper use of our lter system.

The primary lter (rst lter) is the most important lter, as it lters 99.97% of particles. Failure to use this primary lter will

cause damage to the secondary lter, vacuum motor and disperse ne particles into the air.

Feel free to contact us should you have any questions regarding the proper use of the vacuum and lters.

The Fast Track is designed for the four lters to be used in unison.

Proper and improper use of the lter system

IPC Eagle

Proper Use

1. Primary Filter

6qt HEPA Micro-Ply Filter Bag

Code: IT-27102

2. Secondary Filter- Cloth Bag with

Gasket Code: IT-27103

Dangers of Improper Bag Use

g

a

B

M

r

e

t

l

i

F

y

r

a

m

i

r

P

u

s

t

B

e

U

s

e

d

The Fast Track Vac removes large quantities of deeply

embedded ultra-ne particles. Not using both vacuum

bags to lter the ultra-ne particles is hazardous. Misuse

will cause the HEPA ltration to be compromised, causing

the operator to inhale invisible particles. Coughing, lung

irritation and respiratory distress are possible.

Use the lters properly, discard/replace the HEPA dome

lter when discoloration occurs. Coloration of this lter

indicates a failure or non-use of the primary lter (6 qt

HEPA Micro-Ply Filter Bag).

This primary lter bag must

be used or you can inhale

dangerous particles.

Danger

3. HEPA Dome Motor Filter

Code: IT-27106

4. Dual Cell Noise Reduction Exhaust

Filter Code: IT-27128

Clean exhaust when

primary and secondary

bags are used.

Motor Life

The Fast Track Vac motor uses air-ow to cool the heat

generated by the motor. Proper use of the lters allow

clean cool air to pass through and cool the motor.

When primary and secondary lter bags are not used,

ultra-ne particles pass through the motor. This will

cause the motor to over heat as dust coats the motor

windings and fan blades. Heat will cause the motor life

to be reduced and will void the warranty on the motor.

Unltered Particles

Dirty exhaust when

primary bag is not used.

13

OPM-V.1-8-16

https://harrissupplyind.com - To Order Parts Call 608-268-8080

https://harrissupplyind.com - To Order Parts Call 608-268-8080

https://harrissupplyind.com - To Order Parts Call 608-268-8080

Loading...

Loading...