OPERATIONS MANUAL

& PARTS LIST

B1500, B2000, FM17, FM20

IPC Eagle • 3650 Dodd Rd, Eagan MN 55123 • 800.486.2775 • www.ipceagle.com

WHEN THE MACHINE IS DELIVERED

Check the carton carefully for signs of rough handling. Remove the machine from the carton. If the

machine is damaged, notify the carrier IMMEDIATELY and request an inspection. Be sure to keep the

carton, packing inserts, packing lists and carrier’s receipt until the inspector has verified your claim.

IPC’s liability ceases when the carrier picks up the shipment but our customer service staff will be glad to

furnish any information needed in connection with the claim and will expedite repair of the machine.

BEFORE OPERATING THE MACHINE

Read the manual carefully and completely before attempting to operate the unit. This manual has

important information for the use and safe operation of the machine. Keep this manual handy at all times.

This machine will assure years of satisfactory service if operated and maintained according to

recommendations in this manual. If additional information is needed, please contact your local distributor

or write to:

IPC EAGLE

3650 Dodd Rd

Eagan, MN 55123

All information and specifications printed in the manual and parts list are current at the time of printing;

however, because of IPC’s policy of continual product development, we reserve the right to make changes

at any time without notice.

WARRANTY

To protect your investment, promptly fill in the required information on the warran ty card that comes with

the unit and mail it back to IPC.

WARNING

To reduce the risk of fire, electric shock, or injury:

• Do not operate the machine unless trained and authorized.

• Do not leave the machine when plugged in. Unplug from the outlet when not in use, before servicing,

and when changing the brushes or pads.

• Use indoors only.

• Do not allow to be used as a toy. Close attention is necessary when used by or near children.

• Do not bypass or defeat the safety “lock-out lever.”

• The machine was designed for use as per instruction and recommendations written in this manual. Any

deviation from its proper use or purpose and the consequential damage that may occur is the sole

responsibility of the end user.

• Do not use with damaged cord or plug. If the machine is not working as it should, or it has been

dropped, damaged, left outdoors or dropped into water, return it to an authorized service center.

WARNING

• Do not pull or carry by cord, use cord as handle, close a door on the cord or pull cord around sharp

edges or corners. Do not run machine over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Make sure the machine is plugged into an electrical outlet with the same voltage and frequency rating

as shown on the nameplate of the machine. Do not attempt to plug a 115- volt machine into a 230- volt

outlet.

• Do not immerse or use this machine in standing water. Such use can cause electric shock.

• Keep the electrical supply cord from contacting the rotating brush or drive block.

• Do not expose machine to freezing temperatures.

• To avoid electric shock, do not expose the unit to rain. Store indoors only.

• Connect to a properly grounded outlet only. See “Grounding Instructions.”

• Turn off all controls before unplugging.

• When using an extension cord, use a 3 conductor grounding cord, 12 gauge wire or heavier.

• Do not put any object into openings. Do not use with any opening blocked. Keep free of dust, lint, hair

and anything that may reduce air flow.

• Do not operate machine in flammable or explosive areas.

• All servicing of IPC’s equipment should be performed by an IPC authorized service center.

• Keep hair, loose clothing, fingers and all parts of body away from openings and moving parts.

• Use extra care when cleaning on stairs. When servicing machine, use manufacturer’s supplied or

approved replacement parts.

FAILURE TO COMPLY WITH THE WARNING INSTRUCTIONS WILL VOID THE

WARRANTY.

GROUNDING INSTRUCTIONS

Machine must be grounded. If it should malfunction or breakdown, grounding provides a path of least

resistance for electrical current to reduce the risk of electric shock. This machine is equipped with a cord

having an equipment-grounding plug. (Figure 1) The plug must be plugged into an appropriate outlet that

is properly installed in accordance with all local codes and ordinances. Do not remove ground pin; if

missing, replace plug before use.

Fig. 1

PREPARING THE MACHINE FOR OPERATION

Your floor machine will operate in a wide variety of hard floors and carpet cleaning applications. Consult

with your local dealer or IPC’s Customer Service to select the correct accessories for the job you are

going to perform.

BRUSH, PAD DRIVER, AND PAD INSTALLATION

WARNING:

installing or removing the brushes, pad drivers or pads from machine.

Brush & Pad Driver installation:

Lock the handle in the upright position and tip the machine back so it

rests on the handle and wheels. Fit the three slots of the clutch plate in

the back of the brush or pad driver over the three lugs of the drive plate.

Push it firmly into position and turn it counterclockwise until it locks in

place.

To remove: Tip the machine back so it rests on the handle and wheels.

Turn the brush or pad driver clockwise until it disengages and lifts off.

Do not store the machine with the brush or pad drivers installed. Fig. 2

Make sure the power cord is disconnected from the electrical outlet before

Pad Installation:

To install pad, tilt the machine back on wheels until machine is resting on handle. Center the pad on

the pad holder and insert pad center lock by twisting clockwise. Make sure the center lock is tight.

To remove: Twist the center lock counterclockwise.

SHAMPOO TANK INSTALLATION (Dual & Low Speed Units Only)

Position the shampoo tank in front of the floor machine with the water release lever of the shampoo tank

resting below the floor machine lever. There should be enough room for you to pull the shampoo tank

lever without accidentally pulling the floor machine lever. (Figure 3).

Attach the tank to the machine using the two “V” bolts already included on the tank. (Figure 4).

The base of the shampoo tank has a solution hose connected to it on one end. Insert the other end of the

solution hose in the motor frame. (Figure 5)

fig. 3 fig. 4 fig. 5

MACHINE OPERATION

1. Install the pad driver and pad, brush or attachment.

2. Plug in machine.

3. Lower the handle to the desired operating position.

4. Place both hands on the handle grips with your fingers around the on/off

lever which extends from one side to the other underneath the handle grips.

5. The safety “lock-out” lever is located underneath the right side handle

grip and switch lever. To unlock the “lock-out” lever, use your right hand

fore finger to press the lever down toward the back of the switch box. fig. 6

(Figure 6)

6. While still pressing the lever, pull the on/off switch lever to start the

machine, then release the “lock-out” lever. The “lock-out” lever will automatically engage when you

release the on/off switch lever.

TO MANEUVER YOUR FLOOR MACHINE

1. Raise the handle slightly and the machine will go to the right. The higher you raise it, the faster it will

go.

2. Lower the handle and the machine will go left. The more you lower it, the faster it will go.

3. Practice on a smooth surface until you gain experience in operating the unit.

TO RE-ADJUST THE HANDLE-LOCK MECHANISM

Unlock the handle and place it in the upright position. Tighten the adjusting

nuts until there is a slight drag when the handle is raised or lowered.

(Figure 7)

fig.7

TO ADJUST THE DRIVE BELT:

(High-speed models only: 20HS1500, 20HS2000, 17HS2000)

1. Loosen, but do not remove the 4 bolts, that hold the motor to the

frame. (Figure 5)

2. Tighten the 2 screws at the back of the frame until the belt is tight.

Test and re-adjust the belt until the belt does not slip. Re-tighten the

four motor bolts.

WARNING: Do not over-tighten the belt.

fig. 8

OPERATING INSTRUCTIONS FOR MODELS 17DS AND 20DS DUAL SPEED MACHINES

These units operate to all instructions already described except the following:

These models can run at either 175 RPM for scrubbing or at 300 RPM for buffing. To switch the RPM,

use the rocker switch located between the motor and the base of the handle. Do not buff in the 175 RPM

setting because it might overload the motor.

CLEAN UP & STORAGE

1. Unplug and wrap it under the cord hook and around the left side handle grip. Clean the cord and

inspect it for cuts, gashes and loose prongs.

2. Wipe down the machine and store in clean dry place.

WARNING: Do not store the machine with the drive block, pad driver or brush on the

machine.

NOTES

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

_____________________________________________________________________________________

1

2

3

4

5 6

9

10

12 13 14 15

11

7

8

16

17

52

51

50

68

67

62

61

60

59

49

48

47

66

58

65

64

63

555657

54

53

18 19

20

21

22

23

24

25

26

27

28

29

30

31

46

45

44

43

42

41

40

39

32

33

34

35

36

37

38

FM17

IPC Eagle

FM17

#

#

Y

ITEM

1 B11487 POWER CORD, 14-3, 50 FT, SJTW 1

2 K11498 GRIP 2

3 C11528 SCREW, 10-32 X .25 IN 1

4 LABEL, 1.5HP 1

5 LABEL, IPC 1

6 D11496G SWITCH BOX COVER, GREY 1

7 H11493 LABEL, SAFETY, FLOOR MACHINE 1

8 C11529 SCREW, 10-32 X .375 IN 2

9 K11519 LEVER GRIP, LOCKOUT, BLACK 1

10 C00278 LOCKNUT, 10-32, NYLON, SS 1

11 D11494 LOCKOUT BRACKET 1

12 D11524 SPRING, LOCKOUT 1

13 C90007 SCREW, 10-32 X .625 PHILLIPS, TRUSS HEAD, SS 1

14 C11491 SCREW, 10-32 X 1 IN, SS 1

15 D11479 HANDLE, CHROME, FLOORMACHINE 1

16 C00306 ROLL PIN, .125 X 1.75 2

17 D11523 SPRING, TRIGGER 2

18 D11495 TRIGGER, ZINC PLATED 1

19 K11520 LEVER GRIP, TRIGGER BLACK 2

20 11507A ASSEMBLED LOCKING HANDLE, CORD HOOK 1

21 C11619 ALLEN WRENCH, .31 IN 1

22 D11497 HANDLE, LOCKING CLAMP 1

23 C11538 CAP NUT, .31 IN PUSH-ON 1

24 C00259 WASHER, SLOTTED, ZINC 1

25 C11536 SPADE BOLT, .375-16 X 4IN 1

26 D11507 CORD HOOK CLAMP 1

27 D11507-2 CORD HOOK BODY 1

28 C11558 LOCKNUT, BLACK OXIDE, THIN 2

29 C11502 SOCKET CAP SCREW, .375-16 X 2.5 IN 1

30 C11537 DOWEL PIN, .31 X 1.5 IN 1

31 C13101 SCREW, HEX CAP, M14-2.0 1

32 K00674 BUSHING, .50IN NYLON 2

33 D11510 AXLE, FLOOR MACHINE 1

34 D11482 HANDLE BRACE, RIGHT, BLACK 1

35 C00240 WASHER, SHOULDER, NYLON 6

36 C11559 WASHER, .515 X .875 X .032 6

37 G11943 WHEEL, 5 IN SATURN 2

38 C02305 CAP NUT, .5IN PUSH ON 2

39 C11501 SOCKET CAP SCREW, .31-18 4

40 C00251 LOCKWASHER, .31, SPLIT 4

41 E11477 BUMPER, 17 IN FLOOR MACHINE 1

42 D11485G BRUSH COVER, 17 IN, GREY 1

43 K11521 SPACER, BASE, FLOOR MACHINE 4

44 D11483 FRAME, MOTOR, BLACK 1

45 G11468 MOTOR W- GEARBOX, 1.5 HP 1

46 D11481 HANDLE BRACE LEFT, BLACK 1

47 H10976-1 LABEL, UL STD 561-507 1

48 H00565-5 LABEL, SERIAL # STANDARD 1

49 H03545 COVER, SERIAL #, LABEL 1

50 D11490G DRIP COVER, GREY 1

51 H12913 LABEL, DRIP COVER, WHITE 1

52 C11916 SCREW, 10-32 X .375 PHILLIPS 1

53 C13100 NUT, M14-2.0 NYLON INSERT 1

54 B10734 STRAIN RELIEF, HANDLE 1

55 B11513 CORD, HANDLE, 14-3 SJTW 1

56 B11762 TERMINAL LUG, NYLON, FEMALE 2

57 B11465 SWITCH, DPST, PUSHBUTTON 1

58 B00177 TERMINAL LUG, FEMALE, QD, .25 X .032 2

59

60

61 B11518 SWITCH INSULATION 1

62 C00284 SCREW, 10-32 X .375 GROUND 1

63

64

65 B11505 STRAIN RELIEF NUT, METAL 1

66 C11560 WASHER, .93 ID X 1.5OD 1

67 B11504 STRAIN RELIEF, METAL 1

68 H02548-2

PART

C00252 WASHER, .375 IN, FLAT 1

C11541 WASHER, .375 IN STAR 1

B00187 CABLE CLAMP, NYLON, .43 IN 1

B00180-10-3 RING TERMINAL, #10 CENTER 2

LABEL, IMPORTANT CORD 1

DESCRIPTION QT

1

2

3 5 6 7 8

4

10 11 12 13 14

9

15

52

51

50

68

67

66

62

61

60

59

58 57 56

49

48

65

63

64

55

54

53

16

17

18 19

20

2930 28

21

22

23

24

25

26

27

46

45

44

43

42

41

40

39

47

31

32

33

34

35

36

37

38

FM20

IPC EAGLE

FM20

#

#

Y

ITEM

1 B11487 Power Cord, 14-3, 50 FT, SJTW 1

2 K11498 Grip 2

3 C11528 Screw, 10-32 X .25 in 1

4 Label, 1.5 HP 1

5 Label IPC 1

6 D11496G Switch Box Cover, GREY 1

7 H11493 Label, Safety, Floor Machine 1

8 C11529 Screw, 10-32 X .375 in 2

9 K11519 Lever Grip, Lockout, Black 1

10 C00278 Locknut, 10-32, Nylon, SS 1

11 D11494 Lockout Bracket 1

12 D11524 Spring, Lockout 1

13 C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS 1

14 C11491 Screw, 10-32 X 1 in, SS 1

15 D11479 Handle, Chrome, Floormachine 1

16 C00306 Roll Pin, .125 X 1.75 2

17 D11523 Spring, Trigger 2

18 D11495 Trigger, Zinc Plated 1

19 K11520 Lever Grip, Trigger, Black 2

20 11507A Assembled Locking Handle, Cord Hook 1

21 C11619 Allen Wrench, .31 in 1

22 D11497 Handle, Locking Clamp 1

23 C11538 Cap Nut, .31 in, Push-On 1

24 C00259 Washer, Slotted, Zinc 1

25 C11536 Spade Bolt, .375-16 X 4 in 1

26 D11507 Cord Hook Clamp 1

27 D11507-2 Cord Hook Body 1

28 C11558 Locknut, Black Oxide, Thin 2

29 C11502 Socket Cap Screw, .375-16 X 2.5 in 1

30 C11537 Dowel Pin, .31 X 1.5 in 1

31 C13101 Screw, Hex Cap, M14-2.0 1

32 K00674 Bushing, .50 in, Nylon 2

33 D11510 Axle, Floor Machine 1

34 D11482 Handle, Brace, Right, Black 1

35 C00240 Washer, Shoulder, Nylon 6

36 C11559 Washer, .515 X .875 X .032 6

37 G11943 Wheel, 5 in Saturn 2

38 C02305 Cap Nut, .5 in Push-On 2

39 C11501 Socket Cap Screw, .31 - 18 4

40 C00251 Lockwasher, .31, Split 4

41 E11478 Bumper, 20 in Floor Machine 1

42 D11486G Brush Cover, 20 in, GREY 1

43 K11521 Spacer, Base, Floor Machine 4

44 D11483 Frame, Motor, Black 1

45 G11468 Motor w/Gearbox, 1.5 HP 1

46 D11481 Handle Brace, Left, Black 1

47 H10976-1 Label, UL STD 561-507 1

48 H00565-5 Label, Serial #, Standard 1

49 H03545 Cover, Serial #, Label 1

50 D11490G Drip Cover, GREY 1

51 H12913 Label, Drip Cover, White 1

52 C11916 Screw, 10-32 X .375 Phillips 3

53 C13100 Nut, M14-2.0 Nylon Insert 1

54 B10734 Strain Relief, Handle 1

55 B11513 Cord, Handle, 14-3 SJTW 1

56 B11762 Terminal Lug, Nylon, Female 2

57 B11465 Switch, DPST, Pushbutton 1

58 B00177 Terminal Lug, Female, QD, .25 X .032 2

59 C00252 Washer, .375 in, Flat 1

60 C11541 Washer, .375 in, Star 1

61 B11518 Switch, Insulation 1

62 C00284 Screw, 10-32 X .375, Ground 1

63 B00187 Cable Clamp, Nylon, .43 in 1

64 B00180-10-3 Ring Termal, #10 Center 2

65 B11505 Strain Relief Nut, Metal 1

66 C11560 Washer, .93 ID X 1.5 OD 1

67 B11504 Strain Relief, Metal 1

68 H02548-2

PART

DESCRIPTION QT

Label, Important, Cord 1

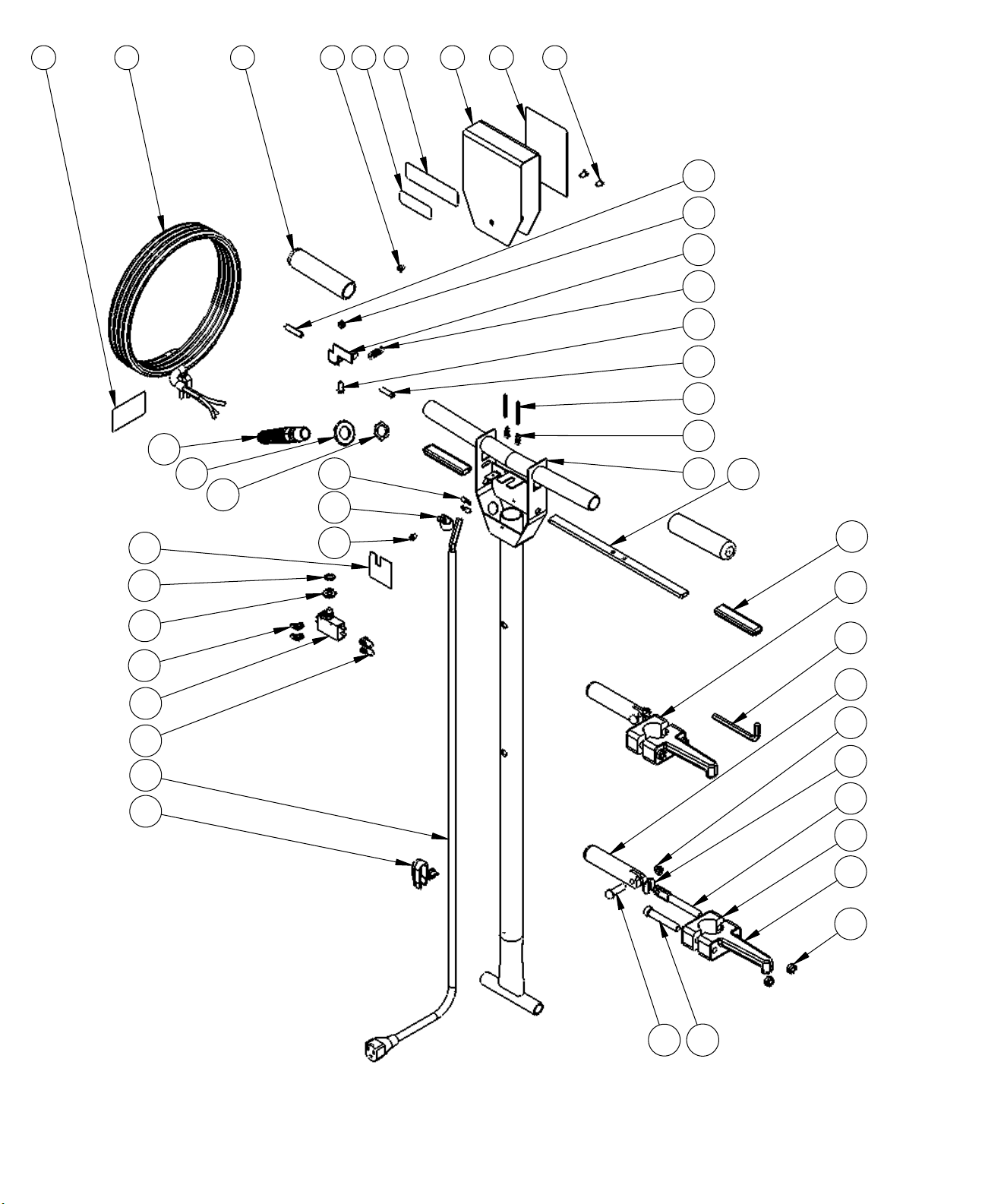

1 2 3 4

5

6 7 8 9

10

11

12

13

14

15

16

39

38

37

36

35

34

33

32

45

44

43

42

41

40

17

18

19

20

21

22

23

24

25

26

27

28

B2000/B1500

Handle

IPC

29

31 30

B2000/ B1500

#

Y

HANDLE

ITEM #

1 H02548-2 Label, Important, Cord 1

2 B11900 Power Cord, 12-3, 75 FT, SJTW 1

3 K11498 Grip 2

4 C11528 Screw, 10-32 X .25 in 1

5 H12069 Label, 2000 RPM, Saturn 1

6 H11831 Label, EDIC, Black-Silver 1

7 D11496B Switch Box Cover, Black 1

8 H11493 Label, Safety, Floor Machine 1

9 C11529 Screw, 10-32 X .375 in 2

10 K11519 Lever Grip, Lockout, Black 1

11 C00278 Locknut, 10-32, Nylon, SS 1

12 D11494 Lockout Bracket 1

13 D11524 Spring, Lockout 1

14 C90007 Screw, 10-32 X .625 Phillips, Truss Head, SS 1

15 C11491 Screw, 10-32 X 1 in, SS 1

16 C00306 Roll Pin, .125 X 1.75 2

17 D11523 Spring, Trigger 2

18 D11479 Handle, Chrome, Floor Machine 1

19 D11495 Trigger, Zinc Plated 1

20 K11520 Lever Grip, Trigger, Black 2

21 11507A Assembled Locking Handle, Cord Hook 1

22 C11619 Allen Wrench, .31 in 1

23 D11497 Handle, Locking Clamp 1

24 C11538 Cap Nut, .31 in, Push-on 1

25 C00259 Washer, Slotted, Zinc 1

26 C11536 Spade Bolt, .375-16 X 4 in 1

27 D11507 Cord Hook Clamp 1

28 D11507-2 Cord Hook Body 1

29 C11558 Locknut, Black Oxide, Thin 2

30 C11502 Socket Cap Screw, .375-16 X 2.5 in 1

31 C11537 Dowel Pin, .31 X 1.5 in 1

32 B10734 Strain Relief, Handle 1

33 B11513 Cord, Handle, 14-3 SJTW 1

34 B11762 Terminal Lug, Nylon, Female 2

35 B11465 Switch, DPST, Pushbutton 1

36 B00177 Terminal Lug, Female, QD, .25 X .032 2

37 C00252 Washer, .375 in, Flat 1

38 C11541 Washer, .375 in, Star 1

39 B11518 Switch Insulation 1

40 C00284 Screw, 10-32 X .375 Ground 1

41 B00187 Cable Clamp, Nylon, .43 in 1

42 B00180-10-3 Ring Terminal, #10 Center 2

43 B11505 Strain Relief Nut, Metal 1

44 C11560 Washer, .03 ID X 1.5 OD 1

45 B11504 Strain Relief, Metal 1

PART

DESCRIPTION QT

1

2

3

4

5

6

7

53

52

51

50

49

48

47

46

54

32

34

24

25

10

1211

13

14

15

16

31

30

17

32

33

34

8

9

19 20 22

18

22

23

24

25

26

27 28 29

45

44

43

42

41

40

39

38

37

50

35

36

37

B1500

Base

IPC

36

B1500

#

Y

BASE

ITEM #

1 B02196-1 LIGHT, MOTOR CARBON BRUSH WEAR 1

2 C11916 SCREW, 10-32 X .375 PHILLIPS 6

3 H11830 LABEL, SATURN, DRIP COVER 1

4 D11490C-H DRIP COVER, CHROME W/ HOLE FOR GREEN LIGHT 1

5 C00297 SCREW, #8 X .25 IN PAN HEAD 2

6 D11545 MOTOR SCREEN 1

7 C00293 #8 X .5 IN PAN, BLACK SMS, PHILLIPS 1

8 B00187 CABLE CLAMP, NYLON, .43 IN 1

9 G11557 MOTOR, HIGH SPEED 1

10 B00177 TERMINAL LUG, FEMALE, QD, .25 X .032, 16-14 AWG, FULLY INSULATED 2

11 D11543 HANDLE BRACE, LEFT 1

12 H03545 COVER, SERIAL #LABEL 1

13 H10976-1 LABEL, UL STD 561-507 1

14 H00565-5 LABEL, SERIAL #, STANDARD 1

15 C11568 HEX BOLT, .31-18 X 2.5 IN 4

16 D11526 FRAME, MOTOR, BLACK 1

17 D11563 AXLE, HANDLE 1

18 K00674 BUSHING, .50 IN, NYLON 4

19 C00261 NUT, .25-20, HEX 6

20 D11542 TENSION ADJUSTMENT BRACKET 2

21 C00233 WASHER, FLAT, .25 IN 2

22 C00319 HEX TAP BOLT, 1-4 X 20 X 3.5 IN 2

23 D11544 HANDLE BRACE, RIGHT 1

24 C00252 WASHER, .375 IN, FLAT 6

25 C11569 HEX TAP BOLT, 3-8 X 1.25 IN 4

26 K11561 SPACER, .25 LG, NYLON, NATURAL 14

27 C11559 WASHER, .515 X .875 X .032 12

28 G11943 WHEEL, 5 IN SATURN 4

29 C02305 CAP NUT, .5 IN PUSH-ON 4

30 C11558 LOCKNUT, .375-16 2

31 D11562 AXLE, WHEEL 1

32 C11555 KEY, MOTOR, .187 IN 2

33 D11532 PULLEY 1

34 C11567

35 K00662-50 SPACER, .5 IN 2

36 C00250 LOCKWASHER, .375, SPLIT 5

37 C11571 HEX TAP BOLT, 3-8 X .75 IN 3

38 D11535 WASHER, 1.75 IN STEEL 1

39 E11478 BUMPER, 20 IN FLOOR MACHINE 1

40 F11988 PAD, HI SPEED, 20 IN 1

41 2004BR PAD HOLDER, 20 IN, HIGH SPEED 1

42 C00262 NUT, .31-18, HEX 4

43 C00251 LOCKWASHER, .31, SPLIT 4

44 D11565 BEARING PLATE, LOWER 1

45 D11486-SS BRUSH COVER, 20 IN, STAINLESS 1

46 K11521 SPACER, BASE, FLOOR MACHINE 4

47 G11531 BEARING 2

48 D11547 PULLEY, 3.875 IN (1500 RPM) 1

49 L11530 BELT 1

50 C11556 WAVE WASHER 2

51 D11534 SHAFT, 4.11 IN 1

52 D11566 BEARING PLATE, UPPER 1

53 C11574 RETAINING RING 1

54 D11490G DRIP COVER, GREY 1

PART

DESCRIPTION QT

SET SCREW, .312 IN 3

1

2

3

4

5

6

7

53

52

51

50

49

48

47

46

54

32

34

24

25

10

1211

13

14

15

16

31

30

17

32

33

34

8

9

19 20 22

18

22

23

24

25

26

27 28 29

45

44

43

42

41

40

39

38

37

50

35

36

37

B2000

Base

IPC

36

B2000

#

Y

BASE

ITEM #

1 B02196-1 Light, Motor Carbon Brush Wear 1

2 C11916 Screw, 10-32 X .375 Phillips 6

3 H11830 Label, Saturn, Drip Cover 1

4 D11490C-H Drip Cover, Chrome w/Hole for Green Light 1

5 C00297 Screw, #8 X .25 in, Pan Head 2

6 D11545 Motor Screen 1

7 C00293 #8 X .5 in Pan, Black SMS, Phillips 1

8 B00187 Cable Clamp, Nylon, .43 in 1

9 G11557 Motor, High Speed 1

10 B00177 Terminal Lug, Female, QD, .25 X .032, 16-14 AWG, Fully Insulated 2

11 D11543 Handle Brace, Left 1

12 H03545 Cover, Serial # Label 1

13 H10976-1 Label, UL STD 561-507 1

14 H00565-5 Label, Serial #, Standard 1

15 C11568 Hex Bolt, .31-18 X 2.5 in 4

16 D11526 Frame Motor, Black 1

17 D11563 Axle, Handle 1

18 K00674 Bushing, .50 in, Nylon 4

19 C00261 Nut, .25-20, Hex 6

20 D115242 Tension Adjustment Bracket 2

21 C00233 Washer, Flat, .25 in 2

22 C00319 Hex Tap Bolt, 1-4 X 20 X 3.5 in 2

23 D11544 Handle Brace, Right 1

24 C00252 Washer, .375 in, Flat 6

25 C11569 Hex Tap Bolt, 3-8 X 1.25 in 4

26 K11561 Spacer, .25 lg, Nylon, Natural 14

27 C11559 Washer, .515 X .875 X .032 12

28 G11943 Wheel, 5 in Saturn 4

29 C02305 Cap Nut, .5 in, Push-on 4

30 C11558 Locknut, .375-16 2

31 D11562 Axle, Wheel 1

32 C11555 Key, Motor, .187 in 2

33 D11532 Pulley 1

34 C11567

35 K00662-50 Spacer, .5 in 2

36 C00250 Lockwasher, .375, Split 5

37 C11571 Hex Tap Bolt, 3-8 X .75 in 3

38 D11535 Washer, 1.75 in, Steel 1

39 E11478 Bumper, 20 in Floor Machine 1

40 F11988 Pad, Hi Speed, 20 in 1

41 2004BR Pad Holder, 20 in, High Speed 1

42 C00262 Nut, .31-18, Hex 4

43 C00251 Lockwasher, .31, Split 4

44 D11565 Bearing Plate, Lower 1

45 D11486-SS Brush Cover, 20 in, Stainless 1

46 K11521 Spacer, Base, Floor Machine 4

47 G11531 Bearing 2

48 D11533 Pulley, 3.125 in w/Grooves 1

49 L11530 Belt 1

50 C11556 Wave Washer 2

51 D11534 Shaft, 4.11 in 1

52 D11566 Bearing Plate, Upper 1

53 C11574 Retaining Ring 1

54 D11490G Drip Cover, GREY 1

PART

DESCRIPTION QT

Set Screw, .312 in 3

NOTES

Loading...

Loading...