Service Manual

Rev.1.0 January 2013

PW-C25 & PW-C25P

Models

1509P-M 230V 50Hz

I1509P-M 230V 50Hz

1813P-T 400V 50Hz

I1813P-T 400V 50Hz

I1310P4-M 230V 50Hz

Pag. 2

PW

-

C25 / PW

-

C25P

outer layout

High pressure hose – spray gun – lance

Hose reel handle

Main switch 0-I

Chemical tap and regulator

Lance holder

Water inlet fitting

Water outlet fitting

Pressure adjust

Pump oil window

Pressure gauge

Hose reel rotation lock

Chemical tank

Lance holder

High pressure outlet

Foot lever

Refill cap

Pag. 3

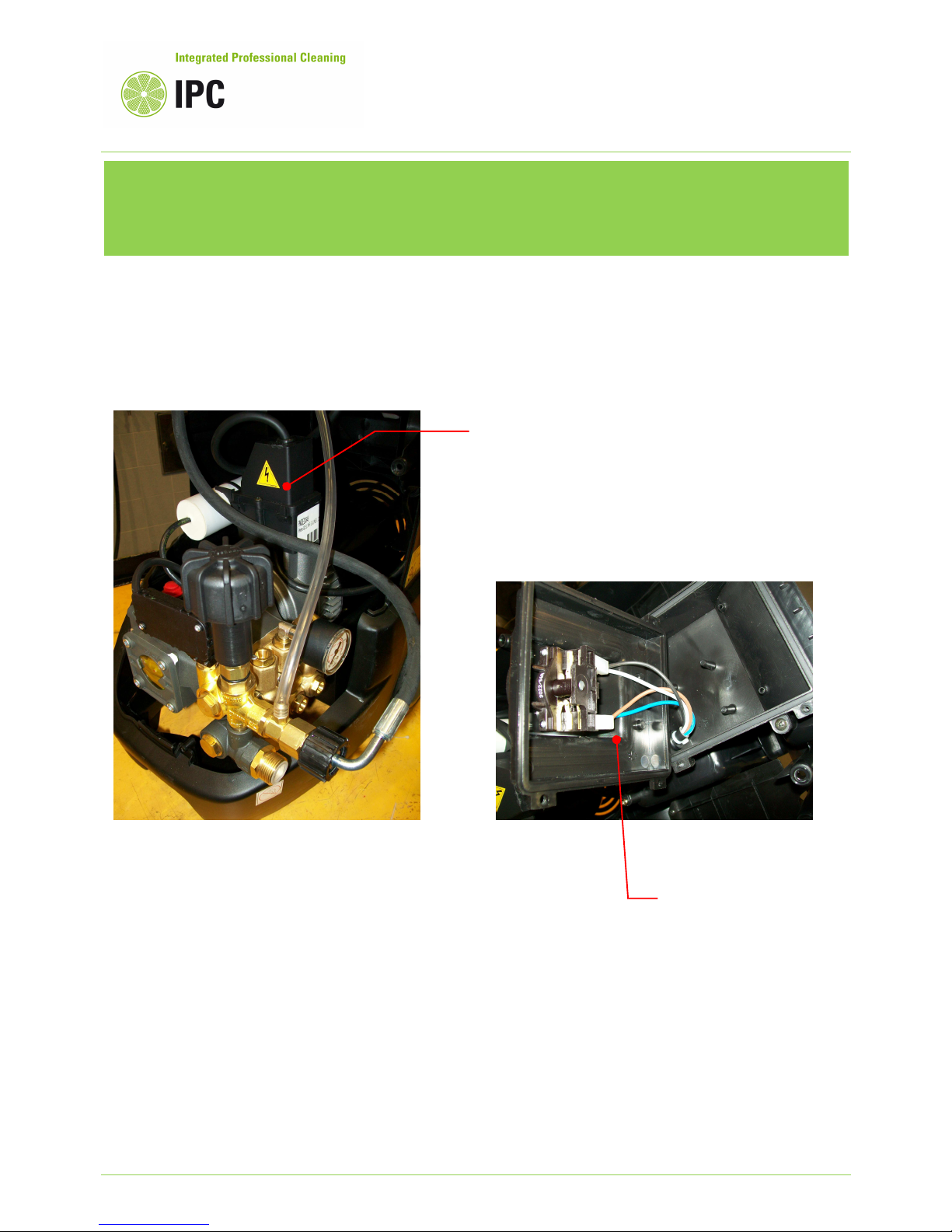

PW

-

C25 / PW

-

C25P inner

layout

Water outlet fitting

Water inlet fitting

Pressure gauge

Oil cap with air breath

By-pass valve

Total stop micro-switch

Pressure adjusting knob

Oil cap for handling and

transportation

High pressure pump

Oil level window

Electric motor starting

capacitor

Electric motor

Electric enclosure

Chemical injector

Chemical tap and dose

Main switch

Standard accessories

set, that includes the

inlet water filter and

“garden” quick inlet

fitting.

Pag. 4

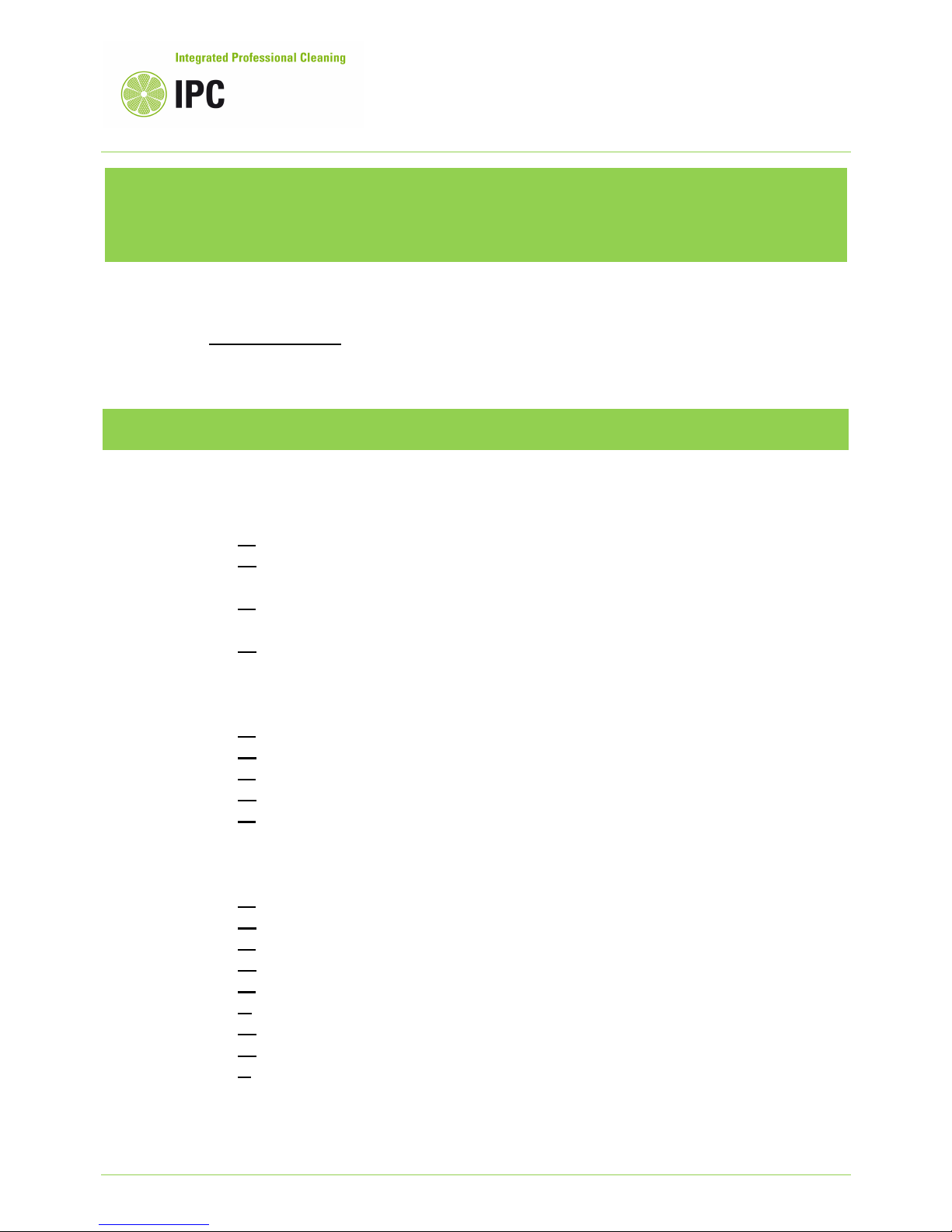

PW-C25 / PW-C25P

electric box components

layout

Electric box for wiring

the electric motor, the

starting capacitor, the

total stop switch and the

power cord.

Electric box for on – off

main switch

Pag. 5

Service Manual

INDEX

Topics

1. The machine doesn’t starts Page

1a No electrical connection 7

1b No electrical supply to the electric motor or

motor thermal sensor overload intervened or burnt fuses 7

1c The micro-switch of bypass valve not working

(only for machine with total stop system)

12

1d Contactor not working (on versions three phase or P4) 13

2. No water jet at the lance nozzle Page

2a Bad or missing water feeding connection 14

2b Inlet water filter clogged 14

2c Air intake from the water feeding circuit 15

2d Pump head valves ceased 15

2e High pressure nozzle clogged 16

3. No pressure to the lance Page

3a Defective water feeding connection 17

3b Inlet water filter clogged 17

3c Air intake from the water feeding circuit 18

3d Pump head valves ceased or worn 18

3e Lance nozzle set in low pressure mode (detergent mode) 19

3f High pressure nozzle worn or deformed 19

3g Pressure adjusting valve setting at minimum position 20

3h Seat of pressure adjusting valve damaged 20

3i Pump gaskets worn or water leaks from the pump head 23

Ip Cleaning S.p.A.

Viale Treviso, 63 – 30026 Summaga di Portogruaro – VENICE – ITALY

Tel. +39 0421 205511 (r.a.) – Fax +39 0421 204227

Internet address: www.ipcportotecnica.com

e-mail address: infoipcportotecnica@ipcleaning.com

Pag. 6

4. Poor detergent delivery Page

4a Detergent tap closed/off or clogged 24

4b Empty detergent tank or nozzle not set in detergent mode 25

4c The check valve of the detergent circuit is sticky or clogged 25

4d High pressure outlet pipes clogged or too much extended (over 20 m).

Wear and tear of the detergent nozzle 26

4e Pressure regulator is not set at maximum position 26

5. Oil and water emulsion phenomena to the high pressure pump oil Page

5a Extremely high environment humidity percentage 27

5b High pressure pump gaskets worn 28

5c High pressure pump pistons damaged 28

6. The total stop system doesn’t intervenes

(only for machines having this option) Page

6a Water leaks from the high pressure outlet circuit 29

6b Micro-switch of the bypass valve, or contactor, not functioning 29

Pag. 7

1. The machine doesn’t starts

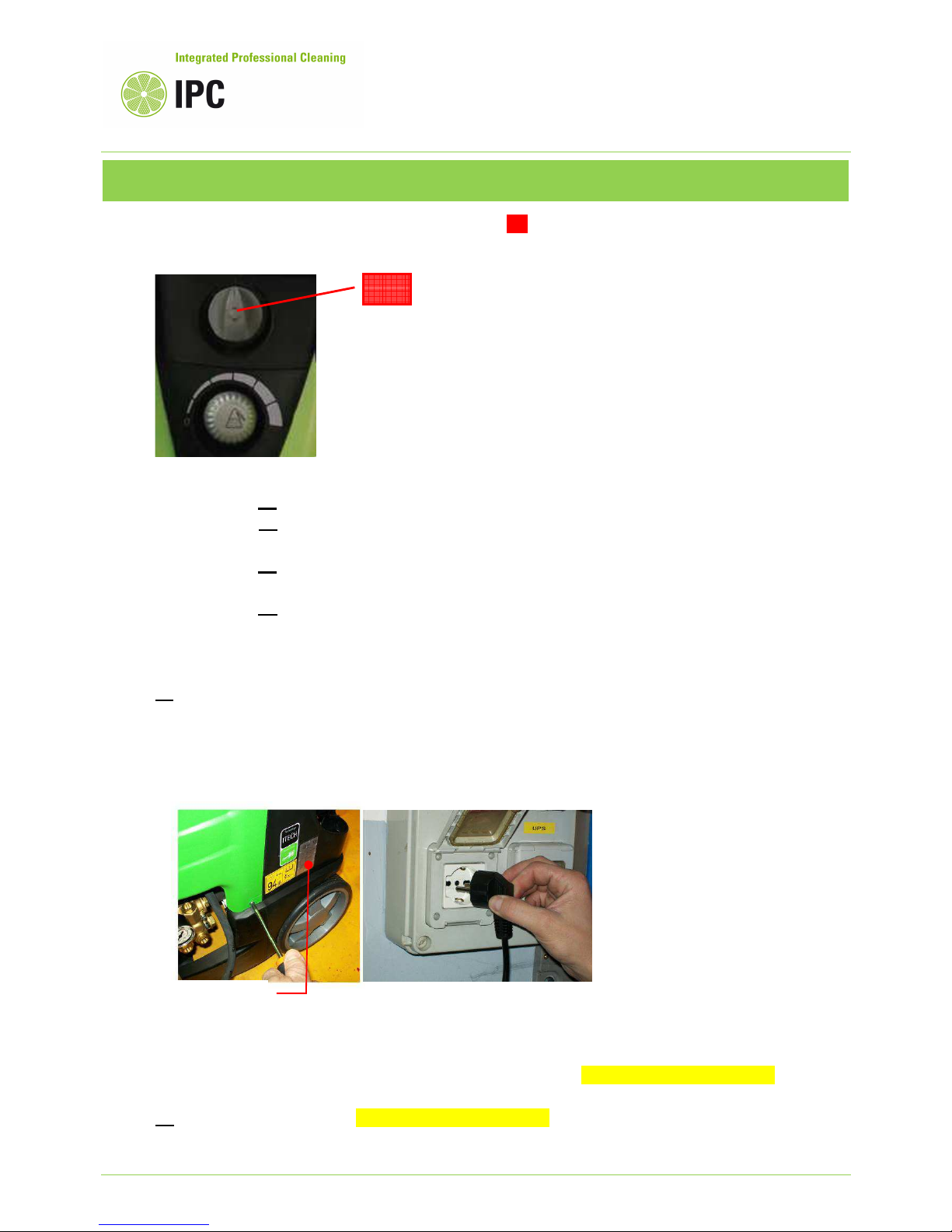

1) TROUBLE: Rotating the main switch “0 – I” (A) the high pressure cleaner doesn’t starts or

starts, but suddenly stops after a while.

CAUSES: 1a No electrical connection

1b No electrical supply to the electric motor or motor thermal sensor overload

intervened or burnt fuses

1c The micro-switch of bypass valve not working

(only for machine with total stop system)

1d Contactor not working (on versions three phase or P4)

REMEDIES:

1a Check the power supply voltage using a “multimeter”.

The machine power supply characteristics are indicated on the machine data plate placed on the

rear side of its chassis.

For single-phase models, the allowed voltage tolerance is +/- 5%.

For three-phase models, the allowed voltage tolerance is +/- 10%.

If the voltage is over or lower than the above mentioned tolerance, the machine electric

components may become damaged.

Pay maximum attention while checking electric component: danger of electric shocks.

1b Pay maximum attention: danger of electric shocks.

Disconnect the machine from the power supply before opening the electric enclosures, hence:

(A)

Machine data plate

Pag. 8

- check using a multimeter, the conductivity of the main switch contacts, rotate the switch knob to

position “I” and in case of problems, replace the switch with a new component.

To open the electric enclosures, proceed as following described:

Opening:

3. Remove the main switch knob

1. Remove the machine cover

5. Check the main switch contacts continuity using a

multimeter, if damaged replace it.

2. Remove the handle cover

4. O

pen the electric box cover

Pag. 9

- If the thermal sensor of the electric motor is intervened, the electric motor is disconnected and

the machine cannot work.

The thermal sensor, intervenes when the motor winding temperature is over 155°C and in order

to cool it down and allows its automatic reset, are required some minutes with the electric motor

off.

The thermal sensor is built-in into the motor winding of single phase models, while is wired into

the electric box for three-phase models or for P4 models.

The thermal sensor is a protection against overload and needed to prevent burning of the motor

windings, but has a limited life in term of number of interventions and if the machine has been

used continually under overloaded, the thermal sensor can become damaged and loose the

capacity to self reset, hence not allowing the motor to restart when decreases the winding

temperature.

In order to restore a damaged thermal sensor, is needed to replace the complete electric motor

stator.

- If the fuses of the socket or to the plug are burnt, the machine is not power supplied; replace the

fuses and check if their amperage is enough for the machine Amperage characteristics that are

readable on its data plate.

Take into consideration that a low voltage supply can cause difficulties to the motor starting and

as a consequence can makes that fuses burn.

We recommend to check the machine amperage using a clamp meter in order to be sure that the

machine working at the maximum pressure is not absorbing more Ampere than what indicated on

its data plate.

Measured

Amperage

should be less or

equal than Amperage wrote to the machine

data plate.

Check the Amperage with a A clamp meter

after switching on the machine and checking

that the machine is correctly power supplied

by the fuses.

Pag. 10

Electric diagrams

Single phase by-pass Single phase total stop

Pag. 11

On which :

•

IQ = Main switch of the power supply socket

•

F = Fuses of the power supply socket

•

CV1 = Machine power cord

•

IG = Machine main switch

•

M = Electric motor

•

TP = Thermal overload protection (clicson)

•

C = Electric motor starting capacitor

•

K = Contactor

•

A1 – A2 = Contactor coil

Three phase by-pass Three phase total stop

Pag. 12

1c Total stop versions have a micro-switch “S” that controls the contactor “C” on three phase

models and that controls directly the electric motor on single phase models, hence makes the

pump and motor unit to start and to stop accordingly with the position of the spray gun trigger:

- When the spray gun trigger is activated, and the lance is ready to spray water, the micro-

switch “S” is closed (on), the contactor (if present) is activated (on) and the electric motor is

power supplied.

- When the spray gun trigger is released, the lance stops to spray water, the micro-switch “S” is

open (off), the contactor (if present) is open (off) and accordingly the electric motor is not

power supplied and stops in “total stop mode”.

In case that the micro-switch “S” is defective or the piston that activate the micro-switch is not

sliding inside of the by-pass valve, the machine cannot start.

Check the pressure-switch continuity using a multimeter as following described:

Dismount the and open the micro

-

switch enclosure.

Check the pressure

-

switch switching capacity and continuity by using a multimeter.

Unscrew the piston that

activates the micro-switch

Slide out the piston and its

spring, check if parts

are wear and tear and if necessary replace them.

Lubricate with grease at the reassembly.

Pag. 13

1d The contactor “C” is installed only on three phase or P4 models and power supplies the

electric motor accordingly to the status of the micro-switch “S” and main switch “IG” for machine

total stop version and only the status of main switch “IG” for machines by pass version.

Check using a multimeter if the contactor coil “A1-A2” is power supplied and check if the power

contact of contactor have continuity when are closed.

We recommend to check the proper functioning of safety electric

components, at least once a year.

Pag. 14

2. No water jet at the lance nozzle

2) TROUBLE: No water jet sprayed from the lance nozzle.

CAUSES: 2a Bad or missing water feeding connection

2b Inlet water filter clogged

2c Air intake from the water feeding circuit

2d Pump head valves ceased

2e High pressure nozzle clogged

REMEDIES:

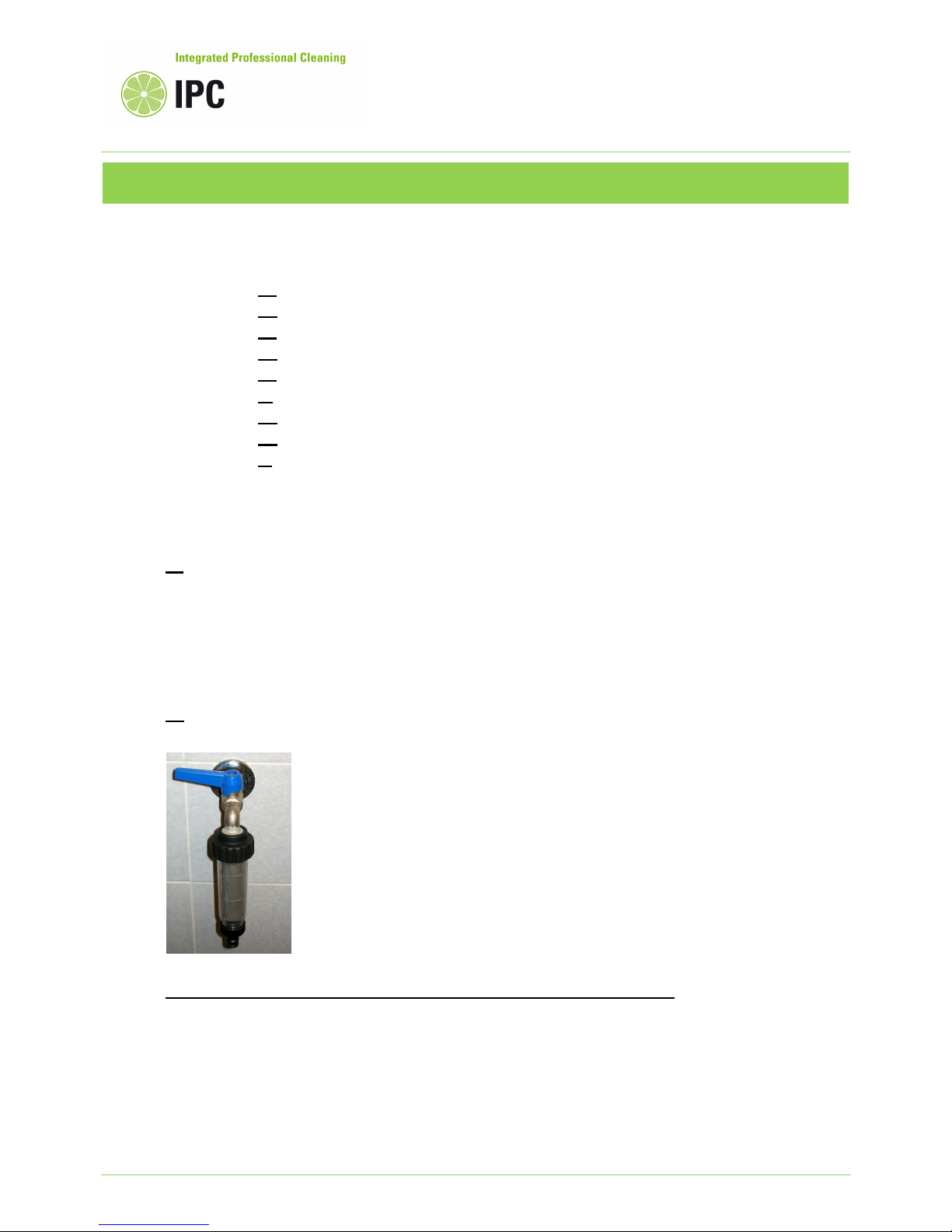

2a Check the supply water flow (l/min), in order to ensure that supply water available is

sufficiently high compared with the machine characteristics.

The supply water flow (l/min) must exceed at least 10%, than the water flow characteristics

declared in the machine data plate.

Check the fittings to the water inlet circuit and particularly ensure they are not damaged or not

properly sealed, causing flow obstruction or air intakes.

2b Check and clean the water supply inlet filters and if necessary, replace them.

We recommend to check the water filter every 50 hours (or every week)

Check and clean the filter place the high pressure pump inlet or at the water tap outlet.

Pag. 15

2c Check the water circuit that connects the water tap to the high pressure pump inlet,

particularly check that fittings are properly tightened and not leaking water.

This model has not capacity to intake water from a tank placed lower than the machine inlet

fitting, hence this machine can only to intake the water from a tank placed above than the

machine water inlet fitting.

In the above functioning circumstance is important to check that the inlet circuit is perfectly

sealed to avoid air intakes.

2d Check the inlet and outlet valves placed into the pump head; if the valves are sticky, unstick

the valve from its seat manually pressing gently the valve disk until released.

If the valves are dirty, disassemble them and clean.

We recommend the replacement of inlet and outlet valves every 500 hours or one a year.

Strip out the valves, use a screw M4 to link and pull out the valve

Unscrew the inlet valve caps

Remove the 6 valve from the pump

head and replace them if wear and

tear

Unstick the valve from its seat

pressing gently with a pin.

Reassemble the caps using sealing

glue type Loctite 542.

Pag. 16

2e Clean the high pressure nozzle and if necessary, replace it with a new genuine part.

Check the spare part book in order to identify the nozzle size.

The nozzles are colored with different colors to make possible the identification of their size, the

part number description include the color information (see the part manual for PW-C25).

We recommend the high pressure nozzle replacement every 200 hours or any time the machine

working pressure become 20% lower than rated pressure.

Unscrew the nozzle using an Allen key

size 2 mm.

Clean the nozzle orifice with

the help of a steel wire

diameter ≤ 1 mm.

Pag. 17

3. No pressure to the lance

3) TROUBLE: The high pressure pump rotates, but doesn’t achieve the rated pressure or the

pressure is not stable and fluctuates.

CAUSES: 3a Defective water feeding connection

3b Inlet water filter clogged

3c Air intake from the water feeding circuit

3d Pump head valves ceased or worn

3e Lance nozzle set in low pressure mode (detergent mode)

3f High pressure nozzle worn or deformed

3g Pressure adjusting valve setting at minimum position

3h Seat of pressure adjusting valve damaged

3i Pump gaskets worn or water leaks from the pump head

REMEDIES:

3a Check the feeding water flow (l/min), in order to ensure that feeding water available is

sufficiently high compared with the machine characteristics.

The feeding water flow (l/min) must exceed at least 10%, than the water flow characteristics

declared in the machine data plate.

Check the fittings to the water inlet circuit and particularly ensure they are not damaged or not

properly sealed, causing flow obstruction or air intakes.

3b Check and clean the water inlet filters and if necessary, replace them.

We recommend to check the water filter every 50 hours (or every week)

Pag. 18

3c Check the water circuit that connects the water to the high pressure pump inlet, particularly

check that fittings are properly tightened and not leaking water.

In case of leakages, proceed with the circuit repair.

If the machine is in-taking water from an external tank, being its high pressure pump, not

designed for self priming, is possible that its working pressure being lower and the machine can

operate under this condition only temporarily, we do not recommend to use this machine

continuously as self-priming.

The maximum deep to allow this pump self priming is 50 cm.

3d Check the inlet and outlet valves placed into the pump head; if the valves are sticky, unstick

the valve from its seat manually pressing gently the valve disk until released.

If the valves are dirty, disassemble them and clean.

If the valves are worn or deformed, replace them and also replace the o-ring placed under the

valves.

We recommend the replacement of inlet and outlet valves every 500 hours or one a year.

Check wear and

tear of the o-ring

Pag. 19

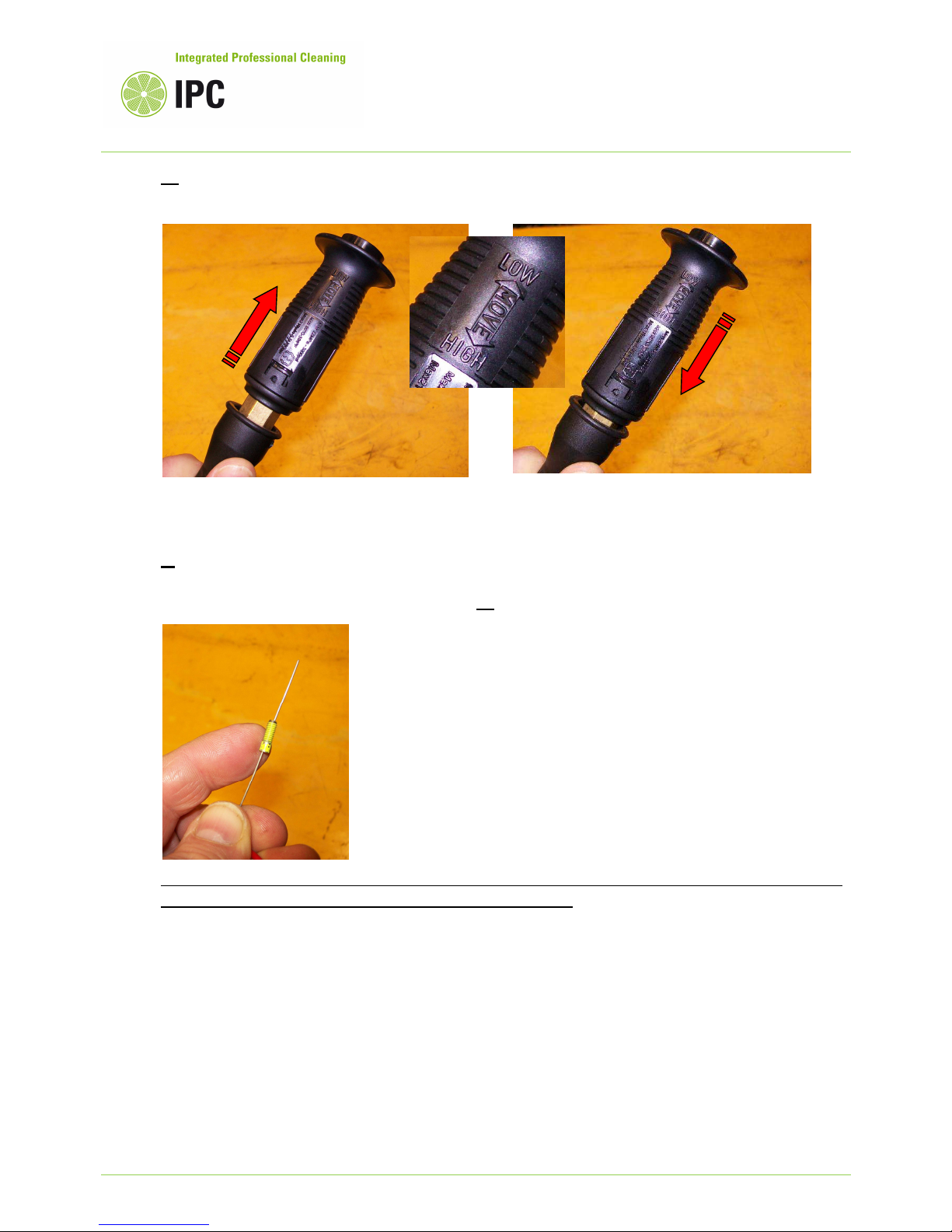

3e Check the lance head (nozzle) position, it must be set in high pressure mode, not in detergent

mode; during the detergent mode the water flow is discharged without pressure.

3f Replace the high pressure nozzle with a new genuine part.

Check the spare part manual to identify the correct nozzle size.

Instruction to disassembling the nozzle: see 2e

We recommend the high pressure nozzle replacement every 200 hours or any time the machine

working pressure become 20% lower than rated pressure.

Detergent mode

High pressure mode

Pag. 20

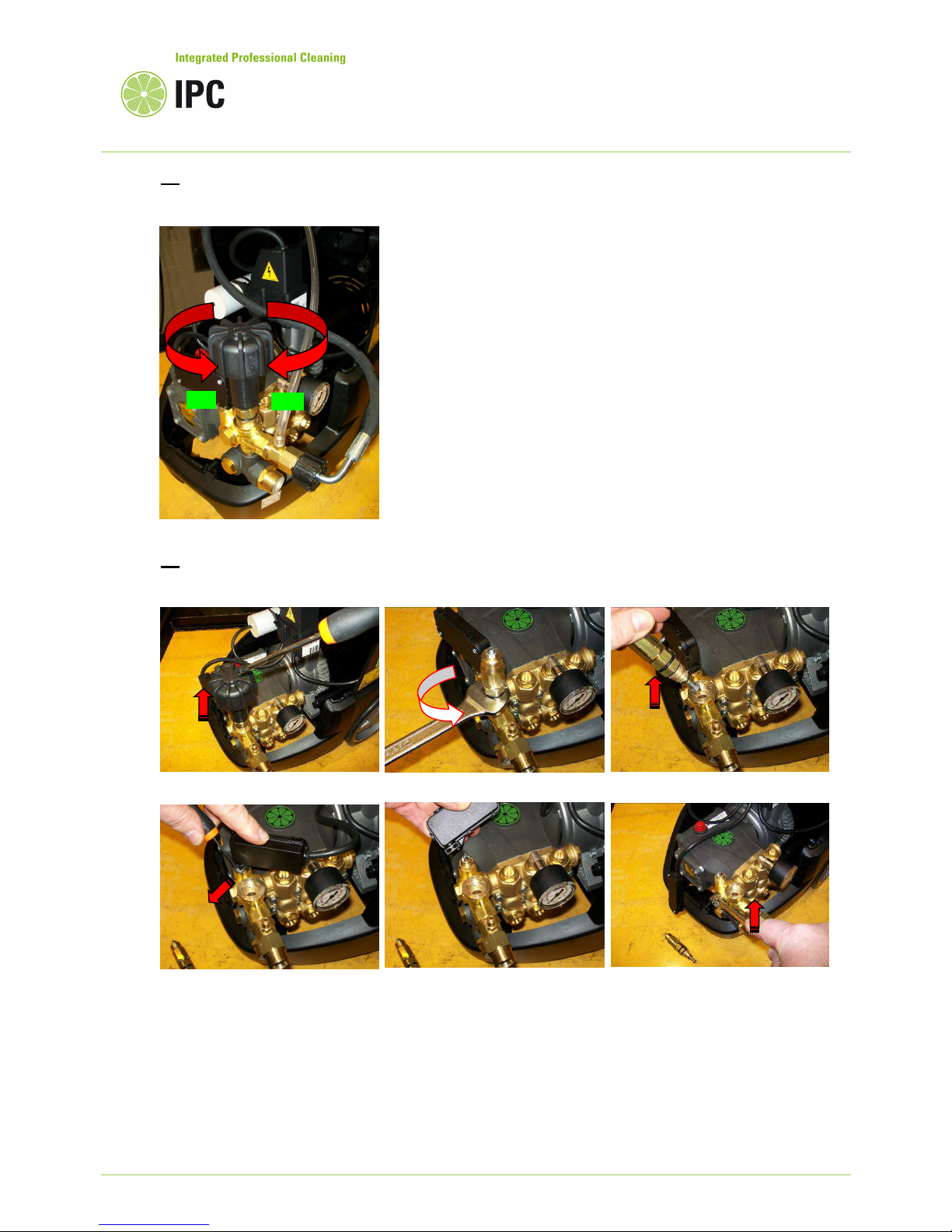

Strip out the switch box

Unscrew the fixation bolt of

the by-pass place at the

high pressure side.

3g Check if the pressure adjusting knob is set to maximum position.

The position maximum is when the knob it fully rotated clockwise.

3h Repair the pressure adjusting valve (by pass valve) by replacing its cartridge that is part of

the dedicated repairing kit.

Remove the knob by pulling it out

Unscrew the valve cartridge

Strip out the valve

Remove the pin holding the switch

MAX

MIN

Pag. 21

Slide out the fixation bolt

of

the by-pass

The by

-

pass valve is so

disassembled, if necessary

it can be replaced with a

new one.

To disassemble the

by-pass

seat, push it out with the

help of a screwdriver, as in

the picture.

To disassemble the by

-

pass

piston, slide out and

remove the locking pin.

To disassemble the by

-

pass

piston, push out and

remove the locking pin.

The by

-

pass system is now completely disassembled

and can be repaired or replaced by a new by-pass repair

kit.

To

reassemble the by

-

pass

whole cartridge to the bypass valve, we recommend

the use of Loctite 542.

Pag. 22

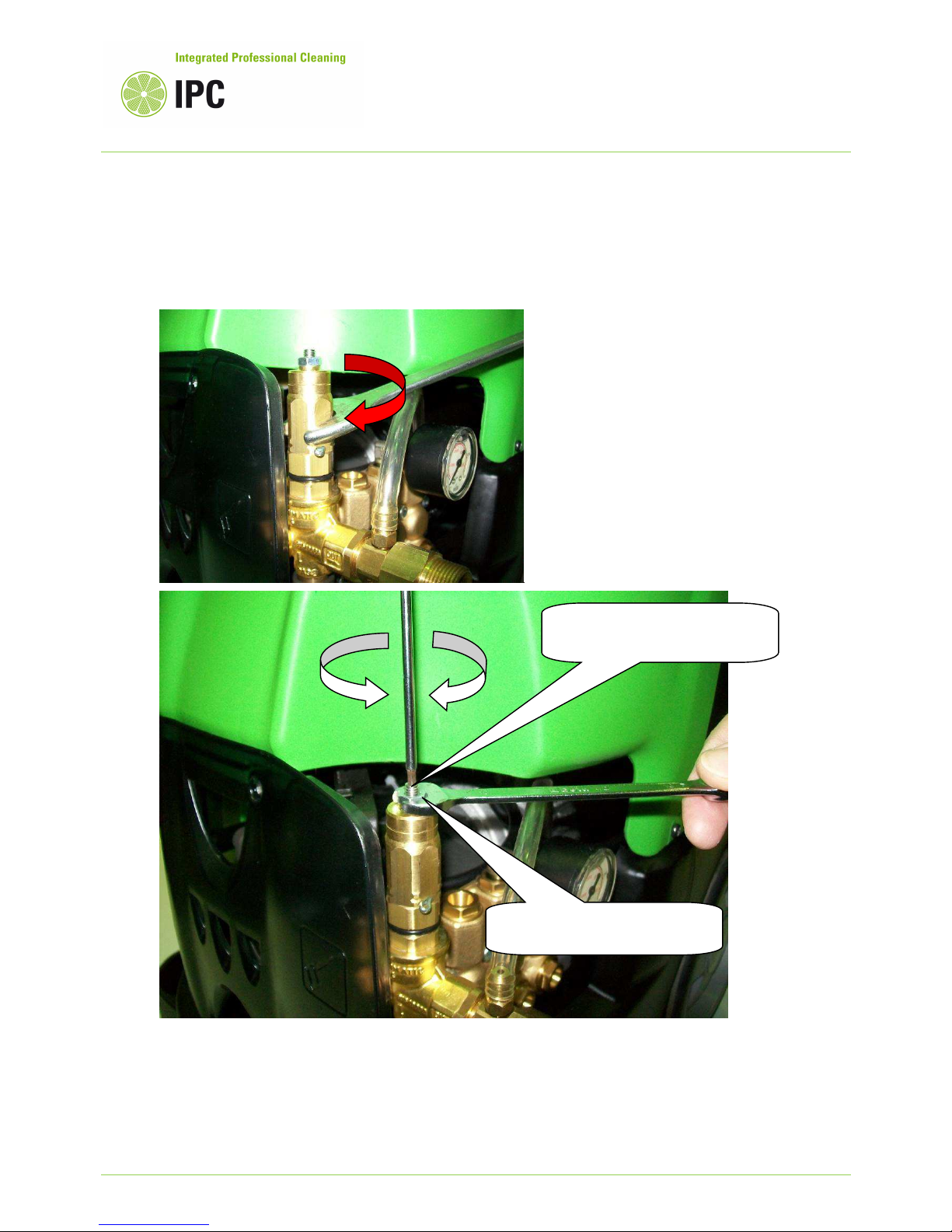

Before adjust the bypass, maximum pressure

setting, ensure that the pressure adjust knob is

completely screwed-in.

After replaced the by-pass valve kit, will be necessary to readjust the machine maximum working

pressure.

The pressure adjustment can be done trough the adjusting screw as indicated in the following

picture:

In order to readjust the machine pressure setting, the lance high pressure nozzle must be

brand new; for setting values, check the pressure characteristics indicated in the machine data

plate.

The working pressure setting can be done looking at the pressure displayed to the machine

pressure gauge.

Nut to lock the maximum

pressure setting

Nut

for

maximum

pressure limit.

- Press

+ Press

Pag. 23

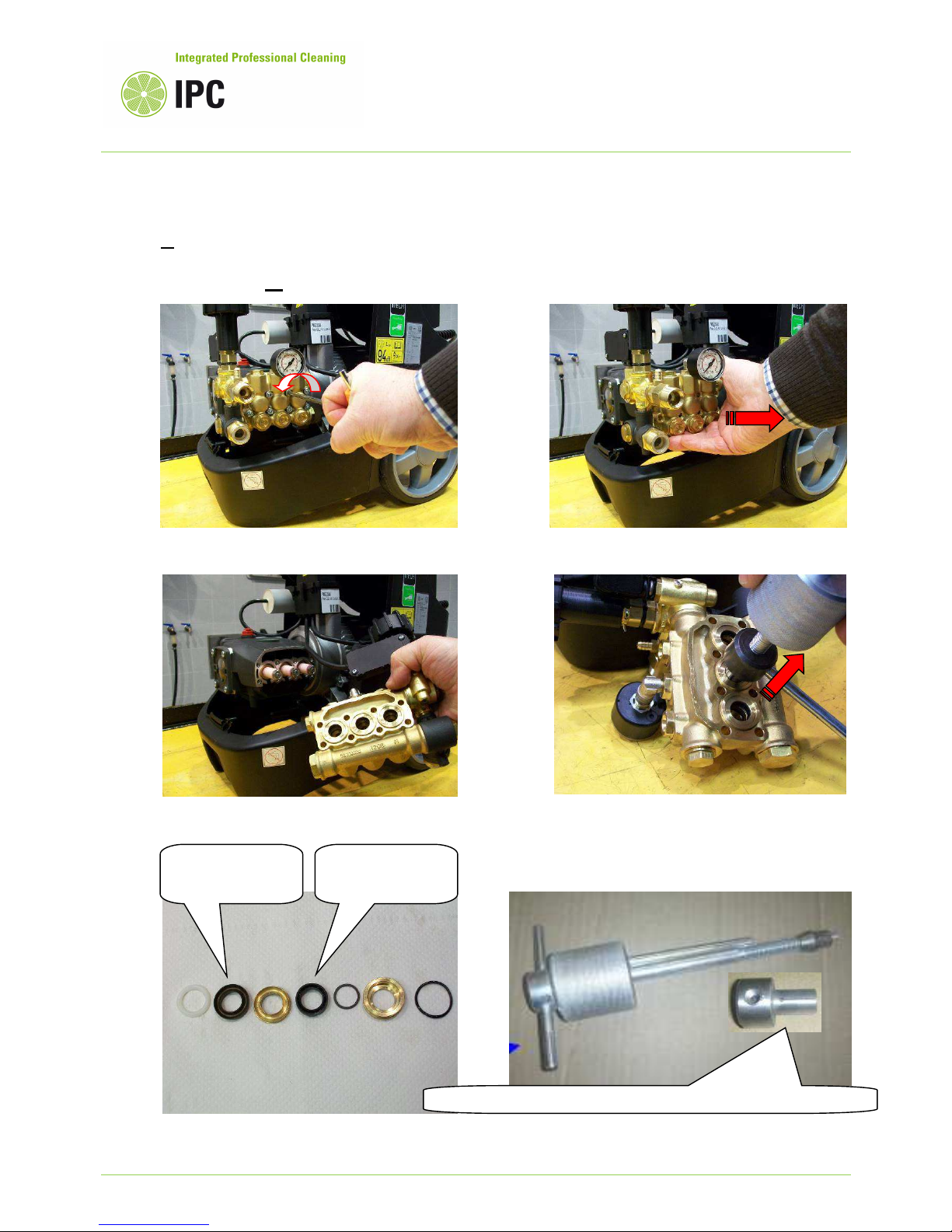

3i Replace the high pressure pump gaskets kit and ensure that the ceramic pistons are not

damaged. If ceramic pistons are cracked, replace them following the instruction as described in

the paragraph 5c.

Unscrew the 6 screws that hold the pump head

Pull out the

pump head

Remove the pump head

Tool head AZMC10761

for gaskets with diameter

15

Extract the seals packing using the extractor

tool part number PVVR31382.

High pressure

gasket

Low pressure

gasket

Pag. 24

4. Poor detergent delivery

4) TRUBLE: Poor detergent delivery

CAUSES: 4a Detergent tap closed/off or clogged

4b Empty detergent tank or nozzle not set in detergent mode

4c The check valve of the detergent circuit is sticky or clogged

4d High pressure outlet pipes clogged or too much extended (over 20 m)

4e Pressure regulator is not set at maximum position

4f Wear and tear of the detergent nozzle

REMEDIES:

4a Check first if the tap for detergent adjust is open.

If it is open, but doesn’t allow the detergent suction, it may be defective and not functioning (i.e.

clogged), hence replace it with a new one.

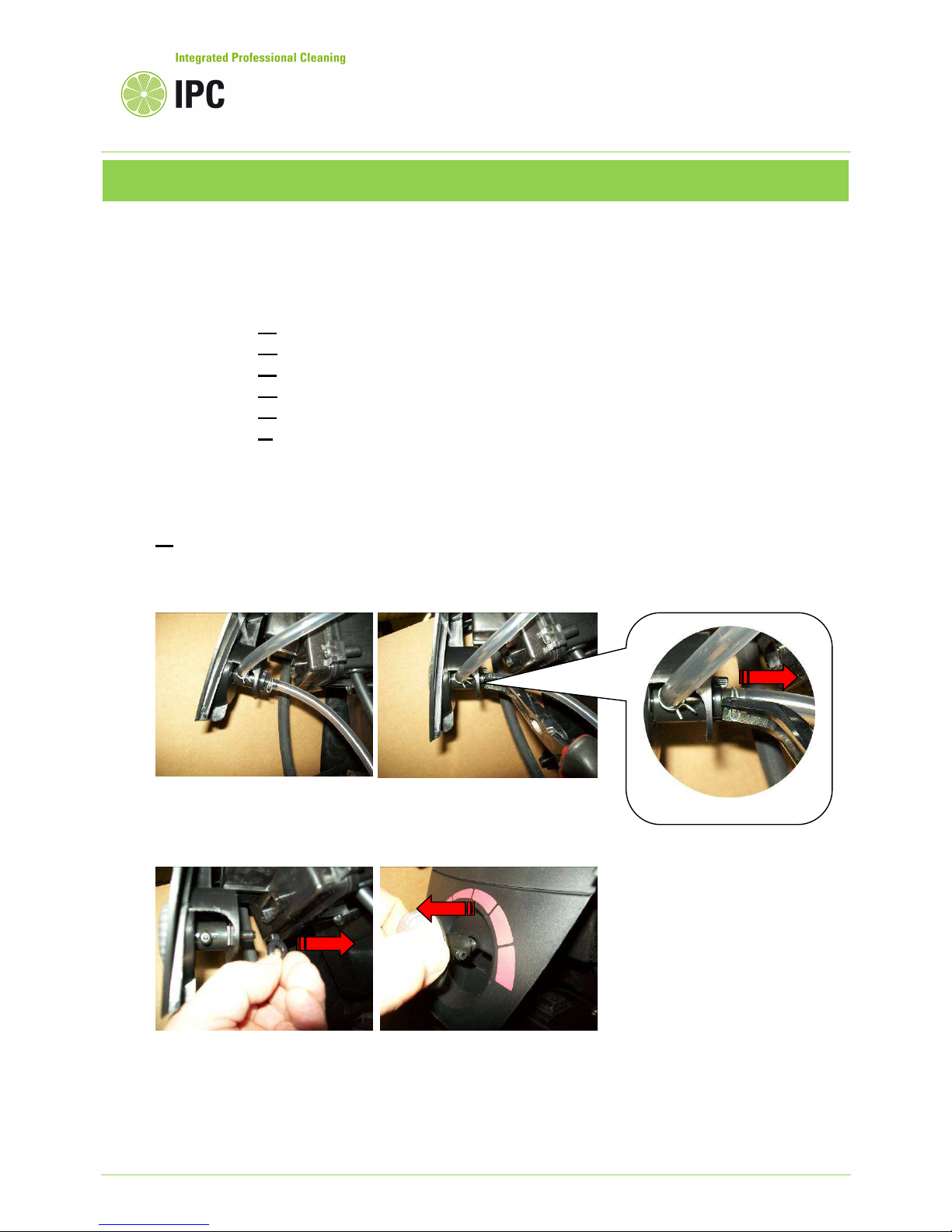

The access to the

detergent

tap is possible just after the

machine cover has been

Remove the clips that hold the

pipes.

Remove the detergent tap

holding ring.

Slide out the detergent tap

and replace it if necessary.

Pag. 25

4b Refill with detergent the chemical tank if it is empty; we recommend to use only the

detergents listed in the catalogue.

Switch the head to the lance in detergent mode (LOW).

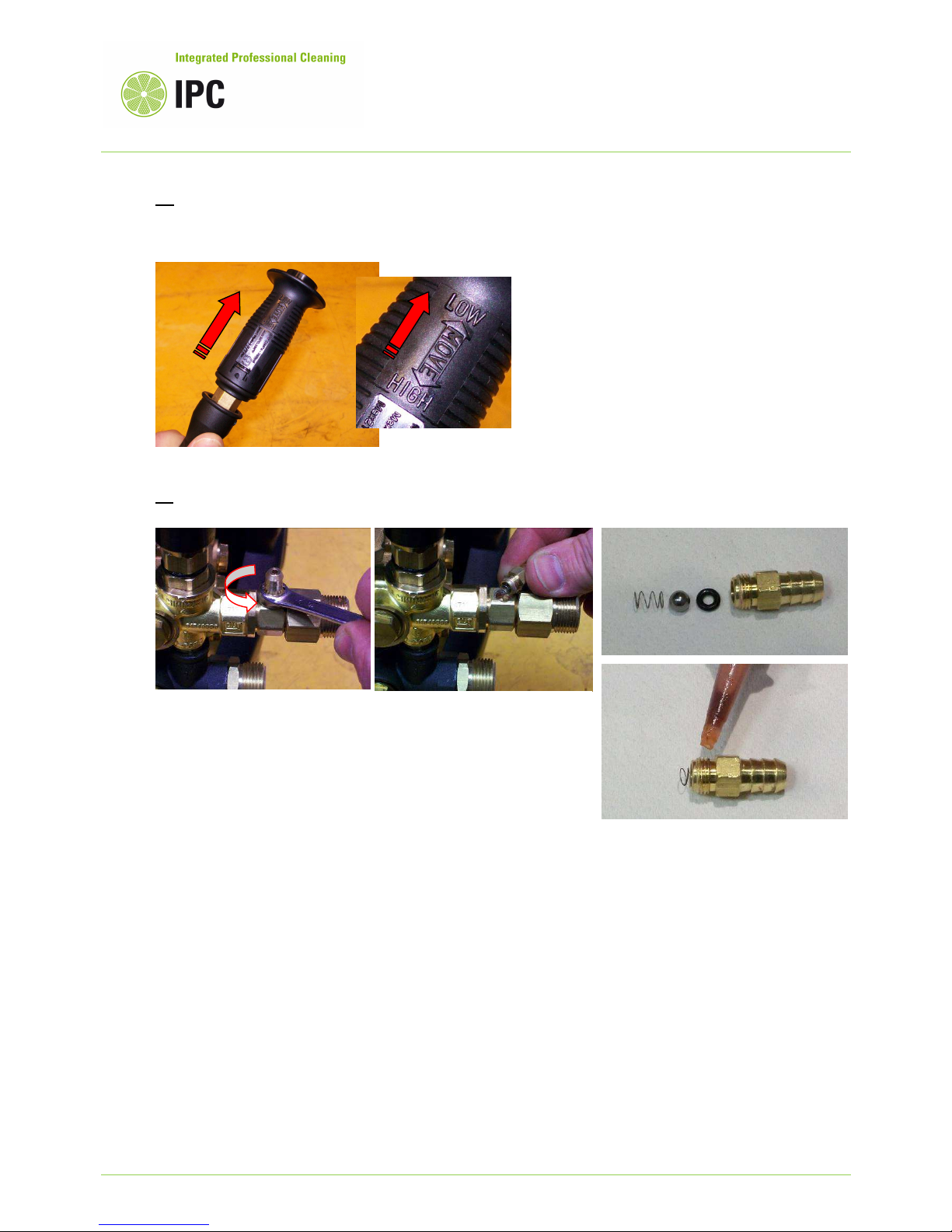

4c Dismantle and clean the detergent check valve.

Check the cleanness of o-ring, ball and spring that are inside of the valve and replace them if

wear and tear.

Reassemble using some sealing glue, we recommend Loctite 542.

Unscrew and dismantle the detergent check valve

placed at the

machine outlet.

Pag. 26

4d If using an high pressure hose longer than 20 m, the detergent suction can result

compromised, since the Venturi system cannot work.

At the same, a wrong functioning occurs when the high pressure outlet circuit of the machine is

clogged or when using not genuine accessories.

Reduce the length of the high pressure hose at maximum 20 m and ensure that there are not

obstruction to the outlet circuit that causes counter pressure, hence not allowing the functioning

of the Venturi system.

The Venturi system can be wear and tear and in case has to be replaced as following described:

4e Adjust the machine working pressure at maximum position.

Unlock the nut that avoid the

rotation of the outlet fitting.

Unscrew the Venturi system.

Replace, if necessary, the whole

Venturi nozzle and note that the

Venturi holds the outlet check

valve of the by pass.

The outlet check valve is part of

the by-pass and can be wear and

tear, if necessary replace it with a

new one while checking the

Venturi.

Reassemble the Venturi using a

bit of Loctite 542 to seal the

threads.

MAX

Pag. 27

5. Oil and water emulsion phenomena to the high pressure pump oil

5) TROUBLE: The oil, inside of the high pressure pump looks white color (oil and water

emulsion phenomena)

CAUSES: 5a Extremely high environment humidity percentage

5b High pressure pump gaskets worn

5c High pressure pump pistons damaged

REMEDIES:

5a Replace the pump oil using oil quality SAE 20W40:

Unscrew the cap “A” in order to drain the oil from the high pressure pump; wait until the oil being

totally drained out to the recovery tank.

Oil, must be wasted in compliance with the country rules in force for oils. Screw the cap “A” and

refill the oil into the pump from the port “B”; the oil level is detectable from the oil window .

We recommend a proper ventilation of the place where the machine operates, in order to reduce

as much as possible the environment humidity percentage.

OIL WINDOW

Pag. 28

5b Replace the pump water gaskets as described in the section 3i

5c Replacement of the pump pistons:

Check if pistons are cracked

Unscrew the piston lock screw

Slide out the damaged piston

Assemble the new piston and

secure the screw with “Loctite

541” glue.

Tighten

the screw at max. torque 15Nm

Check the o-ring wear

If the o

-

ring is wear and tear

replace it with a new one.

Max. torque 15 Nm

Pag. 29

6. The total stop system doesn’t intervenes

(only for machines having this option)

6) TROUBLE: When the spray gun trigger is released, the pump and motor unit does not stop

automatically or does not restart, when the trigger is reactivated.

CAUSES: 6a Water leaks from the high pressure outlet circuit.

6b Micro-switch of the by-pass valve, or contactor, not functioning.

REMEDIES:

6a Check the if the outlet check valve, placed at the outlet of the by-pass , is worn or teared.

If damaged, replace the whole check valve or only the o-ring if damaged.

Check and remove any water leak from the outlet circuit and particularly check the high pressure

hose couplings and the spray gun.

When the spray gun trigger is released, the outlet circuit is under pressure and this is necessary

to maintain the machine in total stop phase. Any water leak, can cause the restart of the machine

and as consequence the total stop failure.

6b Check the micro-switch of the by-pass valve and the piston that activates the switch as

described in the section 1c.

Check the contactor as described in the section 1d.

The outlet check valve is part of

the by-pass and can be wear and

tear, if necessary replace it with a

new one.

Pag. 30

Periodical maintenance

Every

day

Every

50h

Every

100h

Every

200h

Every

300h

Every

500h

Every

year

Check the power cord and the high pressure quick couplings.

First pump oil replac ement

P u m p o i l r e p l ac e m e n t

Water feedi ng filters clean ing

Pump’s water gaskets replacement

High pressure nozzle replacement

Check and adjust of the safety devices or components

Repairing kits

For a quicker and easier maintenance and repair of this model, some repair kits are available as

following shown.

In order to identify their part number accordingly to the machine model, please refer to this machine's

spare parts manual.

Pump gasket kit

Pump valves kit

Pump oil seals kit

Loading...

Loading...