CT80 - CT81 - PT80 - LAVAMATIC 80

MANUALE ISTRUZIONI PER L’USO /

OPERATOR’S MANUAL / MANUEL D’INSTRUCTIONS /

BEDIENUNGSANLEITUNG /

MANUAL DE INSTRUCCIONES / BRUKERHÅNDBOK /

GEBRUIKERSHANDLEIDING / MANUAL DE UTILIZAÇÃO /

INSTRUKTIONSBOK / МАШИНА ДЛЯ МОЙКИ И СУШКИ ПОЛОВ /

KULLANIM KILAVUZU

Consultare attentamente questo manuale prima di procedere a qualsiasi intervento sulla macchina

Read this manual carefully before carrying out any work on the machine

Lire attentivement ce manuel avant toute intervention sur la machine

Vorliegendes Handbuch vor jedem Eingri an der Maschine aufmerksam durchlesen

Consulte detenidamente este manual antes de llevar a cabo cualquier trabajo en la máquina

Konsulter denne håndboken nøye før du går i gang med noen som helst type inngrep på maskinen

Raadpleeg deze handleiding aandachtig alvorens met enige werkzaamheid aan de machine te beginnen

Consulte atentamente este manual antes de efectuar qualquer intervenção na máquina

Läs noggrant igenom denna handbok innan du utför något som helst ingrepp på maskinen

Внимательно ознакомьтесь с данной инструкцией до проведения любой работы с машиной

Makine ile herhangi bir işlem yapmadan önce bu kılavuzu dikkatle okuyun

ENGLISH

(Translation of original

instructions)

GB

2

TECHNICAL SPECIFICATIONS ............................................................................. 4

MACHINE DIMENSIONS ........................................................................................ 6

SAFETY SYMBOLS ................................................................................................7

GENERAL INFORMATION ..................................................................................... 8

Purpose of this manual .................................................................................................................. 8

Identifying the machine .................................................................................................................. 8

Documentation provided with the machine .................................................................................... 8

TECHNICAL INFORMATION .................................................................................. 9

General description ........................................................................................................................ 9

Parts of the machine ...................................................................................................................... 9

Danger zones ................................................................................................................................ 10

Accessories ................................................................................................................................... 10

SAFETY INFORMATION .......................................................................................11

Safety precautions ........................................................................................................................ 11

MOVEMENT INSTALLATION ...............................................................................14

Lifting and transporting the packaged machine ............................................................................ 14

Delivery checks ............................................................................................................................. 14

Unpacking ..................................................................................................................................... 14

Batteries (Battery version)............................................................................................................. 14

Batteries: preparation .................................................................................................................... 15

Batteries: installation and connection............................................................................................ 15

Batteries: removal ......................................................................................................................... 16

Choosing a battery charger ........................................................................................................... 16

Preparing the battery charger ...................................................................................................... 16

Squeegee installation and adjustment .......................................................................................... 17

Squeegee adjustment ................................................................................................................... 17

Brush installation ........................................................................................................................... 18

Lifting and transporting the machine ............................................................................................. 19

PRACTICAL GUIDE FOR THE OPERATOR .........................................................20

Preparing the machine for work .................................................................................................... 20

Controls ......................................................................................................................................... 21

Working ......................................................................................................................................... 24

Some useful tips to get the most from your scrubber drier ........................................................... 24

Emptying the collection tank: ........................................................................................................ 24

Emptying the water/detergent tank ............................................................................................... 25

Filling the water/detergent tank ..................................................................................................... 25

Filling the Chem-Dose tank (accessory) ....................................................................................... 26

Finishing work ............................................................................................................................... 26

Moving the machine when not in operation................................................................................... 26

PERIODS OF INACTIVITY ....................................................................................27

MAINTENANCE INSTRUCTIONS ......................................................................... 28

Maintenance - General rules ......................................................................................................... 28

Cleaning the suction motor air lter............................................................................................... 28

Cleaning the water/detergent tank lter ........................................................................................ 29

Cleaning the dirty water tank oat ................................................................................................. 29

Fuses: replacing ............................................................................................................................ 30

Battery maintenance and charging ............................................................................................... 32

Replacing the squeegee blades .................................................................................................... 33

Pushing and pulling the machine: ................................................................................................. 34

Periodic checks ............................................................................................................................. 35

TROUBLESHOOTING ........................................................................................... 36

DISPLAY ALARMS ................................................................................................37

TECHNICAL MENU ...............................................................................................39

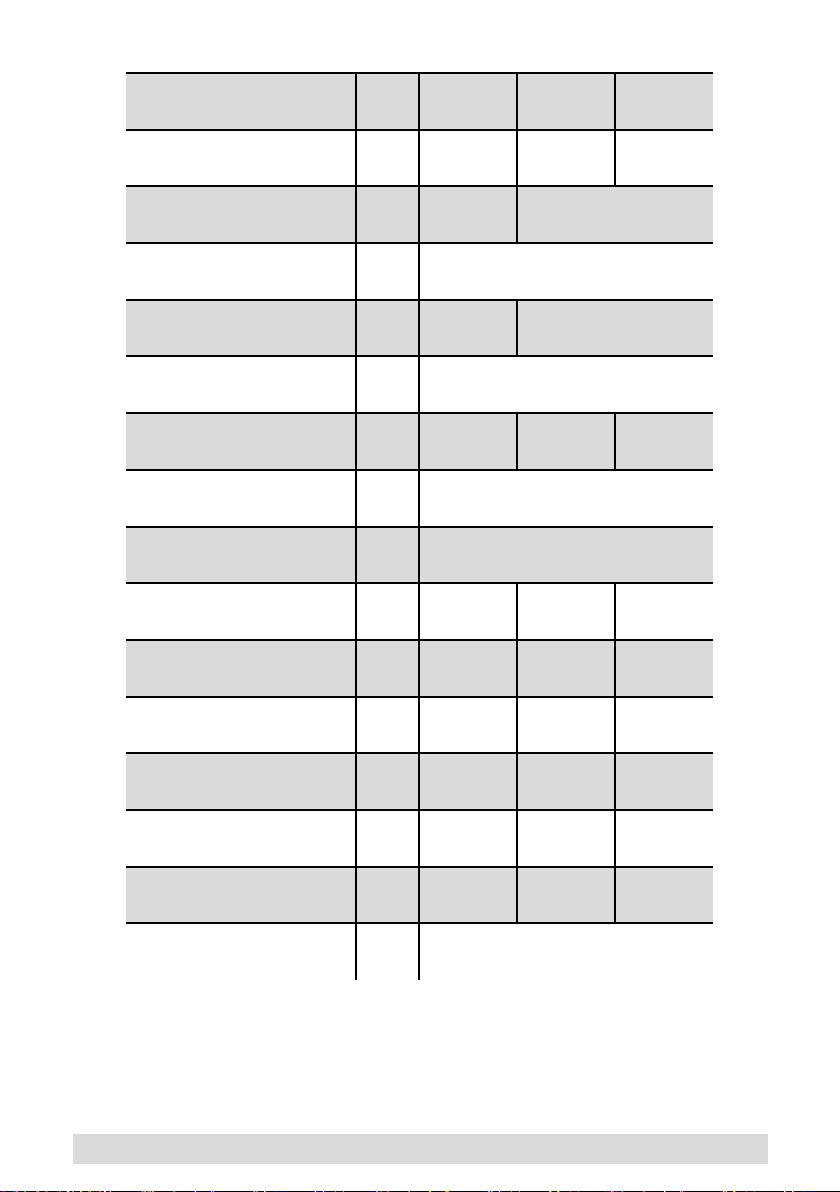

TECHNICAL SPECIFICATIONS

55 60 70

Cleaning width mm 530 614 678

Squeegee width mm 710 942

Cleaning capacity per hour m

Number of brushes n° 1 2

Brush diameter mm 530 310 345

Maximum brush pressure g/cm

Brush rotation speed g/1° 150 220

Brush motor power W 400 2 x 400

Drive motor power W 300

Maximum speed Km/h 6

Suction motor power W 480 (2 stadi) 480 (3 stadi)

Solution tank L 75

Dirty water tank L 80

2

/h 3180 3684 4068

2

10,3 62,6 43,7

Rear wheel diameter mm 225

Maximum slope % 8 16

GB

4

Gross weight Kg 418 430 431

Transported weight Kg 293 293 293

Number of batteries n° 2 4

Battery voltage V 12

Individual battery capacity Ah (5h) 105 180

Power system voltage V 24

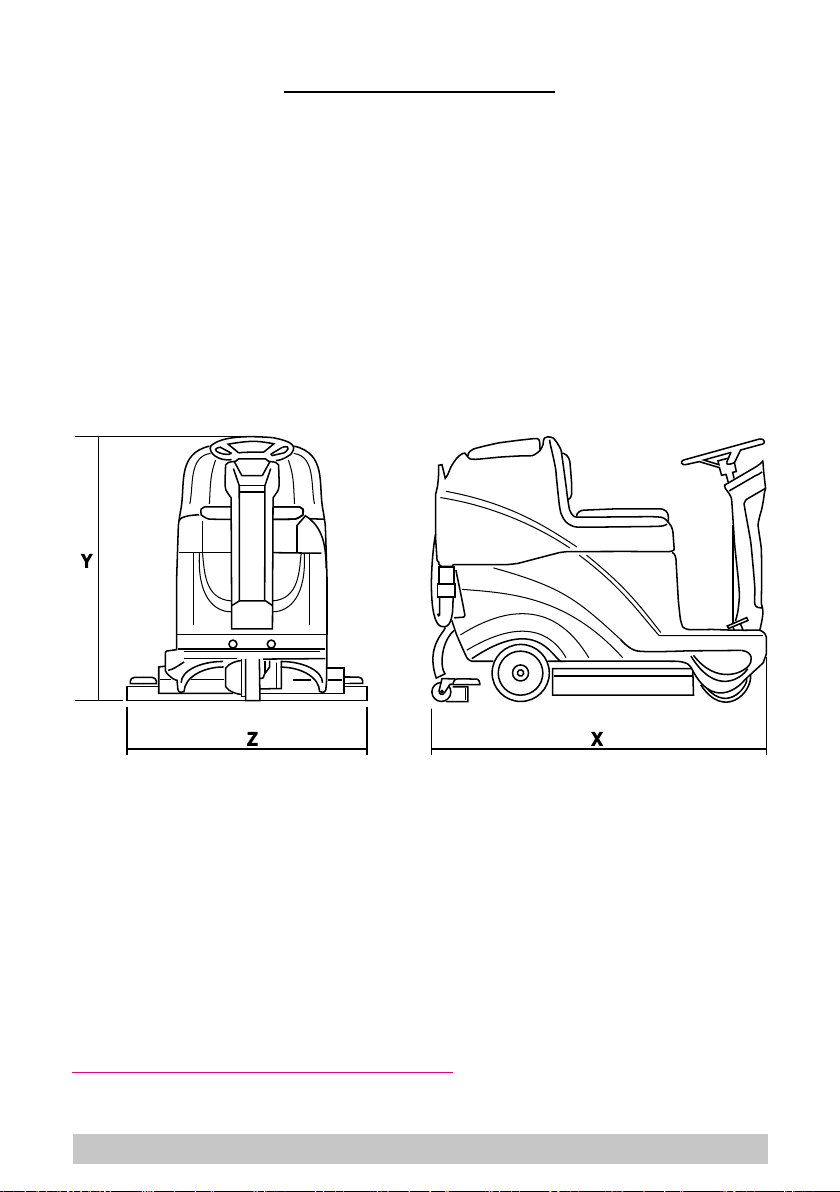

Machine dimensions mm

Battery compartment dimensions

(length, width, height)

mm 390x478x260

X=1310

Z=673

Y=1030

X=1310

Z=675

Y=1030

X=1310

Z=760

Y=1030

Packed size (length, width, height) mm 1445X795X1140

Sound pressure

Measurement uncertainty

Vibration level (hand)

LpA

(dB)

K

(dB)

HAV

m/sec2

67 69 69

3,2 3,2 3,2

1,5 1,3 1,3

Measurement uncertainty, k m/sec2 0,8 0,6 0,6

Vibration level (body)

HBV

m/sec2

0,6 0,6 0,6

Measurement uncertainty, k m/sec2 0,3 0,3 0,3

Maximum water and detergent

temperature

°C da 4 a 55

Data subject to variation without warning.

GB

5

MACHINE DIMENSIONS

X-Y-Z: See “TECHNICAL SPECIFICATIONS” table

GB

6

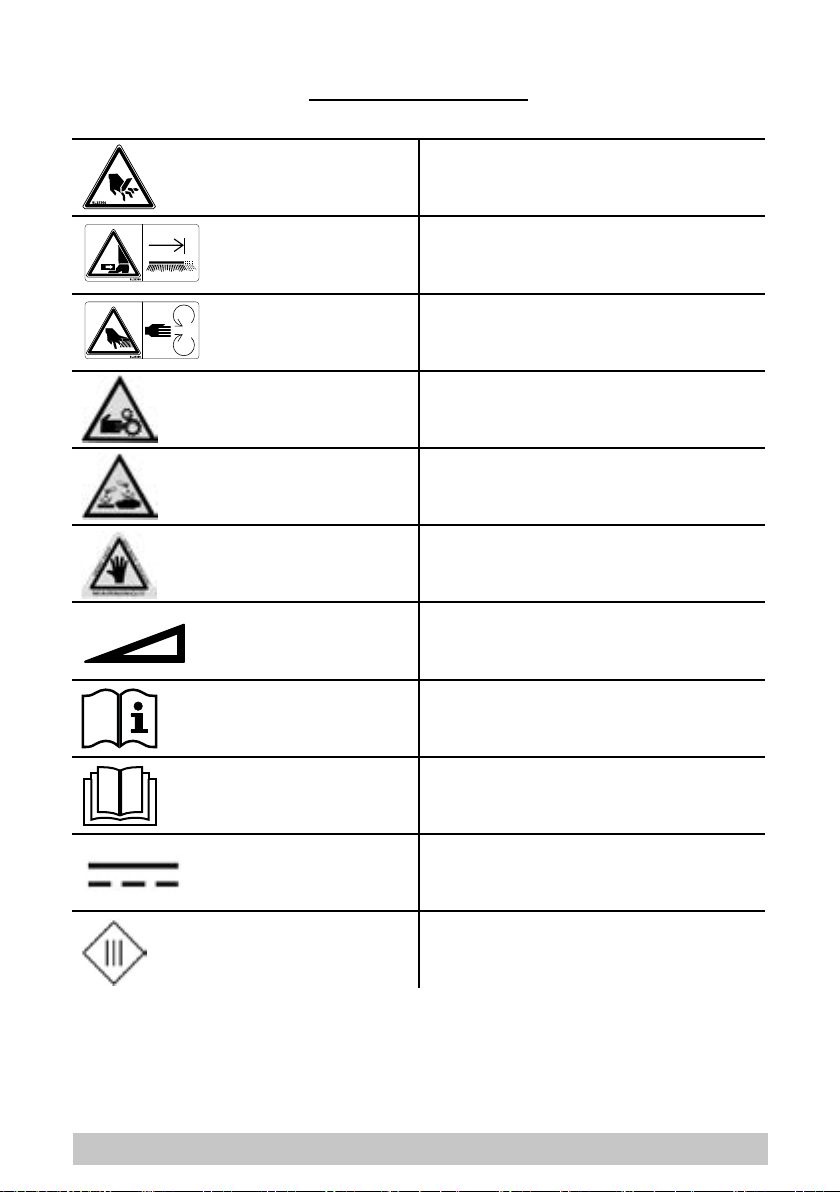

SAFETY SYMBOLS

WARNING! RISK OF CUTTING

WARNING! RISK OF CRUSHING LIMBS

WARNING! RISK OF ABRASION

WARNING! RISK OF ENTANGLEMENT

WARNING! RISK OF ACID BURNS

WARNING! RISK OF BURNS

MAXIMUM SLOPE

OPERATOR’S MANUAL, OPERATING INSTRUCTIONS

READ THE OPERATOR’S MANUAL

DIRECT CURRENT SYMBOL

INSULATION CLASS, THIS CLASSIFICATION ONLY APPLIES TO MACHINES POWERED BY BATTERIES.

GB

7

Purpose of this manual

GENERAL INFORMATION

This manual has been written by the Manufacturer and is an integral part of the machine1.

It denes the purpose for which the machine has been designed and constructed and contains all

the information required by operators2.

In addition to this manual, which contains information for operators, other publications are available

providing specic information for maintenance personnel3.

The terms “right” and “left”, “clockwise” and “anti-clockwise” refer to the forward movement of the

machine.

Constant compliance with the instructions provided in this manual guarantees the safety of the op-

erator and the machine, ensures low running costs and high quality results and extends the working

life of the machine. Failure to follow these instructions may lead to injury to the operator or damage

to the machine, oor and environment.

Consult the table of contents at the beginning of the manual to nd the section you need rapidly.

Parts of the text requiring special attention are printed in bold and preceded by the symbols illus-

trated and described here.

Indicates the need for attention in order to avoid a series of consequences which could

cause death or serious injury to personnel.

! DANGER!

Indicates the need for attention in order to avoid a series of consequences which could

cause injury to personnel or damage to the machine or work environment or nancial loss.

In line with the company’s policy of constant product development and updating, the Manu-

facturer reserves the right to make modications without prior notice.

Although your machine may dier appreciably from the illustrations in this document, the

correctness and validity of the instructions contained in this manual are guaranteed.

! WARNING!

! IMPORTANT!

Important information.

Identifying the machine

The nameplate provides the following information:

► Model

► Battery voltage

► Total rated power

► Rated current draw

► Serial number

► Year of manufacture

► IP Index of Protection

► Dry weight

► Maximum negotiable gradient

► Name of manufacturer

Documentation provided with the machine

► Operator’s manual

► Certicate of warranty

► CE certicate of conformity

1 The denition "machine" replaces the trade name covered by this manual.

2 Persons responsible for using the machine without performing any operations requiring precise technical skills.

3 Persons with experience, technical training and a knowledge of legislation and standards, able to perform all the

necessary operations and to recognise and avoid possible risks in handling, installation, use and maintenance of this

machine.

GB

8

TECHNICAL INFORMATION

1

4

3

2

5

General description

This machine is a scrubber drier for sweeping, washing and drying at, horizontal, smooth or moderately rough, even and obstacle free oors in civil and industrial premises.

The scrubber drier spreads a solution of water and detergent in the correct concentration on the

oor and then scrubs it to remove the dirt. By carefully choosing the detergent and brushes (or

abrasive disks) from the wide range of accessories available, the machine can be adapted to a wide

range of combinations of types of oor and dirt.

A suction system incorporated in the machine dries the oor after washing by means of the low

pressure generated in the dirty water tank by the suction motor. The squeegee connected to the

tank collects the dirty water.

Parts of the machine

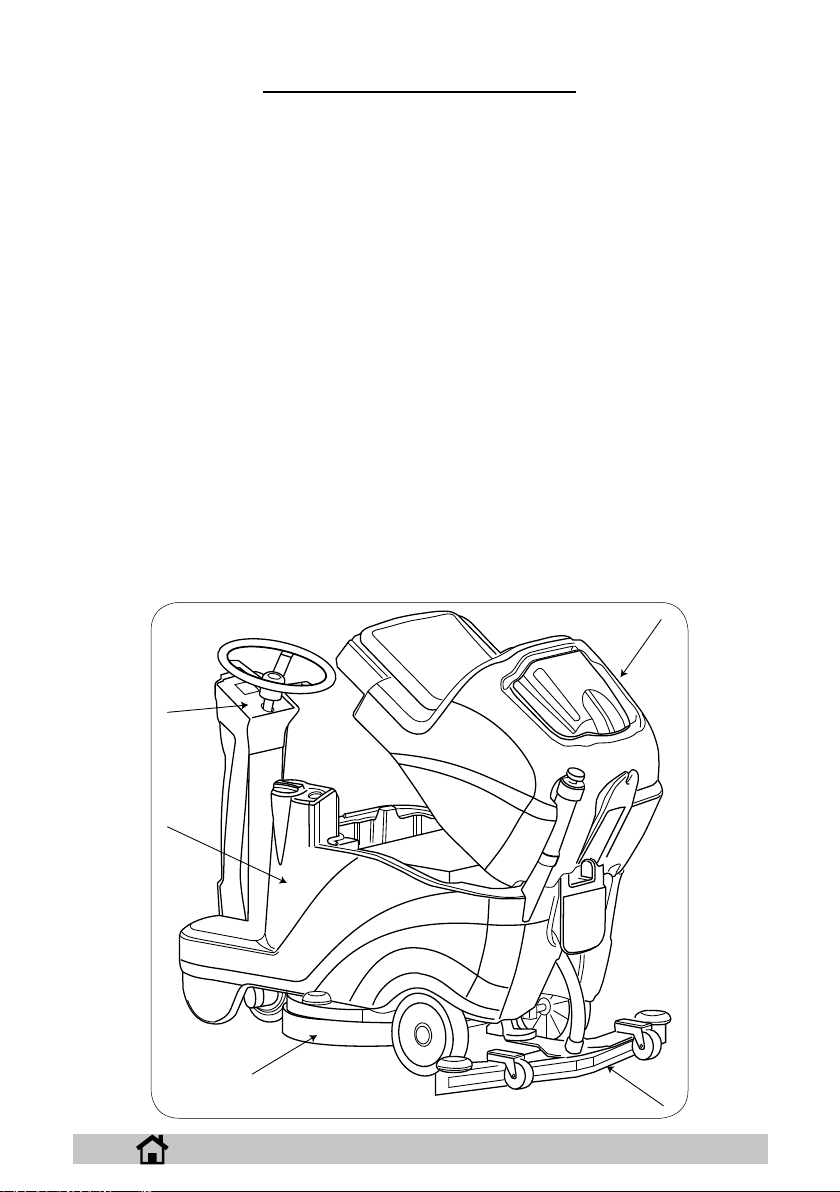

The machine comprises the main parts described below (g. 1).

► The water/detergent tank (g. 1, ref. 1) contains and carries the mixture of clean water and

cleaning product.

► The dirty water tank (g. 1, ref. 2) collects the dirty water picked up from the oor after

washing;

► Control panel (g. 1, ref. 3).

► Head assembly (g. 1, ref. 4), the main element comprises the brushes/rollers which dis-

tribute the detergent solution onto the oor and remove the dirt.

► Squeegee assembly (g. 1, ref. 5): wipes and dries the oor by collecting the water.

1

GB

9

Danger zones

► Control panel: risk of injury from short circuits.

► Tank assembly: when using certain detergents, danger of irritation for eyes, skin, mucous

membranes and respiratory tract and of asphyxia. Danger represented by the dirt collected

from the environment (germs and chemical substances). Danger of crushing between the

two tanks when the dirty water tank is replaced on top of the detergent tank.

► Washing head assembly: danger due to brush rotation.

► Front/rear wheels: risk of crushing between the wheels and chassis.

► Danger of short circuit between the battery poles and presence of hydrogen during charg-

ing.

Accessories

► Soft, hard and abrasive brushes.

► Chem-Dose tank.

► NORD ELETTRONICA NE284 battery charger for single-brush version

► S.P.E. CBHD3 battery charger for double-brush version

GB

10

SAFETY INFORMATION

Safety precautions

Read this Operator’s Manual carefully before start-up and use and before performing any

maintenance or other work on the machine.

! DANGER!

Rigorously follow all the instructions in this Operator’s Manual (in particular those marked

“Danger!” and “Warning!”. Also respect the safety labels applied to the machine (see the

The Manufacturer declines all liability for injury to persons or damage to property resulting

from failure to follow instructions.

The machine must be used exclusively by persons trained in its use and/or who have demonstrated

their ability and have been expressly authorised to use it.

The machine must not be used by minors.

The machine must not be used for purposes other than those for which it was expressly designed.

Scrupulously respect all safety standards and conditions applicable to the type of building in which

the machine is to be operated (e.g.: pharmaceutical companies, hospitals, chemicals, etc.).

This machine is intended for use in commercial applications, such as hotels, schools, hospitals,

factories, shops and oces, or for hire.

The machine must only be used indoors.

Do not use the machine without a protection structure (FOPS) in areas where the

operator could be struck by falling objects.

Warning, the machine must be kept in closed environments at all times.

Do not use the machine in inadequate lighting, explosive atmospheres, on public roads, to clean dirt

that is hazardous to health (dust, gas, etc.) or in unsuitable environments.

The machine is designed to operate in temperatures between +4°C and +40°C. It can be stored in

temperatures between +0°C and +50°C when not in use.

The machine is designed to operate at relative humidity levels between 30% and 95%.

Never use the machine to clean up ammable or explosive liquids (e.g. petrol, fuel oil, etc.), acids or

solvents (e.g. paint solvents, acetone etc.) even if diluted. Never clean up burning or incandescent

objects.

Never use the machine on slopes or ramps more than specied in “Technical specications”; never

drive sideways across even gentle slopes. Always manoeuvre with care and avoid reversing. When

transiting steeper ramps or slopes, take the utmost care to prevent tipping and/or uncontrolled ac-

celeration.

Never park the machine on a slope.

Never leave the machine unattended with the motor or engine on. Before leaving it, turn the motor

or engine o and make sure it cannot move accidentally.

Always pay attention to other people, especially children, in the place where you are working.

Children must be supervised to make sure they do not play with the machine.

The machine is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they are supervised by a person

responsible for their safety and have received instruction in the use of the machine.

Never use the machine to transport people or goods or to tow things.

Do not tow the machine.

Never rest objects of any weight on the machine for any reason.

Never obstruct the ventilation and heat dispersion openings.

Never remove, modify or circumvent safety devices.

Numerous unpleasant experiences have shown that a wide range of personal objects may cause

serious accidents. Before beginning work, remove jewellery, watches, ties, etc..

The operator must always use personal protection devices: protective apron or overalls, non-slip

waterproof shoes, rubber gloves, protective goggles and ear protectors and mask to protect the

! WARNING!

“Safety symbols” section.

GB

11

respiratory tract.

Keep hands away from moving parts.

Make sure the power sockets used for the battery charger are connected to a suitable earth system

and protected by thermal magnetic and earth leakage breakers.

Make sure the electrical characteristics of the machine (voltage, frequency, power) given on the

nameplate correspond to those of the mains electricity supply.

It is indispensable to respect the battery manufacturer’s instructions and applicable legislation. The

batteries should always be kept clean and dry to avoid surface leakage current. Protect the batteries from impurities such as metal dust.

Never rest tools on the batteries as they could cause short circuits leading to explosions.

When using battery acid, always follow scrupulously the safety instructions given in the “Batteries:

preparation” section.

Battery charger (OPTIONAL): check the power cable regularly for damage. If the power cable is

damaged, do not use the charger; to replace the cable, contact a specialist service centre.

If particularly strong magnetic elds are present, assess their possible eect on the control elec-

tronics.

To recharge the batteries, always use the battery charger supplied with the machine (when provi-

ded).

Never wash the machine with water jets.

In the case of malfunction and/or faulty operation, turn the machine o immediately (disconnecting

it from the mains power supply or batteries) and do not tamper with it. Contact a service centre

authorised by the Manufacturer.

All maintenance operations must be performed in an adequately illuminated area and only after

disconnecting the machine from the power supply.

All work on the electrical system and all maintenance and repair operations other than those explicitly described in this manual must be performed by specialist and experienced personnel only.

When lifting the dirty water tank (after having rst been emptied) to access the compartment,

the safety bracket must be inserted in position, to stop the tank from accidentally closing

! DANGER!

again (Fig. 29).

29

GB

12

Only use original accessories and spare parts supplied by the Manufacturer to guarantee safe and

problem-free operation of the machine. Never use parts removed from other machines or from

other kits.

The machine is designed and constructed to provide ten years’ service from the date of manufac-

ture shown on the nameplate. After this period, whether the machine has been used or not, it should

be disposed of according to current legislation in the country in which it is used.

It should be disconnected from the power supply, emptied of all liquids and cleaned prior to disposal.

The machine is classied as WEEE type special waste and is covered by the requirements of ap-

plicable environmental protection regulations (2002/96/EC WEEE).

The machine must be disposed of separately from ordinary waste in compliance with current legislation and standards.

If you decide to stop using the machine, remove the batteries and dispose of them through an au-

thorised recycling centre.

Also make sure that all parts of the machine that could represent a hazard, particularly to children,

are made safe.

Alternatively, return the machine to the Manufacturer for a complete overhaul.

GB

13

MOVEMENT INSTALLATION

Lifting and transporting the packaged machine

During all lifting operations, make sure the packaged machine is rmly secured to avoid it

tipping up or being accidentally dropped.

Always load/unload lorries in adequately illuminated areas.

The machine is packaged on a wooden pallet by the Manufacturer. It must be loaded on to the trans-

porting vehicle using suitable equipment (see EC Directive 89/392 and subsequent amendments

and/or additions). At destination, it must be unloaded using similar means.

A fork lift truck must always be used to lift the packaged body of the machine. Handle with care to

avoid knocking or overturning the machine.

Delivery checks

When the carrier delivers the machine, make sure the packaging and machine are both whole and

undamaged. If the machine is damaged, make sure the carrier is aware of the damage and before

accepting the goods, reserve the right (in writing) to request compensation for the damage.

Unpacking

When unpacking the machine, the operator must be provided with the necessary personal

protection devices (gloves, goggles, etc.) to limit the risk of injury.

Proceed as follows to unpack the machine.

► Cut and remove the plastic straps using scissors or nippers.

► Remove the cardboard packaging.

► Remove the bags from the battery compartment and check their contents:

this Operator’s Manual, the maintenance manual, declaration of conformity, certicate of

warranty;

battery bridges with terminals;

connector for battery charger.

Depending on the model, remove the metal brackets or cut the plastic straps xing the machine

chassis to the pallet.

Using a sloping ramp, push the machine backwards o the pallet; see the paragraph “Pushing and

pulling the machine” for details on engaging/disengaging the electric brake on the drive wheel.

Unpack the brushes from their packaging.

Clean the outside of the machine, taking care to respect safety regulations.

Once the machine is clear of the packaging, proceed to install the batteries (see the “Batteries:

installation and connection” section).

The packaging may be kept and reused to protect the machine if it is moved to another site or to a

repair workshop.

Otherwise it must be disposed of in compliance with current legislation.

Batteries (Battery version)

Two dierent types of battery may be installed on these machines:

► Leak-proof tubular batteries: these require regular checks on electrolyte level. When nec-

essary, top up with distilled water until the plates are covered. Do not over-ll (5 mm max.

above the plates).

► Gel batteries: this type of battery requires no maintenance.

Battery technical characteristics must correspond to those listed in the Technical specications sec-

tion. The use of higher capacity batteries could seriously jeopardise manoeuvrability and lead to

the drive motor overheating. Batteries with a lower capacity and weight will require charging more

frequently.

Batteries must be kept charged, dry and clean and the connections must be kept tight.

! WARNING!

! WARNING!

GB

14

Follow the instructions below to congure the machine’s software for the type of batteries

+

+

+

+

-

-

-

-

Battery

+

+

-

-

Battery

see the “Technical menu section”.

! IMPORTANT!

installed:

Batteries: preparation

During battery installation and any type of battery maintenance, the operator must be provided with the necessary personal protection devices (gloves, goggles overalls, etc.) to limit

the risk of injury. Keep clear of naked ames, avoid short circuiting the battery poles, avoid

Batteries are normally supplied lled with acid and ready for use.

If the batteries are dry, proceed as follows before installing them in the machine.

Remove the caps and ll all elements with sulphuric acid solution specic for batteries until the

plates are entirely covered (this requires at least a couple of passes for each element).

Leave the batteries stand for 4-5 hours to allow air bubbles to come to the surface and the plates

to absorb the electrolyte.

Make sure the level of electrolyte is still above the plates and if necessary top up with sulphuric

acid solution.

Close the caps.

Install the batteries in the machine (following the procedure described below).

Charge the batteries before starting up the machine for the rst time. Follow the instructions in the

“Battery maintenance and charging” section.

! DANGER!

sparks and do not smoke.

Batteries: installation and connection

Make sure you connect the terminals marked with a “+” to the positive poles of the battery.

Check that all switches on the control panel are in the “0” (o) position.

Do not check the battery charge by sparking.

Meticulously follow the instructions given below as short circuiting the batteries could

Place the batteries in the battery compartment, orienting them as shown in the drawings (gs. 2

and 3). On machines tted with two batteries, place the polystyrene spacers supplied between the

compartment and the batteries, see the drawing (g. 3)

Referring to the cable layout shown in the above diagram, connect the battery cables and bridge

terminals to the battery poles. Arrange the cables as shown in the diagram, tighten the terminals on

the poles and coat with Vaseline.

Lower the tank into the working position.

When using the machine, follow the instructions below.

Never allow the batteries to become excessively at as this could damage them irreparably.

! DANGER!

cause them to explode.

! WARNING!

2

3

GB

15

Batteries: removal

When removing the batteries, the operator must be equipped with suitable personal protection devices (gloves, goggles, overalls, safety shoes, etc.) to reduce the risk of injury. Make

sure the switches on the control panel are in the “0” position (o) and the machine is turned

o. Keep away from naked ames, do not short circuit the battery poles, do not cause sparks

and do not smoke. Proceed as follows.

► Disconnect the battery cables and bridge terminals from the battery poles.

► If necessary, remove the devices xing the battery to the base of the machine.

► Lift the batteries from the compartment using suitable lifting equipment.

! DANGER!

Choosing a battery charger

Make sure the battery charger is compatible with the batteries to be charged.

Tubular lead batteries: an automatic charger is recommended. Consult the battery charger manufacturer and manual to conrm the choice.

Gel batteries: use a charger specic for this type of battery.

Use CE-marked battery chargers that comply with the relevant product standards (EN603352-29), featuring double or reinforced insulation between input and output, and a SELV output

! DANGER

circuit.

Preparing the battery charger

If you wish to use a battery charger not provided with the machine, you must t it with the connector

supplied with the machine.

The connector supplied for the external battery charger is suitable for cables with a minimum cross-

section of 16 mm2.

Proceed as follows to t the connector:

Remove about 13 mm of protective sheath from the red and black cables of the battery charger.

Insert the wires into the connector contacts and squeeze them forcefully with suitable pliers.

Respect the polarity (red wire + black wire –) when inserting the wires into the connector.

GB

16

Squeegee installation and adjustment

1

Switch the machine on, lower the squeegee by pressing the suction motor button.

Place the squeegee in the slots provided on the support (g. 4), then tighten the fastening knobs

and insert the suction hose.

4

Squeegee adjustment

The squeegee blades scrape the lm of water and detergent from the oor and prepare the way

for perfect drying. With time, the constant rubbing makes the edge of the blade in contact with the

oor rounded and cracked, reducing the drying eciency and requiring it to be replaced. The state

of wear should be checked frequently.

For perfect drying, the squeegee must be adjusted in such a way that the edge of the rear blade

bends during operation by about 45° with respect to the oor at every point. The angle of the blades

can be adjusted using the screw (g. 5, ref. 1), while the height of the squeegee from the oor can

be adjusted by changing the height of the two wheels (g. 6).

5 6

GB

17

Brush installation

Single-brush machine:

position the brush underneath the head, in the centre (Fig. 7); switch the machine on. Pressing

the ATTACH/RELEASE button once after starting the machine releases the brushes, pressing the

button a second time activates automatic brush attachment; the button is only enabled when all the

functions are deactivated (suction motor and brushes).

7

Double-brush machine:

position the brushes underneath the head on both sides (Fig. 8), the brushes should rest on the

brush centering device in the centre of the head; switch the machine on.

Pressing the ATTACH/RELEASE button once after starting the machine releases the brushes,

pressing the button a second time activates automatic brush attachment; the button is only enabled

when all the functions are deactivated (suction motor and brushes).

8

GB

18

Follow the instructions given below to congure the machine’s control software to use the

See the “Technical menu” section.

! IMPORTANT!

display language you require.

Lifting and transporting the machine

All phases of lifting and moving must be performed in an adequately illuminated

environment with the adoption of the safety measures most appropriate to the situation.

The operator must always use personal protection devices.

Proceed as follows to load the machine onto a means of transport.

► Empty the tanks.

► Remove the batteries.

► Position the machine on a pallet and x it in place with plastic straps or metal brackets.

► Lift the pallet (with the machine) using a fork lift truck and load it onto the means of trans-

port.

► Anchor the machine to the means of transport with cables connected to the pallet and to

the machine itself.

! WARNING!

GB

19

PRACTICAL GUIDE FOR THE OPERATOR

Before starting work, wear overalls, ear protectors, non-slip and waterproof shoes, mask to

protect the respiratory tract, gloves and all other personal protection devices necessitated

Do not leave the machine unattended or parked with the key in the switch and the parking

If you are using the machine for the rst time, we recommend trying it out on a large obsta-

cle-free surface rst to acquire the necessary familiarity.

To avoid damaging the surface of the oor you are cleaning, avoid rotating the brushes with

The machine is tted with a driver detection device. It is only possible to start the machine

while seated correctly in the driving seat. The device halts the machine if you get up from

Always dilute the detergent according to the manufacturer’s instructions. Do not use sodium hypochlorite (bleach) or other oxidants, particularly in strong concentrations. Do not

use solvents or hydrocarbons. The water and detergent temperature must not exceed the

maximum indicated in the “Technical specications”. They must be free of sand and/or other

The machine has been designed for use with low-foam biodegradable detergents made spe-

For a complete and up-to-date list of the detergents and chemicals available, contact the

Use products suitable for the oor and dirt to be removed only.

Follow the safety regulations on use of detergents given in the section “Safety regulations”.

! WARNING!

by the work environment.

! WARNING!

brake disengaged.

! IMPORTANT!

! WARNING!

the machine stationary.

! IMPORTANT!

the seat.

! WARNING!

impurities.

cically for scrubber driers.

Manufacturer:

Preparing the machine for work

Proceed as follows before starting work.

► Check that the display shows the batteries to be fully charged. Recharge if necessary. See

the “Battery maintenance and charging” section.

► Make sure that the dirty water tank is empty. Empty it if necessary, see “Emptying the dirty

water tank”.

► Make sure that the solution tank is full. Fill it if necessary, see “Filling the water/detergent

tank”. If the machine is not tted with the “Chem-Dose” accessory, add detergent to the

tank in the required percentage, using the measuring cap.

GB

20

Controls

1

2

BATTERY

CHARGER

1

► Emergency switch (g. 9, ref. 1): pushing

the safety lever towards the tank, when nec-

essary or in the event of imminent danger,

stops all the machine’s functions, opening

the electrical circuit that supplies power to

the machine.

► Accelerator pedal (g. 9, ref. 2): press this

pedal to control the speed of the machine.

If the accelerator pedal is released for more

than three seconds while the machine is

switched on, the “ AUTO POWER-OFF”

function switches o all machine functions.

To start again, simply press the accelerator

pedal. To enable/disable and change the de-

lay for “AUTO POWER-OFF” mode, go to the

”Technical menu”.

► Battery charger socket (g. 10): if the ma-

chine is not tted with a battery charg-

er, to recharge the batteries, plug in the

connector highlighted, see ”Preparing

the battery charger”.

► Main switch (g. 11, ref. 1): Switches

power to all machine functions on/o.

9

10

11

GB

21

► Suction button (g. 12, ref. 1): during operation with the AUTO, ECO or APC programs,

6

7

8

6

7

8

1

9 10 11

9 10 11

2

3

4

5

1

2

3

4

5

APC

starts/stops the suction motor; outside of these programs, starts the suction motor in ma-

nual mode, lowering the squeegee.

► Water/detergent button (g. 12, ref. 2): during operation with the AUTO, ECO and APC

programs, starts and stops (holding the button for two seconds) delivery of water/deter-

gent; outside of these programs, starts/stops delivery in manual mode. In the AUTO pro-

gram, the quantity of water/detergent can be adjusted by pressing the button; each time

the button is pressed, the set level increases, Lev1, Lev2,..... Lev Auto (delivery proportio-

nal to travel speed).

► Variant with APC (ADVANCED PRODUCTIVITY CONTROL): during operation

with the APC program, delivery of water/detergent cannot be adjusted.

If the AUTO program is active, setting the delivery parameter will exit the program and

activate manual mode.

► CHEM-DOSE (accessory): pressing the “water/detergent” + “brush” buttons together ac-

tivates detergent quantity adjustment mode; once the chemical symbol (ask) is shown

on the display, pressing the “+” and “-” buttons adjusts the level, from OFF to 0.2%, 0.3%

etc. up to 7%.

► Variant with APC (ADVANCED PRODUCTIVITY CONTROL): during operation

with the APC program, the quantity of detergent cannot be adjusted.

► Brush button (g. 12, ref. 3): inside the AUTO, ECO and APC programs, starts/stops the

brushes; outside of these programs, starts/stops operation of the brushes in manual mode.

In the AUTO program, pressing and holding the button (for two seconds) activates brush

pressure adjustment mode; pressing the “+” and “-”buttons performs the adjustment, from

1 to 5 (VERSION WITH TWO BRUSHES ONLY). Setting the parameter exits the program

and activates manual mode.

► Attach-release brushes “CLICK-ON-OFF” (g. 12, ref. 4): used to automatically attach

and detach the brushes. Pressing the button once after starting the machine releases the

brushes, pressing it a second time activates automatic brush attachment. The button is

only active when all the functions are deactivated (suction motor and brushes); the same

button can be used to navigate the “Technical Menu”. .

► Variant with APC (ADVANCED PRODUCTIVITY CONTROL): during operation

with the APC program, pressing this button changes the type of display.

12

GB

22

► Horn button (g. 12, ref. 5): Press to sound the horn.

6

7

8

6

7

8

1

9 10 11

9 10 11

2

3

4

5

1

2

3

4

5

APC

► Forwards travel button (g. 12, ref. 6): selects the machine’s travel direction; when se-

lecting reverse gear, the display shows the letter “R” and the buzzer sounds intermittently.

► ECO program button (g. 12, ref. 7): all the functions are activated in “ECO” mode:

brush pressure, water/detergent ow-rate, brush speed and suction motor speed. In this

program, energy consumption is reduced and the machine emits less noise.

► APC program button (ADVANCED PRODUCTIVITY CONTROL) (g. 12, ref. 7): the

APC system continuously monitors the quantity of water/detergent delivered. This control

improves washing quality and optimises the cleaning operations. The display shows the

quantity of water/detergent contained in the tank in real time, as well as the remaining

operating autonomy in minutes and m2.

► AUTO program button (g. 12, ref. 8): all the functions are activated in “AUTOMATIC”

mode: brush pressure, water ow-rate and detergent delivery are preset by the manufac-

turer, however can be modied from the “Technical Menu”.

► “+ , -” buttons (g. 12, ref. 9-10): these are used to set travel speed, or increase or de-

crease the user parameters.

► Display (g. 12, ref. 11): displays the remaining battery charge, expressed as a percenta-

ge, the logo of the active functions, “hour counter” - the machine operating hours, the set

travel speed and any alarms, see chapter “Alarms on the display”.

► Variant with APC (ADVANCED PRODUCTIVITY CONTROL): when the machine

is on, as well as the values described above, the number of litres remaining in the

solution/detergent tank is displayed. During operation with the AUTO or APC programs, the display shows the remaining machine operating autonomy in minutes,

which depends on the quantity of water/detergent in the tank. During operation,

pressing the “CLICK-ON-OFF” button changes the type of display, and the remaining number of litres is replaced by the remaining useful area that can be washed,

expressed in m2.

12

GB

23

Working

1

1

► Sit correctly in the seat.

► Turn the main switch to position “1”.

► Select the direction of travel with the direction selector.

► Select the AUTO or ECO program.

► Press the accelerator pedal to move o and start work.

Some useful tips to get the most from your scrubber drier

In the event of particularly stubborn dirt on the oor, washing and drying can be performed in two

separate operations.

Prewashing with brushes or pads:

► Turn the main switch to position “1”.

► Select the AUTO or ECO program.

► Press the suction motor button to stop suction.

► Press the accelerator pedal to move o and start work.

► If necessary, adjust the ow of detergent delivered to the brush, using the water/detergent

button; the outlet ow must be metered in relation to the required travel speed; the slower

the machine travels, the less detergent must be delivered.

► Persist when washing particularly dirty points to give the detergent time to perform its

chemical action detaching and suspending the dirt and the brushes time to exert an eec-

Drying:

tive mechanical action.

► Lower the squeegee and with the suction motor on, pass over the same area washed pre-

viously. The result is equivalent to in-depth washing and subsequent ordinary maintenance

will take less time.

Emptying the collection tank:

If the tank is full, the display shows the corresponding alarm, see “Display alarms”; after a few

seconds, the suction motor shuts down, then stop the machine and empty the tank following the

instructions shown below:

► Switch o all the machine’s functions.

► Take the machine to the disposal area.

► Unhook the hose from the clip.

► Empty the tank using the hose (g. 13, ref. 1), at the end rinse the tank with clean water.

13

GB

24

Emptying the water/detergent tank

To empty the tank, follow the instructions shown below:

► Switch o all the machine’s functions.

► Take the machine to the disposal area.

► Stop the machine.

► Empty the tank by unscrewing the plug (g. 14).

14

Filling the water/detergent tank

Fill the tank through the opening provided (g. 15). The machine is equipped with a graduated

measuring cap that can be used to dilute the detergent inside the tank. If the tank is empty, the display shows the corresponding alarm, see “Display alarms” . The quantity of water/detergent in the

tank can be checked using the level tube on the side of the machine (g. 15).

15

CT80

GB

PT80

25

Filling the Chem-Dose tank (accessory)

Lift the dirty water tank.

Fill the tank (g. 16) with the detergent as highlighted.

16

Finishing work

Empty the dirty water tank and recharge the batteries

When ending work, switch o the machine at the main switch. The machine does not have a parking

brake as it is tted with an electric brake, which automatically brakes the machine when the drive

pedal is not pressed.

! IMPORTANT!

Moving the machine when not in operation

Proceed as follows to move the machine.

► Select the direction of travel.

► Press the accelerator pedal.

If the machine cannot be moved using the electric drive, the machine can be pushed after having

disengaged the electric brake, see “Pushing and pulling the machine”.

GB

26

If the machine is not used for some time, for example, on display in a showroom or stored in the

PERIODS OF INACTIVITY

warehouse for a period or more than one month, the following operations are required:

► Completely recharge the batteries before storing them. During long periods of inactivity,

you should charge the batteries regularly (at least once every two months) to keep them

constantly at maximum charge.

► Disconnect the batteries from the machine using the connector provided.

► Unplug the battery charger (if present) from the mains power supply.

► Remove the squeegee and brushes (or abrasive disks), wash them and put them away in

a dry place (preferably in a bag or wrapped in plastic lm) away from dust.

► Make sure the tanks are completely empty and perfectly clean.

If the batteries are not recharged regularly as described above, they may be irrevocably

The manufacturer is not liable for any malfunctions resulting from neglect, improper and/or

! WARNING!

damaged.

incorrect use.

GB

27

MAINTENANCE INSTRUCTIONS

1

Never perform any maintenance operations without rst disconnecting the batteries.

Maintenance of the electrical circuit and all other operations not expressly required by this

manual must be performed by specialised personnel only, in compliance with current safety

legislation and as described in the maintenance manual.

Maintenance - General rules

Performing regular maintenance according to the Manufacturer’s instructions improves performance and extends the working life of the machine.

When cleaning the machine, observe the following precautions.

► Avoid using pressure washers. Water could penetrate the electrical compartment or mo-

tors leading to damage or short circuits.

► Do not use steam to avoid the heat warping plastic parts.

► Do not use solvents or hydrocarbon based products. These can damage the cowling and

rubber components.

Cleaning the suction motor air lter

Open the dirty water tank lid, then remove the lter from it housing (g. 17), wash it under running

water or using the same detergent dispensed by the machine, then when it is dry, replace the lter

in its housing.

! DANGER!

17

GB

28

Cleaning the water/detergent tank lter

1

1

2

To clean the lter, proceed as follows:

► Close the tap (g. 18, ref. 1) on the front left of the machine, next to the drive wheel.

► Unscrew the lter cover (g. 18, ref. 2), remove the lter, then wash it under running water

or using the same detergent dispensed by the machine.

► Replace the lter in its housing, making sure it is correctly positioned and retighten the

screw.

18

Cleaning the dirty water tank oat

Open the dirty water tank lid, clean the oat (g. 19, ref. 1) situated at the front of the dirty water

tank, making sure not to aim the water directly against the oat; make sure it slides freely on its rod.

19

GB

29

Fuses: replacing

1

2

3

This operation must be performed with the machine switched o and the key removed.

Never use a fuse with a higher amperage than specied.

Do not rest the electronic board panel on the batteries, as a short-circuit may cause the bat-

If a fuse continues to blow, the fault in the wiring, boards (if present) or motors must be identied

and repaired. Have the machine checked by qualied personnel.

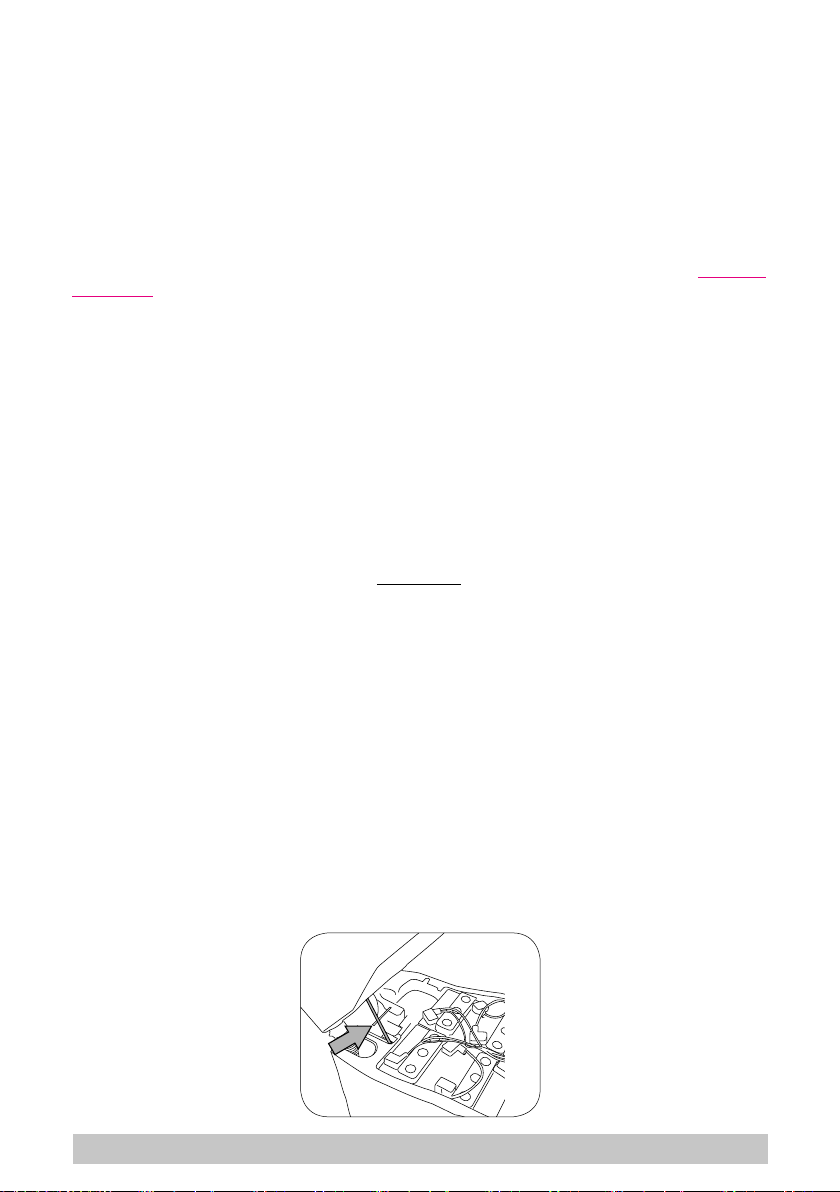

Lift the dirty water tank, disconnect the battery wiring connector from the electrical system (g. 20,

ref. 1-2-3), lift the electronic board panel, secure it to the corner of the tank, as shown in the gure

(g. 21), then check the fuses.

! DANGER!

! WARNING!

! DANGER!

teries to explode.

20 21

GB

30

(g. 22, ref. 1) main fuse.

1 2

3 4

5 1 2 4

5

3

To serial number :

80000262687

From serial number:

80000262688

1

22

(g. 23, ref. 1-2) brush motor fuses.

(g. 23, ref. 3) head actuator, squeegee actuator fuse.

(g. 23, ref. 4) suction motor fuse.

(g. 23, ref. 5) solenoid valve, Chem-Dose pump fuse.

23

GB

31

Battery maintenance and charging

BATTERY

CHARGER

1

2

3

The batteries give o ammable fumes. Put out all res and hot embers before checking or

Perform the operations described below in a ventilated area.

When recharging the batteries, the dirty water tank must be open (rotated backwards) so as

Charge the batteries as instructed in

Disconnect the connectors at the end

To avoid permanent damage to the

batteries, do not run them down com-

“STANDALONE” battery charger, electri-

cal connection to the machine:

to allow correct air ow in the battery and battery charger compartment.

In the case of gel batteries, use a specic charger for gel batteries only.

To avoid permanent damage to the batteries, do not run them down completely.

the battery charger manual.

of charging.

pletely.

► Lift the dirty water tank.

► Press the emergency switch (g.

24, ref. 1).

► Lift the connector (g. 24, ref.

2-3), removing it from the two

pins.

► Attach the connector to the bat-

tery charger.

► Start the recharge cycle.

► Disconnect the connectors at the

end of charging.

► Reconnect the battery wiring

connector to the machine con-

nector.

Do not check the batteries by sparking.

topping up the battery level.

! DANGER!

! DANGER!

! WARNING

! WARNING!

! WARNING!

! WARNING!

24

GB

32

“ONBOARD” battery charger:

► Lift the dirty water tank

► Unplug the battery charger.

► Plug the cable into the power socket (g. 25).

► Start the recharge cycle.

► The display will show when the recharge cycle ends, see “Display alarms”

► At end of the recharge cycle, unplug the cable from the power socket.

25

Replacing the squeegee blades

► Switch the machine on, lower the squeegee by pressing the suction motor button.

► Remove the suction hose from the squeegee (g. 26).

► Unscrew the fastening knobs.

► Remove the squeegee from the slots on the support.

26

GB

33

► Open the hook (g. 27, ref. 1).

1

U

N

LOC

K

1

2

► Push the two blade pressing devices (g. 27, ref. 2) outwards, then remove them.

► Remove the blade.

► Reuse the same blade by reversing the edge in contact with the oor until all four edges

are worn out, or replace with a new blade, tting it onto the screws on the body of the

squeegee.

► Reposition the two blade pressing devices by centering the wider part of the slots on the

squeegee body fastening pins, then push the blade pressing devices inwards.

► Close the hook again.

► Replace the squeegee on its support, following the instructions described previously.

27

Pushing and pulling the machine:

When the electric drive cannot be used, the machine can be easily pushed or pulled by turning the

lever (g. 28) clockwise, so as to release the electric brake. After moving the machine, set the lever

back to the original position.

If the lever is in the position where the electric brake is disengaged (lever turned clockwise),

the machine’s brake will be disabled.

Never start the machine with the electric brake disabled.

! WARNING!

28

GB

34

Periodic checks

CHECK

DAILY OPERATIONS

WEEKLY OPERA-

TIONS

EMPTY AND WASH THE DIRTY WATER TANK X

CLEAN THE SQUEEGEE BLADES AND CHECK THEM FOR WEAR X

CHECK THAT THE SUCTION HOLE IN THE SQUEEGEE IS NOT BLOCKED X

RECHARGE THE BATTERIES X

CLEAN THE DIRTY WATER TANK FLOAT X

CLEAN THE SUCTION MOTOR AIR FILTER X

CLEAN THE WATER/DETERGENT TANK FILTER X

CLEAN THE SUCTION MOTOR HOSE X

CLEAN THE DIRTY WATER TANK AND THE SOLUTION TANK X

CHECK THE BATTERY ELECTROLYTE LEVEL X

HAVE THE ELECTRICAL SYSTEM CHECKED BY QUALIFIED PERSONNEL. X

SIX MONTHLY OP-

ERATIONS

GB

35

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

The machine does not work The batteries are disconnected Connect the batteries to the machine

The batteries are at Recharge the batteries

Battery disconnect lever pressed Return the lever to its correct position

The brushes do not turn The dirty water tank is full Empty the dirty water tank

Blown fuse Replace

Faulty switch Replace

The batteries are at Recharge the batteries

Damaged motor Replace

Wire detached Check

The machine does not clean uniformly The brush or disks are worn Replace

No solution comes out of the detergent

tank

Detergent ow does not stop Damaged solenoid valve Replace

The suction motor does not start The dirty water tank is full Empty the dirty water tank

The squeegee does not clean or has poor

suction

The machine does not move The batteries are at Recharge the batteries

The machine does not brake Electromagnetic brake disengaged Check

The batteries do not provide the normal

working time

The tap upstream of the lter is closed Open the tap

Damaged solenoid valve Replace

Dirty solenoid valve Check

The detergent tank is empty Top up

The hose delivering detergent to the

brush is blocked

Blown fuse Replace

Damaged solenoid valve wiring Check

Blown fuse Replace

Faulty switch Replace

The batteries are at Recharge the batteries

Damaged motor Replace

Wire detached Check

The edge of the rubber blades in contact

with the oor is worn

Blockage or damage in the squeegee or

in the hose

The dirty water tank oat is activated or is

blocked by dirt, or is faulty

Blockage in the suction hose Check

The suction hose is not connected to the

squeegee or is damaged

Suction motor not powered or faulty Check

Drive wheel actuator problem Check the alarm code shown on the dis-

The battery poles and charging terminals

are dirty and oxidised

The battery charger does not work or is

not suitable

Unblock

Replace the blades

Check

Empty the dirty water tank, check the

oat.

Check

play

Clean and grease the poles and termi-

nals, charge the batteries

Check

GB

36

DISPLAY ALARMS

Alarm Possible cause What to do

BRUSH PROTECTOR The brush motor has overheated.

DRIVE PROTECTOR The drive wheel has overheated.

NO OPERATOR The driver detection microswitch is not de-

ACCELERATOR KEY Incorrect start-up sequence

WATER RESERVE Solution tank almost empty.

NO WATER Solution tank empty.

DITRY WATER THANK Dirty water tank full.

CHEMICAL FINISHED Chem-Dose tank empty.

FUNCTON BOARD NOT

DETECTED

BATTERY

FLAT

BATTERY RESERVE Battery voltage less than : 21.5 V GEL/AGM

CALL SERVICE The set number of hours for scheduled ser-

BATTERY CHARGING The on-board battery charger is operating, all

CHARGING COMPLETE The on-board battery charger is operating,

ERROR FROM C.B. Battery charger malfunction Replace the battery charger

BATTERY NO CONNECT Battery not connected

O.C. BRUSH Brush motor short-circuit Replace the brush motor

BRUSH FUSE Brush motor fuse blown Replace the fuse

Faulty thermal protector contact on the motors.

Faulty connection.

Faulty thermal protector contact on the motor.

Faulty connection.

tecting an operator.

Faulty accelerator pedal microswitch.

Faulty connection.

Stuck sensor.

Faulty sensor or connection.

Stuck sensor.

Faulty sensor or connection.

Stuck sensor.

Faulty sensor or connection.

Stuck sensor.

Faulty sensor or connection.

Communication with functions board interrupted.

Faulty auxiliary boards.

Battery voltage less than: 20.7 V GEL/AGM

- 20.3 V ACID.

Flat batteries.

- 20.5 V ACID.

Flat batteries.

vice have been reached/exceeded.

the machine’s functions are disabled.

the charge is complete, all the machine’s

functions are disabled.

Fuse inside the battery charger blown

Wait for the brush motors to cool down.

Replace the brush motor.

Check the connection.

Wait for the drive wheel to cool down.

Replace the drive wheel.

Check the connection.

Sit correctly in the seat.

Check the connection.

Check the seat microswitch.

Release the accelerator pedal

during start-up.

Replace the accelerator pedal microswitch.

Check the connection.

Fill the solution tank.

Clean the level sensor.

Replace the level sensor.

Check the connection.

Fill the solution tank.

Clean the level sensor.

Replace the level sensor.

Check the connection.

Empty the dirty water tank.

Clean the level sensor.

Replace the level sensor.

Check the connection.

Fill the Chem-Dose tank.

Clean the level sensor.

Replace the level sensor.

Check the connection.

Check the connection between the boards.

Check the auxiliary boards.

Recharge the batteries.

Replace the batteries.

Recharge the batteries.

Replace the batteries.

Call a service centre to arrange scheduled service.

Disconnect the battery charger

Disconnect the battery charger

Connect the battery

Replace the battery charger

GB

37

DISCONNECT EMERGENCY Electronic board communication problem Press the emergency switch and reset it after

10 seconds. If following this procedure, the

“update software” message is shown on the display, do not switch the machine o, but rather

wait for the procedure to end.

DRIVE BOARD DISPLAY ALARMS

DRIVE BOARD

TEMPERATURE

ACCELERATOR FAULT Faulty potentiometer connections.

SPEED FAULT Speed signal connections interrupted.

DRIVE BOARD U.V. Battery voltage less than 17 V.

DRIVE BOARD O.V. Battery voltage over 31 V.

RELAY FAULT Faulty relay.

INPUT FAULT Emergency input activated on the drive

HDP 10 SEC. Accelerator pedal pressed when starting for

ELECTRIC BRAKE FAULT Faulty drive board.

PRE-CARCHE FAULT Check electric brake short.

HDP Accelerator pedal pressed when starting.

TRACTION DRIVE FAULT Drive motor short

DRIVE BOARD FAULT Faulty drive motor connection.

DRIVE BOARD POWER

SUPPLY

OVERCURRENT Excessive machine eort.

TRACTION ALARM Drive system problem Wait a few seconds with the machine on until

Board temperature between -10°C and

+80°C.

Excessive vehicle eort.

Electric brake engaged.

Faulty potentiometer.

Incorrect potentiometer type setting.

Faulty functions board.

Connection error between batteries and controller.

Machine moving with battery charger con-

nected.

Faulty battery connection.

Faulty drive board.

board.

Key connection on the drive board.

more than 10 seconds.

Potentiometer not adjusted.

Faulty electric brake.

Faulty board.

MOSFET failure.

Potentiometer not adjusted.

Drive motor connection short.

Faulty board.

Faulty board.

Battery not connected.

Faulty battery connection.

Drive motor damaged.

Cool or heat the board.

Do not overwork the machine on long ramps.

Check the electric brake.

Check the connection.

Replace the potentiometer.

Set the correct potentiometer.

Check connection between functions board and

drive board.

Replace functions board.

Charge or replace the batteries.

Check battery connection.

Check or replace the batteries.

Disconnect the battery charger.

Check battery connection.

Replace the drive board.

Check connection between functions board and

drive board.

Release accelerator pedal when starting the

machine.

Check potentiometer adjustment.

Replace the drive board.

Check / replace the electric brake.

Replace the drive board.

Release accelerator pedal when starting the

machine.

Check potentiometer adjustment.

Check / replace the drive motor.

Check motor connections.

Replace the drive board.

Check motor connection.

Replace the drive board.

Connect battery cables.

Check battery cables

Do not overwork the machine on long ramps.

Check / replace the drive motor.

the correct message is shown on the display.

GB

38

Enter the menu by pressing “+” and “-” together when no functions are active.

TECHNICAL MENU

The “+” button increases the selected parameter or the variable relating to the selected parameter.

The “-” button increases the selected parameter or the variable relating to the selected parameter.

The “Attach-release brushes” button selects the parameter to be set and conrms the entered vari-

able.

WORK AREA

LANGUAGE IT, GB, ES.......

AUTO PROGRAM

POWER OFF

BATTERY TYPE

REVERSE SPEED

BRUSH PRESSURE

WATER FLOW-RATE

SPEED REDUCTION

DETERGENT FLOW-

RATE

EXIT

1.......5

1.......5

0.....100%

OFF - 0,2 - 0,3 - ...10%

OFF - 1 - 2 - ...30

GEL-AGM

LEAD -ACID

0.....100%

SERVICE

EXIT

PASSWORD

RETURN TO PREVIOUS MENU

GB

39

IP CLEANING S.r.l

Sede Legale - Registered Oce

Viale Treviso n° 63 - fraz. Summaga

30026 Portogruaro (VE) ITALY

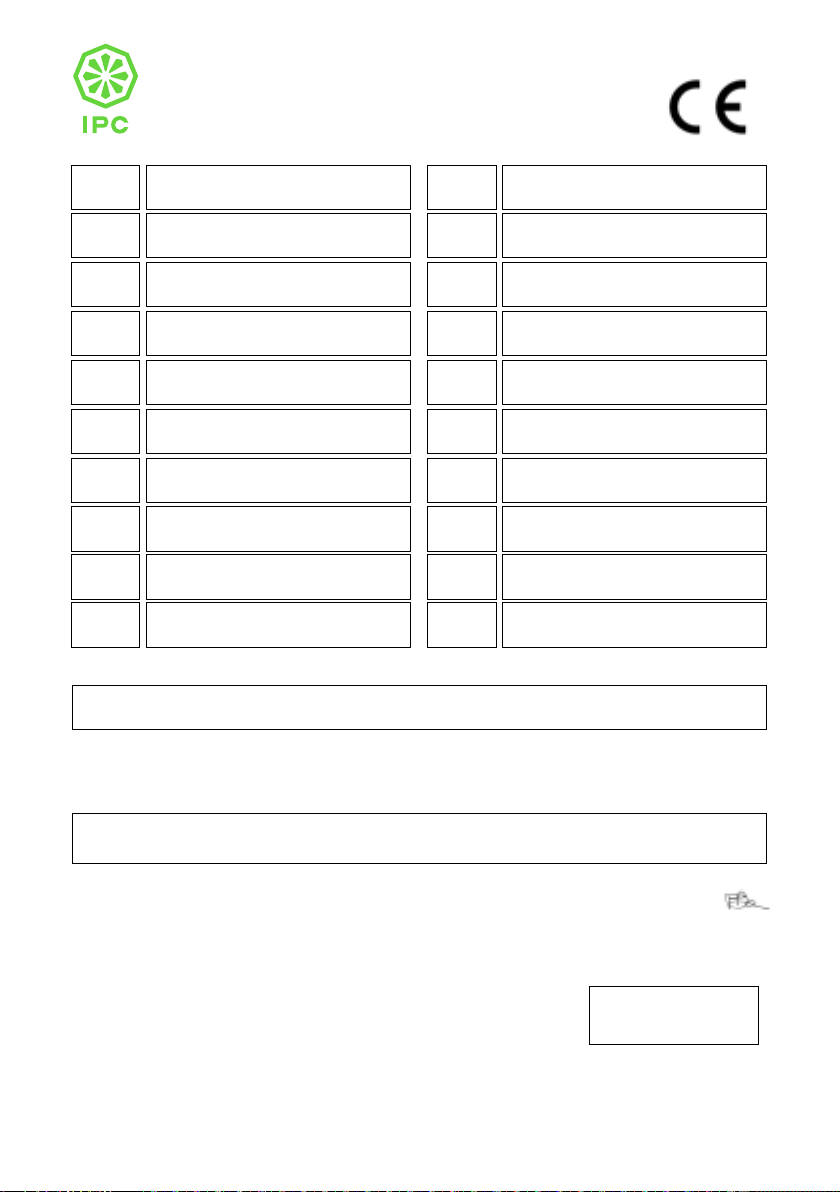

DICHIARAZIONE DI CONFORMITA’ “CE”

Dichiariamo sotto la nostra esclusiva responsabilità che il prodotto al

IT FI

quale questa dichiarazione si riferisce è conforme alle seguenti Direttive

Comunitarie:

“CE” CONFORMITY DECLARATION

We declare on our own responsibility that the product to which this

EN EL

declaration refers is in accordance with the following European

Community Directives :

DECLARATION DE CONFORMITE “CE”

Nous déclarons sous notre exclusive responsabilité que le produit

FR SK

auquel cette déclaration se réfère est conforme aux directives européen-

nes suivantes communautaire:

“CE” KONFORMITÄTSERKLÄRUNG

Auf unserer Alleinverantwortung erklären wir, daß das Produkt, auf das

DE HU

sich diese Erklärung bezieht entspricht den folgenden Richtlinien der

Europäischen Gemeinschaft :

DECLARACIÓN “CE” DE CONFORMIDAD

Bajo nuestra exlusiva responsabilidad, declaramos que el producto,

ES CS

al que esta declaraciòn se reere, es conforme con las siguientes

directivas comunitarias:

DECLARAÇÃO “CE” DE CONFORMIDADE

Declaramos sob a nossa exclusiva responsabilidade que o produto ao

PT ET

qual esta declaração se refere está em conformidade com as seguintes

directivas comunitárias:

DECLARAÇÃO “CE” DE CONFORMIDADE

Declaramos sob a nossa exclusiva responsabilidade que o produto ao

NL LT

qual esta declaração se refere está em conformidade com as seguintes

directivas comunitárias:

OVERENSSTEMMELSESERKLÆRING “CE”

Vi forsikrer under eget ansvar at folgende produkt som omfattes af

DA SL

denne erklæring er i overensstemmelse med vilkårene i folgende EU

direktiver:

FÖRSÄKRAN OM ÖVERENSSTÄMMELSE “CE”

Vi försäkrar under eget ansvar att följande produkt som omfatts av den-

SV PL

na försäkran i överensstämmelse med villkoren i följande Europeiska

gemenskapens direktiv:

BEKREFTELSE OM OVERENSSTEMMELSE “CE”

Vi forsikrer under eget ansvar at folgende produkt som omfattes av

N LV

denne bekreftelsen er i overensstemmelse med vilkärene i folgende

disse EU-direktivene:

YHDENMUKAISUUSVAKUUTUS “CE”

Vakuutamme omalla vastuulamme, että seuraava tuote jota tämä

vakuutus koskee, on yhdenmukainen seuraavassa Euroopan yhteisön

direktiivit :

Δηλώνουμε φέροντας την αποκλειστική ευθύνη ότι το προϊόν στο οποίο

αναφέρεται η δήλωση αυτή είναι σύμφωνη με τις ακόλουθες οδηγίες της

Ευρωπαϊκής Κοινότητας:

Prehlasujeme na vlastnú zodpovednosť, že výrobok, na ktorý sa

vzťahuje toto prehlásenie je zhodný s nasledujúcimi Európskeho

spoločenstva:

Saját felelősségünk alatt kijelentjük, hogy a termék, amelyre a nyilatkozat vonatkozik, megfelel az következő európai közösségi irányelvek:

Prohlašujeme výlučně na vlastní zodpovědnost, že výrobek, na který

se vztahuje toto prohlášení je ve shodě s následujícími Evropského

společenství:

Deklareerime meie ainuvastutuse juures, et see toode vastab järgmiste-

le standarditele ja Euroopa Ühenduse direktiivide:

Prisiimdami visą atsakomybę, mes pareiškiame, kad produktas, kuriam

taikoma ši deklaracija, atitinka šiuos Europos Bendrijos direktyvas:

Izjavljamo na našo odgovornost, da je izdelek, na katerega se nanaša ta

deklaracija, v skladu s sledečimi direktivami Evropske skupnosti :

Oświadczamy na naszą wyłączną odpowiedzialność, że produkt, którego dotyczy niniejsza karta gwarancyjna, jest zgodny z następującymi

dyrektywami Wspólnoty Europejskiej:

Prisiimdami visą atsakomybę, mes pareiškiame, kad produktas, kuriam

taikoma ši deklaracija, atitinka šiuos Eiropas Kopienas direktīvas:

D»lwsh snmbatÒthtaj “CE”

PREHLÁSENIE “EÚ” O ZHODNOSTI

“CE” MEGFELELŐSÉGI NYILATKOZAT

PROHLÁŠENÍ “CE” O SHODĚ

“CE” VASTAVUSDEKLARATSIOON

“CE” ATITIKTIES DEKLARACIJA

IZJAVA O SKLADNOSTI “CE”

DEKLARACJA ZGODNOŚCI “UE”

“CE” ATITIKTIES DEKLARACIJA

2006/42/CE - 2014/30/CE - 2000/14/CE - 2011/65/EU - 2014/35/CE

Norme armonizzate applicate - Applied harmonised standards: Altri standards applicati - Others applied standards:

Prodotto-Product:

LAVASCIUGAPAVIMENTI - AUTOMATIC SCRUBBER

Modello-Model-Modèle-Modell-Modelo-Modell-Malli-MonteloMudel-Modelis:

Matricola-Serial n.-Matricule-Maschinennummer-Matricula-Serienummer-Sarjanumero-Registratienummer -(Ariqmos) MhtrwonVýrobné číslo-Sorozatszám-Výrobní číslo-Seeria nr-Serijos

Nr.-Serijska številka-Nr seryjny-Serijos Nr.:

Persona autorizzata a costituire il Fascicolo Tecnico.

Person authorised to compile the Technical File.

IP CLEANING S.r.l

Viale Treviso n° 63 - fraz. Summaga

30026 Portogruaro (VE) ITALY

Serial n°

Incollare la matricola sulla garanzia.

Coller la matricule sur la carte garantie.

Pegar la matricula en la garantia.

Registtratie-nummer op de garantie plakken.

Klistr serienummeret på garantiseddelen.

Liimaa sarjanumero takuutodistukseen.

Stik the serial number on the warranty card .

Maschinenummer auf den Garantieschein Kleben.

Cole o número de matrícula na garantia.

Klistr serienummeret pà garantiseddelen.

Kollƒste ton ariqmÒ mhtrèon sthnsh eggÚhs

Výrobné číslo nalepte na záručný list.

A sorozatszámot ragassza a garancialevélre.

Nalepit výrobní číslo na záruku.

Seerianumber tuleb kinnitada garantiikaardile.

Garantiniame pase turi būti nurodytas serijos

numeris.

Serijska številka mora biti nalepljena na garanciji.

Należy nakleić numer seryjny na kartę

gwarancyjną.

POSITION: General Manager Date: 27/08/15

NAME: Federico De Angelis Signature:

Testato - Checked - Essayé - Geprüft - Testado - Provekort - Koeajettu - Getest -

Leverans -Dokimasmeno - Vyskúšané - Bevizsgált - Testováno - Kontrollitud - Patikrinta

- Preizkušeno -Sprawdzono - Patikrinta

Il collaudatore:

Serial n°

IP Cleaning S.r.l

Viale Treviso 63

30026 Summaga di Portogruaro

Venezia (Italy)

T: +39 0421 205511

F: +39 0421 204227

E: www.ipcworldwide.com

W: info@ipcworldwide.com

PLDC02110_10

Loading...

Loading...