1250 - 1280

MANUALE ISTRUZIONI PER L’USO /

OPERATOR’S MANUAL / MANUEL D’INSTRUCTIONS /

BEDIENUNGSANLEITUNG /

MANUAL DE INSTRUCCIONES / BRUKERHÅNDBOK /

GEBRUIKERSHANDLEIDING / MANUAL DE UTILIZAÇÃO /

INSTRUKTIONSBOK / МАШИНА ДЛЯ МОЙКИ И СУШКИ ПОЛОВ

/ KULLANIM KILAVUZU

Consultare attentamente questo manuale prima di procedere a qualsiasi intervento sulla macchina

Read this manual carefully before carrying out any work on the machine

Lire attentivement ce manuel avant toute intervention sur la machine

Vorliegendes Handbuch vor jedem Eingriff an der Maschine aufmerksam durchlesen

Consulte detenidamente este manual antes de llevar a cabo cualquier trabajo en la máquina

Konsulter denne håndboken nøye før du går i gang med noen som helst type inngrep på maskinen

Raadpleeg deze handleiding aandachtig alvorens met enige werkzaamheid aan de machine te beginnen

Consulte atentamente este manual antes de efectuar qualquer intervenção na máquina

Läs noggrant igenom denna handbok innan du utför något som helst ingrepp på maskinen

Внимательно ознакомьтесь с данной инструкцией до проведения любой работы с машиной

Makine ile herhangi bir işlem yapmadan önce bu kılavuzu dikkatle okuyun

ENGLISH

(Translated instructions)

ITGB

2

TECHNICAL CHARACTERISTICS ........................................................................4

MACHINE DIMENSIONS ........................................................................................ 7

SAFETY SYMBOLS ................................................................................................8

GENERAL INFORMATION ..................................................................................... 9

Purpose of this manual .................................................................................................................. 9

Identifying the machine .................................................................................................................. 9

Documentation provided with the machine ................................................................................... 10

TECHNICAL INFORMATION ................................................................................. 11

General description ....................................................................................................................... 11

Parts of the machine ..................................................................................................................... 11

Hazard areas................................................................................................................................. 12

Accessories ................................................................................................................................... 12

SAFETY INFORMATION .......................................................................................13

Safety precautions ........................................................................................................................ 13

MOVEMENT INSTALLATION ...............................................................................15

Lifting and transporting the packaged machine ............................................................................ 15

Delivery checks ............................................................................................................................. 15

Unpacking ..................................................................................................................................... 15

Batteries (Battery version)............................................................................................................. 15

Batteries: preparation .................................................................................................................... 16

Batteries: installation and connection............................................................................................ 16

Batteries: removal ......................................................................................................................... 17

Choosing a battery charger ........................................................................................................... 17

Preparing the battery charger ...................................................................................................... 17

Preparing the engine (Petrol and Dual Power versions) .............................................................. 17

Preparing the hydraulic circuit (Petrol and Diesel versions).......................................................... 17

Fitting the side brushes ................................................................................................................. 17

Lifting and transporting the machine ............................................................................................. 18

PRACTICAL GUIDE FOR THE OPERATOR .........................................................19

Preparing the machine for work .................................................................................................... 19

Controls of the Battery and Dual Power versions ......................................................................... 20

Operating the Battery and Dual Power versions ........................................................................... 22

Controls of the Petrol and Diesel versions .................................................................................... 22

Operating the Petrol and Diesel versions...................................................................................... 25

Emptying the bottom unloading debris bin .................................................................................... 25

Emptying the top unloading debris bin .......................................................................................... 26

Finishing work ............................................................................................................................... 26

Moving the machine when not in operation................................................................................... 26

PERIODS OF INACTIVITY ....................................................................................27

MAINTENANCE INSTRUCTIONS ......................................................................... 28

Maintenance - General rules ......................................................................................................... 28

Replacing/installing the main brush ............................................................................................. 28

Adjusting the main brush............................................................................................................... 29

Replacing/installing the side brushes ............................................................................................ 29

Adjusting the side brushes ............................................................................................................ 30

Replacing/installing the suction lter ............................................................................................. 30

Fuses: replacing ............................................................................................................................ 32

Battery maintenance and charging ............................................................................................... 32

Changing the engine oil ................................................................................................................ 33

Periodic checks ............................................................................................................................. 34

TROUBLESHOOTING ........................................................................................... 35

DISPLAY ALARMS ................................................................................................37

TECHNICAL MENU ...............................................................................................39

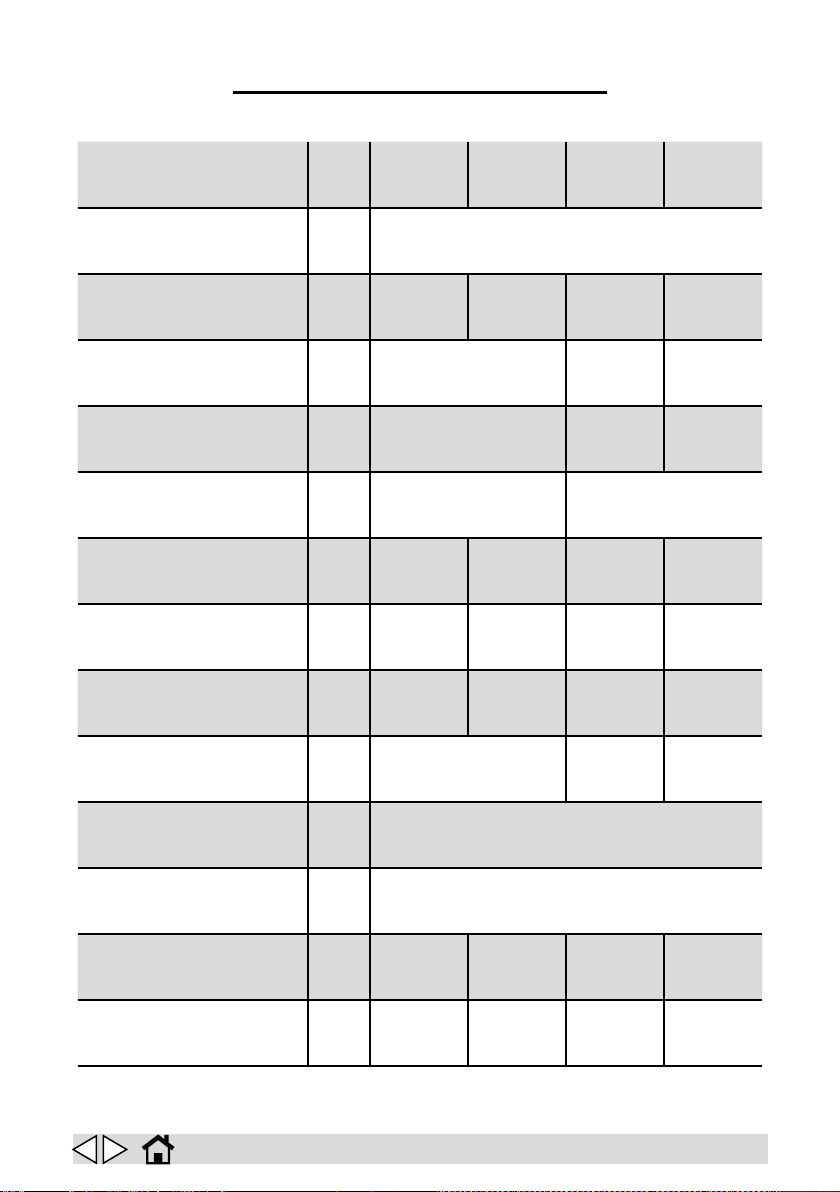

TECHNICAL CHARACTERISTICS

BATTERY DUAL POWER PETROL DIESEL

Cleaning width mm 1100

Cleaning capacity per hour m

Main brush motor power W 600 - -

Side brush motor power W 90 - -

Drive motor power 450 W 98 Cm

Internal combustion engine starting W -

Internal combustion engine power W - 4125 4125

Fuel tank capacity l - 3,1 3,1

Suction motor power W 260 - -

Panel lter shaker motor power W 90

2

/h 3800-5600 3800-5600 3800-5600 3800-5600

3

/rpm

Pocket lter shaker motor power W 110

Alternator A - 80 - -

Maximum forward speed Km/h 6.2 6.2 6.2 6.2

GB

4

Maximum reverse speed Km/h 6.2 6.2 4.6 4.6

Maximum negotiable gradient % 12

Debris bin capacity (bottom unloading) l 61

Debris bin capacity (top unloading) l 56

Rear wheel diameter mm 250

Front wheel diameter mm 250

Main brush diameter mm 280

Side brush diameter mm 400

Panel lter surface area sq.m. 4

Pocket lter surface area sq.m. 4

Maximum bin tipping height (top unload-

ing)

Gross weight 1250 Kg 552 371

Gross weight 1280 Kg 607 424

Transported weight 1250 Kg 279 75

Transported weight 1280 Kg 279 75

mm 1460

GB

5

Number of batteries n° 4 2 1 1

Battery voltage V 12

Individual battery capacity Ah (5h) 180 75 45

Power system voltage V 24 24 12 12

Machine dimensions (bottom unloading) mm

Machine dimensions (top unloading) mm

Battery compartment dimensions

(length, width, height)

Packed size (length, width, height) mm 1740X1100X1410

Sound pressure

Measured sound power

Guaranteed sound power

Vibration level (hand)

Measurement uncertainty, k m/sec2 1,3 1,5 1,3 1,7

mm 500X500 (305x185) x 2 / /

LpA

(dB)

Lwa

(dB)

Lwa,g

(dB)

HAV

m/sec2

70 84 82 88

82 94 94 99

83 95 95 100

2,6 3 2,5 3,3

X=1615

Z=905

Y=1210

X=1550

Z=905

Y1=1868

Y2=1210

Vibration level (body)

Measurement uncertainty, k m/sec2 0,3 0,3 0,3 0,3

HBV

m/sec2

0,5 1 0,5 0,7

Data subject to variation without warning.

GB

6

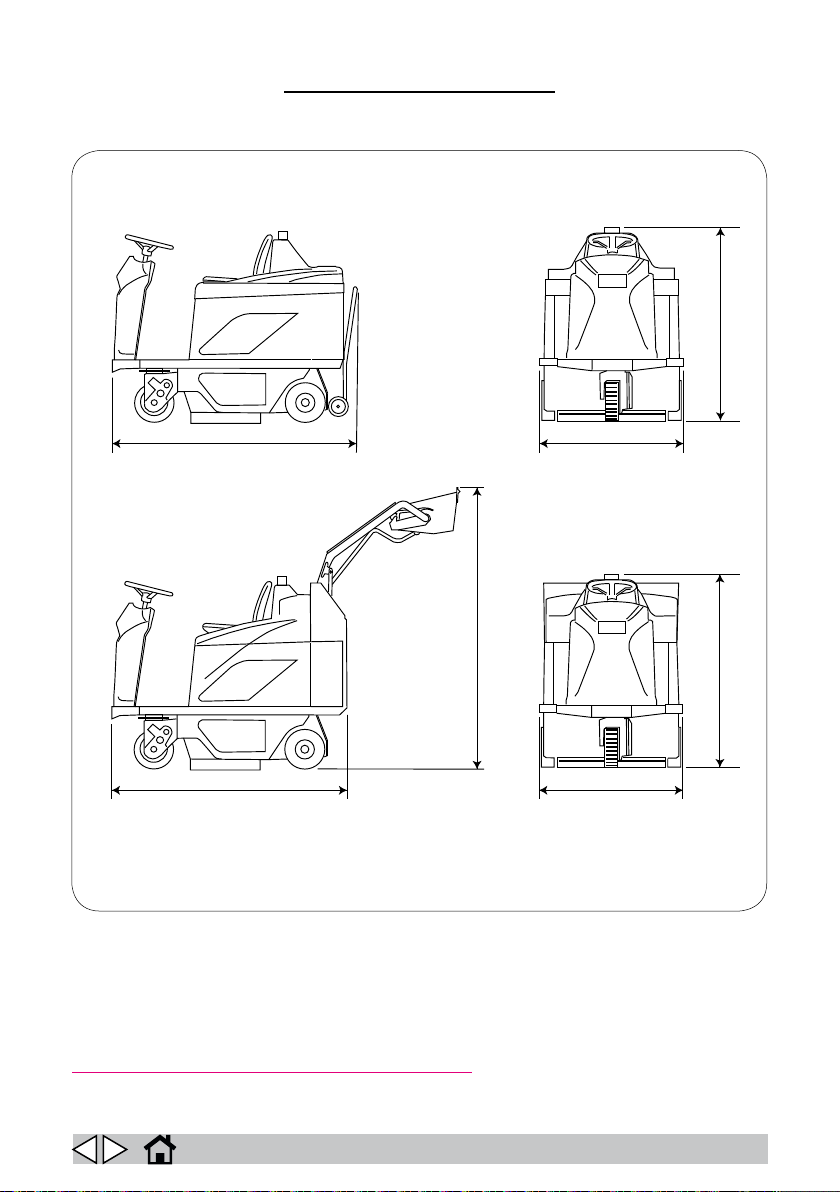

MACHINE DIMENSIONS

Y

X

X

Z

Y1

Y2

Z

X-Y-Z: See “TECHNICAL CHARACTERISTICS” table

ITGB

7

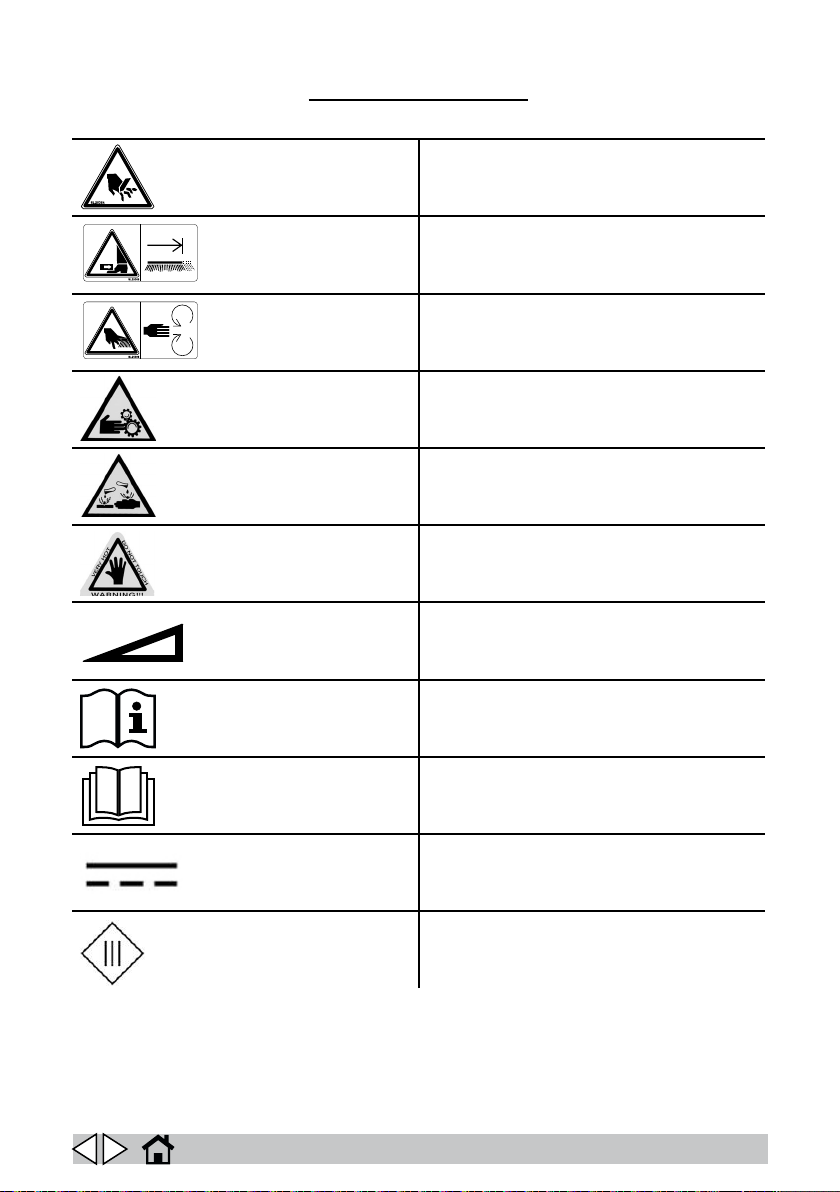

SAFETY SYMBOLS

WARNING! RISK OF CUTTING

WARNING! RISK OF CRUSHING LIMBS

WARNING! RISK OF ABRASION

WARNING! RISK OF ENTANGLEMENT

WARNING! RISK OF ACID BURNS

WARNING! RISK OF BURNS

MAXIMUM SLOPE

OPERATOR’S MANUAL, OPERATING INSTRUCTIONS

READ THE OPERATOR’S MANUAL

DIRECT CURRENT SYMBOL

INSULATION CLASS, THIS CLASSIFICATION ONLY APPLIES TO MACHINES POWERED BY BATTERIES.

GB

8

GENERAL INFORMATION

Purpose of this manual

This manual has been written by the Manufacturer and is an integral part of the machine1.

It denes the purpose for which the machine has been designed and constructed and contains all

the information required by operators2.

In addition to this manual, which contains information for operators, other publications are available

providing specic information for maintenance personnel3.

The terms “right” and “left”, “clockwise” and “anti-clockwise” refer to the forward movement of the

machine.

Constant compliance with the instructions provided in this manual guarantees the safety of the op-

erator and the machine, ensures low running costs and high quality results and extends the working

life of the machine. Failure to follow these instructions may lead to injury to the operator or damage

to the machine, oor and environment.

Consult the table of contents at the beginning of the manual to nd the section you need rapidly.

Parts of the text requiring special attention are printed in bold and preceded by the symbols illus-

trated and described here.

Indicates the need for attention in order to avoid a series of consequences which could cau-

se death or serious injury to personnel.

! DANGER!

Indicates the need for attention in order to avoid a series of consequences which could

! WARNING!

cause injury to personnel or damage to the machine or work environment or nancial loss.

! IMPORTANT!

Important information.

In line with the company’s policy of constant product development and updating, the Manu-

facturer reserves the right to make modications without prior notice.

Although your machine may differ appreciably from the illustrations in this document, the

correctness and validity of the instructions contained in this manual are guaranteed.

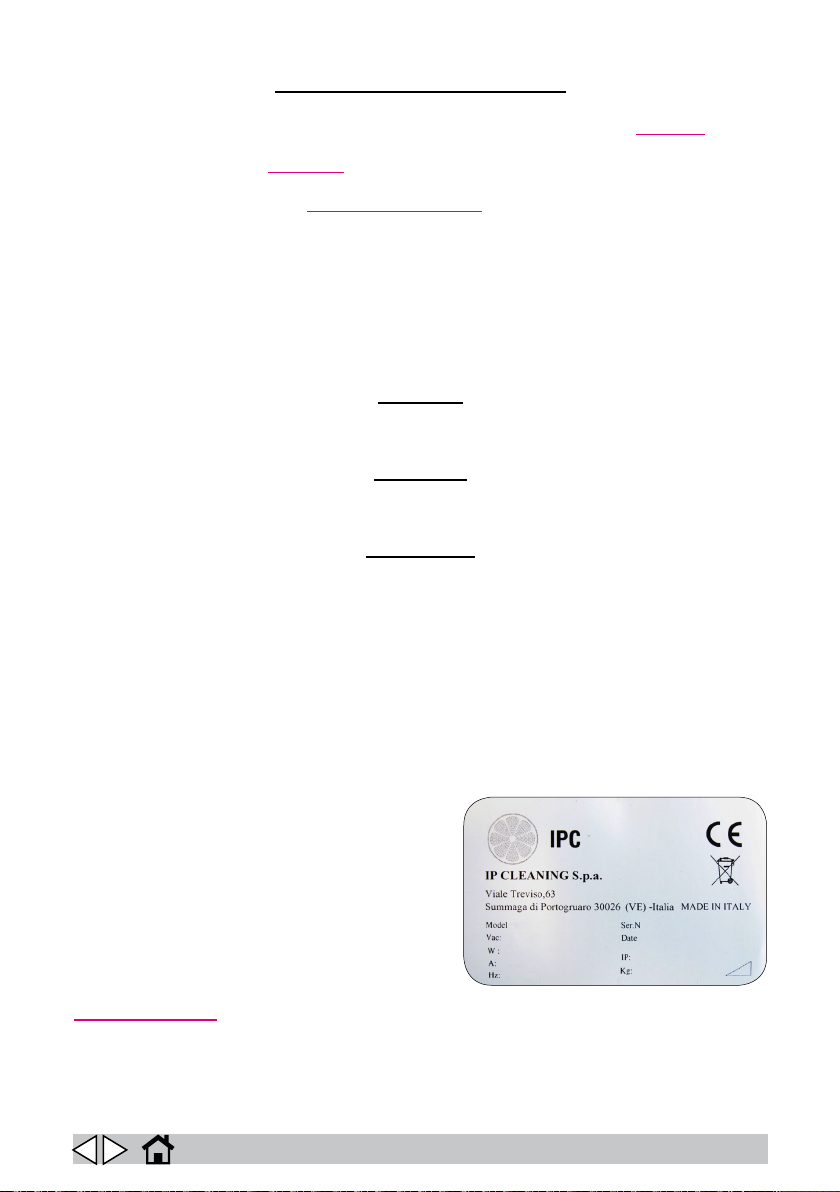

Identifying the machine

The nameplate provides the following information:

► Model

► Battery voltage

► Total rated power

► Rated current draw

► Serial number

► Year of manufacture

► IP Index of Protection

► Dry weight

► Maximum negotiable gradient

► Name of manufacturer

1 The term "machine" replaces the trade name of the machine described in this manual.

2 Persons responsible for operating the machine but not for performing maintenance operations requiring special

technical skills.

3 Persons with technical experience, training and a knowledge of applicable legislation and standards, able to perform

all necessary operations and to recognise and avoid possible risks in handling, installing, operating and maintaining the

machine.

GB

9

Documentation provided with the machine

► Operator’s manual

► Certicate of warranty

► CE certicate of conformity

GB

10

TECHNICAL INFORMATION

1

2

5

6

37

4

General description

The machine described in this manual is a motorised sweeper designed to sweep oors in civil and

industrial premises.

It may be used to clean the residues of industrial processes, dust and dirt in general on all relatively

even, at and hard surfaces such as concrete, asphalt, porcelain stoneware, ceramic tiles, sheet

metal, marble, embossed or smooth rubber or plastic mats indoors or outdoors.

Parts of the machine

The machine comprises the main parts described below (g. 1).

► Debris bin (1, g. 1). This collects the debris picked up by the main brush and dust from

the lter.

► Control panel (2, g. 1).

► Main brush (3, g. 1). This is the most important part of the machine, and transfers dust

and debris to the bin. Brushes are available in different hardnesses and with different bristles to suit the type of material to be picked up.

► Side brushes (4, g. 1). These convey dust and debris towards the main brush. They only

clean edges, corners and proles.

► Suction lter (5, g. 1). This lters the air drawn in by the suction fan.

► Suction fan (6, g. 1). This enables the machine to sweep without raising dust.

► Flaps (7, g. 1). These surround the main brush and maintain the suction created by the

fan.

1

GB

11

Hazard areas

► Control panel: risk of injury from short circuits.

► Main brush: risk of injury by rotating brush.

► Side brushes: risk of injury by rotating brushes.

► Front/rear wheels: risk of crushing between the wheels and chassis.

► Motor/engine/battery compartment: risk of injury from short circuits between battery poles;

risk of serious burns if maintenance is performed with the engine off but still hot (Petrol and

Dual Power versions).

► Debris bin: risk of crushing during lifting/lowering and rotation.

Accessories

► Soft, hard and abrasive brushes.

GB

12

SAFETY INFORMATION

Safety precautions

Read this Operator’s Manual carefully before start-up and use and before performing any

maintenance or other work on the machine.

! DANGER!

Rigorously follow all the instructions in this Operator’s Manual (in particular those marked

“Danger!” and “Warning!”. Also respect the safety labels applied to the machine (see the

The Manufacturer declines all liability for injury to persons or damage to property resulting

from failure to follow instructions.

The machine must be used exclusively by persons trained in its use and/or who have demonstrated

their ability and have been expressly authorised to use it.

The machine must not be used by minors.

The machine must not be used for purposes other than those for which it was expressly designed.

Scrupulously respect all safety standards and conditions applicable to the type of building in which

the machine is to be operated (e.g.: pharmaceutical companies, hospitals, chemicals, etc.).

Do not use the machine in inadequate lighting, explosive atmospheres, on public roads, to clean dirt

that is hazardous to health (dust, gas, etc.) or in unsuitable environments.

The machine is designed to operate in temperatures between +4°C and +40°C. It can be stored in

temperatures between +0°C and +50°C when not in use.

The machine is designed to operate at relative humidity levels between 30% and 95%.

Never use the machine to clean up ammable or explosive liquids (e.g. petrol, fuel oil, etc.), acids or

solvents (e.g. paint solvents, acetone etc.) even if diluted. Never clean up burning or incandescent

objects.

Never use the machine on slopes or ramps of more than 12%. Never drive across even gentle

slopes. Always manoeuvre with care and avoid reversing. When transiting steeper ramps or slopes,

take the utmost care to prevent tipping and/or uncontrolled acceleration.

Never park the machine on a slope.

Never leave the machine unattended with the motor or engine on. Before leaving it, turn the motor

or engine off and make sure it cannot move accidentally.

Always pay attention to other people, especially children, in the place where you are working.

Children must be supervised to make sure they do not play with the machine.

The machine is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they are supervised by a person

responsible for their safety and have received instruction in the use of the machine.

Never use the machine to transport people or goods or to tow things.

Do not tow the machine.

Never rest objects of any weight on the machine for any reason.

Never obstruct the ventilation and heat dispersion openings.

Never remove, modify or circumvent safety devices.

Numerous unpleasant experiences have shown that a wide range of personal objects may cause

serious accidents. Before beginning work, remove jewellery, watches, ties, etc..

The operator must always use personal protection devices: protective apron or overalls, non-slip

waterproof shoes, rubber gloves, protective goggles and ear protectors and mask to protect the

respiratory tract.

Keep hands away from moving parts.

Make sure the power sockets used for the battery charger are connected to a suitable earth system

and protected by thermal magnetic and earth leakage breakers.

Make sure the electrical characteristics of the machine (voltage, frequency, power) given on the

nameplate correspond to those of the mains electricity supply.

It is indispensable to respect the battery manufacturer’s instructions and applicable legislation. The

! WARNING!

“Safety symbols” section.

GB

13

batteries should always be kept clean and dry to avoid surface leakage current. Protect the batteries from impurities such as metal dust.

Never rest tools on the batteries as they could cause short circuits leading to explosions.

When using battery acid, always follow scrupulously the safety instructions given in the “Batteries:

preparation” section.

Battery charger ( OPTIONAL ): check the power cable regularly for damage. If the power cable is

damaged, do not use the charger.

If particularly strong magnetic elds are present, assess their possible effect on the control electron-

ics.

Never wash the machine with water jets.

In the case of malfunction and/or faulty operation, turn the machine off immediately (disconnecting

it from the mains power supply or batteries) and do not tamper with it. Contact a service centre

authorised by the Manufacturer.

The debris bin raising and release/tipping lever area is a “danger zone”. Keep away during the

relevant movements.

The motor/battery area is a “danger zone”. The machine must be off and the emergency button

pressed before access.

All maintenance operations must be performed in an adequately illuminated area and only after

disconnecting the machine from the power supply.

All work on the electrical system and all maintenance and repair operations other than those

explicitly described in this manual must be performed by specialist and experienced personnel

only.

Only use original accessories and spare parts supplied by the Manufacturer to guarantee safe and

problem-free operation of the machine. Never use parts removed from other machines or from

other kits.

The machine is designed and constructed to provide ten years’ service from the date of manufacture

shown on the nameplate. After this period, whether the machine has been used or not, it should be

disposed of according to current legislation in the country in which it is used.

It should be disconnected from the power supply, emptied of all liquids and cleaned prior to disposal.

The machine is classied as WEEE type special waste and is covered by the requirements of applicable environmental protection regulations (2002/96/EC WEEE).

The machine must be disposed of separately from ordinary waste in compliance with current legislation and standards.

If you decide to stop using the machine, remove the batteries and dispose of them through an authorised recycling centre.

You should also make sure that all parts of the machine that could represent a hazard, particularly

to children, are made safe.

Alternatively, return the machine to the Manufacturer for a complete overhaul.

GB

14

MOVEMENT INSTALLATION

Lifting and transporting the packaged machine

During all lifting operations, make sure the packaged machine is rmly secured to avoid it

tipping up or being accidentally dropped.

Always load/unload lorries in adequately illuminated areas.

The machine is packaged on a wooden pallet by the Manufacturer. It must be loaded on to the trans-

porting vehicle using suitable equipment (see EC Directive 89/392 and subsequent amendments

and/or additions). At destination, it must be unloaded using similar means.

A fork lift truck must always be used to lift the packaged body of the machine. Handle with care to

avoid knocking or overturning the machine.

Delivery checks

When the carrier delivers the machine, make sure the packaging and machine are both whole and

undamaged. If the machine is damaged, make sure the carrier is aware of the damage and before

accepting the goods, reserve the right (in writing) to request compensation for the damage.

! WARNING!

Unpacking

When unpacking the machine, the operator must be provided with the necessary personal

protection devices (gloves, goggles, etc.) to limit the risk of injury.

Proceed as follows to unpack the machine.

► Cut and remove the plastic straps using scissors or nippers.

► Remove the cardboard packaging.

► Remove the bags from the battery compartment and check their contents:

this Operator’s Manual, the maintenance manual, declaration of conformity, certicate of

warranty; battery bridges with terminals; connector for battery charger.

Depending on the model, remove the metal brackets or cut the plastic straps xing the machine

chassis to the pallet.

Using a sloping ramp, push the machine backwards off the pallet.

Unpack the brushes from their packaging.

Clean the outside of the machine, taking care to respect safety regulations.

Once the machine is clear of the packaging, proceed to install the batteries (see the “Batteries:

installation and connection” section).

The packaging may be kept and reused to protect the machine if it is moved to another site or to a

repair workshop.

Otherwise it must be disposed off in compliance with current legislation.

! WARNING!

Batteries (Battery version)

Two different types of battery may be installed on these machines:

► Leak-proof tubular batteries: these require regular checks on electrolyte level. When nec-

essary, top up with distilled water until the plates are covered. Do not over-ll (5 mm max.

above the plates).

► Gel batteries: this type of battery requires no maintenance.

Battery technical characteristics must correspond to those listed in the Technical characteristics

section. The use of higher capacity batteries could seriously jeopardise manoeuvrability and lead to

the drive motor overheating. Batteries with a lower capacity and weight will require charging more

frequently.

Batteries must be kept charged, dry and clean and the connections must be kept tight.

GB

15

Follow the instructions below to congure the machine’s software for the type of batteries

+

+

+

+

+

-

-

-

-

-

Battery

+

-

-

-

+

+

Dual Power

see the “Technical menu section”.

! IMPORTANT!

installed:

Batteries: preparation

During battery installation and any type of battery maintenance, the operator must be provided with the necessary personal protection devices (gloves, goggles overalls, etc.) to limit

the risk of injury. Keep clear of naked ames, avoid short circuiting the battery poles, avoid

Batteries are normally supplied lled with acid and ready for use.

If the batteries are dry, proceed as follows before installing them in the machine.

Remove the caps and ll all elements with sulphuric acid solution specic for batteries until the

plates are entirely covered (this requires at least a couple of passes for each element).

Leave the batteries stand for 4-5 hours to allow air bubbles to come to the surface and the plates

to absorb the electrolyte.

Make sure the level of electrolyte is still above the plates and if necessary top up with sulphuric

acid solution.

Close the caps.

Install the batteries in the machine (following the procedure described below).

Charge the batteries before starting up the machine for the rst time. Follow the instructions in the

“Battery maintenance and charging” section.

! DANGER!

sparks and do not smoke.

Batteries: installation and connection

Make sure you connect the terminals marked with a “+” to the positive poles of the battery.

Meticulously follow the instructions given below as short circuiting the batteries could

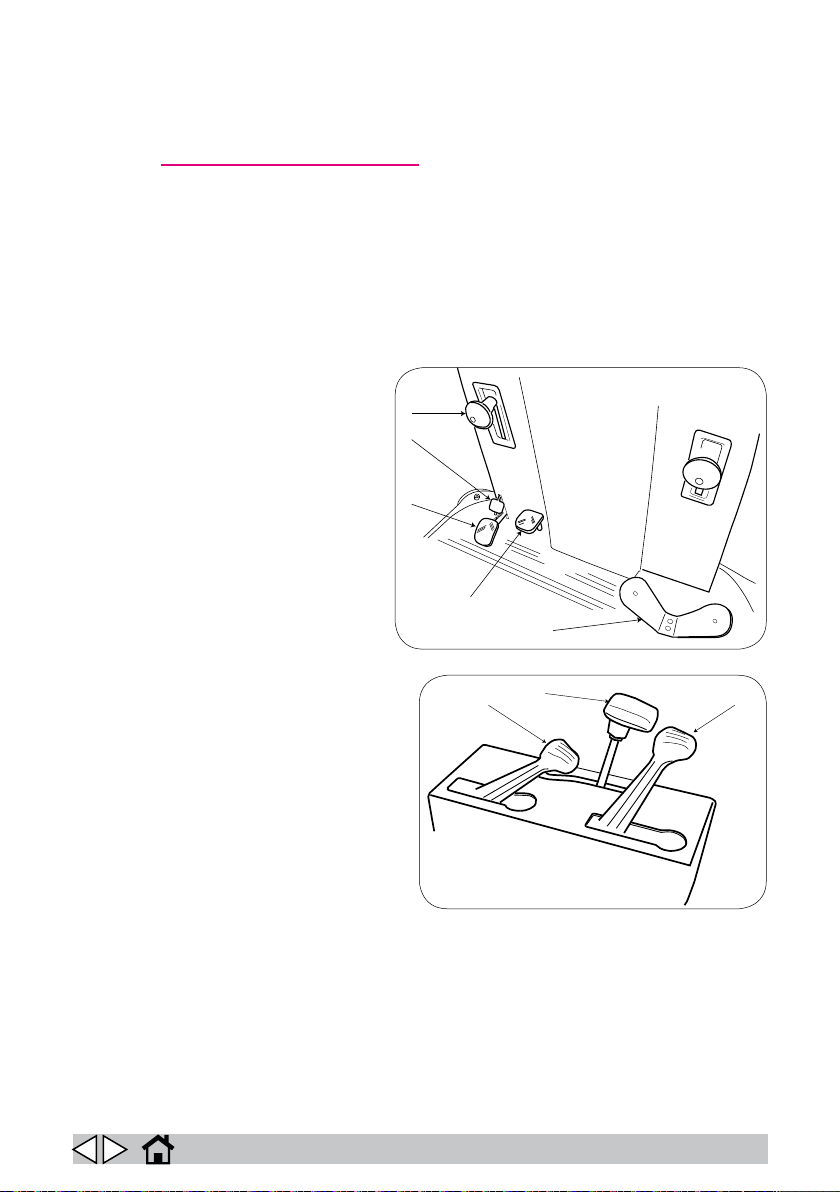

Place the batteries in the battery compartment, orienting them as shown in the drawings (gs. 2

and 3).

Referring to the cable layout shown in the above diagram, connect the battery cables and bridge

terminals to the battery poles. Arrange the cables as shown in the diagram, tighten the terminals on

the poles and coat with Vaseline.

Lower the cowling into the working position

When using the machine, follow the instructions below.

Never allow the batteries to become excessively at as this could damage them irreparably.

Check that all switches on the control panel are in the “0” (off) position.

Do not check the battery charge by sparking.

3

! DANGER!

cause them to explode.

! WARNING!

2

GB

16

Batteries: removal

When removing the batteries, the operator must be equipped with suitable personal protection devices (gloves, goggles, overalls, safety shoes, etc.) to reduce the risk of injury. Make

sure the switches on the control panel are in the “0” position (off) and the machine is turned

off. Keep away from naked ames, do not short circuit the battery poles, do not cause sparks

and do not smoke. Proceed as follows.

► Disconnect the battery cables and bridge terminals from the battery poles.

► If necessary, remove the devices xing the battery to the base of the machine.

► Lift the batteries from the compartment using suitable lifting equipment.

! DANGER!

Choosing a battery charger

Make sure the battery charger is compatible with the batteries to be charged.

Tubular lead batteries: an automatic charger is recommended. Consult the battery charger manu-

facturer and manual to conrm the choice.

Gel batteries: use a charger specic for this type of battery.

Preparing the battery charger

If you wish to use a battery charger not provided with the machine, you must t it with the connector

supplied with the machine.

Proceed as follows to t the connector.

Remove about 13 mm of protective sheath from the red and black cables of the battery charger.

Insert the wires into the connector contacts and squeeze them forcefully with suitable pliers.

Respect the polarity (red wire + black wire –) when inserting the wires into the connector.

Preparing the engine (Petrol and Dual Power versions)

► Fill the fuel tank.

► Check the engine oil level.

Preparing the hydraulic circuit (Petrol and Diesel versions)

► Check the hydraulic oil level.

Fitting the side brushes

See the “Replacing/installing the side brushes” section.

Follow the instructions given below to congure the machine’s control software to use the

See the “Technical menu” section.

! IMPORTANT!

display language you require.

GB

17

Lifting and transporting the machine

All phases of lifting and moving must be performed in an adequately illuminated environ-

ment with the adoption of the safety measures most appropriate to the situation.

The operator must always use personal protection devices.

Proceed as follows to load the machine onto a means of transport.

► Empty the debris bin.

► Remove the batteries.

► Position the machine on a pallet and x it in place with plastic straps or metal brackets.

► Lift the pallet (with the machine) using a fork lift truck and load it onto the means of trans-

port.

► Anchor the machine to the means of transport with cables connected to the pallet and to

the machine itself.

! WARNING!

GB

18

PRACTICAL GUIDE FOR THE OPERATOR

Before starting work, wear overalls, ear protectors, non-slip and waterproof shoes, mask to

protect the respiratory tract, gloves and all other personal protection devices necessitated

Do not leave the machine unattended or parked with the key in the switch and the parking

If you are using the machine for the rst time, we recommend trying it out on a large obsta-

cle-free surface rst to acquire the necessary familiarity.

Do not use the machine to clean up wire, string, plastic straps, water or other liquids.

When picking up large but light objects (e.g. paper, leaves, etc.) raise the aps.

To avoid damaging the surface of the oor you are cleaning, avoid rotating the brushes with

Each 30 minutes of work, press the lter shaker button for 30 seconds to clean the suction

lter. During this operation, the suction fan shuts off automatically (Battery and Dual Power

Avoid passing over puddles of water. If the oor is wet, you can still use the machine, but

you must turn off the suction fan since damp/wet dirt reduces the performance of the suc-

For best results, empty the debris bin often and use the lter shaker frequently to keep the

The machine is tted with a driver detection device. It is only possible to start the machine

while seated correctly in the driving seat. The device halts the machine if you get up from

! WARNING!

by the work environment.

! WARNING!

brake off.

! IMPORTANT!

! WARNING!

! IMPORTANT!

! WARNING!

the machine stationary.

! WARNING!

versions).

! WARNING!

tion lter.

! WARNING!

lter clean.

! IMPORTANT!

the seat.

Preparing the machine for work

Proceed as follows before starting work.

► Check the battery charge level (and recharge if necessary). On Petrol and Dual Power

versions, check whether the fuel tank needs topping up.

► Make sure the debris bin is empty. If necessary, empty it.

GB

19

Controls of the Battery and Dual Power versions

1

2

3

4

5

1

1

2

► Brake lock pedal (2, g. 4): Press

this pedal along with the service brake

pedal to engage the parking brake. To

disengage the brake lock and release

the parking brake, simply press the service brake pedal.

► Service brake pedal (3, g. 4): Press

this pedal to stop the machine during

operation.

► Flap lift pedal (4, g. 4): Press this

pedal to lift the aps in order to pick

up large but light objects. Release the

pedal when not needed.

► Accelerator pedal (5, g. 4): Press

this pedal to control the speed of the

machine. If the accelerator pedal is released for more than three seconds while the ma-

chine is switched on, the “ AUTO POWER-OFF” function switches off all machine functions. To start again,

simply press the accelerator pedal. You can enable/

disable and change the delay for “ AUTO POWEROFF” mode from the “Technical menu”.

► Left and right side brush control lever (1, g. 4):

Push this lever down to lower the side brushes to

working position and start rotation. Raise the lever to

lift the brushes and stop rotation.

► Main brush control lever (1, g. 5): Push this lever

forwards to lower the main brush to working position

and start rotation. Raise the lever again

to lift the brushes and stop rotation on

completion of work. The suction fan starts

automatically when the main brush starts

rotating.

► Emergency stop button (1, g. 6):

Press this mushroom head button in the

event of imminent danger or need to deactivate all machine functions and disconnect power to the machine. Switch off

all the previously active functions (side

brushes, main brush) before resetting the

emergency stop button.

► Battery charger socket (2, g. 6): Plug the battery charger into this socket. See the

”Preparing the battery charger” section.

4

5

6

GB

20

► Bin tipping lever (top unloading) (g. 7): Pull this

1

2

0

1

START

00:00

100%

1 2 3 4 5

6 7 8 9 10 11

7

lever to rotate the bin and empty its contents.

► Display (1, g. 8): This displays the current battery

charge level expressed as a percentage, logos for

active functions, an hour counter showing the total

hours of use of the machine and any active alarms,

see the “Display alarms ” section.

► Menu button (2, g. 8): On the Battery version, this

button is only active in the “Technical menu”. On the

Dual Power version, it serves to display the hours of

functioning of the engine.

► Bin up/down switch (3, g. 8): Lifts or lowers the debris bin.

► Speed control (4, g. 8): Regulates the forward and reverse speed of the machine.

► Direction selector (5, g. 8): Turn this selector to engage forward or reverse travel.

► Main switch (6, g. 8): Switches power to all machine functions on/off.

► Horn button (7, g. 8): Press to sound the horn.

► Light switch (8, g. 8): Turns the lights (OPTIONAL) on and off.

► Engine start switch (9, g. 8): Starts and shuts down the engine.

► Suction switch (10, g. 8): Switches suction on and off.

► Filter shaker button (11, g. 8): Press and hold this button for 30 seconds to shake and

clean the suction lter. As soon as the shaker motor starts, the suction and drive motors

are switched off. You can select the “automatic lter shaker” function from the “Technical

menu”. When this function is active, the lter shaker is automatically

switched on at the end of the set interval.

29

► Bin up/down movement enabling button (1, g. 29): Press this

button to enable bin movement by the bin up/down switch.

8

GB

21

Operating the Battery and Dual Power versions

1

2

3

4

5

1

2

3

► Sit correctly in the seat.

► Turn the main switch to position “1”.

► Check that the display shows the batteries to be fully charged. Recharge if necessary. See

the “Battery maintenance and charging” section.

► Select the direction of travel with the direction selector.

► Release the parking brake.

► Lower the side brushes.

► Lower the main brush.

► Press the accelerator pedal to move off and start work.

► Press the ap lift pedal only when you need to pick up large but light objects.

► Cleaning quality depends largely on the cleanliness of the suction lter. Operate the lter

shaker at intervals suitable to the environment in which you are using the machine.

Controls of the Petrol and Diesel versions

► Brake lock pedal (2, g. 9): Press

this pedal along with the service

brake pedal to engage the parking

brake. To disengage the brake lock

and release the parking brake,

simply press the service brake

pedal.

► Service brake pedal (3, g. 9):

Press this pedal to stop the ma-

chine during operation.

► Flap lift pedal (4, g. 9): Press

this pedal to lift the aps in order to

pick up large but light objects. Re-

lease the pedal when not needed.

► Direction selector pedal (5, g.

9): Press this pedal to select the

direction and the speed of travel.

► Left and right side brush control le-

ver (1, g. 9): Push this lever down

to lower the side brushes to working

position and start rotation. Raise the

lever to lift the brushes and stop rota-

tion.

► Main brush control lever (2, g. 10):

Push this lever forwards to lower the

main brush to working position and

start rotation. Raise the lever again

to lift the brushes and stop rotation on

completion of work.

► Suction control level (1, g. 10): Ad-

just this lever to increase or reduce suction.

► Engine drive lever (3, g. 10): Enables/disables all functions powered by the engine.

9

10

GB

22

► Emergency bypass (1, g. 11): Use this lever to

O

F

F

O

N

S

T

A

R

T

2 3 4 5

6 7 8

9 10

1

1

1

move the machine with the engine off. Press in the

direction shown to disengage the hydraulic pump.

► Bin tipping lever (top unloading) (g. 7): Pull this

lever to rotate the bin and empty its contents.

► Emergency stop button (1, g. 12): Press this

mushroom head button in the event of imminent dan-

ger or need to deactivate all machine functions and

disconnect power to the machine.

► Choke (1, g. 13): Pull to engage the choke for cold

starting.

► Filter shaker button (2, g. 13): Shut off suction with

the suction control lever and then press and hold this

button for 30 seconds to shake and clean the suction

lter.

► Bin up/down switch (3, g. 13): Lifts or lowers the

debris bin.

► Horn button (4, g. 13): Press to sound the horn.

► Main switch (5, g. 13): Switches power to all machine

functions on/off.

► Voltage indicator (6, g. 13): Shows correct electric

circuit voltage.

► Hour counter (7, g. 13): Shows machine operating

hours.

► Engine speed control lever (8, g. 13): Move this le-

ver to adjust engine speed.

11

7

12

13

GB

23

► Light switch (Fig. 13-Ref. 9): used to switch the

1

2

O

F

F

O

N

S

T

A

R

T

2 3 4 5

6 7 8

9 10

1

lights on and off (OPTIONAL)

► “Oil alert” light (Fig. 13-Ref.10): engine oil

pressure problem.

► Bin up/down movement enabling button (1,

g. 29): Press this button to enable bin move-

ment by the bin up/down switch.

29

13

GB

24

Operating the Petrol and Diesel versions

► Sit correctly in the seat.

► Release the parking brake.

► Move the engine speed control lever to START position.

► Pull out the choke.

► Move the engine drive lever to position 1-START and hold it there while turning the ignition

key to START position.

Do not engage the starter motor for more than ve seconds at a time. If the engine fails to

start, release the ignition key and wait ten seconds before trying again.

► Allow the ignition key to return to ON position as soon as the engine starts and release the

engine drive lever.

► Press on the direction selector pedal to move off. Press the right side to move forwards.

Press the left side to move backwards.

► Lower the side brushes.

► Lower the main brush.

► Adjust the suction control lever to obtain the required strength of suction.

► Press the ap lift pedal only when you need to pick up large but light objects.

► Cleaning quality depends largely on the cleanliness of the suction lter. Operate the lter

shaker at intervals suitable to the environment in which you are using the machine.

! WARNING!

Emptying the bottom unloading debris bin

When emptying the bin, always wear a mask to protect the respiratory tract from the dust

which is always present during this operation.

Before emptying the debris bin, operate the lter shaker for 30 seconds to clean the lter

► Release the bin lock (g. 14).

► Pull out the rear bin by means of its handle.

► Take the bin (which is tted with wheels) to the rubbish collection point and empty it.

! WARNING!

! WARNING!

14

GB

25

Emptying the top unloading debris bin

1

2

When emptying the bin, always wear a mask to protect the respiratory tract from the dust

which is always present during this operation.

Before emptying the debris bin, operate the lter shaker for 30 seconds to clean the lter

When you open the bin, all functions are disabled on Battery and Dual Power versions, and

the engine is also switched off on the Dual Power version.

► Press and hold the bin movement enabling button (1, g. 29) then operate the bin up/down

switch (2, g. 29) to raise the bin to the required height.

► Pull the lever (g. 7) to rotate the bin and empty its contents.

► Turn the bin back to its horizontal position.

► Press and hold the bin movement enabling button (1, g. 29) then operate the bin up/down

switch (2, g. 29) to lower the bin again.

! WARNING!

! WARNING!

! IMPORTANT!

7

29

Finishing work

Shake the lter at the end of every work session.

When you nish work, switch the machine off at the main switch, lift the side brushes and main

brush and engage the parking brake.

! IMPORTANT!

Moving the machine when not in operation

Proceed as follows to move the machine.

► Raise the side brushes.

► Raise the main brush.

► Select the direction of travel.

► Press the accelerator pedal.

GB

26

Proceed as follows to prepare the machine for extended periods of inactivity.

PERIODS OF INACTIVITY

► Empty the debris bin.

► Clean the suction lter.

► Disconnect the machine from the power supply.

► Completely recharge the batteries and deposit them in the battery store. During long peri-

ods of inactivity, you should charge the batteries regularly (at least once every two months)

to keep them constantly at maximum charge.

If you do not charge the batteries regularly, they may be irreparably damaged.

! WARNING!

GB

27

MAINTENANCE INSTRUCTIONS

Never perform any maintenance operations without rst disconnecting the batteries.

Maintenance of the electrical circuit and all other operations not expressly required by this

manual must be performed by specialised personnel only, in compliance with current safety

legislation and as described in the maintenance manual.

Maintenance - General rules

Performing regular maintenance according to the Manufacturer’s instructions improves performance and extends the working life of the machine.

When cleaning the machine, observe the following precautions.

► Avoid using pressure washers. Water could penetrate the electrical compartment or mo-

tors leading to damage or short circuits.

► Do not use steam to avoid the heat warping plastic parts.

► Do not use solvents or hydrocarbon based products. These can damage the cowling and

rubber components.

Replacing/installing the main brush

This operation must be performed with the machine switched off and the key removed.

Proceed as follows to replace the main brush.

► Unscrew the knob and open the door on the left of the machine.

► Unscrew the three knobs securing the brush compartment cover (g. 15).

► Remove the brush compartment cover (g. 16).

► Pull out the brush (g. 17).

► Remove the adapter from the core of the old brush and t it to the new brush, taking care

to keep the bristles aligned in the same direction (g. 18).

► Fit the adapter with the new brush in the machine, taking care to ensure that the adapter

engages the drive hub securely. Fit the cover over the brush compartment and x it in place

with the three knobs removed previously.

! DANGER!

! DANGER!

15

17

GB

16

18

28

Adjusting the main brush

The main brush makes a major contribution to the efciency of the whole machine. Correct adjustment ensures better quality cleaning in shorter times.

The machine is delivered correctly adjusted. The main brush therefore only needs further adjust-

ment when it becomes worn. Proceed as follows to adjust the main brush.

► Unscrew the knob (g. 19).

► Turn the adjuster anti-clockwise until the knob xing hole can be engaged (g. 19).

► Screw the knob back in (g. 19).

19

Replacing/installing the side brushes

! DANGER!

This operation must be performed with the machine switched off and the key removed.

For ease of transport, the side brushes are not installed on the machine when it is delivered.

Proceed as follows to install the side brushes.

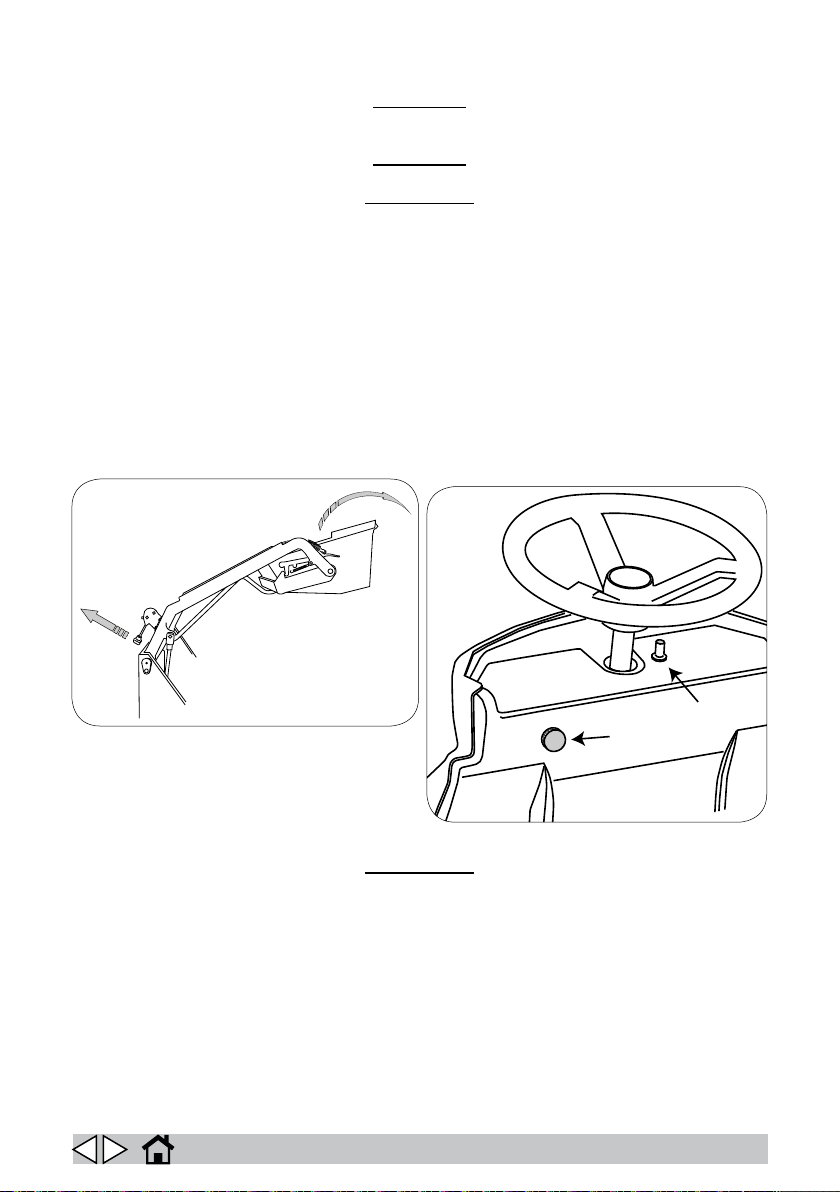

► Raise the side brush holders (g. 30).

► Unscrew the screw on the side brush motor shaft (g. 20).

► Remove the keyway protector.

► Position the brush complete with ange over the motor shaft (g. 20).

► Fit and tighten the brush locking screw again (g. 20).

Repeat the above procedure to replace worn side brushes.

30 20

GB

29

Adjusting the side brushes

The side brushes direct dirt and debris towards the centre of the machine. The most efcient height

Never operate the machine without the side brushes installed.

for this purpose is when the side brushes gently touch the oor. Proceed as follows to increase or

reduce the pressure of the side brushes on the oor, if necessary.

► Lower the side brushes into work position (g. 21).

► Loosen the two locking screws under the brush lifting knob (g. 22).

► Manually move the brush to the required position.

► Tighten the locking screws again (g. 22).

► Return the brushes to idle position.

! WARNING!

21 22

Replacing/installing the suction lter

This operation must be performed with the machine switched off and the key removed.

The suction lter makes a major contribution to the efciency of the whole machine.

Its correct maintenance keeps the machine at maximum efciency at all times. If the sweeper begins

to raise dust as it sweeps, check the condition of the suction lter.

The suction lter can be cleaned in two ways.

Semiautomatic lter cleaning:

► This method provides a quick and easy way to keep the suction lter clean and ready for

work. Press and hold the lter shaker button for a number of seconds, then repeat four or

ve times. On Petrol and Diesel versions, shut off suction with the suction control lever

before pressing the lter shaker button.

! DANGER!

GB

30

Manual cleaning of the panel lter:

FLOW

! DANGER!

This operation must be performed with the machine switched off and the key removed.

If the action of the lter shaker proves insufcient, proceed as follows to clean the lter manually.

► Remove the lter compartment cover.

► Lift the two levers and remove the lter shaker bracket complete with the lter shaker mo-

tor, carefully disconnecting the power cable from the lter shaker (g. 23).

► Remove the suction lter (g. 23).

► Blow the lter clean with compressed air (maximum pressure 6 bar).

! IMPORTANT!

The lter is marked to show the correct direction for tting.

23

Manual cleaning of the pocket lter:

! DANGER!

This operation must be performed with the machine switched off and the key removed.

If the action of the lter shaker proves insufcient, proceed as follows to clean the lter manually.

► Remove the lter compartment cover.

► Unscrew the four screws securing the two lter holder brackets (g. 24).

► Remove the two brackets (g. 24).

► Remove the lter, carefully disconnecting the power cable from the lter shaker (g. 24).

► Blow the lter clean with compressed air (maximum pressure 6 bar).

24

GB

31

Fuses: replacing

Petrol - Diesel

1 2 3

Battery - Dual Power

Battery - Dual Power

1

2

This operation must be performed with the machine switched off and the key removed.

Never use a fuse with a higher amperage than specied.

If a fuse continues to blow, the fault in the wiring, boards (if present) or motors must be identied

and repaired. Have the machine checked by qualied personnel.

Regulator fuse (1, g. 25), lter shaker and ashing beacon fuse (2, g. 25), hour counter and horn

fuse (3, g. 25), Petrol and Diesel versions.

(g. 26) Main fuse .

Manual reset cutouts for side brush motors (g. 27), Battery and Dual Power versions.

Filter shaker and suction fan fuse (1, g. 28), central brush motor fuse (2, g. 28), Battery and Dual

Power versions.

! DANGER!

! WARNING!

25 26

28

27

Battery maintenance and charging

The batteries give off ammable fumes. Put out all res and hot embers before checking or

Perform the operations described below in a ventilated area.

Do not check the batteries by sparking.

! DANGER!

topping up the batteries.

GB

32

To avoid permanent damage to the batteries, do not run them down completely.

Charging procedure

Connect the battery charger connector to the battery wiring connector.

In the case of gel batteries, use a charger specic for gel batteries only.

Charge the batteries as instructed in the battery charger manual.

Disconnect the connectors at the end of charging.

! WARNING!

! WARNING!

Changing the engine oil

On Dual power machines, change the engine oil when the “CHANGE ENGINE OIL” warning

appears on the display. On Petrol and Diesel machines, change the engine oil at the intervals

specied in the operation and maintenance manual provided by the engine manufacturer on

the basis of the hour counter on the machine’s dashboard. Always change engine oil with

the machine switched off and the engine cold.

Check that all machine functions are disabled, then lift the top cowling. Check that the engine is not

hot enough to cause burns then proceed as follows.

► Find the engine oil drain pipe and pass it through the hole in the engine compartment bot-

tom plate.

► Remove the oil level dipstick to facilitate drainage of the old oil.

► Position a suitable container under the drain pipe and unscrew the plug to let the old oil out.

► When the old oil has all drained out, t the plug back in the drain pipe and arrange the

pipe back inside the engine compartment, making sure that it does not interfere with any

moving parts.

► Add new oil through the dipstick hole in the quantity specied in the engine’s own manual.

► Once the right quantity of new oil has been added, t the oil level dipstick and check that

the level is correct.

► Close the top cowling.

! WARNING!

GB

33

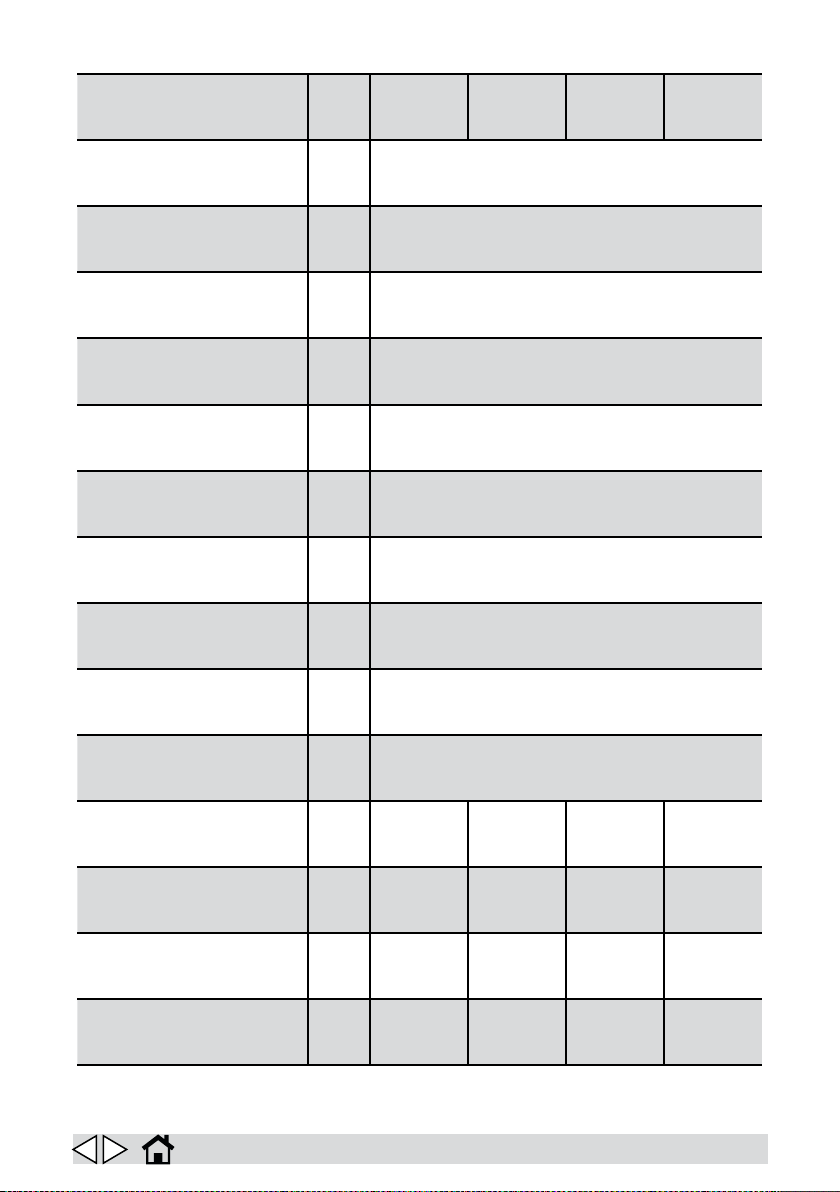

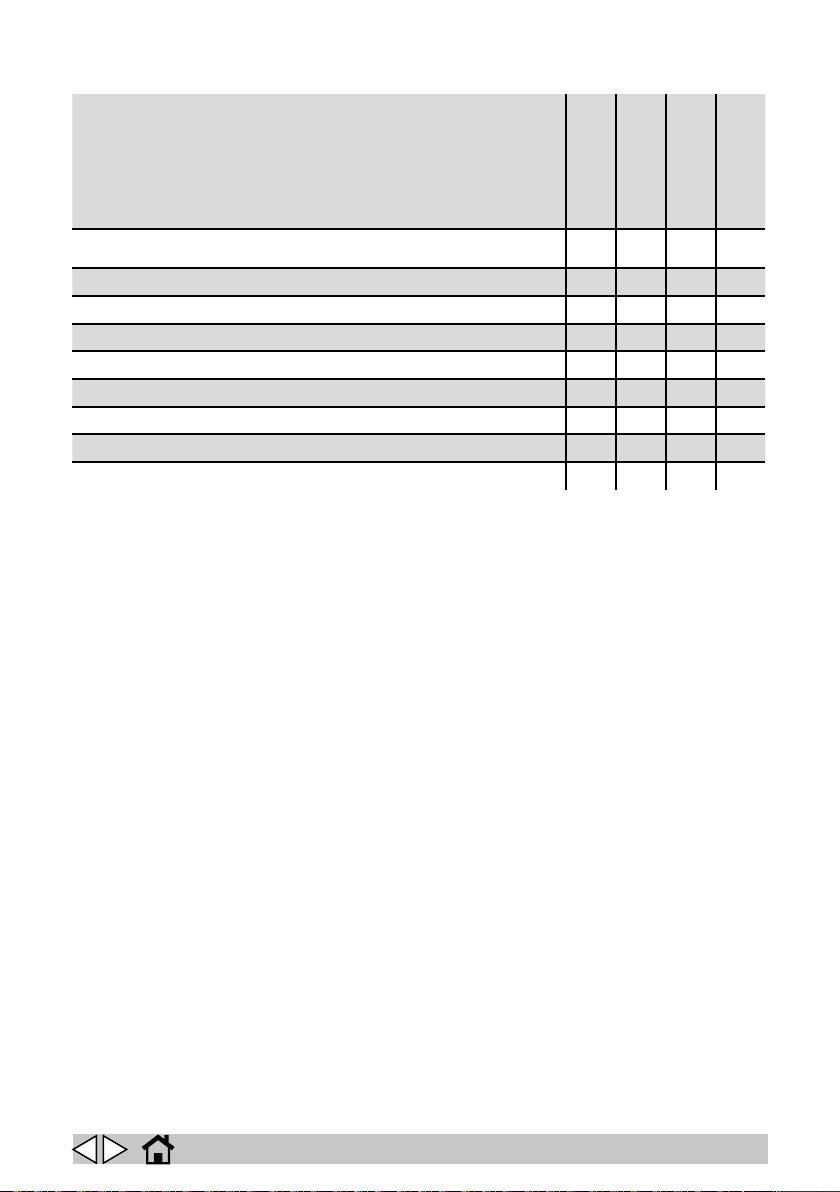

Periodic checks

CHECK

ON DELIVERY

EVERY 10 HOURS

EVERY 50 HOURS

CHECK THE BATTERY ELECTROLYTE X X

CHECK THE HYDRAULIC OIL X X

CHECK THE CONDITION OF THE BELTS X

ADJUST THE BRAKE X

CHECK THE TIGHTNESS OF NUTS BOLTS X

CHECK THE CONDITION OF THE BRUSHES X

CHECK THE TIGHTNESS OF THE SEALS X

CHECK THE FUNCTIONING OF DEVICES X X

GREASE THE STEERING CHAIN X

EVERY 100 HOURS

GB

34

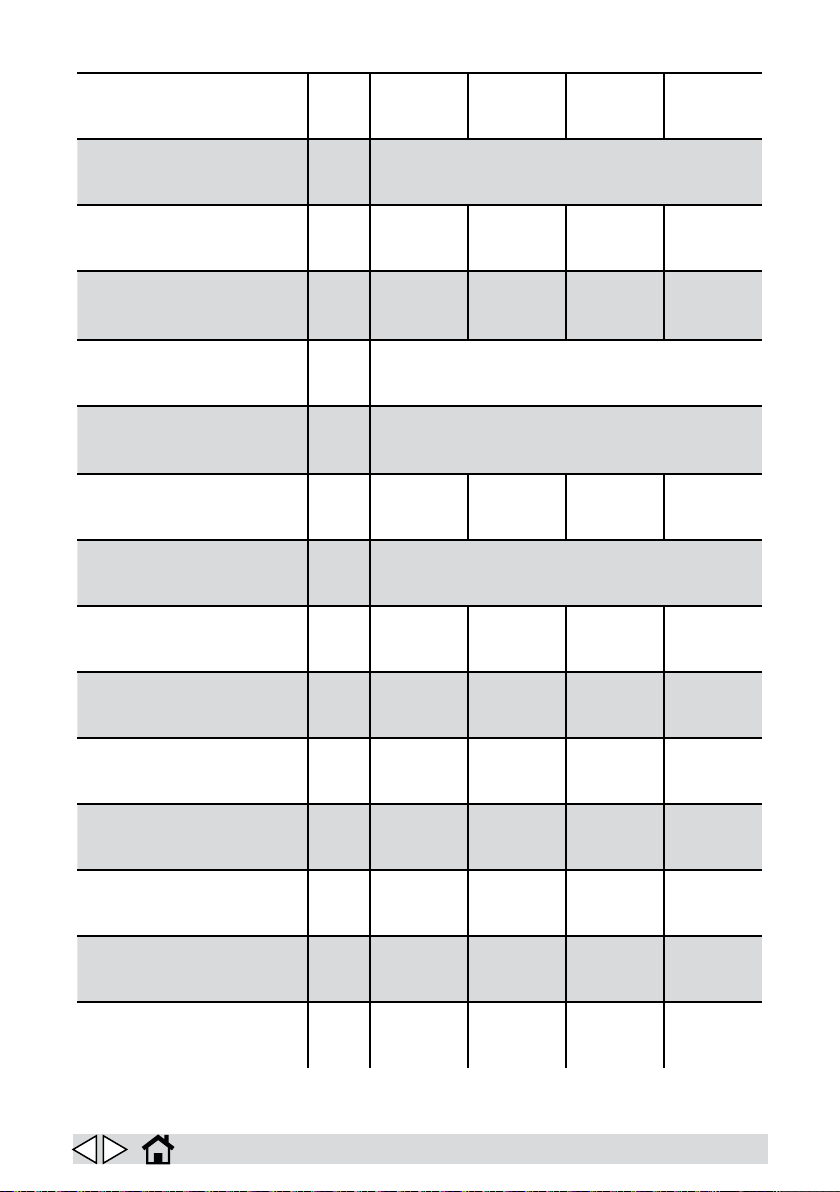

TROUBLESHOOTING

B= Battery

DP= Dual Power

P= Petrol

D= Diesel

PROBLEM CAUSE REMEDY

The machine raises dust. Filter clogged. (B,DP,P,D) Shake the lter with the lter shaker

Filter damaged. (B,DP,P,D) Replace the lter.

Filter incorrectly tted. (B,DP,P,D) Fit the lter correctly in its housing.

The machine leaves dirt on the ground. The main brush is not adjusted correctly

The main brush does not rotate. Belt broken. (B,DP,P,D) Replace.

The side brushes do not rotate. Belt broken. (P,D) Replace.

The suction motor does not work. Fuse burned out. (B,DP) Replace.

The lter shaker motor does not work. Fuse burned out. (B,DP,P,D) Replace.

or is worn. (B,DP,P,D)

The main brush has collected string or

wire. (B,DP,P,D)

The aps are damaged. (B,DP,P,D) Replace the aps.

Debris bin full. (B,DP,P,D) Empty the debris bin.

Fuse burned out. (B,DP) Replace.

Microswitch faulty. (B,DP) Replace.

Cable disconnected. (B,DP) Check.

Gearmotor faulty. (B,DP) Replace.

Cutout tripped. (B,DP) Reset.

Microswitch faulty. (B,DP) Replace.

Cable disconnected. (B,DP) Check.

Switch faulty. (B,DP) Replace.

Cable disconnected. (B,DP) Check.

Motor faulty. (B,DP) Replace.

Switch faulty. (B,DP,P,D) Replace.

Cable disconnected. (B,DP,P,D) Check.

Motor faulty. (B,DP,P,D) Replace.

and, if necessary, remove and clean it

thoroughly.

Adjust or replace the main brush as necessary.

Remove the string and wire picked up.

GB

35

The machine won’t start. Battery terminals disconnected.

The batteries do not hold their charge. Electrolyte low. (B,DP,P,D) Top up.

(B,DP,P,D)

Batteries discharged. (B,DP,P,D) Recharge.

Emergency stop button pressed.

(B,DP,P,D)

No fuel. (DP,P,D) Top up.

No engine oil. (DP,P,D) Top up.

Driver detection device faulty. (B,DP,P,D) Replace.

Operator not correctly seated. Sit correctly in the seat.

Clutch not engaged. (P,D) Engage.

Main fuse burned out. (B,DP) Replace.

Power control board fuse burned out.

(B,DP)

Battery terminal loose. (B,DP,P,D) Tighten.

Check.

Reset.

Replace.

GB

36

DISPLAY ALARMS

BRUSH MOTOR CUTOUT

TRIPPED

BRAKE The parking brake is engaged or the drive motor has over-

STAND-BY The driver detection microswitch is not detecting an operator.

RELEASE ACCELERATOR Incorrect starting sequence. Release the accelerator pedal

EEPROM 1 FAULT Replace the display board.

DRIVE CONTROL BOARD

CUTOUT TRIPPED

ACCELERATOR FAULT There is a problem with the accelerator cable.

MAX. SPEED POTENTIOMETER FAULT

UNDERVOLTAGE FAULT Check the batteries.

The brush motor has overheated.

heated.

when starting.

The drive control board has overheated.

There is a fault in the maximum speed potentiometer cabling.

OVERVOLTAGE FAULT Check the batteries.

RELAY FAULT Replace the drive control board.

HPD Check the accelerator pedal. Switch the machine off and back

MOSFET FAULT Replace the drive control board.

EEPROM 2 FAULT Replace the drive control board.

on with the accelerator released.

GB

37

SERVICE Call a service centre to arrange servicing.

BATTERY DISCHARGED Battery discharged.

START ENGINE Dual Power version only: start the engine to continue work.

BATTERY CHARGED Dual Power version only: batteries charged.

ALTERNATOR CUTOUT

TRIPPED

CHANGE ENGINE OIL Dual Power version only: change the engine oil.

COWLING OPEN

SWITCH OFF MOTOR/

ENGINE

Dual Power version only: the alternator has overheated.

GB

38

To access the technical menu, turn the main switch on then press and hold the menu and suction

TECHNICAL MENU

buttons for three seconds.

Press the “SUCTION” button to scroll up through items or increment the selected parameter value.

Press the “FILTER SHAKER” button to scroll down through items or decrement the selected pa-

rameter value.

Press the “MENU” button to select the parameter to change. The selected parameter appears in

negative.

LANGUAGE

BATTERY TYPE

AUTO POWER-OFF

FILTER SHAKER

MACHINE TYPE

BATTERY DUAL POWER

ALTERNATOR

TIME

IT, GB, ES....

ACID

GEL

OFF

TIME-OUT 0-10

SECONDS

MANUAL

AUTOMATIC 5-30

MINUTES

20-120 SECONDS

FROM ENGINE

STARTUP

EXIT

SAVE

GB

SERVICE MENUSERVICE MENU

39

Sede legale - Registered Ofce

V.le Treviso, 63

30026 Summaga di Portogruaro (Venice) Italy

Tel. +39 0421 205511 - Fax +39 0421 204227

Internet address: http://www.ipcleaning.com

Email address: http: info@ipcleaning.com

Sede produttiva - Production premises

Via Cartesio, 39

42100 Villa Bagno (R.E) Italy

Tel. +39 0522 266000 - Fax +39 0522 342045

Internet address:

http://www.ipcgansow.com

PLDC02107_2

Loading...

Loading...