Page 1

INSTALLING, OPERATING, AND MAINTAINING

INSTALLING, OPERATING, AND MAINTAINING

INSTALLING, OPERATING, AND MAINTAININGINSTALLING, OPERATING, AND MAINTAINING

MODEL D1086/D280

5 AMP GENERATOR FIELD CONTROL

WITH ‘S’ SHAPE PATTERN

GENERATOR

INSTRUCTION MANUAL # 910-1252-003

Page 2

INSTALLING, OPERATING AND MAINTAINING

THE MODEL D1086/D280

5 AMP GENERATOR

2

FIELD CONTROL

WITH ‘S’ SHAPE PATTERN GENERATOR

REVISION: 2.1

OCTOBER 2003

Page 3

TABLE OF CONTENTS

INTRODUCTION...........................................................................................................................................................................4

SAFETY.......................................................................................................................................................................................5

WARRANTY...............................................................................................................................................................................5

Q.C. TESTING.............................................................................................................................................................................5

STORAGE....................................................................................................................................................................................6

SECTION TWO..............................................................................................................................................................................7

GENERAL DESCRIPTION...........................................................................................................................................................7

INTRODUCTION........................................................................................................................................................................7

CONTROL SPECIFICATIONS...................................................................................................................................................7

Speed Settings:.........................................................................................................................................................................7

Acceleration and Deceleration Rates and Configuration: ......................................................................................................8

‘S’ Shape Curve Knee Settings ................................................................................................................................................ 8

Dead Zone Time Delay............................................................................................................................................................9

3

SECTION THREE........................................................................................................................................................................10

INSTALLATION INSTRUCTIONS ...........................................................................................................................................10

INTRODUCTION......................................................................................................................................................................10

INPUT CONNECTIONS...........................................................................................................................................................10

SPEED SELECTION CONTACTS ...........................................................................................................................................11

RUN CONTACTS......................................................................................................................................................................11

SUPPLY VOLTAGE .................................................................................................................................................................11

OUTPUT POWER CONNECTIONS ........................................................................................................................................11

GENERATOR FIELD CONNECTION.....................................................................................................................................11

FEEDBACK CONNECTION....................................................................................................................................................12

Page 4

INTRODUCTION

Thank you for purchasing an IPC Automation elevator control.

At IPC we are committed to designing and manufacturing high quality controls that meet or exceed our

customers needs. This manual provides the information you will need in order to properly install, operate and

troubleshoot the Model D1086 5 Amp Generator Field Control with ‘S’ Shape Pattern Generator. Please

read this manual completely before attempting to install or operate the Model D1086/D280.

Please feel free to call IPC Automation with any questions you may have BEFORE performing installation

or start-up.

IPC Automation

4615 West Prime Parkway

McHenry, IL 60050

4

Phone: (815) 759-3934

Fax: (815) 363-1641

Page 5

SAFETY

There are certain fundamental warnings, which must be kept in mind at all times. These include:

THE D1086/D280 SHOULD BE INSTALLED, ADJUSTED AND SERVICED BY QUALIFIED

ELECTRICAL MAINTENANCE PERSONNEL WHO ARE FAMILIAR WITH THE

CONSTRUCTION AND OPERATION OF ALL EQUIPMENT IN THE ELEVATOR SYSTEM.

PERSONAL INJURY AND/OR EQUIPMENT DAMAGE MAY OCCUR IF INDIVIDUALS ARE

NOT FAMILIAR WITH THE HAZARDS REZULTING FROM IMPROPER OPERATION.

THE USER IS RESPONSIBLE FOR CONFORMING WITH THE NATIONAL ELECTRICAL

CODE WITH RESPECT TO MOTOR, CONTROLLER AND OPERATOR DEVICE

INSTALLATION, WIRING AND START-UP. THE USER IS ALSO RESPONSIBLE FOR

UNDERSTANDING AND APPLYING ALL OTHER APPLICABLE LOCAL CODES WHICH

GOVERN SUCH PRACTICES AS WIRING PROTECTION, GROUNDING, DISCONNECTS AND

OVERCURRENT PROTECTION.

5

WARRANTY

Standard conditions of sale for the company include a Statement of Warranty, which covers the control

equipment. This Statement of Warranty covers all new equipment.

The D1086/D280 Generator Field Control with ‘S’ Shape Pattern Generator has been designed as a

standard product to meet the general criteria for providing an ‘S’ shape reference signal to be used

in conjunction with a solid state generator field control for controlling Motor Generators for Elevator

use. IPC does not warrant that the control will meet all application requirements, codes and safety

standards.

Q.C. TESTING

Each unit is carefully tested at the factory prior to shipment. The control must pass rigorous static and

dynamic performance tests as well as a final inspection for quality of workmanship. A unit is allow to ship

only after passing all aspects of this Q.A. testing and inspection process.

Page 6

STORAGE

Should it become necessary to store th e co ntrol for any length of ti me, plea se k eep the f ollo wing precautions

in mind to ensure the proper operation of the control.

" Store the control in a clean, dry (non-corrosive ) lo cation that is pr otected from sudden temper atu re

changes, high levels of moisture, shock and vibration.

" Ambient temperature should be maintained between 0 and 50 degrees Centigrade.

" The control should be covered to protect from dust and dirt conta mination (utilize origina l shipment

packaging if available).

6

Page 7

SECTION TWO

GENERAL DESCRIPTION

INTRODUCTION

The Model D1086/D280 Generator Field Control, in its typical operating mode, varies the Generator field

voltage in proportion to an input command signal. Adjustment potentiometers are provided for adjusting

six contact-selectable speed setpoints (including high speed), two acceleration rates and three deceleration

rates. Four potentiometers are also provided for the individual adjustment of the ‘S’ Shape Curve knees.

All potentiometers used for speed, acceleration, deceleration and knee adjustment are four-turn

potentiometers.

7

CONTROL SPECIFICATIONS

Input Supply: Input Line Voltage – 208 to 230 Volts AC Single Phase 50/60Hz

Output: Zero (0) to 180 Volts DC at 5 Amps.

Dimensions: Length: 10.00 inches

Width: 7.75 inches

Height: 5.00 inches

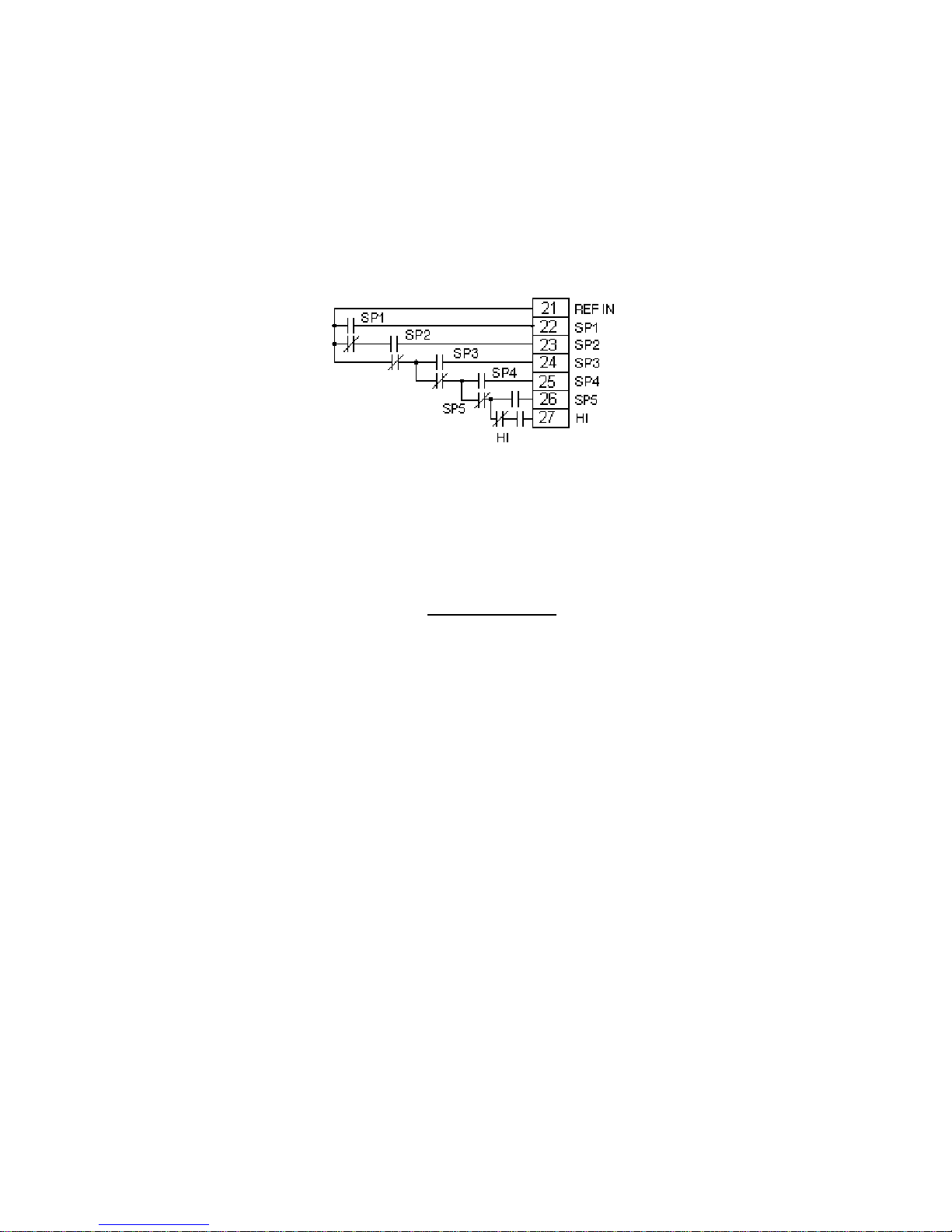

Speed Settings:

Speed

Pot Termina

SP1 TB3-22 0 to 15% 0 to 1.5 VDC

SP2 TB3-23 0 to 25% 0 to 2.5 VDC

SP3 TB3-24 0 to 100% 0 to 10 VDC

SP4 TB3-25 0 to 100% 0 to 10 VDC

SP5 TB3-26 0 to 100% 0 to 10 VDC

HI TB3-27 100% Fixed 10 VDC

Adjustable

% of Full

Speed

l

Range of Input

Reference

Voltage

Speed settings SP1 through SP5 can be adjusted withou t an UP or Down sig nal appl ied or a speed contact

pulled in. Monitor the voltage between each speed terminal connection and common (TB1-3) to set each

speed.

Page 8

Acceleration and Deceleration Rates and Configuration:

The D1086/D280 ‘S’ Shape Curve Board is factory preset with the J1 jumper in the 1-2 position. This

configuration provides two Acceleration rates (ACC1, ACC2) and three Deceleration rates (DCC1, DCC2,

and DCC3).

Figure One

Moving the jumpe r to the 2-3 position ch ang es the ACC2 poten tiome ter to a fourth De c ele r a tio n po t. In this

position there are four deceleration rates (DCC1, DCC2, DCC3, and ACC2) and only one Acceleration rate

pot (ACC1).

8

Figure Two

‘S’ Shape Curve Knee Settings

Figure Three

The ‘S’ shape of the output pattern is controlled by potentiometers P1 through P4. The curve will be very

smooth with the pots fully counter-clockwise and very sharp with the pots fully clockwise. These

adjustments will have more effect when the acceleration or deceleration rates are slow and will have less

effect when the acceleration and deceleration rates are fast.

Page 9

Dead Zone Time Delay

The Dead Z o ne Ti me D e la y allows t he c on tr ol re fe rence output si gn a l at TB2-9 to ra mp to zer o- sp e e d du ring

the interval between the drop out of the Run input direction signal, and the engagement of the mechanical

brake. The time delay circuit will produce a del ay in forcing the reference signal at TB 2-9 from the selected

speed (SP1-5,HI) to Zero vo lts up on dr opp ing the UP or DN i npu t c ont act s (TB3-35,36,37). This delay time

is adjustable from 10 milliseconds to 0.5 seconds with the R54 potentiometer.

R54 Full Counter-clockwise 0.5 second delay

R54 Full Clockwise 10 millisecond delay

9

Page 10

SECTION THREE

INSTALLATION INSTRUCTIONS

INTRODUCTION

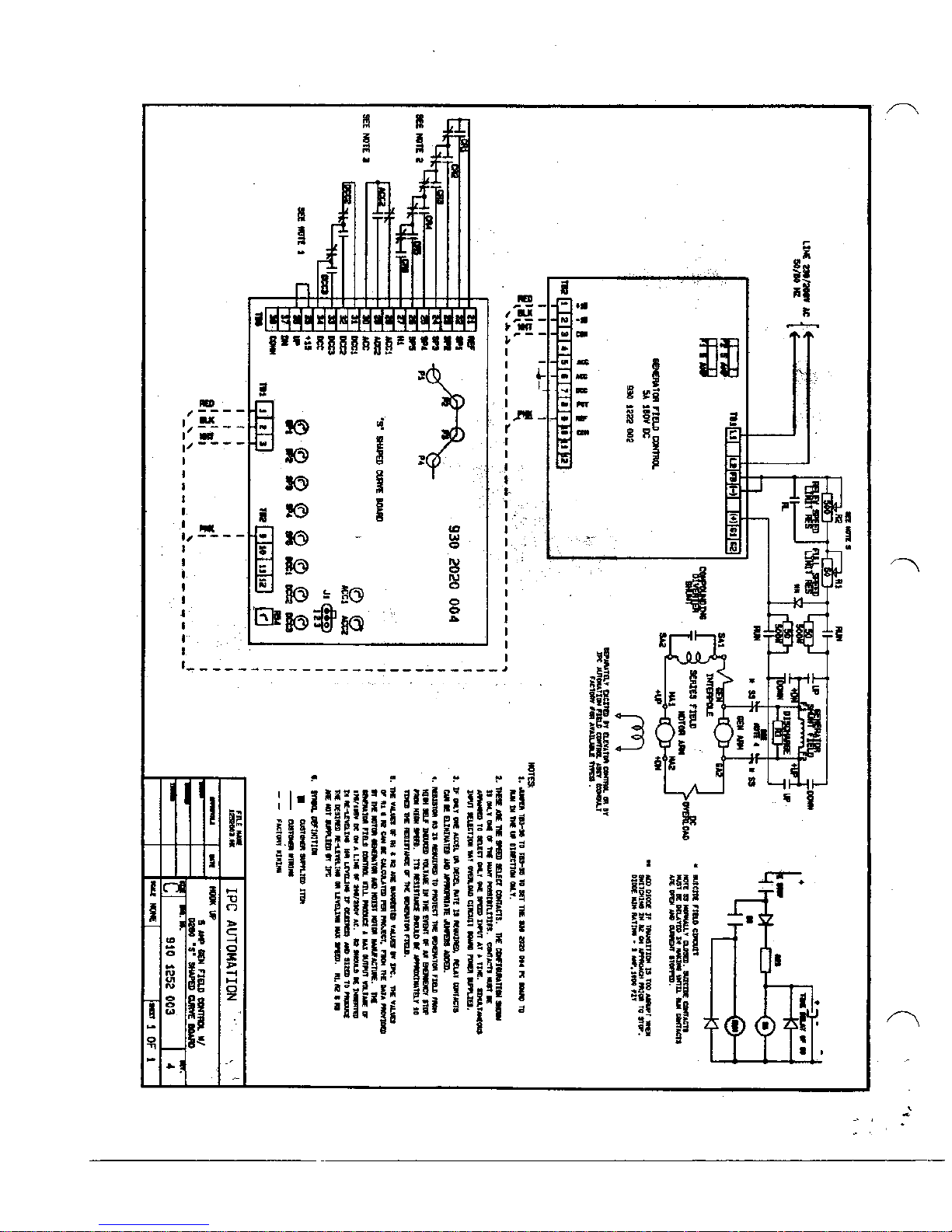

The following section contains hook-up notes and drawings for the model D1086/D280 Generator Field

Control with ‘S’ Shape Curve. The hook-up notes refer to the hook-up diagram supplied as part of this

manual.

THE D1086/D280 SHOULD BE INSTALLED, ADJUSTED AND SERVICED BY QUALIFIED

ELECTRICAL MAINTENANCE PERSONNEL WHO ARE FAMILIAR WITH THE

CONSTRUCTION AND OPERATION OF ALL EQUIPMENT IN THE ELEVATOR SYSTEM.

PERSONAL INJURY AND/OR EQUIPMENT DAMAGE MAY OCCUR IF INDIVIDUALS ARE

NOT FAMILIAR WITH THE HAZARDS REZULTING FROM IMPROPER OPERATION.

10

THE USER IS RESPONSIBLE FOR CONFORMING WITH THE NATIONAL ELECTRICAL

CODE WITH RESPECT TO MOTOR, CONTROLLER AND OPERATOR DEVICE

INSTALLATION, WIRING AND START-UP. THE USER IS ALSO RESPONSIBLE FOR

UNDERSTANDING AND APPLYING ALL OTHER APPLICABLE LOCAL CODES WHICH

GOVERN SUCH PRACTICES AS WIRING PROTECTION, GROUNDING, DISCONNECTS AND

OVERCURRENT PROTECTION

INPUT CONNECTIONS

All connections are referenced to the hook-up diagram. The configuration that is shown in the hook-up

diagram is not a recommendation, it is only one of many possibilities.

Page 11

SPEED SELECTION CONTACTS

Contacts must be arranged to select only one speed input at a time. Simultaneous input selection may

overload the circuit board power supplies.

11

Figure Four

RUN CONTACTS

The D1086 is a Uni-Directional control. In order to work properly with the D1086, the D280 ‘S’ Shape

Curve Board must be configured to run in the UP direction only. If you would like to utilize the Dead Zone

Time Delay feature of the D280 board, y o u may insert a contact from terminal 35 (+15 ) to t ermin al 36 (UP).

This contact must close to enable the elevator to run and open to enable the Dead Zone feature (during the

setting of the brake). If you do not wish to utilize the Dead Zone feature, a jumper may be used to configure

the D280 board to run in the UP direction.

SUPPLY VOLTAGE

Connect a 208 to 23 0 V olt 50 /60 Hz Sin g le Ph ase AC line to L 1 a nd L2 of TB1 on th e D 108 6 Board (bottom

Board). Internal 5 Amp fusing is provided on the D1086 board.

OUTPUT POWER CONNECTIONS

Refer to the hook-up diagram for all output power connections. The use of 16 AWG or higher rated wire

for all Generator Field connections is recommended.

GENERATOR FIELD CONNECTION

Connect the generator field to “+” and “-“ on TB1 of the D1086 (bottom) Board. Ensure proper polarity of

the field connections to avoid improper operation or damage to the control.

Page 12

FEEDBACK CONNECTION

Connect a jumper from “-“ to “FB” on TB1 of the D1086 (bottom) board.

Failure to install this jumper will cause the control to produce full output voltage when any speed is

selected.

12

Page 13

13

Loading...

Loading...