1404 - LION 1460

(IT) MANUALE ISTRUZIONI PER L’USO / (EN) OPERATOR’S MANUAL /

(FR) MANUEL D’INSTRUCTIONS / (DE) BEDIENUNGSANLEITUNG /

(ES) MANUAL DE INSTRUCCIONES / (NO) BRUKERHÅNDBOK /

(NL) GEBRUIKERSHANDLEIDING / (PT) MANUAL DE UTILIZAÇÃO /

(SE) INSTRUKTIONSBOK / (RU) РУКОВОДСТВО ОПЕРАТОРА /

(BG) РЪКОВОДСТВО ЗА ЕКСПЛОАТАЦИЯ

Consultare attentamente questo manuale prima di procedere a qualsiasi intervento sulla macchina

Read this manual carefully before carrying out any work on the machine

Lire attentivement ce manuel avant toute intervention sur la machine

Vorliegendes Handbuch vor jedem Eingri an der Maschine aufmerksam durchlesen

Consulte detenidamente este manual antes de llevar a cabo cualquier trabajo en la máquina

Konsulter denne håndboken nøye før du går i gang med noen som helst type inngrep på maskinen

Raadpleeg deze handleiding aandachtig alvorens met enige werkzaamheid aan de machine te beginnen

Consulte atentamente este manual antes de efectuar qualquer intervenção na máquina

Läs noggrant igenom denna handbok innan du utför något som helst ingrepp på maskinen

Внимательно ознакомьтесь с данной инструкцией до проведения любой работы с машиной

Прочетете внимателно това ръководство, преди да започнете работа с машината

(Translation of original instructions)

TECHNICAL SPECIFICATIONS ............................................................................................. 2

SAFETY SYMBOLS ................................................................................................................ 4

INTRODUCTION / GENERAL WARNINGS ............................................................................ 5

INTRODUCTION ..................................................................................................................... 5

GENERAL SAFETY RULES ...................................................................................................5

MODIFICATIONS AND IMPROVEMENTS ............................................................................. 6

SAFETY .................................................................................................................................. 6

SERIAL NUMBER – CE MARKING ....................................................................................... 7

UNPACKING ........................................................................................................................... 7

THE CONTROLS AND THE CONTROL PANEL .................................................................... 7

PREPARING THE MACHINE .................................................................................................8

BATTERY REMOVAL ............................................................................................................ 10

USING THE MACHINE .......................................................................................................... 10

AUTO-POWER ON/OFF ........................................................................................................ 11

WORKING .............................................................................................................................. 12

FURTHER PERFORMANCES OF THE MACHINE FEATURING AN ENGINE .................... 13

EMPTYING THE DEBRIS BIN ............................................................................................... 14

CLEANING AND SERVICING THE FILTER .......................................................................... 14

REPLACING/INSTALLING THE SIDE BRUSHES ................................................................ 15

REPLACING THE CENTRE BRUSH ..................................................................................... 16

BATTERY MAINTENANCE AND CHARGING ...................................................................... 16

ADJUSTING THE SIDE BRUSHES FOR WEAR .................................................................. 17

ADJUSTING THE BRAKE ..................................................................................................... 18

COMBUSTION ENGINE MAINTENANCE ............................................................................. 18

AIR FILTER OF THE ENGINE ............................................................................................... 18

“CHANGE OIL” ALARM CODE ............................................................................................ 19

MAINTENANCE OF THE BATTERY VERSION .................................................................... 20

COMBUSTION ENGINE VERSION MAINTENANCE ........................................................... 21

TROUBLESHOOTING TABLE ..............................................................................................22

DRIVE BOARD ALARMS ...................................................................................................... 24

USER MENU .......................................................................................................................... 25

EN

1

(Translation of original instructions)

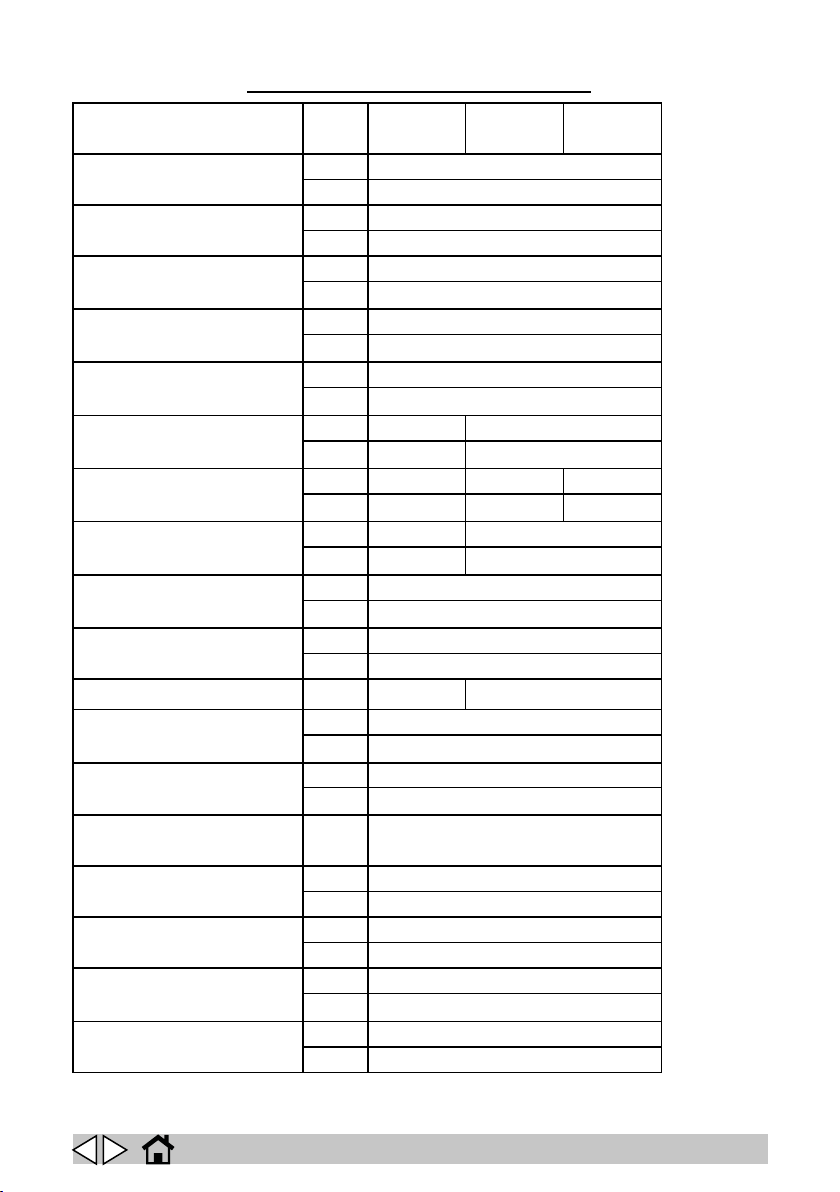

TECHNICAL SPECIFICATIONS

B

Cleaning width

Cleaning capacity per hour

Main brush motor power

Side brush motor power

Drive motor power

Internal combustion engine starting

Internal combustion engine power

Fuel tank capacity

Suction motor power

Panel lter shaker motor power

Alternator A / 80

Maximum forward speed

Maximum reverse speed

mm 800

inches 31,49

2

/h 8250 - 10500

m

2

/h 88802 - 113021

ft

W 500

HP 0,67

W 60

HP 0,08

W 1000

HP 1,34

W / 300

HP / 0,4

W / 48470,5 73824,3

HP / 6,5 9,9

l / 5

galls. / 1,32

W 2X180

HP 2X0.24

W 2X90

HP 2X0.12

Km/h 6,5

mph 4,03

Km/h 3,4

mph 2,11

DUAL POWER

PETROL

DUAL POWER

DIESEL

Maximum negotiable gradient % 16

Debris bin capacity

Rear wheel diameter

Front wheel diameter

Main brush diameter

l 150

galls. 39,62

mm 315

inches 12,4

mm 315

inches 12,4

mm 330

inches 13

EN

2

(Translation of original instructions)

Side brush diameter

Panel lter surface area

Gross weight

Transported weight

Number of batteries no. 4 2 2

Battery voltage V 6 12 12

Individual battery capacity Ah (5h) 250 105 105

Power system voltage V 24

Machine dimensions

Battery compartment dimensions

(length, width, height)

Packed size (length, width, height)

Sound pressure

Measured sound power

Guaranteed sound power

Vibration level (hand)

mm 510

inches 20,07

sq.m. 6

2

ft

kg 765 647 675

lbs

kg 375 210 210

lbs

mm 1600X1080X1280

inches 63x42.5x50.4

mm 480x370x360

inches 18.9x14.6x14.1

mm 1870x1200x1500

inches 73.62x47.24x59.05

LpA

(dB)

Lwa

(dB)

Lwa,g

(dB)

HAV

m/sec2

70 78 81

76 93 96

77 93 97

1,8 2,1 2,3

64,58

Measurement uncertainty, k m/sec2 0,9 1,1 1,2

Vibration level (body)

Measurement uncertainty, k m/sec2 0,2 0,4 0,4

Gross weight (GVW): maximum permissible weight with the machine fully loaded and ready for use. The gross weight of the

vehicle includes, when applicable, full clean water tanks, empty dirty water tanks (half full in the case of recycling systems), empty

dust bags, the hopper lled to its rated capacity, the largest recommended batteries and all accessories such as cables, hoses,

detergent, mops and brushes.

Transported weight: the weight of the machine including the batteries, but excluding optionals (for example, the operator’s cabin,

FOPS, second and third side brushes and front brush attachment), fresh water (in the case of scrubbers or combined machines)

and the weight of a standard operator (75 kg).

Data may vary without warning.

HBV

m/sec2

0,5 0,7 0,8

EN

3

(Translation of original instructions)

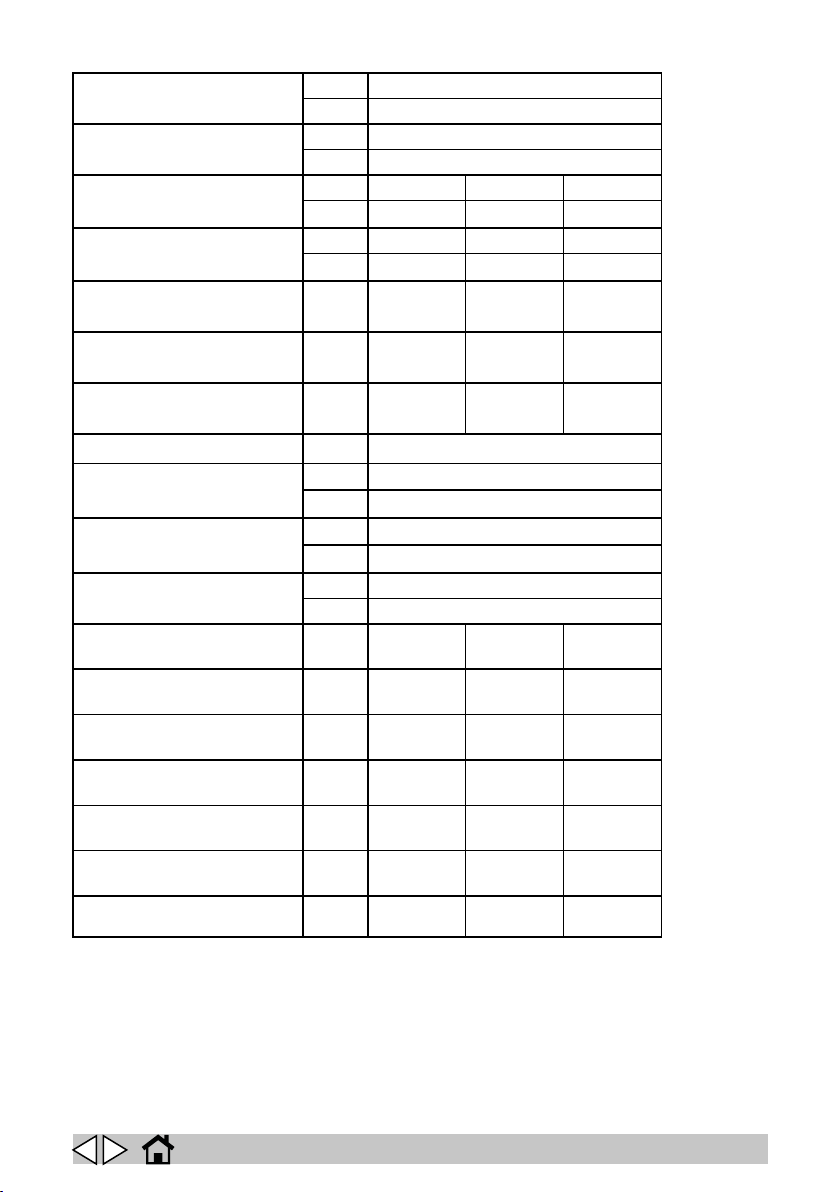

SAFETY SYMBOLS

WARNING! RISK OF ENTANGLEMENT

WARNING! RISK OF ACID BURNS

WARNING! RISK OF BURNS

MAXIMUM SLOPE

OPERATOR MANUAL, INSTRUCTIONS FOR USE

READ THE OPERATOR'S MANUAL

DIRECT CURRENT SYMBOL

CLASS III APPLIANCE. AN APPLIANCE IS IDENTIFIED

AS CLASS III WHEN ITS EXPLOSION-PROOF

PROTECTION IS BASED ON THE FACT THAT THERE

ARE NO VOLTAGES HIGHER THAN THE ULTRA-LOW

SAFETY EXTRA-LOW VOLTAGE (SELV). THIS MEANS

IN PRACTICE THAT THE APPLIANCE IS POWERED BY

A BATTERY OR A SELV TRANSFORMER.

SPECIAL WASTE. DO NOT DISPOSE OF AS NORMAL

WASTE.

EN

4

(Translation of original instructions)

INTRODUCTION / GENERAL

WARNINGS

This manual has been written by the

Manufacturer and is an integral part of the

machine1.

It denes the purpose for which the machine

has been designed and constructed and

contains all the information required by

operators2.

In addition to this manual, which contains

information for operators, other publications

are available providing specic information for

maintenance personnel3.

The terms “right” and “left”, “clockwise” and

“anti-clockwise” refer to the forward movement

of the machine.

Constant compliance with the instructions

provided in this manual guarantees the safety

of the operator and the machine, ensures

low running costs and high quality results

and extends the working life of the machine.

Failure to respect the instructions may lead to

damage to the operator, machine, oor and

environment.

To nd the topic that interests you more

quickly, see the list of contents at the beginning

of the manual.

INTRODUCTION

This instruction handbook contains guidelines

and practical information concerning the use,

adjustment and routine maintenance of your

new machine.

Your machine has been designed and built

to oer the best in terms of performance,

comfort and ease-of-use in a variety of dierent

conditions. Before delivery, your machine

has been checked at our factory and by our

dealer to guarantee that it is handed over to

you in perfect working order. To maintain the

machine in this condition and ensure problemfree operation, strictly follow the instructions

given in the handbook. Before attempting to

use the machine, read this handbook and

keep it to hand for any future consultation. For

further information regarding the machine, do

The denition "machine" replaces the trade name covered by this manual.

Persons responsible for using the machine without per-

forming any operations requiring precise technical skills.

Persons with experience, technical training and a knowledge of legislation and standards, able to perform all the

necessary operations and to recognise and avoid possible

risks in handling, installation, use and maintenance of this

machine.

not hesitate to contact your dealer, who has

competent maintenance sta, original parts

and the equipment needed to respond to your

needs.

NOTE: the machine version called DUAL

POWER refers to the model equipped with

an combustion engine and battery pack.

GENERAL SAFETY RULES

IMPORTANT: the following rules must be

carefully observed to avoid harm to the

operator and damage to the machine.

Carefully read the labels on the machine and

do not cover them for any reason; replace

them immediately if they are

damaged.

The storage temperature ranges from 0° to +

50°C.

The optimal working temperature should range

from 0° and + 40°C.

The ambient humidity must range from 0 to 95

%.

The machine must be kept indoors at all times.

The machine must be used exclusively by

operators trained in its use and/or who have

demonstrated their ability and have been

expressly authorised to use it.

The machine must not be used by minors.

Always pay attention to other people,

especially children, in the place where you are

working.

Children must be supervised to make sure they

do not play with the machine.

The machine is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they are

supervised by a person responsible for their

safety and have received instruction in the use

of the machine.

Do not inhale exhaust gases. Use the machine

indoors only when sucient ventilation can be

guaranteed and when there is another person

on stand-by, ready to assist in situations of

potential danger.

Do not bump against shelves or scaolding

when there is a risk of objects falling over.

In areas where the operator could be struck

by objects falling from overhead, do not use

the machine without a FOPS (Falling Object

Protective Structure)

Do not use the machine as means of transport.

Never use the machine to clean up ammable

or explosive liquids (e.g. petrol, fuel oil, etc.),

acids or solvents (e.g. paint solvents, acetone

EN

5

(Translation of original instructions)

etc.) even if diluted.

Never clean up burning or incandescent

objects.

Adapt the speed of the machine to the

conditions of adherence.

Avoid using the machine if its stability is not

guaranteed.

In the event of re, use a powder re

extinguisher, DO NOT USE WATER.

Do not use solvents or similar substances to

clean the machine.

Do not wash the machine by spraying directly

with water or using high pressure water jets.

Do not remove any guards that require the use

of tools to be removed.

NEVER use the machine without its guards

and safety systems. For your safety, make sure

all guards and safety systems are closed and

correctly mounted before starting the machine.

If you notice that the machine is not working

properly, make sure this does not depend on

failure to carry out the routine maintenance

operations. If this is not your case, contact

anauthorised service centre.

Always use the battery charger supplied by

the manufacturer, or alternatively, a charger

bearing the CE mark and certied by a third

party body in accordance with the latest edition

of the pertinent standard (EN 60335-2-29).

The charger must be equipped with double

or reinforced insulation between input and

output and with a SELV type output circuit with

maximum 24V output voltage.

Make sure the battery charger is compatible

with the batteries to be charged.

Make sure that the power socket used for the

battery charger is connected to a suitable earth

system and protected by thermal overload and

residual current circuit breakers.

Make sure the electrical characteristics of the

battery charger (voltage, frequency, absorbed

power) given on the rating plate are the same

as those of the mains power supply.

Check the battery charger power cable

regularly for damage. If the power cable is

damaged, do not use the charger.

If replacing parts, order ORIGINAL spare parts

from an authorised dealer or reseller.

Maintenance operations on the electrical

circuit and in any event all other operations

not explicitly described in this operating

manual must be performed by maintenance

personnel only, in compliance with current

safety regulations and as indicated in the

maintenance manual.

Always disconnect the power supply to the

machine before carrying out any maintenance.

Every 200 hours of work, have the machine

checked by an authorised service centre.

The product is classied as WEEE type special

waste and is covered by the requisites of the

new environmental protection regulations

(2002/96/EC WEEE). It must be disposed of

separately from ordinary waste in compliance

with current legislation and standards.

MODIFICATIONS AND

IMPROVEMENTS

Our company aims to constantly improve its

products, and consequently reserves the right

to make any changes and improvements when

deemed necessary, without having to apply

such to any machines sold previously.

SAFETY

You too can help avoid accidents.

No accident prevention program can be

eective without the full cooperation of the

operator directly responsible for operation of

the machine.

Most accidents that occur in a company, during

work or transport are caused by failure to

observe the basic rules concerning safety.

A careful and prudent operator is the best

guarantee against accidents and proves more

eective than any prevention program.

During work, pay attention to the persons

standing in the area to clean, especially

children.

EN

6

(Translation of original instructions)

SERIAL NUMBER – CE

MARKING

Make sure that the machine is equipped with a

rating plate showing the serial number and CE

mark, positioned as shown in (g. 1). If this is

not the case, notify the dealer immediately.

Model :

Ser.N :

Vac :

Date :

W :

IP :

A :

Kg :

Hz :

g. 1

machine operation; assemble as described in

the chapter “REPLACING/INSTALLING THE

SIDE BRUSHES”.

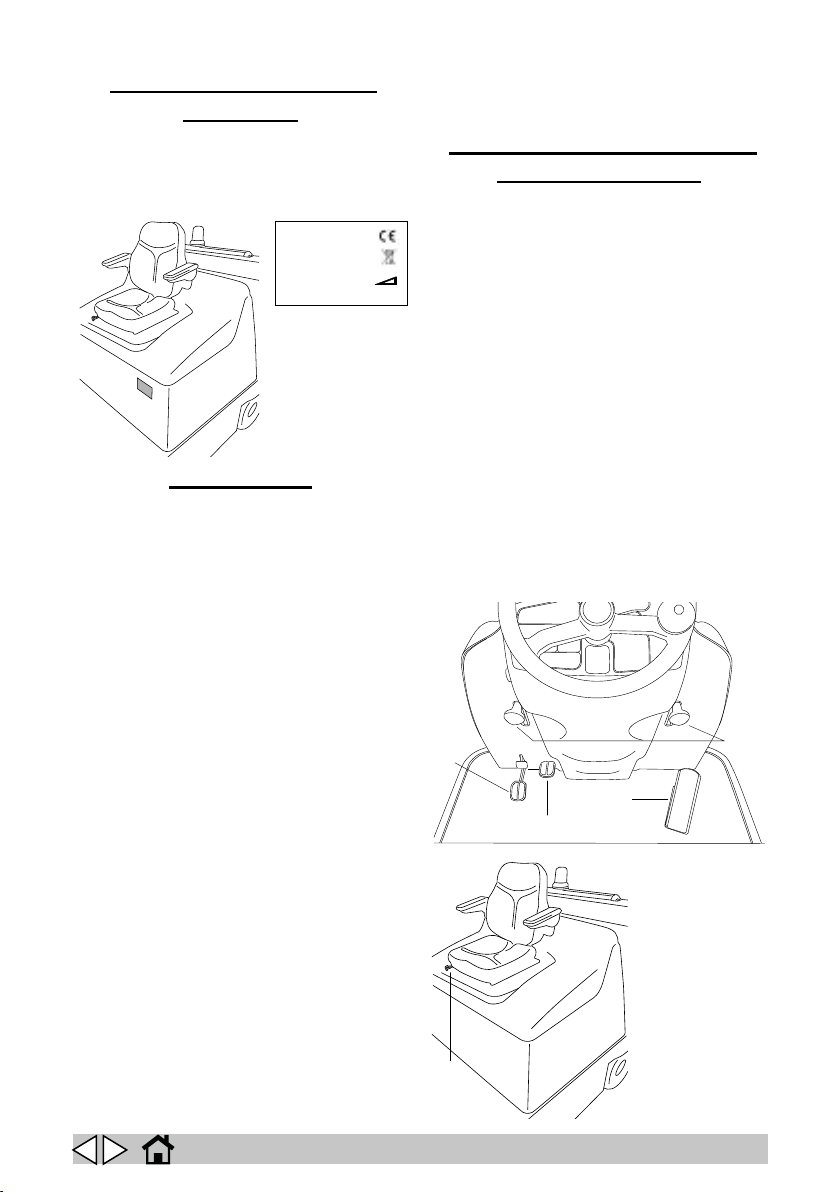

THE CONTROLS AND THE

CONTROL PANEL

• Brake lock pedal and service brake pedal

(g. 2, ref. 1).

• Raise ap pedal (g. 2, ref. 2), pressing

this allows the centre brush to pick up

bulky objects.

• Accelerator pedal (g. 2, ref. 3).

• Right side brush control lever (g. 2, ref.

4), used to lower or raise the side brush.

• Left side brush control lever (g. 2, ref.

4A), used to lower or raise the side brush.

• Seat adjustment lever (g. 2, ref. 5).

Unpack your machine with great care, avoiding

UNPACKING

any manoeuvre that could lead to damage.

Once you have unpacked it, make sure all

parts are in a good condition. If you notice

any damage, DO NOT use the machine and

contact your retailer immediately.

Due to packaging and transport requirements,

some parts and optionals may be supplied

separately; for correct assembly, follow

the instructions given in the corresponding

chapters of this booklet.

Contents of the package

• Side brush

• Ignition key

• User and maintenance manual

Declaration of conformity

• Warranty coupon

• Batteries (if required)

Battery connection kit

• Battery charger (if required)

• For the Dual Power version, combustion

engine user manual.

If you notice that any of the above are missing,

contact your retailer immediately.

NOTE: To avoid losing it during transport,

the ignition key is placed inside the bag

containing the technical documents.

Make sure the packaging materials (bags –

cartons – pallets – hooks – etc.) are put away,

out of the reach of children.

To simplify transport, the side brush/brushes

are not mounted in the position intended for

4-4A

1

3

2

5

g. 2

EN

7

(Translation of original instructions)

1

2

• Display button, selects the data shown on

the display (g. 3, ref. 1).

• Display (g. 3, ref. 2):

• Button P1, select work program 1 (g. 3,

ref. 3).

• Button P2, select work program 2 (g. 3,

ref. 4).

• Button P3, select work program 3 (g. 3,

ref. 5).

• Filter shaker activation button (g. 3, ref.

6):

• Suction activation button (g. 3, ref. 7):

• Knob for adjusting the speed of the side

brushes (g. 3, ref. 8).

• Combustion engine start/stop button (g.

3, ref. 9).

• Ignition key (g. 3, ref. 10):

• Horn button (g. 3, ref. 11):

• Light switch (g. 3, 12) OPTIONAL.

• Emergency button (g. 3, ref. 13):

• Knob for adjusting the maximum speed

(g. 3, ref. 14).

• Drive board alarm indicator light; the

frequency at which the LEDs light up

indicates the error code. In the absence of

malfunctions, the status LED is on steady

while the machine is operating (g. 3, ref.

15).

• Machine direction selector (g. 3, ref. 16).

• Raise bin control button (g. 3, ref. 17).

• Lower bin control button (g. 3, ref. 18)

• Tip bin control button (g. 3, ref. 19)

• Fuel reserve indicator light (g. 3, ref. 20)

• Oil alarm indicator light (g. 3, ref. 21)

• Button for raising, lowering and tipping the

bin (g 3, ref. 22).

14 15

11

4

3

6

7

8 17 18 19

12

21

5

13

START

OFF

20 9 10

22

O

FF

N

O

g. 3

PREPARING THE MACHINE

IMPORTANT: Competent battery specialists

should preferably be contacted to choose

and install the new batteries.

Two dierent types of battery may be installed

on these machines:

• Leak-proof tubular batteries: these require

regular checks on electrolyte level. When

necessary, top up with distilled water until

the plates are covered. Do not over-ll (5

mm max. above the plates).

• Gel batteries: this type of battery requires

no maintenance.

Leak-proof tubular batteries are normally

supplied lled with acid and ready for use.

If the batteries in use are dry charged, they

must be activated before being installed in the

machine. Proceed as follows:

Remove the caps and ll all elements with

sulphuric acid solution specic for batteries

until the plates are entirely covered (this

requires at least a couple of passes for each

element).

Leave the batteries to stand for 4-5 hours to

16

EN

8

(Translation of original instructions)

DIESEL

allow air bubbles to come to the surface and

the plates to absorb the electrolyte.

Make sure the level of electrolyte is still

above the plates and if necessary top up with

sulphuric acid solution;

Close the caps.

Take special care when working with sulphuric

acid, as it is corrosive. Observe the following

precautions:

• Contact with the skin can cause irritation;

wash with soap and water.

• Inhalation of vapours can cause irritation

to the airways; stay out in the open air

and consult a doctor.

• Contact with the eyes can cause irritation;

ood the eyes with water immediately and

thoroughly for at least 15 minutes, and

consult a doctor.

Install the batteries in the machine (following

the procedure described below).

It is recommended to perform a rst top-up

before starting the machine; for this operation

see the chapter “BATTERY MAINTENANCE

AND CHARGING” and the battery instruction

booklet.

Lift the cowling toward the steering wheel of

the machine, and locate the batteries in the

compartment, positioning them as indicated in

the drawing (g. 4).

+12V

DIESEL

The electrical connection cables supplied

with the machine may be used to connect the

batteries.

IMPORTANT: in the battery compartment

on the DUAL POWER version equipped

with the DIESEL engine, there is a red wire

marked with the label “+ 12V”; this wire

must be connected to the +12V battery pole

(starter motor power supply).

With the batteries installed, plug the battery

connector into the machine (g. 5).

g. 5

NOTE: when the batteries are installed, set

the language to be used for the messages

shown on the display in the machine's

software menu; see the chapter “USER

MENU”.

NOTE: with the batteries installed, set the

type of battery selected in the machine’s

“TECHNICAL MENU”; contact the dealer.

For the combustion engine version, ll the fuel

tank: the type of fuel is specied on a label

near the fuel cap (g. 6).

g. 4

+12V

EN

g. 6

9

(Translation of original instructions)

Check the engine oil level (see the chapter

“COMBUSTION ENGINE MAINTENANCE”).

Climb onto the machine and adjust the seat as

desired (g. 7).

USING THE MACHINE

Insert the ignition key (g. 8), turn it clockwise:

the display will show all zeros for about 3

seconds, after which the battery voltage value

will be shown.

g. 7

BATTERY REMOVAL

IMPORTANT: when removing the batteries,

operators must use the necessary

equipment (gloves, goggles, protective

overalls, safety shoes, etc.) to limit the risk

of accidents.

Check that all the switches on the control panel

are in position “0” (o) and that the machine

is switched o, away from any naked ames;

do not short-circuit the battery poles, do not

cause sparks and do not smoke, and proceed

as follows:

• disconnect the battery wiring and bridge

terminals from the battery poles.

• if necessary, remove the devices xing

the battery to the base of the machine.

• lift the batteries from the compartment

using suitable lifting equipment.

IMPORTANT: When disposing of the

batteries, ensure compliance with local by-

laws or regulations.

STA R T

OFF

O

FF

N

O

g. 8

NOTE: in the operator’s seat is a safety

device that prevents drive (forward and

backward) when the operator stands up

from the seat.

NOTE: temporary activation of the indicator

lights on the console and of the horn is to

be considered normal.

Let at least three seconds pass after you have

turned o the machine, before turning it on

again.

Check the battery charge shown on the

machine’s display.

The display has two functions: Voltmeter and

Hour meter.

The voltmeter incorporates an undervoltage

shutdown function that automatically disables

all services except for drive when the battery

drops to a voltage of 20.5V (the BATTERY

DISCHARGED error code ashes on the

display).

In this case, recharge the battery (see the

chapter “BATTERY MAINTENANCE AND

CHARGING” and the battery user manual).

If the batteries are suciently charged, work

can now resume.

If the machine features a petrol engine, rst

start the engine.

EN

10

(Translation of original instructions)

STA R T

O

FF

O

N

IMPORTANT: DUAL POWER version

equipped with DIESEL engine, during

operation with the combustion engine o,

the “OIL ALARM” light remains on (g. 9);

this is normal.

g. 11

g. 9

IMPORTANT: the “OIL ALARM” indicator

light (g. 9) comes on when ignition is

started; on ignition the engine starts and

the indicator light goes o. If the light

comes on when driving, stop the machine

and check the engine oil level.

To start the combustion engine, push the

selector to the START position (g. 10), the

lever returns automatically.

STA R T

OFF

O

FF

N

O

g. 10

If the combustion engine does not start

immediately, the starter motor must not be

engaged for more than 5 seconds. This interval

can be repeated after a short rest period (about

8 - 10 seconds).

To stop the engine, turn the selector back

to the OFF position. In the event where

the alternator overheats, there is an

overtemperature protection device that stops

the machine; the “PAUSE MOTOR” error code

will be shown on the display

To start the machine, select forward or reverse

gear using the selector (g. 11).

NOTE: if needing to push the machine

when o or without the batteries, turn the

appropriate key to disengage the electric

drive motor; this will disable the machine’s

automatic braking function (g. 12).

g. 12

AUTO-POWER ON/OFF

The machine is equipped with an automatic

system for switching the functions on or o.

Selecting one of the three work programs, P1,

P2 or P3 temporarily activates the following

functions: centre brush, suction, side brushes;

the LED for the selected program lights up

together with the centre brush LED.

If the accelerator pedal is not pressed, after

a few seconds the functions will stop and the

LEDs will start ashing: the machine is now in

AUTO-POWER-OFF mode.

All of the functions are automatically

reactivated whenever the operator presses the

accelerator pedal.

By releasing the accelerator, all the functions,

except for the combustion engine, are

automatically deactivated.

NOTE: the “AUTO-POWER ON/OFF” system

can be disabled in the machine’s software

menu; see the chapter “USER MENU”.

EN

11

(Translation of original instructions)

STA RT

O

FF

O

N

START

OFF

O

FF

O

N

WORKING

IMPORTANT: do not inhale exhaust gases.

Use the machine indoors only when

sucient ventilation can be guaranteed and

when there is another person on stand-by,

ready to assist in situations of potential

danger.

IMPORTANT: the machine must only be

used on dry surfaces.

IMPORTANT: in areas where the operator

could be struck by objects falling from

overhead, do not use the machine without a

FOPS (Falling Object Protective Structure)

IMPORTANT: do not drive the machine with

the bin raised, except when approaching or

moving away from the garbage container.

Once the machine has been switched on and,

if necessary, after starting the combustion

engine, select the most suitable of the three

work programs for cleaning by pressing one of

the three buttons.

BUTTON P1 (light interior cleaning of quartz

concrete, smooth oors, etc.) (g. 13).

BUTTON P2 (cleaning carpets or other

surfaces) (g. 13).

BUTTON P3 (heavy exterior cleaning, asphalt

or uneven surfaces with large debris, etc.) (g.

13).

NOTE: the working parameters for

programs 1 - 2 - 3 are preset by the

manufacturer; to change the values contact

the dealer.

Lower the left and/or right side brush by pulling

the appropriate levers up or down (g. 15).

NOTE: the respective left and/or right

indicator light will light up on the control

panel.

NOTE: a resettable fuse is tted above

each side brush lever. If a side brush stops

working, press the button to reset the fuse

(g. 15).

To return the side brushes to the OFF position,

lift the two levers upwards.

OFF

SIDE

BRUSH

ON

g. 15

The speed of the side brushes can be adjusted

by turning the knob (g. 16).

g. 16

g. 13

Adjust the maximum drive speed according to

the working conditions by turning the knob (g.

14).

g. 14

The machine is equipped with an emergency

stop button (g. 17); pressing this button

immediately stops all the functions of the

combustion engine. To reactivate the machine,

release the button, then activate the desired

functions.

g. 17

EN

12

(Translation of original instructions)

If needing to work on wet ground, in order to

protect the paper lters, it is essential to stop

the suction motor by pressing the suction

button (g. 18).

g. 18

When work is nished, deselect the work

program used (1-2-3) and switch o the

combustion engine by moving the lever to the

OFF position.

Before leaving the machine, make sure that

the side brushes are raised from the oor, the

parking brake is engaged and that the ignition

key has been take out of the instrument board.

FURTHER PERFORMANCES

OF THE MACHINE

FEATURING AN ENGINE

The version featuring an engine can guarantee

the same working eciency even when the

motor is o, for instance when the fuel has run

out or when working in closed environments.

Operating autonomy in this case will depend

on the capacity of the batteries installed, on the

intensity of the chosen work program and on

initial battery charge.

To guarantee the working life of the batteries,

the machine features some safety systems:

• when the battery voltage drops below

20.5 volts, all of the functions except

for drive are automatically stopped.

When this situation occurs, recharge the

batteries or turn on the engine.

• Protection against battery overcharging:

this machine, having a current generator

with an electronic circuit that acts as a

voltage regulator, ensures the batteries

are correctly charged without damaging

them due to excessive load.

When the batteries are fully charged,

this system automatically ensures no

additional charge will be applied.

Based on tests carried out in the eld and

the results obtained on the energy balance of

our hybrid system (DUAL POWER system),

this can work in complete autonomy without

the need to stop the machine and externally

recharge the battery pack. Repeated tests

with the three work programs (P1, P2, P3) on

asphalted surfaces and with normal working

slopes have demonstrated that the machine

operates in complete autonomy.

However, being the machine designed also for

heavy duty working conditions (slopes of over

20%, extremely rough surfaces to clean), the

batteries may need to be recharged.

In this case, it is advisable to use an electronic

battery charger with a specic charge curve for

the batteries installed.

EN

13

(Translation of original instructions)

EMPTYING THE DEBRIS BIN

NOTE: to unload the debris bin, hold the

control button, then choose the desired

function.

• press the raise bin control button (g. 19).

• move alongside the garbage container.

• press the tip bin button (g 19).

NOTE: if the tip bin button is released, the

bin will return to the horizontal position.

NOTE: the machine is equipped with a

safety device that prevents the bin from

rotating before reaching a safe distance

from the machine.

• move away from the garbage

container, then lower the bin.

CLEANING AND SERVICING

THE FILTER

The suction lter makes a major contribution to

the eciency of the whole machine.

Proper lter maintenance will allow you

to obtain the best performance from your

machine.

The suction lter can be cleaned as follows:

• using the automatic cleaning system;

selecting the work program (P1-P2-P3)

the machine is programmed for automatic

and cyclical cleaning of the lter at predened intervals.

NOTE: automatic cleaning can be enabled/

disabled in the machine’s software menu;

see the chapter “USER MENU”.

• using the manual cleaning system; press

the lter shaker button (g. 20) and hold

it down for a few seconds. Repeat this

g. 19

g. 20

operation 4 or 5 times while using the

machine.

This operation should be performed at the

end of every working cycle. If the machine

is used in a dusty environment (e.g.

sawmills, warehouses where vehicles

operate, etc.), make sure to use the lter

shaker more frequently.

• manually cleaning the lter; if the lter

shaker is not eective in cleaning the

lter, and in any case every 20 operating

hours, clean the lter manually. Before

carrying out any type of work on the

machine, make sure that it is switched

o and that all of the functions are

EN

14

(Translation of original instructions)

deactivated. To do this, turn the key switch

to the OFF position.

• remove the back panel from the

machine (g. 21).

• remove the two lters from their

seat by turning locking restraining

handles (g. 21).

• blow the lter clean with compressed

air (maximum pressure 6 bars).

• reassemble the two lters.

• close the back panel.

REPLACING/INSTALLING

THE SIDE BRUSHES

To facilitate transport, the side brush (or

brushes) is not tted in its expected working

position. To install the side brush in the correct

position, proceed as follows:

• move the side brush control lever to the

up position.

• unscrew the screw on the side brush

motor shaft.

• remove the key protector.

• position the brush complete with ange on

the shaft.

• tighten the brush locking screw again (g.

22).

To replace worn side brushes, carry out the

operations listed above.

g. 22

g. 21

EN

15

(Translation of original instructions)

REPLACING THE CENTRE

BRUSH

IMPORTANT: this operation must be

performed with the machine switched o

and the key removed..

This machine features a system for

automatically adjusting the pressure exerted

and compensating for wear.

The need to replace the centre brush is

indicated by the BRUSH WORN code on the

display.

To replace the centre brush, proceed as

follows:

• Unscrew the knob and open the

door on the left of the machine (g.

23).

• Unscrew and remove the three

knobs xing the brush compartment

cover (g. 23).

• Remove the cover of the brush

compartment.

• Remove the worn brush (g. 24).

• Remove the adapter from the core

of the old brush and t it to the

new brush, taking care to keep the

bristles aligned in the same direction

(g. 24).

• Fit the new brush and make sure

that the adapter is inserted on the

drive hub.

• Replace the brush compartment

cover, following the dismantling

operations in reverse order.

g. 23

g. 24

BATTERY MAINTENANCE

AND CHARGING

IMPORTANT: the use of an unsuitable

battery charger can lead to dangerous

situations! If in doubt, contact your local

dealer.

IMPORTANT: make sure the battery charger

is compatible with the batteries to be

charged.

IMPORTANT: Check the electrolyte level

inside the leak-proof tubular batteries:

every 30 hours for the battery version, and

every week for the version with combustion

engine. If necessary top up with distilled

water.

The level of electrolyte is indicated in the

battery instruction handbook.

After you have lled the battery, close the

cells with their caps and clean the top

surface.

The battery compartment is located under the

operator’s seat.

The battery is a sealed unit and guaranteed

safe under normal circumstances; in the

unlikely event of uid leaking from the battery,

do not touch the uid and be sure to take the

following precautions:

• Contact with the skin can cause irritation;

wash with soap and water.

• Inhalation of vapours can cause irritation

to the airways; stay out in the open air

and consult a doctor.

• Contact with the eyes can cause irritation;

ood the eyes with water immediately and

thoroughly for at least 15 minutes, and

consult a doctor.

When necessary, recharge the batteries

according to the following instructions:

IMPORTANT: only recharge in a well-

ventilated area.

• the machine must be switched o and the

key removed.

• lift the cowling.

• unplug the battery connector from the

machine (g. 25).

EN

16

(Translation of original instructions)

• open all the cell (or element) covers on

the batteries (leak-proof tubular batteries).

• plug the battery connector into the

charger (g. 26).

• connect the battery charger to the mains.

• after charging, disconnect the batteries

from the battery charger and reconnect

them to the machine.

• close all the caps (leak-proof tubular

batteries) and clean the top surface of the

batteries.

ADJUSTING THE SIDE BRUSHES FOR WEAR

If the side brushes (when lowered) do not

touch the oor due to wear, they can be

adjusted as follows:

• Move the side brush to the working

position.

• Loosen the two adjustment screws

underneath the brush levers (g. 27).

• Manually move the brush to the required

position.

• Tighten the adjustment screws.

OFF

SIDE

BRUSH

ON

g. 25

24V

g. 26

EN

g. 27

17

(Translation of original instructions)

ADJUSTING THE BRAKE

When the eect of the service or parking brake

action is too weak, it can be adjusted using the

register “A+B”(g. 28).

A

B

g. 28

screws.

Gain access to the oil drainage pipe.

Remove the dipstick to check the engine oil

level.

Take the cap o the drainage pipe and let the

exhaust oil drain out.

NOTE: it is recommended to drain the oil

when the engine is hot.

Add the amount of new oil specied in the

engine user and maintenance manual. We

recommend only SAE 15/40 multigrade oil,

which guarantees good engine lubrication at

temperatures from -15°C to over 40°C (g. 30).

COMBUSTION ENGINE

MAINTENANCE

NOTE: in addition to carefully reading the

combustion engine user and maintenance

manual, below are some practical tips.

Check the engine oil level at least once a week

using the dipstick (g. 29); for topping up, use

the oil specied below.

g. 29

The engine oil must be changed the rst time

after 20 operating hours, or in any case after

no more than 1 month.

Subsequently, every 100 hours, or at most

every 8 months.

To replace the oil in the engine, proceed as

follows:

Remove the side sump on the right-hand

side of the machine by unscrewing the xing

g. 30

AIR FILTER OF THE ENGINE

NOTE: in addition to carefully reading the

combustion engine user and maintenance

manual, below are some practical tips.

Periodically check the engine air lter, and

replace it when necessary.

Check and if necessary wash the sponge (pre-

lter) with water and soap or other household

detergent; wring it out and leave it to dry.

EN

18

(Translation of original instructions)

“CHANGE OIL” ALARM

CODE

The CHANGE OIL error code tells the operator

to change the combustion engine oil every 100

operating hours (only active on combustion

engine versions). Pressing the display button

once (g. 31) shows the partial operating hour

counter for the combustion engine.

This is a four-digit display: the rst digit on the

left (0-9 range) and the three remaining digits

display the actual hours of work of the engine.

When having reached 100 operating hours, the

machine shows the “CHANGE OIL” message

ashing on the display, telling the operator

to change the engine oil (see the chapter

“COMBUSTION ENGINE MAINTENANCE”).

After having changed the engine oil, reset the

hour counter as follows:

• press the display button twice to view the

partial operating hour counter.

• press the display button again and hold it

for at least 5 seconds (the machine partial

operating hour counter will be reset). The

rst digit on the display increases by one

unit, so that the operator will know how

many times oil has been replaced.

NOTE: if the engine oil is not changed,

every time the machine is switched on

again, the operator will hear a sound

emitted by the horn ve times, and the

“CHANGE OIL” message will ash on the

display. The “CHANGE OIL” message can

be cleared by pressing the display button.

g. 31

EN

19

(Translation of original instructions)

IMPORTANT: this operation must be performed with the machine switched o and the key

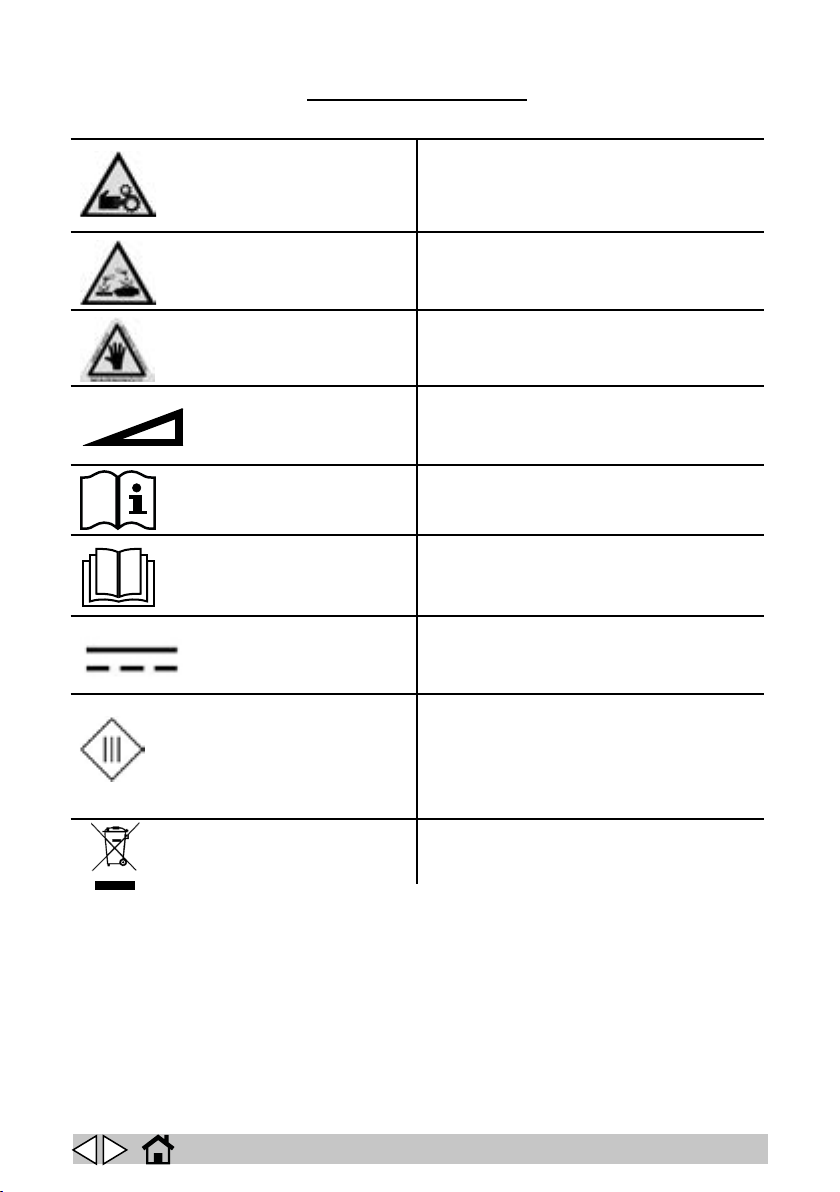

MAINTENANCE OF THE BATTERY VERSION

removed..

All routine or special maintenance must be performed by competent personnel or at an

authorised service centre.

NOTE: battery life depends on regular maintenance (check electrolyte level and density in

leak-proof tubular batteries). If the machine is not used for a long time (for example, 4 to

6 weeks) the batteries will need to be recharged in order to ensure that the voltage never

falls below the threshold of 20.5 V; in fact unused batteries suer from the self-discharge

phenomenon.

A : On receipt

B : Every 30 hours

C : Every 50 hours

D: Every 100 hours

E : Every 400 hours

CHECK A B C D E

Battery liquid and

voltage levels

Check the brushes (or

carbon brushes) on all

of the electric motors

and replace if worn

□

□

or every

two weeks

□

Tightness of the belts □ □

Brake adjustment □ □

Tightness of the nuts

and screws

State of the side brush

Panel lter cleaning □

Tightness of the bin,

lter, ap gaskets

□ □

EN

□

□

20

(Translation of original instructions)

IMPORTANT: this operation must be performed with the machine switched o and the key

COMBUSTION ENGINE VERSION MAINTENANCE

removed..

All routine or special maintenance must be performed by competent personnel or at an

authorised service centre.

For all maintenance on the combustion engine, see the instruction manual.

NOTE: battery life depends on regular maintenance (check electrolyte level and density in

leak-proof tubular batteries). If the machine is not used for a long time (for example, 4 to

6 weeks) the batteries will need to be recharged in order to ensure that the voltage never

falls below the threshold of 20.5 V; in fact unused batteries suer from the self-discharge

phenomenon.

A: On receipt

B: Twice a week

C: Every week

D: Every 20 hours

E: Every 50 hours

F: Every 100 hours

G: Every 150 hours

H: Every 300 hours

I: Every 400 hours

CHECK A B C D E F G H I

Battery liquid and voltage levels □ □

Clean the engine air lter □

Panel lter cleaning □

Oil and engine □ □

Change engine oil, petrol version

1st

time

□

Change engine oil, diesel version

Check the brushes (or carbon

brushes) on all of the electric

motors and replace if worn.

Tightness of the belts □ □

Brake adjustment □ □

Tightness of the nuts and screws □

State of the side brush □

Tightness of the bin, lter, ap

gaskets

□ □

EN

1st

time

□

21

□

(Translation of original instructions)

TROUBLESHOOTING TABLE

Error code Machine behaviour Description of the

problem

PAUSE MOTOR Drive stops Drive motor

overtemperature >

95°C, or alternator

overtemperature >

150°C

Possible solution

If having driven up a

slope this may can be

normal, let the motor

cool down for 20

minutes.

Check that the cooling

fan is working

Check that the brake

is not locked.

Check that the front

wheel turns freely.

PAUSE DRIVE Drive stops Electronic

BRUSH CURRENT The working functions

CHANGE OIL This is only shown if

BATTERY RESERVE This is simply a

BATTERY

DISCHARGED

are disabled

the machine has a

combustion engine

warning that the

battery charge is

getting low

The machine’s

functions are stopped,

excluding drive

control circuit

overtemperature >

85°C

Excess current or

centre brush blocked

It is activated after 99

operating hours

It is shown when the

battery voltage falls

below 21.3V

If the voltage read

falls below 20.3V

for 3 seconds

consecutively

If the air temperature

is high, stop the

machine for 20

minutes, then start

again. If the problem

remains, contact a

service centre.

Check free brush

movement or for

the presence of any

impediments (ropes,

plastic and so on)

It warns the operator

to change the engine

oil (to reset it, press

the display button

for 5 seconds while

the hour counter is

displayed)

No action needed,

except to charge the

battery

Charge the battery

EN

22

(Translation of original instructions)

BATTERY

EXHAUSTED

BRUSH WORN The machine

The machine stops If the voltage read

continues working

falls below 18V

for 3 seconds

consecutively

The brush is no

longer able to apply

pressure to the oor

because it is worn

Charge the battery

Replace the centre

brush

EN

23

(Translation of original instructions)

If drive is interrupted, the error code can be identied by means of the status LED. In the absence

DRIVE BOARD ALARMS

of malfunctions, the status LED is steadily on while the machine is in operation. If a malfunction is

detected, the status LED provides two types of information, a slow ash (2 Hz) or a rapid ash (4

Hz) to indicate the severity of the malfunction.

Malfunctions with a slow ash are cancelled automatically once the malfunction has been repaired

and the machine functions normally again. Malfunctions with a rapid ash ("*" in the table) are

considered more serious. The machine must be turned o to reset operation after repairing the

malfunction.

The indication of severity remains active for 10 seconds, after which the status LED ashes

constantly showing a two digit malfunction code until the repairs have been carried out.

For example, error code "1,4" is displayed as follows:

□ □ □ □ □ example alarm code 1,4

LED CODES DESCRIPTION

1,1 □ □ Drive motor output malfunction - Overcurrent error

1,2 □ □ □ EEPROM malfunction, main contactor malfunction,

1,3 □ □ □ □ NOT USED

1,4 □ □ □ □ □ NOT USED

2,1 □ □ □ Incorrect machine start up sequence (with key)

2,2 □ □ □ □ Incorrect machine start up sequence (with key)

2,3 □ □ □ □ □ Incorrect start up sequence for more than ve seconds

2,4 □ □ □ □ □ □ Malfunction of speed limiter potentiometer on control

3,1 □ □ □ □ NOT USED

3,2 □ □ □ □ □ NOT USED

3,3 □ □ □ □ □ □ Accelerator pedal malfunction

3,4 □ □ □ □ □ □ □ NOT USED

4,1 □ □ □ □ □ Battery voltage too low (voltage < 21 V)

4,2 □ □ □ □ □ □ Battery voltage too high (voltage > 48 V)

4,3 □ □ □ □ □ □ □ Drive motor > 80°C thermal cutout tripped

4,4 □ □ □ □ □ □ □ □ NOT USED

malfunction of board components, incorrect drive motor

voltage.

panel

EN

24

(Translation of original instructions)

Enter the menu by pressing and holding the display button for 5 seconds while the machine is on,

USER MENU

but with no active function.

Pressing button P1 increases the value of the selected variable.

Pressing button P3 decreases the value of the selected variable.

Pressing the display button, the set data is saved and the next item is displayed.

Exit the menu by pressing and holding the display button for 5 seconds.

1. LANGUAGE, language setting parameter.

2. PROG.1, brush pressure P1 parameter. Default value 020.

3. PROG.2, brush pressure P2 parameter. Default value 040.

4. PROG.3, brush pressure P3 parameter. Default value 060.

5. POWER OFF, enables/disables the AUTO-POWER ON/OFF system. Default value YES.

6. RAISE BRUSH, enables/disables lifting of the centre brush in reverse. Default value YES.

7. FILTER SHAKE, enables/disables automatic activation of the lter shaker and the activation

time. Default value 120”.

EN

25

IP Cleaning S.p.A.

Viale Treviso 63

30026 Summaga di Portogruaro

Venezia (Italy)

T: +39 0421 205511

F: +39 0421 204227

E: www.ipcworldwide.com

W: info@ipcworldwide.com

PLDC01969

Rev.03 (03-2019)

Loading...

Loading...