I-160

SERIES AC

EMERGENCY

P.O. BOX 11846 TUCSON, AZ 85734

(520) 294-3292 • FAX (520) 741-2837

www.iotaengineering.com

INSTRUCTION MANUAL

IMPORTANT SAFEGUARDS

When using electrical equipment, basic safety precautions should always be followed, including the following:

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

1. CAUTION – To prevent electrical shock, do not mate unit connector until installation is complete and A.C. power

is supplied to the unit.

2. CAUTION – This fixture provides more than one power supply output source. To reduce the risk of electrical

shock, disconnect both normal and emergency sources by turning off the A.C. branch circuit and by disconnect

ing the unit connector.

3. CAUTION – The integral, high temperature Ni-Cad battery is replaceable. To replace the battery, disconnect the

unit connector and remove both switched and unswitched A.C. power to the fixture. Remove the lid screw and

open the lid to expose the battery. Unplug the battery connector and replace with part number 44203-412 (14.4V

Ni-Cad battery only). Recycle or dispose of the used nickel-cadmium battery properly.

4. DO NOT USE OUTDOORS. The I-160 is for use with grounded, UL Listed, damp location rated, indoor fixtures.

Not for use in heated air outlets or hazardous locations.

5. The I-160 requires an unswitched A.C. power source of either 120 or 277 volts. Properly cap the unused A.C.

lead.

6. When the I-160 is installed on the same branch circuit, refer to Illustration 3, Figures A and B for input wiring. When

installed on separate branch circuits, refer to Illustration 3, Figures C and D for input wiring. Per NEC, the I-160 and

A.C. ballast must be on the same panel board.

7. Do not mount near gas or electric heaters.

8. The I-160 should be mounted in locations and at heights where it will not readily be subjected to tampering by

unauthorized personnel.

9. The I-160 mounts on top of the fixture or adjacent to the fixture on an optional T-bar mounting bracket.

10. The I-160 will cold strike and operate one 2′–4′ 24W-95W T5, one 17W-59W T8 lamps, one 25W to 50W long com

pact, one 18W-70W 4-pin compact lamp, one or two 17W 2′ T8 or one or two 18W 4-pin compact fluorescent lamp.

11. The I-160 operates lamps as follows:

One or two 2′–4′ T8 lamps, or one or two 4-pin compact fluorescent lamps, or one 8′ select linear lamp for 90 minutes.

12. Suitable for use in damp locations.

13. For use in 0° C minimum, 50° C maximum ambient temperatures.

14. The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition,

warranty, and result in non-compliance with UL specifications

15. Do not use this equipment for other than intended use.

16. Install in accordance with the National Electrical Code and local regulations.

17. Installation and servicing should be performed by qualified personnel.

18. Lighting fixture manufacturers, electricians, and end-users need to ensure product system compatibility before

final installation.

.

LIGHTING EQUIPMENT

-

-

void

SAVE THESE INSTRUCTIONS

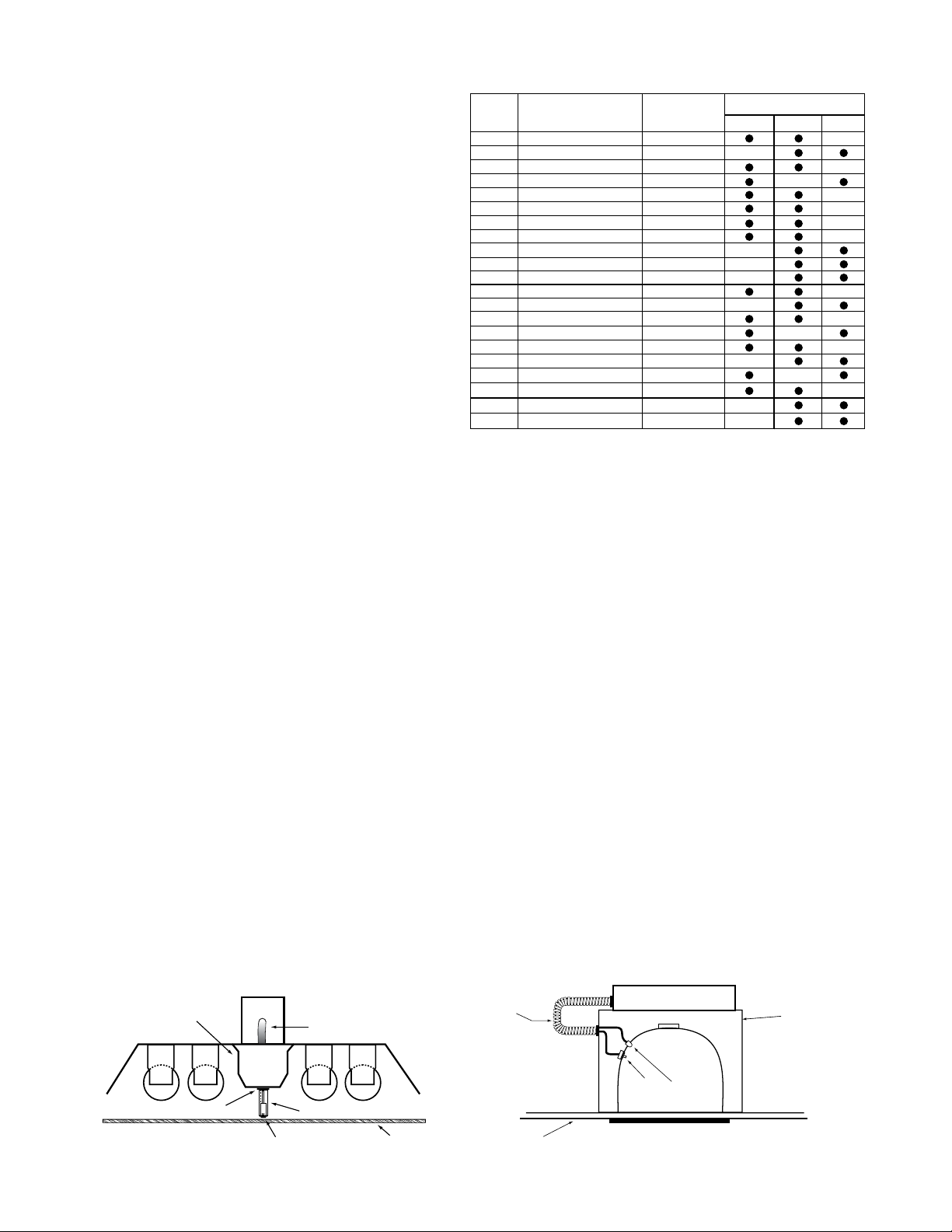

7/8" BUSHING

PLASTIC TUBE

CHARGE INDICATOR LAMP

BALLAST CHANNEL

COVER

FLEX CONDUIT

FIXTURE LENS

INSTALLATION INSTRUCTIONS

FLEX

CEILING

TILE

A.C. BALLAST &

LAMP SOCKET

COMPARTMENT

TEST

SWITCH

CHARGE

LIGHT

CAUTION: Before installing, make certain the A.C. power is off and the I-160 unit connector is disconnected.

1. LAMPS OPERATED

The I-160 can be used with most 2′–8′ T8, 2′–4′ T5, or

4-pin compact lamps. Refer to the chart for the type of

lamp(s) operated and the number of lamps to be operated in emergency mode. Contact Customer Service

with questions about specific lamps.

*The lamp selector leads each have a 3 position short-

ing P-nut connector. Select the proper wire combination

from the chart for the desired lamp(s) used. Cut and

strip one of the selected wires (

P-nut of the second wire.

2. MOUNTING THE I-160

Remove the ballast channel cover. Mount the I-160 on

the fixture top in a position that does not interfere with the

existing A.C. ballast or any other hardware. Extend the

flex conduit to a convenient location on top of the fixture

and punch a

7

/8″ hole. Feed the wires and flex connector

down through the hole in the fixture and secure in place

3

/8″) and plug it into the

OPTION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

LAMP TYPE

17 Watt 2-ft. T8

17 Watt 2-ft. T8

32 Watt 4-ft. T8

59 Watt 8-ft. T8

24W 2-ft. T5

39W 3-ft. T5

28W 4-ft. T5

47W 4-ft. T5

54W 4-ft. T5

95W 4-ft. T5

95 Watt 8-ft. T12

18W Compact

18W Compact

26W Compact One Lamp

26W Compact

32W Compact

42W Compact

70W Compact

25W Long Compact

30W Long Compact

50W Long Compact

EMERGENCY

OPERATION

One Lamp

Two Lamps

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

Two Lamps

Two Lamps

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

One Lamp

with the flex connector nut. An optional T-bar mounting kit is available to mount the I-160 above the ceiling tile adjacent to the

emergency fixture. To order the optional T-bar mounting kit (part number TBMK-160) contact Customer Service.

When battery packs are remote mounted, consult Customer Service for the maximum allowable distance between the battery pack

and the lamp(s).

CAUTION: Properly secure the I-160 in the ceiling grid to insure compliance with local, state, and federal guidelines

regarding ceiling mounted equipment.

*LAMP SELECTOR LEADS

Brn/Wht

Brown

Violet

3. WIRING

Refer to the wiring diagrams on the back page for the appropriate wiring of lamp(s) and ballast. Install in accordance with the

National Electrical Code and local regulations. For additional wiring diagrams consult Customer Service.

4. INSTALLING THE CHARGE INDICATOR

Recessed Troffer Fixture – Select a convenient location with proper clearance in the ballast cover and drill or punch a 7/8″ hole

1

(

/2″ knockout). Insert the 7/8″ bushing into the hole. Push the plastic tube through the bushing. Disconnect the leads from the

LED housing and route the leads down the plastic tube. Reconnect the leads to the housing, observing the proper polarity

(Red/Black or Red lead w/connector to positive (+) red tab). Push the entire assembly back into the tube until the lens collar

rests against the plastic tube. The plastic tube should be adjusted so that the Charge Indicator is within ¼″ of the fixture lens.

The Charge Indicator must be visible after installation. Refer to Illustration 1.

Ceiling-Mounted Downlight Fixture – Select a convenient location on the side of the fixture so the Charge Indicator can be

seen after installation. Allow for proper clearance inside the fixture and drill or punch a 1/2″ hole. Disconnect the leads from

the LED housing. Push the LED housing into the

1

/2″ hole until it is firmly locked in place. Reconnect the leads, observing the

proper polarity (Red/Black or Red lead w/connector to positive (+) red tab). Refer to Illustration 2. For remote mounting the

charge indicator and test switch, the optional RTK accessory kit can be ordered.

Note: For proper operation, use only the accessory components provided with the unit. See Page 1 of the Instruction Manual.

5. INSTALLING THE TEST SWITCH

The Test Switch should be mounted on the ballast channel cover of a recessed troffer, or on the side of a strip fixture, prefer-

ably adjacent to the charge indicator. Drill or punch a

Illustration 1 Recessed Troffer Fixture Illustration 2 Downlight Fixture

I-160

1

/2″ mounting hole.

I-160

OBSERVE PROPER POLARITY

Page 2

Loading...

Loading...