IRPT2056A

PD 6.099

PRELIMINARY

Power Module for 3 hp Motor Drives

· 3 hp (2.2 kW) power output

Industrial rating at 150% overload for 1 minute

· 180-240V AC input, 50/60 Hz

· 3-phase rectifier bridge

· 3-phase, short circuit rated, ultrafast IGBT inverter

· HEXFRED ultrafast soft recovery-freewheeling diodes

· Brake IGBT and diode

· Low inductance (current sense) shunts in positive

and negative DC rail

· NTC temperature sensor

· Pin-to-baseplate isolation 2500V rms

· Easy-to-mount two-screw package

· Case temperature range -25°C to 125°C operational

IRPT2056A

™

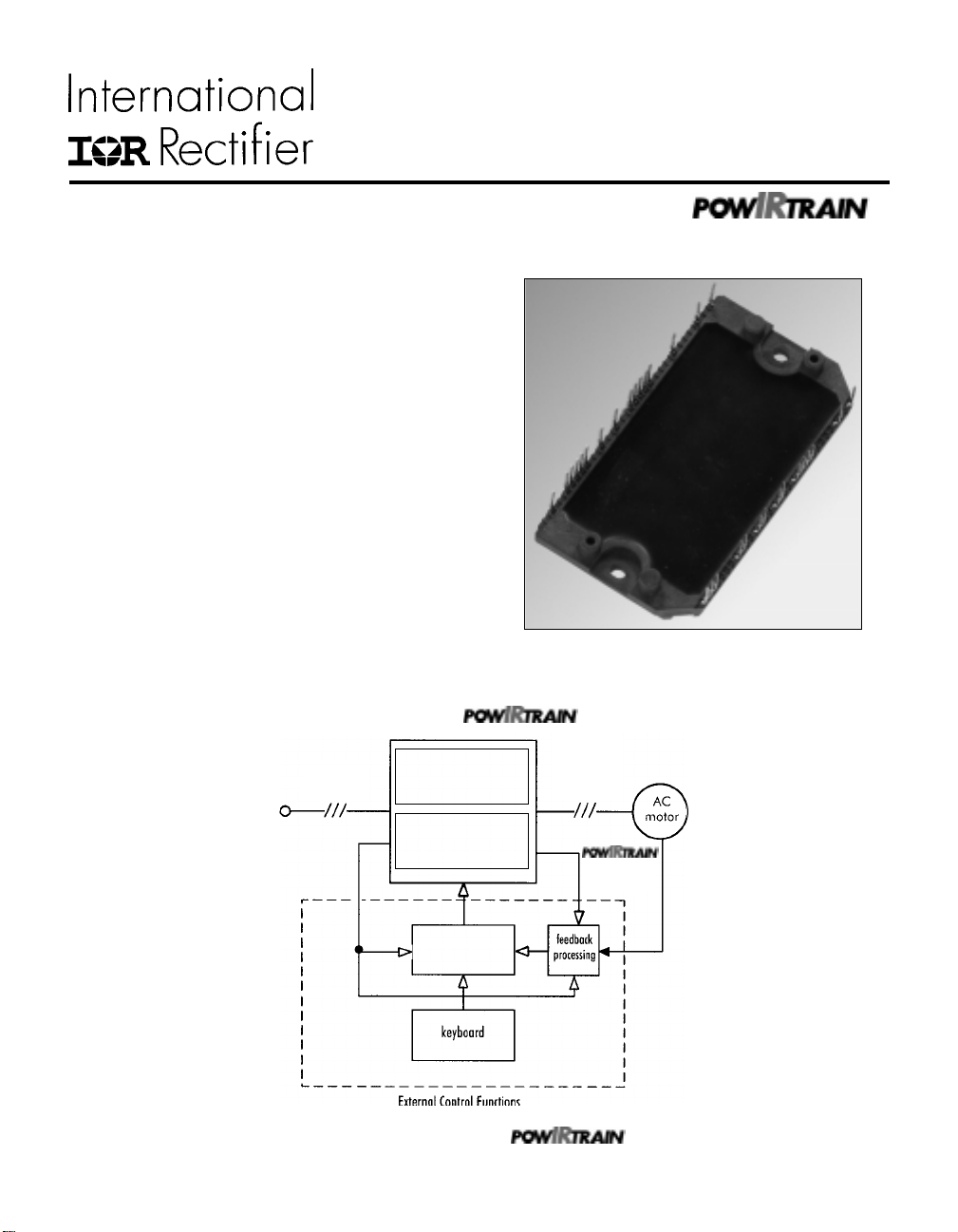

Figure 1. IRPT2056A Power Module

IRPT2056C

PWM

180-240V

3-phase input

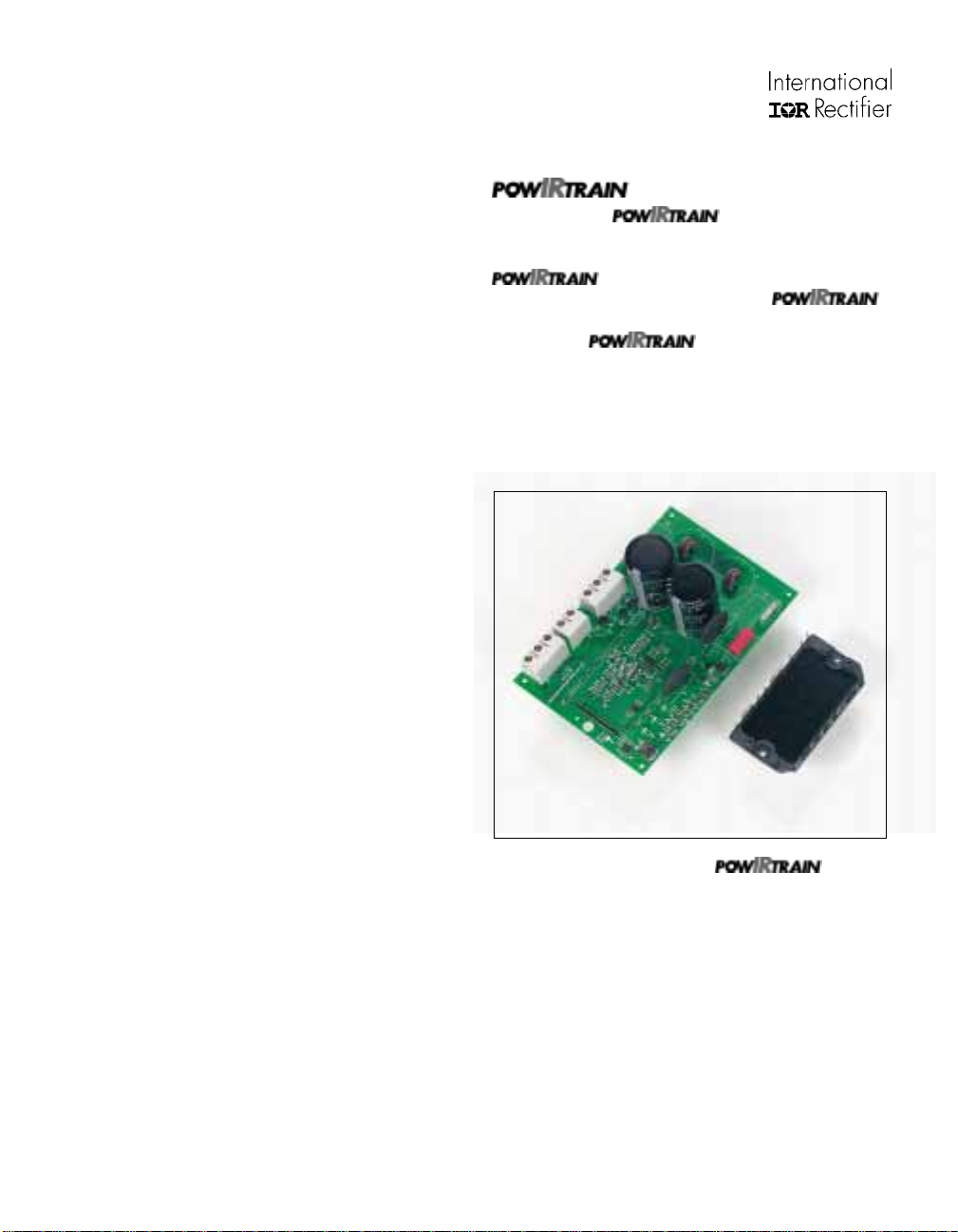

Figure 2. The power module and within a

IRPT 2056A

Power

Module

IRPT 2056D

Driver-

Plus

Board

PWM

generator

motor control system

variable

frequency

output

feedback

(non-isolated)

page 1

IRPT2056A

System Description

Power Module

The IRPT2056A Power Module, shown in figure 1, is a chip

and wire epoxy encapsulated module. It houses input rectifiers,

output inverter, current sense shunts and NTC thermistor. The 3phase input bridge rectifiers are rated at 800V. The brake circuit

uses 600V IGBT and freewheeling diode. The inverter section

employs 600V, short circuit rated, ultrafast IGBT's and ultrafast

freewheeling diodes. Current sensing is achieved through 25

mΩ low inductance shunts provided in the positive and negative

DC bus rail. The NTC thermistors provide temperature sensing

capability. The lead spacing on the power module meets UL840

pollution level 3 requirements.

The power circuit and layout within the module are carefully

designed to minimize inductance in the power path, to reduce

noise during inverter operation and to improve the inverter

efficiency. The Driver-Plus Board required to run the inverter

can be soldered to the power module pins, thus minimizing

assembly and alignment. The power module is designed to be

mounted to a heat sink with two screw mount positions, in order

to insure good thermal contact between the module substrate and

the heat sink.

and Design Kit

The IRPT2056C (Figure 3) provides the

complete power conversion function for a 3 hp (2.2 kW) variable

voltage, variable frequency AC motor controller. The

combines the Power Module (IRPT2056A)

with a Driver-Plus Board (IRPT2056D). The

Design Kit, IRPT2056E includes the following:

• Complete integrated power stage

• Specification and operating instructions

• Bill of materials

• Electrical schematic

• Mechanical layout of the Driver-Plus Board

• Software transferrable file for easy design integration

• Application information and layout considerations

page 2

Figure 3. IRPT2056C

IRPT2056A

Specifications

PARAMETERS VALUES CONDITIONS

Input Power

Voltage 220V AC, -15%, +10%, 3-phase

Frequency 50/60 Hz

Current 15.4A rms @ nominal output TA = 40°C, R

I

FSM

400A 10ms half-cycle, non-repetitive surge

Output Power

Voltage 0-230V rms defined by external PWM control

Nominal motor hp (kW) 3 hp (2.2 kW) nominal full load power Vin = 230V AC, f

Nominal motor current 11A nominal full load power T

150% overload for 1 minute fo = 60 Hz,

= 40°C, R

16.5A 150% overload for 1 minute

A

DC Link

DC link voltage 400V maximum

Brake

Current 20A

Sensor

Temp. sense resistance 50 kOhms ±5% @ T

3.1kOhms ±10% @ T

Current sense 25mOhms ±5% @ T

Protection

IGBT short circuit time 10 µs DC bus = 400V, VGE = 15V,

line to line short

Recommended short circuit- 70A peak

shutdown current

Gate Drive

Q

G

Recommended gate driver IR2133 (see Figure 10)

120 nC (typical) @ VGE = 15V, refer figure 5b

Module

Isolation voltage 2500V rms pin-to-baseplate, 60 Hz, 1 minute

Operating case temperature -25°C to 125°C 95% RH max. (non-condensing)

Mounting torque 1 Nm M4 screw type

Storage temperature range -40°C to 125°C

Soldering temperature for 10 sec. 260°C maximum at the pins (.06" from case)

thSA

thSA

NTC

NTC

SHUNT

= 25°C

= 100°C

= 25°C

= 0.42°C/W

= 4kHz,

pwm

= 0.42°C/W

page 3

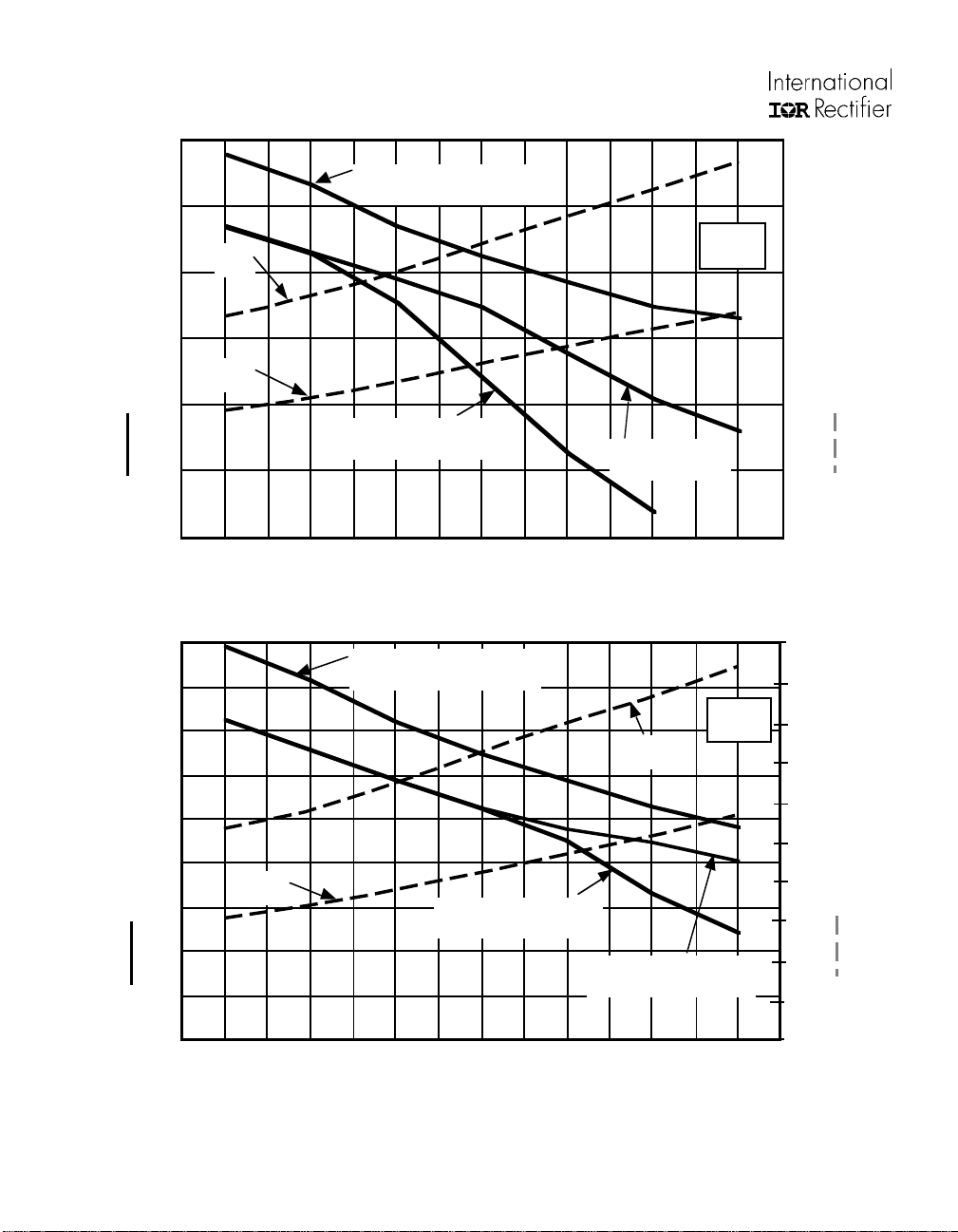

IRPT2056A

0.6

0.5

°C/W)

thSA

0.4

0.3

Power

150%

R

100% Load Continuous

thSA

10-60 Hz

3 hp

(2.2 kW)

300

250

200

150

Power

100%

Thermal Resistance (R

0.2

0.1

R

150% Load (1 min.)

thSA

Down to 3 Hz

0

1 4 8 12 20

R

150% Load

thSA

1 min.)10-60 Hz

16 24

100

50

0

PWM Frequency (kHz) – (Induction Motor Load)

Figure 4a. 3hp/11A output Heat Sink Thermal Resistance and Power Dissipation vs. PWM Frequency

0.9

0.8

0.7

°C/W)

thSA

0.6

R

100% Load Continuous

thSA

10-60 Hz

Power

150%

2 hp

(1.5 kW)

200

180

160

140

120

0.5

100

0.4

0.3

Thermal Resistance (R

0.2

0.1

Power

100%

R

150% Load (1 min.)

thSA

Down to 3 Hz

R

150% Load (1 min.)

thSA

10-60 Hz

80

60

40

20

Total Power Dissipation (Watts)

Total Power Dissipation (Watts)

0

1 4 8 12 16 20 24

PWM Frequency (kHz) – (Induction Motor Load)

Figure 4b. 2hp/8A output Heat Sink Thermal Resistance and Power Dissipation vs. PWM Frequency

NOTE: For Figures 4a and 4b: Operating Conditions: Vin = 230V

during 1 minute overload to 10°C

page 4

, MI =1.15, PF = 0.8, TA = 40°C, Tj < 145°C, Ts < 95°C, Z

rms

0

thSA

limits ∆T

c

Loading...

Loading...