Ion Technologies WC33 Operation Manual

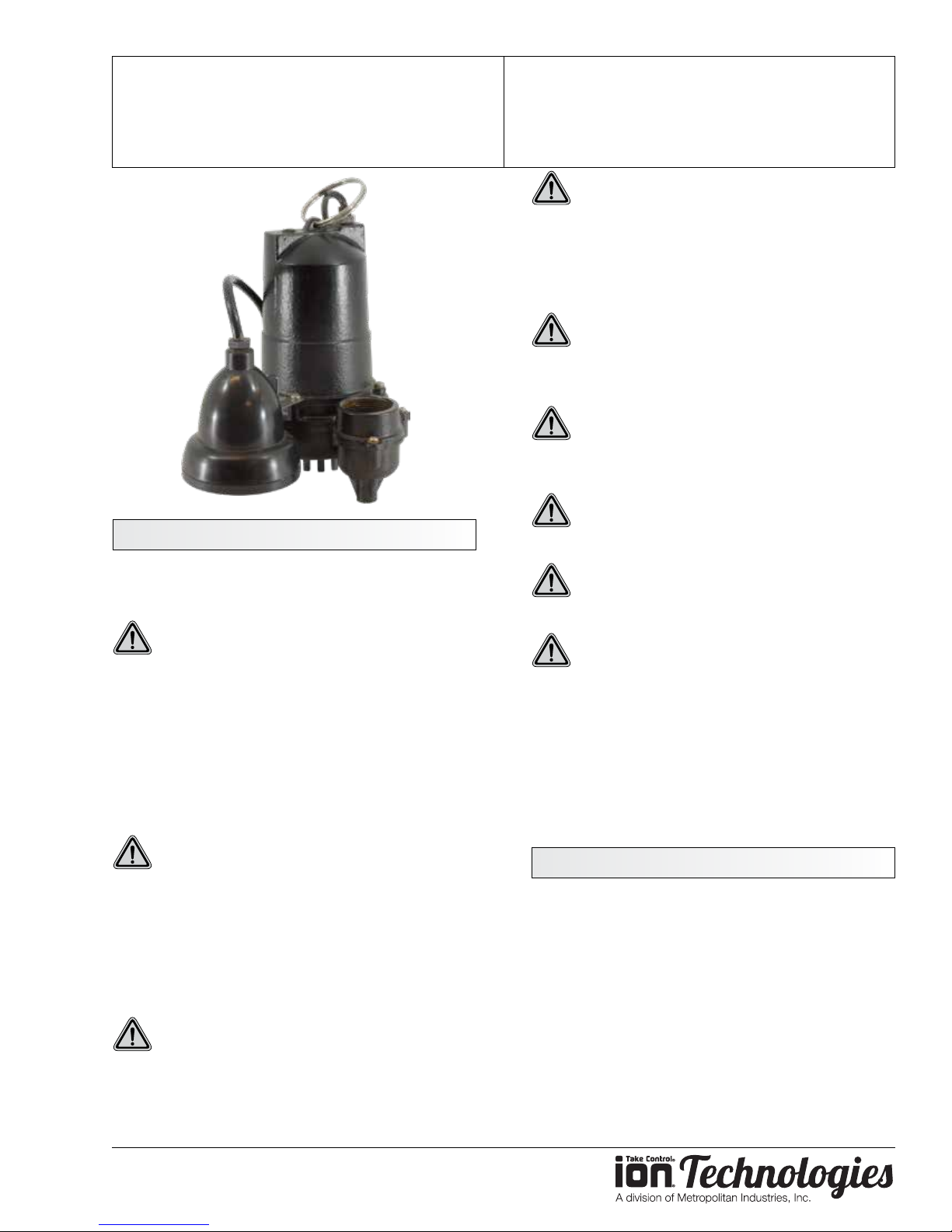

Ion Technologies WC33

Submersible Sump Pump

Safety Warnings

Thank you for purchasing your Ion Technologies

Pump. To help ensure years of trouble-free operation,

please read the following manual carefully.

CAUTION: Read these safety warnings rst

before installing, servicing, or operating any

pump.

Before Installation

This manual contains important information for the

safe use of this product. Read this manual completely

and follow the instructions carefully. Reasonable care

and safe methods relating to the installation and

operation of this product should be practiced. Check

local codes and requirements before installation.

OPERATION MANUAL

Dated: 04/09/2018

Document Name: WC33_OM

Page 1 of 8

WARNING: Risk of Fire or Explosion. Do not

smoke or use open ames in or around this

system. This system is not intended for use in

hazardous locations per NFPA 70 National Electric

Code. Do not pump ammable liquids. Consult factory

for optional equipment rated for hazardous location

use.

WARNING: Cutting Risk. Risk of serious

cutting or amputation exists. Disconnect all

power sources prior to servicing pump. Pump may

start without warning.

CAUTION: Do not modify the cord and plug.

When using the cord and plug, plug into a

grounded outlet only. When wiring to a system control,

connect the pump ground lead to the system ground.

CAUTION: Do not run the pump dry. Dry

running can overheat the pump (causing burns

to anyone handling it) and will void the warranty.

CAUTION: The pump normally runs hot. To

avoid burns, allow it to cool for 30 minutes after

shutdown before handling it.

Submersible sump pumps are not approved

for use in swimming pools, recreational water

installations, decorative fountains or any installation

where human contact with the pumped uid is

common. Pump designed to be installed in a sump or

wet location where drainage collects.

Do not throw away or lose this manual. Keep it in a safe

place so that you may refer to it often for the continued

safe operation of the product.

WARNING: Risk of Electrical Shock or

Electrocution. May result in serious injury or

death or re hazard. Installer must disconnect all

electrical sources prior to installation, handling or

servicing. Only qualied personnel may install this

system. NFPA 70/National Electric Code (NEC) or

local codes must be followed. System must be properly

grounded according to NEC. Do not lift pump by power

cord.

WARNING: Risk of Asphyxiation. Installer(s)

and/or service personnel must use proper

personal protective equipment and follow OSHA 29

CFR 1910.146 or OSHA 29 CFR 1926. Pump may be

installed in a location classied by as a conned space.

www.ionproducts.net

Pump Installation

These important instructions must be followed for

satisfactory performance of your pump. Before

installation, check your local electrical and plumbing

codes.

1. Provide proper sump. Minimum sump diameter

is 18″.

2. Make sure sump is free of string, cloth, nails,

gravel, etc. before installing pump.

3. Do not set pump directly on the bottom of sump

if it is not solid. Raise the pump by placing bricks

or concrete blocks underneath it.

Ion Technologies WC33

Submersible Sump Pump

OPERATION MANUAL

Dated: 04/09/2018

Document Name: WC33_OM

Page 2 of 8

4. Use steel or plastic pipe for all connecting lines

between pump and sewer outlet.

Note: Some city regulations do not allow installing a

pump with plastic pipe. Check local regulations.

5. Drill a 1/8″ inch hole into discharge pipe 4 inches

above the pump’s discharge.

6. A check valve should be installed in discharge

pipe, above the cover of the basin.

7. Connect to power source using 3-prong

grounded 115 volt AC receptacle. Do not remove

ground pin from electrical plug. Do not use an

extension cord.

8. Use pump submerged for pumping water-like

liquids (temperature to 120° F).

9. In applications where the pump may sit idle for

months at a time, it is recommended that the

pump(s) be cycled every few months to ensure

the pumping system is working properly when

needed.

10. An audible alarm for high water conditions should

be installed for additional protection against high

water conditions.

Your pump warranty is void...

If...power cord has been cut.

If...pump has been used to pump mud, cement,

tar, abrasives or chemicals.

If...pump has been used for pumping hot water

(above 120°F ).

If...cord tag has been removed.

Note: Automatic thermal overload protects the sealedin-oil motor. Running dry may overheat the motor and

activate the overload protector until the unit cools.

Troubleshooting

Pump does not run or just hums.

1. Line circuit breaker may be o, blown or loose.

2. Cord prong may not be making contact in

receptacle.

3. If all symptoms check okay, motor winding may

be open; take to authorized service center for

check.

Pump runs but does not deliver water.

1. Check valve may be installed backward. Arrow

on valve points in direction of ow.

2. Discharge gate valve, if used, may be closed.

3. Pump may be air locked. Start and stop several

times by plugging and unplugging cord. Check

vent hole in pump case for plugging.

4. Ion Technologies pumps have a small air vent

hole in the impeller cavity to let out trapped air. If

this hole becomes plugged, pump may air lock.

To break the air lock, use a small screwdriver to

clear hole in the impeller cavity.

5. As a secondary precaution in installations of this

type – 1/16″ hole should be drilled in the discharge

pipe below the check valve. The check valve

should be installed in pump discharge above the

cover on the basin.

Note: In sumps where the pump is operating daily, air

locking rarely occurs.

Pump Servicing

Servicing should be performed only by an authorized

service center.

WARNING: Always disconnect the pump from

power source before handling or making any

adjustments. Always wear rubber boots when

there is water on the oor and you must unplug the

pump or make any adjustments.

www.ionproducts.net

1. Pump head may be too high. Pump cannot

deliver water over 24' vertical lift. Horizontal

distance does not aect pumping, except for

friction loss through the pipe.

2. Inlet in pump base may be clogged. Remove

pump and clean out openings.

3. Impeller or volute openings may be plugged or

partially plugged. Remove pump and clean out.

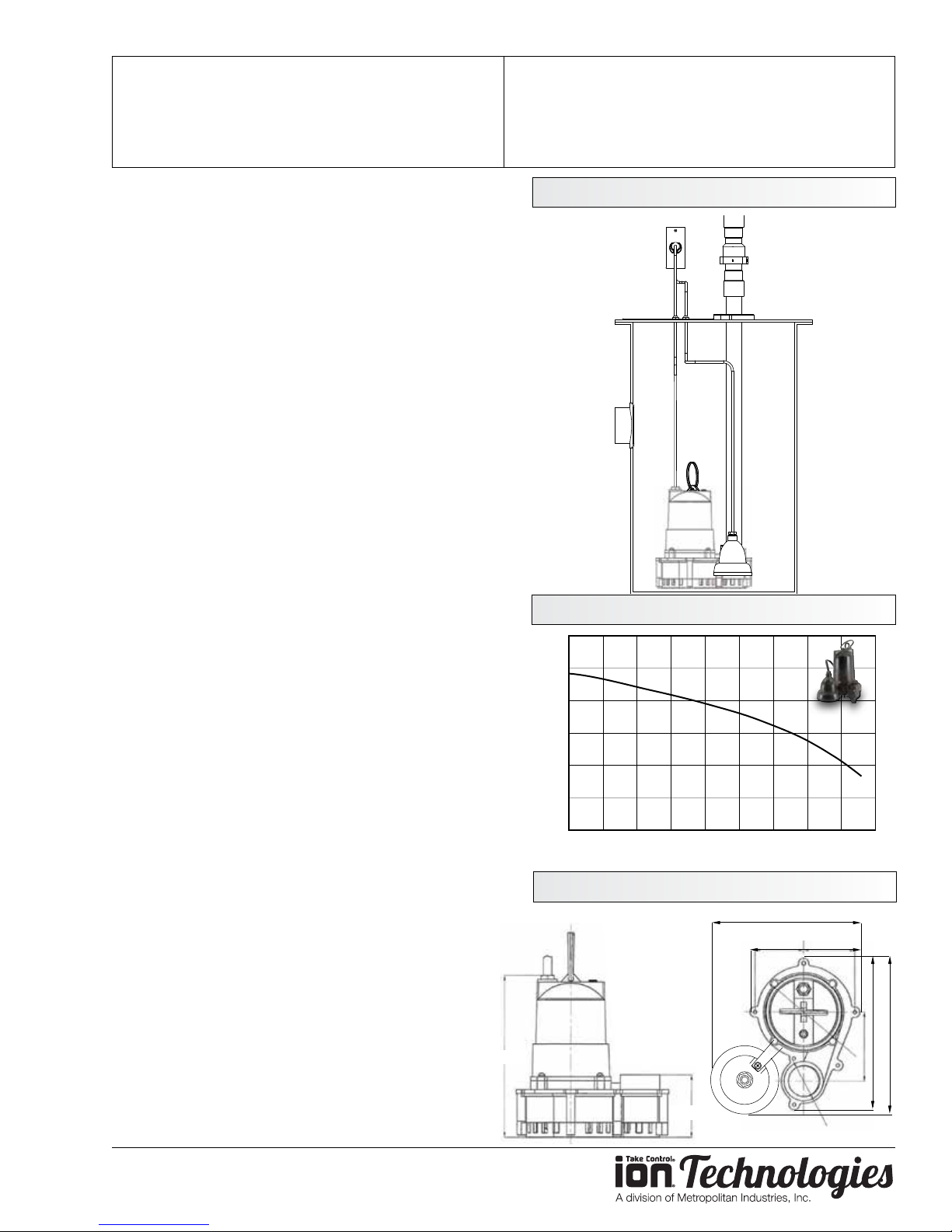

Ion Technologies WC33

Head - feet

Capacity - US GPM

0

25

15

5

10

20

30

0 252015105 30 35 40 45

Submersible Sump Pump

OPERATION MANUAL

Dated: 04/09/2018

Document Name: WC33_OM

Page 3 of 8

Pump runs but delivers only small amount of

water.

1. Pump may be air locked. Start and stop several

times by plugging and unplugging cord. Check

vent hole in pump case for plugging.

2. Pump head may be too high. Pump cannot

deliver water over 24' vertical lift. Horizontal

distance does not aect pumping, except loss

due to friction through discharge pipe.

3. Inlet in pump base may be clogged. Remove

pump and clean out openings.

4. Impeller or volute openings may be plugged or

partially plugged. Remove pump and clean out.

5. Pump impeller may be partially clogged causing

motor to run slow, resulting in motor overload.

Clear impeller.

Fuse blows or circuit breaker trips when pump

starts.

1. Inlet in pump base may be clogged. Remove

pump and clean out openings.

2. Impeller or volute openings may be plugged or

partially plugged. Remove pump and clean out.

Installation Drawing

Performance

3. Pump impeller may be partially clogged causing

motor to run slow, resulting in motor overload.

Clear impeller.

4. Fuse size or circuit breaker is too small.

5. Defective motor stator; return to authorized

service center for verication.

Motor runs for short time then stops. Then after

short period starts again. Indicates tripping

overload caused by symptom shown.

1. Inlet in pump base may be clogged. Remove

pump and clean out openings.

2. Impeller or volute openings may be plugged or

partially plugged. Remove pump and clean out.

3. Pump impeller may be partially clogged causing

motor to run slow, resulting in motor overload.

Clear impeller.

4. Defective motor stator; return to authorized

service center.

Dimensions

9”

6-1/2”

9-1/2”9”

10”

3-5/8”

1-1/2”

www.ionproducts.net

Loading...

Loading...