Page 1

Unrivalled Detection. www.ionscience.com

SF6 P1:p

Instrument User Manual V1.1

Page 2

SF6 P1:p MANUAL Ion Science Ltd

Register your instrument online for extended warranty

Thank you for purchasing your Ion Science instrument.

The standard warranty of your instrument can be extended to up to two years

on PhoCheck Tiger and two years on other Ion Science instruments.

To receive your extended warranty, you must register your instrument online

within one month of purchase (terms and conditions apply.)

Visit www.ionscience.com/instrument-registration

Part number:

Page 3

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Declaration of conformity

Name und Adresse des Herstellers / Manufacture´s name and address / Nom et adresse du fabricant

ISM Deutschland GmbH, Laubach 30, D-40822 Mettmann, Germany

Die ISM Deutschland GmbH bescheinigt die Konformität für das Produkt / The ISM Deutschland GmbH

declares conformity of the product / ISM Deutschland GmbH dérclare la conformite du produit

Bezeichnung / Product name / Designation:

SF6-Lecksuchgerät / SF6-Leakseeker / Les détecteuers de fuite SF6

Typ / Type / Type:

SF6 LEAKCHECK P1:p

Mit den folgenden Bestimmungen / with applicable regulations / avec les directives suivantes

EMV Richtlinie 89/336/EWG ergänzt durch 91/263/EWG, 92/31/EWG

EMC Drective 89/336/EEC amended by 91/263/EWG, 92/31/EEC

Directive EMC 89/336/CEE amendée par 91/263/EWG, 92/31/CEE

Niederspannungsrichtlinie 73/23/EWG ergänzt durch 93/68/EWG

Low-Voltage Equipment Directive 73/23/EEC amended by 93/68/EEC

Directive des equipements basse tension 73/23/CEE amendée par 93/68/CEE

Angewendete harmonisierte Normen / Harmonized standards applied / Normes harmonisées utilisáes

Sicherheit / Safety / Sécurité

EN 61010-1 : 1993 / IEC (CEI) 1010-1 : 1990 A 1 : 1992 / VDE 0411: 1994

Überspannungskategorie / Overvoltage category / Catégorie de surtension: II

Verschmutzungsgrad / Degree of pollution / Degré de pollution: 2

Elektromagnetische Verträglichkeit / Electromagnetic compatibility / Compatibilité electromagnétique

EN 50082-2: 1995 / VDE 0839 T82-2

ENV 50140 : 1993 / IEC (CEI) 1001-4-3 : 1995 / VDE 0847 T3

ENV 50141 : 1993 / IEC (CEI) 1000-4-6 / VDE 0843 / 6

ENV 61000-4,2 : 1995 / IEC (CEI) 1000-4-2 : 1995 / VDE 0847 T4-2:

Prüfschärfe /Level / Niveau = 2

EN 61000-4-4: 1995 / IEC (CEI) 1000-4-4: 1995 / VDE 0847 T4-4:

Prüfschärfe /Level / Niveau = 3

EN 50081-1 : 1992 / EN 55011 : 1991 / CISPR11 : 1991 / VDE0875 T11 : 1992

Gruppe / group / groupe = 1, Klasse / Class / Classe = B

Datum / Date / Date

17.10.2001

Unterschrift / Signature / Signatur

Hr. Becker – Technical Director

2 of 41

Page 4

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Contents

Declaration of conformity ............................................................................................................................... 2

Remarks ............................................................................................................................................................ 4

Target group ................................................................................................................................................... 4

General information ........................................................................................................................................ 4

Safety instructions .......................................................................................................................................... 4

Correct use ..................................................................................................................................................... 4

New design handset ....................................................................................................................................... 4

Versions ............................................................................................................................................................ 5

SF6 LEAKCHECK P1:p – Portable case instruments ................................................................................... 5

Usage in practice ............................................................................................................................................. 6

For leak detection ........................................................................................................................................... 6

For leak measurements ................................................................................................................................. 6

For concentration rise measurements (integral atm.) .................................................................................... 6

System properties ........................................................................................................................................... 7

General properties ......................................................................................................................................... 7

Measuring principle ........................................................................................................................................ 7

Measurement reliability .................................................................................................................................. 7

Control and display elements ........................................................................................................................ 8

Control and display elements on the base unit .............................................................................................. 8

Control and display elements on the handset ................................................................................................ 9

Putting into operation ................................................................................................................................... 11

Operation modes ........................................................................................................................................... 12

Search Mode ................................................................................................................................................ 12

Measuring Mode .......................................................................................................................................... 12

Operation ........................................................................................................................................................ 13

Ready for measuring .................................................................................................................................... 13

Saving of measurement data ....................................................................................................................... 13

Possible malfunctions when starting the system ......................................................................................... 14

Possible malfunctions during operation ....................................................................................................... 14

Turning off ...................................................................................................................................................... 16

Switching off when there is a failure ............................................................................................................ 16

Setting up the operating parameters ........................................................................................................... 17

Entry of passwords and numbers ................................................................................................................ 17

Activating the operating mode menu ........................................................................................................... 17

Setting volume and screen contrast ............................................................................................................. 18

Operator level ............................................................................................................................................... 18

The technical level ....................................................................................................................................... 19

The supervisor level ..................................................................................................................................... 26

Service life of the SmartSensor ................................................................................................................... 28

Exchanging the SmartSensor ...................................................................................................................... 29

Known problems ............................................................................................................................................ 30

Calibration in the ppm mode ........................................................................................................................ 30

Calculating the concentration ....................................................................................................................... 30

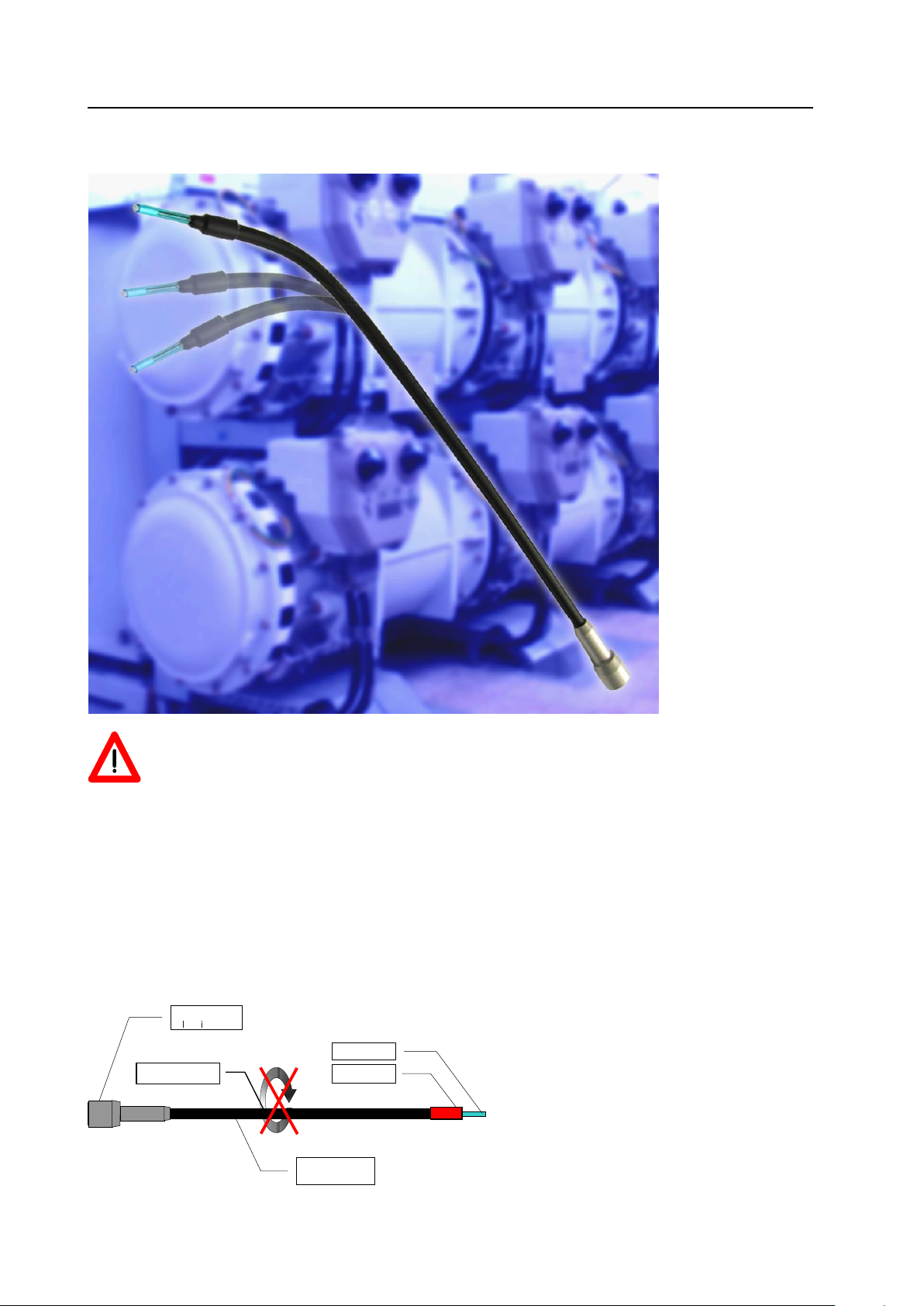

Accessories .................................................................................................................................................... 31

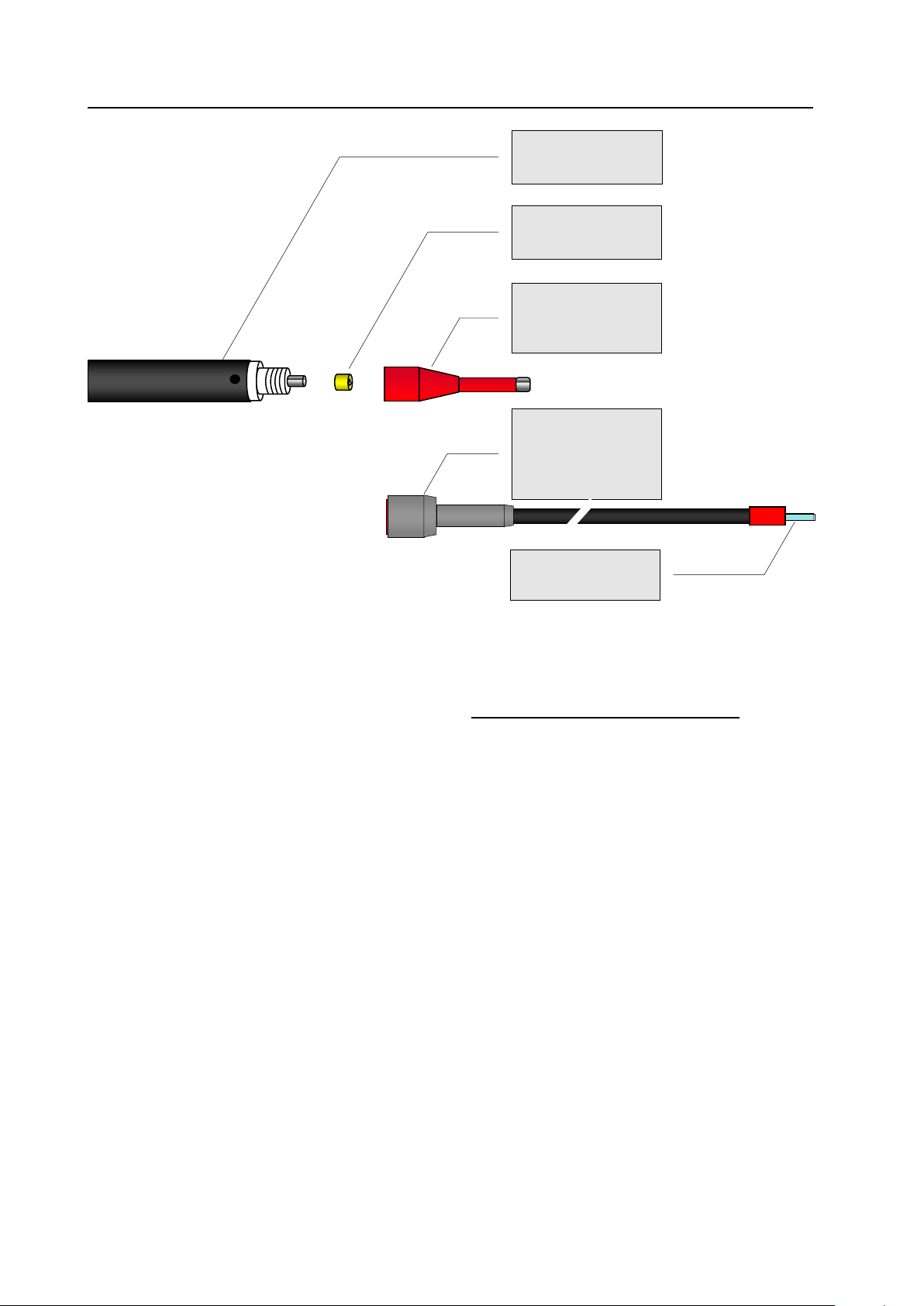

Sniffer probe extension ................................................................................................................................ 31

Leads extender ............................................................................................................................................ 32

SF6 Leak Detector Calibrator ...................................................................................................................... 32

Filter replacement .......................................................................................................................................... 33

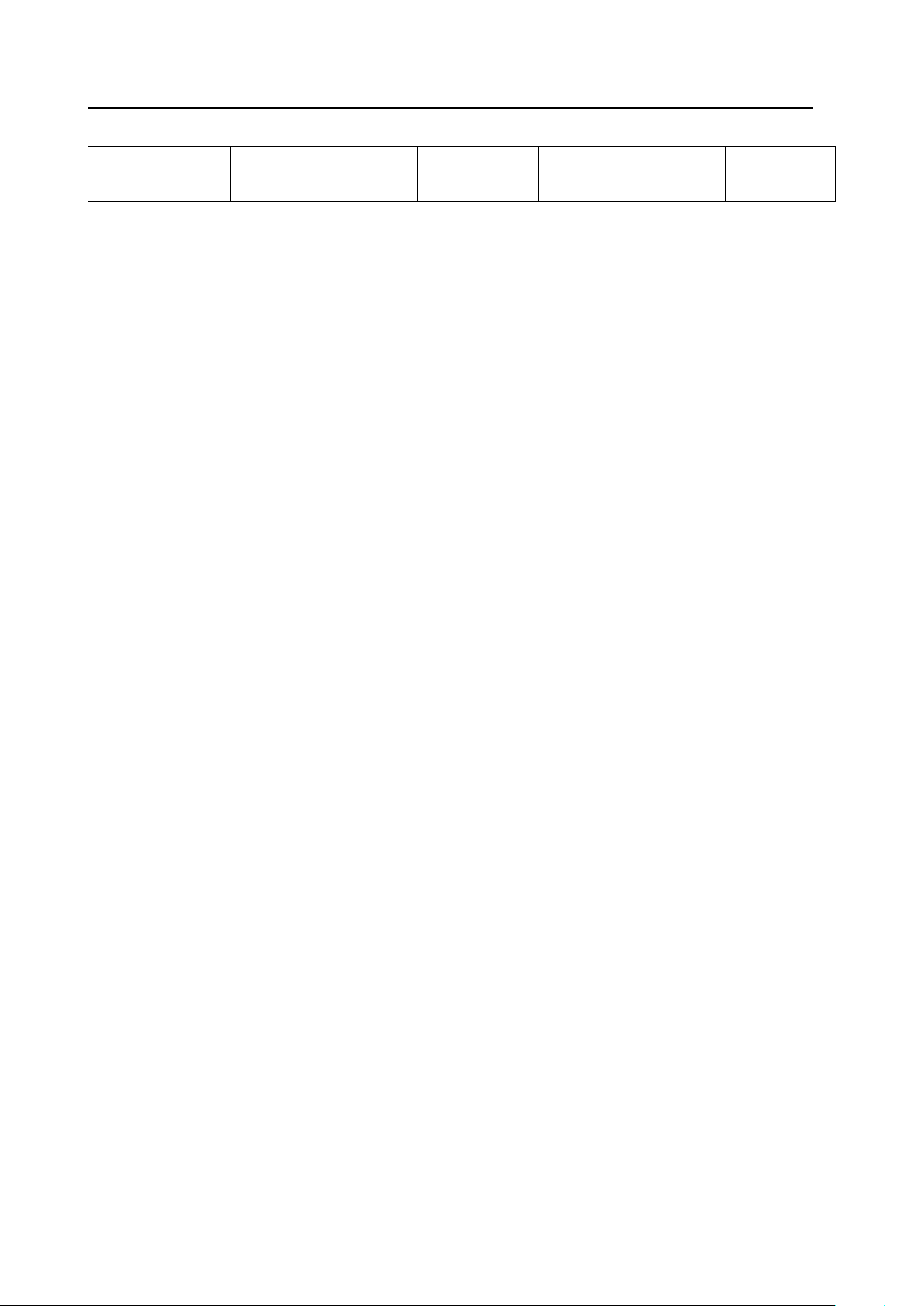

Technical data ................................................................................................................................................ 34

Error messages .............................................................................................................................................. 35

Notes ............................................................................................................................................................... 39

Instrument warranty and service ................................................................................................................. 40

Contact details ............................................................................................................................................. 40

Manual log ...................................................................................................................................................... 41

3 of 41

Page 5

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Remarks

Target group

This Instruction Manual is intended for operators who perform operation-specific settings on the SF6

LEAKCHECK P1:p leak detectors.

General information

The Instruction Manual applies to the software version stated in the header (e.g. V3.06).

Safety instructions

Before you use the instrument, please read and comply with these instructions:

– Keep the Instruction Manual in a safe place.

– Only ISM employees may open the instrument or parts of it.

– There are no components in the instrument that require maintenance.

– Protect the instrument from moisture.

– Use the instrument only in dry places.

– Only use earthed systems that are without current.

Correct use

The P1:p leak detectors are intended only for detecting leaks and making measurements on components

filled with SF6 or FM-200. Any other use is considered as incorrect.

New design handset

Only handsets from and including serial number 00125 upwards can be operated in connection with the SF6

LEAKCHECK P1:p. The serial number of the handset can be read off from underneath the grip part. For

this, push the grip part slightly upwards.

4 of 41

Page 6

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Versions

SF6 LEAKCHECK P1:p – Portable case instruments

SF6 LEAKCHECK P1:p Standard

Detection limit: 1 x 10E-7 ml/s

1.0 ppm

SF6 LEAKCHECK P1:p HIGHsens

Detection limit: 1 x 10E-8 ml/s

0.1 ppm

5 of 41

Page 7

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Usage in practice

Owing to the practice-oriented design of the instruments, work with these is simple and reliable when

observing the following:

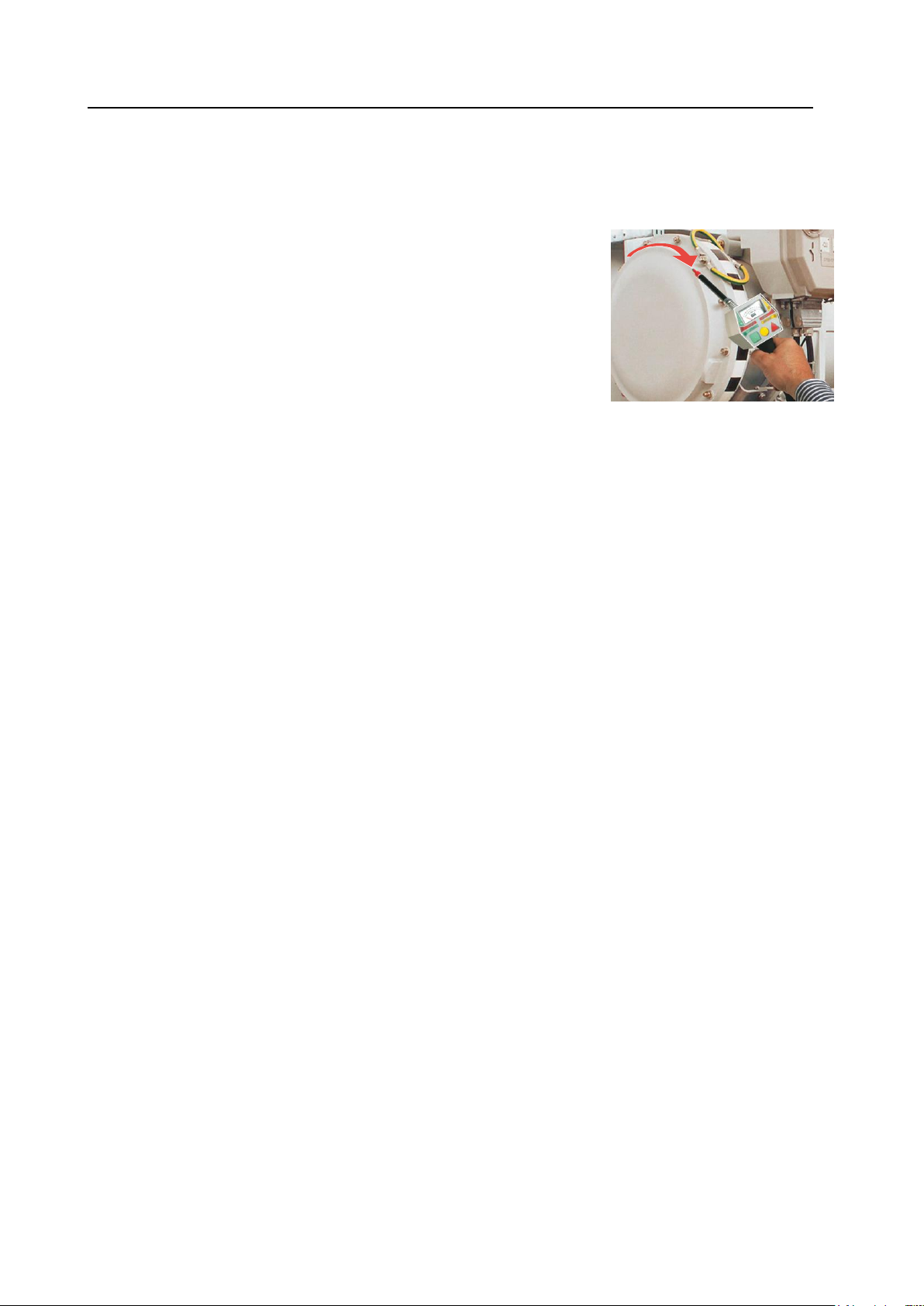

For leak detection

- Switch the instrument to the Search Mode (Chap. 0, “

- Search Mode“, Page 12).

- Guide the sniffer probe as closely as possible to the suspected

leaking locations. Establishing material contact with the sniffer probe

will be useful.

- The velocity at which the sniffer probe is advanced should be at about

20 mm/s.

- Please do not push the sniffer probe over the test specimen, but pull

it instead so as to effectively prevent the ingress of grease and dirt,

for example.

For leak measurements

- Switch the instrument to the Measurement Mode (Chap. 0, “

- Measuring Mode“, Page 12). Observe the displayed unit of measurement (cc/s or g/a) which is desired.

- Guide the sniffer probe as closely as possible to the suspected leaking locations. Establishing material

contact with the sniffer probe will be useful.

- The magnitude of the leak can be considered as being correctly acquired when the measured value

does not change within 2 seconds.

For concentration rise measurements (integral atm.)

- In the user set-up select the unit of measurement “ppm”.

- Place the test specimen within the chamber free of SF6, close the chamber.

- Zero the leak detector in clean ambient air by operating the “Zero” button.

- For the initial measurement with the P1:p leak detector, push the sniffer probe for approximately 10 to 20

seconds through a corresponding connection directly into the chamber. Save the measured

concentration (red triangle button). Remove the sniffer probe from the chamber.

- After the measurement time defined by the customer has elapsed, Zero the leak detector in clean air by

operating the “Zero” button, introduce the sniffer probe into the chamber again and perform the final

measurement for a duration of approximately 10 to 20 seconds. Save the measured concentration (red

triangle button). Remove the sniffer probe from the chamber.

The difference between the two saved measured values gives the rise in concentration within the

measurement time specified by the customer.

6 of 41

Page 8

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

System properties

General properties

The P1:p leak detectors are rugged, mains power independent instruments for leak detection and leek

measurements involving electron capturing gases, SF6 in particular. All necessary operating and display

elements have been combined in the handset. The quantitative determination of a leak is performed through

the numeric display on the screen of the base unit (P1:p case cover). For documentation purposes,

measured values can be saved, subsequently reviewed on the screen and printed out or transferred to a

computer.

All components subject to wear have been combined in the exchangeable ISM SmartSensor. Base unit and

handset will not require any maintenance or care except for external cleaning from time to time. Worn out

sensors are replaced.

During leak searching, the operator is supported through the following facilities:

1. An easy to read pointer gauge, which, depending on the operating mode indicates the measured value

by way of a percentage of the preset limit, thus excluding the possibility of any incorrect interpretation,

or (in the Search Mode) a full-scale response is attained whenever a leak is detected.

2. The peak-hold function for the pointer gauge which can be programmed to an adjustable time or for

manual deleting.

3. A vibration alarm which lets the handset vibrate noticeably as soon as a certain limit is exceeded.

4. A notification LED which comes on as soon as the measured value exceeds 20% of the preset limit and

which can be reset by operating the Zero button or the Save button.

5. A differentiated audible alarm, enabling unrestricted leak searching even at inaccessible places, when

you cannot see the display.

Measuring principle

A further developed high-voltage ionization detector (NIC©) is used and which has been optimised in

consideration of the following:

– sensitivity

– precision

– service life

– reliability

Through miniaturisation it has been possible to accommodate the sensor directly in the measurement tip,

thereby attaining excellent response and recovery timings.

Measurement reliability

The processor constantly monitors all operating values relevant for the measurements, and, if necessary,

adjusts them. For example, drift of the sensor and reducing air permeability of the front filter are

compensated for.

Proper operation of the SmartSensor is only possible under constant and precise control through the

software. For this reason there exists a closed signal loop from the processor, over the high-voltage

generator, the sensor itself and the processing circuitry back to the processor. A fault at any place within this

loop will immediately cause the sensor signal to fail resulting in an error message.

Together through monitoring of the taken in the airflow, the possibility of the worst conceivable fault

condition is excluded: An instrument which presents itself to the operator as being ready but which

actually is incapable of “seeing” existing leaks.

Programmable parameters which have an influence on the measurements, are protected through password

queries within the different levels against unauthorised or inadvertent changes. Access to the LCD touch

screen is only necessary when wanting to change the programming.

7 of 41

Page 9

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

LCD touch screen

On/Off button

Mains power and charging light

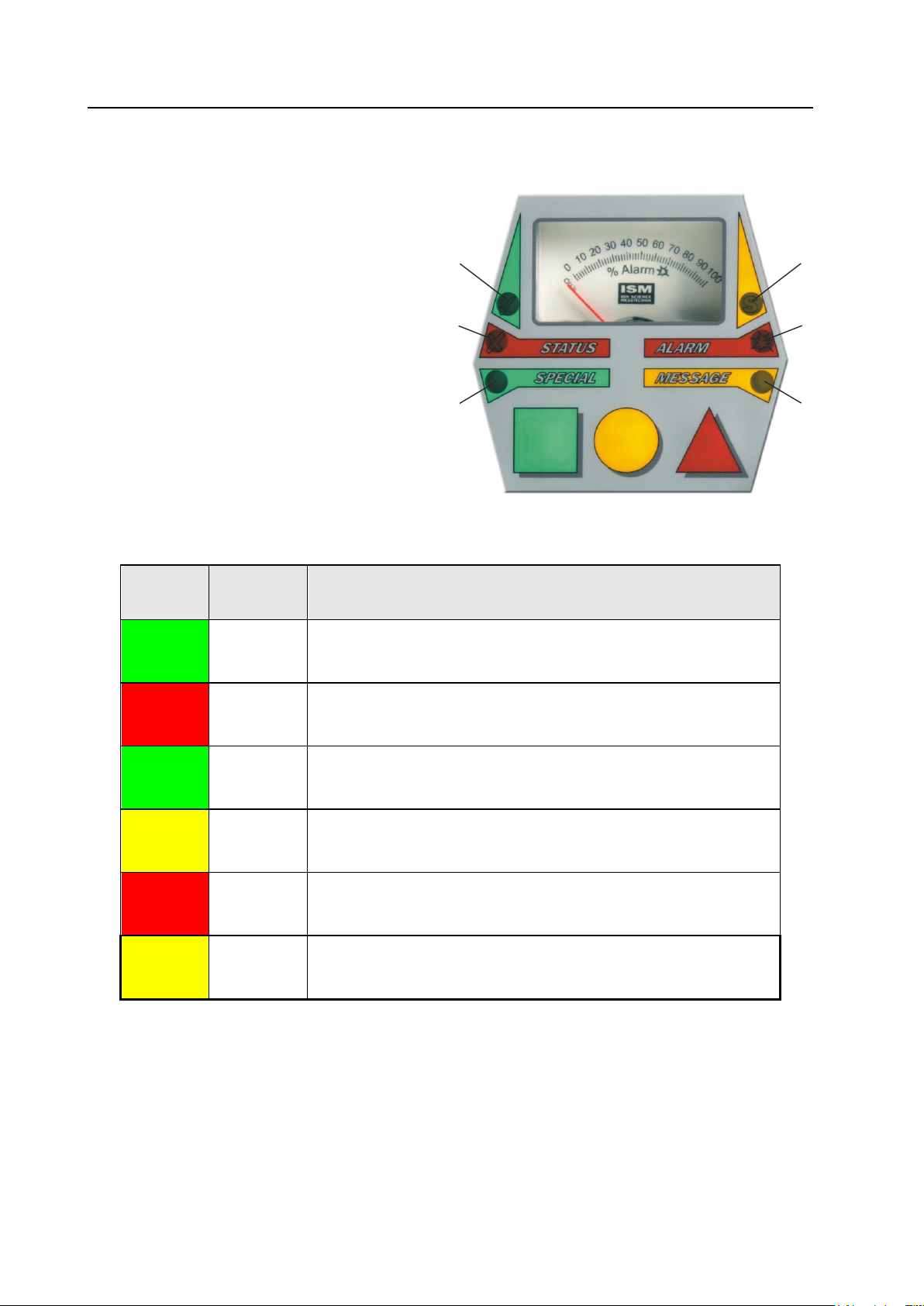

Control and display elements

Control and display elements on the base unit

Located at the base unit are the following elements:

1. LCD touch screen for numeric display of the leak rate as well as for entering parameters.

2. P1:p the On/Off button, illuminated red when the instrument has been switched on.

3. White mains and charging indicator lamp. It flashes while the built-in rechargeable battery is being

charged after having connected the instrument to the mains power supply. As soon as the battery has

been fully charged, the light stays on constantly, without mains power it remains off.

8 of 41

Page 10

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

COLOUR

NUMBER

Description

1

READY FOR MEASURING. Is turned off when the instrument is in

the programming or standby mode or when a fault is present.

Flashes in the Search Mode.

2

NOT READY FOR MEASURING. Is turned on when the

instrument is in the programming mode or if a fault is present.

Flashes in the Standby Mode

3

SPECIAL. For additional custom functions. Currently the LED will

flash when selecting the extended display range.

4

SIGNAL. Is on when a measured value has exceeded 20% of the

preset limit. Is turned off after operating the Zero or memory

button.

5

ALARM. Is on as long as the measured value reaches or exceeds

the preset limit.

6

MESSAGE. Requests the operator to read a message indicated on

the display.

1

2

3

4

5

6

Control and display elements

Control and display elements on the handset

The handset is equipped with the following display elements:

1. The pointer gauge for displaying the

currently measured value. In the Search

Mode the gauge will either indicate only

“Zero” or “Full scale”.

In the Measuring Mode the currently

measured leak rate is indicated. Instead of

an absolute value, the leak rate is indicated

in percent of the preset limit thereby

excluding any possibility of misinterpreting

the displayed values.

Example:

Alarm preset: ................. 10 E-7 ml/s,

Current meas. value: ....... 8 E-7 ml/s,

Analogue readout: ......... 80%.

The corresponding absolute value may in the

Measuring Mode be read off from the

display of the base unit.

Six LEDs are provided to indicate the different operating modes:

9 of 41

Page 11

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

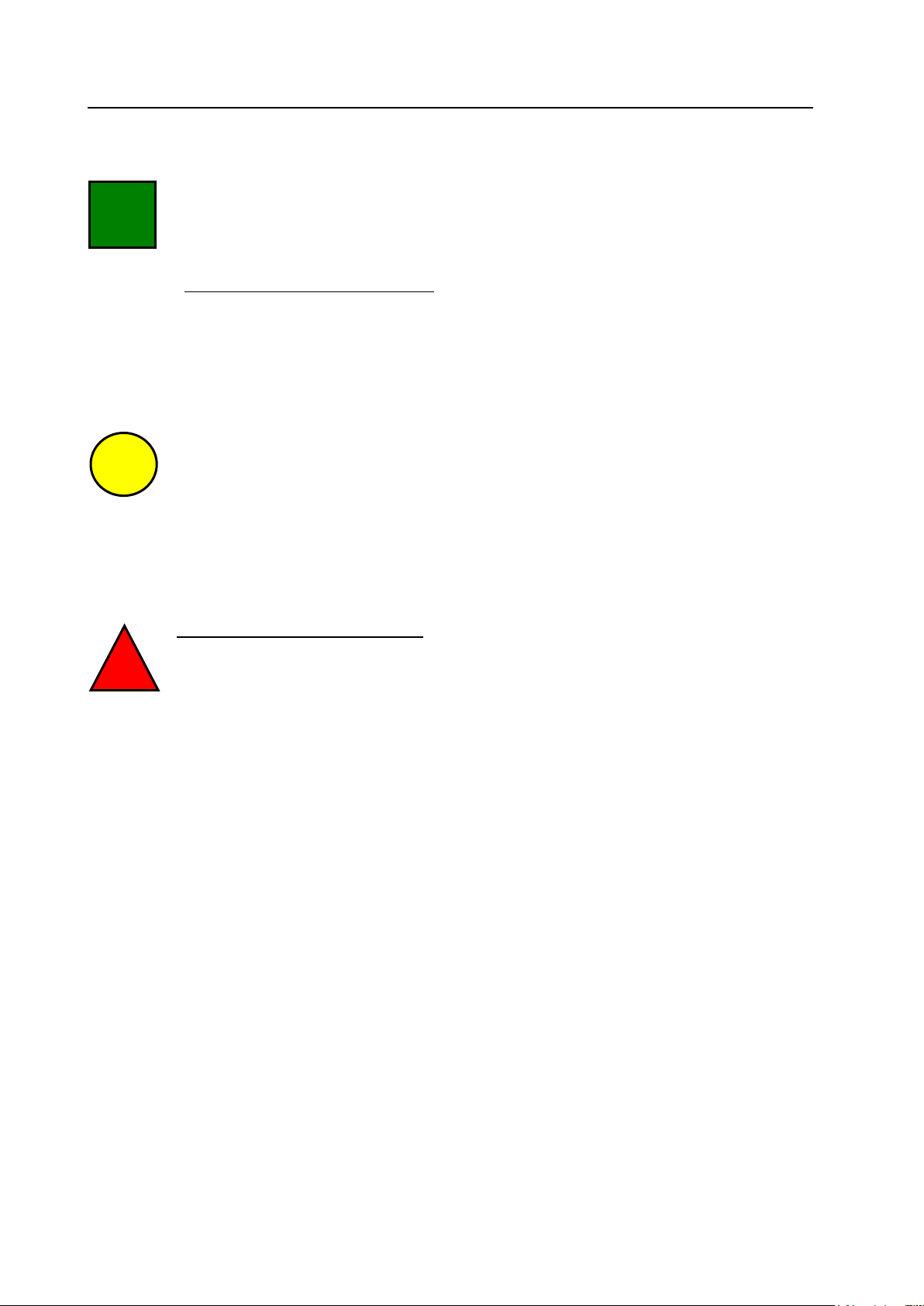

Control and display elements

3. The three control buttons:

This button has two functions:

1) When pressing this button for a long time, the system switches between Search and

Measuring Mode. For this, the button is pressed until the red “STATUS” LED is turned off again.

Before switching over, the instrument performs a Zero setting so that there will be a short delay.

2) IN THE MEASURING MODE ONLY: Pressing this button briefly will expand the display range

of the analogue pointer gauge of the handset. Pressing this button once will select factor 1 set up in the user

setup (green “SPECIAL” LED flashes slowly). Pressing this button once more selects factor 2 (green

“SPECIAL” LED flashes rapidly). When pressing this button once more briefly, or pressing the Zero button,

the SF6 LEAKCHECK P1:P will switch back again to the normal display mode.

Setting of the measured value to Zero. For a brief moment the LED indicator will change from

“READY “ to “NOT READY”. Since during this time and if necessary the energy flow to the

sensor is corrected, the Zero button should be in any case operated from time to time even if no

deviation from the Zero level is present.

When the extended display range is active, it will also be disabled.

IN THE MEASURING MODE ONLY: The peak value indicated on at the bottom on the right of

the screen is saved and thereafter set to Zero. Saved values may later be output through the

serial interface to a computer or printer. Pressing this button for a long time, displays the option

“Data Memory Control” serving the purpose of administrating saved measured values.

10 of 41

Page 12

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

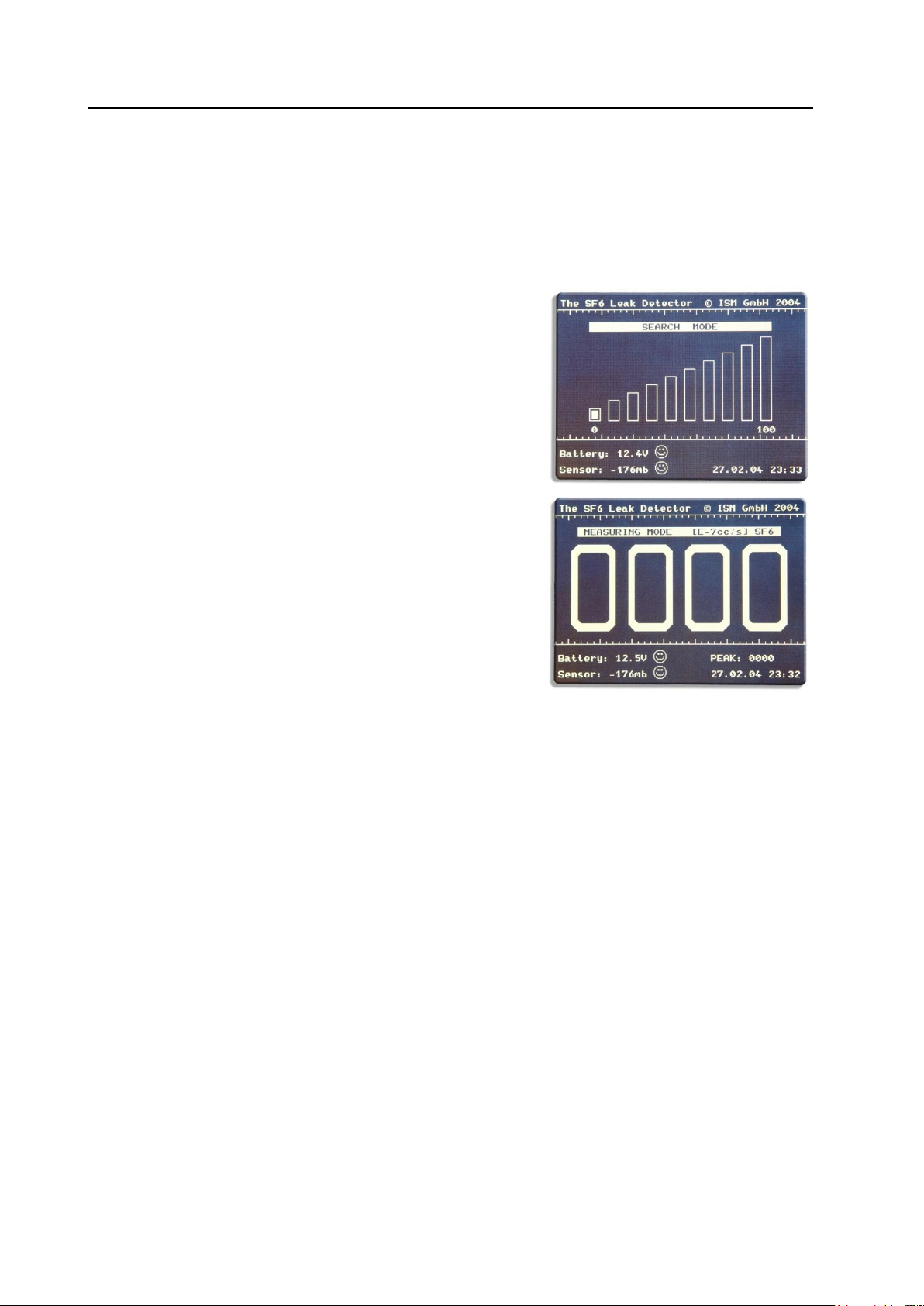

Start screen

„Search Mode“ display

„Measuring Mode“ display

Putting into operation

Preparations for putting the P1:p leak detectors into operation are limited to connecting the handset, the

sensor, and, if available, the mains power. When connecting the handset and the sensor you must ensure

that the markings on the plug and socket the line up with each other and that the slide piece of the plug has

reached the locking position, in which it is completely in contact with the collar of the socket.

When briefly pressing the red On/Off button, the instrument will start. Approximately 20 to 30 seconds after

the start-up screen has been displayed, the normal operating screen will be displayed. Should this not be the

case, then please read the message on the screen as well as the information provided in the Chapter

"Possible malfunctions when starting the system" and "Switching off when there is a failure".

11 of 41

Page 13

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Operation modes

The P1:p leak detectors offer two different measurement operating modes which are explained in the

following.

The user himself may define the mode which will be enabled when switching the instrument on. During

operation it is possible to change between the modes at any time by pressing the green SQUARE button for

a longer time until the red LED “Not READY” on the handset lights up again.

Search Mode

In the Search Mode, the instrument operates with the greatest possible sensitivity. However, there is no

quantitative display of leaks. Instead, each leak which is found

results in a full scale response of the analogue gauge in the

handset as well as a corresponding audible alarm. For

approximately estimating and locating the leak, there is a bar

display on the screen. The advantage of the Search Mode is the

fact that even small leaks or leaks not completely determined are

not easily "overlooked“. Moreover, by dispensing with a

quantitative readout, sensitivity is, compared to the

Measurement Mode even slightly higher.

The Search Mode is indicated on the bar display of the screen

as well by flashing of the “READY" lamp on the handset.

Measuring Mode

In the Measuring Mode, the leak rate is indicated on the screen

using large digits. The gauge on the handset indicates the

measured leak rate in percent of the limit. Therefore a leak which

is as great as the selected limit will give a readout of 100%. In

the Measuring Mode, the green “READY” lamp will be on

constantly. In this operating mode, it is possible through the

“User Setup” to select and indicate the required unit of

measurement (cc/s, g/a, ppm).

12 of 41

Page 14

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Operation

Ready for measuring

The P1:p leak detectors are ready when the “Search Mode” bar is visible on the screen or in “Measuring

Mode” the large digits of leak rate display are visible. This situation comes about only, if:

1. the SmartSensor functions within its operating limits,

2. the suction airflow is within the nominal range, and

3. as long as the continuous self tests run successfully.

At the same time, the “READY” lamp lights up on the handset. In the Search Mode, this lamp flashes when

the instrument is ready for measuring.

Saving of measurement data

The leak detectors are capable of separately saving the measurement data for several test specimens and

outputting such data through the serial interface to a printer or a computer. Saved data is also retained when

switching the instrument off. The memory capacity permits 100 measured data for a maximum of 96 different

test specimens. Saving of a measured value is only possible in the Measuring Mode, since in the Search

Mode no quantitative measurements are run. Briefly pressing the red TRIANGLE button on the handset will

save the highest measured value which has occurred. This highest value is displayed on the screen at the

bottom on the right under “PEAK:”. Each time a value is saved or after zeroing, the peak memory is erased

and will be ready to accept the next measured value.

Using the measured value memory

As to the internal processing of the peak memory, the following applies:

- Upon pressing the red TRIANGLE button, the value of the peak memory indicated on the screen is

carried over by way of a new entry to the dataset for the test specimen.

- The peak memory as indicated on the screen is simultaneously erased and ready to accept the next

measurement.

- By operating the yellow Zero button, the peak memory is also erased.

- A dataset for a test specimen can be “open” or “closed”. Only one test specimen dataset can be open at

a time. New data is always written to the opened test specimen dataset. A closed test specimen dataset

cannot be opened again.

- An opened test specimen dataset is closed when:

- the programme section “User Setup” is activated

- a new worker test specimen identifier is entered (simultaneously opening a new test specimen

dataset)

- the measurement data memory is erased

- a new test specimen dataset is opened manually

- or the instrument is switched off.

- A new test specimen dataset is automatically opened, when

- the TRIANGLE button is operated and when currently no test specimen dataset is open. This will

always be the case after having switched the instrument on

- a new worker or test specimen identifier is entered.

13 of 41

Page 15

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Operation

On the operator level (OPERATOR LEVEL) a variety of administration functions for the data and the memory

are available. The basic functions like “Start print out”, “Open new test specimen dataset” and “Erase data

memory” can be invoked also through the buttons of the handset.

In contrast to earlier versions of the P1:p leak detectors, the data is not automatically deleted after a

successful print out. Instead the data is retained until being deleted manually. The operator should, for this

reason, before starting a new measurement run, not forget to delete the “old” data.

In each test specimen dataset the following information is also saved besides the actual measurement data:

- The serial number of the leak detector

- The unit of measurement selected for the display at the point of time of the measurement

- The type of gas (SF6 or FM-200) selected at the point of time of the measurement

- Creation time and date for the test specimen dataset

- Optionally, a worker identifier

- Optionally, a test specimen identifier, serial or batch number, for example

- The leak rate limit applicable when taking the measurement

- The total of all saved measured values (total leak rate).

For each individual measured value, the time of the measurement as well as any apparent exceeding of the

limit are also printed out.

The output is effected in the text format through the serial interface. If instead of a printer, a computer is to

receive the data, then a so-called Null Modem Cable must be used where the signal lines are crossed. The

transmission format is 9600-8-N-1 (9600 baud, 8 data bits, no parity, 1 stop bit). When using a printer, the

leak detector must be set up for the same handshake as used by the printer (0 Handshake ), so that the

printer can control the data flow. For this please also refer to the manual of your printer.

On the supervisor level (SUPERVISOR LEVEL) the entry of a worker or test specimen identifier can be

made mandatory. When such entries have been made mandatory, the instrument will query the entries upon

opening a new test specimen dataset. Also if such entries are not made mandatory, such entries can be

entered at any time, however, the operator is not asked to do so. The information relating to the

identification, needs to be entered BEFORE creating the test specimen dataset in which it shall appear.

Possible malfunctions when starting the system

Most severe errors are already detected and indicated upon switching the instrument on. Running up of the

instrument is then interrupted and a corresponding error message is indicated. At the bottom of the screen, a

countdown will run which switches the instrument off after 15 seconds. This countdown can be cancelled

through the [ STOP ] button. After operating this button, its designation changes to [ EXIT ] allowing the

operator to enter the menu system where he may then change settings, read out technical data or run a

diagnosis.

Inasmuch as the displayed message is not self-explanatory, please get in touch with ISM or your ISM

certified distributor stating the kind of error message so as to allow the malfunction to be analysed. If an error

message relating to the SmartSensor is encountered, please always first exchange the SmartSensor.

Possible malfunctions during operation

If during operation a relevant malfunction occurs, the display on the handset will change from “READY” to

“NOT READY”, and the “MESSAGE” lamp will light up indicating to the operator to read the error message

displayed on the screen and if required acknowledge it.

14 of 41

Page 16

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Operation

The following error messages can occur:

LOW SAMPLE FLOW

(low intake air flow)

When blocking the air intake opening of the sensor totally or partly, an error message is produced requesting

the operator to check the condition of the sensor.

Two buttons are available to confirm this error message:

[ RESTART ] requests the instrument to try and resume measurement operation. For this, the operating vacuum

is controlled anew. If unsuccessful, then the error message will appear again after a short while.

[ POWER DOWN ] switches the instrument off so as to allow the sensor to be replaced.

The selection can also be performed through the buttons of the handset. Corresponding symbols are

displayed in the buttons on the screen.

TOO MUCH GAS (failure of the discharge in the SmartSensor)

For this kind of malfunction there are two possible causes:

1. a very high concentration of detectable gas,

2. an operating vacuum which is too high due to a worn out or partially blocked SmartSensor. Since the

quantity of taken in air is maintained at a constant level, a reduction in the air flow through the filter or

the intake opening will result in an increased operating vacuum. When the operating vacuum is found to

be much increased, the discharge in the SmartSensor becomes unstable and can fail.

3. A malfunction in the SmartSensor caused by contamination within the ionization chamber can also

cause the discharge to fail.

The operator is then requested to remove the SmartSensor from the possible gas source and confirm this by

pressing a button. After having acknowledged the condition, the discharge is, if possible, reignited and

controlled. If this is unsuccessful or if the error message appears without any apparent reason, then please

replace the SmartSensor.

PUMP RATIO HIGH (overloading of the suction pump)

This error condition is detected when the suction pump must run significantly more frequently or longer than

expected so as to maintain the operating vacuum. The reason for this can be a leak in the pneumatic system

of the leak detector or a malfunction affecting the suction pump. Since in any case the reliability of the

measurement is endangered, the options [ DIAGNOSTICS ] (change to the diagnosis screen) or [ POWER

DOWN ] (shut down) are offered to the operator.

LOW BATTERY VOLTAGE

If without a mains power connection being present, the voltage of the rechargeable battery reaches the total

discharge level threshold, the user is informed as to the imminent shutdown. If no mains power is available,

operation can be continued for a short while, however, from now on the instrument may shut down itself at

any time so as to avoid damaging the rechargeable battery.

15 of 41

Page 17

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Turning off

When switching off, the processor of the instrument powers down in several steps. Here, among other

things, the non-volatile memories of the sensor, the handset and the base unit are updated.

In order to turn off the instrument, the red ON/OFF button must be pressed for several seconds. Running of

this holding time is indicated on the screen through a time bar. When releasing the button before the holding

time has elapsed, then the instrument will return to normal operation. After the holding time has elapsed, the

screen will indicate “GOODBYE”, and the button may now be released.

Switching off when there is a failure

Normally the processor will control the turning off process as described above. Should, owing to a severe

malfunction, this process no longer be operational, then the instrument can be de-energised in spite of this

by a forced hardware controlled shutdown. For this the On/Off button needs to be depressed for

approximately 8 seconds until the forced shutdown has occurred.

16 of 41

Page 18

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

Described in this section are the parameters which define the behaviour of the P1:p leak detectors as well as

the procedures for setting up the parameters.

All parameters are protected by passwords against unauthorised or inadvertent changes. Three groups of

related parameters can be protected by different passwords:

- The operator level (OPERATOR LEVEL) contains settings and entries which can be accessed by the

worker during measurement operation. These include entries for operator and test specimen

identification as well as functions for administration of the measurement data memory.

- The technical level (TECH. LEVEL) contains besides settings which define the way in which the leak

detector responds, also reading out of technical data for support and after sales service as well as

the calibration process and the entry of the limits.

- The supervisor level (SUPERVISOR LEVEL) finally ensures administration of the passwords as well

as the settings relating to mandatory worker and test specimen identification entries.

Through different passwords, each functional group can be made accessible to a certain range of persons.

Entry of passwords and numbers

At several points within the menu system, the entry of passwords and numbers is required. For this, in each

case a 10 digit keypad or an alphanumeric keypad is displayed.

For entering, simply touch the required number or letter keys.

Incorrect entries may be corrected through the

[ <- ] button, upon which the character which was entered last is

deleted. To end the entry process, please use the RETURN

button.

In the case of many entries, the current value of the parameter is

displayed by default. You may then simply confirm this value by

operating RETURN or enter it anew. Through the [ <- ] button,

also partial deletions are possible. The [ ESC ] button cancels

the entry process and any changes made so far rejected.

Activating the operating mode menu

When the instrument is running in the Search Mode or in the

Measuring Mode (large display of the leak rate) then the main

menu may be invoked by touching the touch screen anywhere.

From here further menu sections can be accessed by touching

the displayed buttons.

Returning to the Measuring Mode is effected by operating the

[ EXIT ] (End) buttons shown on all of the screens.

In the following description of the individual setting up functions, it

is assumed that the main menu has already been invoked.

Branch offs are indicated by stating the [Buttons] which need to

be touched in square brackets and blue colour.

Displayed (screen messages) are shown in round brackets.

17 of 41

Page 19

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

Pre-set passwords in the delivered state

In the delivered state, all passwords have been preset to “000”. Details on how to change passwords are

provided in Chapter.

Setting volume and screen contrast

[ SET VOLUME / CONTRAST ]

Through the buttons [ + ] and [ - ] it is here possible to change the volume of the sound output (separately for

base unit and handset) as well as the screen contrast.

Operator level

(OPERATOR LEVEL)

In the operator level all functions have been combined which are accessible to the worker during

measurement operation. The operator level is reached from the main menu through the button [ OPEN

OPERATOR LEVEL ] and thereafter entering the operator password.

Entry of worker identification

[ OPEN OPERATOR LEVEL ] / [ OPERATOR ID ]

If on a subsequent data print out an identification of the worker shall appear, then here a name or a

corresponding identifier can be entered.

If the entry of a worker identification has been made mandatory then this entry screen will be displayed

automatically upon opening a new test specimen data set .

Also when the entry has not been made mandatory, the identifier can be entered at any time during

operation. This must be done BEFORE opening the test specimen dataset in which the identifier shall

appear.

Entry of test specimen identification

[ OPEN OPERATOR LEVEL ] / [ PRODUCT ID ]

If on a subsequent data printout an identification of the test specimen shall appear, then here a batch or

serial number can be entered.

If the entry of a test specimen identification has been made mandatory then this entry screen will be

displayed automatically upon opening a new dataset.

Also when the entry has not been made mandatory, the identifier can be entered at any time during

operation. This must be done BEFORE opening the test specimen dataset in which the identifier shall

appear.

Printing stored data

[ OPEN OPERATOR LEVEL ] / [ DATA PRINTOUT ]

If during the measurement, data has been saved by operating the TRIANGLE button at the handset, then

here outputting of the saved data through the serial interface can be initiated. If there exist data for several

test specimens in the memory, then a selection screen is displayed before the printing process starts where

the test specimen data sets which are to be printed can be selected. The button [ GO ] starts the printing

process, the button [ EXIT ] cancels the process and returns to the Measuring Mode.

Viewing of the saved data is possible through [ DATA MEMORY CONTROL ].

Data memory administration

[ OPEN OPERATOR LEVEL ] / [ DATA MEMORY CONTROL ]

This function can also be reached from the Measuring Mode (NOT the Search Mode) by pressing the red

triangle button longer. The more important options available here can also be controlled through the buttons

of the handset. Because of this it is possible during measurement operation to keep the transparent cover of

the touch screen closed and secured. Symbols corresponding to the buttons on the handset are displayed in

the respective buttons.

From here all administration functions for the measured data memory can be controlled. In addition, a

summary of the current memory usage is shown at the bottom of the screen.

The individual buttons are:

[ DATA PRINTOUT ] (or yellow circle button).

Starts a printout of the saved measurement data through the serial interface. Before, the test specimen date

sets which are to be printed out can be selected. When starting this through the button on the handset, no

selection is possible, in this case the entire memory contents are printed.

18 of 41

Page 20

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

[ NEW COMPONENT ] (or red TRIANGLE button).

Measurement data for several test specimens can be saved. The button [ NEW COMPONENT ] opens a

new blank test specimen dataset. For a maximum number of 96 test specimens 100 measurement data for

each can be saved. If the entry of a worker or test specimen identification has been made mandatory, the

entry of this data is queried automatically.

[ CLEAR DATA MEM. ] (or simultaneously SQUARE and TRIANGLE button).

This deletes all saved measured values. This function should be utilised before starting any new

measurement run so as to remove possibly present values which are no longer valid. Upon initialisation

through the screen, a safety query is displayed before erasing the data. Upon initiation through the

buttons on the handset, there will be no such query since inadvertent operation is not possible.

[ VIEW DATA ]

Viewing saved data on the screen. In the data area of the screen, the measured values may be scrolled

upwards and downwards using the arrow buttons. In the operator area information on the respective test

specimen dataset as well as the buttons for selecting the displayed test specimen dataset is available.

The technical level

(TECH LEVEL)

On the technical level, functions like running of the final calibration, operator-specific settings and reading of

technical data have been combined. From the main menu, the technical level is accessed through the button

[ OPEN TECH. LEVEL ] with subsequent password entry.

The functions which are available on this level are:

Final calibration

[ OPEN TECH. LEVEL ] / [ CALIBRATION ]

With the aid of the final calibration, the accuracy of the quantitative determination of leaks can be improved

compared to the system calibration.

In the course of the final calibration, the actual value of the calibration leak, respectively the concentration of

the calibration gas must be entered. If always the same calibration leak/calibration gas is used, this entry will

be required only once. The value is saved by the instrument and only needs to be confirmed by the operator

by pressing RETURN. Separate memory locations are available for the calibrated values for each operating

mode. Therefore, when changing between operating modes, the actual value will not have to be entered

once more.

When entering a new value, it may possibly required to convert the actual value stated on the calibration leak

to the unit of measurement used by the P1:p (E-7cc/s, E-8cc/s, ppm or gm/yr). After acknowledging the

entry, the actual calibration process is run. The instrument first determines the background level. For this the

sniffer probe must be placed in the air of the room which is free of SF

and a time bar are displayed.

After the time on the time bar has elapsed, the operator is requested to guide the SmartSensor to the

calibration leak. The corresponding time bar will only start to run after this has been done. During the

measurement, the intake opening of the SmartSensor must be constantly held precisely at the opening of the

calibration leak. If this is not done, then there is the risk of producing a faulty calibration. The measurement

can be cancelled at any time through the [ EXIT ] button. Then the instrument returns to the Measuring

Mode, and the previous calibration remains unchanged. Use this possibility when wanting to enter the actual

value of your calibration leak/calibration gas but without wanting to run a calibration.

After the calibration has been completed, the operator is requested to remove the sensor from the calibration

leak. The new calibration factor is displayed. If the factor is outside the permissible range, then the leak

detector will assume an error during the calibration. Such errors may, for example, be due to removing the

sensor from the calibration leak during the process or missing agreement of the entered actual value with the

value of the calibration leak. In this case the new calibration factor is rejected and the initial calibration factor

is maintained. An acceptable new calibration factor is marked by a check mark and an unacceptable

calibration factor is marked by a warning triangle.

. The message “Calibrating clean air:”

6

19 of 41

Page 21

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

Setting date and time

[ OPEN TECH. LEVEL ] / [ SET CLOCK ]

The built in real time clock supplies time marks to saved measured values and calibration data, and should

for this reason be corrected in the case of noticeable deviations.

Setting the real-time clock can become necessary under the following circumstances:

– Daylight saving time change

– Transportation to a different time zone

– Normal running deviation

– When the instrument was separated from the built-in rechargeable battery.

Through [ NEXT ] select day, month, year, hour or minute to be changed and then set through [ + ] and [ - ]

the desired value. Upon exiting the entry through [ EXIT ] the real-time clock is updated with the new

values.

User specific settings

[ OPEN TECH. LEVEL ] / [ USER SETUP ]

In the User Setup, different parameters have been combined which are described in the following. To change

a parameter, first the inverted entry cursor needs to be placed on the corresponding line using the arrow

keys. Through the buttons [ + ] and [ - ] the value may then be changed within the permissible range. When

exceeding the upper limit of the valid range, the entry then skips to the lower range limit and vice versa.

Display operating mode

(DISPLAY UNITS)

The numerical display on the screen as well as the entries for the limits and actual values for calibrations are

output in the unit of measurement selected here. For the different display operating modes, there exist for all

these values as well as for the calibration factor separate memory locations. Therefore when changing

between the display modes “ppm”, “gm/yr” and “cc/s” these will not have to be entered once more.

Currently the following display modes are available:

- E-7 cc/s (leak rate, corresponds to ml/s – mbarl/s)

- E-8 cc/s (leak rate) only for HIGHsens instruments

- ppm (concentration)

- gm/yr (leak rate).

The display operating mode “ppm” is special. Since it requires a higher sensitivity compared to the other

modes, and since on the other hand the response and recovery times during concentration measurements

are irrelevant, an additional low pass filter has been placed in the signal path of this display mode. This filter

smoothes the measured signal, blocks short-term fluctuations thereby ensuring a smooth reading.

In the case of concentration measurements you will, for this reason, have to expect significantly longer

response and recovery times, which, depending on the measured concentration, can amount to up to 10

seconds.

Moreover, in the “ppm” display operating mode, the Search Mode is not available, since the extended

response time does not agree with the intentions of the Search Mode.

Peak hold function of the pointer gauge

( PEAK HOLD (GAUGE) )

Owing to the short recovery time of the P1:p, this function is useful during leak detection. The current peak

value is held for the preset time by the pointer instrument of the handset. In the OFF position, this function is

switched off, position MANUAL requires deleting of the peak value by pressing the Zero or the memory

button at the handset.

Start-up measurement mode

( STARTUP MODE )

Here it is possible to define which mode (Search Mode or Measurement Mode) the instrument shall run after

switching on. During operation of the instrument, it is possible to change at any time between the two modes.

20 of 41

Page 22

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

Screen appearance

( SCREEN APPEARANCE )

The screen display is selectable either to white on black or black on white.

Language selection

( LANGUAGE )

This option is reserved for future extensions, currently only English is available as the operator language. In

coordination with ISM also other languages can be implemented.

Entry of the alarm limit

( ALARM LEVEL )

Here enter the desired limit for the active display operating mode. As soon as this limit is reached, the pointer

instrument of the handset will indicate 100%, and the “ALARM” LED comes on. Saved measured values

which are above this limit, are clearly marked in the data printout.

The units of measurement in the active display mode are shown as a reminder in the entry area. In order to

change the limit for a different display mode, this display mode will have to be activated first. The instrument

remembers the limits separately for each display mode so that when changing the display mode they will not

have to be entered anew.

It may possibly be required to convert the entered value in consideration of the currently displayed unit of

measurement. The entry may if required, being effected including decimal places.

Threshold for the sound signal during measurements

( WARNING BEGINS AT )

This setting defines the threshold upon which the sound signal as well as the vibration alarm during the

measurements set in. Both set in when the measured value exceeds the limit by the entered percentage.

In the case of the setting NO WARNING, no sound signal nor vibrations are produced during the

measurement. Sound warning signals in the case of error conditions are not affected by this setting.

For leak detection purposes we consider a setting of approximately 20 to 50% as sensible. In practice not

every leak is immediately acquired in full and could be overheard at higher settings.

Vibration alarm on/off

( HAND UNIT VIBRATION )

When this parameter is set to OFF, then the vibration alarm of the handset is disabled.

Display factor 1 analogue gauge in the handset

( DESENS. FACTOR 1 )

Functions only in the measurement mode. Permits pinpointing of larger leaks where full scale of the

analogue gauge is quickly reached. By operating the green SPECIAL button once, the display range is

expanded by the entered factor. In the case of an active factor of 1, the green “SPECIAL” LED will flash

slowly.

Display factor 2 analogue gauge in the handset

( DESENS. FACTOR 2 )

Functions only in the measurement mode. The display range is expanded by the entered factor by operating

the SPECIAL button twice. With the setting OFF, selection of Desens Factor 2 is disabled. In the case of an

active Factor 2, the green “SPECIAL” LED will flash rapidly

Note: The display factors will only affect the analogue gauge and the sound output, not however, the numeric

display. For this reason also such values can be saved and printed out which have been saved while the

display was in the extended mode.

Selection of the standby operating mode

( STANDBY MODE )

A motion sensor in the handset permits automatic shutting down of the leak detector fully or partially during

operating breaks. When the handset is not moved within a preset period of time, one of the standby

operating modes described in the following is enabled. Running of the standby mode is indicated at the

handset by a slowly flashing red LED “NOT READY”. When moving the handset again, the instrument will

resume full operation (exception: setting POWER DOWN).

21 of 41

Page 23

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

Returning to normal operation can also be effected by operating one of the buttons on the handset or by

(briefly!) pressing one of the On/Off buttons.

- NONE: Standby operation is disabled.

- LIGHT: The screen illumination is switched off. This extends the battery operating time and

conserves the fluorescent lamp behind the screen (service life according to the manufacturer: 10,000

hours).

The instrument remains unconditionally ready for measurements, there is no warning before the

instrument enters the standby mode.

- LIGHT AND SENSOR: Both the illumination behind the screen, the discharge in the sensor as well

as the flow controller are switched off, the operating vacuum is decayed. Thus all system

components, however, the sensor in particular, are spared and above all protected against “silent

wear”. This condition differs from that of a complete shutdown, in that the instrument is capable of

restarting when picking up the handset.

Before enabling this standby operating mode, a sound signal and a note on the screen with a time

bar are generated. During the running time of the time bar of 20 seconds, it is possible to cancel the

process and return to the measurement mode by moving the handset or pressing one of its buttons.

- POWER DOWN: The instrument shuts down completely. If longer operating brakes are to be

expected, especially in the case of mains independent operation, this setting should be preferred.

Before enabling this standby operating mode, a sound signal and a note on the screen with a time

bar are generated. During the running time of the time bar of 20 seconds, it is possible to cancel the

process and return to the measurement mode by moving the handset or pressing one of its buttons.

Delay for standby operation

( STANDBY DELAY )

Here set up the time after which the standby operating mode is enabled (see section above). Delays of under

approximately 10 minutes should only be selected in connection with switching off the screen illumination

(LIGHT option).

Gas selection

( GAS )

As the gas for the leak detection process, it is here possible to select SF6 or FM-200. Since the sensitivity of

the P1:p leak detectors for FM-200 is slightly lower, higher calibration factors are permitted here. The

instrument can be calibrated separately for both gases and for this reason when changing the type of gas a

recalibration is not absolutely necessary

Sensitivity for Zero tracking

( Zero Tracking )

Here the way in which the automatic Zero tracking facility operates, can be influenced. Zero tracking is

required so as to compensate for slight changes in the ambient air and the sensor. For setting up the Zero

tracking facility, we recommend the following:

NORM is the default setting which is recommended for all applications with the exception of the special

cases described in the following.

HIGH effects a stronger Zero tracking effect. This setting can be used so as to compensate for greater

background concentration variations or to extend the service life of an already much used SmartSensor. Use

of this setting only when searching for leaks greater than approximately 5 E-7 cc/s or 10 ppm. When using

this setting, there is the risk of suppressing the indication of smaller leaks.

LOW is only available for the HIGHSens instruments. This setting reduces the Zero tracking effect and

improves the response characteristic for very small leaks, respectively concentrations. This advantage is

attained at the expense of suppressing small changes in the background and in the sensor. This setting

should only be used when searching for leaks smaller than approximately 1 E-7 cc/s or 5 ppm and when the

ambient air is substantially free of any background contamination.

22 of 41

Page 24

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

OFF switches the Zero tracking facility off completely and should only be used when searching for

particularly low and/or slowly increasing concentrations. Before each measurement, the Zero level of the

instrument will have to be set manually and there exists no suppression of sensor noise or changes in the

ambient air

Running this option is recommended only under controlled laboratory conditions and it is left to the operator

to decide whether or not it is helpful in connection with the specific application in each case.

Coupling calibration factors (“Cross Mode Calibration”)

(Couple Cal. Fctrs)

The P1:p leak detectors provide for separate calibration factors for the basic operating modes “Leak rate”

[cc/s, gm/yr] and “Concentration” [ppm]. Normally the final calibration for both operating modes is performed

independently of each other.

By optionally coupling of the calibration factors (Setting “YES”) it is possible to calibrate the leak detector

through a single final calibration in any operating mode simultaneously for both operating modes. This is

particularly useful when a suitable calibration source for the desired operating mode is not available.

The calibration factor for the second operating mode is here determined through an internal calculation.

Although this calculation is subject to a certain error tolerance owing to the tolerance range of the taken in

quantity of air, the attained accuracy can be considered as sufficient for most applications.

Handshake protocol for the serial interface

( RS232 PROTOCOL )

The handshake protocol is required by the printer so as to indicate to the leak detector its readiness to

receive data. Without this function the data would be received much faster compared to the processing

capability of the printer.

The protocols “CTS / RTS” and “DTR / DSR” are hardware based, i.e. they utilise additional lines of the

interface and for this reason require a connection cable which complies with the RS 232 standard.

In contrast to this, the “XON / XOFF” protocol is software based and utilises only the minimum configuration

for connection cable and serial interface. A three-wire connection cable is sufficient for this.

The serial interface of the leak detector can be set up for all commonly used handshake protocols. Both leak

detector and printer must be set to the same protocol. As to the protocols supported by the printer and how

to set up these on the printer, refer to the corresponding printer manual.

When connecting a computer, the protocol must be set up on both sides to (NONE). Due to the pin

configuration defined by the RS 232 standard a so-called Zero Modem Cable (which is commercially

available) must be used when connecting a computer. When using a standard printer cable, leak detector

and computer cannot communicate with each other.

Reading out technical data

[ TECH. DATA READOUT ]

For all principal components of the P1:p leak detectors, the serial number, the number of operating hours

and further data is indicated which are mostly intended for servicing. If this data is of interest to the users,

this is pointed out in the corresponding section of this Instruction Manual. Therefore only a brief description is

provided here.

Technical data of the base unit

[ TECH. DATA READOUT ] / [ CONSOLE ]

The following information is available:

01 Serial Number ...................... : Serial number of the base unit

23 of 41

Page 25

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

02 Total Hours .......................... : Total operating hours

03 Battery Hours ....................... : Operating hours running the instrument off the battery

04 Active Hours ........................ : Operating hours of active measurement operation

05 Cal. Factor THIS MODE ...... : Calibration factor in the active display mode

06 Software Version ................. : Software version of the instrument

07 Author .................................. : The project manager of the software department

08 Pneumatic System Type ...... : STANDARD or HIGHSENS instrument

09 Pneumatic Sys. Version ...... : Software version of the pneumatic system

10 REM ..................................... : Remarks for the base unit, normally blank

Technical data of the handset

[ TECH. DATA READOUT ] / [ HANDGUN ]

The following data on the handset can be read out:

01 Serial Number ...................... : Serial number of the handset

02 Hours ................................... : Number of operating hours

03 Rated Flow Value ................ : Calibration value for the taken in air flow

04 No-Flow Value ..................... : Reference value

05 Software Version ................. : Software version of the handset

Readout of all calibration factors

[ TECH. DATA READOUT ] / [ CAL. FACTORS ]

After operating this button, first the calibration factors for the “Leak rate” operating modes are displayed. The

button [ ppm >> ] will display the calibration factors for the “Concentration” operating mode.

For each individual calibration factor, the following additional information is displayed:

- (calibrated on :) Date and time of the final calibration

- (in Mode :) The display mode used for this

- (using Reference :) The actual value of the calibration source used

- (with Sensor S/N :) The SmartSensor used.

If at the additional information “(-UNKNOWN-)” is indicated, then the corresponding calibration factor will still

be at its factory default value. Based on this additional information it is possible at any time to determine

whether the final calibration, for example in the case of calibration intervals defined by the customer, is still

valid or if in the meantime the SmartSensor was replaced. A Cross Mode calibration (see 0, Coupling

calibration factors (“Cross Mode Calibration”)) can also be identified based on the type of display mode used.

Technical data of the SmartSensor

[ TECH. DATA READOUT ] / [ SMARTSENSOR ]

The following information on the SmartSensor is available:

01 Serial Number .......... : Serial number of the SmartSensor

02 Hours ....................... : Number of operating hours (is reset after maintenance by ISM).

03 First used ................. : Date of first start-up

04 Initial Vacuum .......... : Initial operating vacuum pressure

05 Last used ................. : Date of last usage

06 Final Vacuum ........... : Vacuum pressure during last usage

07 Writes ....................... : Write access counter for the memory of the SmartSensor

08 Noise ........................ : Share of noise in percent in the sensor signal, i.e. an indicator for the signal quality.

Should in the case of a good SmartSensor be under 0.20%. At the latest when the

value increases to over 1%, the SmartSensor must be considered as being worn

out.

09 REM ......................... : An optional remark on the SmartSensor, normally blank.

24 of 41

Page 26

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

Diagnosis screen

[ TECH. DATA READOUT ] / [ DIAGNOSTICS ]

The diagnosis screen permits insights into all relevant functions of the P1:p leak detectors and it thus

represents the main troubleshooting tool in coordination with your service partner. Although intended for the

technical service, the individual items are described briefly in the following:

Displays for the base unit (CONSOLE):

01 Mains PWR .............. : Mains voltage present/not present

02 CTS .......................... : Status of the CTS handshake line of the serial interface

03 DSR ......................... : Status of the DSR handshake line of the serial interface

04 Lo Bat Warn ............. : Low battery warning. Must also respond when briefly operating the [ POWER ]

button.

05 Touch Scn X and

06 Touch Scn Y ............ : Raw values of the two axes of the touch screen. Default values (applicable to both):

When touching the upper left-hand corner, approximately 20.

When touching the bottom right-hand corner, approximately 240.

When touching the centre, approximately 128.

Since the touch screen is an analogue component, only in the case of considerable deviations will a

malfunction have to be considered.

Handset ( Hand Unit ):

10 Keys ........................ : Status of the three handset buttons.

11 Motion Sw. .............. : Status of the inclination switch. Must respond when rolling the handset about the

horizontal axis.

12 Sens Drv 1 and

13 Sens Drv 2 .............. : Current values for the energy supplied to the sensor.

14 Sens. Curr ............... : Raw value of the measurement signal.

15 Zero Flow ................ : Reference value

16 Rated Flow .............. : Calibration value for the taken in quantity of air

17 Actl. Flow ................ : Raw value of the measurement for the taken in quantity of air. Must agree with

“Rated Flow” when the diagnosis function was invoked from normal operation.

Pneumatic system ( Pneumatic System ):

20 Rated Vac ............... : Setpoint of the operating vacuum. Is determined in the course of a system start.

Arbitrary value when systems start was cancelled due to a malfunction or by the

operator.

21 Actual Vac ............... : Actual value of the operating vacuum. Must agree with the setpoint (see above)

when the diagnosis function was invoked from normal operation (i.e. no fault

condition).

22 Pump Ratio ............. : Display of “HIGH”, when the intake pump is required to operate exceptionally often

or long so as to maintain the operating vacuum. Suspicion of leakage or impaired

performance of the intake pump.

At the bottom section of the screen, the following buttons are available:

[ CHANGE VAC: 0 / 100 / 200 / 500 ] : Setpoint entry for the operating vacuum (for testing purposes only).

[ VIBR ] : Test for the vibration alarm in the handset. The vibration motor is triggered 15 times.

[ EXIT ] : Return to the main menu. If while running the diagnosis function the operating vacuum was

changed or the sensor was shut down, then the instrument will restart.

[ SEAL CHECK ] : This runs an automatic leak test on the SmartSensor. After operating this button, the

operator is requested to seal off the intake opening of the SmartSensor in am air-tight manner. This is

preferably done using a piece of rubber which is not too soft. In the case of benchtop instruments, the rubber

cover of the carrying handle is ideally suited. In order to attain a perfect seal, the tip of the SmartSensor

should be placed vertically and centrally onto the rubber material. Do not exert a great pressure, usually the

own weight of the handset will suffice.

25 of 41

Page 27

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

This seal needs to be maintained during the entire running time of the automatic leak test. After the

automatic leak test has been completed, the result is displayed and the operator requested to remove the

seal.

This automatic test serves the purpose of identifying the presence of any leaks within the pneumatic system

of the SmartSensor. Currently a routine check of this kind, for example after having replaced the

SmartSensor is not recommended, since new, respectively refurbished SmartSensors are meticulously

checked before being delivered. Perform this test in coordination with your service partner or when receiving

upon starting the system a warning as to an operating vacuum which is too low.

[ OFF: SENSOR ] : Shuts down the sensor.

[ OFF: POWER ] : Switches the instrument off. When operated briefly indication 04 (Low Bat Warn) must

respond.

While running the diagnosis function, the LEDs in the handset as well as the analogue gauge are cyclically

driven so that the operation of these components can be checked visually.

Printing out all technical data

[ TECH. DATA READOUT ] / [ PRINT TECH. DATA ]

New to software version V3.06 is the capability of being able to transfer besides the technical data of base

unit, handset and SmartSensor also the calibration data as well as all operator specific settings to a printer or

a computer. Through the buttons [ CALIBRATION DATA ], [ USER SETTINGS ] and [TECHNICAL DATA ]

all required groups of data can be marked for printing out or removed from the printing out process. The

shortcut buttons [ ALL ] and [ NONE ] mark all, respectively no groups of data for printing out. The button [

GO ] starts the printing process.

As to how connect to a printer or computer, see Chapter 0, Handshake .

The supervisor level

(SUPERVISOR LEVEL)

The supervisor level ensures administration of the passwords as well as the settings for the limits and the

entries which are mandatory. The supervisor level is accessed from the main menu through the button [

OPEN SUPERVISOR LEVEL ] with subsequent entry of the supervisor password.

This level offers the following functions:

Making/deleting worker identification mandatory

[ OPEN SUPERVISOR LEVEL] / [ OPERATOR ID MODE ]

With worker identification having been made mandatory, the worker will then have to identify himself before

saving any measured values. If he has not done this at the point of time of saving the first measured value,

he will then be requested to do so. Without having entered an identification, no measured value can be

saved. The same applies to opening a new test specimen data set in the memory.

To make worker identification mandatory, touch the button [ REQUIRED ]. A check mark in the button

confirms the activation.

In the case worker identification has not been mandatory, the worker identification can be entered but is not

demanded from the operator.

To disable mandatory worker identification touch the button [ NOT REQUIRED ]. A check mark in the button

confirms the deactivation.

Making/deleting test specimen identification mandatory

[ OPEN SUPERVISOR LEVEL] / [ PRODUCT ID MODE ]

With test specimen identification having been made mandatory, the test specimen must be identified before

saving any measurement data by entering a serial or batch number, for example. If this is not done this at the

point of time of saving the first measured value, the operator then be requested to do so. Without having

entered an identification, no measured value can be saved. The same applies to opening a new test

specimen data set in the memory.

To make identification mandatory, touch the button [ REQUIRED ]. A check mark in the button confirms the

activation.

26 of 41

Page 28

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Setting up the operating parameters

In case test specimen identification has not been made mandatory, the test specimen identification can be

entered but is not demanded from the operator.

To disable mandatory test specimen identification, touch the button [ NOT REQUIRED ]. A check mark in the

button confirms the deactivation.

Administration of the passwords

[ OPEN SUPERVISOR LEVEL] / [ ACCESS CODES ]

Here the passwords for the three access levels can be changed. On each level, a password having a length

of 1 to 5 digits can be entered.

When assigning a blank password, the corresponding level can be accessed without having to enter a

password. For this simply end the entry with a blank entry field. You are now requested to confirm the blank

password so as to avoid the possibility of making a mistake.

Special attention must be paid to changing the password for the supervisor level (SUPERVISOR LEVEL). If

the supervisor enters unintentionally a different password with respect to the one he wants to enter, he would

then have effectively excluded himself from any access. For this reason the supervisor password must be

entered twice. If both entries do not agree, then the program returns to the first entry.

27 of 41

Page 29

SF6 P1:p MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Service life of the SmartSensor

The service life to be expected of the SmartSensors is approximately 200 to 300 hours of continuous (!)

operation under average conditions of the air in the room. On the basis of an active measurement time of

approximately 2 hours per workday, this gives a utilisation duration of approximately 6 months.

In the case of discontinuous measurement operation, the utilisation duration may be optimised by using the

standby option. Through the use of the standby modes “Light and Sensor” or “Power Down” the

SmartSensor is shut down during breaks and for this reason then not subjected to any wear.