Page 1

Unrivalled Gas Detection. ionscience.com

Instrument User Manual V1.0

GASCLAM 2

Page 2

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

2

Thank you for purchasing your Ion Science instrument.

Register your instrument online for the warranty

The standard warranty of your GasClam 2 is for one year.

To receive the warranty, you must register your instrument online within one month of

purchase (terms and conditions apply).

Visit ionscience.com/instrument-registration

Part number: 873203

Page 3

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

1

Contents ________________________________________________________________________

Declaration of conformity 4

Statements 5

Validity of this Manual ..................................................................................................................................................... 5

Responsibility for Correct Use .......................................................................................................................................... 5

Warnings .......................................................................................................................................................................... 5

Quality Assurance ............................................................................................................................................................. 5

Disposal ............................................................................................................................................................................ 5

Legal Notice ...................................................................................................................................................................... 5

Warranty .......................................................................................................................................................................... 5

Service .............................................................................................................................................................................. 5

Contact details.................................................................................................................................................................. 6

Introduction to GasClam 2 7

Package Contents ............................................................................................................................................................. 8

Parts Description .............................................................................................................................................................. 8

How the GasClam 2 Works ............................................................................................................................................... 9

User Accessible Parts........................................................................................................................................................ 9

Planning Monitoring and Site Preparation 9

Number of Units and Site Layout ................................................................................................................................... 10

Hazardous Areas............................................................................................................................................................. 10

Borehole Headworks ...................................................................................................................................................... 10

GasClam 2 Configuration and Setup 11

Software ......................................................................................................................................................................... 11

Power Supply Options .................................................................................................................................................... 11

External Power Supply ................................................................................................................................................... 12

Remote Data Acquisition................................................................................................................................................ 12

Battery Life and Sample Count....................................................................................................................................... 12

The Effects of Temperature and Humidity on Sample Count ........................................................................................ 13

Temperatures Below 0°C................................................................................................................................................ 14

The Effects of Water on a GasClam 2 ............................................................................................................................. 14

How the GasClam 2 Prevents Water Entering From Below ........................................................................................... 14

How the GasClam 2 Prevents Water Entering From Above........................................................................................... 15

Optimising GasClam 2 Performance .............................................................................................................................. 15

Start Monitoring 15

Changing Batteries ......................................................................................................................................................... 15

Connecting the GasClam 2 to a PC ................................................................................................................................. 17

Check Voltages and Settings .......................................................................................................................................... 17

Installing the GasClam 2 in a Borehole.......................................................................................................................... 17

Turning the GasClam 2 On ............................................................................................................................................. 18

Leaving the Site .............................................................................................................................................................. 18

Site Visits 18

Regular Checks ............................................................................................................................................................... 19

Data Retrieval ................................................................................................................................................................. 19

Leaving the Site .............................................................................................................................................................. 19

Calibration, Servicing and Storage 19

Unit Calibration and Service ........................................................................................................................................... 19

Storing the GasCalm when Not In Use ........................................................................................................................... 20

Filter Management ......................................................................................................................................................... 20

Inspecting and Replacing the Moisture Filter ................................................................................................................ 20

User Serviceable Parts .................................................................................................................................................... 21

User Spare Parts ............................................................................................................................................................. 22

Fault Finding 23

Software ......................................................................................................................................................................... 23

The Effects of Flooding on Data and the GasClam 2 ...................................................................................................... 23

Potential Problems when GasClam 2 used Below 0°C ................................................................................................... 23

Technical Specification 24

General Specification ..................................................................................................................................................... 24

Dimensions ..................................................................................................................................................................... 25

Built-in Sensors ............................................................................................................................................................... 25

Gas Sensor Specifications ............................................................................................................................................... 25

Page 4

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

2

Cross sensitivities and Sensor Performance: ................................................................................................................. 26

Page 5

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

3

Symbols ________________________________________________________________________

WARNING!

USED TO INDICATE DANGER WARNINGS WHERE THERE IS A RISK OF INJURY OR

DEATH.

WARNING! - DANGER OF ELECTRIC SHOCK

USED TO INDICATE DANGER WARNINGS WHERE THERE IS A RISK OF INJURY OR DEATH

FROM ELECTRIC SHOCK.

CAUTION

USED TO INDICATE A CAUTION WHERE THERE IS A RISK OF DAMAGE TO EQUIPMENT.

PROHIBITED ACTION

USED TO INDICATE ACTIONS THAT ARE NOT PERMITTED; E.G. 'YOU MUST NEVER'.

INFORMATION

IMPORTANT INFORMATION OR USEFUL HINTS ABOUT USAGE.

Recycling and Disposal ____________________________________________________________

RECYCLING

RECYCLE ALL PACKAGING.

WEEE REGULATIONS

ENSURE THAT WASTE ELECTRICAL EQUIPMENT IS DISPOSED OF CORRECTLY.

Page 6

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

4

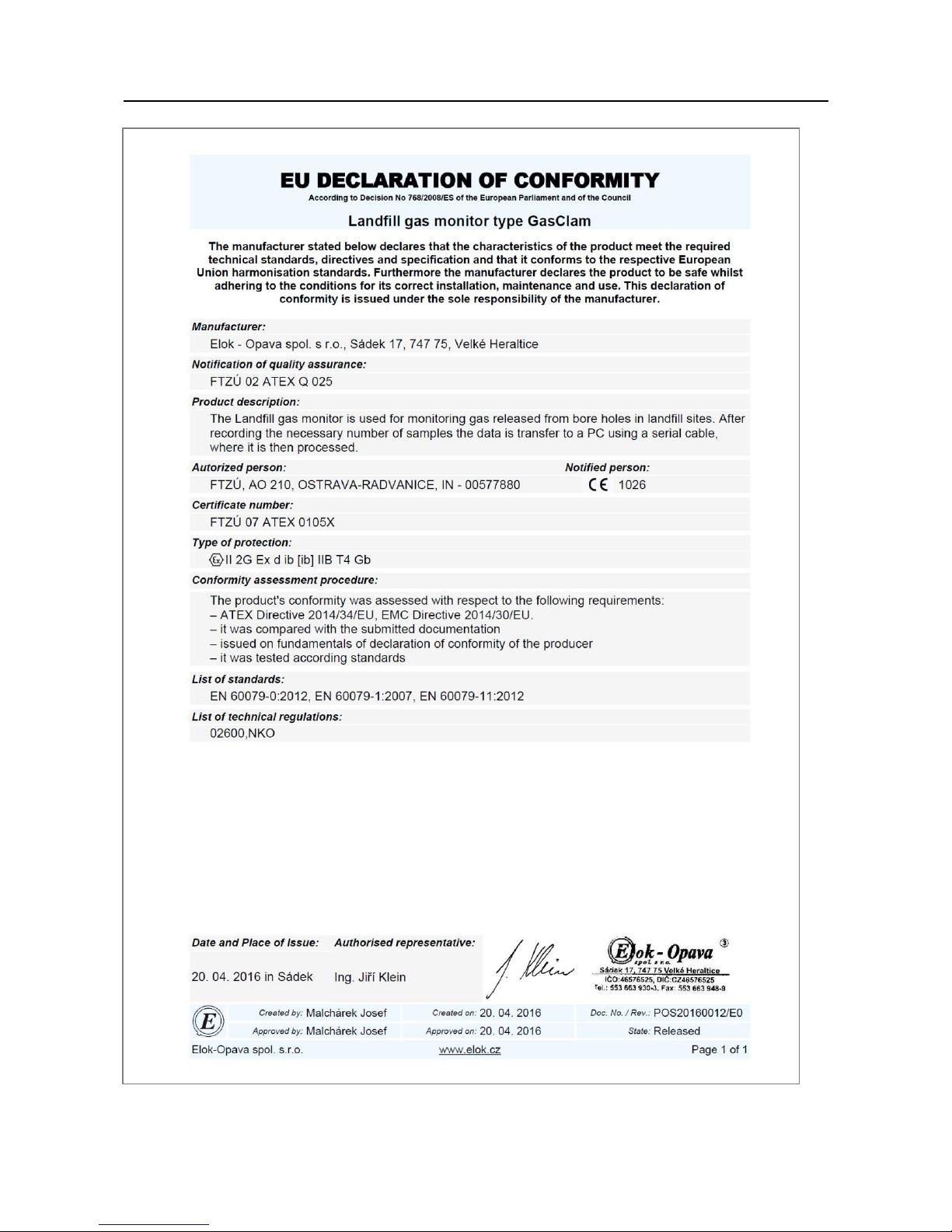

Declaration of conformity __________________________________________________________

Page 7

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

5

Statements______________________________________________________________________

Validity of this Manual

This User Manual gives information and procedures for the firmware version shown on the front page of this manual.

If you have different versions of firmware, please obtain the correct User Manual.

Responsibility for Correct Use

Ion Science Ltd accepts no responsibility for incorrect adjustments that cause harm or damage to persons or property.

The users are responsible to respond appropriately to the readings and alarms given by GasClam 2.

Use the equipment in accordance with this manual, and in compliance with local safety standards.

Reduced performance of gas detection might not be obvious, so equipment must be inspected and maintained

regularly. Ion Science recommends:

• you use a schedule of regular checks to ensure it performs within calibration limits, and that

• you keep a record of calibration check data.

Warnings

1. Read and understand this Manual fully before you install or operate the GasClam 2.

2. For safety, the GasClam 2 must only be operated by qualified personnel.

3. Substitution of components can result in unsafe conditions and will invalidate the warranty.

4. Surface mount fuses must only be replaced by Ion Science service centres.

Quality Assurance

The GasClam 2 is manufactured in compliance with ISO9001:2008. That ensures that the equipment is:

• designed and assembled reproducibly, from traceable components,

• calibrated to the stated standards before it leaves our factory.

Disposal

Dispose of GasClam 2 and its components in accordance with all local and national safety and environmental

requirements. This includes the European WEEE (Waste Electrical and Electronic Equipment) directive. Ion Science Ltd

offers a take-back service. Please contact us for more information.

Legal Notice

Whilst every attempt is made to ensure the accuracy of the information contained in this manual, Ion Science accepts

no liability for errors or omissions, or any consequences deriving from the use of information contained herein. It is

provided "as is" and without any representation, term, condition or warranty of any kind, either expressed or implied.

To the extent permitted by law, Ion Science shall not be liable to any person or entity for any loss or damage which

may arise from the use of this manual. We reserve the right at any time and without any notice to remove, amend or

vary any of the content which appears herein.

Warranty

To receive your 2 Year Warranty, you must register within one month of purchase (Terms and Conditions apply). You

will then receive a confirmation email that your Warranty Period has been activated and processed.

Full details, along with a copy of our Warranty Statement can be found by visiting: http://ionscience.com/customer-

support/instrument-registration

Service

Ion Science recommends a twelve-month service replacement of the MiniPID sensor lamp.

Contact Ion Science or your local distributor for service options in your area.

Page 8

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

6

Contact details

UK Head Office

Ion Science Ltd

The Hive, Butts Lane,

Fowlmere,

Cambridge,

SG8 7SL

UNITED KINGDOM

Tel: +44 (0)1763 208503

Fax: +44 (0) 1763 208814

Email: info@ionscience.com

Web: ionscience.com

USA Office

Ion Science Inc

4153 Bluebonnet Drive

Stafford

TX 77477

USA

Tel: +1 (877) 864 7710

Email: info@ionscienceusa.com

Web: ionscienceusa.com

German Office

Ion Science Messtechnik GMBH

Laubach 30

Metmann-Neandertal

40822

GERMANY

Tel: +49 2104 14480

Fax: +49 2104 144825

Email: info@ism-d.de

Web: ism-d.de

Italian Office

Ion Science Italia

Via Emilia 51/c

40011 Anzola Emilia

Bologna

ITALY

Tel: +39 051 0561850

Fax: +39 051 0561851

Email: info@ionscience.it

Web: ionscience.it

French Office

Ion Science France

41 Rue des Etoiles

83240 Cavalaire-Sur-Mer

FRANCE

Tel: +33 613 505 535

Email: info@ionscience.fr

China Office

Ion Science China Ltd

1101, Builiding B

Far East International Plaza

No. 317 Xiaxia Road

Shanghai

CHINA

Tel: +86 21 52545988

Fax: +86 21 52545986

Email: info@ionscience.cn

Web: ionscience.cn

Page 9

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

7

Introduction to GasClam 2 _________________________________________________________

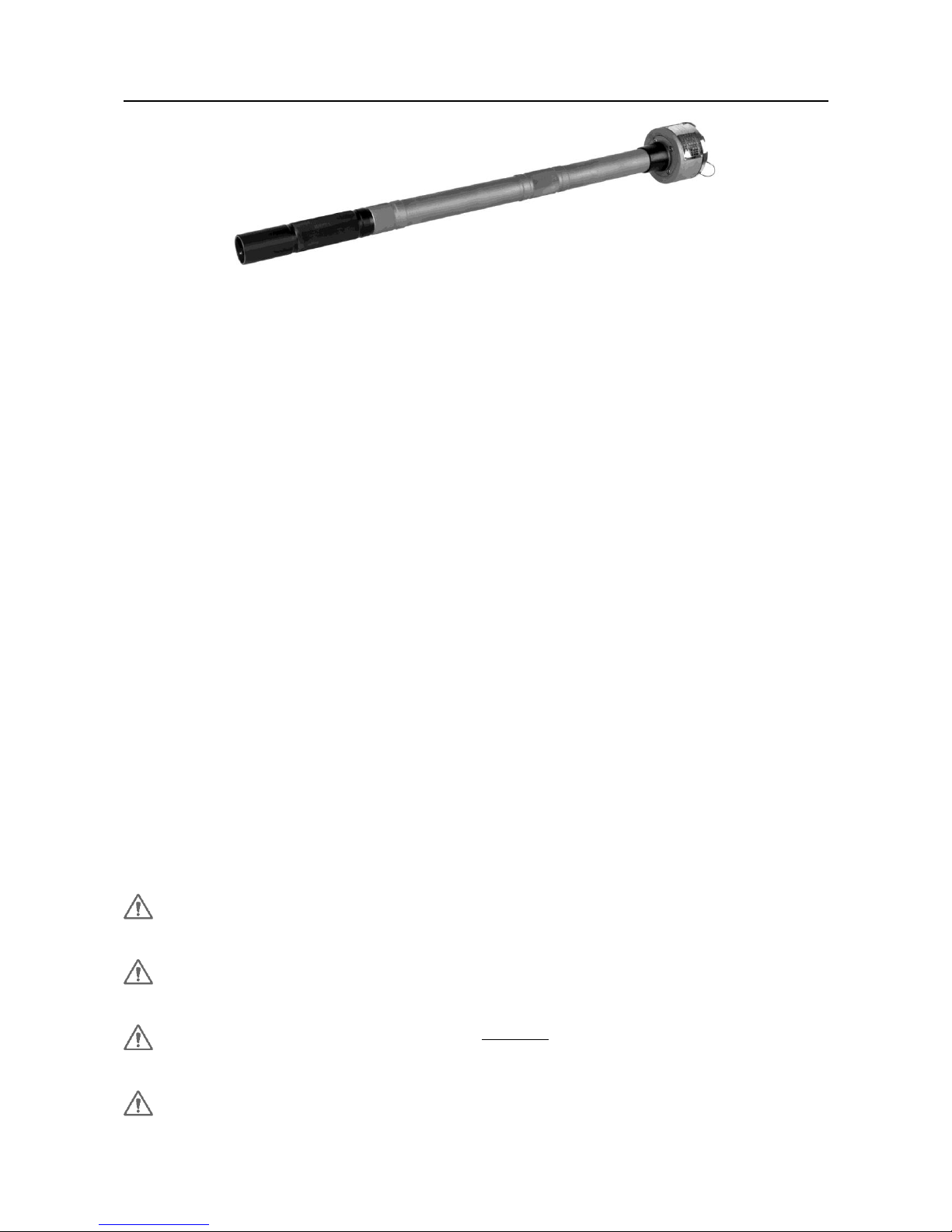

GasClam 2 is the world’s first in-situ continuous borehole gas monitor and logging instrument. It is an invaluable

tool for detecting and recording the concentration of a wide range of gases commonly required in monitoring

applications, including Methane (CH4), Carbon Dioxide (CO2), Oxygen (O2), Carbon Monoxide (CO), Hydrogen

Sulphide (H2S) and Volatile Organic Compounds (VOC).

In addition to the selected gases, the GasClam 2 also records temperature, barometric pressure and borehole

pressure. An optional borehole water level sensor can be fitted to measure fluctuations in the water table should

this data be required.

Samples can be taken at programmable intervals, providing an invaluable set of data. The GasClam 2’s default

setting is to take a sample every hour, giving it an operational life of approximately one month (using the

rechargeable battery packs supplied) which can be extended up to 3 months (using optional proprietary long-life

Lithium battery packs).

The GasClam 2 can operate as either a stand-alone logger or real-time monitor linked to data acquisition systems

(Telemetry) via an optional modem system or communication cable. Recorded data can be viewed using the

GasClam 2 software or exported for analysis to a spreadsheet.

The software is also used to setup the GasClam 2 for logging, including logging intervals, total number of samples,

power supply and venting options.

The GasClam 2 itself is built to the highest standards with the outer casing from stainless steel, is intrinsically safe

and is certified for use in explosive environments in hazardous zone 1 and conforms to International Protection

code IP68.

Ion Science Ltd recommends that users perform regular bump tests in conjunction with an annual service and

calibration, which is provided by the Ion Science service department or an Ion Science approved service centre.

In this manual a Warning identifies conditions and actions that pose a hazard to the User or the Unit.

WARNING: Before using the GasClam 2ou must read this and the software manual paying particular attention

to the sections covering optimisation of GasClam 2 performance and the effects of water.

WARNING: Do not connect or disconnect any cables in hazardous areas and do not use non-approved

equipment in hazardous areas such as laptops, notebooks and mobile phones.

WARNING: For reasons of intrinsic safety, batteries MUST NOT be changed within hazardous areas. Always

ensure you are in a safe area before carrying out any type of work on your GasClam 2.

WARNING: To maintain the Unit’s certification and intrinsic safety use ONLY GasClam 2 approved batteries,

external power supply junction boxes and spare parts.

Page 10

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

8

Package Contents

When first unpacking take a little time to check and examine the contents of the GasClam 2 package:

• GasClam 2

• Power option (standard Charger, Power Supply and 2x Ni-MH rechargeable battery packs)

• Instrument Case

• Serial Communication Cable

• Push-Button Cable

• Allen key (no.5) for battery cover

• Box spanner for Barbs

• Allen key (no.4) for Vent Plug

• Vent Plug Set

• Spare Moisture Filters 2x

• Snorkel Set

• Spare Snorkel Filter

• CD Manual & Software, Calibration Certificate and Warranty

The GasClam 2 is packed for transport with caps on the inlet, outlet and vent barbs, these black caps must be

removed before the Unit is used. If it is intended to store the Unit for a longer period of time it is recommended to

replace the caps on the barbs to stop moisture and dust ingression.

Parts Description

GasClam 2 Head GasClam 2 Base

Identification Plates

Battery Cover

Plate

Communication

Port

Above-ground

Vent Barb

Port

Cap & Lanyard

Gas Inlet Barb

Gas Outlet Barb

Water Level

Sensor Port

Cap + Lanyard

Rubber Collar

Moisture Filter

Foldable Lifting

Handle

Water Proximity

(flooding) Sensor

Sensor Hook

Intrinsically Safe

Connection

Specifications

Version Number

Approval

Serial Number

Values are defined for

certification purposes

only. See

“Specification” for

operating values.

Page 11

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

9

How the GasClam 2 Works

When logging is started the GasClam 2 instantly takes its first sample. A click is heard and then the pump starts

which takes a sample of air from the borehole. First the pressure and temperature readings are taken. While the

pump is on readings from gas flow sensors are taken. The pump then switches off and after a short pause readings

from static gas sensors are taken. The whole process takes approximately 2 ½ minutes depending on sensor

configuration.

A set of readings is created and stored in non-volatile memory, the number of readings varies with the number of

sensors used. This set of readings is one “Sample”. The next sample can be taken after about ½ minute, hence the

minimum interval between samples which is the “logging interval” is 3 minutes.

The sampled gas is returned back into the borehole, however if required, a venting system can open a pathway

from the borehole to the atmosphere at specified intervals and for specified durations.

User Accessible Parts

WARNING: To ensure the GasClam’s intrinsic safety DO NOT dismantle or attempt any unauthorised servicing.

The GasClam 2 has only two main User

changeable parts: the Moisture Filter

which is accessed by unscrewing the

black Filter Cover tube (see section

“Servicing”) and the batteries which are

accessed by removing the Battery Cover

Plate (see section “Changing Batteries”).

Planning Monitoring and Site Preparation

Gas Inlet and

Battery

Communication

Moisture

Sensor

Vent

Barb

Main Gas Route

Above-ground Venting Option

Battery Packs

Battery Cover Plate

Moisture

Filter Cover

Page 12

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

10

Number of Units and Site Layout

To achieve the required effectiveness of site monitoring the types of

gases (see section “Specification”) and additional parameters including

water level that need be monitored should be defined and the GasClam

2 units need to be configured and calibrated accordingly prior to

deployment in the field.

Also the number of GasClam 2 units to be used and the location of the

boreholes should be planned with consideration to access, ground water

and possible flooding.

Hazardous Areas

It is important to define the extent of hazardous areas in accordance with national and local standards and how

far these areas extend away from the boreholes where GasClam 2 will be deployed.

Borehole Headworks

The GasClam 2 is designed to fit in a 50 mm (2”) borehole. The recommended Headworks are 8” Monitoring wells

from Stuart Wells (http://wellservices.stuartgroup.ltd.uk/) or a similar type and should be installed following the

diagram below:

It is important to have the standpipe a maximum of 3 cm above the base of the Headworks, this will ensure the

GasClam 2 will fit under the lid of the cover. The Headworks must be concentric to the standpipe for the GasClam

2 to be housed correctly. The standpipe must also be cut square to allow a good seal.

If a protective cover is to be used make sure this ends below the top of the standpipe otherwise the GasClam 2will

not fit correctly.

Concrete Collar

GasClam 2

Gravel

Max clearance 3 cm

Standpipe

Page 13

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

11

GasClam 2 Configuration and Setup

Software

Installation

The GasClam 2 software will run on: Windows XP SP 2, Windows 7, Windows 8.0 and 8.1.

The GasClam 2 software is on the CD (latest version can be provided by your service centre), it includes an

installation package with .Net Framework 4 (x86) (downloadable also from the Microsoft website) and a PDF

manual. The software needs 45 MB of free space on the hard disk for installation.

WARNING: All connections between the GasClam and a PC and all software settings must be performed outside

the hazardous areas.

Function

The software is used to configure the GasClam 2 for logging, downloading logging data, performing analysis and

exporting data for more detailed analysis in other programs such as spreadsheets. The software is also used to

perform periodic “Bump Test” and “User Calibration”.

The main settings are the logging interval, variable logging interval

programme, the number of samples (sample count), the outlet gas

venting method and whether a borehole water level sensor is fitted.

To help make data analysis easier the software can set each GasClam 2

a “friendly” name. If more than one GasClam 2 is being used on a

monitoring site it is good practice to also label each GasClam 2 so that

they are not put in the wrong boreholes.

Power Supply Options

The GasClam 2 can use 4 approved power sources:

• 2x 1.5 V Alkaline-Manganese Duracell - MN1300 (Alk-Mn) (logging interval 3 minutes to 24 hours)

• 2.6 V Nickle Metal Hydride rechargeable battery pack (Ni-MH) (logging interval 3 minutes to 24 hours)

• 7.2 V Lithium non-rechargeable battery pack (Li) (logging interval 15 minutes to 24 hours)

• 12 V External dc power supply (Ext) (logging interval 3 minutes to 24 hours)

The GasClam 2 can operate as either a stand-alone logger or linked to a data acquisition system.

The Ni-MH battery packs are rechargeable lasting up to a month with a 1-hour logging interval. The Li packs are

non-rechargeable primary cells that can last up to 3 months with a 1-hour logging interval. The lifespan of individual

types of battery packs depends on the logging interval, GasClam 2 sensor configuration, operating temperature

and for rechargeable packs in particular, age and time since they were last charged.

An external power supply is particularly useful if shorter logging intervals are required (sampling up to every 3

minutes) when a battery pack would not last a month and frequent site visits are not feasible. This option is also

advantageous if remote monitoring is required either using the optional modem (which can also be powered

externally) or external telemetry (see section “External Power”). Note: Moisture Filter life is dependent on logging

interval.

The GasClam 2 will automatically select the power source and adjust accordingly (see Software Manual).

Page 14

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

12

External Power Supply

WARNING: The external power supply and communications can only be designed and installed by persons

suitably qualified and trained while adhering to national and local standards and regulations.

A GasClam 2 can be powered by an external power supply using either

the optional “External Power and Com Cable” which is 10m long or for

longer distances using the optional “Junction Box” and a suitable cable.

Either cable is then connected to the external power supply via barriers

which must have the following parameters to maintain intrinsic safety.

External Power Supply Parameters

Nominal Voltage Un ................................ = 12V DC ±10%

Power Output Pn ..................................... ≧ 5W

Maximum Voltage Uo ............................. ≦ 15.6V

Capacitance Co ........................................ ≧ 600pF + C cable

Impedance Lo .......................................... ≧ 0.2mH + L cable

Remote Data Acquisition

Stand-alone with external power

If the stand-alone solution requires monitoring with more frequent logging

intervals which would be outside the capability of the battery packs it is also

possible to power the GasClam 2 via the optional “Junction Box”.

The external power supply and barriers must have the parameters defined

above to maintain intrinsic safety.

Custom remote data with external power

The optional “External Power and Com Cable” (as above) can also be used to

access logging data or change GasClam 2 settings from outside the hazardous

area. Cable length is 10m which is the maximum guaranteed distance for the

GasClam 2 RS232 interface.

Battery Life and Sample Count

The battery life and the number of samples taken will depend on the battery type, the operating temperature,

humidity and the logging interval.

All batteries will have reduced maximum lifespans at low temperatures.

Power Supply

Voltage

[V]

Capacity

[Ah]

Operating

range

[°C]

Maximum Number of Samples for

Logging Interval

(1)

Nominal Battery Life

in days for Interval

(2)

5 min

15 min

1 hour

15 min

1 hour

Alkaline Duracell 2x

3.0

13.5

0 – 50

197

963

963 8 32

Ni-MH Rechargeable

2.6

9.5

0 – 40

680

666

666 5 23

GasClam 2s without batteries

Page 15

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

13

Li Long Life

7.2

19.0

0 – 50

na

2937

2937

24

98

The average number of samples for each logging interval is shown (1). This value can vary depending on operating

temperature, the number and type of gas sensors fitted in the GasClam 2 and the state of the filters. These values

are for temperatures at 20 °C with the maximum number of sensors and clean filters.

The “Nominal Battery Life” (2) is a conservative calculation of the number of days a battery will last under

“nominal” conditions (battery is fully charged at the start of logging, operating temperature is 20 °C, the filters are

clean) and using all the sensors. This value is 80% of the average value for 15min and 1 hour logging intervals.

Other factors such as relative humidity can also affect the battery lifespan (see below).

Alkaline Batteries

The GasClam 2 is fitted with Alkaline batteries for initial testing and checks. However, for normal field work it is

recommended to use either the Ni-MH rechargeable or Li long-life battery packs. The Duracell batteries can be

stored in the instrument case as a reserve and can be used when the rechargeable battery has not been charged

and the GasClam 2 must be deployed immediately. Alkaline batteries have a long “shelf life” but do not use after

the date shown on the battery. Short logging intervals will reduce the maximum number of samples taken.

Ni-MH Rechargeable

The Ni-MH rechargeable battery packs should be fully charged using the charger provided (see instructions) and

used for logging as soon as possible. Rechargeable batteries do not have a long “shelf life” as they will self-

discharge over time.

This also means that battery life is not proportional with an increase in logging interval, e.g. if the logging interval

is increased from 1 hour to 12 hours the nominal battery life will not increase 12 times to 276 days (9 months).

The NiMH batteries self-discharge at a rate of 15% - 20% per month.

To obtain the maximum working life from the Ni-MH battery packs it is recommended that they are always first

fully discharged and then charged using the charger provided (see Charger instructions). Also Ni-MH battery packs

should be charged at least once every 6 months even if they are not being used.

Li Long-Life

The Long-life battery pack will last up to 3 months at an hourly logging interval. Only the Li battery pack has a

restriction on the minimum logging interval that can be used and that is 15 minutes.

The Li battery pack has a built-in fuse to maintain intrinsic safety and if the GasClam 2 is switched on/off rapidly

using the Push-button cable in rare cases this can cause the fuse to blow. If the GasClam 2 does not react with a Li

battery pack first check the battery using a voltmeter.

Adhere to the conditions of use and safety instructions enclosed with the Li battery packs.

The Effects of Temperature and Humidity on Sample Count

To ensure that the gas sample is dry before measurement by the CH4 and CO2 sensors a Moisture Filter is fitted in

the GasClam 2. Over time this will hydrate and its ability to remove moisture will decrease. If moisture is not

successfully removed, concentration readings can be affected. The amount of samples that can be taken will

depend on temperature and humidity. The table below shows how many samples can be taken at 90% Relative

Humidity (RH) at different temperatures (90% RH is assumed to be worst case).

Temperature °C

1°C

5°C

10°C

15°C

20°C

25°C

30°C

35°C

38°C

Samples at 90% RH

3455

2620

1850

1320

950

700

520

390

330

Page 16

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

14

Typically, temperatures in a borehole will not go below 3°C and will not exceed 15°C however, this will depend on

installation. If the GasClam 2 is used above ground then temperatures can vary more widely.

The Ni-MH rechargeable battery on the GasClam 2 lasts approximately 670 samples (hourly sampling). To ensure

the GasClam 2 does not take more samples than the filters capacity use the table above to set the sample count

(see Software “Setup”), e.g. if the borehole is at 30°C set the sample number to less than 520.

It is unlikely that RH in a borehole will exceed 90% all the time and to help assess how to manage the filter after

the first installation there is an indicator system. The indicators work differently below 30°C and above 30°C (see

section “Servicing”).

Temperatures Below 0°C

If the temperature drops below 0°C and there is high humidity the valves in the GasClam 2 may freeze and prevent

correct sampling and a pump error will be flagged. This will not damage the GasClam 2; when temperature rises

above 0°C it will function correctly (see section “Fault Finding”).

Typically the GasClam 2 is installed in boreholes below the ground and the GasClam 2 will not go below 0°C due to

ground heat. If the GasClam 2 is installed above the ground, insulation or a heater will be needed to prevent

freezing. If you are unsure about your GasClam 2 installation contact your local supplier.

The Effects of Water on a GasClam 2

The GasClam 2 is designed to:

• measure gas concentrations,

• measure borehole and atmospheric pressure,

• allow a venting pathway between the borehole and atmosphere,

• the GasClam 2 software enables a selection of venting options.

To measure gas concentrations the gas must be dry and measurements of atmospheric pressure should not include

the pressure of overlying water. As the GasClam 2 can be in a position liable to flooding from above (flooded

Headworks) and below (borehole water level) it is necessary to:

• carrying out simple preventive and remedial maintenance and

• being aware of the limitations of data gathered under flood conditions.

How the GasClam 2 Prevents Water Entering From Below

To prevent water entering the GasClam 2 from below a water proximity sensor is situated below the gas inlet. If

water rises up the borehole and comes into contact with the proximity sensor the GasClam 2 will pause logging.

When water level drops GasClam 2 will resume logging after 1 hour.

To prevent water from reaching the gas inlet barb and flooding the GasClam 2, the Filter Cover creates an air

pocket at the base of the GasClam 2 (Always check to see if the cover is not damaged or cracked as this could then

let water in).

The air pocket should stop water from reaching the gas inlet for at least 7 days when the GasClam 2 is completely

submerged with 20 cm of water above its head. If the GasClam 2 is immersed for longer, the User must check to

ensure water has not reached the inlet barb before restarting the GasClam 2. If the User suspects that water may

have reached the gas inlet they must contact their local service centre.

NOTE: The water proximity sensor works on the principle of conductivity and when water comes into contact

with the sensor it completes the circuit switching off the GasClam. If a non-conducting fluid, such as oil, is

Page 17

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

15

floating on top of the water in a borehole the water proximity sensor will not detect it and therefore it can be

sucked into the GasClam.

How the GasClam 2 Prevents Water Entering From Above

To prevent water reaching the vent pathway the Snorkel Set should

always be attached to the Vent Barb. The open end tube should be

supported so it is located at the top of the Headworks to reduce the

chance of water ingress.

In locations where the Headworks are likely to be flooded the Vent Barb

must be replaced with the Vent Plug. The supplied box spanner is used

to remove the Vent Barb and the supplied Alan key (no.4) used to insert

the Vent Plug and washer.

If the Vent Plug is inserted it should be configured in the software (see

software “Setup”). Atmospheric pressure will not be recorded in this

mode.

Optimising GasClam 2 Performance

Read the ‘Cross sensitivities and sensor performance’ section to

understand how each gas is detected and the implication of

environmental conditions on their detection.

Understand the implication on sampling and bump testing if a 5% CO2

sensor is installed (see section “Technical Specification”).

Periodically (on a monthly basis) the GasClam 2 should be removed from

the borehole if installed for long periods and checked (see section “Site

Visit”).

If conditions of 85% RH and 40°C have persisted for more than 10 days

the H2S, CO and O2 sensors may need to be reconditioned (see section

“Service”).

The GasClam 2 software (see Software Manual) offers a selection of

venting options during logging.

Start Monitoring

Changing Batteries

WARNING: For reasons of intrinsic safety, batteries MUST NOT be changed within hazardous areas. Always

ensure you are in a safe area before carrying out any type of work on your GasClam.

WARNING: To maintain the Unit’s certification and intrinsic safety use ONLY GasClam approved batteries.

Page 18

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

16

The battery compartment is accessed by loosening the four (no.5) Allen key

bolts on the Battery Cover Plate – note that the bolts do not unscrew

completely, they remain with the plate.

To replace batteries follow the instructions below:

1) First clamp the Battery Cover Plate so that the spring under

the plate does not exert unequal force on the bolts

ensuring that bolts loosen smoothly without forcing the

thread.

This can be done by clamping the plate with the thumb on the

“GasClam 2” logo and the rest of the fingers under the head.

2) Loosen the bolts first by applying force on the long end of

the Allen key in a cross pattern (1,2,3,4).

3) When the bolts are loose and while still clamping the

Battery Cover Plate unscrew fully.

4) To remove the batteries tilt the GasClam 2 until they slide

out.

5) Replace with only GasClam 2 approved batteries positive

terminal facing DOWN into the GasClam 2.

6) Check the integrity of the O-ring, if damaged it MUST be

replaced. The O-ring should be checked every time the

batteries are replaced.

7) When the O-ring is resting on the battery compartment

push the cover plate down evenly to ensure it travels down

square. This will prevent damage to the O-ring.

The cover plate must sit flush with the head of the GasClam 2

otherwise the intrinsic safety of the unit will be compromised.

8) Again clamp the plate with the thumb on the “GasClam 2”

logo and the rest of the fingers under the head.

9) First tighten the bolts by hand taking care that the bolts

tighten smoothly without crossing the threads.

10) When the bolts are finger tight use the Allen Key, alternate

between the bolts in a cross pattern (1,2,3,4) applying

moderate force on the short end of the Allen Key.

11) Repeat this several times tightening the bolts in a cross

pattern.

12) When the bolts are tight repeat one more time applying

moderate force on the long end of the Allen key.

If this procedure is not followed carefully, damage to the O-ring may be caused compromising the intrinsic safety

of the Unit.

WARNING: Do not connect or disconnect any cables in hazardous areas and do not use non-approved

equipment in hazardous areas such as laptops, notebooks and mobile phones.

4

1

3

2

Page 19

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

17

Connecting the GasClam 2 to a PC

Whilst the GasClam 2 is outside the hazardous area it can be programmed using a computer with the GasClam 2

software (see Software Manual). This is done using the Serial Communication Cable (supplied) and an RS232-USB

converter (not supplied).

1. Remove the cap from the Com Port on the GasClam 2.

Carefully connect the Serial Communication Cable

ensuring that the two red dots are aligned, then push

for a firm click.

2. Connect the Serial Communication Cable to the RS232

converter and connect to the USB port of the computer

(the RS232 convert will need to install drivers the first

time it is connected to the computer).

3. Start the GasClam 2 software either using the desktop

icon or from the start menu.

Check Voltages and Settings

The GasClam 2 will automatically detect the power source when it is first

inserted and adjust accordingly (see software manual).

After new batteries have been inserted check in the “Home” window

that the appropriate power source has been selected by the GasClam 2

in the line “Power Source” and that “Power Status” meter is showing the

correct voltage:

Alkaline Duracell: New above 3 V.

Ni-MH rechargeable: Fully recharged 2.5 – 2.7 V.

Li Long-life: New battery pack 7.0 – 7.2 V.

After ensuring that the battery type and voltage corresponds with the

newly fitted batteries, proceed to set up the GasClam 2 for the

monitoring application (and specific borehole) by clicking on the “Setup”

button in the “Home” window.

In the “Setup” window first check that the time and date are correct,

that if a water level sensor is fitted it is selected, that the correct venting

option is selected and then add a friendly name for the GasClam 2. After

configuring the GasClam 2 then setup the logging intervals and sample

counts required. When finished, write the setup to the GasClam 2.

Check the settings in the “Home” window then run one test sample.

Afterwards check that the status is “Sleeping”. Switch off the software,

disconnect the Serial Communication Cable and replace the Com Port

Cap on the GasClam 2.

Check that the black Barb Caps have been removed.

The GasClam 2 is ready for deployment.

Installing the GasClam 2 in a Borehole

Using the Lifting Handle carefully lower the GasClam 2 into the borehole

and check that it sits in the standpipe smoothly with the Rubber Collar

forming a good seal.

Page 20

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

18

Ensure that either a Snorkel Set or the Vent Plug is fitted.

If a water level sensor is to be used first hook it and then connect it to

the GasClam 2 outside the hazardous area. Take the GasClam 2 with the

water level sensor to the borehole. First lower the sensor and then the

GasClam 2 again ensuring a good fit with the Rubber Collar and the

standpipe (see water level sensor instructions).

Turning the GasClam 2 On

The only way to manually start the GasClam 2 when it has been deployed

is to use the supplied Push-Button Cable. It connects to the Com Port on

the head of the GasClam 2 in the same way as the Serial Communication

Cable.

It is intrinsically safe and is the ONLY piece of equipment that can be

connected and disconnected from the Unit in a hazardous area.

To start the GasClam 2, hold the button down for two seconds, the red

LED will flash rapidly indicating the GasClam 2 has started logging and is

currently sampling.

After sampling has finished (approximately 3 minutes) the red LED

flashes intermittently indicating that the GasClam 2 is Logging but

between Samples.

To stop the GasClam 2, press the button for two seconds, the red LED

will stop flashing indicating that the GasClam 2 is “Sleeping”.

The Push-Button cable can also be used to perform occasional checks of

the state of the GasClam 2 without the need to take the Unit out of the

borehole

It is recommended that when a GasClam 2 is deployed and logging is first

started to check that the LED starts to flash rapidly indicating that

sampling has started and then to wait until the LED starts to flash

intermittently indicating that the first sample has finished before

disconnecting the Push-Button Cable.

Leaving the Site

When leaving a borehole check that:

1. the Snorkel Set is fitted correctly and above the flood level,

2. the Com Port Cap is fitted to prevent dust entering the socket,

3. the Headworks cover has been securely fitted.

Site Visits

WARNING: Do not connect or disconnect any cables in the hazardous area and do not use non-approved

equipment in the hazardous area such as laptops, notebooks and mobile phones.

WARNING: Before removing the GasClam from the field it must be run at least once (purged) in a nonhazardous atmosphere to clear any hazardous gasses from the unit.

Page 21

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

19

Regular Checks

It is recommended that at least once a month (or sooner depending on the power option and logging interval) the

GasClam 2 is safely removed from the borehole and inspected outside the hazardous area in a dry location. When

removed:

• Inspect the GasClam 2 for any signs of wear and tear (especially the Filter Cover Tube).

• Check for signs of water ingress prior to purging the unit (see section “Effects of Flooding”).

• If there are no signs of water ingress, purge the unit.

• Download and backup the logging data.

• Check the data for any faults (see Software Manual) and if required take appropriate action.

• Change batteries if required and check the integrity of the battery O-ring.

• Check and change the Moisture Filter if required (see section “Service”).

• Perform a Bump Test on the sensor channels if required (see Software Manual).

Note: If conditions of 85% and higher RH and +40°C are expected to have persisted for more than 10 days the H2S,

CO and O2 sensors may need to be reconditioned (see section “Specification”).

Data Retrieval

Manual Download

Remove the GasClam 2 from the borehole using the Lifting Handel. Take

the GasClam 2 outside the hazardous area.

Under no circumstances take or connect a laptop to the GasClam 2 in a

hazardous area!

Place the GasClam 2 on a clean dry surface and wipe the head around

the Com Port Cap if dirty. Connect the GasClam 2 to the PC using

procedure previously described.

Download the data using the software as described in the Software

Manual. Sampling will cease when the GasClam 2 logging memory is full.

Ensure memory is cleared for extended sampling once logging data has

been checked, validated and backed-up.

Leaving the Site

When leaving the site after a regular visit, check as before. If leaving the site after monitoring is complete ensure

that the borehole is secured safely and not open.

Calibration, Servicing and Storage

Unit Calibration and Service

To ensure correct and accurate operation it is recommended that the GasClam 2 should be recalibrated and

serviced every 12 months (or sooner depending on the logging interval and sensor configuration). The GasClam is

ATEX certified for use in potentially explosive areas, therefore it must only be serviced and fully calibrated by an

authorised GasClam 2 service centre. Failure to do so will invalidate the warranty and may invalidate the

certification.

Page 22

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

20

Storing the GasCalm when Not In Use

When the GasClam 2 is not in use it should be cleaned thoroughly, run for several cycles in clean preferably dry

air, the batteries removed and placed in the instrument case. If it is intended to store the Unit for a longer period

it is recommended to replace the caps on the barbs to stop moisture and dust ingression. When storing for a longer

period (more than 3 month) the GasClam 2 should be fitted with 2x 1.5 V Alkaline-Manganese Duracell - MN1300

(Alk-Mn) batteries to ensure the functionality of the electronics

Filter Management

Below 30°C the bottom indicator turns pink after approximately 40% of

filter life and the top turns pink after 50% of filter life. For 15°C and 90%

RH, the indicators will change in accordance to the table below. Above

30°C and high humidity the indicators on the Moisture Filter correspond

to less samples.

Environmental

conditions

Max number

of samples

Bottom indicator

turns pink after:

[samples]

Top indicator

turns pink after:

[samples]

15°C - 90% RH

1320

490

730

38°C - 98% RH

300

240

360

To assess if the filter needs to be replaced when the batteries are

changed inspect the filter indicators. If both indicators are blue, the filter

does not have to be replaced. The table below shows what actions to

take depending on the state of the top and bottom indicators with

respect to temperature and humidity.

Bottom

indicator

Top

indicator

Action at 15°C - 90% RH

Action at 38°C - 98% RH

Blue

Blue

Don’t replace

Don’t replace

Pink

Blue

Don’t replace

(probably need to replace next time)

Replace

Pink

Pink

Replace

Check GasClam 2 for signs of moisture in the unit.

Contact local service centre if any signs of

moisture within the GasClam 2 or tubing.

Replace

Check GasClam 2 for signs of moisture in the unit.

Contact local service centre if there are any signs

of moisture within the GasClam 2 or tubing.

If sampling in the same borehole again reduce

the total number of samples taken so both

indicators do not turn pink.

If both indicators turn pink after 1 battery life (670 samples) contact your local supplier for sampling advice.

Inspecting and Replacing the Moisture Filter

WARNING: The GasClam must never be operated without the

Moisture Filter.

To inspect the Moisture Filter follow the instructions below:

1. Place the GasClam 2 on a table with the head

down.

Top

Bottom

Page 23

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

21

2. Carefully unscrew the black plastic Filter Cover

using both hands placed on the knurled sections for

better grip.

3. Check the colour of the indicators.

4. Check the sealing O-rings, if damaged replace

immediately.

5. If the result is ok then screw the Filter Cover back

on.

To replace the Moisture Filter follow the instructions below:

1) Place the GasClam 2 on a table with the head down.

2) Carefully unscrew the black plastic Filter Cover.

3) Using both hands, put the thumbs beneath the filter and push

it up and out of the connecting barb and nozzle.

4) Leaning the new filter to right and first connect the tube

(Tygon) to the barb.

5) Push the tube firmly down on the barb.

6) Lean the filter back upright making sure the other inlet sits

down on the nozzle.

7) Push the filter completely down firmly from the top.

8) Run the “Leak Test” from the software to check that the

system is correctly sealed

9) Check the sealing O-rings, if damaged replace immediately.

10) If the result is ok then screw the Filter Cover back on.

User Serviceable Parts

Battery compartment O–ring:

When changing the batteries always inspect the O-ring on the Battery

Cover Plate, if there is any sign of damage replace.

Moisture Filter

The GasClam 2 must never be operated without a Moisture Filter! Follow the

advice regarding Moisture Filter management and the instructions on how to

change the filter.

Filter Compartment O–rings:

When inspecting the Moisture Filter check O-ring 1 and 2, if there are any signs

of damage replace the corresponding O-ring immediately.

Snorkel

The snorkel should be checked regularly, if there is any damage replace immediately.

Rubber Collar

Inspect the collar regularly, if there is any signs of damage replace immediately.

Page 24

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

22

User Spare Parts

Item

Description

1

Serial Communication Cable (2m)

2

Push-Button Cable (1m)

3

Rubber Collar

4

Moisture Filter (18ml)

5

Snorkel Set

6

Snorkel Filter

7

Vent Plug Set

8

Barb (Vent, Inlet and Outlet)

9

Battery Pack NiMH L1X2 (2.4V - Rechargeable)

10

Battery Charger ECH 1.1

11

Battery Charger Power Supply

12

Battery Pack Lithium Primary Li72-190F

13

Moisture Filter Cover (Plastic)

14

Communication Port Cap and Lanyard

15

Water Level Sensor Cap and Lanyard

16

O-Ring 1 and O-Ring Battery Cover (ᴓ 032 x 2 mm)

17

O-Ring 2 (ᴓ 033 x 2 mm)

18

Battery Cover Plate (Complete)

19

Allen Key no.5 (Battery Cover)

20

Box Spanner no.7 (Vent Barb)

21

Allen key no.4 (Vent Plug)

22

ATEN – USB-RS232 Converter

9

10

15

2

1

22

11

1

16

12

18

19

6

3

16

17

13

20

8

14

Page 25

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

23

Fault Finding

Software

The primary fault finding tool is the “Error Log” which can be checked after downloading a set of logging data and

the “Error Box” in the software’s home window (see Software Manual).

The Effects of Flooding on Data and the GasClam 2

When the GasClam 2 unit is not taking any samples it has a protection rating of IP68, however immersion will effect

data and may require subsequent corrective action.

These effects and requirements will differ whether immersed from above (flooded Headworks) or from below (rise

in borehole water level) see table below:

Flooded Headworks

Remedial Action

Preventive Maintenance

Effects on

data

Should Vent breather be submerged:

• Atmospheric pressure readings will be

incorrect.

• Scheduled venting will be ineffective.

To replace lost atmospheric data

use borehole pressure as an

approximate replacement or use

data from another source.

If the chamber is known to flood, or is

already full of water:

• Choose another chamber.

• Or replace the Snorkel with a Vent

Plug.

Effects on

GasClam 2

If submerged for an extended period the

vent pipe may become flooded.

The vent breather may become clogged

by dirty water.

When the GasClam 2 is visited

check data and call the service

centre if atmospheric pressure

looks strange, they will advise.

If chamber is liable to flooding:

• Replace Snorkel Filter each visit.

• Position the Snorkel at a higher

location.

Flooded Borehole

Remedial Action

Preventive Maintenance

Effects on

data

Should water reach the base of the Unit

the inflow and outflow valves will close,

no samples will be taken:

• Borehole pressure readings will be

incorrect.

• Gas concentration readings will be

incorrect.

Data points for the set logging

interval will be marked when

samples have not been taken.

If borehole water level is known to be

high or is already full of water:

• Choose another chamber.

• Or extend the borehole above ground

level.

Effects on

GasClam 2

Should water reach the base of the

GasClam 2 the water proximity

(flooding) sensor will react and the

inflow and outflow valves will close and

no samples will be taken.

A flooding error will be flagged up in the

software.

None

Every time a GasClam 2 is removed from

a borehole the inlet barb should be

checked to see if a water droplet is on it.

If so dry with a cloth.

If there is any chance that water may

have entered the inlet contact your local

service centre and DO NOT start or

purge the GasClam 2.

Potential Problems when GasClam 2 used Below 0°C

If the temperature of the body of the GasClam 2 drops below 0°C and there is high humidity the valves inside may

freeze and prevent correct sampling. This will not damage the GasClam 2 and when temperatures rise above 0°C

it will function correctly.

Another indication that the valves have frozen is that the

O2 sensor will go off scale either positively or negatively

and the atmospheric pressure reading will also

dramatically increase.

The graph illustrates a cycle between -10 and 10 °C at 98%

RH. When the temperature reaches -5°C O2 goes off scale

positively and atmospheric pressure increases by 20 mBar.

Page 26

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

24

When temperature rises the valve thaws and O2

concentrations are correct.

Technical Specification

General Specification

GasClam 2

V8

Material

Outer case and frame: High Quality Stainless Steel. Filter Cover: PP plastic

Weight

7.5 kg (16.8 lb)

Dimensions

Overall length 90 cm, head ᴓ 11 cm

Ingress Protection

IP 68 (continuous submersion, 20 cm above the GasClam 2 head for 7 days)

Working Environment

0 to +40 °C (32 to 104 °F) RH up to 95%

Storage Environment

+5 to +25 °C dry conditions

Power Supply Options

2x 1.5 V Alkaline-Manganese Duracell - MN1300 (Alk-Mn) – LR20

2.6 V Nickle Metal Hydride rechargeable battery pack (Ni-MH) – L1X2

7.2 V Lithium primary battery pack (Li) – Li72-190F

12 V External dc power supply (Ext) – 12V dc ± 10% max 660 mA

Power Consumption

Sampling max 300 mA @ 12V

Sleep 60μA @ 12V

Logging Interval

3 minutes to 24 hours (Lithium battery packs 15 minutes to 24 hours)

Internal Memory

Maximum 30,000 date/time stamped sample set, depending on configuration

If errors are recorded maximum memory is reduced to 15,000 sample sets

Internal Memory Mode

Sampling will stop when the memory is full.

Date and Time

Internal clock

Sensors

5x gas sensors optional), 2x pressure, 1x temperature (built-in), water level (optional)

Communication

RS232 – 115200 baud

Configuration and Setup

GasClam 2 Software

Approvals

CE, EMC

ATEX

-20 °C to +50 °C Alkaline batteries

-10 °C to + 40 °C Ni-MH rechargeable battery pack

-20 °C to +50 °C Li Long-life battery pack

-20 °C to +50 °C External

Protection

II 2G Ex d ib [ib] IIB T4 Gb

Certificate number

FTZU 07 ATEX 0105 X

IECEx (Pending)

-20 °C to +50 °C Alkaline batteries

-10 °C to + 40 °C Ni-MH rechargeable battery pack

Protection

Ex d ib [ib] IIB T4 Gb

Certificate Number

IECEx FTZU 09.0026

CSA C US (Pending)

-20 °C to +50 °C Alkaline batteries

-10 °C to + 40 °C Ni-MH rechargeable battery pack

Protection

Class 1, Zone 1, Ex d ib IIB, T4 Class I, Zone I, AEx d ib IIB, T4

Certificate Number

2320892

Page 27

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

25

Patent

European and Worldwide Patent granted

Dimensions

The main dimensions of the GasClam 2 are show below (mm):

Built-in Sensors

Sensor

Type

Range

Resolution

Barometric Pressure

Piezoelectric

800 - 1250 mBar

1 mBar

Borehole Pressure

Piezoelectric

800 - 1250 mBar

1 mBar

Temperature

Internal Chip

-20 to +50 °C (-4 to 122 °F)

0.1°C (1°F)

Water depth (optional)

Piezoelectric

0 - 27 m

0.01 m

Gas Sensor Specifications

Position

Sensor

Type

Range

Resolution

Accuracy

5

CO2

Infrared

0 - 100 %

1% above 50%

0.5% below 50%

± 2% FSD

5

CO2

Infrared

0 - 5%

-

-

4

CH4

Infrared

0 - 100 %

1% above 50%

0.5% below 50%

± 2% FSD

4

CH4 0 - 5%

-

-

3

O2

Electrochem

0 - 25 %

0.10%

± 5% of reading

± 1 digit

2

CO

Electrochem

0 - 2000 ppm

1 ppm

<± 3ppm at 0

± 5% at 250 ppm

± 10% full scale

2

H2S

Electrochem

0 - 100 ppm

1 ppm

<± 1 ppm at 0

± 2.5% at 50 ppm

2

Dual H2S/CO

CO

Electrochem

0 - 500 ppm

1 ppm

<± 3ppm at 0

± 3% at 250 ppm

H2S

Electrochem

0 - 200 ppm

1 ppm

<± 1 ppm at 0

± 2% at 100 ppm

1

VOC

PID

0 - 4000 ppm

1 ppm

± 5% of reading

± 1 digit

Page 28

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

26

Note: Specifications obtained under laboratory conditions of gas flow, temperature and humidity. Field performance is

dependent on the correct installation procedures being followed, environmental conditions, frequent sensor cleaning and

regular calibration. Some of the sensors have cross sensitivity, for more information contact your local supplier. Details are

subject to change without notice.

Cross sensitivities and Sensor Performance:

100% Carbon Dioxide (CO2)

Carbon Dioxide is measured using an infrared sensor tuned to C=O. There are no other gasses commonly found in

the subsurface that absorb infrared radiation at this wavelength, so the reading will not typically suffer from cross

sensitivity.

5% Carbon Dioxide (CO2)

When sampling concentrations up to 5% the sensor will read 90% of the real value after one sample (typically this

will be within error of the sensor). For example, if you are sampling every hour and the real concentration changes

from 0% – 2.5% in 1 hour (which is unlikely) the senor will read approximately 2.25%. In reality if low concentrations

are present they will change much more gradually i.e.:

• Sample 1 Real concentration 0.0 Measured 0.000

• Sample 2 Real concentration 0.1 Measured 0.090 (within error)

• Sample 3 Real concentration 0.3 Measured 0.279 (within error)

• Sample 4 Real concentration 0.8 Measured 0.750 (within error)

When concentration decreases the reading will also be 90% of the real value after 1 sample. Below are examples

when 4.7% CO2 has been sampled and how the sensor/filter clears down in air.

• Sample 1 4.701 4.738 4.671

• Sample 2 0.326 0.29 0.468

• Sample 3 0.071 0.037 0.042

Methane (CH4)

Methane is measured using an infrared detector tuned to C-H bonds. The sensor is calibrated using certified

methane calibration gas and will give accurate readings providing no other C-H compounds are present. If

additional hydrocarbons are present they will contribute to the reading.

Oxygen (O2)

The oxygen sensor is a Galvanic sensor and very specific. It has a little cross sensitivity with CO2, 5 % CO2 only

causes a 0.1% change in reading. Humidity has a small effect on output, between 0 % to 95% RH the % O2 change

is < 0.7 %. The sensor can work between 5 - 95 % RH continuously and 0 - 99% short term.

Single Carbon Monoxide (CO)

The Single CO sensor has a filter to reduce the cross sensitivity with H2S, NO2, NO and SO2, the following are the

filter capacities for the given gases:

• H2S 250,000 ppm - hours

• NO2 600,000 ppm - hours

• NO 20,000 ppm - hours

• SO2 300,000 ppm - hours

50 ppm NO will read < 5 ppm

Page 29

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

27

400 ppm H2 @ 20°C will read < 60 ppm

400 ppm C2H2 will read < 25

Single Hydrogen Sulphide (H2S)

The cross sensitivities with these gases are:

• 5 ppm NO2 will read approximately -1 ppm on the H2S Channel

• 50 ppm NO will read < 5 ppm on the H2S Channel

• 20 ppm SO2 will read < 4 ppm on the H2S channel

• 400 ppm CO will read < 4 ppm on the H2S channel

• 10 ppm Cl2 will read < -25 ppm on the H2S channel

Dual CO / H2S Sensor

The CO and H2S sensors are electrochemical sensors and suffer from cross sensitivity to other gases that may be

found in the subsurface. The carbon monoxide sensor suffers in particular from the cross sensitivity with H2S, H2

and NO.

The cross sensitivities with these gases are:

• 15 ppm H2S will read < 6 ppm on the CO channel

• 35 ppm NO will read < 0.1 ppm on the CO channel

• 100 ppm H2 will read approx. 20 ppm on the CO channel

The hydrogen sulphide sensor is especially cross sensitive to the following:

• 5 ppm NO2 will read approximately -1 ppm on the H2S Channel

• 35 ppm NO will read < 1 ppm on the H2S Channel

• 5 ppm SO2 will read < 1 ppm on the H2S channel

• 300 ppm CO will read < 6 ppm on the H2S channel

If the sensors have been exposed to gases they are cross sensitive for long periods it may take some time for the

sensors to recover. The sensors can be checked after exposure to these gases by setting the GasClam 2 to sample

every 5 minutes in clean air and the concentrations should return to zero and stabilise. If you suspect a cross

sensitivity problem please contact your supplier for further advice.

Additional CO / H2S sensor performance information

If the GasClam 2 is located in a zero oxygen environment for longer than 24 hours the CO and H2S sensor

performance may be hindered. To return the channels to optimal performance the sensor needs to be left exposed

to an oxygenated environment for the same length of time as it was deprived of oxygen for.

Above 85% RH and 40°C a maximum continuous exposure of 10 days is recommended. Where such exposure

occurs the sensor will recover normal electrolyte volumes when allowed to rest at lower % RH and temperature

for several days.

If very accurate CO or H2S measurements are required it is recommended that a single CO or H2S sensor is used.

Volatile Organic Compounds (VOC)

The VOC sensor is a mini photo ionisation detector (PID) and is sensitive to any VOCs that have an ionisation

potential less than 10.6 eV. The sensitivity of the sensor depends on the VOC present. The sensor is calibrated to

isobutylene and its response to other VOCs can be calculated using that compounds response factor. A response

Page 30

GasClam 2 Instrument User Manual

Ion Science Ltd.

Unrivalled Gas Detection. ionscience.com

28

factor is a number, which relates the PID response to a particular VOC, to the PID response from the calibration

gas (normally isobutylene). If the response of a PID to a particular VOC is eight times smaller than it is for the same

concentration of isobutylene, then the response factor would be 8. Similarly, if the response factor for a particular

VOC is 0.5, the response is twice that for isobutylene at the same concentration.

Concentrations greater than 4% CH4 and CO2 will attenuate the response of the PID sensor.

Some VOCs after ionisation may stick to the PID lamp reducing the amount of ultraviolet light available for future

measurements. Before each PID measurement is made the lamp is turned on for 30s to burn the residual VOCs off.

However, some VOCs may be more persistent and not completely removed, if this happens the PID response will

decrease. To recondition the lamp, set the GasClam 2 to sample every 3 minutes and run for 1 hour in clean air,

then perform a bump test. If the sensor has not completely recovered try reconditioning for longer. If this does

not work contact your local service centre.

Disclaimer: Information in this [manual, document…] is subject to change without notice and does

not represent a commitment on the part of Ion Science. No claims, promises or guarantees are

made about the accuracy, completeness, or adequacy of the information contained herein.

Loading...

Loading...