Page 1

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000

Instrument User Manual V3.1

Part number: 910228

Page 2

Register your instrument online for extended warranty

Thank you for purchasing your Ion Science instrument.

The standard warranty of your instrument can be extended to up to five years

on PhoCheck Tiger and two years on other Ion Science instruments.

To receive your extended warranty, you must register your instrument online

within one month of purchase (terms and conditions apply.)

Visit www.ionscience.com/instrument-registration

Part number: 910228

Page 3

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Declaration of conformity

Manufacturer: Ion Science Ltd, The Way, Fowlmere, Cambridge, SG8 7UJ, UK

Product: Hydrosteel 7000

Product Description: a fixed continuous monitor for the measurement of Hydrogen flux through steel

equipment. The flux is used as indication of internal corrosion. Hydrosteel 7000 is

for use in Oil and Gas operations where H2S, HF-acid, or high temperature corrosion

are present. With a 4-20 mA analogue output Hydrosteel 7000 can be simply

integrated into a DCS control system to give warning or control of high corrosion

levels in the operating equipment.

Directive 94/9/EC ATEX

Identification: II 2G Ex ia IIC T4 (-40

o

C ≤ Ta ≤ +60

o

C)

Notified Body: Baseefa Ltd, 1180, Buxton, UK

EC Type Examination Certificate(s)

Baseefa04ATEX0205 latest supplement Baseefa04ATEX0205 issue 4 issued 13

th

February 2009

Standards

BS EN 60079-0:2006 Electrical Apparatus for Potentially Explosive Atmospheres – General Requirement

BS EN 60079-11:2007 Explosive Atmospheres - Equipment Protection by Intrinsic Safety ‘i’

BS EN 61010-1:2010 Safety requirements for electrical equipment for measurement, control and

laboratory use – General requirements

Directive 2004/108EC Electrical Equipment – Electromagnetic Compatibility (EMC)

BS EN 61326:1997 (+A1/A2) Electromagnetic Compatibility (EMC) Equipment for measurement,

control and laboratory use

CFR 47: 2004 Class B EMC – US standard

Clarifications of EMC performance to standards: With respect to BS EN 61326:1997 (+A1/A2) the

Hydrosteel 7000 achieves performance criteria B (that is the apparatus continues to perform after the

test but during the test a degradation of performance is seen).

Other Standards

BS EN ISO 9001:2008 Quality Management Systems – Requirements

BS EN 13980:2002 Potentially Explosive Atmospheres – Application of Quality Systems

On behalf of Ion Science Ltd, I declare that, on the date this product accompanied by this declaration is

placed on the market, the product conforms to all technical and regulatory requirements of the above listed

directives.

Name: Mark Stockdale Position: Technical Director

Signature: Date: 20th November 2008

Page 3 of 43

Page 4

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Contents

Declaration of conformity ............................................................................................................................... 3

Statements ....................................................................................................................................................... 5

Responsibility for Use .................................................................................................................................... 5

Warnings ........................................................................................................................................................ 5

Quality Assurance .......................................................................................................................................... 5

Calibration Facility .......................................................................................................................................... 5

Legal Notice ................................................................................................................................................... 5

Packing list ....................................................................................................................................................... 5

Introduction to Hydrosteel 7000 ..................................................................................................................... 7

Introduction to safety certification .............................................................................................................. 10

Installation ...................................................................................................................................................... 11

HY7K probe site identification ...................................................................................................................... 11

HY7K analyser site identification ................................................................................................................. 11

Power and signal requirements ................................................................................................................... 12

Cable Requirements .................................................................................................................................... 14

Removal of cladding and insulation ............................................................................................................. 14

Preparation of test site ................................................................................................................................. 14

HY7K probe installation................................................................................................................................ 15

Thermocouple installation ............................................................................................................................ 18

Re-insulation and cladding ........................................................................................................................... 18

Installation of sample conduit ....................................................................................................................... 20

Mounting of Hydrosteel 7000 analyser ........................................................................................................ 23

Commossioning ............................................................................................................................................. 24

Inspection of the equipment installation ....................................................................................................... 24

Probe connection to Hydrosteel 7000 .......................................................................................................... 25

Terminating power and 4-20mA cable to Hydrosteel 7000 .......................................................................... 28

Start up ......................................................................................................................................................... 30

Operation test ............................................................................................................................................... 30

Hand over ..................................................................................................................................................... 31

Hydrosteel setup ............................................................................................................................................ 32

Clock time .................................................................................................................................................... 32

Flux 4-20mA output range ........................................................................................................................... 32

Operation ..................................................................................................................................................... 32

Hydrosteel 7000 PC software ....................................................................................................................... 33

Installation of Hydrosteel Software .............................................................................................................. 33

Connecting to the Hydrosteel 7000 .............................................................................................................. 33

Downloading data ........................................................................................................................................ 34

Graph operation ........................................................................................................................................... 34

Data table operation ..................................................................................................................................... 35

Data handling ............................................................................................................................................... 35

Print options ................................................................................................................................................. 36

Instrument Settings ...................................................................................................................................... 36

Maintenance and calibration ........................................................................................................................ 37

Hydrosteel 7000 unit maintenance .............................................................................................................. 37

Probe installation .......................................................................................................................................... 37

Fault finding and diagnostics ................................................................................................................ 38

Fault findings ................................................................................................................................................ 38

Diagnostics ................................................................................................................................................... 39

Technical specifications ............................................................................................................................... 40

Instrument warranty and service ................................................................................................................. 42

Warranty ....................................................................................................................................................... 42

Service ......................................................................................................................................................... 42

Contact details ............................................................................................................................................. 42

Manual log ...................................................................................................................................................... 43

Page 4 of 43

Page 5

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Statements

Responsibility for Use

Hydrosteel 7000 flux monitor for permanent installation provides flux readings that are subject to

interpretation. Ion Science Ltd can accept no responsibility for the incorrect use that may causes harm or

damage to persons or property.

Inadequate performance of the gas detection equipment described in this manual may not necessarily be

self-evident and consequently equipment must be regularly inspected and maintained. Ion Science

recommends that personnel responsible for equipment use institute a regime of regular checks to ensure it

performs within calibration limits, and that a record be maintained which logs calibration check data. The

equipment should be used in accordance with this manual, and in compliance with local safety standards.

Warnings

1. Please read and understand this User Manual fully before installing operating or servicing the

Hydrosteel.

2. Ensure you are in a SAFE area before carrying out any type of maintenance on the Hydrosteel 7000

Instrument.

3. Substitution of components may impair intrinsic safety and result in unsafe conditions.

4. For safety reasons, the Hydrosteel must only be operated and serviced by qualified personnel.

5. Refer to the certificate for clarification of any aspects of intrinsic safety or contact Ion Science Ltd or

your local Ion Science Ltd representative.

Quality Assurance

Hydrosteel 7000 has been manufactured in compliance with ISO9001:2008 and BSEN 13980:2002, which

ensures that the equipment supplied to our customers, has been designed and assembled reproducibly, and

from traceable components.

Disposal

Dispose of Hydrosteel 7000, its components in accordance with all local and national safety and

environmental requirements. This includes the European WEEE (Waste Electrical and Electronic Equipment)

directive. Ion Science Ltd offers a take back service. Please contact us for more information.

Calibration Facility

Ion Science Ltd offer a calibration service including the issue of certification using equipment which are

themselves traceable to UK national standards.

Legal Notice

Whilst every attempt is made to ensure the accuracy of the information contained in this manual, Ion Science

accepts no liability for errors or omissions, or any consequences deriving from the use of information

contained herein. It is provided "as is" and without any representation, term, condition or warranty of any

kind, either express or implied. To the extent permitted by law, Ion Science shall not be liable to any person

or entity for any loss or damage which may arise from the use of this manual. We reserve the right at any

time and without any notice to remove, amend or vary any of the content which appears herein.

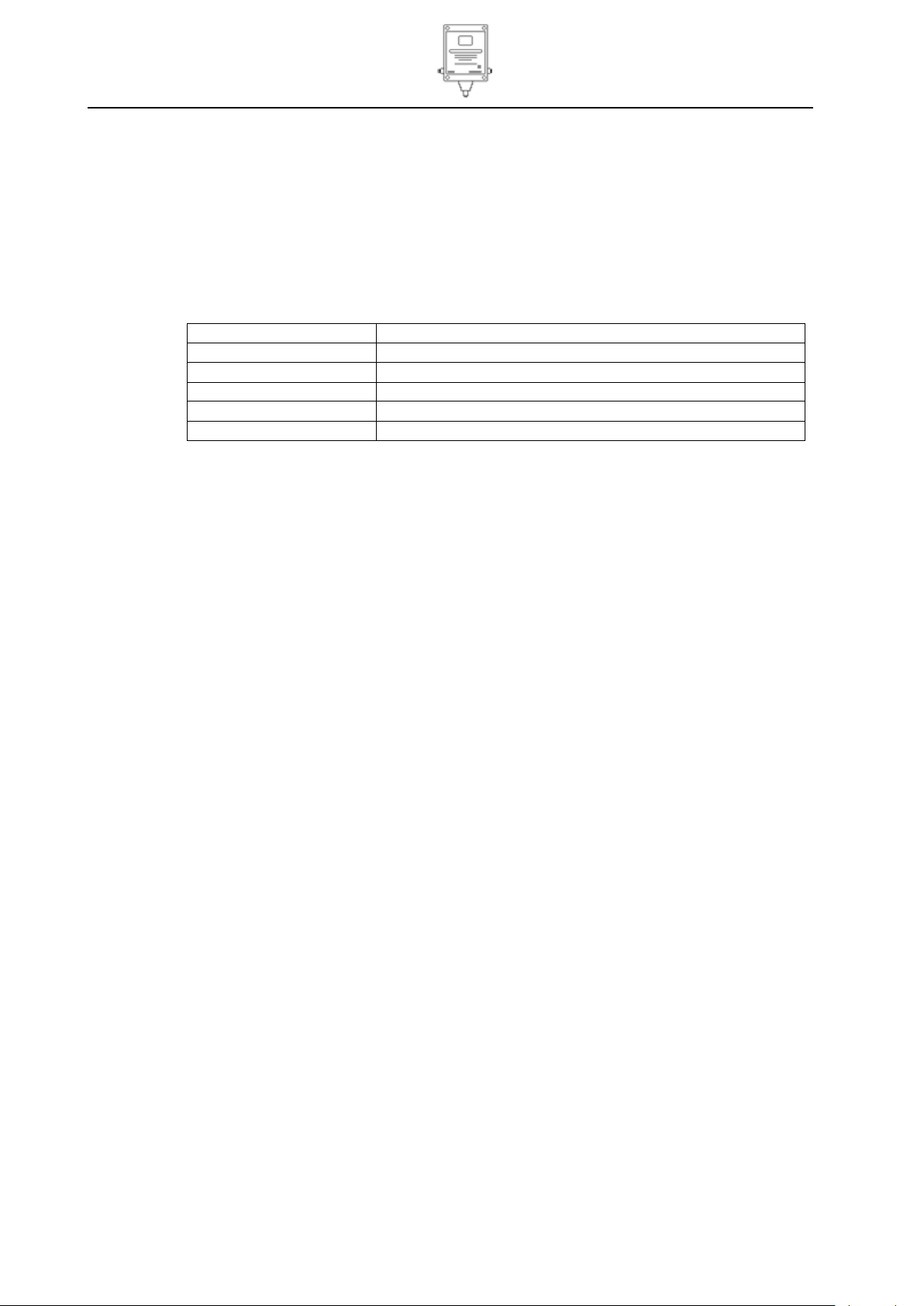

Packing list

Page 5 of 43

Page 6

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Please take a little time to check the contents in the Hydrosteel shipment before installation.

Item Description Qty.

1 Hydrosteel 7000 monitor 1

2 This Manual 1

3 Applications Manual 1

4 Software CD 1

5 Modem cable 1

6 USB to RS232 adapter 1

7 HY7K conduit kit consisting of:

7.1 Sample tube assembly 1

7.2 Han connector assembly 1

7.3 P clips for sample tube conduit 6

7.4 Thermocouple junction box 1

8 HY7K probe kit

8.1 AT-S collector plate 1

8.2 Background probe 1

8.3 Magnetically attachable TC cable 2

8.4 Wire brush 1

Accessories include:

1 Banding kit consisting of:

1.1 Banding tool 1

1.2 Banding (3/8”) stainless steel (box 30.5m) 1

1.3 Buckles box of 100 1

2 Magnetic probe fixing kit (4 high temp magnets) 1

Page 6 of 43

Page 7

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Introduction to Hydrosteel 7000

The Hydrosteel 7000 is an intrinsically safe instrument for the measurement of hydrogen flux from pipes and

vessels. The unit is designed for operator free maintenance for up to one year, subject to correct installation,

and appropriate power supply. During this time the unit will take unlimited measurements and log them

internally. The unit has two 4-20 mA outputs that provide constant output of flux and surface temperature

data. An RS232 port enables the download of internally stored data. The unit has been robustly designed

with IP66 weather proofing for external installation in most environments.

Hydrosteel 7000 has been designed with a view to presenting trouble free installation, commissioning and

maintenance. For maintenance we recommend the service exchange of the product. Disconnection of the

unit for service can be carried out while the instrument is powered, by simple detachment of analyser

connections, under intrinsically safe conditions.

The requirements for installation in Zone 1 hazardous area are summarised below and in the Installation

summary diagram. The reader should refer to Installation section, and to the Hydrosteel 7000 ATEX

certificate for further details.

Power to instrument should be supplied via zener safety barrier or galvanic isolator.

Two 4-20 mA receivers that supply loop power to hazardous area through appropriate safety barrier /

galvanic isolator are needed.

To ensure EMC compliance always use screened cables for bother power and 4-20 mA outputs.

Mounting to wall or frame with appropriate hole centres.

Probe to be installed on equipment with sample tube connection made to Hydrosteel 7000. Unit must

be within 10 m (32 ft) of probe test point.

Weather protection for probe. It is recommended that the probe is insulated and clad professionally.

The Hydrosteel 7000 has been certified intrinsically safe by European notified body BASEEFA 2001 to the

ATEX directive 94/9/EC. Baseefa04ATEX0205.

Page 7 of 43

Page 8

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Introduction to Hydrosteel 7000

Page 8 of 43

Page 9

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Time

Operation

0 to 3 minutes

Hydrogen zero measurement

3 to 6 minutes

Hydrogen background reading

6 to 9 minutes

Hydrogen flux reading

9 to 9.5 minutes

Hydrogen sensor diagnostics

9.5 to 10 minutes

Data stored in memory & 4-20mA outputs updated

Introduction to Hydrosteel 7000

Operation Cycle

Hydrosteel 7000 operates a 10 minute measurement cycle. At the end of each cycle, 4-20 mA outputs step

change to provide the most recent cycle data measurement, and store all data and diagnostic measurements

to the internal memory. The unit draws a controlled flow of sample gas from the probe into the unit, where

the concentration of hydrogen gas in the sample is measured. The instrument sequentially measures

hydrogen in sample gas drawn from the background probe (~3 minutes) and flux probe (~3 minutes). From

the differential response, the flux is calculated and data outputs are updated. The rest of the cycle (~4

minutes) is dedicated to clear down for a zero measurement and diagnostic measurements, as summarised

below.

Connectivity

1 mains power supply 15-24 V @ 34 mA in hazardous area

4-20 mA output #1: hydrogen flux requiring loop power of 8-30 V @20 mA

4-20 mA output #2: pipe temperature requiring loop power of 8-30 V @20 mA

RS232 connection for optional interrogation of unit: all data is logged to the unit’s internal memory

probe connection.

Page 9 of 43

Page 10

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000

S/No: “**-*****”

Manufactured: “Date”

Baseefa04ATEX0205

II 2 G EEx ia IIC T4,

-20 C <= T ambient <= +60 C

Ion Science Ltd, Cambs, England

1180

Introduction to safety certification

Apparatus certification (ATEX)

Hydrosteel 7000 has been issued with EC-type examination certificate Baseefa04ATEX0205 BASEEFA

2001. Confirming compliance with the European ATEX directive 94/9/EC for group II, Category 2 gas

atmospheres, EEx ia IIc T4 (T

conform with PD60079-12:2000 electrical installation in hazardous areas. When designing systems for

installation outside the UK, the local Code of practice should be consulted.

Certification label information

The certification label is fitted on the top outer surface of the enclosure. This shows the certification

information plus the Ion Science Ltd name, location, instrument serial number and year of manufacture.

Other non-European certification information may also appear on this label.

Note: The specified operating temperature range for the Hydrosteel 7000 is –20 C and +50 C, due to

constraints on the internal components.

System certificates

Currently no system certificates have been issued for this equipment. The Hydrosteel 7000 can be operated

safely in the hazardous area utilising a range of safety barriers. See Power and signal requirements in the

Installation section for full details.

Main power supply

When installed in a hazardous area the Hydrosteel 7000 must be powered from galvanic isolator, safety

barrier or IS power supply. The power supply must meet operational and safety requirements. In addition,

the power supply must not create a spark risk in conjunction with the power cable. The specific cable

parameters allowed will depend on the safety barriers use.

4-20mA outputs

The 4-20 mA outputs are 2 wire loop powered. That is, for operation in addition of a 4-20 mA receiver, there

must be a loop power source. This source must be intrinsically safe or supplied through an appropriate

safety barrier or galvanic isolator.

RS232 Connection

Non-hazardous Conditions

Under non-hazardous area conditions the RS232 port may be connected to a self-contained battery powered

computer containing 30 V or less. This allows connection to most laptop computers.

Hazardous Conditions

If the laptop is to be used in the hazardous areas local safety rules must be followed. Often all that is

required is a suitable permit and the use of an explosive gas detector to prove that the local area is safe at

the time of download. Under hazardous conditions this circuit must only be connected to a galvanically

isolated intrinsically safe RS232 connection.

To summarise;

The Hydrosteel 7000 can be installed in zones 1 & 2 in the presence of most common industrial

gasses.

A Safety barrier or isolator is required for the main power supply.

Safety barriers or isolators are required for the 4-20 mA outputs if they are used.

A portable computer may be used to download data provided local rules such as permits and safety

precautions are followed. The use of a standard laptop does not invalidate the HY7K safety

certificate.

See Power and signal requirements in the installation section for full details.

–40 C to +60 C). This instruction manual describes the installations that

amp

Page 10 of 43

Page 11

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

The following sequence of installation steps are recommended.

HY7K probe site identification

HY7K analyser site identification

Power and signal requirements.

Cable requirements

Remove cladding and insulation

Preparation of test site

HY7K probe installation

Thermocouple installation

Re-insulation and cladding

Installation of sample conduit

Mounting of Hydrosteel 7000 analyser

See installation summary drawing for an overview of requirements.

The Commissioning section addresses the following items required to complete the installation:

Attachment of the sample conduit to the analyser

Connection of electrical connection to HY7K

Inspection of the installed equipment

Start up, Set up and operation test

HY7K probe site identification

Suitable sites for Hydrosteel 7000 flux monitoring are primarily identified by the benefits conferred by

measuring flux at the specific location of interest, as further identified in the Hydrosteel Applications Manual,

available from Ion Science Ltd. Frequently, the value of flux measurement at a particular site is confirmed by

routine spot flux measurement with the Hydrosteel 6000 spot flux analyser. Probe compatibility with surface

steel geometry and temperature is defined in the Technical Specifications. The user is also invited to

consider the ease of installation at prospective test sites, and their proximity to sites appropriate for

Hydrosteel 7000 analyser location, see addressed points below.

Caution:

The weather resistance of the Hydrosteel system is dependant on the probe installation. The probe must be

sheltered from water and dust ingress as this will block sample flow and prevent operation. This may be

done by applying insulation and cladding, and/or a suitable shelter as appropriate. Water running down the

outside of the pipes must be considered, especially if the probe is situated on the underside of equipment. It

is important to shield from water access even on hot pipes as in heavy weather conditions the water will

evaporate to form steam which will condense in the sample tube and instrument.

The probe is fixed to the test site by one of the following methods. The appropriate fixing method should be

identified in advance of installation to ensure correct planning of provisions for installation:

Jubilee® clips - to pipes or vessels of minimum 2” (using the AT-S probe)

Banding - to pipes or vessels of 4 to 32” diameter

Magnetic attachment - to pipes or vessels of greater than 32” diameter. Maximum

temperature tolerance is 800F 426C

Stand - for large diameter, very high temperature equipment

HY7K analyser site identification

The Hydrosteel 7000 probe must be installed within reach of the probe, employing the 10m (32ft) long

sample conduit provided. Allowance should be made for securing the conduit between the probe and

analyser to cable trains or other suitable support means.

The Hydrosteel 7000 is housed in a tough glass reinforced polyester enclosure. The lid, RS232 connector,

cable glands and all fittings provide IP66 protection. The unit may be installed in any location provided

environmental limits defined in Technical Specifications, are not exceeded.The ideal location for the HY7K

should be accessible without scaffolding. So that it may be accessed for data downloads and servicing.

Page 11 of 43

Page 12

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Power receivers

Ui

Ii

Pi

Ci

Li

Uo

Io

Po

Units

V

mA W uF

mH V mA

mW

PS 1

30

200

1.2 0 0

PS 2

30

200

1.2 0 0 4-20mA 1

30

200

1.2 0 0

4-20mA 2

30

200

1.2 0 0

RS232

30 0 0

13 3 50

Thermocouple

Thermocouple

junction box

1

3

E

2

SCREEN

E

3

2

+V RD

1

0V BK

Red Connector

Hydrosteel 7000

Yellow Connector

1

2

Electrical connections (Non IS)

+V RD

0V BK

SCREEN

RD

BK

BK

RD

0V BK

+V RD

SCREEN

+V

+V

0V

0V

3

E

Blue Connector

RD

BK

4-20mA 2

4-20mA 1

Control equipment

Power

+V

0V

Installation

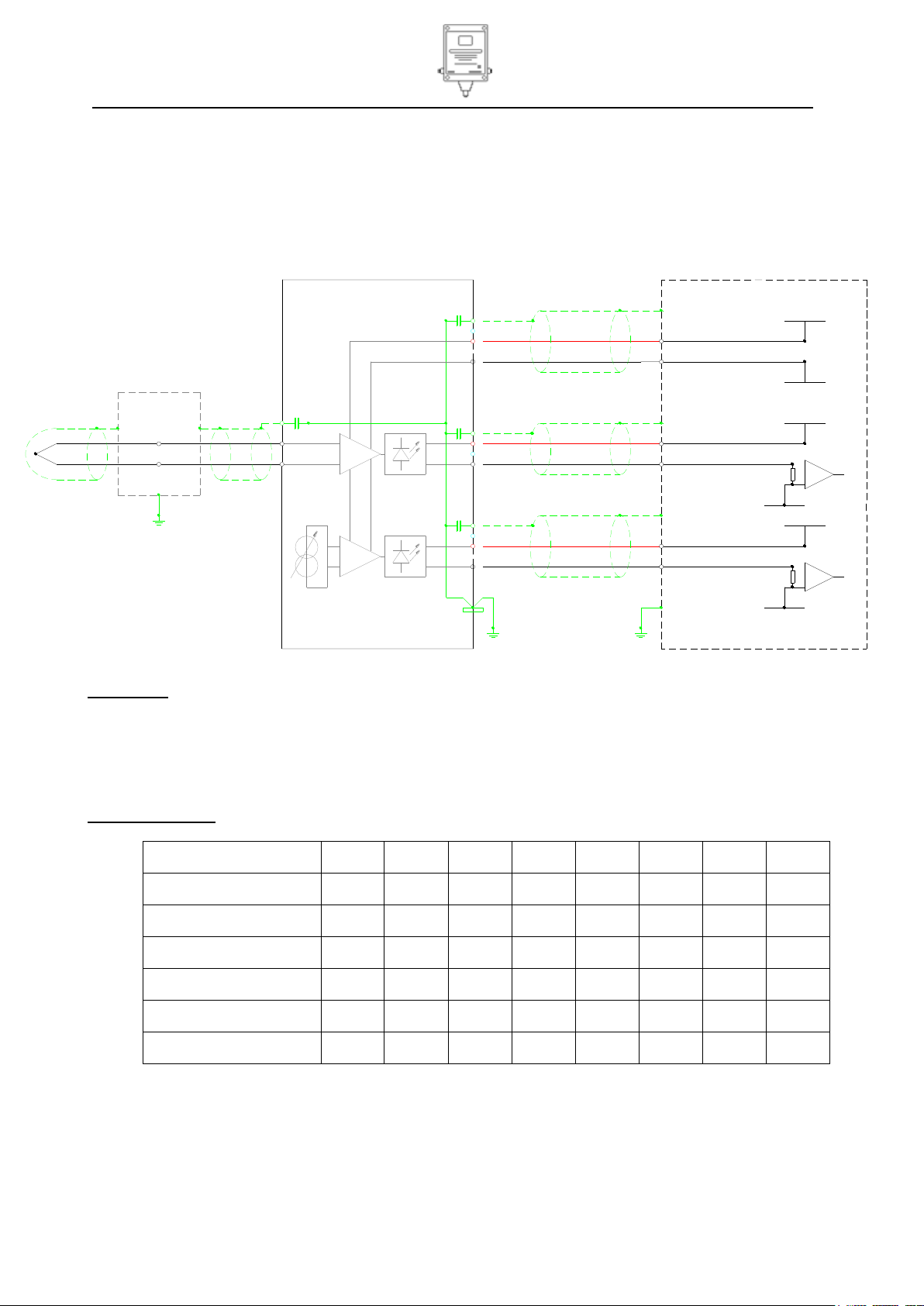

Power and signal requirements

Non Intrinsically Safe (Non IS) applications

Input power 15-24 Volts 35mA

4-20 mA power 8-35 V dc. 22mA

The Hydrosteel is to be wired up as per the wiring diagram below.

WARNING! Non Intrinsically Safe (Non IS) applications

When the unit is installed with a non IS rated power supply the IS details on the front of the unit are not

appropriate for the system. The IS label should be covered up or blocked out. This will prevent safety

discrepancies and or mis-use in the future should the equipment be moved or the site be re-defined as a

hazardous area.

Intrinsically Safe (IS) applications

Entry parameters

For information only see safety certificate before installation

Page 12 of 43

Page 13

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Electrical connections (IS) with safety barriers

Yellow Connector

Thermocouple

junction box

Thermocouple

2

3

E

SCREEN

+V RD

0V BK

Red Connector

SAFE AREA

1

SCREEN

+V RD

0V BK

1

E

3

2

SCREEN

0V BK

+V RD

2

E

3

1

Blue Connector

Hydrosteel 7000

0V

+V

BK

RD

4-20mA 1

0V

+V

0V

RD

BK

Power

+V

BK

RD

4-20mA 2

Control equipment

Manufacture

Manufactures pt. no.

Type

Cable length estimate

m

Pepperl & Fuchs

KFD2-VD-Ex1.1835

Galvanic Isolator

560

Stahl

9175-10-16-11

Galvanic Isolator

335

MTL Ltd

MTL4023

Galvanic Isolator

365

MTL Ltd

MTL7728P

Zener barrier

288

Turck

MK72S06-EX

Galvanic Isolator

686

Manufacture

Manufactures pt. no.

Type

Pepperl+Fuchs

Z728

Zener barrier

Pepperl+Fuchs

KFD2STC4-Ex1

Galvanic isolator

MTL

MTL7787 (dual channel)

Zener barrier

MTL

MTL5044 (dual channel)

Galvanic isolator

Stahl

9001/51-280-110-141

Zener barrier

Stahl

9160/13-11-11S

Galvanic isolator

Installation

Ion Science Ltd suggest using the following or similar safety barrier or IS isolator for IS approved

applications. The system must be designed by a suitably trained engineer and approved by the local safety

authority.

Power Supply:

Suggested barriers for INLET power supply

* Note

All cable lengths are estimated for Zone 1 IIC installation of the equipment

Using 1 mm2 C.S.A. conductors S.T.P. cables with capacitance of 250 pF/m, L/R ratio of 25 uH/

conductor resistance at 20 C of 18.4 /Km

Calculation assumes that cables are at 80 C (maximum operating temperature).

Signal Output

Suggested barriers for 4-20mA OUTLET

WARNING! Intrinsically safe (IS) applications

HY7K fuses may not be replaced in the field.

If a fuse is blown the Hydrosteel 7000 will require inspection by Ion Science Ltd or and Ion Science Approved

Service Centre before it is used in an IS application.

Page 13 of 43

Page 14

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000

Thermocouple

junction box

Thermocouple

1

0V

SCREEN

0V BK

+V RD

2

E

3

1

2

3

E

SCREEN

+V RD

0V BK

Red Connector

Blue Connector

4-20mA 1

4-20mA 2

0V

+V

+V

BK

RD

BK

RD

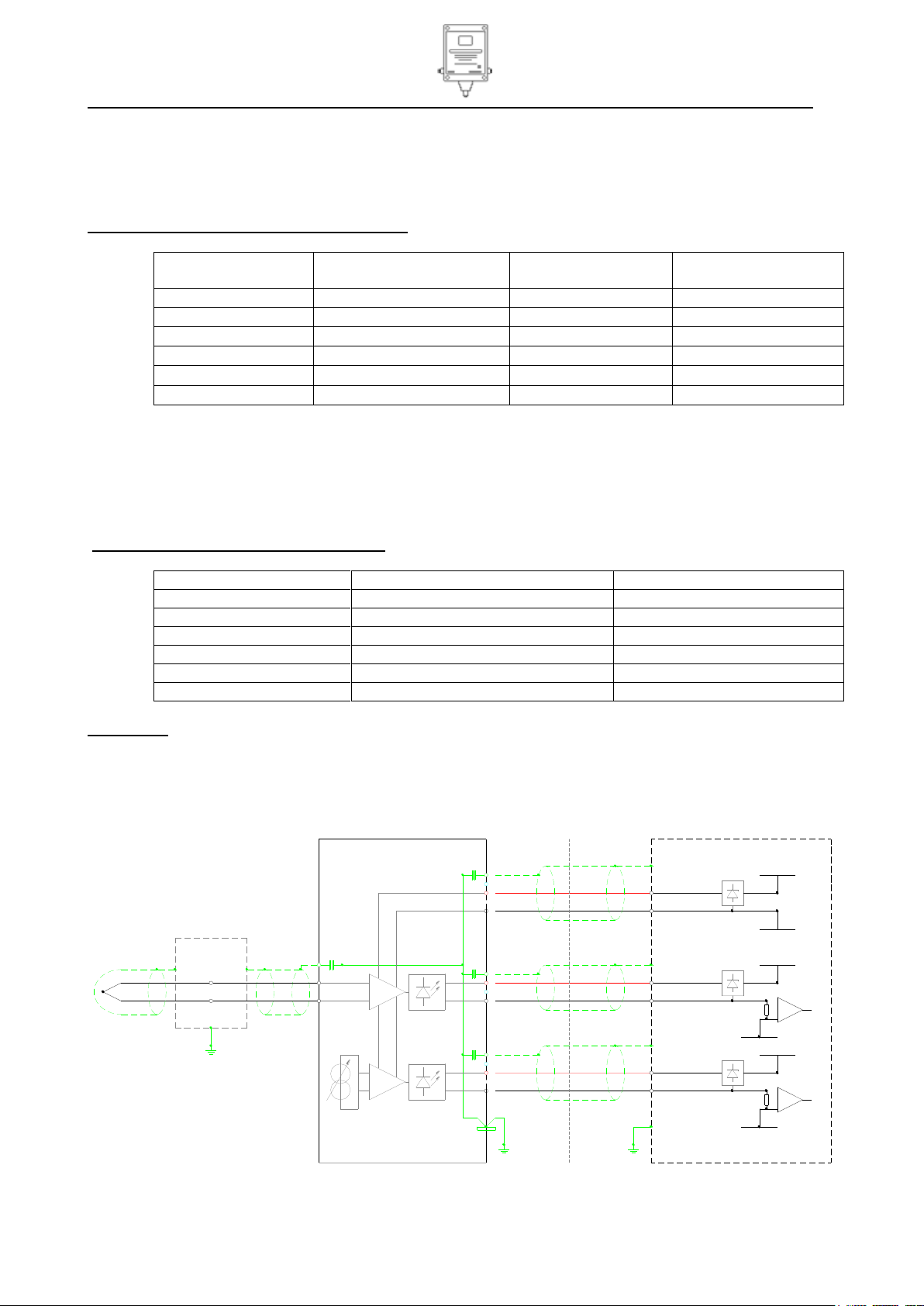

Electrical connections (IS) using galvanic isolator and alternative grounding

SCREEN

+V RD

0V BK

1

Yellow Connector

E

3

2

Power

+V

0V

RD

BK

Control equipment

SAFE AREA

IS Galvanic

Isolator

Screens no longer grounded

at the control equipment end

Capacitors and Power OV shorted

to ground stud inside HY7K

JB earth

Note: JB earth and HY7K earth must be

equi-potential and have no more than 1 Ohms

resistance between them

HY7K earth

Installation

Use of Galvanic isolator and alternative grounding

Galvanic isolators may be used instead of safety barriers in the above circuit. If an isolated supply is used,

the supply at the instrument should be checked for AC noise. Measure the AC voltage between the 0 V and

the local earth. If there is AC noise this needs to be removed. It might be due to a faulty power supply or

induction of AC onto the cables. To remove the noise it might be necessary to ground the 0 V to an earth

point either in the control equipment or at the HY7K instrument. For electrically noisy environments the

optimum grounding is shown in the wiring diagram below. It is essential to follow the following key rules:

1. Screens may only be grounded at one end.

2. If the Power supply 0 V is grounded at the Hydrosteel then a suitable rated Galvanic isolator must be

used.

Cable Requirements

To meet the EMC compliance for immunity it is required that power and 4-20 mA current loops are supplied

with screened twisted pairs. Pairs should be individually screened with the screens terminated in the safe

area and to the terminals on the Hydrosteel 7000. (Note the Hydrosteel does not allow DC earth loops to

ground down the screens).

Removal of cladding and insulation

Hydrosteel flux measurement requires intimate contact between the probe plate and test surface, so it is

necessary to remove any insulation from the target sites.

For ease of access during probe installation, cladding and insulation should be removed from a 1 ft distance

from the centre of the site for flux monitoring. Additionally, if the probe is to be fixed with banding (to pipes

and vessels of less than 32” diameter), insulation and cladding must be removed from the entire

circumference of the vessel or pipe under test.

Preparation of test site

The surface should be free from ridges such as weld filets which could prevent the collector plate from

making intimate contact with the steel surface.

The identified test site surface should be at least 4”, in diameter, to accommodate both the probe and

magnetic thermocouple assembly. This surface should be free from rust and flaking paint which might

otherwise prevent hydrogen flux from exiting the steel surface.

Page 14 of 43

Page 15

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

HY7K probe installation

The probe consists of the AT-S probe the background probe and the Thermocouple probe. The AT-S probe

may be fixed in place using magnets or banding depending on the test site geometry. The background probe

is attached to the AT-S probe using clips. The thermocouple probe is magnetic and may be placed directly

on to the surface of magnetic steels.

AT-S and background probe installation with banding

Components

To affix the probe, you will need two equal lengths of banding appropriate for the target pipe diameter. That

is the pipe circumference plus 30 cm for tool operation and fitting of buckles. Ion Science recommends that

standard 3/8” (9.31 mm) width 0.015” (0.38 mm) gauge Stainless steel banding and buckles be used. This

uses a specialist band-tightening tool. Banding kit may be purchased as an accessory.

Items required are:

AT-S probe collector plate

Back ground probe

Probe clips A-910227

Band tensioning tool

Band cuters

x2 Banding buckles

x2 Banding lengths to suit pipe (3/8” - 0.015” guage)

Wire bush for preparing the metal surface

PPE (personal protective equipment)

Pre-assembly

Best done in a clean environment off-site,

Assemble the background probe on to the AT-S probe using the probe clips.

Prepare the banding by cutting it to length. Equal to the Pipe circumference plus approximately 30

cm. For difficult installations longer lengths may be required with the banding being cut afterwards to

remove the excess.

Fit the buckles to the banding following the manufactures instructions

Fit the banding into the support bracket on the AT-S.

Manually adjust the collector so that it is located at a distance equal to ¼ of the target pipe

circumference from the buckle end of the strap. Loosen or tighten the butterfly nuts as required.

Ensure the collector cap is secured to finger tightness.

Page 15 of 43

Page 16

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

If it is desired to measure the flux on opposite sides of a pipe e.g the 12 O’clock and 6 O’clock (top

and bottom) then a second AT-S probe may be fitted to the same banding. Fit the seconds AT-S

probe at length of three quarters of the target pipe circumstances along the banding.

Relocation to target site

A hot work permit is not required for installation of the probe as the requirements are purely

mechanical and non-destructive.

Ensure you are equipped with the collector assembly, banding assemblies, band tensioning tool

suitable PPE (personal protective equipment), and a stiff wire brush to remove loose rust from the

test site if necessary.

Step 1: Check again that you can access the entire circumference of the target pipe section and that it is free

from loose rust. Use the wire brush to remove residual rust if necessary.

Step 2: Fit the collector plate to the appropriate place and pass the banding round the pipe circumference;

secure this into the buckle and tension following the manufacturer’s instructions. For hot pipes, it is very

important to let the banding heat up to the temperature of the pipe as the banding will expand and lengthen.

In these circumstances, tension the banding using the tightening tool and leave the tool in place for sufficient

time for the banding to reach temperature, re-tension the banding as necessary before locking the banding

off.

Step 3: Check that the probe is held correctly in position and that they are fully pressed against the piping

surface, particularly at the probe perimeter points identified in the accompanying diagrams.

Page 16 of 43

Page 17

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

Also check that the bands are fully parallel. NB: The probe can slide along the banding by loosening the

thumbscrews on the probe brackets, provided the banding is not too tight onto the pipe. Check the banding

buckles are a reasonable distance from the plate so that the banding runs flat against the steel surface and

then onto the collector plate. If the band buckles are very close to the collector edge the banding may not

pull the collector plate flat on to the surface with no or only a very small gap.

Step 4: Lock off the banding as normal, following the banding manufactures instructions. Wait 3-5 minutes!

Due to expansion of the banding attached to pipe at elevated temperatures, it may require tightening after

some time. Re-check probe tightness and positioning as per step 3 and retighten or refit banding as

necessary.

Step 5: Position the background probe so that it is sampling from the edge of the plate.

Page 17 of 43

Page 18

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

A

x

i

s

o

f

A

x

i

s

o

f

A

x

i

s

o

f

Axis of pipe or vessel:

Note magnet orientation

Installation

AT-S Probe Installation with Magnets

Step 1: Press the collector plate against the target steel surface so that it conforms to pipe or vessel

curvature.

Step 2: With the probe held in place, attach the magnets as shown in the diagram below. Note: The max

working temperature for magnets are 800F 426C

Thermocouple installation

Care should now be taken to prevent the magnet from

tugging the thermocouple lead. The thermocouple is

semi-flexible and further care must be taken when

handling to prevent damage by repeated flexing of the

lead at a single point.

Max working temperature for magnets is 800F 426C

The magnet thermocouple should be fitted so the magnet

legs bridge across the pipe or vessel curve near the

location of the mounted probe, as illustrated below.

Once fitted the screw should be tightened using an Allen

key, until the thermocouple tip is pressed firmly against

the steel as illustrated. (Care should be taken when

doing this as excess tightening could crack the ceramic

block)

Re-insulation and cladding

Weather shielding for the probe is essential to prevent

water ingress blocking the sample flow and preventing

operation. This may be achieved by installing insulation

and cladding with the use of sealing bungs or tape.

Alternatively a custom made cloche might be used

for exposed pipes or where insulation is not needed. Ion

science recommends that a short segment of insulation

capped at each end is used to cover the probe. (See the

diagram below).

Page 18 of 43

Page 19

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

The cladding joints and probe exit from the cladding should be sealed with a suitable sealant to prevent the

ingress of water. This arrangement has a number of advantages:

The insulation around the probe is isolated from the general equipment insulation by the cap. This will

prevent / reduce water that gains access through damaged cladding from penetrating to the area of the

probe.

When inspecting the integrity of weather protection only the short section of insulation needs to be

inspected.

When repairing the cladding, checking for water ingress or inspecting the probe only the short section

needs to be opened.

The test site should be insulated and clad with the probe thermocouple and AT-S probe now in place. Note

that the AT-S probe and ambient gas probe caps should not be removed during this procedure; in order to

prevent insulation debris and fibres from entering them. The probe capillaries will withstand flexing to about

2" radius; however, flexing of the thermocouple lead should be minimised. It is essential that the AT-S probe

plate remains firmly in place, and is not distorted by tugging of the capillary conduit.

Make sure the probe cap is in place. The free ends of the probes and sample conduit should either be

pushed through a hole in the insulation as it is laid over them, or a slit can be made in the insulation to

accommodate them.

Page 19 of 43

Page 20

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

A hole in the cladding should be formed to enable the AT-S probe, ambient gas probe, and thermocouple to

emerge approximately radially from the pipe or vessel. A 60 mm cavity such as one for UT inspection ports is

often suitable, together with a rubber bung with a radial slit through which the probe capillaries and

thermocouple lead emerge.

Installation of sample conduit

Fixing of probe conduit bracket

It is unlikely that the sample conduit, routed from the probe to the analyser, is of exactly the correct length.

Generally it is preferable to loop spare conduit at or near the analyser terminus and to work from the secured

probe towards it.

The probe bracket is affixed to the 10 m sample conduit and must be secured to enable the AT-S, ambient

gas probes, and thermocouple lead to be attached to it. Generally, it will be necessary to fix the bracket to

outside of the pipe cladding. The probe bracket may be banded, riveted or bolted into position. It is

important to ensure;

Secure support for the probe bracket, as it prevents forces being loaded onto the probes if the

conduit is tugged.

Page 20 of 43

Page 21

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

Conduit and tails do not rest against hot piping or equipment. As they contain thermoplastic

components that may be damaged.

WARNING!

Sample Conduit and tails must not be exposed to elevated temperatures above 100 C. These temperatures

can easily be experienced if the conduit or tails are in surface contact with high temperature process pipes.

Connection of probes to sample conduit

Remove the probe caps. Simply attach the AT-S and ambient gas probes manually using the threaded

unions provided. Ensure that the correct capillaries are attached to the correct conduit cable

Tube with nut marked F (red tube or red cable tie) to AT-S probe

Tube with nut marked B (white tube or white cable tie) to

background probe.

Tighten the conduit nuts securely (1/8 turn) using 11mm

spanners.

Use cable ties through the slots in the probe bracket to hold

the probe connections in place.

Connection of thermocouple cables

The thermocouple lead terminates in two wires; these must be connected to the thermocouple cable in the

conduit at the thermocouple junction box. To maintain the continuity of the thermocouple screen, EMC

cables glands supplied must be used. Clamp the thermocouple pot into the cable gland. The internal

conductive spring tabs will make electrical contact with the thermocouple sheath and the pot will be

mechanically secured when the seal is compressed tight. Please see photographs below that follow.

Page 21 of 43

Page 22

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

If it has not already been terminated, terminate the thermocouple conduit cable into the gland, bend the

screen wire back and jam it between the insert and the housing. Please see the photographs below.

Connect the thermocouple wires using the terminals inside

the junction box. The thermocouple junction box is mounted

onto the probe bracket so it is fixed in place when the

bracket is fitted to the pipe cladding. A ground connection

should be made from the thermocouple bracket to the local

earth for the purposes of screening. This earth may be

through the contact between probe bracket and cladding.

However if the cladding is electrically isolated or of a non

conductive material an earth connection should be made

directly to a stud on the probe bracket.

Fixing of sample conduit

Use P clips (1/HF-02) and M5 screws or bolts (not

supplied) to fix the conduit to appropriate refinery structures

or cable trunking from the probe bracket towards the

analyser location. Avoid structures which are liable to exceed 100 oC.

Page 22 of 43

Page 23

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Installation

Mounting of Hydrosteel 7000 analyser

Dimensions for mounting are shown below. The Hydrosteel 7000 can be mounted in any orientation, except

upside down, which does not cause entry of water into the exhaust port, for example, during drench testing.

Page 23 of 43

Page 24

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Commossioning

Commissioning is a matter of terminating the probe and electrical connections to the Hydrosteel 7000 unit

checking the installation and confirming correct operation. The commissioning consists of the following sub

sections:

Inspection of the equipment installation

Terminate probe connection to Hydrosteel 7000

Terminating power and 4-20 mA cables to Hydrosteel 7000

Start-up

Operation test

Hand over

Inspection of the equipment installation

The installation should be inspected prior to commissioning. The following is a check list of features for

inspection:

Probe (if accessible):

Clean test surface, without ridges such as welds

Secure fitting with the collector plate firmly pressed against the test surface

Protect the probe from ingress of water

Probe bracket to sample conduit:

Secure

Free of features that might present a danger to personnel

Sample tube:

Be fixed securely so that is safe from foreseeable damage

Hydrosteel 7000 mounting

Secure and accessible

Sample conduit and electrical connections accessible for connections.

Electrical cables

Continuity of cable cores has been tested

Insulation resistance between cores and between cores and screen has been tested

Connection of cables to correct services has been tested

In a hazardous area, the Power and 4-20 mA cables are labelled so that correct connections can

be made to the Hydrosteel

Page 24 of 43

Page 25

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Cut back 30 mm of outer

sheath.

Remove aluminum foil

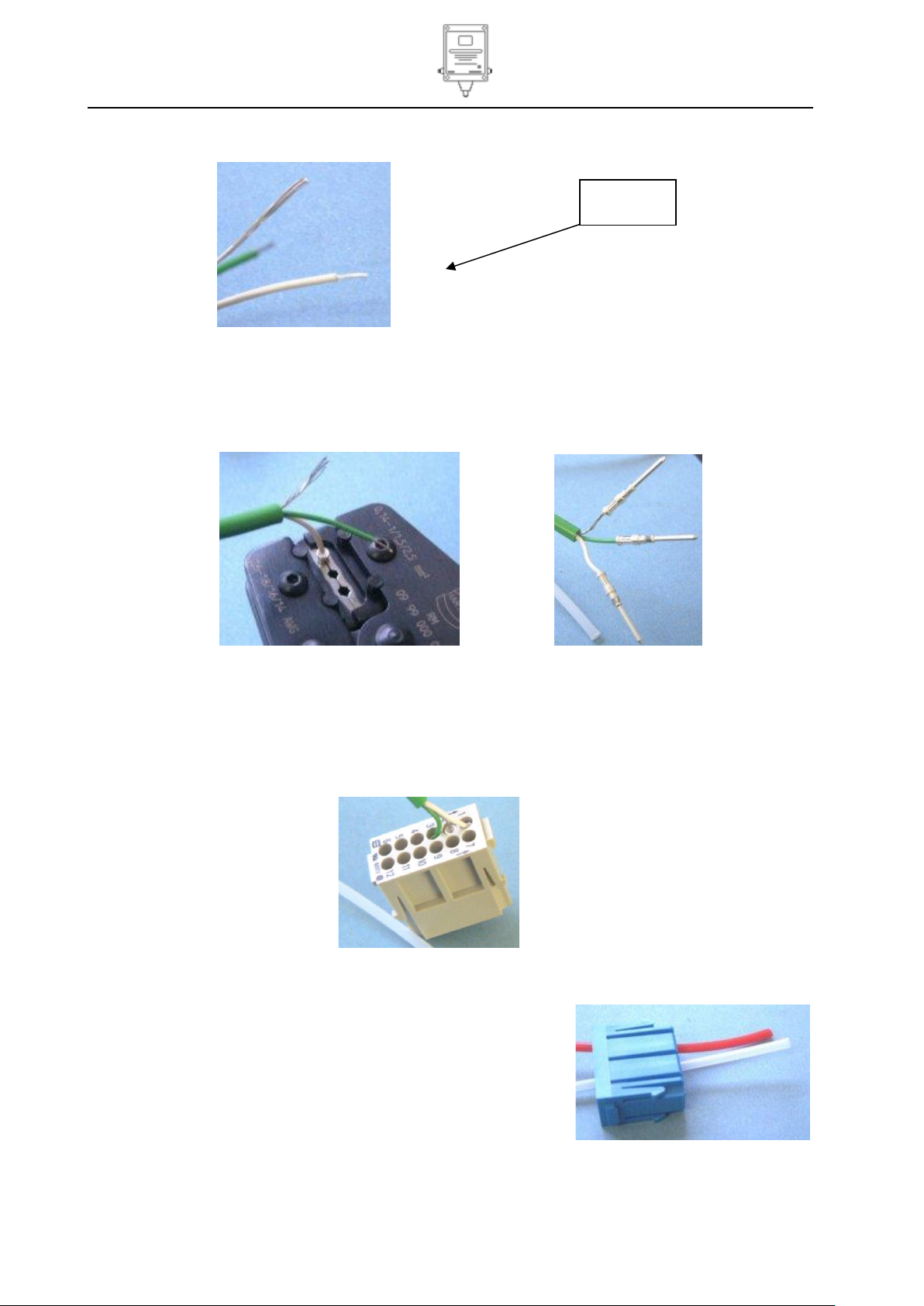

Commissioning

Probe connection to Hydrosteel 7000

Termination of sample conduit with Han connector

1. Fit Harting connector assembly to the Hydrosteel 7000. This assembly is complete with a special Cable

gland.

2. Offer the sample conduit from the probe up to the Hydrosteel 7000 and mark the required length of the

spiral sheath where it will enter the cable gland on the Harting connector.

3. To maintain traceability of the pneumatic lines after cutting. Mark the tubes above the point at which they

are to be cut so that they may be differentiated (using a wrap of insulating tape is an ideal marking).

4. Pull the spiral conduit so that it extends by at least 30 cm. Cut through the conduit using a hacksaw. By

extending the conduit this ensures that the sub components (pneumatic tubes and thermocouple) have a

30 cm excess protruding from the conduit when it relaxes.

5. If it has not been possible to mark the tube or the marking has been

lost the lines must be traced through by blowing or sucking on the

tube.

6. Fit the M20 conduit adapter (1/HG-03) to the sample tube conduit.

7. The cable gland supplied may be one of two types. Type one uses a

sealing epoxy compound, type two uses a machined rubber gland. If

cable gland that use’s a sealing compound is supplied, then the

sealing compound should not be applied until the sample conduit has been completed to ensure correct

fit. The cable assembly should be fitted dry, following the fitting instructions supplied with the cable

gland. Split the cable gland and thread the pneumatic tubes and

thermocouple through.

8. Close the cable gland and tighten following the cable gland fitting

instructions.

9. Trim the nylon tubes and the thermocouple cable so that 10 cm

extends out of the end of the conduit gland. If any extra length is

required, the conduit can be compressed to reveal a greater length of cable and tubes.

10. On the end of the thermocouple cable strip 30 mm of PVC outside sheath to expose screen and sub

cores.

11. Remove aluminium foil screen to the point of exit from the PVC sheath.

Page 25 of 43

Page 26

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Strip 8mm of

insulation

Commissioning

12. Strip 8mm length off white and green wires.

13. Crimp all three wires using crimp contact pins Pt No. 1/JCPB-01. Push the exposed conductor ends into

contact pins. Please Note the screen is tight into crimp socket so don’t twist the conductors together and

tease gently into avoid bending the conductors. If necessary cut 1 or 2 conductor strands out of the

bundle to enable it to fit. Use the end location of “Harting service tool” (Harting part number 09 99 000

0021) to crimp.

14. Feed the nylon tubes and the thermocouple cable through the male reducer and Han connector housing.

15. Fit crimps into Han DD module (1/JSIB-01) from the rear. The rear of the module is the flat fully

numbered sided. The crimps should be fitted as follows according to the numbering on the Han DD

module. Pin 1 = white, pin 2 = screen, pin 3 = green. Use “insert tool” (Harting part number 0999 000

0171) (or with care a small flat blade screw driver) to push crimp sockets until they are securely located.

(Note: to remove the crimps from the sockets if they are incorrectly placed or require maintenance the

“Harting extraction tool” is required.

16. Check the adapter and M20 cable gland parts are tightly fitted to the Han connector housing.

17. Feed nylon tubes through the pneumatic module (1/JNIB-01).

Flux through position 1 and background through position 2.

Since both tubes are natural in colour marking using black tape

for background and red tape for flux has been fitted to the unterminated end. This may have been lost when the conduit was

cut to length. If so trace through the liens by blowing or sucking.

Page 26 of 43

Page 27

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Note orientation

Hing

Commissioning

18. Fit the pneumatic connectors on to the nylon tubes.

19. Snap the pneumatic connectors into the pneumatic module.

20. The Han frame ((1/JFIB-02) hinges to allow fitting of the insert modules from the rear.

21. Note frame and modules have keyways to allow only one orientation of fitting. The Aand B arrows

point to the top of the pneumatic module. With the pneumatic module on the side marked with capital

“B”

22. Fit the frame into the Han connector housing.

Page 27 of 43

Page 28

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Commissioning

23. Join the gland housing together.

24. Check the full assembly has been assembled correctly. If cable gland supplied requires the use of a

sealing epoxy, open the cable gland and follow the fitting instructions supplied with the cable gland.

Apply the sealing compound. The cable gland must be closed before the sealing compound has cured.

25. Once complete, probe connection will be capable of disconnection and reconnection with Hydrosteel

7000. Tighten Han connector screws with flat blade screwdriver to secure the connector.

Additional fixing of conduit if necessary

Use P clips (1/HF-02) and M5 screws or bolts (not supplied) to fix the sample tube conduit to appropriate

refinery structures or cable trunking. Alternatively use cable ties.

Connect conduit to Hydrosteel 7000

Connect the Han connector from the sample tube to the Hydrosteel 7000. Tighten Han connector screws

with flat blade screwdriver to secure the connector.

Terminating power and 4-20mA cable to Hydrosteel 7000

IP67 rated cable connectors are supplied with Hydrosteel 7000 so that the instrument may be quickly

disconnected, and then reinstalled after servicing. These are colour coded using cable ties. Note the

connector pins have been changed to provide key ways and ensure that each connector is individual to the

appropriated panel socket. The connectors will fit cable diameter’s 6-12 mm.

Terminate the cables following to the connectors as show by the commissioning diagram overleaf. If any

connection is not made to the Hydrosteel the mating face of the connector must be protected from water

ingress by the fitting protective caps or covering with a plastic bag.

Page 28 of 43

Page 29

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

NOTES:

1) REFER TO EC-TYPE EXAMINATION CERTIFICATE FOR INTRINSIC

SAFETY PARAMETERS

2) REFER TO TECHNICAL SPECIFICATION IN MANUAL FOR SUPPLY

VOLTAGES AND CURRENTS

H2 FLUX

SAMPLE TUBE

ASSEMBLY

SAMPLE TUBE FIXING BRACKET

2 2

22

H2 BACK GROUND

PNEUMATICS

PNEUMATICS

HAN PLUG

2

PANEL PLUG

TAGGED BLUE

PANEL SOCKET

TAGGED GREEN

BACKGROUND

PLANT EARTH LOCAL TO PROBE

NOTE PROBE IS ELECTRICALLY

CONNECTED TO SAMPLE TUB

EQUIPMENT UNDER TEST

THERMOCOUPLE PROBE

NATURAL

NATURAL

GREEN

WHITE

12

FLUX

3

2

2

3

3

2

1

1

1

3

21

6

5

4

3

2

1

1

2

3

- +

SCREEN

THERMOCOUPLE

10

9

8

7

11

E

3

2

1

SCREEN

PS1

POWER

SUPPLY 1

BK 0V

RD +V

FREE PLUG

TAGGED YELLOW

PANEL SOCKET

TAGGED YELLOW

EARTH POST

MUST BE CONNECTED TO

LOCAL (PLANT) EARTH TO

PROVIDE EFFECTIVE SCREENING

HAN RECEPTACLE

4-20mA 1

E

1

2

3

E

SCREEN

SCREEN

0V BK

+V RD

PANEL PLUG

TAGGED RED

FREE SOCKET

TAGGED RED

4-20mA 2

1

0V BK

RS232

CONNECTION

Red / Alarm

LED

Green / power

LED

FREE SOCKET

TAGGED BLUE

BK

+VRD

BK

0V

+V

0V

0V

+V RD RD

3

RD

BK

0V

+V

0V

Control equipment

Hydrosteel 7000

Hydrosteel 7000 Commissioning Diagram

Commissioning

Page 29 of 43

Page 30

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Detector

Range

Resolution

Accuracy

4 mA

20 mA

10 mA

Flux (AT-F probe)

0 pl/cm2/s

2400 pl/cm2/s*

1 pl/cm2/s

10 % at cal. Value

Pipe temp

-40 C

500 C

2 C

2 C at cal value

Commissioning

Start up

Power up intrinsically safe circuit. Green LED on Hydrosteel 7000 should light to show correct power

is available to the unit. (the measurement cycle will start automatically)

Power up 4-20 mA circuit. 4mA should register on each circuit.

If any discrepancy from the above is encountered see fault finding and diagnostics in the

Maintenance section

Operation test

Basic test

1. Allow the Hydrosteel to complete one measurement cycle (10+ minutes from switch on). If the green

LED is continuously lit, the power is confirmed as correct. If the Green LED starts to flash then the power

dropped below 15 V (browned-out) during the measurement cycle and it has restarted. See fault finding

and diagnostics in the Maintenance section.

2. If the red LED illuminates, a fault has occurred during the measurement cycle. See fault finding and

diagnostics in Maintenance section.

3. Perform a data download. Check that no diagnostics have failed during the first measurement cycle. If

any diagnostics have failed again, please refer fault finding and Diagnostics in the Maintenance section.

4. The flux reading can be correlated by using a Hydrosteel 6000 close to the Hydrosteel 7000 probe point.

Record a Flux reading on the hand over document.

5. The pipe temperature can be correlated by measuring the temperature at the probe steel surface or by

connecting the Thermocouple to a hand held thermocouple thermometer. Record the first thermocouple

reading on the hand over document.

Test if Hydrosteel function test is available

1. Disconnect the flux (AT-S) probe and connect hydrogen flood leak sample conduit.

2. Allow the Hydrosteel to complete one measurement cycle (10+ minutes from switch on).

3. Perform a data download.

4. The flux reading should be between 280 pl/cm2/s and 380 pl/cm2/s. Record the flux reading on the hand

over document.

5. The pipe temperature can be correlated by measuring the temperature at the probe steel surface or by

connecting the thermocouple to a hand held thermocouple thermometer. Record the first thermocouple

reading on the hand over document.

4-20 mA test

1. Both 4-20 mA outputs should be 4mA from unit switch-on of the 4-20 mA power supplies for each output.

After the first measurement cycle is complete the 4-20 mA output will be up dated to reflect the current

reading.

2. The 4-20 mA output after the first measurement cycle can be ascertained by performing a data download

and using the flux and pipe temperature readings to calculate the 4-20 mA outputs. See the table below:

3. Note: Flux 4-20 mA output range may be changed see Hydrsoteel setup section.

4. Check the initial 4 mA reading and any subsequent readings have been correctly measured by the 4-20

mA receivers.

5. Program the correct units and range for each output into the “data collection system”. See the table

above.

Page 30 of 43

Page 31

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Commissioning

Hand over

1. With the permission of the owner, photograph the unit as installed. The photographs will provide a

documentary record of sound installation. Photographs should show the following.

Correct probe installation

Probe is securely mounted and safe from foreseeable damage

Sample conduit has been mounted securely and is safe from foreseeable damage

HY7K is mounted securely and is safe from foreseeable damage

All connections have been made securely to the HY7K and are safe from foreseeable damage

2. Produce hand-over document with the following details:

Customer details

Customers PO no

Hand-over date

Site or location reference

Equipment tag number or other reference

Add the photographs

Operation test results

First flux and pipe temperature measurements

3. Have the installation inspected and the hand-over the signed document.

Page 31 of 43

Page 32

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel setup

Clock time

The clock is set to GMT at factory. When unit is interrogated using data download package. The time

associated with data points will be automatically adjusted to the time zone set on the computer operating

system (Microsoft windows). Whenever a previously saved data file is opened the times are not adjusted.

If the instrument clock time is incorrect for any reason, it can be reset using the data download software.

Note that the time is set with reference to the clock on the computer; this must be correct before the clock in

the instrument is set. See Data download software for further instructions.

Flux 4-20mA output range

The Flux 4-20mA range default is 4mA = 0 pl/cm2/s and 20 mA = 2400 pl/cm2/s. This may be change to 20

mA being from 1 pl/cm2/s to 2400 pl/cm2/s using the “Flux 4-20 mA range” calibration option in the

“instrument” menu of the DDP. The Flux range is variable so that it may be optimised for the corrosion

application. Please refer to the applications manual or contact Ion Science for assistance.

Operation

One switched on the Hydrsoteel will operate continuously. Every 10 minutes the HY7K will data log and

output over 4-20 mA loops new readings.

As users you may decide for a full integrated system where the 4-20 mA data is collected by a data collection

system (DCS) and is available immediately for daily use in optimising a process. Alternatively the data log

may be relied upon to collect the data. The data would then be analysed periodically in conjunction other

corrosion and process data. The analysis and use of data is outside the scope of this manual. Please refer to

the Hydrosteel applications manual or contact Ion Science Ltd for technical support.

To download data the Data Download Program is needed. This is software that should be installed on a

portable PC so that it may be connected to the HY7K using an RS232 cable, (and if necessary USB adapter

supplied). The section below details the operation of the Software. The Hydrosteel has a number of internal

diagnostics. If one of these detects a fault then it will be displayed as a red LED on the outside of the

instrument, output on the 4-20 mA and saved in the data log. See maintenance section for full details.

Page 32 of 43

Page 33

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000 PC software

The PC software is designed solely to allow the download and viewing of data recorded using the Hydrosteel

7000 unit. Once downloaded data files may then be stored on any computer system and opened for review

as needed. The data is displayed in two formats; graphically and as a table of data entries with each row

being the data recorded for a given measurement cycle.

The software follows a standard windows format for main functions and is therefore self-explanatory for

common operations such as open file, save file etc.

Installation of Hydrosteel Software

PC Requirements

Hydrosteel Software must be used in conjunction with a PC/laptop using Microsoft Windows 98 or later.

First remove any older version of “7K PC software” if they are installed. This is done using “Add / remove

programs” option in the Microsoft windows control panel. Select 7K PC from the list and click on the remove

button. Note in “Add / remove programs” it may be necessary to pan to the bottom of the list using the scroll

bar to find the 7K PC listing. This is because Microsoft has a large number of blanked out entries in the

middle that look like the list has ended when in fact they are just hidden.

1. Double click the file called “7K PC setup.exe” located on the Ion Science software CD

2. Follow the on screen prompts saving the software in a drive of your choice (typically your C drive).

3. Click on the 7K PC icon in the ISL directory to start the software. This is found in the Microsoft start “all

programs” menu.

On start-up of 7K PC software a quick start menu appears with the most likely initial commands, Open file,

Connect to Instrument, Settings and Close.

Open file - Allows a file previously saved to the PC memory to be viewed.

Connect to Instrument – connects to the Hydrosteel 7000 for data download.

Settings – enables the user to select the coms port for connection to the instrument or search for a

Hydrosteel 7000 instrument connected to one of the coms ports.

Setup of USB to RS232 coms port

If the Lap –top or PC does not have a dedicated coms port then the USB to RS232 coms port adapter

supplied with the Hydrosteel kit should be used. Follow the instructions with this item to load the drivers and

set up the operation.

Connecting to the Hydrosteel 7000

1. Connect modem cable from PC coms port to Hydrosteel 7000 coms port. Make sure the instrument is

switched on.

2. Start the 7K PC software and select settings. Note if the USB adaptor is used and is attached before PC

switch on, then the Software will not be able to open the PC coms port. Simply disconnect and reconnect

the USB adaptor to make things operational and continue with the instructions below.

3. Select “Search for instrument”. The PC software will pole the existing com ports in ascending order to

find which port the Hydrosteel is attached to. Once the instrument has been found select OK to continue.

(If the instrument is not found check the power and connections to the HY7K and if necessary use

another coms port).

4. Select “connect to instrument” A window will appear as the software attempts to communicate to the

Hydrosteel 7000. The top box will confirm the instrument status if the connection has been correctly

made. If the communication fails an error message will be displayed “error failed to get data”. See Fault

Finding, under ‘Operation’.

Page 33 of 43

Page 34

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000 PC software

The Connect to instrument window

Instrument status - reflects the diagnostic situation of the instrument

Current status and Historic status confirm the current operation and flag if a diagnostic fail has occurred in

past operation (since switch on or last data download) respectively. See Diagnostics, under ‘Operation’.

Instrument Details – gives the following information on the instrument

Instrument serial number

Instrument firmware version

Clock (This is the current date time stamp from the instrument Clock)

Data of first stored record

Last calibration date

Download options

Download data from – this accept a date time to short the download.

Download data

Download calibration – This is for ISL servicing of instruments

Memory dump – This is a last resort option if the memory has become corrupted

Downloading data

Each Hydrosteel 7000 has its own unique serial number. This number is printed on the front of the unit and

contained in the unit software. All data downloaded from an instrument is stamped with this serial number.

This allows data from multiple units to be distinguished. The serial number is displayed at the top of the

graph and data table, and also saved to the top of a “*CSV” export file.

Data download

1. To download the data press download button. There is an option to download data only from a specific

date. This might be the date of the last data download. A status bar will appear while the data downloads

if the memory is full (1year +) this will take some time.

2. One the data has downloaded it will be displayed as graph and table.

3. Save the data as required

Erasing logged data

Once the data has been downloaded and saved we recommend that the logged data is erased. This will

minimise the data download time and prevent multiple files having the same data.

Graph operation

The graph automatically plots the flux data. For graph options use the graph drop down menu on the tool

bar or right click with the mouse on the graph. Option include different data plots, horizontal and vertical

gridlines or liner/stair-step interpolation.

A data point can be selected by clicking on graph with the mouse. The corresponding data point in the table

will be highlighted blue.

A region of data points can be selected by clicking and dragging on the graph again the data points will be

highlighted blue on the graph and table.

Zoom in

To zoom in select "zoom in" icon (Magnifying glass with a doted box), point the mouse pointer at a corner of

the area to zoom in on, click the left mouse button, and drag a zoom box over the required area then left

mouse click again. The graph will zoom in on the boxed region. You may zoom in repeatedly as needed.

Page 34 of 43

Page 35

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000 PC software

Zoom out

Use the magnifying glass icon with the minus sign in the middle to zoom out to view complete data set.

Use the magnifying glass icon with the undo arrow to return to the last zoom section.

Status bar

The status bar at the bottom of the graph above the table will indicate Green for correct operation yellow for

off and red if there was a diagnostic fault detected with the instrument reading. Data displayed in red

indicates a diagnostic flag see diagnostics section on under ‘Operation’.

Data table operation

The table shows the data in chronological order with the first data point at the top of the table. Use the scroll

bar (quickest) or up down arrows to navigate up or down the table. A data point may also be selected with

the mouse. The selected data point will be high lighted on the graph as a fine vertical dashed line. A region

of data points may be selected using the arrow keys and holding down the shift key the data selected will be

highlighted blue on the graph and the table.

As a default the table shows the following columns of data:

Date time,

Flux,

Pipe temperature,

Diagnostic flag.

The diagnostic flag will indicate the status of the instrument at the time of the measurement. It there was a

fault it will be stated see diagnostics section for details.

The table may be expanded to show the complete set of readings logged during a measurement cycle by

using the expand/shrink table in the windows drop down menu or the expand shrink icon on the tool bar.

These are listed below:

Date time,

Flux,

Valid - Logged data point check sum valid

Supply - Supply voltage at the instrument

Internal temperature

Pipe temperature

Pump voltage

Pump current

Flow

Background - Hydrogen background reading

Variance

Zero - Hydrogen sensor zero reading

SR - Hydrogen sensor impedance diagnostic SR pins

RC - Hydrogen sensor impedance diagnostic RC pins

SC - Hydrogen sensor impedance diagnostic SC pins

Diagnostic flag

Data handling

The software can create two file types “*.HY7”, and “*.CSV”. The “*.HY7” is specific to the HY7K PC

package, and cannot be opened by another software package. The package is not designed to edit the data

or provide any processing functionality. The “*.CSV” file can be imported into spreadsheet packages such as

Microsoft Excel for editing and performing detailed analysis. In addition to the basic operations of open, save

and export, the user can save file sections to a new file and merge files together.

Page 35 of 43

Page 36

Hydrosteel 7000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 7000 PC software

Save section

A specific episode of flux in data can be saved on its own. To save a section, highlight the section on the

graph with the mouse, then select the “Save Section As” option from the file menu. A save data as dialogue

box will appear and ask for a file name and location to save the file.

Merging files

This enables new data to be added to existing files so that a continuous data record is created. Files may

only be merged if they do not contain any overlapping data and are from the same instrument. To merge two

files, open a file and then select merge from the drop down file menu. This will prompt your to select the

second file to merge.

Print options

There are options to print and print preview the displayed graph, table or table section. The graph area

printed will be that on display at the time of printing. Should a particular section be desired for printing then

the zoom and pan functions should be used to select this as the displayed graph area.

As the Hydrosteel is capable of storing large numbers of data points caution should be exercised when

deciding to pint table data as it could run to a very large number of pages. It is possible to print a limited

section of the table. Simply use the curser to highlight a section of the graph in blue which will select the

corresponding table data points. Alternatively select the table data points using the curser arrows. Print table

section will print this section only.

Instrument Settings

There are the following instrument settings that may be accessed using the 7K PC software:

Set Clock

The clock is set to Greenwich Mean Time (GMT) at factory.

When unit is interrogated using data download package, the time associated with data points will be

automatically adjusted to the time zone set on the computer operating system (Microsoft Windows).

Whenever a previously saved data file is opened the times are not adjusted.

The clock can be changed by selecting the “Set Clock/Erase Data” option from the “instrument” pull down

menu and choosing the appropriate option. Note the time is set with reference to the clock on the computer

so this must be correct before the clock in the instrument is set. In changing the instrument clock time all the

data in the memory will be erased to maintain data integrity.

Erase logged Data

If the instrument memory is full, data is stored on a scrolling basis. Use the ‘Erase data’ option only in order

to delete all data from the instrument memory.

Flux 4-20mA Range menu

This menu enables the Flux 4-20 mA output range to be changed. It is necessary for the instrument to be

connected for this operation. Simply connect the RS232 cable activate the “flux 4-20 mA range” window and

follow the on screen prompts.

Firmware Upgrade

This enables the instrument firmware to be upgraded for improved operation. Simply connect the RS232