Page 1

Unrivalled Detection. www.ionscience.com

Hydrosteel 6000

Instrument User Manual V2.2

Part number: 40010

Page 2

Register your instrument online for extended warranty

Thank you for purchasing your Ion Science product.

The standard warranty of your instrument can be extended to up to five years

on Tiger and two years on other Ion Science instruments.

To receive your extended warranty, you must register your instrument online

within one month of purchase (terms and conditions apply.)

Visit www.ionscience.com/instrument-registration

Part number: 40010

Page 3

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Declaration of conformity

Manufacturer: Ion Science Ltd, The Way, Fowlmere, Cambridge, England. SG8 7UJ

Product: Hydrosteel 6000

Product description: the ultimate portable monitoring tool for sour, HF and high temperature corrosion and

diffusible hydrogen damage in steel. The intrinsically safe instrument is totally non-intrusive and with minimal

test surface preparation, and no consumables such as grease required, reliable measurements can be made

within a minute.

Marking: ll 2 G Baseefa 02ATEX0093 Ex ia IIC T4 -20C Ta +60C

Ref Baseefa Cert Report 05©0007, 07©0772

Baseefa Certificate number Baseefa02ATEX0093 Issued 28 of August 2008

Notified body: ATEX: Baseefa 2001 Ltd, Rockhead Business Park, Staden Lane, Buxton, Derbyshire,

SK17 9RZ

Notified body No: EC 1180

Directives: 94/9/EC ATEX 100A

89/336/EC EMC

Standards: BS EN 13908:2002 ATEX – Application of quality systems

BS EN 50014:1998 ATEX - general requirements

BS EN 50020:2002 ATEX – Intrinsic safety “i”

BS EN 61010-1:2010 Safety requirements for measurement, control & lab equipment use

BS EN ISO 9001:2008 Quality management systems

BS EN 61326-1:1997 EMC – Equipment for measurement, control and laboratory

I the undersigned hereby declare that the equipment specified above conforms to the stated Directives and

Standards.

Signed By:

Name: Mark Stockdale,

Position: Technical Director

Date: 23rd April 2007

Safety: This intrinsic safety rating permits its deployment in all potentially explosive atmospheres of the

quoted (or less demanding) rating. That is, in areas where explosive gases (of Group IIA, IIB and IIC) are

intermittently present (Zone 1); within an ambient temperature range of -20C and +60C.

Hydrosteel complies with the requirements of 73/23 EEC low voltage directive and, apart from a low voltage

pump, there are no moving parts within the instrument so that the machinery directives are not applicable.

Page 3 of 39

Page 4

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Contents

Declaration of Conformity............................................................................................................................... 3

Statements ....................................................................................................................................................... 5

Responsibility for Use .................................................................................................................................... 5

Legal Notice ................................................................................................................................................... 5

Contents of the Hydrosteel 6000 Complete Kit ............................................................................................ 6

About Hydrosteel 6000 .................................................................................................................................... 7

Principle of Operation ..................................................................................................................................... 7

Application specific measurements ................................................................................................................ 7

About Hydrosteel 6000 .................................................................................................................................... 8

Deployment Methods ..................................................................................................................................... 8

Calibration Check Facility............................................................................................................................... 8

Initial Appraisal ............................................................................................................................................... 9

System Assembly and Start-up ...................................................................................................................... 9

Using Hydrosteel 6000 .................................................................................................................................. 10

Analyser Operation Menu ............................................................................................................................ 13

Analyser display ........................................................................................................................................... 14

Guide to Field Measurements ...................................................................................................................... 16

Data Logging and Computer Interface ........................................................................................................ 19

Using the Data logging Facility .................................................................................................................... 19

Data Logging and Computer Interface ........................................................................................................ 23

Routine Maintenance ..................................................................................................................................... 26

Checking system performance .................................................................................................................... 26

Hydrosteel function test instructions .......................................................................................................... 27

Flow test ....................................................................................................................................................... 27

Hydrogen gas test ........................................................................................................................................ 28

Battery Replacement .................................................................................................................................... 32

Probe plate Replacement............................................................................................................................. 32

Cleaning ....................................................................................................................................................... 33

Instrument Warranty and Service ................................................................................................................ 34

Warranty ....................................................................................................................................................... 34

Service ......................................................................................................................................................... 34

Contact details ............................................................................................................................................. 34

Appendix A ..................................................................................................................................................... 35

Appendix B ..................................................................................................................................................... 37

Update Log ..................................................................................................................................................... 39

Page 4 of 39

Page 5

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Statements

Responsibility for Use

Inadequate performance of the gas detection equipment described in this manual may not necessarily be

self-evident and consequently equipment must be regularly inspected and maintained. Ion Science

recommends that personnel responsible for equipment use institute a regime of regular checks to ensure it

performs within calibration limits, and that a record be maintained which logs calibration check data. The

equipment should be used in accordance with this manual, and in compliance with local safety standards.

Legal Notice

Whilst every attempt is made to ensure the accuracy of the information contained in this manual, Ion Science

accepts no liability for errors or omissions, or any consequences deriving from the use of information

contained herein. It is provided "as is" and without any representation, term, condition or warranty of any

kind, either express or implied. To the extent permitted by law, Ion Science shall not be liable to any person

or entity for any loss or damage which may arise from the use of this manual. We reserve the right at any

time and without any notice to remove, amend or vary any of the content which appears herein.

Page 5 of 39

Page 6

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Hydrosteel 6000

Peli field case

Extension poles and

swivel joint

2 replacement LT-R

plates

LT-R 6 ft

LT-R Probe

LT-R 2 ft sample conduit

Very HT-R

extension

6 replacement

HT-R plates

Manual and

software CD

HT-R

probe

HT-R sample

conduit

Mains

adaptor

IR Link

Battery Key

Battery

Pack

HT-R

HT-R conduit spanner

small (2)

HT-R

Contents of the Hydrosteel 6000 complete kit

sample

conduit

Introduction to TVOC

For installation requirements please refer to Installation and Technical Specification of this manual. Before

attempting an installation, please fully read and understand this user manual, and for hazardous area (IS)

installations please also refer to the TVOC Intrinsically safe certificate for further details.

The TVOC safety rating permits its deployment in all hazardous areas of the quoted (or less demanding)

rating. For detail please refer to the marking on your instrument (found on the front main label). As of 1st of

October units will be manufactured with two protection concepts applied by separate certifications. Intrinsic

safety (ia) and Non sparking (nA). All units manufactured up to that date will only have intrinsic safety.

a) Intrinsic Safety (ia) permits the deployment in areas where explosive gases (of group IIA, IIB and IIC) are

intermittently present (zone 1) with an ambient temp range of -20°C to 50°C. Intrinsically safe installations will

require the use of safety barriers and appropriate wiring.

b) Non sparking (nA) permits deployment in areas where explosive gases (of group IIA, IIB, IIC) are unlikely

but possible (Zone 2) with ambient temp range of -20°C to 50°C. Non sparking installations do not require

safety barriers however the maximum working voltage should be strictly adhered to as a matter of safety. As

no safety barriers are required there is complete flexibility on the implementation of 3 wire system.

TVOC does require regular calibration onsite please see the Calibration section for more information. TVOC

calibration mode is accessed via a magnetic read switch system.

plate

Key

analyser in leather

jacket

conduit

spanner

large

conduit

Page 6 of 39

Page 7

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

About Hydrosteel 6000

Principle of Operation

Collecting a hydrogen sample

Hydrosteel 6000 enables measurements to be made of gaseous hydrogen flux emanating from a steel

surface. The steel surface can be of variable curvature and surface condition.

To make the measurement, a stream of ambient air is drawn across the steel surface by a high performance

low-power-demand pump. This test-gas stream is confined within a specially designed ‘collector plate’

contained in the probe assembly which is attached to the steel surface. The probe assembly and collector

plates vary according to application. The probe types are listed with their features in Section – Application

specific measurements.

The collected hydrogen is conveyed through narrow bore tubing, into the measurement analyser, and across

the face of a very sensitive amperometric detector.

Determining the level of the collected hydrogen

The zero hydrogen datum point for Hydrosteel 6000 measurement is the background hydrogen

concentration in air at sea level, namely 0.5 ppm1. Rapid diffusion, and hence rapid dispersion of hydrogen

in air, results in a very low and stable background prevailing in the ambient air of most environments, even

indoors. This condition enables the Hydrosteel 6000 to be used in measuring a very small flux of hydrogen

emanating from steel as a result of its interaction with hydrogen occluders and hydrogen occluding

processes. The integrity of the measured data is circumscribed by drift in the ambient air hydrogen content,

and this drift is usually very low.

The flow of the test-gas stream F across the steel surface is carefully regulated by means of restrictions, and

a flow bypass, between the pump and the detector to ensure that it remains smooth and constant. An

additional feature of the flow bypass is to ensure that in the event of a probe blockage, the pump is not

working against a negative pressure differential. Flow regulation is particularly important as the flux J of

hydrogen emanating from the steel is given by:

J = c x F / A

where A is the effective area over which hydrogen is captured, and c the enhanced hydrogen concentration

resulting from hydrogen entrainment.

Output from the amperometric sensor is an electric current, which is proportional to the concentration of

hydrogen presented to it. This current is amplified and scaled for display, and logging, as a hydrogen flux.

To summarise, the prowess of Hydrosteel 6000 technology stems from capturing the hydrogen flux from a

well-defined area of steel surface in a known flow of air, and measuring the very small enhancement in

hydrogen concentration entrained in the air stream. By this means, the very small hydrogen flux commonly

emanating from steel can be quantitatively measured, easily, rapidly and reliably.

Application specific measurements

Hydrosteel can be used to locate, map, and monitor hydrogen flux as detailed in Section – Deployment

Methods on the next page. Hydrosteel engages interchangeable probes to enable attachment to steel of

diameter greater than 2 in., 5 cm, and surface temperatures from -40 to +500 ºC, -40 to 930 ºF. The

interchangeable probes are classified as follows:

LT-R: Low Temperature – Roaming Probe

This probe utilises a collector plate 6 in., 15 cm across to deliver the maximum sensitivity, and is

magnetically attached to steel of 3.5 in., 9 cm diameter or greater, of surface temperatures up to 130 oC, 265

o

F for short periods (quick spot measurements only), and 110 oC, 230 oF for general use (for extended

periods please consider use of AT-S probe). To ensure efficient hydrogen capture in wet or windy conditions,

the LT-R probe incorporates a flexible seal around its perimeter.

Page 7 of 39

Page 8

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

About Hydrosteel 6000

HT-R: High Temperature – Roaming Probe

This utilises a small collector plate to give the instrument the maximum dynamic range commonly required

with hot steel for which hydrogen permeation is enhanced. The roaming probe is magnetically attachable to

steel of at least 8 in., 20 cm diameter, and has an operating temperature range extending to 500 oC, 930 oF.

The probe is sufficiently small to access steel through standard inspection ports.

AT-S: All Temperature – Stationary Probe

This probe is 6 inches in diameter and designed to be semi-permanently attached to a steel surface, down to

2 inches in diameter, for frequent monitoring at the same site. The probe can be attached to steel at

temperatures up to 500 C, 930 F.

HT-S: High Temperature – Stationary Probe

This small collector is designed for semi-permanent attachment to pipe bends and other curved areas, where

corrosion can be significant, and steel pipes with a diameter as small as 1.5 in., 4 cm, at temperatures up to

500 oC, 930 oF.

Notes: When changing probe you should re-programme the instrument during start-up, as described in

Section – System Assembly and Start-up. Maintenance and replacement of the probes is described in

Section – Probe Plate Replacement.

Deployment Methods

Hydrosteel 6000 can be deployed to meet several different objectives as described below.

Hydrogen flux search

The Hydrosteel analyser has a real time display of flux which can be used to search for sites of hydrogen

permeation. Since the analyser commences measurement at the time of attachment to a surface, and a 50%

response is achieved in approximately 20 seconds, prospective hydrogen permeation at a given site can be

established within this time. An extension arm can be used to deploy the collector to a surface some 6 ft (2

m) beyond normal reach.

Spot measurements

Once a site of interest has been located, the hydrogen flux can be measured within a period of one minute. It

may be convenient to log the measurement using the handheld Hydrosteel ‘short log’ facility. Whilst waiting

for the measurements to be logged, the handheld analyser can be attached to the steel pipe under test using

its magnetic leather case. This procedure allows you to make notes or demarcate the site for re-testing in

the future.

Continuous monitoring

A site can be monitored for up to the lifetime of the batteries using the Hydrosteel ‘long log’ facility (see

Section – Using the Data Logging Facility). Logging can be extended indefinitely using external power (see

Section – Using an External Power Supply).

Zone Programming

When performing the above measurements data can be logged with respect zone or area of test. Available

to the user are 199 zones that act as memory tags for saved logs. Each zone can be named with a 64character header.

Calibration Check Facility

Hydrosteel is calibrated in-house, but the equipment is offered with a function test facility to enable you to

check that your equipment is performing within specification. Please refer to Section – Checking System

Performance for the check procedure.

Page 8 of 39

Page 9

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

WARNING

The analyser batteries must be alkaline-type AAsize. Using any other type of battery will

invalidate the Intrinsic Safety approval.

Use the special key to

open/close the battery

compartment

Using Hydrosteel 6000

Initial Appraisal

A number of accessories accompany the Hydrosteel 6000 Analysis Kit. When you first receive your Analysis

Kit, we suggest that you check the items received against the Packing List. If any item is damaged or

missing, notify your supplier, stating the serial number stamped on the rear of the handheld analyser,

together with your order number and the supplier’s invoice number. Familiarise yourself with the components

of the Hydrosteel 6000 Analysis Kit by going to the ‘Contents of the Hydrosteel 6000 Complete Kit’.

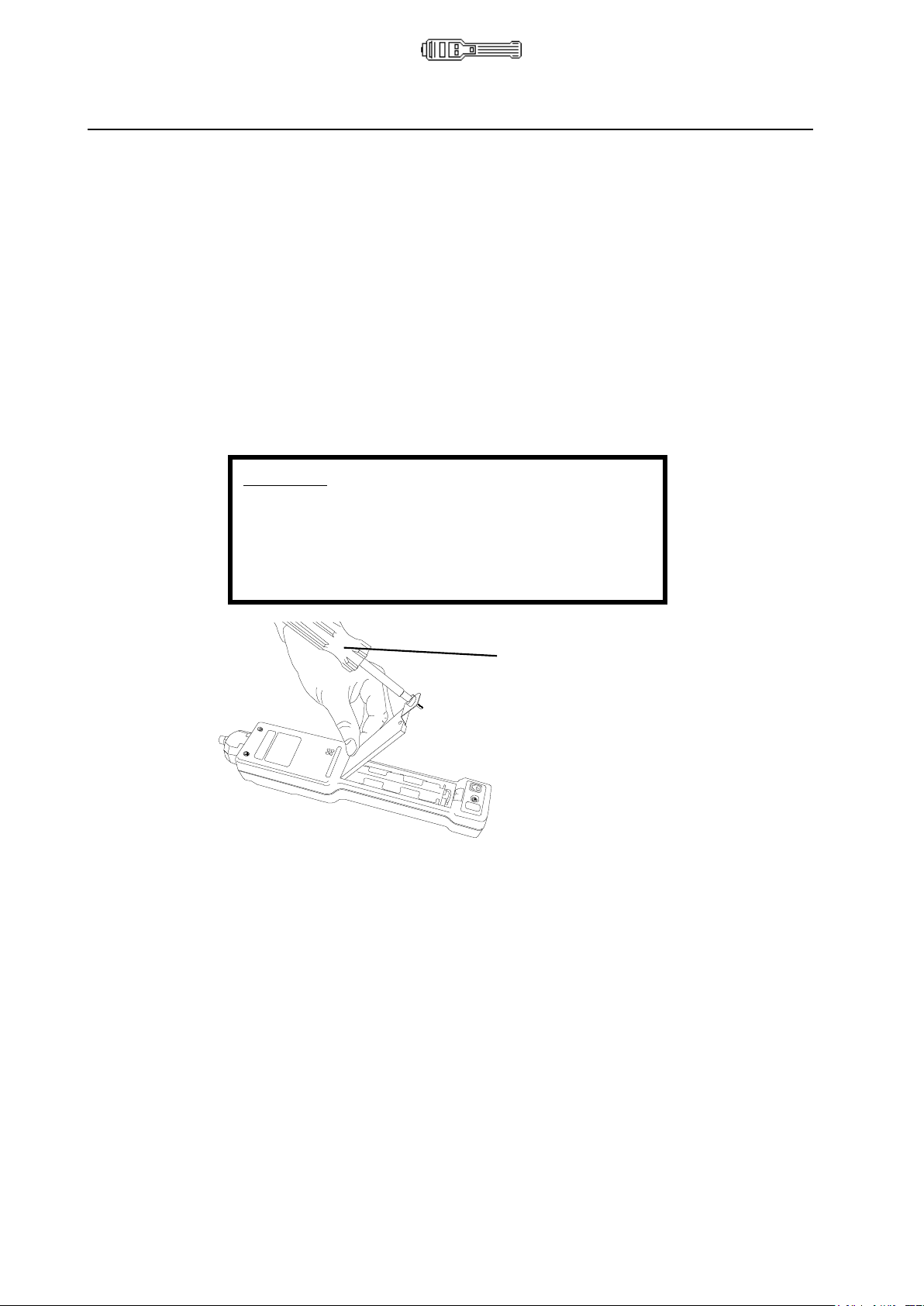

System Assembly and Start-up

Normalising the analyser

1 Remove the analyser from the field case.

2 Remove the leather outer case.

3 Using the special key provided, open the battery compartment (at the rear of the analyser) and insert

the four batteries complete with their holder (supplied) – see the diagram below.

Close and lock the battery compartment.

4 Refit the leather outer case. Press the on/off key (I/O), which is located on the analyser front panel.

5 A countdown shows the time remaining, and a red LED flashes. The detector is then normalised,

and a hydrogen flux measurement of (default units of pl/cm2/s) is displayed.

6 Your Hydrosteel 6000 analyser is now operational.

7 When not required for immediate use, switch off the analyser by pressing the on/off key (I/O). The

analyser takes a few seconds to shut down, during which time you can abort the switch-off by again

pressing the I/O key.

Page 9 of 39

Page 10

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Using Hydrosteel 6000

Connecting the low temperature (LT-R) probe to the analyser

1 Attach one end of either the 70 cm or 200 cm gas sample tubes to the connector at the top of the

analyser as shown below. Tighten finger tight. Note: we recommend that you use the shorter of the

two sample tubes. However, if you require the extension arms, you may find it necessary to use the

longer (200cm) sample tube.

2 Attach the other end of the sample tube to the LT-R probe. Tighten finger tight.

3 If required for extended use, attach one or both of the extension arms to collector assembly, as on the

next page.

Page 10 of 39

Page 11

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Probe plate

locking screw

Collector

handle

HT-R gas sample

tube

Probe plate

locking screw

HT-R gas sample

tube

Collector

handle

Collector

handle

Probe bracket

HT-R gas

sample tube

Using Hydrosteel 6000

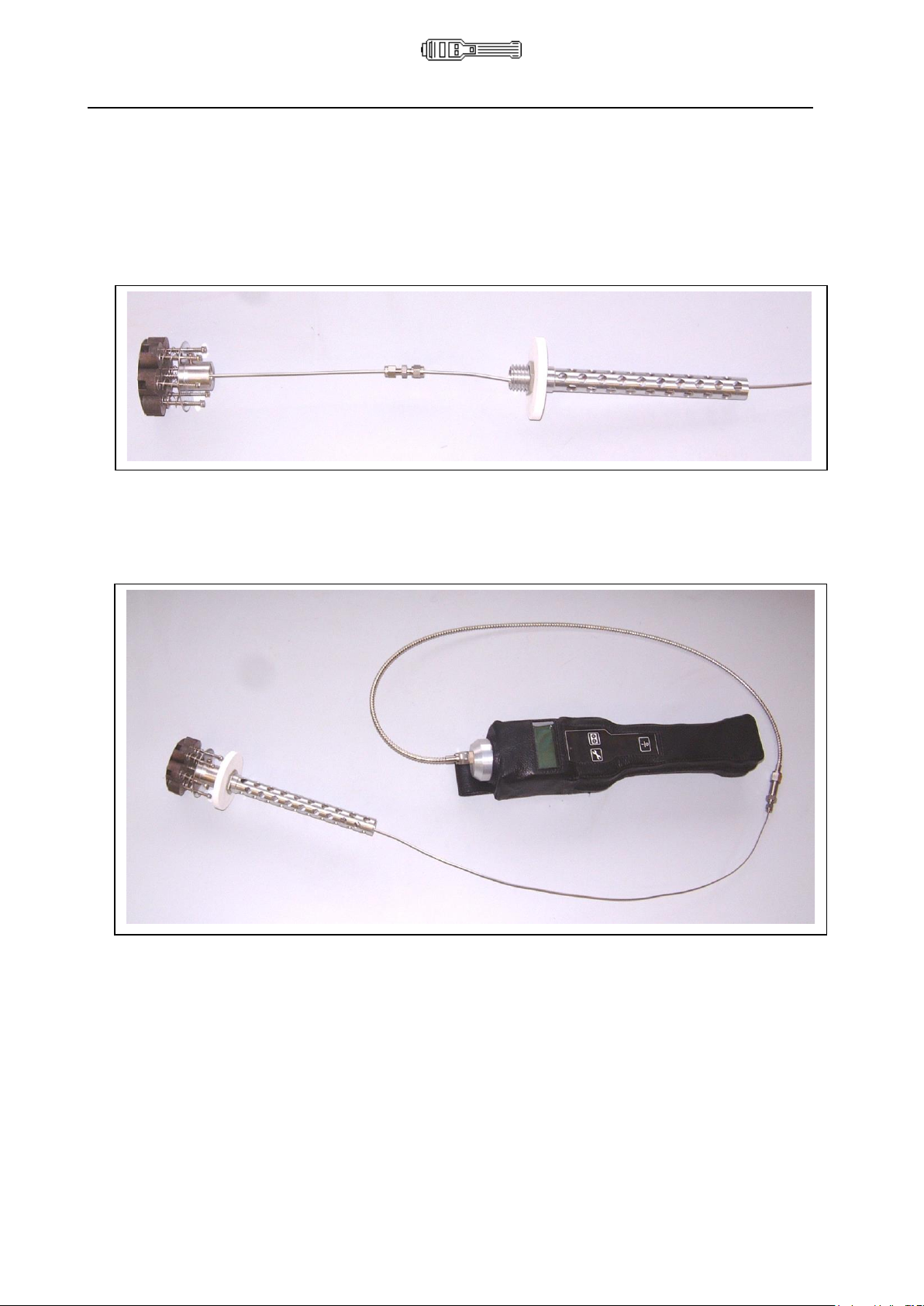

Connecting the high temperature roaming (HT-R) probe to the analyser using HT-R flexible conduit

1 Remove HT-R collector assembly from the box and remove the magnet sleepers.

2 Manually unscrew the collector handle from the assembly. (The handle unscrews below the white heat

shield).

3 Insert the HT-R 2ft flexible conduit assembly (A-41019) through the handle as shown below. Tighten the

nut onto the collector plate until it is finger tight. Screw into place the HT-R handle.

Page 11 of 39

Page 12

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Using Hydrosteel 6000

Connecting the High Temperature roaming (HT-R) probe to the analyser using HT-R very HT extension

conduit.

1 Remove HT-R collector assembly from the box and remove the magnet sleepers.

2 Manually unscrew the collector handle from the assembly. (The handle unscrews below the white heat

shield).

3 Insert the HT-R very HT extension conduit assembly (A-41017) through the handle as shown below.

Tighten the nut onto the collector plate until it is finger tight. Screw into place the HT-R handle.

4 The HT-R very HT extension conduit assembly is connected to the analyser using the HT-R 2ft flexible

conduit assembly (A-41019) as shown below.

Page 12 of 39

Page 13

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Key

Start-up mode

Operating mode

S

adjust time, flux units, probe,

temperature scale

select zone, check calibration

D

handle data log

log data

O

turn off / zero

turn off / zero

Ex

Ex

Ex98E2316

Eex ia IIC T4

-20 C<Ta< 60 C

Hydrosteel

S D O

Using Hydrosteel 6000

Before proceeding further, ensure that you are familiar with the user recommendations and the analyser

menu structure described below.

User recommendations

Hydrosteel 6000 is a robust unit with electrical and pneumatic design features to ensure that accidental

misuse does not represent a threat to the user or to the sensitive system components. However, we

recommend that you:

* consult this manual or the service team at Ion Science when you are unsure of how to proceed.

* avoid exposing any part of the system to corrosive media or liquids.

* avoid exposing the system components to ambient temperatures that exceed 50 oC for more than a

few hours.

* when not in use, store all the system components and equipment in a cool dry place.

Analyser Operation Menu

Three front-panel keys

On the analyser front panel, the three keys

S (Spanner),

D (Data) and

O (On/Off)

have dual functions, according to

whether the analyser is in:

‘start-up mode’, for 90 s normalisation after the analyser is switched

on, or…

‘operating mode’, after normalisation.

The key options available are shown on the analyser display. After completing a function, the analyser

returns to start-up mode or operating mode, as appropriate. For example, in start-up mode, you can divert to

reset the clock because of a change to Summer Time and, on completion of this function, the analyser

automatically completes the normalising procedure.

For reference, a complete list of the key sequences, together with countdowns and available interrupt keys is

provided in Appendix B.

Page 13 of 39

Page 14

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

5 pl/cm

2

/s

24oC

LT

Probe indicator

Battery life

indicator

Temperature

indicator

Flux measurement

Using Hydrosteel 6000

Analyser display

As part of the start-up procedure, the analyser sequentially displays the instrument name, manufacturer, data

log details and calibration details. Thereafter a countdown is displayed until normalisation of the analyser is

complete. Note: If the analyser has been used recently, the normalisation countdown can be reduced by

pressing the O key twice.

After normalisation, three measurements are displayed, as described below.

Hydrogen flux

In normal operating mode the analyser display indicates measured hydrogen flux, or flow per unit area,

collected from a surface, in units of ‘pl/cm

The flux units are corrected for standard temperature and pressure. That is, 1 pl/cm2/s = 10

hydrogen at a pressure of one atmosphere, (760 mm Hg, 1014 mbar), and 20 oC, emanating from each

square centimetre of surface per second. Flux measurements exceeding 1000 pl/cm2/s are displayed in units

of nl/cm2/s to two decimal places (1000 pl/cm2/s = 1 nl/cm2/s).

When the collector is not attached to a steel surface, a flux continues to be displayed in order to give a clear

indication of any background drift, which may affect the integrity of subsequent measurements.

Battery level indication

At the base of the display a battery icon is indicated together with the temperature in degrees Centigrade. As

the battery becomes exhausted the battery icon progressively empties, until the icon is shown in outline only

and, subsequently, it flashes.

When the battery symbol is flashing, data logging may not be possible and, although the system is still

functional, quantitative measurements of hydrogen flux are not recommended.

Temperature indication

Located at the bottom right of the display, the indicated temperature measurement is one taken from inside

the analyser, near the hydrogen sensor. During temperature changes, the displayed measurement flashes,

indicating that you can expect some temporary background signal drift as the detector re-adjusts to the

change in temperature. If you are experiencing temperature changes to the unit during operation it is highly

recommended that you use the thermally insulating leather jacket.

2

/s’ or ‘nm/s’.

-12

litres of

Page 14 of 39

Page 15

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

LT

LT-R (low temperature roaming)

HT

HT-R (high temperature roaming)

(blank)

ambient hydrogen measurement

(probe independent)

WARNING

If the Hydrosteel analyser is to be used in an intrinsically safe zone, any

external power supply must have appropriate safety certification.

Using Hydrosteel 6000

Probe indication

To the left of the battery icon the display one of the following, denoting the probe in use. Ensure at all times

that the probe in use and probe indicator correspond. If not, reconfigure the analyser to indicate the correct

probe from the analyser start up menu, as indicated in Appendix B. The probe indicator should correspond

to the probe in use as follows:

Using an External Power Supply

To extend the continuous operation time of the analyser, particularly for long term monitoring applications, an

external power supply can be used.

For satisfactory operation, the analyser requires a 6 V dc regulated power supply, capable of delivering 200

mA minimum.

Note: It is important to ensure that the centre pin of the connector is positive with respect to the shroud.

Failure to provide this connection may cause damage to the analyser circuitry.

Page 15 of 39

Page 16

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Guide to field measurements

Step 1: Preparing the equipment for flux measurements.

Open the field case. Connect the hand held analyser to either the 6” diameter LT probe in the field case or

the HT probe in the HT-probe kit box, using the appropriate gas sampling tube. This comprises essential test

equipment, it weighs 1 kg, and can be conveniently carried in a shoulder bag or small rucksack. Before

commencing a prolonged series of spot measurements, or extended monitoring at one particular site, ensure

sufficient battery power is indicated by a full battery indicator on the analyser display. If necessary replace

batteries using the battery tray key.

Step 2: Confirming suitability of ambient conditions. Turn on the analyser (I/O key) in the open air at

least 10 m from any source of hydrogen. If you are using a different probe than previously, reconfigure the

analyser during the normalisation countdown (see Appendix B for menu) to indicate the correct probe (LT low temperature or HT – high temperature). The analyser’s internal temperature will be indicated on the

display panel. A flashing reading indicates that the analyser is experiencing an abrupt change in

temperature, in which case allow several minutes for the flashing to subside. It is highly recommended to

use the thermally insulating leather jacket to reduce the effect of abrupt temperature changes. Abrupt

temperature changes may occur for many reasons. Most common are moving from a heated or air

conditioned environment to the cold or hot local conditions. Alternatively the radiant heat from hot pipes or

equipment may create a significant temperature change. When approaching hot pipes use the 2 meter high

temperature sample tube (in addition to the thermal jacket) this will allow the analyser to be shielded and

kept at a greater distance from the hot test area. Connect the appropriate probe.

After the countdown the analyser will display a reading of less than 5 pl/cm2/s with the LT probe and 0.03

nl/cm2/s with the HT probe.

Approach the test site location of interest. The only gas liable to compromise dependable measurement of

hydrogen flux is hydrogen itself, for example within a few metres of hydrogen leaking from a flange. This will

be registered on the analyser display and in the analyser’s memory, enabling confidence in the logged

measurements to be calculated when data is downloaded to a PC.

Step 3: Steel test surface site selection and preparation.

With the LT-R (6 inch diameter low temperature) probe:

7 inch diameter test surface sites should be identified on mild steel vessels or piping of 3.5 inches diameter

or greater, and of surface temperature of less than150 oC, 300 oF. Locate sites which are smooth,

particularly avoiding ridges or grooves.

Remove dust, loose rust and liquids and disbonded paint work from the site. Disbonded paint is usually

evident from flaky or cracked paint in the locale of the target site, and should be completely removed.

With the HT-R (2.3 inch diameter high temperature) probe:

3 inch diameter test sites should be identified on carbon or low alloy steel vessels or piping of 8 inches

diameter or greater, and of surface temperature of less than 500 oC, 930 oF. For tests through inspection

ports, ensure that there is a clear pathway

through the port to the steel surface, so that when the probe is inserted, it engages fully with a 3 inch

diameter surface of steel, without the intervention of insulation wool. Ensure that the test surface is

completely free of any layers of rust.

Step 4: Data handling. If required, access the test site zone menu and data logging menu by pressing the

keypad Data key.

Page 16 of 39

Page 17

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Guide to field measurements

Step 5: Deployment procedure.

With the LT-R (6 inch diameter low temperature) probe:

Ensure the probe plate underside is not damaged and is free from dust or magnetic detritus. Manipulate the

probe by using the probe handle or extension arms. Introduce it directly to the test site, ensuring that the

probe ‘ALIGNMENT’ indicator runs in the same direction as the pipe or axis of the vessel, as illustrated.

Confirm the probe’s flexible plate conforms snugly to the steel surface. On piping of less than 8 inches

diameter, use the strap provided. The strap should be drawn tight as shown below, so as to ensure the

probe plate is tight against the steel, when the hands are released.

With the HT-R (2.3 inch diameter high temperature) probe:

Introduce the probe directly to the steel surface. Any orientation of the probe is acceptable, but take

particular care with piping of less than 12 inches diameter to ensure the probe’s flexible plate is attached

snugly to the metal surface. Note: the high temperature magnets are attracted to steel less strongly than

conventional magnets: be particularly careful during measurements not to pull away the probe from the steel.

Step 6: During measurement and monitoring. The analyser - in its jacket - can also be secured

magnetically to any steel nearby at ambient temperature. A significant response should be evident within 2025 s of probe engagement, and flux measurement obtained within one minute. For spot measurements,

allow ‘remove probe’ to appear on the display before removing the probe. Extended monitoring is terminated

automatically on loss of sufficient battery power, or by operator intervention (RECORD key). Demarcate the

site as required during the test measurement.

Page 17 of 39

Page 18

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

WARNING

The HT-R probe and associated equipment includes a heat shield which partially

reduces the temperature of the collector handle. It does NOT enable handling of

the collector without gloves. ALWAYS wear suitable heat resistant gloves when

handling the high temperature collector

Guide to field measurements

Step 7: Completing the task. To download data to computer, remove the analyser from the jacket, activate

‘PC connect’ (TOOL-RECORD keys), align with the IRDA link box, and execute the file ISPLC.EXE. Make

sure test equipment is clean and dry, return to the field case, and store field case in a cool dry location.

Page 18 of 39

Page 19

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Memory bar

data log mode

and prompts

17 pl/cm

2

/s

60 s

24oC

LT

Data logging and computer interface

Using the Data logging Facility

Two data logging modes are available – ‘short’ and ‘long’.

‘Short’ data logging stores measurements over a one minute interval and is used for obtaining a spot flux

measurement at a specific site. In this mode, a record is obtained, not only of the analyser response, but also

of recent measurement stability. When the data is downloaded to computer the response of the analyser

due to attachment of the device is computed and displayed as a measurement together with the

measurement uncertainty due to any background hydrogen drift.

During ‘long’ data logging, measurements are first recorded every five seconds then at a reducing rate until

stopped manually, or by an analyser feature (memory overflow or battery empty).

During both forms of data logging, the data memory used is indicated by a memory bar extending across the

display from left to right. This memory bar blinks on each occasion that data is recorded. Appropriate log

prompts are indicated at the bottom of the display.

Short data logging

1 From normal operating mode, access ‘short’ data logging by pressing the D (data) key twice. While

attach probe is displayed, attach the probe to the target steel surface.

The memory bar flashes at one-second intervals.

2 Twelve 5-second time-averaged measurements are recorded, together with the date/time stamp,

analyser temperature, selected probe, and zone number and description.

3 When ‘short’ data logging is complete, remove probe will be displayed. Remove the probe from the

steel surface. The analyser reverts to normal operating mode automatically.

Making a single measurement

In order to make a single measurement, ‘short’ data logging can be abbreviated, as follows:

1 As above, from normal operating mode press the D key twice to enter ‘short’ data logging.

2 As soon as the memory bar appears (which signifies that one flux measurement has been recorded)

press the D key.

While the prompt to end log is displayed, press the D key again twice.

Long data logging

1 As above, from normal operating mode, access ‘short’ data logging by two D key presses.

2 Wait for the memory bar to be displayed.

3 Press the D key again once.

The prompt to end log is displayed and ‘long’ data logging has started.

4 Measurements are automatically recorded:

at five-second intervals for the first 10 minutes,

at one minute intervals for the next 120 minutes,

then every 10 minutes.

Page 19 of 39

Page 20

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Connect the serial ca-

ble betw een the IR

Link Box and y our PC

IR Link Box

Connect the

output of the 6V

supply to the back

of the IR Link

Box

Connect the serial

cable between the IR

Link Box and your PC

IR Link Box

Connect the output

of the 6V supply to

the back of the IR

Link Box

Data logging and computer interface

During each 10-minute period of ‘long’ data logging, the analyser enters a sleep cycle, during which

analyser functions such as the measurement circuitry, including the pump, are only active for about

90 s. During the sleep cycle, the prompt sleeping is displayed for the remainder of the 10 minute

period.

5 To exit data logging from ‘sleep’ mode, press the D key slowly, twice.

Communication between analyser and PC

Communication between the analyser and computer requires the use of the IR Link Box, Hydrosteel software

and Windows PC connect software ISLPC.EXE. The IR Link Box is provided with your Hydrosteel 6000

Analysis Kit as is the ISLPC software on floppy disk.

Communication between the instrument and a PC allows the following functions to be performed.

Downloading of logged data from the instrument to the PC for storage and analysis.

Erasing logged data.

Downloading or updating zone headers to instrument.

Checking instrument details, eg, serial number, logged memory used.

Displaying and recording flux measurements on PC in real time.

Re-programming analyser with a firmware upgrade.

Hardware requirements

ISLPC data interface software runs on a PC under Windows 95 (or later), or NT, for the processing of

saved data files.

Data downloading, interfacing and upgrading of an instrument requires the use of an IR link Box (supplied by

ISL) connected to the RS232 communications port of a (user supplied) PC.

The IR Link Box works with serial communications to your PC, running at 19200 baud, 8-bit data, no parity

and 1 stop bit.

About the IR Link Box

The IR Link Box enables serial communications to take place between the communications port on your PC

and the IR port on the Hydrosteel analyser. Ensure that no other program on your PC is using the serial

communications port when you want to transfer data from the Hydrosteel analyser.

Page 20 of 39

Page 21

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Position the data transfer port (at the rear of

the analy ser) against

the window of the IR

Position the data transfer

port (at the rear of the

analyser) against the

window of the IR

Data logging and computer interface

Connecting the IR Link Box

1 Connect the 6 V dc power supply (provided) to an ac supply.

2 Connect the output of the 6 V dc power supply to the back of the IR Link Box.

A red LED will blink regularly when the IR Link Box has power applied to it.

3 Connect the serial cable (provided) between the back of the IR Link Box and the serial connection

on your PC.

NB A USB to Serial (RS232) adaptor may be used if your PC or laptop no longer has an RS232 port.

Installing the ISL data interface software

Copy the complete ISL directory (Ion Science Ltd) from the disk provided onto your computers C: drive.

When using the software for the first time you will be required to select the appropriate communications

(serial) port that your IR Link box is connected to. To select a port enter the ISLPC software program and

click on the Settings tab.

Downloading Data from your Hydrosteel

1 Remove the Hydrosteel analyser’s leather jacket. Turn the analyser on. To enter normal

operation either allow mode (90 s countdown) or press the on/off key twice to zero the

instrument. Now press the Spanner, then the Data key. The instrument will display PC

connect.

2 Locate the infrared port at the rear of the Hydrosteel and then position this port at about 5cm

(2”) away from the data-transfer window of the IR LINK Box, ensuring that the IR port is

oriented downwards, ie, adjacent to the desk surface as shown below.

3 Ensure that no other program on your PC is using the serial communications (IR) port.

4 Within the ISL Directory on your PC, double click on the islpc.exe icon.

Page 21 of 39

Page 22

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Data logging and computer interface

1 If the message window ‘Connected to

Hydrosteel’ is displayed, Proceed to

step 7.

2 If the ‘Link Failed’ window is displayed,

check the Hardware as instructed,

using Retry as required.

To change the prescribed serial port,

click on OK, select Hydrosteel, and

from the ‘ISL Instrument Interface’

window menu bar, select Settings, Port. Click on

an alternative serial port (usually Com 1 or Com 2),

click ok, and close the ‘ISL instrument interface

menu’ panel. Return to step 4.

If problems persist, please contact the supplier or Ion Science Technical staff.

3 The ‘ISL Instrument Interface’ window is now displayed. From the menu bar, click on Data,

download. During data transfers, an additional LED in the IR_Link box will flash occasionally.

The progress in data downloading is displayed.

The Interface program will display other messages if there are problems. If the communication

with the analyser fails, the message window shown in step 6 will be displayed.

Data download display

Data files downloaded from an instrument are presented in three windows:

1/ Data file index, summary data is ordered sequentially according to zone, and then log file number. Spot

(60 s) measurement log files include a ‘computed flux’, with an associated uncertainty, based on the

response transient of the instrument and prevailing instrument drift (if any).

2/ Data file graphical analysis: flux transients corresponding to each data file are displayed. See also Section

– Data Logging and Computer Interface.

3/ Data file numerical data: detailed data for each recorded data log.

The horizontal menu bar at the top of the ‘ISL Data Interface’ window provides access to the main features

of the ISLPC Software. Depending on the displayed feature, abbreviated versions of these menus are

available by right-clicking the mouse.

Caution: Before closing the programme, from the Data sub-menu, ensure you either Save data downloaded

from the analyser, or export the data, for use in spreadsheets such as Microsoft Excel. More details on

specific menu options are given below.

Page 22 of 39

Page 23

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Data logging and computer interface

Graphical analysis of data

Setting the time and response scales

Choose Elapsed/Real time as required for time scale.

Choose Spread/Zero reference and Log/Linear scale required for the recorded response.

Using the cursor Right Click on the graphical analysis window to reveal the dropdown menu with the

following options:

Elapsed/Real time

No Markers

Cursor on/off

Log/Linear scale

Spread/Zero reference

Alarms on/off

Choose No Markers to remove all the crosses from the display.

Choose Cursor on and use mouse and a Left Click to position the cursor on the Graph. The data

(x,y) will be shown top right.

Page 23 of 39

Page 24

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Data logging and computer interface

Main ISLPC Menu Functions

File

Print

Print highlighted (Numerical or Graphical) data file via your PC.

Print Preview

Allows you to view the currently chosen data file for next print.

Print Set-up

Allows the characteristics of the printer that is connected to your PC to be selected.

Recent File

Allows access to recently used files.

Exit

Exit the ISL Data Interface Software application.

Data

Download Data

Reads measurement data from the ISL instrument.

Save, Save As

Saves highlighted (Numerical and Graphical) data to PC file, in an encrypted format (*.phd). This is

highly recommended to avoid having to download the same data again later, or to avoid losing data

later on.

There are 2 levels of protection used to stop changes to records: the first level is data encryption

and the second level is the watermark inserted by the islpc program into the encrypted data.

Open

Allows access to stored measurement data files. Refer to Section 4. The islpc program searches for

the file validity before opening data, and VALID will then be inserted into the header data of an open

file.

Close

Closed highlighted (Numerical or Graphical) window. Caution: Before closing the programme, from

the Data sub-menu, ensure you either Save data downloaded from the analyser, or export the data,

for use in spreadsheets such as Microsoft Excel.

Export

Saves highlighted data as a comma separated variable file, *.csv file, for external analysis using

standard spreadsheets, e.g. Excel. Please note *.csv files cannot be read by islpc.exe. The *.csv

file contains a summary of all data files, followed by data presented in chronological order.

Instrument

Download Data

Downloads measurement data from the ISL

instrument. Provides the same facility as the Data

menu.

Erase All Data

Erases all data stored in the ISL instrument.

Caution: Ensure that any relevant data has been

downloaded before using this option.

Clear Zone Headers

Clears the zone headers stored in the ISL instrument.

As a consequence, all stored data is also erased caution: ensure that any relevant data has been

downloaded before using this option.

Instrument Details

Reads details of the ISL instrument currently interrogated using the IR_Link. Serial Number, Log

Memory Used, Log Memory Free and the Instrument On-time are specified.

Page 24 of 39

Page 25

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Data logging and computer interface

Show Reading

Enables a real-time display of the instrument measurement to be shown on your PC. Close this

window to access any other.

Diagnostics

Allows instrument data to be downloaded prior to hardware fault finding. Click on Read Flash,

following instructions as they appear.

Firmware Upgrade

Downloads an ION SCIENCE ‘upgrade’ file (*.upg) to the analyser. A complete upgrade consisting 4

files usually lasts about 4 minutes.

Caution: Ensure that all relevant data has been downloaded and saved to PC before

using this option.

Zones

New

Allows you to create a set of zone headings. Enter up to 60 characters into each of the 199 zone

addresses. These can then be downloaded to Hydrosteel. Having created the headings, you can

also save them as type (*.zon) files on your PC for future use.

Open

Provides access to an existing set of zone headings, which can be upgraded and/or downloaded to

the analyser.

View

Toolbar

Normal Windows® feature.

Status Bar

Normal Windows® feature.

Window

Window provides the normal Windows® features, but is only available when data is displayed.

Settings

Port

Enables the correct PC port to be selected for the RS232 connection to the ISL instrument. Only

used if the port used has been altered or for first time installation of the IR_Link & ISLPC.

Help

Help Topics

Refer to this manual until the ISL Help software file is available.

About ISLPC

Version reference details for the ISL Data Interface Software.

Page 25 of 39

Page 26

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

Only authorised and qualified persons must handle the Hydrosteel analyser, using all normal safety

practices. Except for procedures described in this manual, the Hydrosteel analyser must be serviced by Ion

Science, according to a prevailing contractual agreement.

Please feel free to ring our customer services department or e-mail us at service@ionscience.com if

difficulties are encountered which have been inadequately covered by this manual.

Checking system performance

Normally, the HT-R and LT-R probe plates are only liable to damage and degradation after extensive use,

when attached to a steel surface having ridges or high spots. Damage will be evident from worn or crushed

grooves on the plate under-surface, and poor challenge test results. Replacement collector plates are

supplied and should be fitted as indicated in Section – Probe Plate Replacement.

All Hydrosteel equipment is factory calibrated. ION Science Ltd recommends the instrument and challenge

kit be calibrated yearly. To be assured of analyser flow, pneumatic performance and hydrogen

measurement are within specifications a function test using the Function Test Kit (Part No A-40107) unit is

recommended. The function test does not re-calibrate the instrument.

The function test procedure is detailed over the following pages.

Page 26 of 39

Page 27

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

Hydrosteel function test instructions

To carry out the function test you must have the function test kit displayed above

The Hydrosteel function test is divided into two parts. The first is to check the sample flow. The second is to

check the hydrogen sensor calibration.

Flow test

The Hydrosteel flow is important to the accuracy of flux measurements. The function test uses a variable

area flow meter to check the correct flow is being drawn into the instrument. The flow is determined by

reading the tube markings from the middle of the float point. The readings should be between 40 and 55 for

a unit that has a correct flow. The flow meter has to be on a level surface for correct operation.

1) Switch the Hydrosteel 6000 analyser on and let it complete the stabilisation count down and zero.

2) Ensure that the flow meter is on a level surface.

Page 27 of 39

Page 28

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

3) Connect short flexible sample tube from hydrosteel 6000 inlet to the top port on the flow meter.

4) Determine the flow by reading the tube markings from the middle of the float. The reading should be

between 40 and 55 indicating that the instrument flow is correct.

5) If the reading is outside the limits stated above, retest the flow after checking that all connections

have been made securely, and are leak free.

6) If the unit is still reading outside the limits the unit will need to be returned to ISL for service and

calibration.

Sticking floats. There is limited clearance between the float and the inside of the tube. In some cases flow

tubes are found to ‘stick’ after transport or long periods in storage due to condensation resulting from

temperature changes. It is advised to blow clean dry gas through the meter to free the float.

Hydrogen gas test

The location for carrying out this test must have an ambient atmosphere that is distant from sources

of hydrogen release to the atmosphere.

Because the flood leak unit contains a low concentration of hydrogen gas it is important that the air

in the environs of the calibration equipment is well ventilated.

The temperature in the environs should be stable and the Hydrosteel equilibrated to the ambient

temperature.

Page 28 of 39

Page 29

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

This is performed using a flood leak of 100 ppm of hydrogen gas in air mixture. This gas has a tolerance of

10 ppm. The Hydrosteel provided readings in flux units of pl/cm2/s or nl/ cm2/s.

With the LT probe selected readings should be between 280 pl/cm2/s and 380 pl/cm2/s.

With the HT probe selected readings should be between 2200 pL/cm2/s and 3000 pL/cm2/s.

1) Switch unit on and let it complete the stabilisation count down and zero. Note the probe type

indicated by the analyser display (‘LT’ or ‘HT’).

2) Ensure that the temperature reading in the bottom right hand corner is not flashing. This indicates

that the sensor in the Hydrosteel is currently undergoing a temperature change, which may create a

temporary shift in the background flux.

3) Ensure that the flux reading is stable and approximate zero (<5pl/cm2/s for LT probe or 30 pL/cm2/s

for HT probe selection). In exceptional circumstances base line drift occurs due to the continuous

presence of hydrogen background.

4) Manually fit the regulator to the gas bottle to finger tightness.

Page 29 of 39

Page 30

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

5) Press fit the clear tube to the to the regulator

6) Press the barb of the flood leak adapter into the other end of the tube

7) Check the pressure on the regulator is not zero. If the gas bottle becomes empty then please contact

ION science to arrange a replacement. (The 150ml flood leak will drop once the pressure in the gas

bottle drops below 4 bar 60psi.

Page 30 of 39

Page 31

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

1) Open the regulator. By turning the valve knob as indicated.

2) Connect the Hydrosteel 6000 analyser to the 2 ft LT-R sample tube then connect the end of the

sample tube to the flood leak as shown .

3) Leave the instrument connected for 1 to 2 minutes for the reading to stabilise.

4) For the LT probe the readings should be between 280 pl/cm2/s and 380 pL/cm2/s. For the HT probe

the between 2200 pL/cm2/s and 3000 pL/cm2/s.

Page 31 of 39

Page 32

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

If the reading is outside the limits stated above, the Hydrosteel analyser will need to be returned to ISL for

service and calibration. In this case it is a good idea to retest the hydrogen calibration after checking that all

connections have been made securely, there is sufficient gas pressure in the gas bottle and that the

instrument was zeroed in clean air free from any hydrogen background.

12) On completion of test disconnect all tubing and fittings and return to storage. IMPORTANT: ensure

the regulator is closed (see step 8).

Battery Replacement

When the battery symbol flashes, low battery power exists, and the batteries must be replaced. If the

instrument is left running until the batters fall below the operating voltage the instrument will restart then

sense the battery voltage is too low where will flash the start-up screen before displaying the message

battery voltage too low” and switching off.

If the instrument is switched on with extremely low (but not dead) batteries one of a number of things may

occur first the red LED will illuminate permanently the LCD will show a slight contrast as though the

instrument is trying to witch on. However in this state the instrument will not respond to key presses. Second

the instrument may display and hang at the start up screen. Again the instrument will not respond to key

presses. Third the instrument will start recognise that the battery voltage is too low and switch of in the same

way that it does when the batteries die.

1 Using the battery screwdriver provided, remove the battery cover at the underside of the analyser.

2 Remove the exhausted batteries from the battery tray and replace with four new AA alkaline batteries.

Note: For the correct battery orientation, follow the symbols marked on the tray. Ensure that the

flying power lead is securely fastened to the battery tray.

3 Refit the tray into the analyser body.

To save power, always turn off the analyser when not in use.

Probe plate Replacement

Low temperature collector plate replacement

1 Unscrew the 1/8” nut on the collector plate sample tube to the bulkhead fitting on the back of the

probe assembly.

2 With the collector plate face facing towards you twist the collector plate clock wise 45 relative to the

probe assembly.

3 Slide the collector plate central spindle out of the central hole in the probe assembly.

4 Thread the gas sample tube from the collector through the leather hole in the probe assembly.

5 To secure the new collector plate, carry out the steps 4, 3, 2 and 1 in reverse.

High temperature collector plate replacement

1 Manually unscrew the collector handle from the assembly. Unscrew the HT sampling tube from the

HT probe. (The handle unscrews below the white heat shield – please also see illustration under the

‘Using Hydrosteel 6000’ section of the manual.

2 Using the 2.5 mm hexagonal screwdriver from the HT-kit box, unscrew the hexagonal collector plate

locking screw, to release the collector plate from the bracket. Remove the plate.

3 Remove a new HT-R collector plate from the kit box. Handle the collector plates carefully. Being

designed for maximum flexibility, they are liable to permanently deform if dropped or mishandled.

Page 32 of 39

Page 33

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Routine maintenance

4 Insert the collector plate capillary into the collector assembly until the back of the plate contacts the

magnets. If the capillary is obstructed, the collector plate locking screw may require further loosening

with the 2.5 mm hexagonal screwdriver.

5 Lock the collector plate into position using the hexagonal screwdriver. Re-connect the HT sample

tube nut onto the new collector plate until finger tight. Screw into place the probe handle.

Cleaning

Warning; Organic solvents such as IPA should not be used to clean the analyser or collector plates. The

solvent vapour in strong concentrations may affect the sensor readings.

Attention must be made to keep the following areas clean:

1. All pneumatic joints

2. Analyser inlet

3. Surface of collector plate.

4. Bottom of probe assembly collector plate free from grit and metal filings that may be collected by

magnetic attraction.

Cleaning general

Clean the analyser and equipment using a damp cloth and mild detergent. Care must be taken around the

analyser inlet and all pneumatic openings (sample tube etc.) to ensure that water does not enter. Dry

immediately with suitable towel.

Cleaning magnets

The magnets may with time attract magnetic and ferromagnetic particles. These can easily be removed

using an air jet from a typical air supply (100 psi / 7 bar). Simply play the jet across the surface wiping where

necessary to blow the particles away.

Page 33 of 39

Page 34

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

USA Office

Ion Science LLC

33 Commercial Drive

Waterbury

VT 05676

USA

Tel: +1 802 244 5153

Fax: +1 802 244 8942

Email: info@ionscienceusa.com

Web: www.ionscience.com

UK Head Office

Ion Science Ltd

The Way, Fowlmere

Cambridge

SG8 7UJ

UK

Tel: +44 (0)1763 207206

Fax: +44 (0) 1763 208814

Email: info@ionscience.com

Web: www.ionscience.com

German Office

Ion Science Messtechnik GMBH

Laubach 30

Metmann-Neandertal

40822

GERMANY

Tel: +49 2104 14480

Fax: +49 2104 144825

Email: info@ism-d.de

Web: www.ism-d.de

Instrument warranty and service

Warranty

Standard Warranty can be extended to up to 2 years on the Hydrosteel 6000 when registering

your instrument via our website: www.ionscience.com/instrument-registration

To receive your Extended Warranty, you need to register within one month of purchase (Terms

and Conditions apply). You will then receive a confirmation email that your Extended Warranty

Period has been activated and processed.

Full details, along with a copy of our Warranty Statement can be found by visiting:

www.ionscience.com/instrument-registration

Service

At Ion Science we recommend that all of our gas detection instruments be returned for service

and factory calibration once every 12 months.

Contact Ion Science or your local distributor for service options in your area.

Find your local distributor by visiting: www.ionscience.com

Contact details

Page 34 of 39

Page 35

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Dimensions

Analyser:

320 x 60 x 50 mm

Probe extension:

15 cm high x 150 mm dia.

Collector:

20 cm high x 150 mm dia.

Power requirements

Batteries:

4 x 1.5 V AA alkaline

Time operable with batteries:

30 hr occasional, 40 hr continuous Monitoring

Environmental operating conditions

Ambient temperature range:

15 °F to 120 °F (-10 °C to +50 °C)

Test gas humidity tolerance:

continuous 15% to 100% non- condensing, <15% for a few

hours

Measurement surface:

Steel of >3.5-inch diameter cross section.

temperature range < 230

°

F (110 °C)

265F (130C) is possible for quick spot measurements

only.

Test gas pressure tolerance:

±5% ambient pressure

Appendix A

Hydrosteel 6000 LT-R Technical Specifications

Page 35 of 39

Page 36

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Full range:

0-2500 pl/cm2/s.

Resolution:

< 2 pl/cm2/s hydrogen emanating from steel

Linearity:

Linear over full range

Reproducibility:

5% or 1 pl/cm2/s, whichever is greater.

Rate of response:

%FSD

1%

50%

90%

27-inch (70 cm) conduit

8 s

24 s

42 s

78-inch (200 cm) conduit

17 s

36 s

55 s

Cross sensitivity (versus hydrogen = 100%):

CO <1%; H2S <20%; NO, <30%; C2H4, 80%

Relative response (versus100 ppm @ 20 °C = 1.00):

30 °C = 1.03; 40 °C =1.11; 50 °C =1.21

Pre-set input flow rate:

30 ±1 ml/min

Background signal drift:

<50 pl/cm2/s equivalent per year,

<1 pl/cm2/s per hr.

< 0.5 pl/cm2/s per °C

Operating lifetime:

sensor, 1 year pump, >1500 hr

Appendix A

Analyser specification

Notes: Volumetric specifications are quoted at 20 °C and one atmosphere ambient pressure.

Pre-set input flow, deploying 27-inch (70 cm) gas sampling conduit and LT-R collector unless

otherwise specified.

1 pl = 10

-12

litres

Page 36 of 39

Page 37

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Key press

Main Function

Countdown

Key options

O

Power up, displays system status, time and

power status,

8 s

none

After 8 s, while the prompt start-up mode is displayed, press:

D

Display data log summary

10 s

D

DD

Data download instructions

10 s

D

DDD

Data download

30 s

D

DDDD

Cancel download, and return to Start-up mode

-

none

Also during start-up mode, you can access the following:

DS

Clear memory

4 s

any

O

Turn analyser off

4 s

O

OO

Zero analyser and enter operating mode

4 s

O

SD

Select time/date (clock) parameters sequentially

60 s

O, S, D

SSD

Select units of measurement

10 s

O, S, D

SSSD

Select probe

60 s

O, S, D

SSSSD

Select choice of temperature scale

60 s

S, D

SSSSS

exit, and return to start-up mode

-

none

Appendix B

Analyser Menu Options – start-up mode

The following selections can only be made in start-up mode – up to 90 seconds from turning the instrument

on.

Page 37 of 39

Page 38

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Key press

Main Function

Countdown

Key options

After 80 s of start-up mode, the analyser enters operating mode.

D

Display data log summary

5 s

D

DD

60 s log mode (5 s data intervals)

60 s

D

DDD

Indefinite data log (to 10 min data intervals)

Select D to end logging.

inde- finite

D, low battery,

log full

#D...DS

Access log statistics (file length, maximum flux,

slope of present flux, end log mode, and return to

operating mode

5 s

none

# - only selectable after 1 minute of data logging

From operating mode, you can identify a zone for data logging

DS

Select zone

10 s

S, D, O

O

Return to operating mode

1 s

none

From operating mode, you can download data to your PC:

SD

PC Connect: analyser communicates with PC

via IRDA link

inde- finite

D

SD

return to operating mode

1 s

none

Appendix B

Analyser Display Options – operating mode

Page 38 of 39

Page 39

Hydrosteel 6000 MANUAL Ion Science Ltd

Unrivalled Detection. www.ionscience.com

Manual

Version

Amendment

Date updated

Instrument

Firmware

PC

Software

Hydrosteel

6000

Update log added in back of manual

23/12/08

V2.38

V3.25

Hydrosteel

6000

Page 5 – Specification updates for AT-S

and HT-S Probes.

13/01/09

V2.38

V3.25

Hydrosteel

6000 to V1.9

Warranty added on cover

Declaration of Conformity updated

Contents updated

Warranty and Service info added pg 31

23/07/10

V2.38

V3.25

Hydrosteel

6000 V2.0

Page 1 updated to correct Quality

Management System

Page 3 added to include Responsibility

for use and Legal Notice

Contact details added to page 32

03/03/11

21/03/11

V2.38

V3.25

Hydrosteel

6000 V2.1

Layout updated throughout

Service options/contracts removed from

page 34.

25/11/12

V2.38

V3.25

Hydrosteel

6000 V2.2

Bassefa Issue date added Page 3

3/7/14

V2.38

V3.25

Update Log

Page 39 of 39

Loading...

Loading...