Page 1

ValueLoader™

LTO Tape Autoloader

User Manual

6326709-01

Ver. A, Rel. 01

Page 2

ValueLoader LTO Tape Autoloader User Manual, 6326709-01, Ver. A, Rel. 01, June 2003, Made in USA.

This publication is provided “as is” without warranty of any kind, either express or implied, including but

not limited to the implied warranties of merchantability or fitness for a particular purpose. This publication

may be revisee from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2003 by Quantum Corporation. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

ValueLoader is a trademark of Quantum Corporation, registered in the U.S.A. and other countries. DLTtape

and Super DLTtape are trademarks of Quantum Corporation. Products mentioned herein are for

identification purposes only and may be trademarks or registered trademarks of their respective companies.

All other trademarks are the property of their respective owners.

6207947-00sN 44

Page 3

Contents

Preface xi

Chapter 1 Installing the ValueLoader 1

Installation Overview ............................................................................2

Understanding ValueLoader Features ................................................2

Barcode Reader.................................................................................3

SCSI Requirements ..........................................................................3

Product Overview............................................................................4

Choosing a Location...............................................................................6

Unpacking the ValueLoader.................................................................7

Identifying ValueLoader Accessories..................................................9

Installing the ValueLoader into a Rack ............................................. 11

Connecting the SCSI and Power Cables............................................13

Preparing the Host and Verifying the Connection..........................15

Installing Device Drivers ..............................................................17

ValueLoader LTO Tape Autoloader User Manual iii

Page 4

Chapter 2 Operating the ValueLoader 21

Operator’s Panel Overview.................................................................22

LED Indicators................................................................................24

Operator’s Panel Control Buttons................................................25

Understanding the Menu Structure...................................................26

Using Cartridges...................................................................................27

Importing Cartridges.....................................................................27

Exporting Cartridges .....................................................................29

Loading Cartridges........................................................................30

Unloading Cartridges....................................................................30

Write-Protecting Cartridges .........................................................31

Maintaining Cartridges.................................................................31

Cleaning the Tape Drive......................................................................32

Creating an Inventory of Cartridges..................................................33

Chapter 3 ValueLoader Administration 35

Configuring the ValueLoader.............................................................35

Resetting the ValueLoader ...........................................................36

Changing the SCSI ID....................................................................36

ValueLoader Operating Modes ...................................................38

Updating Firmware..............................................................................40

Using a Firmware Upgrade Tape ................................................40

Using SCSI.......................................................................................42

Running the ValueLoader System Test.............................................42

Retrieving Information About the ValueLoader..............................43

Cycle Count.....................................................................................43

View Event Log ..............................................................................43

Product Revision ............................................................................44

Firmware Revision.........................................................................44

Chapter 4 Diagnostics and Troubleshooting 47

Troubleshooting....................................................................................47

Installation Problems.....................................................................48

Troubleshooting Table ..................................................................50

Removing Stuck Cartridges ................................................................55

iv ValueLoader LTO Tape Autoloader User Manual

Page 5

ValueLoader Error Codes.................................................................... 59

Appendix A Technical Specifications 65

Appendix B Customer Support 69

Information Needed.............................................................................69

Information Needed by Software Vendors ......................................70

ValueLoader LTO Tape Autoloader User Manual v

Page 6

vi ValueLoader LTO Tape Autoloader User Manual

Page 7

Figures

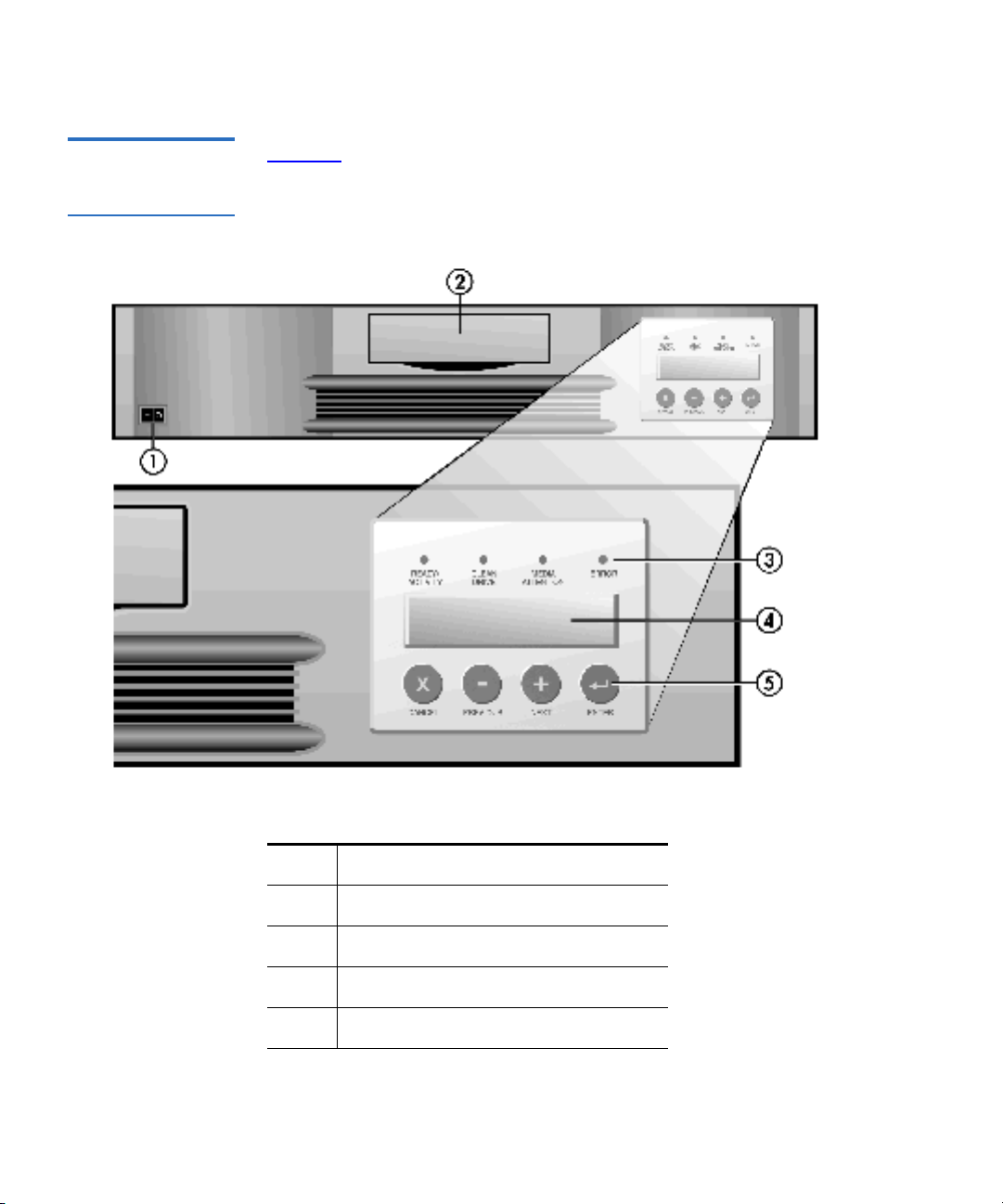

Figure 1 Front Panel...........................................................................4

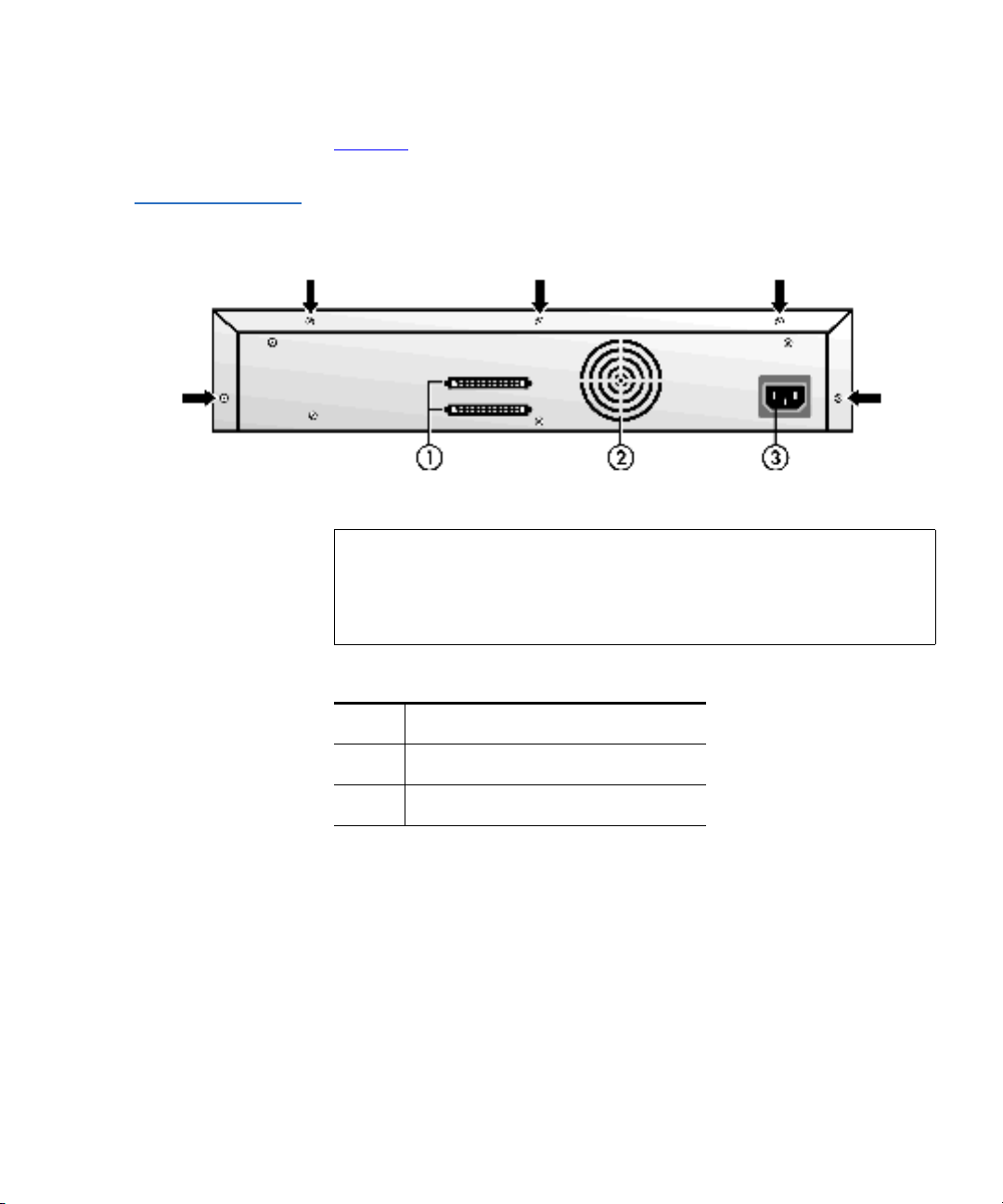

Figure 2 Rear Panel ............................................................................5

Figure 3 Basic ValueLoader Accessories......................................... 9

Figure 4 Rack Kit Components....................................................... 10

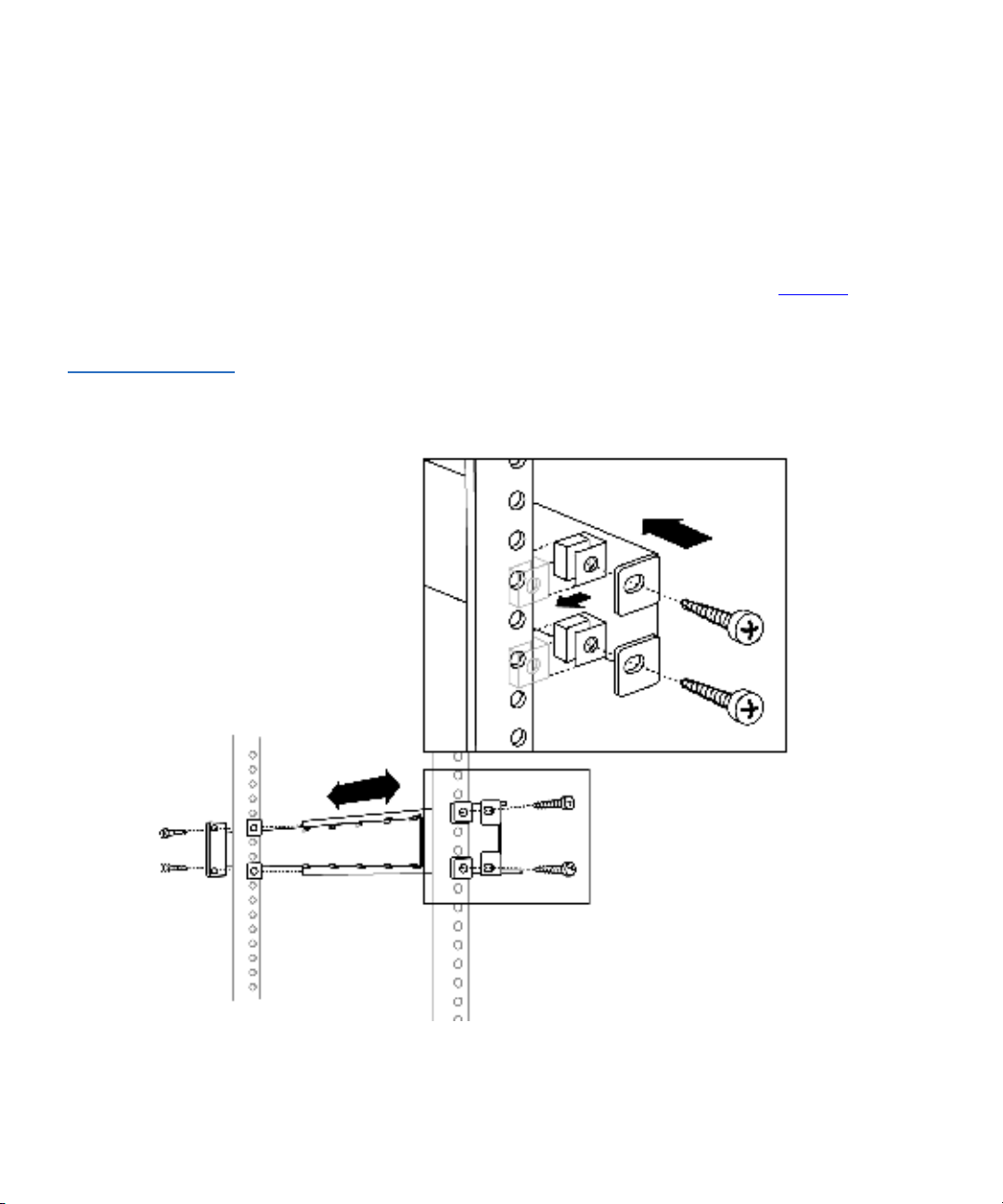

Figure 5 Installing Mounting Brackets (Left Side Shown) ......... 11

Figure 6 Installing Rails in the Rack (Left Side Shown)..............12

Figure 7 Sliding the ValueLoader into the Rack Slot .................. 13

Figure 8 Attaching SCSI and Power Cables .................................14

Figure 9 Operator’s Panel—Drive Empty.....................................22

Figure 10 Operator’s Panel—Drive Loaded ...................................23

Figure 11 Operator’s Panel Menu Structure...................................26

Figure 12 Importing a Cartridge ......................................................28

Figure 13 Exporting a Cartridge....................................................... 29

Figure 14 Write-Protect Switch.........................................................31

Figure 15 Removing Mounting Brackets (Left Side Shown)........ 56

ValueLoader LTO Tape Autoloader User Manual vii

Page 8

Figures

Figure 16 Pulling the Cartridge Release Lever...............................57

Figure 17 Installing the Carrier ........................................................58

viii ValueLoader LTO Tape Autoloader User Manual

Page 9

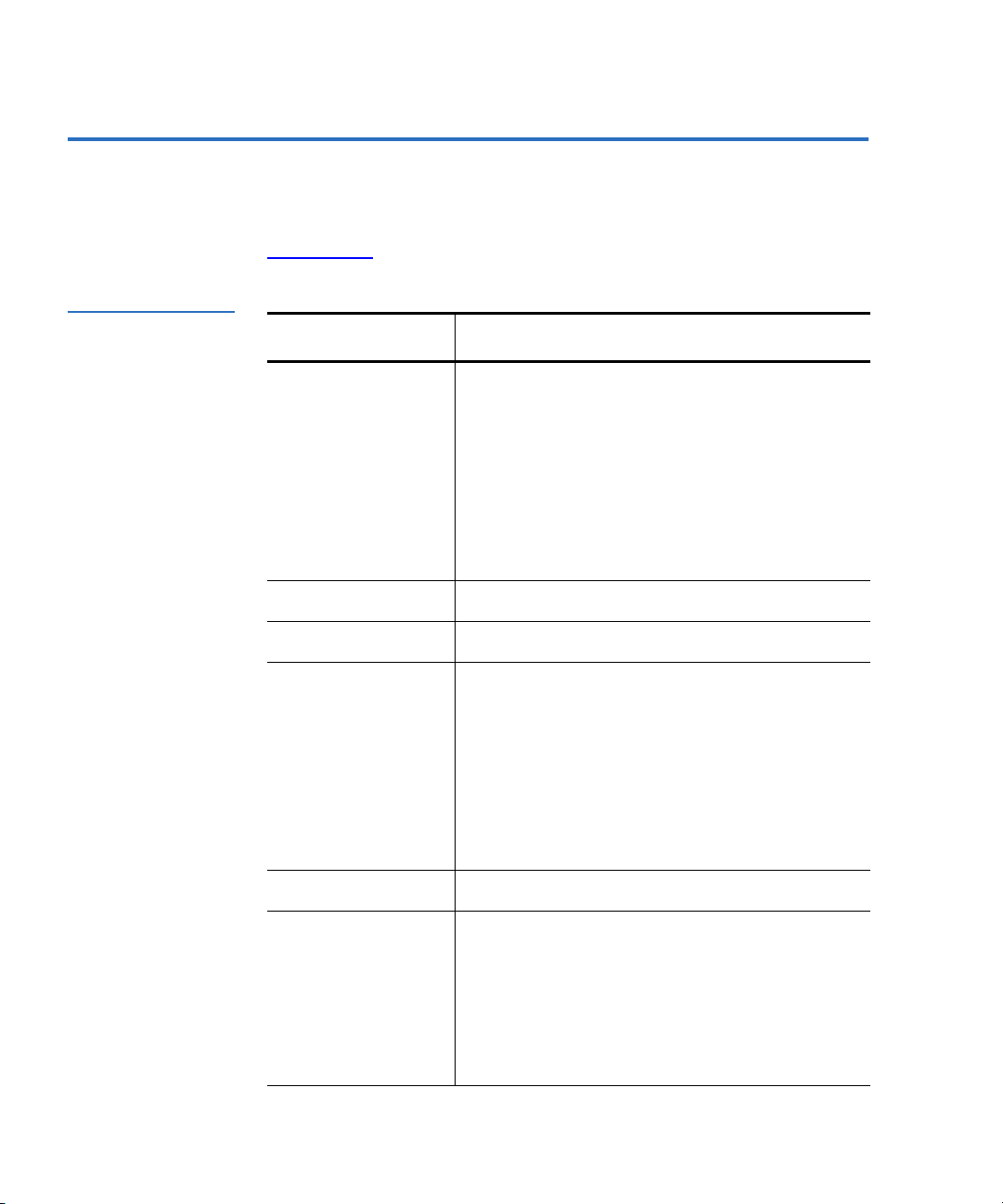

Tables

Table 1 Location Criteria .................................................................6

Table 2 LEDs....................................................................................24

Table 3 Control Buttons .................................................................25

Table 4 Common ValueLoader Problems ................................... 50

Table 5 Error Codes........................................................................60

Table 6 Physical Specifications .....................................................65

Table 7 Operating Specifications..................................................66

Table 8 ValueLoader Environmental Specifications..................66

Table 9 HP LTO Drive Specifications ..........................................67

Table 10 Media Specifications.........................................................68

ValueLoader LTO Tape Autoloader User Manual ix

Page 10

Tables

x ValueLoader LTO Tape Autoloader User Manual

Page 11

Preface

This chapter describes the ValueLoader User Manual’s audience,

purpose, organization, document conventions, and product safety.

Audience

Purpose

This user manual is designed and written for end users and field

service engineers.

The purpose of this manual is to provide end users with the

following information:

• ValueLoader™ LTO description and specifications.

• ValueLoader installation and configuration

• Tape cartridge description and general overview

• ValueLoader operation

• Troubleshooting

• Customer-replaceable components

ValueLoader LTO Tape Autoloader User Manual xi

Page 12

Document

Organization

This manual is organized as follows:

• Chapter 1, Installing the ValueLoader

- This chapter describes

ValueLoader features, accessories, and installation tasks.

• Chapter 2, Operating the ValueLoader

- This chapter describes

the front panel menu structure, menu tree, and drive and tape

operations.

• Chapter 3, ValueLoader Administration

- This chapter

describes how to configure the ValueLoader, upgrade

firmware, and retrieve ValueLoader information.

• Chapter 4, Diagnostics and Troubleshooting

- This chapter

describes how to identify and troubleshoot ValueLoader

problems and resolve error conditions.

• Appendix A, Technical Specifications

- This appendix

describes ValueLoader environmental, operational, drive, and

media specifications.

• Appendix B, Customer Support

- This appendix list support

information for the ValueLoader.

xii ValueLoader LTO Tape Autoloader User Manual

Page 13

Notational

Conventions

This manual uses the following conventions to designate specific

elements:

Note: Notes emphasize important information related to the

Caution: Cautions indicate potential hazards to equipment

Warning: Warnings indicate potential hazards to personal

Customer Support

For information on support, or to access our “Frequently Asked

Questions” database, visit our Web site.

main topic.

and are included to prevent damage to equipment.

safety and are included to prevent injury.

ValueLoader LTO Tape Autoloader User Manual xiii

Page 14

xiv ValueLoader LTO Tape Autoloader User Manual

Page 15

1Installing the ValueLoader

This chapter describes the following:

Chapter 1

• Installation Overview

• Understanding ValueLoader Features

• Choosing a Location

• Unpacking the ValueLoader

• Identifying ValueLoader Accessories

• Installing the ValueLoader into a Rack

• Connecting the SCSI and Power Cables

• Preparing the Host and Verifying the Connection

on page 2

on page 2

on page 6

on page 7

on page 9x

on page 11

on page 13

on page 15

ValueLoader LTO Tape Autoloader User Manual 1

Page 16

Installing the ValueLoader

Installation Overview

Installation Overview 1

Use the following steps to perform the ValueLoader installation.

These steps are fully explained in this chapter.

1 Choose a location for the ValueLoader (page 6).

2 Unpack the ValueLoader (page 7).

3 Identify the accessories for the ValueLoader (page 9).

4 Install the ValueLoader in a computer rack or select a table or

desktop near the host server (page 11

5 Shut down, turn off, and remove power from the server and all

devices attached to the server (page 13

6 Attach ValueLoader to the SCSI bus.

7 Attach the power cable between the ValueLoader and a

grounded power outlet. Power the ValueLoader on to ensure it

passes the power-on self test (POST).

).

).

8 Set the SCSI ID for the ValueLoader, if necessary.

9 Set up the host and verify the connection (page 15).

Understanding ValueLoader Features 1

The ValueLoader is a SCSI-2 low-voltage differential (LVD) data

storage device that incorporates an HP LTO tape drive and eight

tape slots. The ValueLoader operates as a dual SCSI device with

two SCSI IDs, one for the tape drive and the other for the

ValueLoader robotics. The ValueLoader uses up to eight LTO data

cartridges, providing a maximum formatted capacity of 1600

gigabytes (GB) assuming a 2:1 compression ratio.

2 ValueLoader LTO Tape Autoloader User Manual

Page 17

Installing the ValueLoader

Understanding ValueLoader Features

The ValueLoader is compatible with most operating systems and

environments that support the SCSI interface, but requires either

direct support from the operating system or a compatible backup

application to take full advantage of its many features.

Barcode Reader 1

SCSI Requirements

Your ValueLoader may have come equipped with an optional

barcode reader. The barcode reader is enclosed in a plastic housing

that protrudes out of the rear panel of the ValueLoader, just above

the SCSI connectors. The barcode reader automatically scans each

cartridge in the carousel upon power up, after a reset, or when a

re-inventory command is issued. (See Creating an Inventory of

Cartridges on page 33 for instructions.) Beyond that, there is no

user interface with the barcode reader via the front panel operator

controls or LCD display. The information from each label is stored

in memory and available through SCSI to the computer’s

operating system or backup application upon request.

If you plan to utilize the barcode reader, you must adhere a

barcode label into the designated area on the front of each

cartridge. These labels must conform to ANSI/AIM BC1-1995,

Uniform Symbology Specification Code 39. To obtain additional

barcode labels, refer to our Web site.

The ValueLoader incorporates a wide SCSI-2, LVD SCSI bus, but

1

may also be attached to a single-ended (SE) SCSI bus. Make sure

your SCSI host adapter or controller supports these standards. If

you connect the ValueLoader to an SE SCSI bus or if there are SE

devices attached to the same SCSI bus, the ValueLoader’s

performance is limited to the maximum data transfer speed and

maximum cable lengths of the SE bus. The ValueLoader is NOT

compatible with a standard differential (Diff) or high-voltage

differential (HVD) SCSI bus. The ValueLoader is compatible with a

narrow (50-pin) SCSI bus using a customer-supplied 68-pin to 50pin adapter that terminates the unused 18 pins. These adapters are

sometimes labeled high-byte termination.

ValueLoader LTO Tape Autoloader User Manual 3

Page 18

Installing the ValueLoader

Understanding ValueLoader Features

Product Overview 1

Figure 1 Front Panel

Figure 1

describes front panel controls.

1Power switch

2 Import/export slot

3 Front panel LEDs

4 Front panel LCD screen

5 Control keys

4 ValueLoader LTO Tape Autoloader User Manual

Page 19

Figure 2 Rear Panel

Installing the ValueLoader

Understanding ValueLoader Features

Figure 2 describes the ValueLoader rear panel.

Note: The arrows in the figure indicate screws that need to be

removed to remove the top cover. In addition to the

screws pictured, there are three screws on each side of

the ValueLoader.

1 68-pin SCSI connectors

2Fan vent

3 Power connector

ValueLoader LTO Tape Autoloader User Manual 5

Page 20

Installing the ValueLoader

Choosing a Location

Choosing a Location 1

Choose a location that meets the following criteria. (See

appendix A

for more specifications.)

Table 1 Location

Criteria

Requirement Description

Work surface

(standalone

installation)

Rack requirements Standard 19-inch rack with a clearance of 2U.

Room temperature 10-35° C (50-95° F)

Power source AC power voltage: 100-127 VAC; 200-240 VAC

Select a location that is flat, level, sturdy, and

close to a host server. Do not place the

ValueLoader on the floor or other carpeted

surface.

Caution: Do not place the ValueLoader on its

side or upside down, or stack items

that weigh more than 15 kg (33 lbs)

on top of the ValueLoader.

Line frequency: 50-60 Hz

Note: Locate the AC outlet near the

ValueLoader. The AC power cord is the

product’s main AC disconnect device

and must be easily accessible at all

times.

Weight 10 kg (22 lbs)

Air quality Minimal sources of particulate contamination.

Avoid areas near frequently used doors and

walkways, stacks of supplies that collect dust,

printers, or smoke-filled rooms.

Caution: Excessive dust or debris can damage

tapes and tape drives.

6 ValueLoader LTO Tape Autoloader User Manual

Page 21

Installing the ValueLoader

Unpacking the ValueLoader

Requirement Description

Humidity 20-80% RH, non-condensing

Clearance Back: Minimum of 15.4 cm (6 inches)

Front: Minimum of 30.8 cm (12 inches)

Sides: Minimum of 5.08 cm (2 inches)

Unpacking the ValueLoader 1

Before you begin, clear a desk or table so you can unpack the

ValueLoader. You also need to select an open 2U computer rack

location or a desktop location near the server that is to be the host

for the ValueLoader.

Caution:

If the room temperature you are working in differs

from the shipping or storage temperature by 15° C

(30° F) or more, allow the ValueLoader to acclimate

to the surrounding environment for at least 12 hours

before opening the shipping carton.

Unpack and inspect the ValueLoader for shipping damage by

doing the following:

1 Clear a table or desk so that you have room to unpack the

ValueLoader.

2 Inspect the shipping box for damage. If you notice any

damage, report it to the shipping company immediately.

3 Open the shipping box and remove the accessories package.

Set the accessories package aside.

ValueLoader LTO Tape Autoloader User Manual 7

Page 22

Installing the ValueLoader

Unpacking the ValueLoader

4 Lift the ValueLoader and padding out of the box and place it

on the work surface, top facing up. Do not set the ValueLoader

on either end or side.

Caution: Placing the ValueLoader on its side, on end, or

upside down can cause permanent damage to the

unit.

5 Carefully remove the shipping padding from the left and right

sides of the ValueLoader. Then remove the bag from the

ValueLoader.

Note: Save the packing materials in case you need to move

or ship the ValueLoader in the future.

8 ValueLoader LTO Tape Autoloader User Manual

Page 23

Installing the ValueLoader

Identifying ValueLoader Accessories

Identifying ValueLoader Accessories 1

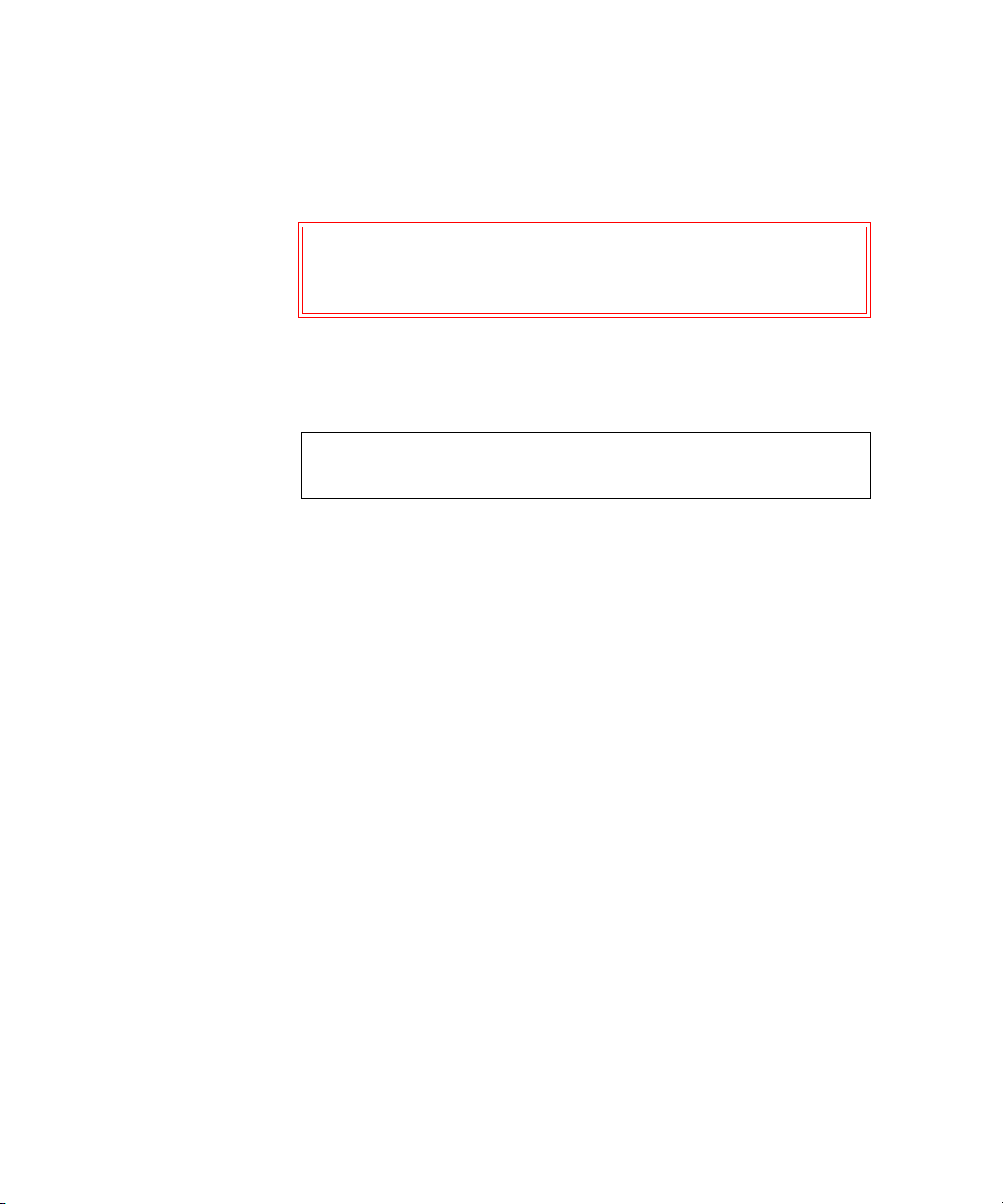

Figure 3 Basic

ValueLoader

Accessories

Figure 3

1 SCSI cable

2SCSI terminator

3Power cable

identifies accessories for use with the ValueLoader.

4 Marketing and regulatory

information

5 Quick Install Guide

ValueLoader LTO Tape Autoloader User Manual 9

Page 24

Installing the ValueLoader

Identifying ValueLoader Accessories

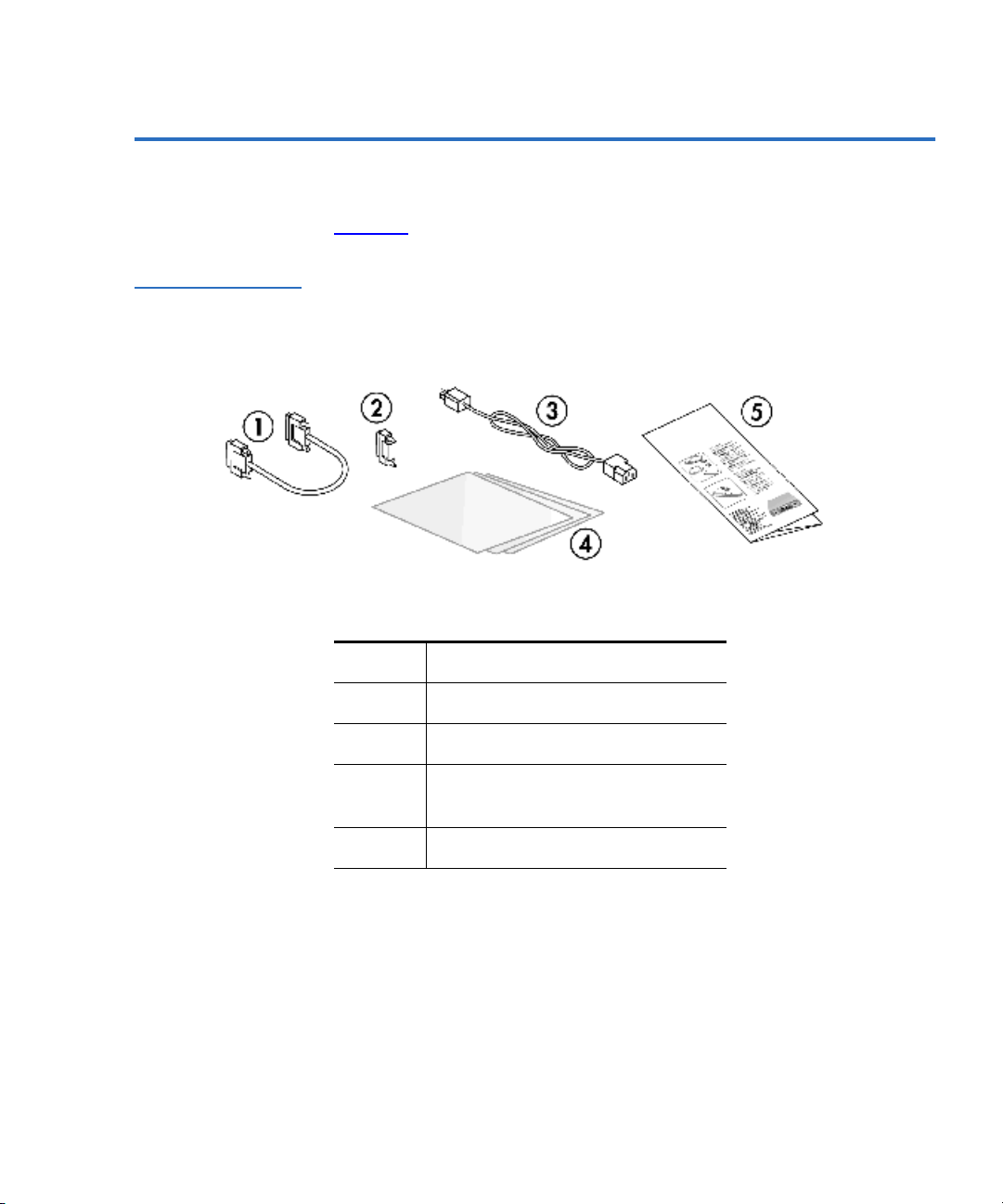

Figure 4 shows additional accessories used for rackmount

installations.

Figure 4 Rack Kit

Components

10 ValueLoader LTO Tape Autoloader User Manual

Page 25

Installing the ValueLoader

Installing the ValueLoader into a Rack

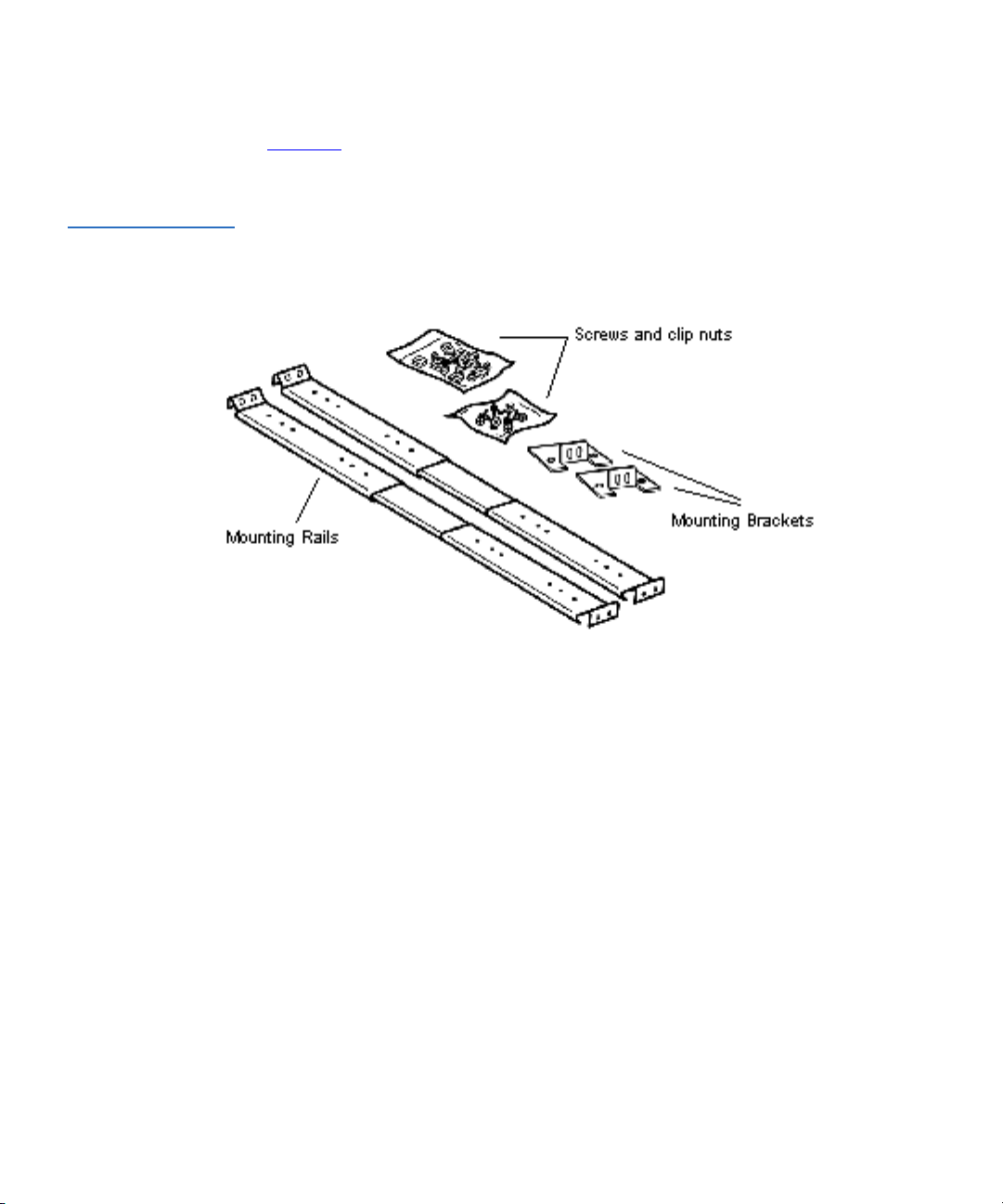

Installing the ValueLoader into a Rack 1

The ValueLoader fits all standard 19-inch racks, taking up 2U of

space. To install the ValueLoader into a rack, you need to install

the mounting brackets on both sides of the ValueLoader and the

rails in the selected rack location.

To install the ValueLoader, follow these steps:

1 Use a screwdriver or Torx T10 to remove the two screws near

the front on each side of the ValueLoader.

2 Using the screws you removed in step 1, secure one mounting

bracket from the rack kit to each side of the ValueLoader, as

shown in figure 5

Figure 5 Installing

Mounting Brackets

(Left Side Shown)

.

ValueLoader LTO Tape Autoloader User Manual 11

Page 26

Installing the ValueLoader

Installing the ValueLoader into a Rack

3 Using screws and clip nuts from the rackmount hardware

package, secure one rail to each side of the rack in the location

where you plan to install the ValueLoader.

• Be sure to secure both the front and rear of each rail. The

rails extend to fit a variety of rack depths.

Figure 6 Installing

Rails in the Rack (Left

Side Shown)

• The correct orientation of the left rail is shown in figure 6

Repeat for the right rail.

.

12 ValueLoader LTO Tape Autoloader User Manual

Page 27

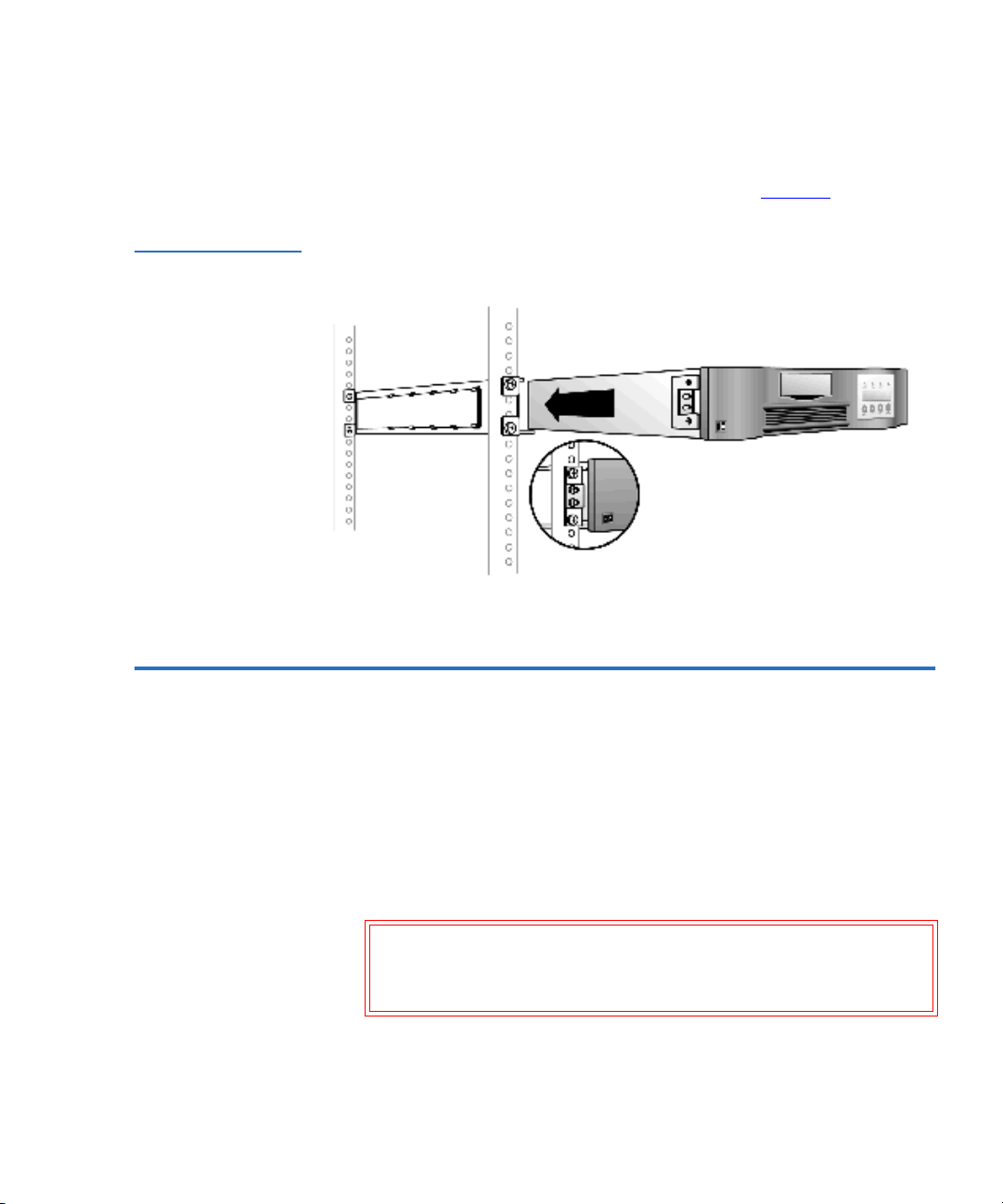

Figure 7 Sliding the

ValueLoader into the

Rack Slot

Installing the ValueLoader

Connecting the SCSI and Power Cables

4 Slide the ValueLoader onto the rails and secure the mounting

bracket to the rack using the screws and clip nuts from the

rackmount hardware package, as shown in figure 7

.

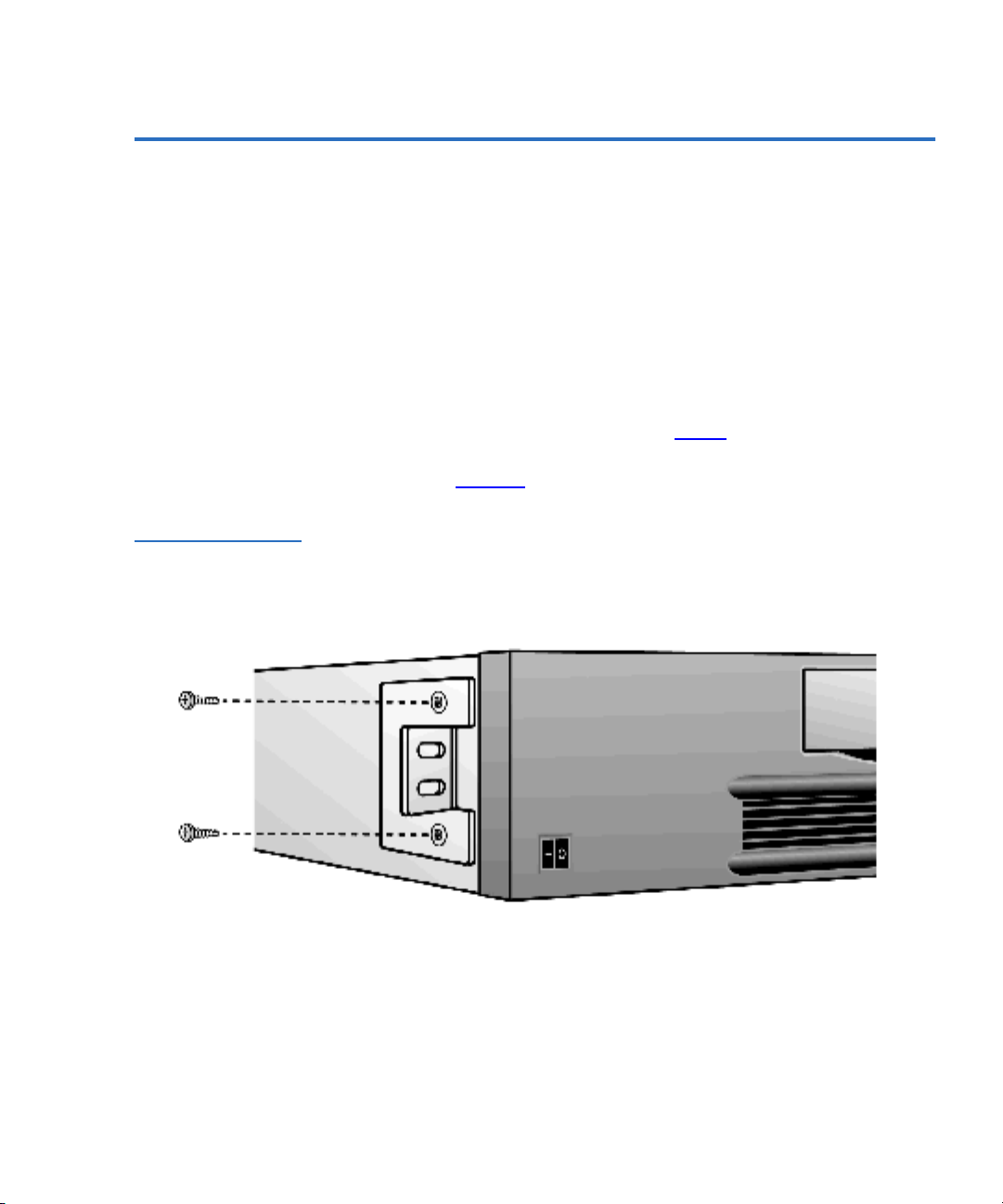

Connecting the SCSI and Power Cables 1

To connect the SCSI and power cables to the ValueLoader, follow

these steps:

1 Shut down and turn off the selected server. Turn off all

attached accessory devices, such as printers and other SCSI

devices. Remove the power cables from the server and all

attached accessories.

Caution: Failure to remove the power cables from these

devices may result in damage to the

ValueLoader.

ValueLoader LTO Tape Autoloader User Manual 13

Page 28

Installing the ValueLoader

Connecting the SCSI and Power Cables

2 Attach one end of the SCSI cable (included in the accessory kit)

to one of the connectors on the rear panel of the ValueLoader.

See figure 8

3 Attach the other end of the SCSI cable to the connector on the

SCSI host adapter or to the connector on the previous device on

the SCSI bus.

Note: If the supplied SCSI cable does not fit the connector

4 If the ValueLoader is the last (or only) device on the SCSI bus,

attach the terminator to the remaining SCSI connector on the

rear panel of the ValueLoader, as shown in figure 8

attach the cable to the next device on the SCSI bus. Make sure

the last device on the SCSI bus is properly terminated.

.

on your SCSI host adapter, you either have an

incompatible SCSI host adapter, or you need to

purchase a cable adapter. For clarification, contact

your service representative or SCSI host adapter

manufacturer.

. Otherwise,

5 Attach the power cable to the power connector on the rear

panel of the ValueLoader as shown in figure 8

Figure 8 Attaching

SCSI and Power

Cables

14 ValueLoader LTO Tape Autoloader User Manual

.

Page 29

Installing the ValueLoader

Preparing the Host and Verifying the Connection

6 Plug the power cable into a properly grounded power outlet.

Note: To disconnect all power from the ValueLoader,

remove the power cord from the outlet.

7 Plug in the host server or workstation and all attached devices.

8 Turn on the ValueLoader by setting the power switch on the

front panel to the ON position. Turn on any other devices you

turned off earlier. Check the LCD display to make sure the

ValueLoader is receiving power. If it is not, check the power

connectors and the power source.

During the power-on self test (POST), all four LEDs are

illuminated briefly, followed by just the Ready/Activity LED

flashing. When the initialization sequence is complete, the LCD

screen displays the Home screen.

9 Turn on the server.

Preparing the Host and Verifying the Connection 1

If necessary, install a SCSI host adapter, software, and compatible

driver(s). Refer to the manuals for the host computer and the SCSI

host adapter for detailed instructions. In addition, follow these

general guidelines:

• When the host server is powered on, install software, and/or

driver(s) that are compatible with the ValueLoader. (See

Installing Device Drivers

Most backup software packages require an additional module

to communicate with the ValueLoader robotics.

• If the host server is connected to a network, check with the

system administrator before turning off power.

• Use proper procedures to prevent electrostatic discharge

(ESD). Use wrist-grounding straps and anti-static mats when

handling internal components.

ValueLoader LTO Tape Autoloader User Manual 15

on page 17 for more information.)

Page 30

Installing the ValueLoader

Preparing the Host and Verifying the Connection

• Make sure the host server has an open expansion slot.

• Make sure your backup application supports the SCSI host

adapter.

• Depending on the server configuration, you may need to

change the SCSI ID of the ValueLoader. For more information,

see Changing the SCSI ID

• Ensure that the ValueLoader is properly terminated. If the

ValueLoader is the only SCSI device (other than the SCSI host

adapter) on the SCSI bus, it must be terminated. Likewise, if

the ValueLoader is physically the last SCSI device on the SCSI

bus, it must be terminated. Only the devices physically at the

beginning and end of the SCSI bus should be terminated.

• Verify the connection between the ValueLoader and host by

making sure the host server’s operating system recognizes the

ValueLoader. To do this:

on page 36.

• For Microsoft® Windows NT®, select

Panel > SCSI Adapter

Settings > Control

• For Windows® 2000, select Settings > Control Panel >

System > Hardware > Device Manager > Tape Drive

Media Changer)

(and/or

For more information on verifying the connection of SCSI

devices, consult the operating system documentation.

16 ValueLoader LTO Tape Autoloader User Manual

Page 31

Installing the ValueLoader

Preparing the Host and Verifying the Connection

Installing Device Drivers

Two device drivers are associated with the ValueLoader: one for

1

ValueLoader robotics and another for the tape drive within the

ValueLoader.

Note: The device drivers supplied at our Web site are required

if you intend to use the Windows 2000 native backup

application. Commercial backup applications provide all

necessary device driver support. Refer to our Web site

for a list of compatible backup applications. Please note

that Windows NT does not include native support for

ValueLoaders (a backup application must be used).

Note: The following instructions assume that you have

downloaded the appropriate device drivers from our

Web site and have saved them in a known location on

your computer system.

Tape Drive Device Driver (Windows 2000) 1

To install the tape drive device driver:

1 Make sure that you are logged onto the host server with

Administrator privileges.

2 Right-click the My Computer icon on the Windows desktop,

then click

Manage, and then click Device Manager.

The tape drive should be listed under the “? Other Devices”

item as “HP Ultrium-1 SCSI Sequential Device.”

3 Right-click the HP Ultrium-1 SCSI Sequential Device listing,

Uninstall, and then click the OK button to confirm that you

click

want to remove the device.

4 Click the Action button in the upper-left corner of the

Computer Management dialog box.

5 Click Scan for Hardware Changes. Windows 2000 scans for the

drive. The drive appears under “? Other Devices” again.

ValueLoader LTO Tape Autoloader User Manual 17

Page 32

Installing the ValueLoader

Preparing the Host and Verifying the Connection

6 Right-click the HP Ultrium-1 SCSI Sequential Device listing and

then click

7 Select the Drivers tab.

8 Click the Reinstall Driver or Update Driver button.

9 When the Upgrade Device Driver Wizard appears, click the

Next button.

10 Click Tape Drives and then click the Next button.

11 Click the Have Disk button. Type the path to where you have

Properties.

saved the device drivers on your system, then click the

button.

12 Click the DLT ValueLoader Tape Drive entry and click the Next

button.

Note: Depending on the status of your system and the exact

path taken to select the device driver, the driver may

appear as

OK

Dltvstp.inf.

13 Click the Next button again to install the driver.

14 Click the Finish button.

15 Close the Device Properties dialog box.

The drive appears in the Device Manager under Tape Drives as

DLT ValueLoader Tape Drive. It is now ready to use.

ValueLoader Device Driver (Windows 2000) 1

To install the ValueLoader device driver:

1 Make sure that you are logged onto the host server with

Administrator privileges.

2 Right-click the My Computer icon on the Windows desktop,

then click

Manage, and then click Device Manager.

The tape drive should be listed under the “Medium Changers”

item as “Unknown Medium Changer Device.”

18 ValueLoader LTO Tape Autoloader User Manual

Page 33

Installing the ValueLoader

Preparing the Host and Verifying the Connection

3 Right-click the Unknown Medium Changer Device listing, click

Uninstall, and then click the OK button to confirm that you

want to remove the device.

4 Click the Action button in the upper-left corner of the

Computer Management dialog box.

5 Click Scan for Hardware Changes. Windows 2000 scans for the

ValueLoader. The ValueLoader appears under “Medium

Changers” again.

6 Right-click the Unknown Medium Changer Device listing and

then click

7 Select the Drivers tab.

8 Click the Reinstall Driver or Update Driver button.

9 When the Upgrade Device Driver Wizard appears, click the

Next button.

10 Click Display a list... and then click the Next button.

Properties.

11 Click the Have Disk button. Type the path to where you have

saved the device drivers on your system, then click the

OK

button.

12 Click the DLT VS Medium Changer entry and click the Next

button.

Note: Depending on the status of your system and the exact

path taken to select the device driver, the driver may

appear as

13 Click the Next button again to install the driver.

14 Click the Finish button.

15 Close the Device Properties dialog box.

Dltvsmc.inf.

The ValueLoader appears in the Device Manager under Medium

Changers as

DLT VS Medium Changer. It is now ready to use.

ValueLoader LTO Tape Autoloader User Manual 19

Page 34

Installing the ValueLoader

Preparing the Host and Verifying the Connection

20 ValueLoader LTO Tape Autoloader User Manual

Page 35

2Operating the ValueLoader

This chapter describes the following:

Chapter 2

• Operator’s Panel Overview

• Understanding the Menu Structure

• Using Cartridges

• Cleaning the Tape Drive

• Creating an Inventory of Cartridges

on page 27

on page 22

on page 32

on page 26

on page 33

ValueLoader LTO Tape Autoloader User Manual 21

Page 36

Operating the ValueLoader

Operator’s Panel Overview

Operator’s Panel Overview 2

The Operator’s Panel consists of four LEDs, four buttons, and a 2line by 16-character LCD screen, as shown in figure 9

Operator’s Panel provides everything you need to monitor

ValueLoader status and to control all ValueLoader functions.

Figure 9 Operator’s

Panel—Drive Empty

. The

The display defaults to the Home screen. The Home screen

consists of the ValueLoader status on the top line and the current

cartridge inventory on the second line. If the tape drive does not

have a cartridge loaded, the top line displays “Drive empty.”

The cartridge inventory indicates all slots that contain a cartridge

by displaying the slot number. Empty slots are indicated by a

hyphen (-).

An exclamation point (!) displayed in the inventory indicates that

the ValueLoader has identified a cartridge in the indicated slot that

either is an invalid cartridge type or has had a media-related error

(e.g, as caused by dirty read/write heads in the tape drive).

The Media Attention LED will be illuminated in this case. See LED

Indicators on page 24 for more information. Exporting the

indicated cartridge should clear the error condition. See Exporting

Cartridges on page 29 for instructions.

22 ValueLoader LTO Tape Autoloader User Manual

Page 37

Operating the ValueLoader

Operator’s Panel Overview

If errors occur on multiple known good cartridges, consider

cleaning the tape drive. See Cleaning the Tape Drive

on page 32 for

instructions.

If a particular cartridge causes error conditions repeatedly, that

cartridge may be defective or invalid.

Occasionally, you may see the message “In Transit,” which may

indicate:

• An error condition has caused a cartridge to be left between its

slot and the drive.

• A cartridge is unexpectedly found in the Import/Export slot

opening.

If either condition occurs, reset or power cycle the ValueLoader to

clear the condition.

If the tape drive has a cartridge loaded, the top line displays

“Drive loaded.” The cartridge currently loaded in the drive is

indicated by an alternating black block and the slot number as

shown in figure 10

. This display can also indicate that the specified

cartridge is being loaded, unloaded, imported, or exported as well

as indications of reading, writing, calibrating, etc. The

ValueLoader status line indicates the current operation.

Figure 10 Operator’s

Panel—Drive Loaded

The block appears on

the corresponding

cartridge position. It

alternates between a

solid block and the

cartridge number to

indicate that the

cartridge is active.

ValueLoader LTO Tape Autoloader User Manual 23

Page 38

Operating the ValueLoader

Operator’s Panel Overview

LED Indicators 2

Table 2 LEDs

The Operator’s Panel includes four LED indicators that provide a

variety of information as detailed in table 2

.

LED Color Description

Ready/Activity Green Illuminated when power is on.

Blinks whenever there is tape drive or

ValueLoader robotics activity.

Clean Drive Amber Illuminated when the tape drive needs to be

cleaned. Turns off when cleaning is successfully

completed.

See Cleaning the Tape Drive

on page 32.

Media Attention Amber Illuminated when a media-related error occurs.

This type of error may occur if an invalid cartridge

type is inserted or if data is written to a tape

cartridge while the drive’s read/write heads are

dirty. The offending cartridge is indicated by an

“!” in the cartridge inventory display for the

corresponding slot. Exporting the indicated

cartridge will clear the error condition. See

Exporting Cartridges

on page 29.

If media-related errors occur on multiple known

good cartridges, consider cleaning the tape drive.

See Cleaning the Tape Drive

on page 32.

If a particular cartridge causes repeated mediarelated errors, that cartridge may be defective or

invalid.

Error Red Illuminated when an unrecoverable tape drive or

ValueLoader error occurs. A corresponding error

message appears on the LCD screen. See

ValueLoader Error Codes

on page 59 for more

details.

24 ValueLoader LTO Tape Autoloader User Manual

Page 39

Operating the ValueLoader

Operator’s Panel Overview

Operator’s Panel Control Buttons

Table 3 Control

Buttons

The Operator’s Panel includes four buttons that provide access to

2

all operations and information menus. These buttons are described

in table 3

Button Description

Cancel Cancels the current menu option and returns to the

Previous Selects the previous item or value in the currently

Next Selects the next item or value in the currently

Enter Executes the current menu or selects the current

.

previous menu level or Home screen.

displayed menu.

displayed menu.

option displayed on the LCD panel.

ValueLoader LTO Tape Autoloader User Manual 25

Page 40

Operating the ValueLoader

Understanding the Menu Structure

Understanding the Menu Structure 2

Figure 11 Operator’s

Panel Menu Structure

Figure 11

Unload Cartridge

displays the menu structure of the Operator’s Panel.

HOME SCREEN

INFORMATION

COMMANDS

Import

Export

Load Cartridge

Cycle Count

View Event Log

Product Rev

Firmware Rev

Clean Drive

CONFIGURATION

Re-inventor y

DIAGNOSTICS

System Test

Reset

Change SCSI ID

Code Update

Circular Mode

Autoload Mode

26 ValueLoader LTO Tape Autoloader User Manual

Page 41

Operating the ValueLoader

Using Cartridges

Using Cartridges 2

Before you use the ValueLoader LTO, make sure you observe these

general rules:

• Use only LTO cartridges. You can order tape cartridges at our

Web site. Make sure all cartridges that you want to use for

writing have either never been written to or have been written

to only with the LTO tape drive in the ValueLoader or

equivalent tape drive. The tape drive rejects all other formats.

• Clean the tape drive when the Clean Drive LED is illuminated,

or if there is any other indication that the drive is having

trouble reading or writing, such as if the Media Attention LED

is illuminated, or there is an exclamation point (!) in the

inventory display. Be sure to use only compatible cleaning

cartridges. The tape drive rejects all other types of cleaning

cartridges.

Importing Cartridges

The option forces the ValueLoader to import a cartridge into a

2

specific empty slot in the carousel. To import tapes into the

ValueLoader:

1 Make sure the write-protect switch is set as desired for each

data cartridge (see Write-Protecting Cartridges

on page 31). If

applicable, adhere a barcode label onto the designated area on

each cartridge. (See Barcode Reader

on page 3 for more

information.)

2 From the Home screen or main menu, press the [+] or [-] button

until “Commands” appears on the top line of the LCD screen.

3 Press the [Enter] button to access the available options.

4 Press the [+] or [-] button until “Import” appears on the LCD

screen. Press

5 Press the [+] or [-] button until the desired slot number appears

on the LCD screen and press the

[Enter] to select.

[Enter] button. You are not

given the option to import a cartridge to an occupied slot.

ValueLoader LTO Tape Autoloader User Manual 27

Page 42

Operating the ValueLoader

Using Cartridges

6 When “Insert Cartridge Slot” appears on the LCD screen and

the Import/Export slot opens, insert the desired data cartridge

into the Import/Export slot so that the write-protect switch is

facing out from the ValueLoader and toward the left, as shown

in figure 12

Note: If you are using the Operator’s Panel to clean the

.

drive, import the cleaning cartridge only when the

front panel indicates that cleaning is needed. You

may keep a cleaning cartridge in the ValueLoader if

the backup software can manage the drive cleaning.

7 Repeat steps 5 and 6 as needed for additional cartridges.

8 Press the [Cancel] button when you have finished importing

cartridges.

9 Verify that the LCD screen shows that the desired slots have

cartridges installed.

Figure 12 Importing a

Cartridge

28 ValueLoader LTO Tape Autoloader User Manual

Page 43

Operating the ValueLoader

Using Cartridges

Exporting Cartridges

This option moves a cartridge from a specific slot to the Import/

2

Export slot. To export one or more cartridges from the

ValueLoader, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Commands” appears on the top line of the LCD screen.

Then, press

2 Press the [+] or [-] button until “Export” appears on the LCD

screen. Then, press

3 Press the [+] or [-] button until the desired slot number appears

on the LCD screen. Then, press the

[Enter].

[Enter].

[Enter] button. You are

given the option to export from an empty slot.

4 When “Remove Cartridge” appears on the LCD screen and the

cartridge is ejected through the Import/Export slot, remove the

exported cartridge from the ValueLoader, and press the

button.

5 Repeat steps 3 and 4 as needed for any additional cartridges.

6 Press the [Cancel] button when you are done exporting

cartridges.

7 Make sure the LCD screen indicates that the desired slots are

empty.

[Enter]

Figure 13 Exporting a

Cartridge

ValueLoader LTO Tape Autoloader User Manual 29

Page 44

Operating the ValueLoader

Using Cartridges

Loading Cartridges

This option loads a cartridge from the ValueLoader carousel into

2

the tape drive. To use this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Commands” appears on the top line of the LCD screen.

Then, press

2 Press the [+] or [-] button until “Load Cartridge” appears on the

[Enter].

LCD screen.

3 Press the [Enter] button to select.

4 Press the [+] or [-] button until the desired slot number appears

on the LCD screen and press the

[Enter] button. The slot

number you select indicates the cartridge to be loaded into the

tape drive.

Note: Only slot numbers that contain cartridges are

displayed.

Status messages appear while the cartridge is loading. “Drive

Stopped” appears when the operation is complete.

5 Press the [Cancel] button when you are done loading the

cartridge.

Unloading Cartridges

This option unloads the cartridge from the tape drive into its

2

original slot. To use this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Commands” appears on the top line of the LCD screen.

Then, press

2 Press the [+] or [-] button until “Unload Cartridge” appears on

the LCD screen. Then, press the

[Enter].

[Enter] button to unload the

cartridge from the tape drive.

Status messages appear while the cartridge is unloading.

“Drive Empty” appears when the operation is complete.

3 Press the [Cancel] button when you are done unloading the

cartridge.

30 ValueLoader LTO Tape Autoloader User Manual

Page 45

Operating the ValueLoader

Using Cartridges

Write-Protecting Cartridges

Figure 14 WriteProtect Switch

All cartridges have a write-protect switch to prevent accidental

2

erasure or overwriting of data (figure 14

). Before loading a

cartridge into the ValueLoader, make sure the write-protect switch

on the front of the cartridge is positioned as desired:

• Slide the switch to the left to write-protect the cartridge. A

small orange rectangle is visible, indicating the cartridge is

write protected.

• Slide the switch to the right to allow the ValueLoader to write

data to the cartridge. The lock icon on the switch indicates that

the cartridge is write-enabled.

Indicator

Write protect

switch

Maintaining Cartridges

Write protected

Write enabled

To ensure the longest possible life for all of your cartridges, follow

2

these guidelines:

• Do not drop or strike a cartridge. Excessive shock can displace

the tape leader, making the cartridge unusable and possibly

damaging the ValueLoader.

• Store cartridges in their storage cases.

• Do not expose cartridges to direct sunlight or sources of heat,

including portable heaters and heating ducts.

ValueLoader LTO Tape Autoloader User Manual 31

Page 46

Operating the ValueLoader

Cleaning the Tape Drive

• The operating temperature range for cartridges is 10° C to 35°

C (50° F to 95° F). The storage temperature range is 16° C to 32°

C (60° F to 90° F). Always store cartridges in their storage cases.

• If a cartridge has been exposed to temperatures outside the

ranges specified above, stabilize the cartridge at room

temperature for the same amount of time as it was exposed to

the extreme temperature or 24 hours, whichever is less.

• Store cartridges in a dust-free environment in which relative

humidity is always between 20% and 80%, non-condensing.

The ideal relative humidity is 40% ± 20%.

• Do not place cartridges near sources of electromagnetic energy

or strong magnetic fields, such as computer monitors, electric

motors, speakers, or X-ray equipment. Exposure to

electromagnetic energy or magnetic fields can destroy data on

cartridges.

• Place identification labels only in the slide-in slot on the front

of the cartridge.

Cleaning the Tape Drive 2

When the Clean Drive LED is on, the ValueLoader’s tape drive

needs to be cleaned. An illuminated Media Attention LED or an

exclamation point (!) in the inventory display may also indicate

that the tape drive needs to be cleaned. Cleaning typically takes

several minutes, during which the Ready LED blinks.

If you are using backup software to manage cleaning, then you

must monitor the software logs or use some other method to

determine when you need to replace the cleaning tape. Refer to the

backup software documentation for more information. Also refer

to the backup software documentation for information on enabling

automatic or scheduled cleanings with the use of a dedicated

cleaning slot.

32 ValueLoader LTO Tape Autoloader User Manual

Page 47

Operating the ValueLoader

Creating an Inventory of Cartridges

Note: If you are using Operator’s Panel commands to clean the

drive, import the cleaning cartridge only after you have

selected the Clean Drive command. If you would like to

keep a cleaning cartridge in the ValueLoader, the backup

software must manage drive cleaning.

Creating an Inventory of Cartridges 2

This option builds a new inventory of cartridges in the

ValueLoader. If using a barcode reader, this option also scans the

barcode label on each cartridge in the carousel. (See Barcode

Reader on page 3 for more information.) To use this option, follow

these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Commands” appears on the top line of the LCD screen.

2 Press the [Enter] button to access the available options.

3 Press the [+] or [-] button until “Re-inventory” appears on the

LCD screen. Then, press

[Enter].

The ValueLoader then checks the drive and each slot for the

presence of a tape in order to update inventory information.

ValueLoader LTO Tape Autoloader User Manual 33

Page 48

Operating the ValueLoader

Creating an Inventory of Cartridges

34 ValueLoader LTO Tape Autoloader User Manual

Page 49

Chapter 3

3ValueLoader Administration

This chapter describes the following:

• Configuring the ValueLoader

• Updating Firmware

• Running the ValueLoader System Test

• Retrieving Information About the ValueLoader

on page 40

on page 35

on page 42

on page 43

Configuring the ValueLoader 3

The Configuration menu provides access to the following

ValueLoader configuration options:

• Resetting the ValueLoader

• Setting SCSI IDs

• ValueLoader operating modes

•Updating firmware

ValueLoader LTO Tape Autoloader User Manual 35

Page 50

ValueLoader Administration

Configuring the ValueLoader

To access the Configuration menu from the Home Screen or main

menu, press the

the top line of the LCD screen. Press the

[-] to access the available options. Press the [Enter] button to

or

[+] or [-] button until “Configuration” appears on

[Enter] button and then [+]

execute the displayed menu option.

Resetting the ValueLoader

This option resets the ValueLoader robotics and the tape drive

3

within the ValueLoader, forces a new cartridge inventory, and

clears any current error condition.

Note: This option is primarily used if the ValueLoader is in an

error state.

To access this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Configuration” appears on the top line of the LCD

screen.

2 Press the [Enter] button to select.

3 Press the [+] or [-] button until “Reset” appears on the LCD

screen.

4 Press [Enter] to reset the ValueLoader.

After initialization, the ValueLoader returns to normal operation

and displays the Home screen.

Changing the SCSI ID

This option changes the SCSI IDs that the ValueLoader uses. The

3

ValueLoader operates as a dual SCSI device with two separate

SCSI IDs: one for the tape drive and the other for the ValueLoader

robotics.

The default SCSI IDs for the ValueLoader are 6 for the tape drive

and 5 for the robotics. You should only need to change the SCSI

IDs if there are other devices on the SCSI bus with the same SCSI

IDs.

36 ValueLoader LTO Tape Autoloader User Manual

Page 51

ValueLoader Administration

Configuring the ValueLoader

To access this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Configuration” appears on the top line of the LCD

screen.

2 Press the [Enter] button to select.

3 Press the [+] or [-] button until “Change SCSI ID” appears on

the LCD screen. The second line displays the current SCSI ID.

4 Press [Enter] to select.

5 Press the [+] or [-] button to change between “Loader” and

“Drive” until the desired item appears on the LCD screen.

6 Press the [Enter] button to select. The second line on the LCD

screen displays “New ID.”

7 Press the [+] or [-] button until the desired SCSI ID appears.

8 Press the [Enter] button to select the new ID number. The LCD

screen displays “Please Cycle Power.”

Note: The ValueLoader will not respond to input from the

Operator ‘s Panel until the power has been cycled.

9 Turn off the ValueLoader. After a few seconds, turn it back on

again.

The selected SCSI ID is now in effect.

Note: If you changed the SCSI ID, you may also need to cycle

power on the host server and reconfigure your backup

software before you can use the ValueLoader. Consult

your hardware and software manuals for more

information.

ValueLoader LTO Tape Autoloader User Manual 37

Page 52

ValueLoader Administration

Configuring the ValueLoader

ValueLoader Operating Modes

The operating mode is set based on whether you have automation

3

software controlling cartridges in the ValueLoader or if you are

manually loading and unloading cartridges using the ValueLoader

Operator’s Panel commands. The ValueLoader always operates in

Autodetect mode, which is transparent to you. In Autodetect

mode, the ValueLoader automatically assumes that you are not

using an automation software package to control cartridge or drive

activity. This is called Stacker or Sequential mode. If the

ValueLoader detects that an automation software package is

controlling tape/drive activity, it will automatically switch to

Random mode.

Random Mode 3

This is the normal mode of operation when a backup software

application is being used. In Random mode, the ValueLoader does

not automatically load tapes into the tape drive; instead, it waits

for commands from the software. To use Random mode, you do

not need to configure anything from the ValueLoader front panel.

In addition, your backup software package must support

ValueLoaders, which often requires the additional installation of a

ValueLoader/library software module.

Sequential Mode 3

Sequence Mode is useful when an adequate software application is

not available. In Sequential Mode, the ValueLoader automatically

loads and unloads tapes from the drive. The operator determines

the first tape to load by loading the desired tape into the tape drive

using the ValueLoader’s front panel controls. See Loading

Cartridges on page 30 for instructions. When the first tape is full or

unloaded for any other reason, the ValueLoader automatically

removes the tape from the drive, puts it in its original slot, then

loads the cartridge in the next available higher numbered slot,

continuing this sequence with each available higher numbered

slot. To further determine how you want tapes loaded into the

ValueLoader’s tape drive while in Sequential Mode, you may set

Circular and Autoload options from the autoload front panel.

38 ValueLoader LTO Tape Autoloader User Manual

Page 53

ValueLoader Administration

Configuring the ValueLoader

Circular Mode On/Off. This option turns Circular Mode on or off,

and is used only in sequential mode. When Circular Mode is on,

the ValueLoader reloads the original first cartridge in the sequence

after cycling through all available cartridges. If Circular Mode is

turned off and the last cartridge has been unloaded, the

ValueLoader stops loading cartridges until you manually load

another cartridge.

Caution: Use caution when choosing Circular Mode as it

makes it possible to overwrite data on previously

written cartridges.

To access this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Configuration” appears on the top line of the LCD

screen.

2 Press the [Enter] button to select.

3 Press the [+] or [-] button until “Circular Mode” appears on the

LCD screen. The second line displays the current status of this

mode.

4 Press [Enter] to select. The LCD screen indicates whether you

are about to turn Circular Mode on or off.

5 Press the [Enter] button to accept the change to Circular Mode

or press

Autoload Mode On/Off. This option turns Autoload Mode on or off,

[Cancel] to exit and not save the changes.

and is only used when in Sequential Mode. When Autoload Mode

is on, the ValueLoader automatically loads the cartridge from the

lowest numbered full slot into the tape drive when powered on. It

then follows standard sequential operation as described in

Sequential Mode

on page 38.

To access this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Configuration” appears on the top line of the LCD

screen.

2 Press the [Enter] button to select.

ValueLoader LTO Tape Autoloader User Manual 39

Page 54

ValueLoader Administration

Updating Firmware

3 Press the [+] or [-] button until “Autoload Mode” appears on

the LCD screen. The second line displays the current status of

this mode.

4 Press the [Enter] button. The LCD screen indicates whether you

are about to turn Autoload Mode on or off.

5 Press the [Enter] button to accept the change to Autoload Mode

or press

[Cancel] to exit and not save the changes.

Updating Firmware 3

This section explains how to update firmware using either a

firmware upgrade tape or SCSI commands.

Caution: Regardless of the firmware update technique, DO

NOT POWER CYCLE OR RESET THE

VALUELOADER DURING THE UPGRADE

PROCESS. Doing so could cause the ValueLoader to

become inoperable.

Using a Firmware Upgrade Tape

This option performs a firmware update for the ValueLoader and/

3

or the HP LTO drive using firmware upgrade cartridge.

Note: This code update operation assumes that a slot is

available in the carousel for the upgrade cartridge, and

the upgrade cartridge is imported as part of this

procedure.

If the carousel is full, export a cartridge to make room for

the firmware upgrade cartridge. (See Exporting

Cartridges on page 29 for instructions.) Do not import

the firmware upgrade cartridge before starting this

procedure.

40 ValueLoader LTO Tape Autoloader User Manual

Page 55

ValueLoader Administration

Updating Firmware

To access this option, follow these steps:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Configuration” appears on the top line of the LCD

screen.

2 Press the [Enter] button to select.

3 Press the [+] or [-] button until “Code Update” appears on the

LCD screen. The second line displays the current status of this

mode.

4 Press the [Enter] button to select.

The ValueLoader selects the first available slot and prompts

you to insert the firmware upgrade cartridge.

Note: If the carousel is full, the LCD screen displays “No

slot free for transfer.” If this happens, press the

[Cancel] button repeatedly until the main menu or

Home Screen appears. Then, export a cartridge as

explained in Exporting Cartridges

on page 29 and

return to step 1 of this procedure.

5 Insert the firmware update cartridge into the Import/Export

slot.

Note: If the cartridge is not a valid firmware upgrade

cartridge, the cartridge is exported, and the LCD

displays “Bad upgrade tape.”

During the firmware update, which can take several minutes,

the LCD screen displays “Code update in Progress.” When the

firmware update is complete, the ValueLoader resets, then

unloads and exports the firmware upgrade cartridge.

6 Remove the firmware upgrade cartridge and press the [Enter]

button when the LCD screen prompts you to do so.

ValueLoader LTO Tape Autoloader User Manual 41

Page 56

ValueLoader Administration

Running the ValueLoader System Test

7 If you removed a data cartridge to make room for the firmware

upgrade cartridge, import the data cartridge to its original slot.

See Importing Cartridges

Note: After a firmware update, the firmware revision

on page 27 for instructions.

displayed on the LCD is not changed until the

ValueLoader is power cycled.

Using SCSI 3

Quantum has files and instructions necessary to update the drive

and ValueLoader firmware via SCSI. Refer to our Web site for

details.

Running the ValueLoader System Test 3

The System Test option cycles the ValueLoader through the

process of loading and unloading all cartridges in the carousel.

Running a System Test verifies the operational soundness of both

the ValueLoader and tape drive. The System Test continues

indefinitely until you press the

and restore operations are suspended while a System Test is in

progress.

Note: At least one cartridge must be present in the carousel in

order to run System Test.

To run a System Test:

[Cancel] button. All regular backup

1 From the Home Screen or main menu, press the [+] or [-] button

until “Diagnostics” appears on the top line of the LCD screen.

2 Press the [Enter] button to select. “System Test” appears on the

LCD screen.

3 Press the [Enter] button to begin the test.

42 ValueLoader LTO Tape Autoloader User Manual

Page 57

ValueLoader Administration

Retrieving Information About the ValueLoader

The “Test Count” displays the number of load-calibrate-unload

cycles that have been completed during the test.

4 Press the [Cancel] button to end the test.

Retrieving Information About the ValueLoader 3

The Information menu provides access to information about the

ValueLoader, including the cycle count, event log, and firmware

revision.

Cycle Count 3

View Event Log 3

This option displays the total system cycle count, incrementing

each time a tape is loaded into the drive or exported from the

ValueLoader.

To use this option:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Information” appears on the top line of the LCD screen.

2 Press the [Enter] button to access the available options.

3 Press the [+] or [-] button until “Cycle Count” appears on the

LCD screen.

The LCD screen displays the total cycle count.

4 Press the [Cancel] button when done.

This option provides access to the most recent ValueLoader errors

and events (see table 5

on page 60 for a description of error codes).

To use this option:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Information” appears on the top line of the LCD screen.

2 Press the [Enter] button to access the available options.

ValueLoader LTO Tape Autoloader User Manual 43

Page 58

ValueLoader Administration

Retrieving Information About the ValueLoader

3 Press the [+] or [-] button until “View Event Log” appears on

the LCD screen. The LCD screen also displays the quantity of

errors and events currently stored in the event log.

4 Press the [Enter] button to access the most recently logged

event.

5 Press the [+] or [-] button to display each event in the log.

6 Press [Cancel] when done.

Product Revision 3

Firmware Revision 3

This option displays the product revision of the ValueLoader.

To use this option:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Information” appears on the top line of the LCD screen.

2 Press the [Enter] button to access the available options.

3 Press the [+] or [-] button until “Product Rev” appears on the

LCD screen.

The LCD screen displays the revision of the firmware currently

installed in the ValueLoader.

4 Press the [Cancel] button when done.

This option displays the revision of the firmware currently

installed in the ValueLoader.

To use this option:

1 From the Home Screen or main menu, press the [+] or [-] button

until “Information” appears on the top line of the LCD screen.

2 Press the [Enter] button to access the available options.

3 Press the [+] or [-] button until “Firmware Rev” appears on the

LCD screen.

The LCD screen displays the revision of the firmware currently

installed in the ValueLoader.

44 ValueLoader LTO Tape Autoloader User Manual

Page 59

ValueLoader Administration

Retrieving Information About the ValueLoader

4 Press the [Cancel] button when done.

Note: After a firmware update, the firmware revision

displayed on the LCD will not be updated until the

ValueLoader is power cycled.

ValueLoader LTO Tape Autoloader User Manual 45

Page 60

ValueLoader Administration

Retrieving Information About the ValueLoader

46 ValueLoader LTO Tape Autoloader User Manual

Page 61

Chapter 4

4Diagnostics and Troubleshooting

This chapter contains some general suggestions to aid you in

solving problems. It also includes information on error codes and

diagnostics.

• Troubleshooting

• Removing Stuck Cartridges

• ValueLoader Error Codes

on page 47

on page 55

on page 59

Troubleshooting 4

This section contains installation problems and a troubleshooting

table.

ValueLoader LTO Tape Autoloader User Manual 47

Page 62

Diagnostics and Troubleshooting

Troubleshooting

Installation Problems

Problems encountered during the installation of the ValueLoader

4

are usually caused by improper SCSI bus configuration,

application software configuration errors, or an incorrectly

configured operating system. If the application software that you

are using is not communicating with the ValueLoader after

installation, check the following:

SCSI ID: The ValueLoader uses two SCSI IDs: one for the tape

•

drive and one for the ValueLoader robotics. Depending on the

SCSI IDs of the other devices on the same SCSI bus, you may

need to change one or both of these SCSI IDs before you can

use the ValueLoader. Select an unused SCSI ID. See the

manuals for the other devices on the SCSI bus or your

operating system to determine which SCSI IDs are currently in

use. If the ValueLoader is attached to a narrow (50-pin) SCSI

bus, only SCSI IDs 0 through 7 are available. See Changing the

SCSI ID on page 36.

SCSI Cabling: Verify that all SCSI cables are securely connected

•

at both ends. Check the length and integrity of your SCSI

cabling. The total length of all cables must not exceed the

following lengths:

• SCSI-1 SE bus: 6 meters (19 feet)

• Fast or Ultra SCSI (Narrow or Wide) SE bus: 3 meters

(10 feet)

• LVD bus with multiple devices: 12 meters (40 feet)

• LVD bus with a single device: 25 meters (82 feet)

The length of the SCSI cabling inside the ValueLoader is 60 cm

(2 feet). This length must be included in any calculations of

total cable length. Replace suspect SCSI cables with known

good cables.

48 ValueLoader LTO Tape Autoloader User Manual

Page 63

Diagnostics and Troubleshooting

Troubleshooting

• Termination: If the ValueLoader is the only SCSI device (other

than the SCSI host adapter) on the selected SCSI bus, it must be

terminated. Likewise, if the ValueLoader is physically the last

SCSI device on the SCSI bus, it must be terminated. Likewise, if

the ValueLoader is physically the last SCSI device on the SCSI

bus, it must be terminated. Only the devices physically at the

beginning and end of the SCSI bus should be terminated. Refer

to the manuals supplied with the other devices on the SCSI bus

for termination on enabling or disabling termination on those

devices.

To terminate the ValueLoader, locate the terminator in the

accessories package and press it firmly into the either of the

two SCSI connectors on the rear panel of the ValueLoader.

Secure the terminator by tightening the finger-screws until

snug. The supplied terminator is “dual mode” and will work

on both LVD and SE SCSI buses. A green LED on the

terminator indicates that the unit is attached to a SCSI bus

running in LVD mode. A red LED on the terminator indicates

that the unit is attached to a SCSI bus running in SE mode. If

the LED is not on, check all SCSI and power connections and

confirm that the unit is attached to a valid SCSI bus.

Compatibility: Ensure that the ValueLoader is compatible with

•

the SCSI host adapter and backup application you plan to use.

For a list of compatible SCSI adapters and application software

packages, check with your SCSI host adapter manufacturer,

backup application vendor, or our Web site.

SCSI Host Adapter Installation: Verify that you have installed

•

your SCSI host adapter correctly. Refer to the manual that

came with your SCSI host adapter for installation and

troubleshooting instructions. Pay particular attention to any

steps describing the settings of various jumpers or switches on

the host adapter or, on newer adapters, the setup application

for the adapter. Make sure that the host adapter is properly

seated in the motherboard slot, and the operating system

correctly detects the host adapter. Make sure that the proper

device driver is installed for the SCSI host adapter.

ValueLoader LTO Tape Autoloader User Manual 49

Page 64

Diagnostics and Troubleshooting

Troubleshooting

• Backup Application Installation: Refer to the documentation

•

included with your backup application for instructions on how

to verify proper installation. Most backup software packages

require an additional module to communicate with the

ValueLoader robotics.

Device Driver Installation: Make sure that the proper device

driver, if applicable, is installed for the ValueLoader. (See

Installing Device Drivers

on page 17.) Also refer to our Web

site for more information.

lists common problems with the ValueLoader and possible

• Check all power cord connections.

• Make sure the power switch on the front panel is in the ON

position.

• Make sure there is power to the outlet. Try another working

outlet.

• Replace the power cord.

• Contact your service representative.

• Make sure the power cord is connected.

• Make sure the power switch is on.

4

Table 4

solutions.

Troubleshooting Table

Table 4 Common

ValueLoader

Problems

Problem Solution

Power

ValueLoader does not

power on.

No display messages

appear.

• Power cycle the ValueLoader.

• Download ValueLoader firmware.

• Contact your service representative.

50 ValueLoader LTO Tape Autoloader User Manual

Page 65

Diagnostics and Troubleshooting

Problem Solution

Tape Movement

Tape stuck in drive. • Power cycle the ValueLoader, allow it to complete

initialization (which in rare cases can take as long as 10

minutes), and then retry unloading the tape using the

ValueLoader Operator’s Panel controls.

• Allow the tape drive to complete all operations. This may take

as long as 10 minutes if you reset or cycle power on the

ValueLoader while the cartridge is positioned at the physical

end of the media.

• Make sure that the backup software is not reserving the slot or

preventing the tape drive from ejecting the cartridge. The

backup software needs to cancel the reservation and any hold

it has on the tape drive. Temporarily disconnecting the

ValueLoader from the host server eliminates the host and its

software as a problem source.

• Contact your service representative.

Troubleshooting

Tape stuck in storage slot. • See Removing Stuck Cartridges

Media

Cleaning or data cartridge

incompatible with drive

• Make sure you are using cleaning and data cartridges that are

compatible with the tape drive. The ValueLoader

automatically unloads incompatible cartridges to their original

slot.

ValueLoader LTO Tape Autoloader User Manual 51

on page 55.

Page 66

Diagnostics and Troubleshooting

Troubleshooting

Problem Solution

Cannot read from, or write

to, a tape

SCSI ID

Change drive or robotic

ID, but the host server

does not recognize the new

ID

• Make sure the cartridge is write enabled. (Move the writeprotect switch to the enabled position.)

• Make sure the cartridge is HP LTO compatible.

• Make sure the cartridge has not been exposed to harsh

environmental or electrical conditions and is not physically

damaged in any way.

• Many backup applications do not read from, or write to,

cartridges that were created using a different backup

application. In this case, you may have to perform an erase,

format, or label operation on the cartridge.

• Make sure you understand any data protection or overwrite

protection schemes that your backup application may be

using, which could prevent you from writing to a given

cartridge.

• Retry the operation with a different, known good tape.

• Clean the tape drive. See Cleaning the Tape Drive

on page 32

for instructions.

• Make sure all SCSI devices on the same bus have a unique ID

number.

• If the SCSI bus is narrow (50-pin), verify that only SCSI IDs 0

through 7 are being used.

• Make sure to cycle power on the ValueLoader after changing

the SCSI ID.

• Reboot the host server.

52 ValueLoader LTO Tape Autoloader User Manual

Page 67

Problem Solution

ValueLoader Performance

Diagnostics and Troubleshooting

Troubleshooting

The ValueLoader is not

efficiently backing up data.

Cleaning

Recurring cleaning

message.

• Check the network bandwidth from the host computer. If you

are backing up data over a network, consider comparing to a

local-only backup.

• Make sure the ValueLoader is on its own SCSI bus and not

daisy-chained to another tape drive or to the hard drive being

backed up.

• Clean the tape drive. See Cleaning the Tape Drive

on page 32.

• Try a new cartridge. A marginal cartridge can cause

performance problems due to bad spots on the tape requiring

retries.

• Make sure the data is being compressed.

• Check the size of the files. Small files can impact performance.

• Confirm that the backup application is utilizing block sizes of

at least 32 KB, preferably 64 KB. Refer to your application’s

documentation for details.

• Make sure you are using an HP LTO cleaning cartridge.

• Replace the existing cleaning cartridge with a new one.

• If the Media Attention LED is cleared using a cleaning

cartridge and then immediately reappears after a particular

data cartridge is reloaded, that data cartridge may

contaminated. If this occurs, check that the data cartridge can

be read, back up data from the suspect cartridge to another

cartridge, and then discard the suspect cartridge.

The Clean Drive LED is

illuminated.

Cannot load the cleaning

cartridge.

• This indicates that you have exceeded the tape motion hours.

• Clean the tape drive. See Cleaning the Tape Drive

on page 32.

• Make sure you are using an HP LTO cleaning cartridge.

• Contact your service representative.

ValueLoader LTO Tape Autoloader User Manual 53

Page 68

Diagnostics and Troubleshooting

Troubleshooting

Problem Solution

Media Compatibility

Media format invalid for

drive type.

• You attempted to load incompatible media into the tape drive.

Ensure the media is compatible with HP LTO.

Media Attention LED Issues

Contamination by loose

debris.

• Avoid contamination by ensuring that the ValueLoader is

installed in a clean, contamination-free environment.

• Store cartridges vertically in their plastic cases.

• Continue cleaning the tape drive as needed.

Contamination by head

staining (caused by

adhesion of chemicals

present in tape media to

the head surface).

• One or two passes with the cleaning cartridge should resolve

the Media Attention LED caused by normal head staining.