Page 1

1

Quick Start Guide

I/S Series SC Series

I/S 60, 85, 110, 130 and 100 System SC-40 & -48

Ioline SmarTrac™

Page 2

2

User Notice

Trademarks

Ioline and SmarTrac are trademarks of Ioline Corporation. Other product names, logos, designs, titles, words or

phrases mentioned within this publication may be trademarks, service marks, or trade names of Ioline Corporation or

other entities and may be registered in certain jurisdictions including internationally.

Ioline Disclaimer

IOLINE CORPORATION PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OR CONDITIONS OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL IOLINE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF

USE OR DATA, INTERRUPTION OF BUSINESS AND THE LIKE), EVEN IF IOLINE HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT.

Limit of Liability Statement

It is the responsibility of the operator of the cutter to monitor the performance of the cutter and maintain it in proper

working condition by following the instructions in this User Guide. It is the responsibility of the operator of the cutter

to follow all safety precautions and warnings that are described in this User Guide. Ioline is not responsible for injuries that may occur as a result of unsafe operating procedures. Ioline is not responsible for substandard operational

performance as a result of failure to maintain the cutter as described in this User Guide.

© 1997-2005 Ioline Corporation. All rights reserved. This manual may not be copied, photocopied, reproduced, translated, transmitted or converted to any electronic or machine-readable form in whole or in part without prior written

approval of Ioline Corporation.

Service and Support

If you require assistance with an Ioline product, your local Ioline dealer or authorized service center is ready to help.

Support information is also available 24/7 on the Ioline Web site—or you may contact Ioline directly:

Ioline Corporation

14140 NE 200th Street

Woodinville, Washington 98072 U.S.A.

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacic Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Part Numbers: (Print) 106916 Rev. 8 • (File) 107109 Rev. 5

Page 3

Please read these safety guidelines before beginning operation of

the cutter. The cutter uses a very sharp blade when cutting. The

parts can move quickly. Always observe the following safety precautions:

n Do not allow the material to become suddenly taut between

the cutter and a roll of material during plotting. A service

loop of unrolled material is required for problem-free operation. Using the Autoloop function (enabled in the Control

Center) will create the required service loop by gently pulling

a set amount of material from the roll before cutting. Ioline

recommends using the Autoloop function when plotting on a

roll of material.

Safety &

Cautions

n Do not try to repair the machine without factory authorization.

Only qualied service personnel should attempt any disassembly or access to internal components. If external mechanical

adjustments are necessary, turn off the cutter and disconnect it

from all power sources (both the computer and the wall outlet).

n Be careful with hair, jewelry, or loose clothing near the cutter.

They can become caught in the mechanical parts.

n Never move the carriage by hand. Use the Arrow keys and let

the machine do it.

n Keep hands away from the carriage when the cutter is in opera-

tion. The carriage will automatically move to its right end position when the power is turned on.

n Be careful when lifting the cutter. Hold the bottom surfaces of

the cutter to lift or move it.

n Keep ngers away from the drive shaft when the cutter is in

operation.

n Use caution when changing a blade in the blade holder. See the

Routine Maintenance chapter of the SmarTrac User Guide for the

recommended procedure.

n Be careful when handling the blades. They are sharp and could

cause an injury if mishandled. Although the blades are made

of an extremely hard material, they are brittle and can break if

dropped or mishandled.

Page 4

4

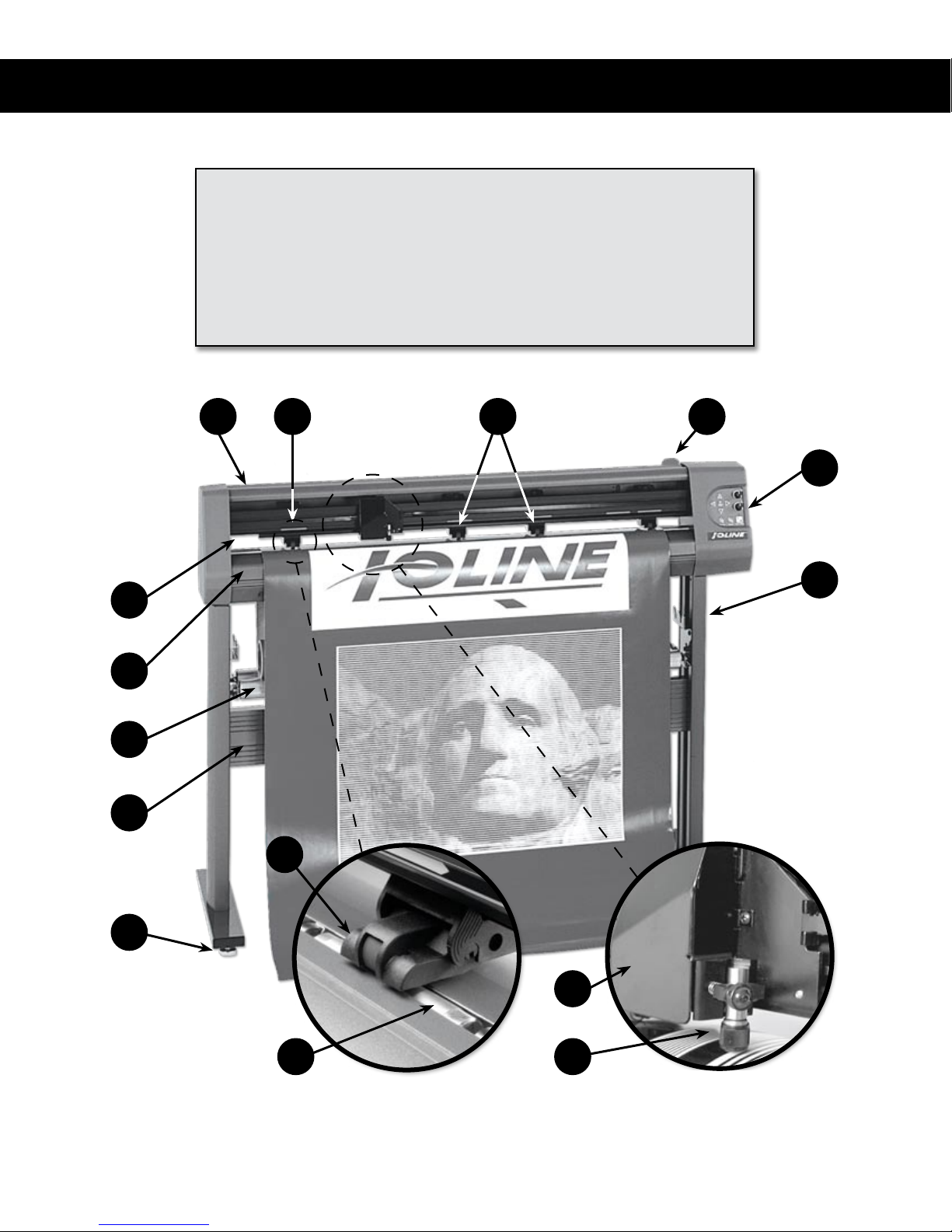

KEY

O

N

A. Dust Cover

B. Drive Shaft Marker

C. Carriage

D. Blade Holder

A B H

E. Idler Wheel

F. Drive Shaft

G. Pinchwheel

H. Pinchwheel Lever

E

I

J

M

L

K

G

F

Figure 1. The Ioline SmarTrac I/S Cutter Front View.

C

D

Page 5

Visual Reference Guide

KEY

5

O

I. Keypad

J. Stand Leg

K. Stand Leveling Foot

L. Cross-member

M. Media Roller

N. Platen

O. Traverse

P. LED Sensor

A B E H

I

J

N

M

L

K

C

G

D

Figure 2. The Ioline SmarTrac Contour (SC) Cutter Front View.

P

F

Page 6

Quick

Setup

Caution

Caution: The SmarTrac

is heavy and could cause

injury if it falls. A minimum

of two people are required to

safely unpack the plotter and attach it to the stand or cradle. One

person should hold the machine

while the second person screws it

to the legs.

Figure 4. Proper lifting pro-

cedure. Requires two people.

This Quick Start Guide shows how to assemble and setup the Ioline

I/S, SC-40 and SC-48 model cutters. Consult the SmarTrac User

Guide on the CD-ROM for more detailed information about installation and operation. The User Guide may be printed from the provided Adobe® Acrobat® viewer if necessary.

Step 1: Unpack

Remove the cutter, stand parts, and Accessory Kit from the box.

Check the Packing List. Always use two people when lifting the cutter, one person at each end. Save all of the packing materials.

Required tools

n Phillips screw driver

n 7/16-in wrench

Step 2: Assemble the Stand

(Optional for I/S 60 model)

Attach the Feet

Attach one foot to

each leg using three

1.5-in (long) Phillips

screws and three 7/16in hex nuts. Repeat

this procedure for

the other leg. Screw

all of the leg levelers halfway into the

ends of the stand

feet. Thread all four

levelers in equally to

ensure your cutter is

level and stable.

Leveler

Foot

Figure 5. Attach the feet.

Leg

Page 7

Connect the

Cross-Member

and Legs

The cross-member

is reversible and can

be attached upside

down or from either

side. Fit the crossmember snugly

into the rectangular

groove in one leg.

Align the holes in the

leg with the threaded

holes in the cross-member. Insert two 1-in (medium) Phillips screws

into the threaded holes. Leave them loose. Repeat this procedure for

the other leg. Tighten all four screws.

Figure 6. Connect the cross-member.

Cross-member

Quick Setup

7

Insert the Media

Roller

Rollers

Insert the front media

roller pins into the

notches in the front

of each leg. There are

extra notches to accommodate different

size rolls of media.

Find the matching

notches on the opposite leg to keep the

roller straight. Repeat

for rear media roller.

Figure 7. Insert the media rollers.

Notch

Step 3: Attach the Stand or Cradle

Place Cutter on the Stand

(I/S 85, 110 and 130 & SC40, and -48 models)

One person should

hold the cutter while

the other person positions it. Slide the tabs

on the bottom of the

cutter inside the top

of both legs. Make

sure that the holes in

the legs line up with

the threaded holes in

the tabs.

Tab

Figure 8. Place cutter on stand.

Page 8

8

Ioline SmarTrac Quick Start Guide

Place Cutter on

the Cradle

(optional on I/S 60)

Tab

Back

Front

Figure 9. Place cutter on cradle.

of the machine. Make sure that the holes line up. The media support

shaft ts in notches at the back of the cradle leg.

Have one person

hold the cutter while

the other person positions the cutter. Slide

bottom tabs of the

cutter outside the top

of both cradle feet.

The longer portion

of the foot should

extend from the back

Figure 10. Insert Screws in legs or cradle feet.

Insert the Screws

Have one person hold

the cutter while the

other person inserts

the screws to secure

the cutter to the legs or

cradle feet. Insert the

3

/8-in (short) Phillips

head screws though

the leg or cradle foot

and into tabs on the

cutter; Tighten.

Finish Assembly

Cut the plastic strap

that holds the carriage in place during

shipment and discard

it. Remove and discard all packing foam

from around the carriage to complete the

assembly.

Figure 11. Remove packing foam and plastic strip.

Page 9

Quick Setup

9

Step 4: Finish Installation

Connect the

Machine Cables

Make sure power is

off to the cutter (the

switch is placed in the

0 position). Connect

the serial or USB cable

and the power cord

to the panel on the

back of the right side

of the cutter. Plug the

machine power cable

into a wall socket or

surge protector.

Connect the

Computer Cable

With power to the

computer off, connect

the serial or USB cable

to one of the ports

on the back of the

computer. See the In-

stallation chapter of the

SmarTrac User Guide

for more information.

Power

Cable

Figure 12. Power cable and communication ports.

Figure 13. Computer communication ports.

Serial

Port

USB Ports

Serial Port

USB

Port

i

A USB cable is provided in the

Accessory Kit.

i

An adapter (not included) is required for 25-pin serial connections.

Note

Note

Install the

Software

Insert the installation

CD-ROM into the

computer CD-ROM

drive. The install

program should start

automatically. If it

does not, select Run

from the Start Menu.

Browse to the CDROM and double-click

on Install Ioline Con-

trol Center from the

list of options. Press

OK to start the install.

Install the Control

Center software.

Figure 14. The Ioline Control Center.

Install USB Drivers

Please see the guide labeled Installing USB Drivers for Ioline Products

on the CD-ROM for the driver installation process.

i

The Setup program also allows

installation of the electronic User

Guides and the necessary viewer.

Note

Page 10

10

Ioline SmarTrac Quick Start Guide

Step 5: Prepare to Cut

Load the Material

Roll

Place a roll of material onto the media

rollers. With the

pinchwheels up,

thread the material

through the machine.

Figure 15. Material loaded on media roller.

Position the Pinchwheels Over the Drive Shaft

Move the material and pinchwheels from side to side to nd a position

where the outermost drive wheels are on the material about 1 inch from

each edge, and over a drive shaft segment. Use the drive shaft markers

(Figure 16) to determine where to place the wheels. The long drive shaft

segment on the right

Drive Shaft

Marker

Drive Shaft

Segment

Figure 16. Place pinchwheels under drive shaft markers.

side of the machine

allows many pinchwheel positions for

a variety of material

widths. Evenly space

the inner idler wheel(s)

(I/S 85, 110 and 130 &

SC-40 and -48 models) over drive shaft

segments. Make sure

there is a minimum of

one inch between the

edge of the roll and the

stand leg.

Square the Material

Lift the pinchwheels off the drive shaft using the pinchwheel lever.

Pull enough material through the machine so that it reaches the roll.

Align the edge of

the material with

the edge of the roll,

making sure the

material is at and

square in the machine. Ensure that the

outer pinchwheels

are at least one inch

from the edge of the

material. Lower the

pinchwheels.

Figure 17. Align the material.

Page 11

Position the Material

Do not let the material become suddenly tight between the cutter

and the material roll. Manually unroll a few feet of material from

the roll to create a

slack loop behind

the machine. Use

the Arrow keys on

the keypad to move

material through the

cutter to check alignment. Adjust the material if necessary so

that it feeds straight.

Position the material

edge two inches in

front of the blade;

Place the carriage an

inch from the right

edge.

Figure 18. Leave slack in the material.

Quick Setup

11

Insert a Blade,

Load the Holder

Blade

Blade

Holder

in the Jaw

Unscrew the foot

from the blade

holder. Insert a blade

into the hole in the

blade holder, making sure it is fully

seated. Replace the

foot and adjust it so

that the blade tip is

barely inside the foot

with no blade exposed. Loosen the thumb screw on the carriage jaw

and insert the blade holder. The ange slides into the slot in the jaw.

Rotate the clamp down onto the ange and tighten the thumb screw

until the blade holder is held securely in place.

Foot

Flange

Figure 19. Inserting the blade (left) and the blade

holder (right).

Adjust the Blade

Exposure and

Force

i

Be very careful when handling

the blades as they are sharp and

brittle and the tips can chip or

break. Using a hard surface to

insert the blade may damage it.

Note

Turn the Force knob

on the keypad clockwise to maximum.

Press the Test Cut

key. There should be

little or no scoring of

the material. Turn the

foot 1/8-turn clockwise (from the bottom). Press the Test Cut key. Weed the test cut

pattern and examine cut quality. Continue adding blade exposure

Deeper

Cut

Figure 20. Adjusting the blade exposure.

Page 12

12

Ioline SmarTrac Quick Start Guide

and pressing Test Cut until the pattern weeds easily and the blade

leaves a clear scoring on the backing.

To extend blade life, only set as much Force and blade exposure as

is absolutely required to get a clean cut and good weed. Reduce the

Force in small increments and perform more test cuts until the test

cut pattern sticks slightly while weeding; Then, set the Force to the

previous position. Press and hold the Test Cut key for 3 seconds. The

cutter will cut a large test pattern as a nal check. Move the carriage

and material to a starting position for the rst le. Press the Set Ori-

gin key on the keypad. The light on the keypad will turn green.

The cutter is ready to cut. Refer to the User Guide and

your design software documentation for more information

about optimizing cutter performance.

Customer Service

Ioline Corporation is committed to providing quality service and

support to our customers. If you need assistance with an Ioline product, contact your local dealer or Ioline authorized service center. You

may also contact:

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacic Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Loading...

Loading...