Page 1

Quick Start Guide

Ioline FlexJet E

Page 2

User Notice

Trademarks

Ioline FlexJet E is a trademark of Ioline Corporation. HP is a trademark of the Hewlett-Packard Company.

Other product names, logos, designs, titles, words or phrases mentioned within this publication may be

trademarks, service marks, or trade names of Ioline Corporation or other entities and may be registered in

certain jurisdictions including internationally.

Ioline Disclaimer

IOLINE CORPORATION PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OR CONDITIONS OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL IOLINE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES

FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS

AND THE LIKE), EVEN IF IOLINE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES

ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT.

Limit of Liability Statement

It is the responsibility of the operator of the printer to monitor the performance of the printer and

maintain it in proper working condition by following the instructions in this Quick Start Guide and

the User Guide. It is the responsibility of the operator of the printer to follow all safety precautions and

warnings that are described in this User Guide. Ioline Corporation is not responsible for injuries that

may occur as a result of unsafe use. Ioline Corporation is not responsible for substandard operational

performance as a result of failure to maintain the printer as described in the Quick Start Guide and the

User Guide.

© 2003-2008 Ioline Corporation. All rights reserved. This manual may not be copied, photocopied, reproduced, translated, transmitted or converted to any electronic or machine-readable form in whole or in

part without prior written approval of Ioline Corporation.

Service and Support

If you require assistance with an Ioline product, your local Ioline dealer or authorized service center is

ready to help. Support information is also available 24/7 on the Ioline Web site—or you may contact Ioline

directly:

Ioline Corporation

14140 NE 200th Street

Woodinville, Washington 98072 U.S.A.

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacific Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Part Numbers: (Print) 109531 Rev. 1 • (File) 109620 Rev. 1

Page 3

The Ioline FlexJet E printer has many fast moving components.

Please read and follow these safety guidelines before beginning

operation of the printer:

n Do not try to repair the machine without factory authoriza-

tion. Only qualified service personnel should attempt any

disassembly or access to internal components. If external

mechanical adjustments are necessary, turn off the printer and

disconnect it from all power sources (both the computer and

the wall outlet).

Safety &

Cautions

n Be careful with hair, jewelry, or loose clothing near the printer.

They can become caught in the mechanical parts.

n Never attempt to move the carriage by hand when the power is

on. Always use the Arrow keys to move the carriage. To park

the carriage safely in

the Service Station

and protect the print

cartridges, press the

Clean button.

n Keep hands away

from the carriage

when the printer is in

operation. The car-

riage will automatically move to touch

the left end plate then

back to the right end

(the Service Station

position) when the

power is turned on.

n Never insert hands or other objects into the Service Station

area on the right side of the printer. The carriage occasionally

enters this area without warning and could collide with an

obstruction, potentially causing and injury.

Hold the bottom surfaces of the end covers

to avoid injury to your ngers.

n Be careful when moving or lifting the printer. Moving the print-

er requires at least 2 people. To avoid injury to your fingers, do

not lift the printer by the end plates. Hold the bottom surfaces

of the end covers to lift or move it. See Figure 1.

n Keep fingers away from the drive shaft when the printer is in

operation. Serious injury could result.

Page 4

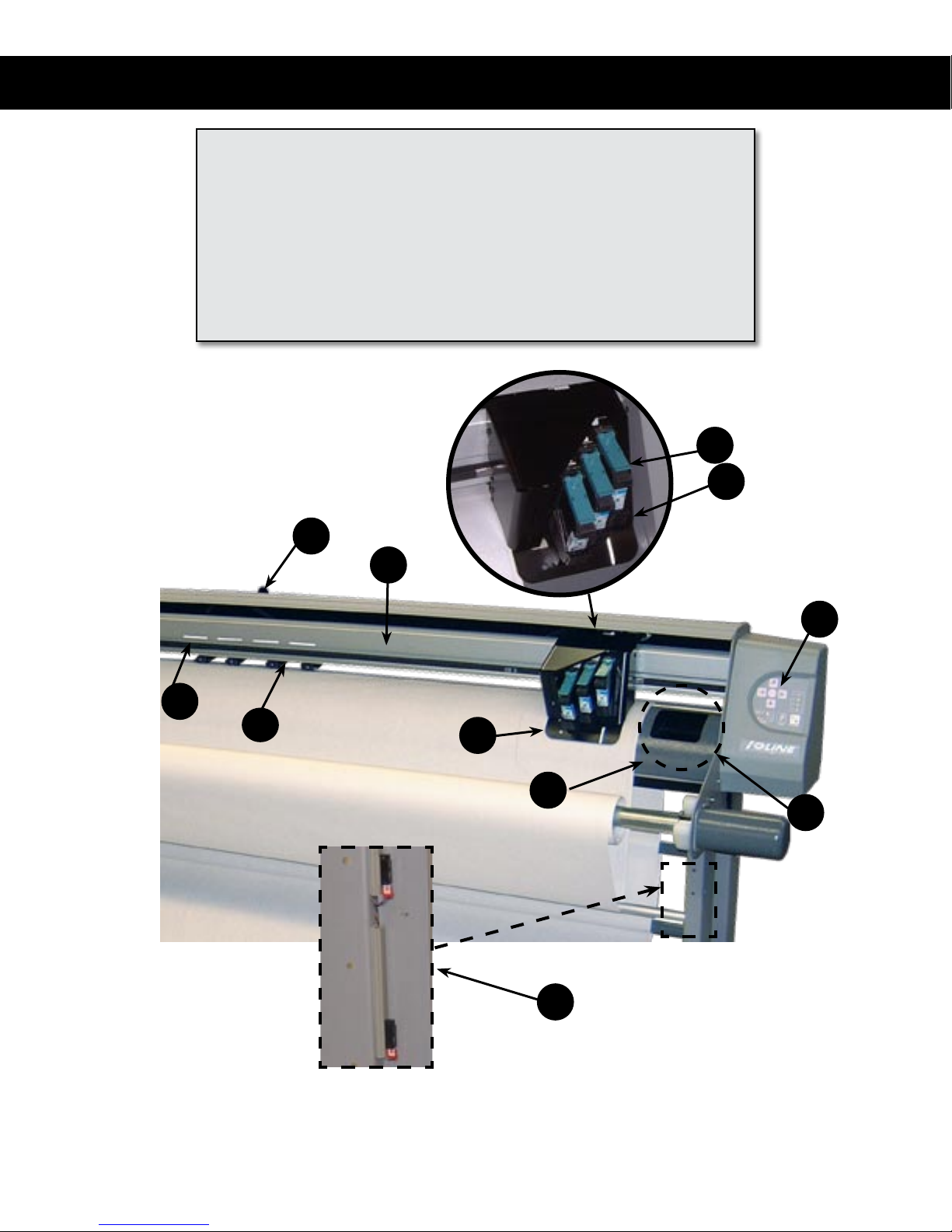

KEY

A

A. Left End Cover

B. Right End Cover

C. Take-up Motor

D. Stand Leveling Foot

E. Feed Roll

F. Take-up Shaft

Rear Panel Behind Right End Cover

G. Feed Shaft

H. Dancer Bar

I. Stand

AA. Power Switch

BB. Serial Port

CC. USB Port

AA BB

CC

B

F

H

I

C

G

E

4

The Ioline FlexJet E Printer Front View.

D

Page 5

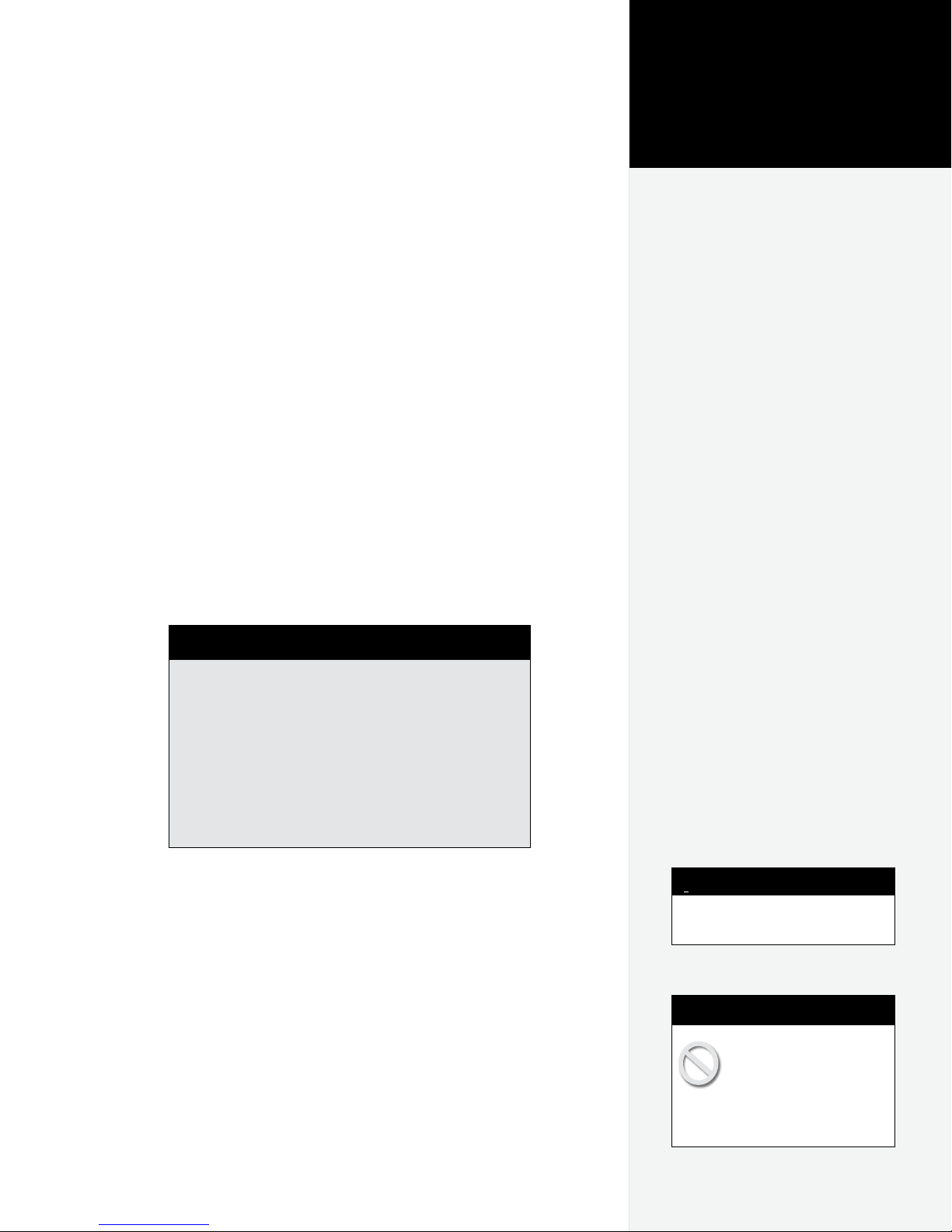

Visual Reference Guide

KEY

J. Drive Shaft Marker

K. Pinchwheel

L. Traverse or Carriage Rail

M. Carriage Assembly

N. Platen

P. Ink Cartridge Latch

R

L

Q. Ink Cartridge Stall

R. Pinchwheel Lever

S. Keypad

T. Service Station

U. Take Up Sensors

P

Q

S

J

K

The Ioline FlexJet E Printer Front View Close-up

M

N

T

U

5

Page 6

NOTES

6

Page 7

Assembly

This Quick Start Guide shows how to assemble and set up the Ioline

FlexJet E printer. Consult the FlexJet E User Guide on the CD-ROM

for more detailed information about installation and operation. Use

the provided Adobe® Acrobat® viewer to read and print the user

guide if necessary.

Unpacking the FlexJet E

Chapter 1

Assembly & Set-up

Remove the printer, stand parts, and Accessory Kit from the box

and check the packing list. Always lift the printer with two people,

one person holding the bottom of the end covers. (See Step 3 for more

details.) Save all packing materials.

Required tools

n Hex (Allen) and 7/16-inch wrenches

and grease (included)

n 7/16, 1/2, and 9/16-inch open

ended or two adjustable wrenches

n A level

n Rubber headed mallet

n Phillips screw driver

i

Save all packing materials.

Note

Caution

The FlexJet E printer is

heavy and could cause

injury if it falls. A minimum

of two people are required

to safely unpack the printer and

attach it to the stand.

Page 8

8

Ioline FlexJet E Quick Start Guide

Step 1: Assemble the Right Leg

1. Find the right leg assembly. It has small sensors attached to it

inside one of the channels. The leg is also labeled, “RIGHT LEG

ASSEMBLY, FJe PRINTER”

2. Find the right foot. It has a plastic block on it.

Sensors on

Right Leg

Plastic Block

on Right Foot

3. Insert the right foot into the right leg between the flanges on

the bottom of the leg so that the plastic block and the small sensors are both on the same side of the assembly.

Page 9

4. Align the holes in the foot with those in the leg. 6 of the holes

should align when correctly positioned.

5. Insert two 1.5-inch long 1/4-20 screws through the foot and

into the threaded nuts in the stand leg. Turn them loosely by

hand only.

1.5-inch screw—at actual size.

1.5-in Screw (2)

9

6. Insert four 1.5-inch long 1/4-20 screws through the holes in

the stand leg and all the way through the foot. Turn four nuts

loosely by hand onto the end of the screws.

1/4-20 Nut (4)

1.5-in Screw (4)

7. Tighten all six screws with the included T-handle Allen wrench

and a 7/16-inch open ended wrench on the four nuts.

Page 10

10

Ioline FlexJet E Quick Start Guide

Step 2: Assemble the Left Leg

1. Find the left leg assembly. A piece of plastic tape is attached to

the inside of one channel. It is also labeled, “LEFT LEG ASSEM-

BLY, FJe PRINTER”

2. Find the left foot. It has a metal bracket with two bearings

bolted to it.

Left Leg with

Plastic Tape in Channel

Metal Bracket with Bearings

on Left Foot

3. Insert the left foot into the left leg between the flanges on the

bottom of the leg so that the metal bracket is on the side opposite the channel with the plastic tape in it.

Page 11

4. Align the holes in the foot with those in the leg. 6 of the holes

should align when correctly positioned.

5. Insert two 1.5-inch long 1/4-20 screws through the foot and

into the threaded nuts in the stand leg. Turn them loosely by

hand only.

1.5-in Screw (2)

11

6. Insert four 1.5” long 1/4-20 screws through the holes in the

stand leg and all the way through the foot. Turn four nuts

loosely by hand onto the end of the screws.

1.5-in Screw (4)

1/4-20 Nut (4)

7. Tighten all six screws with the included T-handle Allen wrench

and a 7/16-inch open ended wrench on the four nuts.

Page 12

12

Ioline FlexJet E Quick Start Guide

i

The cross-member is reversible

and can be attached from either

side.

Note

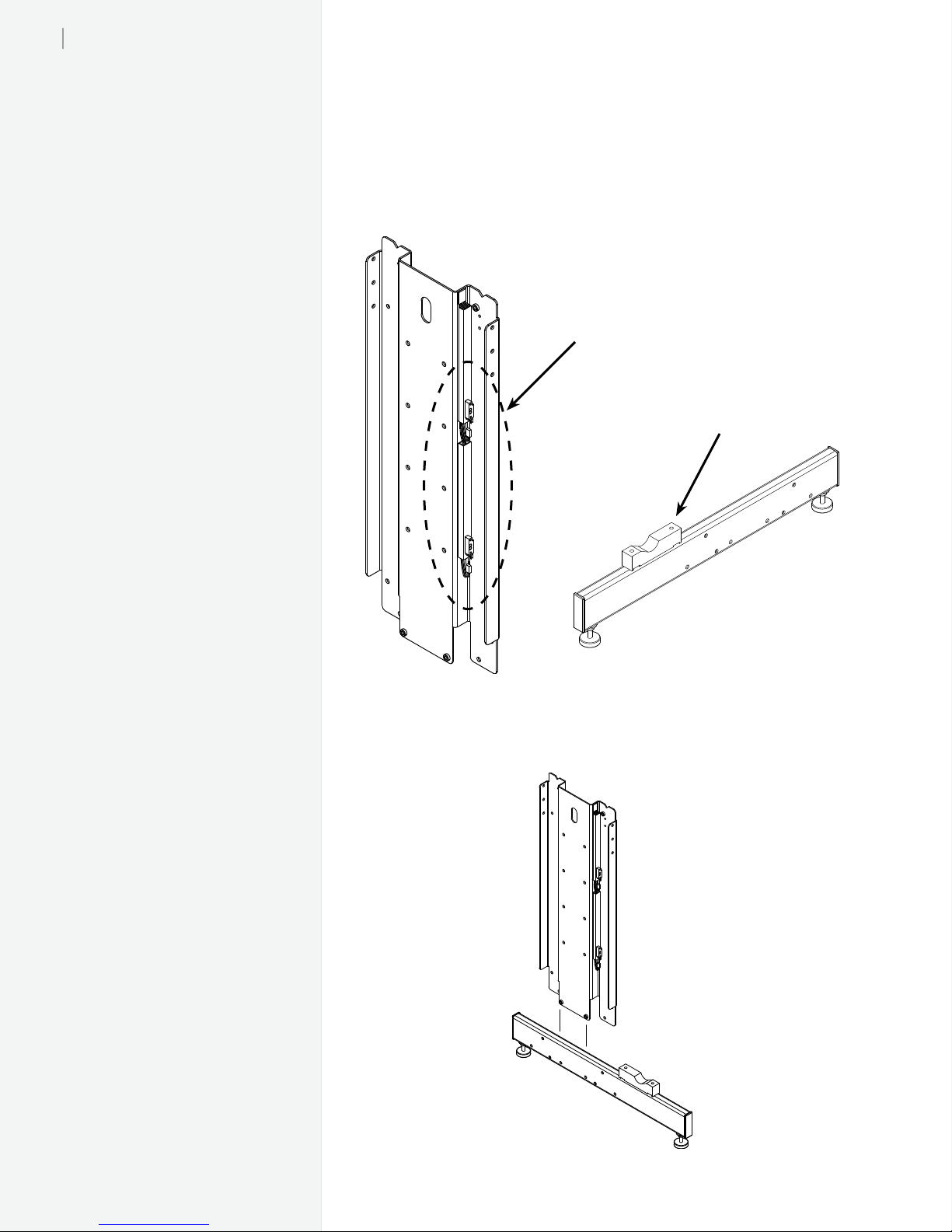

Step 3: Attach the Cross-member

1. Examine the diagrams showing proper placement of the crossmember in the figure below before proceeding with assembly.

2. Align the correct holes in the right leg with the threaded holes

in the cross-member.

3. Insert two 1-inch socket head screws into the threaded holes.

Leave them loose.

4. Repeat this procedure for the left leg. Make sure that the support

blocks on both leg point the same direction.

5. Place the stand assembly upright.

6. Tighten all four cross-member screws.

1-in Screw (4)

Right Leg

Caution

Do not hold the printer

head by the bottom edge

of the end plates when

attaching it to the stand. Fingers

and hands might get pinched

between the end plates and stand

legs. Hold the bottom of the end

covers when handling the printer.

Cross-member

Plastic

Support

Block

Proper placement of the cross-member on FlexJet E model.

1-in screw—at actual size.

Page 13

Step 4: Attach the Top Bar (2H+ FJE Models Only)

1. Some FJE Models with two or more print heads include a high

speed printing kit with a rolling rear top bar. On these machines there are two heavy aluminum rods and one light short

aluminum rod included with the printer. The shorter heavy

aluminum grey rod is the rolling top bar attached to the stand.

The longer heavy aluminum rod (painted black on later models) is the rear dancer bar explained later in Paper Loading,

Step 7.

2. Find the top bar support hardware on the left leg. It is holding

a silver spacer against the left leg.

Top Bar Support

Hardware on Left Leg

13

3. Gather two 7/16-inch or adjustable open ended wrenches.

Hold one of the nuts on the left support hardware with one

wrench and turn the other nut with the other wrench. Take the

‘C’ shaped spacer off the support when the nuts are loose and

set it aside.

Page 14

14

Ioline FlexJet E Quick Start Guide

4. Find the top bar support hardware on the right leg.

Top Bar Support

Hardware on Right Leg

5. Align the top bar shaft with the right support hardware and

slide the shaft on to it until it stops.

6. While holding the bar, move to the left stand leg and find the

left support hardware. Push the hardware assembly away from

the center of the stand until it stops.

Page 15

7. Align the top bar with the hardware then push the hardware

from outside the stand so that it is inserted into the top bar.

8. Re-install the ‘C’ shaped spacer removed in Step 3 then tighten

the nuts with two 7/16-inch or adjustable open ended wrenches.

15

9. Install the protective cap on the exposed thread on the left leg.

Page 16

16

Ioline FlexJet E Quick Start Guide

Step 5: Level the Stand

1. Use the wrench to loosen the 9/16-in lock nut on both of the right

leg leveling feet, turning them counter-clockwise. Place a level

across the top of the right stand leg. (See Figure)

2. Turn the 1/2-in nut on each leveling foot counterclockwise to

lower the foot or clockwise to raise the foot until the leg is level.

Repeat this procedure for the left leg.

Check Stand Level

on legs rst

After legs are level,

check stand level at

Stand Leveling

Foot

Cross-member

Placement of the level on the stand.

3. Place a level on the cross-member. Repeat the adjustment

procedure as above except adjust both front and rear levelers

on each leg the same amount so that the legs stay level but the

cross-member moves. Adjust the threaded feet until the stand

is level on the cross-member.

4. Check the level of the legs again and make small adjustments

as necessary until the stand is level in both directions.

5. Tighten all of the 9/16-in lock nuts on the levelers by turning

them clockwise.

Page 17

Step 6: Attach the Printer to the Stand

1. Using two people, lift the printer head onto the stand. The

front (carriage side) of the printer should face the same direction as the support blocks on the stand feet. Make sure the pin

at the rear of each endplate rests in the ‘V’-shaped notch in the

rear of both legs.

Hold the bottom surface of the

end cover (see image in caution

box at right). DO NOT HOLD

THE BOTTOM EDGES OF THE

END PLATE.

End

Cover

17

Printer head

End Plate

Caution

Do not hold the printer

chassis by the bottom edge

of the end plates when attaching

it to the stand. Fingers and hands

might get pinched between the

end plates and stand legs. Hold the

bottom surface of the end covers

when handling the head.

The end plates slide over the stand legs as shown above. Do not hold the end plates

when you install the printer head (as shown at right).

Page 18

18

Ioline FlexJet E Quick Start Guide

2. Check that the holes in the endplate line up with the threaded

holes in the leg. If they do not align, check to make sure that the

rear alignment pin is resting in the rear notch on both legs.

3. Insert four 5/8-in button-head screws through the two holes in

both end plates to connect the head to the stand. Tighten all

four screws with the included T-handle wrench.

Caution

Make sure power to the

machine is off before connecting the cables.

5

/8-in Screw

(2 per side)

Print head attachment

5

/8-in screws—shown here at actual size.

Step 7: Connect the Paper Sensor Cable

1. Make sure power is off to the machine. Find the small plug

clipped to the bottom inside edge of the right endplate.

Page 19

2. Pull the looped end of the cable out of the front clip so that the

plug hangs free. Make sure part of the cable remains within the

clip as shown.

3. Align the cable with the plug on the right stand leg then connect the plug with the socket. They will only connect one way.

Make sure the locking latch snaps into the catch.

19

Page 20

20

Ioline FlexJet E Quick Start Guide

Step 8: Check Machine Level

1. Place a level on the platen so that it is parallel to and in front of

the drive shaft.

2. Make small adjustments to the threaded feet in the stand if the

machine is not level. Note: If the machine is difficult to level,

check the printer for shipping damage and contact Ioline Customer Service.

Level

Threaded Leveling

Stand Feet (4)

Page 21

21

Step 9 : Connect the Communication and Power Cables

1. Turn power off to the printer. Off is marked with a, “0,”.

2. Connect the supplied serial cable and power cord to the panel on

the back of the right side of the printer. Lock the serial cable to

the port on the printer with the thumb screws.

3. Plug the printer power

cable into a wall socket or

surge protector.

4. Make sure that power is

off to the computer.

5. Connect the serial cable to

a 9 pin-male-serial port on

the back of the computer.

Tighten the thumbscrews.

The serial port and power socket.

i

Note: The FlexJet E User Guide

contains detailed instructions for

communication setup.

i

On the FlexJet E printer, off is

marked with a, “0,” and on with

a,“1.”.

Note

Note

Step 10: Install the Software

1. Insert the installation CD-ROM into the computer CD-ROM

drive. The install program should start automatically. If it does

not, select Run from the Start Menu. Browse to the CD-ROM

and double click on iosetup.exe. Press OK to start the install.

2. Install the Ioline FlexPlot and Control Center software. USB

drivers are installed automatically.

Hint

The Installation Disk also

includes electronic copies of

the FlexJet E User Guide and

FlexJet E Quick Start Guide. It

is recommended that you install

these along with Adobe Acrobat

(also included on the disk) to

make help easily accessible.

Page 22

22

Ioline FlexJet E Quick Start Guide

NOTES

Page 23

Paper Loading

Step 1: Loading the Feed Roll

1. Before loading a new paper roll always make sure the drive

shaft is clean. See the Routine Maintenance section in the FlexJet

E User Guide for more details.

2. Place a paper hub in each end of the paper roll. Use a rubber

mallet to insert the hubs.

Chapter 2

Preparing to Print

3. Slide the feed shaft through the paper hubs and the paper roll.

If a paper hub falls out, press it firmly back into the end of the

paper roll and set it with a rubber mallet.

Support

Block w/

Bearings

Feed

Shaft

Paper Roll

(Unrolls from behind)

Paper Hub (2)

Support Block

(apply grease)

Flanged Coupling

Caution

Never touch the take-up

key or anged coupling

while they are rotating.

Serious

personal

injury

could result. Turn

power

off rst.

Page 24

24

Ioline FlexJet E Quick Start Guide

4. For paper narrower than 70-in, center the paper roll on the feed

shaft. Make sure the hubs remain securely in place. For paper

greater than 70-in in width, offset the paper to the left slightly

to avoid covering the Service Station area. Also leave a minimum 1/4 inch gap between the paper edge and the edge of the

fan on the left side of the rear cover of the machine.

5. Use the supplied hex wrench to tighten both screws on each

paper hub.

6. IMPORTANT: Apply a light coating of grease (supplied in the

Accessory Kit) to the right support block.

7. Lift the feed shaft and paper roll into the support blocks. Make

sure the paper unrolls from behind and towards the printer.

Step 2 : Loading the Take-up Roll

1. Turn on the power to the printer with the switch on the back of

the right cover.

2. If the take-up shaft has printed markers on it, remove them. See

Unloading Completed Markers in the Ioline FlexJet E Printer in

the FlexJet E User Guide for details.

3. Use the keypad Unroll key to rotate the take-up key until it is

oriented perpendicular to the support block opening as shown

below.

4. Put the take-up shaft into the front support blocks with the

flanged coupling at the right (keypad) end. Rotate the shaft

until the slot in the flanged coupling is aligned with the takeup key. When the shaft slot and the key are aligned, push the

take-up shaft into place until it is seated in the support block.

Rectangular

slot

Take-up

Shaft

Flanged

Coupling

Position take-up

key as shown

Support Block

The slot in the anged coupling on the take-up shaft ts into the key in the right front

support block

Page 25

Step 3 : Feeding Paper

25

The figure below shows the proper paper paths. The left side of

the diagram shows the paper path for a 1H FlexJet E. The right side

shows the proper path for a FlexJet E with 2 or more heads and a

high speed printing kit.

1. If the pinchwheels are lowered, raise them by pushing the

pinchwheel lever away from the machine.

2. Pull a long leader of paper off of the paper roll and insert it

through the stand, behind the printer head, over the platen,

and between the platen and pinchwheels.

3. Temporarily lock the paper in place by pulling the pinchwheel

lever toward the machine to lower the pinchwheels.

Front

Dancer Bar

Take-up

Shaft

Hint

An alternate take-up method that

will ease removal of markers is

to slide a cardboard tube over

the take-up shaft then tape paper

to the tube. The cardboard tube

will rotate slowly at rst and may

not raise the front dancer bar

but will still roll up completed

markers. Simply slide the tube off

the take up shaft when plotting is

complete.

i

Ensure that the paper is properly

positioned for its width. See Step

1 under Paper Loading earlier in

this chapter.

Note

Feed Roll

Proper Paper Path

1H FlexJet E

Proper Paper Path

2H+ FlexJet E

Page 26

26

Ioline FlexJet E Quick Start Guide

Step 4 : Taping Paper to the Take-Up Shaft

1. Stand in front of the machine.

2. Temporarily attach a short piece of masking tape to the center

of the cover on top of the machine.

3. Grasp the front edge of the paper. Push the pinchwheel lever to

raise the pinchwheels.

4. Hold the front edge of the paper with both hands and pull 20”

(51 cm) of paper over the platen and under the take-up shaft

(see Step 3 for the proper paper path). On machines with the

high speed printing kit, make sure the paper covers the rear

rolling top bar.

5. Apply pressure to the feed roll with a foot so that it does not

turn.

6. Align the paper by gently pulling it while moving it left and

right until the tension feels even. Attach the paper to the takeup shaft using the piece of tape stuck to the cover.

7. Tape the right and left ends of the paper (about 2” or 5 cm in

from the edge) to the take-up shaft.

Tape the paper

in 3 places

Do not cover the hole in the platen

with paper.

Page 27

Step 5: Positioning the Pinchwheels

1. Ensure that the paper is loaded as described, that the right paper

edge does not encroach on the Service Station area and the left

edge does not touch the fan on the back of the machine.

2. Raise the pinchwheels (if they are not up) by pushing the lever

away from the machine.

3. Move the pinchwheels to the proper position. See Figure below.

Do not place a pinchwheel over any smooth portion of the drive

shaft. Use the white markers on the carriage rail to find drive

shaft segments when they are covered by paper.

27

Pinchwheel

White Driveshaft Markers

Drive Shaft

Segment

Drive Shaft

Bearing

Step 6 : Insert Front Dancer Bar

1. Lower the pinchwheels (if they are not down) by pulling the

lever toward the machine.

2. Insert the front dancer bar into the front dancer bar channel.

Front Dancer

Bar (Silver

light rod)

Page 28

28

Ioline FlexJet E Quick Start Guide

Step 7 : Insert Rear Dancer Bar (2H+ FJE Models Only)

1. FJE models with two or more printheads and the high speed

printing kit require that a heavy dancer bar is inserted in the

rear dancer bar channel (see paper path in Step 3).

2. Take the heavy dancer bar (painted black on some models) and

insert the ends into the notches in the stand legs on the back of

the machine as shown in the image below.

3. Use a hand on the rear rolling bar to slow rotation as the dancer

bar slides into the channel and forms a rear paper loop.

Notch in Stand Leg

Preparing to Print

1. Turn on the power (if it is not already on). There is a brief

pause then the carriage will move to the left end plate then return for a cleaning in the Service Station. After the initial startup process is complete, the OK light turns red and the Square

light turns green.

2. Use the Left Arrow key to move the carriage out of the Service

Station.

3. Remove the protective strip from the bottom of the ink cartridge. Insert the included ink cartridge by lifting the latch, inserting the cartridge, then closing the latch until it locks down.

4. Press the Left (or Right) Arrow key to move the carriage over

the paper until the white marker on the base is over the desired

starting point of the marker.

5. Press the Set Origin key. The OK light will turn green. The

printer is ready to print.

Test the Setup

1. Start the Software.

a. Close all programs that might be using serial port that the

FlexJet E is connected to.

b. Start the FlexJet E Control Center software. A link to the

program is in the Start Menu under Programs>Ioline.

c. A message may appear that the Control Center was un-

able to communicate with the FlexJet E. If you see this

message, click on Yes. When the program starts, open the

menu Communications>Settings. Choose the COM port

that the FlexJet E is connected to. Leave the baud rate set

at 38,400 since this is the default set at the factory.

Page 29

Communications error message.

d. Press the Get Plotter Data button to ensure the connection is

established.

2. Send Test Plot File

a. Select Send Plot File from the File Menu.

b. Browse to the folder c:\ioline\calibrate\.

c. Double click on the test plot file 40x8.plt to send it to the

printer.

d. When the printer prints the test file correctly, the machine

is ready for printing makers.

29

e. Close the FlexJet E Control Center.

3. Send Markers

a. Start FlexPlot or your apparel design software.

b. Setup communications so that the COM port and baud rate

are the same in the FlexJet E and the software. Refer to the

FlexPlot User Guide and FlexJet E User Guide or the manual

of your apparel design software for more information.

c. Send markers to the FlexJet E directly from the software.

Getting Help

Refer to Troubleshooting under the FlexJet E User Guide for assistance with common issues. Upon request, Ioline Customer Service

also offers a more detailed publication—the FlexJet E Service Manu-

al—which contains expanded troubleshooting information.

Customer Service

Ioline Corporation is committed to providing quality service and

support to our customers. If you need assistance with an Ioline product, contact your local dealer or Ioline authorized service center. You

may also contact:

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacific Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Page 30

30

Ioline FlexJet E Quick Start Guide

NOTES

Page 31

31

Page 32

32

Ioline FlexJet E Quick Start Guide

NOTES

Loading...

Loading...