Ioline FlexJet Service Manual

Ser vice Manual

Ioline FlexJet™

User Notice

Trademarks

Ioline and FlexJet are trademarks of Ioline Corporation. HP is a trademark of the Hewlett-Packard Company. Other product names, logos, designs, titles, words or phrases mentioned within this publication

may be trademarks, service marks, or trade names of Ioline Corporation or other entities and may be

registered in certain jurisdictions including internationally.

Ioline Disclaimer

IOLINE CORPORATION PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OR CONDITIONS OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL IOLINE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES

FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS

AND THE LIKE), EVEN IF IOLINE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES

ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT.

Limit of Liability Statement

This manual is provided for informational purposes only. The contents are subject to change without

notice and Ioline Corporation assumes no responsibility for any errors that may be contained herein.

Ioline has made every effort to make the FlexJet easy to operate, maintain, and repair. It is the responsibility of the operator of the printer to monitor the performance of the printer and maintain it in proper

working condition by following the instructions in this manual and in the FlexJet User Guide and to

follow all safety precautions and warnings that are described in these publications. Ioline Corporation is

not responsible for injuries that may occur as a result of unsafe use. Ioline Corporation is not responsible

for substandard operational performance as a result of failure to maintain the printer as described in this

manual and in the FlexJet User Guide.

© 2003-2005 Ioline Corporation. All rights reserved. This manual may not be copied, photocopied, reproduced, translated, transmitted or converted to any electronic or machine-readable form in whole or in

part without prior written approval of Ioline Corporation.

Service and Support

If you require assistance with an Ioline product, your local Ioline dealer or authorized service center is ready

to help. Support information is also available 24/7 on the Ioline Web site—or you may contact Ioline directly:

Ioline Corporation

14140 NE 200th Street

Woodinville, Washington 98072 U.S.A.

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacic Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Part Number: (File) 108675 Rev. 0

Ioline FlexJet™

Ser vice Manual

Images & Illustrations

Figure 1. Proper lifting procedures for the FlexJet . .......................................................... xiii

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

Figure 15.

Figure 16.

Figure 17.

Figure 18.

Figure 19. LED lights

Figure 20. Keypad LED error codes

Figure 21.

Figure 22. HP cartridges have an ink level indicator

Figure 23.

Figure 24.

Figure 25.

Figure 26.

Figure 27.

Figure 28.

Figure 29.

Figure 30.

Figure 31.

Figure 32.

Figure 33.

Figure 34.

Figure 35.

Figure 36.

Figure 37.

The Ioline FlexJet Printer front view . ................................................................. xvi

The Ioline FlexJet Printer rear view . ................................................................. xvii

The Ioline FlexJet Printer front view close-up ............................................... xviii

The Ioline Flexjet . ....................................................................................................19

Paper direction . ........................................................................................................ 21

Carriage movement . ................................................................................................21

Workow: output direct from CAD software (without FlexPlot) . .............. 23

Workow using FlexPlot for le conversion and output ............................ 23

FlexJet Control Center main menu . ................................................................ 25

The Ioline Flexjet power supply . .......................................................................... 29

Rear power panel assembly . .................................................................................. 29

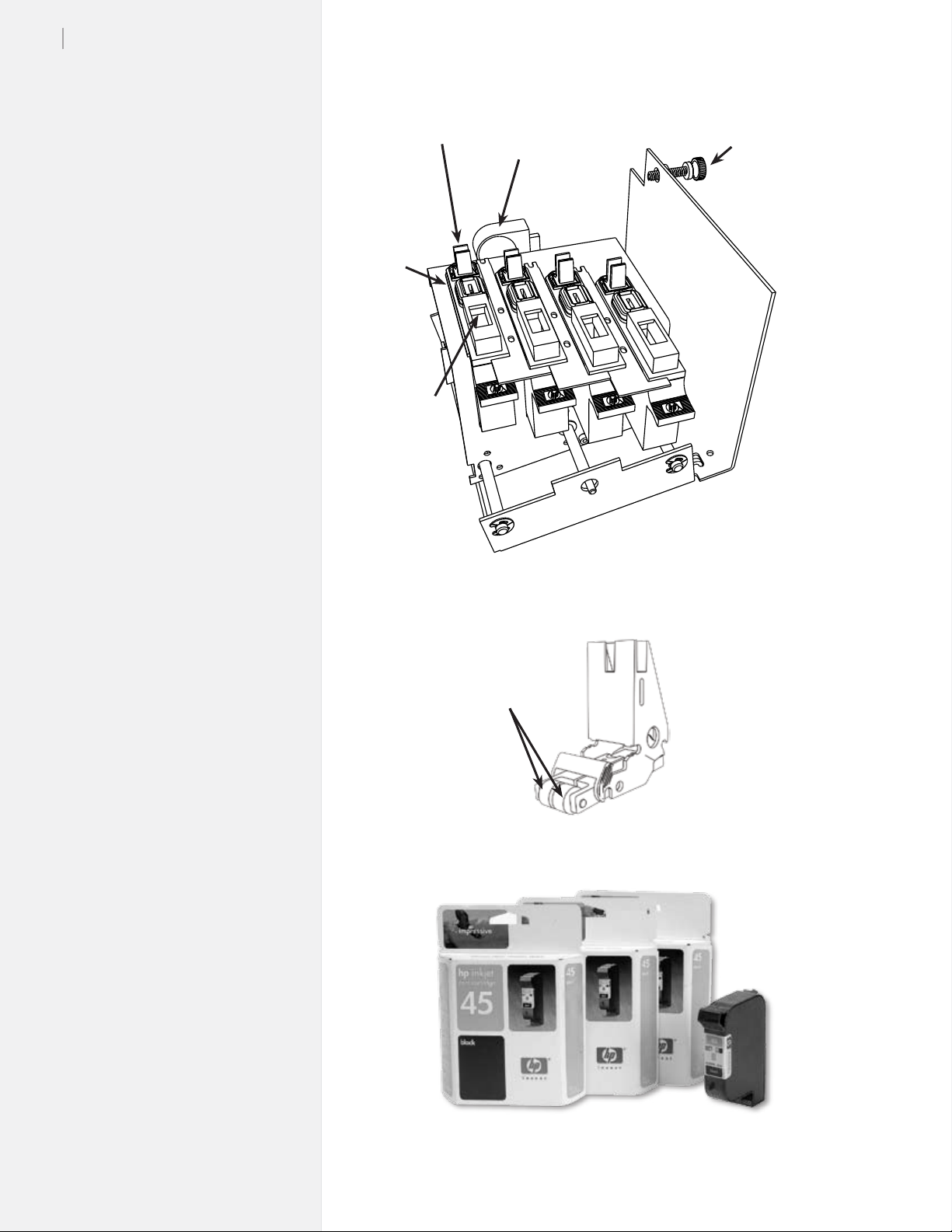

Service Station assembly . ....................................................................................... 30

Pinchwheel assembly . .............................................................................................. 30

Ink cartridges: HP 51645A . .................................................................................... 30

FlexJet logic board (Rev 1, above; Rev 2 below) . ..............................................31

Carriage assembly with cover on . ........................................................................ 32

Carriage assembly with cover off . ........................................................................ 32

on the keypad . ................................................................................... 36

. ................................................................................ 36

The correct paper feeding path on the Ioline FlexJet Printer . ...................... 42

. ...............................................44

The ink cartridge is dirty, dry, or empty . ............................................................ 44

The ink cartridge requires cleaning . ....................................................................45

Damaged and dirty print cartridge . ..................................................................... 45

Use a deliberate frame gap to help calibrate . .................................................... 46

The Cartridge Calibration window in the Control Center . ................ 47

The Cartridge Alignment dialog box . .................................................................. 47

Increase the alignment value for cartridge #2 to improve line quality . .......47

Decrease the alignment value for cartridge #2 to improve line quality . ..... 47

The Motion Adjust window . .................................................................................. 48

The heads are drawing the lines too late on this plot . .................................... 48

The Frame Gap window . ........................................................................................48

Frame gaps on the plot . .......................................................................................... 49

Frame gaps may indicate that the FlexJet platen or stand is not level . ........ 49

The height-adjusting spacer . .................................................................................. 49

The ink stall can crack if the cartridge door is not closed and locked ........ 50

Figure 38. Carriage noise may indicate a dirty or faulty wheel ........................................50

Figure 39.

Figure 40.

Figure 41.

Figure 42.

Figure 43.

Figure 44.

Figure 45.

Figure 46.

Figure 47.

Figure 48.

Figure 49. Rotate the v-wheels free of the traverse rail . ................................................... 66

Figure 50.

Figure 51.

Figure 52.

Figure 53.

Figure 54.

Figure 55.

Figure 56.

Figure 57.

Figure 58.

Figure 59.

Figure 60.

Figure 61.

Figure 62.

Figure 63.

Figure 64.

Figure 65.

Figure 66.

Figure 67.

Figure 68.

Figure 69.

Figure 70.

Figure 71.

Figure 72.

Figure 73.

Figure 74.

Figure 75.

Figure 76.

Figure 77.

Figure 78.

Figure 79.

Figure 80.

Figure 81.

Replacing the fuse . ................................................................................................... 51

A good transitor on the left; the one on the right is blown ..........................52

Testing the Y-Axis motor . ....................................................................................... 54

Mechanical, electrical and electronic diagnostics ow chart . ......................... 61

Removing the right end cover ............................................................................... 64

Loosen the belt tensioner . .....................................................................................64

The carriage cover screw . ......................................................................................65

Unclip the belt from both ends of the carriage . ............................................... 65

Loosen the carriage wheel lock . ...........................................................................66

Gently press down on the carriage . .................................................................... 66

Carriage installation . ................................................................................................67

Use the spacer when attaching each swing arm . .............................................. 67

The carriage belt tensioner . ..................................................................................68

Install the carriage cover . ....................................................................................... 68

Remove the cover .................................................................................................... 69

Install the carriage cover . ....................................................................................... 70

Remove the logic board cover plate .................................................................... 70

Unplug the feed motor and encoder cables from the logic board . ..............71

Unplug the ribbon cables . ......................................................................................71

Make a loop in the ribbon cable to the left of the carriage . .......................... 72

Carriage installation . ................................................................................................73

The carriage belt tensioner . ..................................................................................73

Install the carriage cover . ....................................................................................... 74

There should be a small gap in the ribbon cable loop . .................................... 75

The loop in the cable should not touch the left endplate . ............................. 75

Secure the sleeving with tape . ............................................................................... 76

Remove the right end cover . ................................................................................. 77

Remove the screws and let the keypad hang .....................................................77

Remove the carriage cover . ................................................................................... 77

Install the ink cartridges and turn the power on . .............................................78

Loosen the carriage catch bracket . ......................................................................78

Cover the spit wells . ............................................................................................... 78

Two lines in the spit well holes . ............................................................................ 79

Use the plastic thumbscrew to adjust the lines if necessary . ........................79

Y Fine adjustment is performed within the Control Center . .................... 80

Watch the gap between the carriage and Service Station . ........................80

The Service Station stop screw . ...................................................................... 81

Small gap between the screw and the Service Station . .............................. 82

Tighten the nut to hold the stop bracket . .......................................................... 82

Unplug the take-up motor . .................................................................................... 83

Remove the right cover . ......................................................................................... 83

Unscrew the PCB cover . ........................................................................................ 83

Figure 82. Remove the logic board cover ............................................................................. 83

Figure 83.

Figure 84.

Figure 85.

Figure 86.

Figure 87.

Carefully unplug connections to the board ....................................................... 84

Carefully remove the logic board ........................................................................ 84

Inspect the connections to the logic board ....................................................... 85

Remove the keypad screws and bracket. Unplug the keypad cable .............87

Tighten the screws on the Y-Axis transmission . ...............................................88

Table of Contents

Safety & Cautions

Warranty Policy

Ioline warranty policy ...................................................................................... xiv

How to use this manual

Where to nd information ................................................................................................ xv

What’s in this Service Manual ........................................................................... xv

Visual Reference Guide

Chapter 1 Overview

Product overview ..................................................................................................................... 19

Supported languages ............................................................................................................ 19

Specications ......................................................................................................................... 20

How the FlexJet works ....................................................................................................... 21

Paper movement .................................................................................................................. 21

Carriage movement ............................................................................................................. 21

Serial number identication ............................................................................................... 21

Glossary .................................................................................................................................. 22

Software setup options ....................................................................................................... 22

Power on ...................................................................................................................................... 24

Installing FlexPlot and the Control Center ................................................................ 24

The FlexJet Control Center ............................................................................................... 25

Overview ................................................................................................................................ 25

Changing system settings .................................................................................................... 25

Control Center menu bar features ................................................................................. 26

File ........................................................................................................................................... 26

Communications .................................................................................................................. 26

Tools ........................................................................................................................................ 26

Help ......................................................................................................................................... 26

Control Center menu options ........................................................................................... 27

Software Version ................................................................................................................... 27

Cartridge Count ................................................................................................................... 27

Get Plotter Data .................................................................................................................. 27

Plotter Data (check box) .................................................................................................... 27

Line Width .............................................................................................................................. 27

Scale ......................................................................................................................................... 27

Frame Size .............................................................................................................................. 27

Quality Setting ...................................................................................................................... 28

Measurement Units .............................................................................................................. 28

Chapter 2 Nomenclature

Product components ............................................................................................................. 29

General troubleshooting ...................................................................................................... 33

Error messages ......................................................................................................................... 33

Chapter 3 Troubleshooting & Testing

Control Center software errors ....................................................................................... 34

Keypad error codes ................................................................................................................. 36

Legend ..................................................................................................................................... 36

Power problems ........................................................................................................................ 37

Communications ..................................................................................................................... 37

The FlexJet won’t respond to the computer ................................................................. 37

Serial communication ........................................................................................................... 37

Common problems ................................................................................................................ 38

Paper problems ........................................................................................................................ 42

Regular or intermittent paper tearing ............................................................................. 42

Media tracking ....................................................................................................................... 43

Print quality problems .......................................................................................................... 44

Line quality ............................................................................................................................. 44

Dirty or damaged cartridge ............................................................................................... 45

Cartridge calibration ........................................................................................................... 46

Calibration overview ........................................................................................................... 46

Cartridge alignment ............................................................................................................. 46

Adjusting the cartridge alignment value .......................................................................... 47

Motion adjustment ............................................................................................................... 48

Frame gap ................................................................................................................................... 48

Unexplained frame gaps ...................................................................................................... 49

Ink cartridge stall problems ............................................................................................... 50

Noisy carriage movement ................................................................................................... 50

Mechanical, electrical, and electronic diagnostics .................................................... 51

No power to the FlexJet .................................................................................................... 51

Electrical problems ............................................................................................................... 52

Troubleshooting sensors .................................................................................................. 52

General mechanical / electrical issues ............................................................................. 53

Simple electrical diagnostics test: ........................................................................... 54

Motor problems ................................................................................................................... 54

Testing a motor ..................................................................................................................... 54

Logic board assembly troubleshooting ............................................................................ 55

Logic board troubleshooting steps (Revision 2) ............................................................ 56

Service & support .................................................................................................................... 58

Getting help ............................................................................................................................... 58

Customer service .................................................................................................................... 59

Chapter 4 Repair Procedures

Maintenance procedures ...................................................................................................... 61

Repair procedures ................................................................................................................... 61

Requesting service .................................................................................................................. 62

Carriage procedures .............................................................................................................. 63

FlexJet carriage replacement ............................................................................................. 63

FlexJet Cable replacement ................................................................................................. 69

Service station procedures ................................................................................................. 77

Y Fine adjustment for the Service Station ...................................................................... 77

Logic Board Procedures ....................................................................................................... 83

Logic board replacement .................................................................................................... 83

Updating the rmware ........................................................................................................ 86

Keypad procedures ................................................................................................................. 87

Keypad replacement ............................................................................................................ 87

Y-Axis procedures ................................................................................................................ 88

Y-Axis belt adjustment ........................................................................................................ 88

X-Axis procedures .............................................................................................................. 89

Chapter 5 Parts & Drawings

FlexJet BOM (Bill of Materials) ......................................................................................... 91

Ioline FlexJet (Exploded view) ........................................................................................... 94

Ioline FlexJet (Electronics view) ....................................................................................... 95

Index

The Ioline FlexJet has many fast moving components. To avoid injury and prevent electrical shock, please read and follow these safety

guidelines before attempting to service the printer:

n Do not try to repair the machine without factory authoriza-

tion. Only qualied service personnel should attempt any of

the subsystem testing or replacement procedures that are described in this manual. If external mechanical adjustments are

necessary, turn off the printer and disconnect it from all power

sources (both the computer and the wall outlet).

Safety &

Cautions

n Unless otherwise noted, all subsystem testing or replacement

procedures must be performed with the FlexJet turned off and

the power cord removed from the rear panel to avoid the possibility of electrical shock.

n Before beginning any

subsystem testing or

replacement procedure, make sure that

the FlexJet is on a at,

stable, clean, and dry

surface.

n Keep ngers, hair, and

clothing well clear of

the FlexJet whenever

moving parts are being tested.

n Be careful when

moving or lifting the

printer. Moving the printer requires at least 2 people. To avoid

injury to your ngers, do not lift the printer by the end covers.

Hold the gray bars on the printer to lift or move it. See Figure 1.

Figure 1. Lift the printer head using the gray

bars to avoid injury to your ngers.

xiii

Warranty

Policy

Ioline warranty policy

Ioline Corporation provides a 12 month parts and labor warranty on

all new equipment and 90 days on repaired units, unless specically

noted otherwise. Every unit is recorded by serial number when it

leaves the factory. The warranty period is based on the serial number of the unit and extends from the date of manufacture up to 12

months, plus an extra 3 months for shelf life. Making the total warranty period 15 months from the date of manufacture.

For warranty service, the end user must work through their dealer.

Ioline Customer Service is available to assist Authorized Dealers

with customer and equipment support.

How to use

Four publications are available to assist you in setting up, operating

maintaining and servicing the FlexJet:

n FlexJet Quick Start Guide

n FlexJet User Guide

n FlexJet Service Manual

n FlexPlot User Guide

Where to nd information

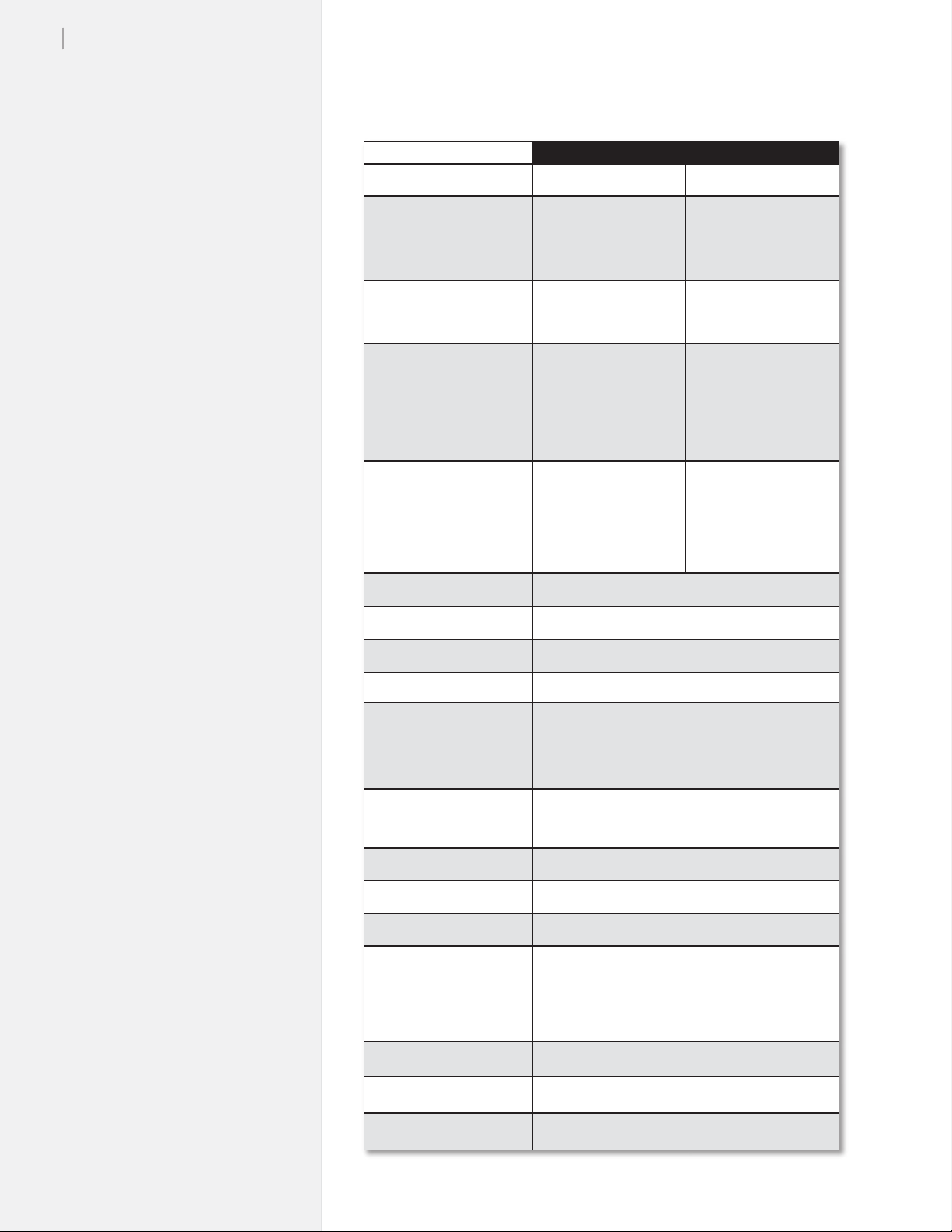

The table below provides a quick directory of topics and resources:

Topic Manual

Assembly & setup FlexJet Quick Start Guide

Paper loading FlexJet Quick Start Guide

Removing markers FlexJet User Guide

The Ioline Control Center (adjusting plot

parameters)

Ioline FlexPlot software FlexPlot User Guide

Design software set-up guides FlexPlot User Guide

Maintenance FlexJet User Guide

Basic troubleshooting FlexJet User Guide

Advanced troubleshooting for qualied service

personnel

Specications, part names, drawings FlexPlot Service Manual

FlexJet User Guide

FlexPlot Service Manual

this manual

What’s in this Service Manual

The FlexJet Service Manual provides extensive product specications, testing and repair procedures.

Chapter 1 Introductory information and general specications.

Chapter 2 Descriptive drawings listing part names for the

FlexJet. This section is intended to supplement the

FlexJet User’s Guide.

Chapter 3 Troubleshooting and testing guide.

Chapter 4 Details for repair and maintenance of the FlexJet.

Chapter 5 Technical drawings and reference material.

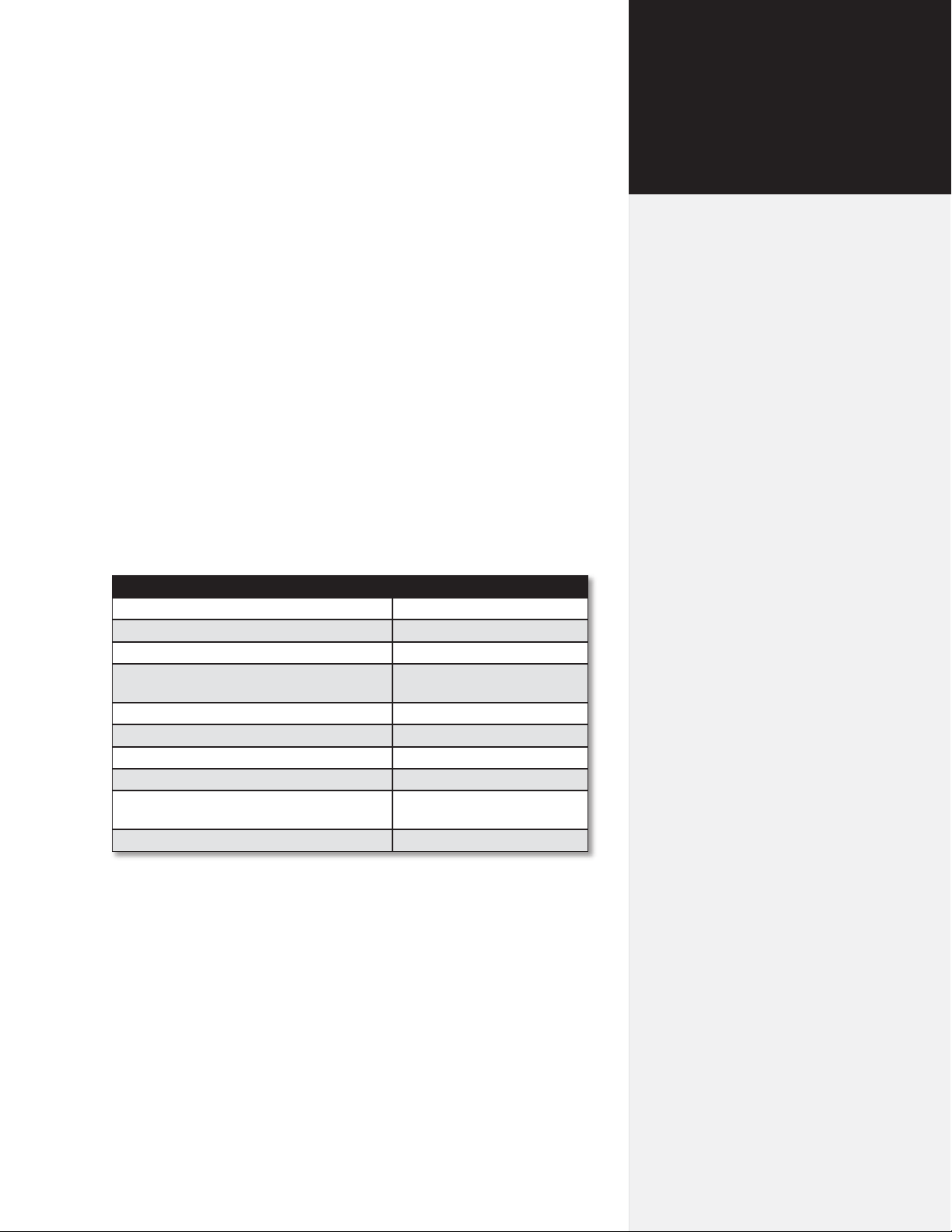

KEY

A

A. Left End Cover

B. Safety Cover

C. Right End Cover

D. Take-up Motor

E. Stand Leveling Foot

B

F. Feed Roll

G. Take-up Shaft

H. Paper Hub (2)

Feed Shaft

I.

J. Support Block (2)

C

D

G

I

J

Figure 2. The Ioline FlexJet Printer front view.

xvi

H

F

E

Visual Reference Guide

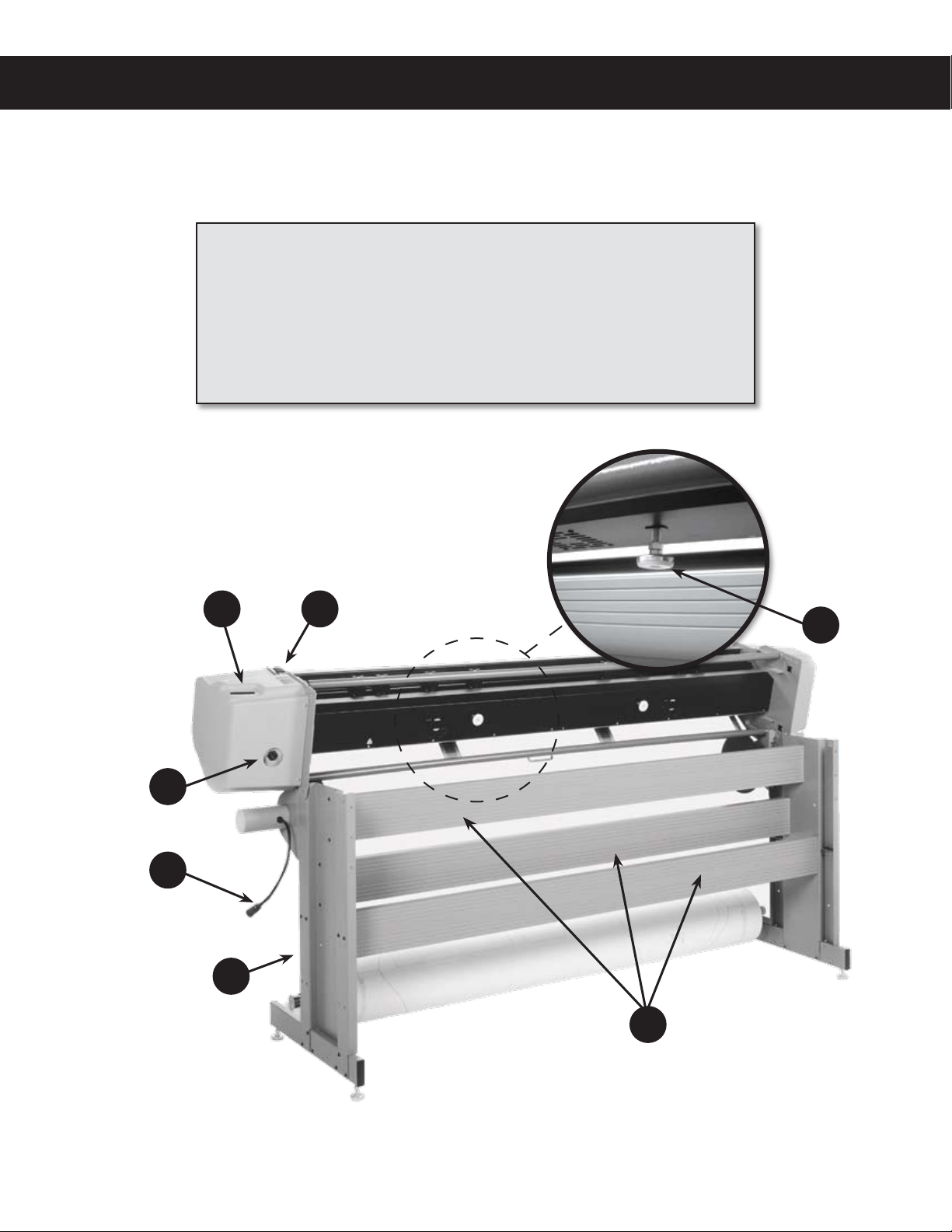

KEY

K. Stand Leg (2)

L. Take-up Motor Cable

M. Take-up Motor Outlet

N. Serial & USB Ports

N O

O. Power Switch and fuse

P. Platen Leveling Foot

Q. Cross-member (3)

P

M

L

K

Figure 3. The Ioline FlexJet Printer rear view (head tilted in maintenance position.)

Q

xvii

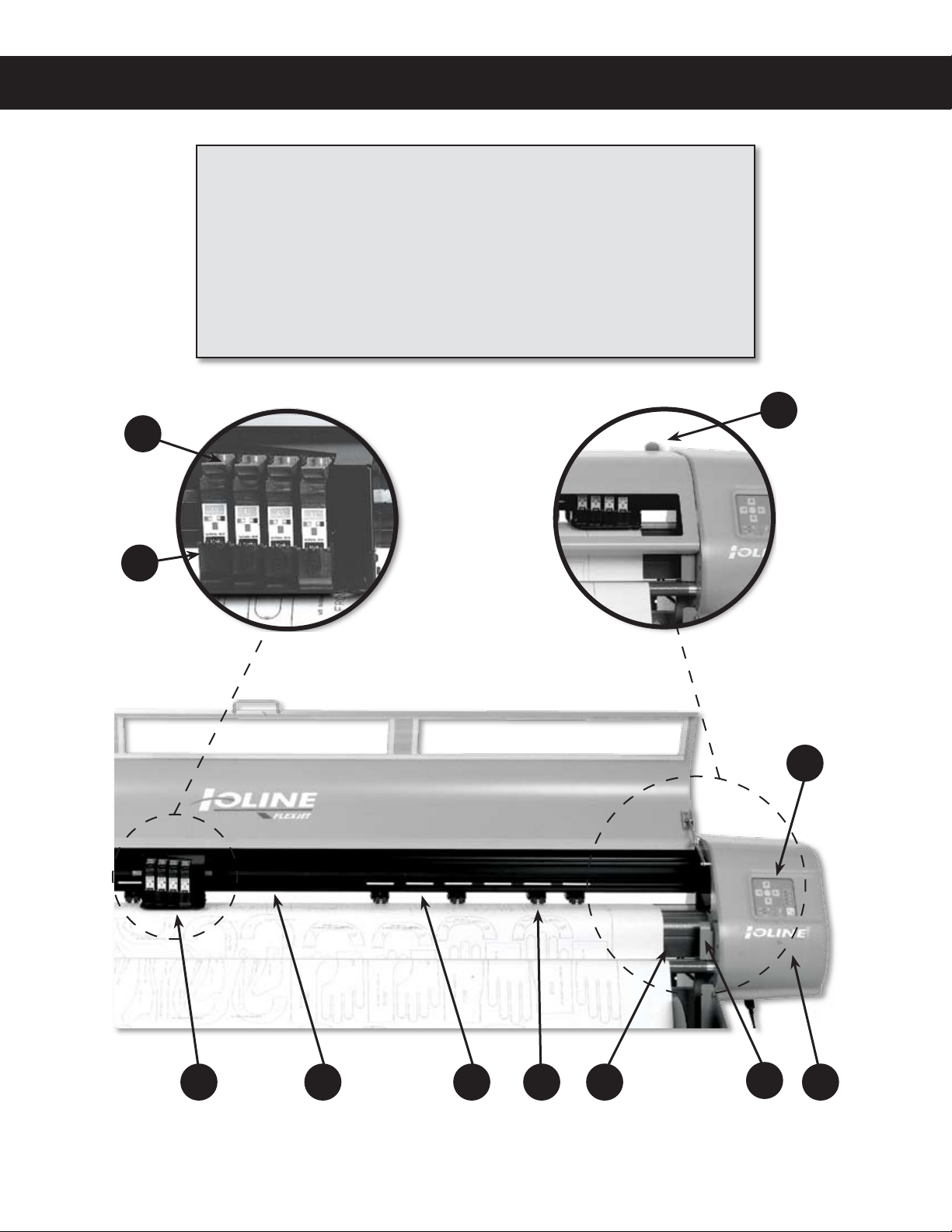

KEY

S

R

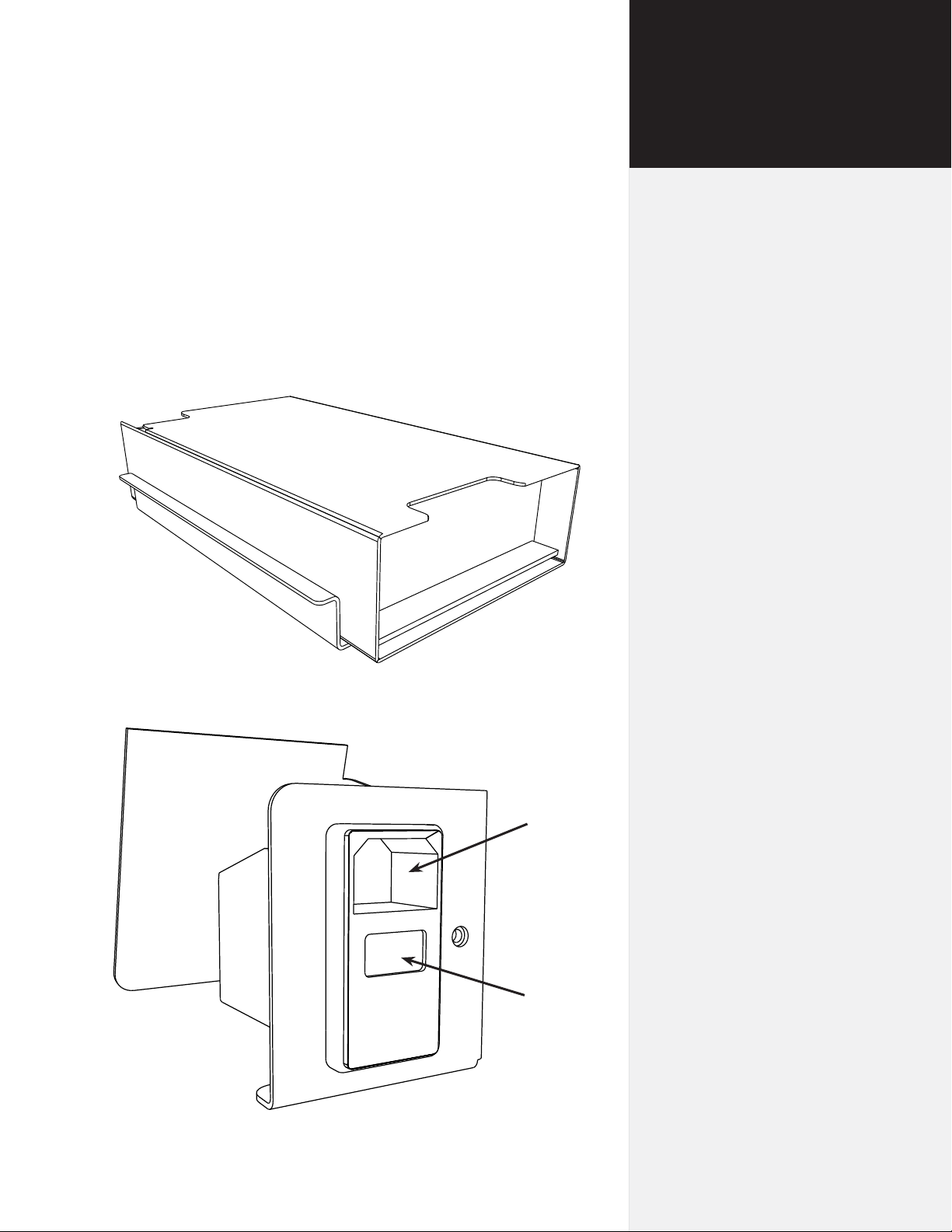

R. Ink Cartridge Stall

S. Cartridge Stall Latch

T. Pinchwheel Lever

U. Keypad

V. Service Station

(Beneath Cover)

W. Take-up Sensor

X. Platen

Y. Pinchwheel

Z. Drive Shaft Marker

aa. Traverse

ab. Carriage Assembly

T

ab aa

Figure 4. The Ioline FlexJet Printer front view close-up (safety cover lifted for clarity.)

Z

Y X

W

U

V

xviii

Product overview

The FlexJet is

most commonly

used in conjunction with popular

apparel software

for printing

marker patterns,

used in the manufacture of clothing. The FlexJet

also comes with

FlexPlot software that allows

printing of the

most popular

formats such as

AutoCad® (DXF),

CorelDraw!® (PLT),

Adobe® Illustrator® (DXF), Gerber® (STD, PLT or ASTM), Lectra®

(ASTM), Investronica® (ASTM).

Figure 5. The Ioline Flexjet.

Chapter 1

Overview

The Ioline FlexJet can handle many different printing operations

up to 72 inches wide and 600 yards long. Three industry standard

printer languages (HPGL 7475, and DM/PL) are supported.

The Ioline FlexJet also supports direct cable connection from many

popular programs such as PAD®, Scanvec® Optitex®, Polytropon®,

Ioline IPS software, and other applications.

Supported languages

Language Application

HPGL Direct from software or Ioline FlexPlot.

DM/PL Direct from software or Ioline FlexPlot.

DXF Ioline FlexPlot only.

STD Ioline FlexPlot only.

ASTM 6959 FlexPlot only.

Ioline syntax Direct special control characters for FlexJet.

20

Ioline FlexJet Service Manual

Specications

Metric Empirical

Max. plotting width 1.83 m 72-in

Media width

min.

max.

Marker length 548.6-m

Floor space requirements

Height

Width

Depth

Weight

Actual

Dimensional (US)

Dimensional (Int’l)

Paper type Recycled to bond

Feed roll position Front oor loading

Paper take-up roll position Ergonomic waist-level off-loading from front

Line thickness Thin, normal or thick

.91-m

1.88-m

(Unattended)

2.4-m x .7-m

1.2-m

2.4-m

.7-m

150 kg

190 kg

221 kg

36-in

74-in

600 yds

(Unattended)

96-in x 26-in

46-in

89-in

26-in

330 lbs

417 lbs

487 lbs

Resolution

Best mode:

Draft mode:

Ink cartridges Off-the-shelf

PC interface USB / Serial (RS-232)

Protocol HPGL / DM/PL

Languages DM/PL, DXF, HP-GL, HP-GL/2, MicroJet STD, ASTM

Compatibility

Power requirements 85-260 VAC, 0.25 KVA, Single phase, 47-440 Hz

Humidity Non-condensing

Warranty 1-year parts and labor

600 dpi

300 dpi

HP® 51645A cartridges

Gerber® (Accumark®, MicroMark®, and Micro-

dynamics®), Assyst®, AutoDesk® (AutoCAD®),

Investronica®, IPS, Lectra®, Scanvec® (Optitex®),

PAD®, Polygon®, Polytropon® (PolyPattern®), Vetigraph® and others

How the FlexJet works

The Ioline FlexJet combines paper and ink cartridge motion to create

vector outputs in a wide 72-in format. The data are sent to the FlexJet

via either a standard RS-232 serial or USB cable. When a le is sent to

the printer, the electronic system translates the vectors into instructions for the “X” (paper motion) and “Y” (Ink cartridge motion) motors. At the same time instructions are sent to the carriage assembly

to apply ink to the paper.

Paper movement

Paper motion is accomplished by pulling paper through the

machine with a traction shaft. The shaft is

connected to the X-axis

motor with a timing belt

transmisison assembly.

The drive-shaft rotates

in one direction.

Figure 6. Paper direction.

Chapter 1: Over view

21

Carriage movement

The Y-Axis transmission powers a timing belt that transports a V

wheel carriage along the Y-Axis traverse extrusion. The ink cartridges are attached to the carriage and are made to apply ink to the paper

by actuating the electronics of the ink cartridge. When not printing,

the carriage assembly is stored in the FlexJet Service Station to keep

the ink cartridges clean and capped so they don’t dry out.

Serial number

identication

Identication of Ioline

Corporation products is

accomplished by use of

a serial number located

on the back of the right

side cover on the printer. You can determine

the model and date of

manufacture using the

following guidelines:

Figure 7. Carriage movement.

22

Ioline FlexJet Service Manual

FJ 03 26 01

{

Glossary

{

{

{

Number of machine manu-

factured in that week

Week of manufacture

Year of manufacture

Model number

i

An expanded Glossary is available

in the FlexJet User Guide.

Note

BOM Bill(s) of Material for Assembly

Bottom Pan Metal housing protecting the underside of the printer.

Carriage The component that holds the ink cartridges. It traveles

along the Y-Axis on the traverse assembly.

Keypad Where the user controls simple printer functions. Carriage

and media motion is accessible from here during stop

mode.

Traverse Assembly The structure that supports and guides the carriage as-

sembly.

X-Axis The direction of the paper moving through the machine.

Y-Axis The direction of the carriage moving back and forth.

Software setup options

Ioline recommends using FlexPlot for marker making on the

FlexJet. FlexPlot offers the most robust and exible workow

available for creating output. It’s especially useful when many le

formats are used, a common situation for service bureaus. To set-up

and learn how to use the software, see the FlexPlot User Guide.

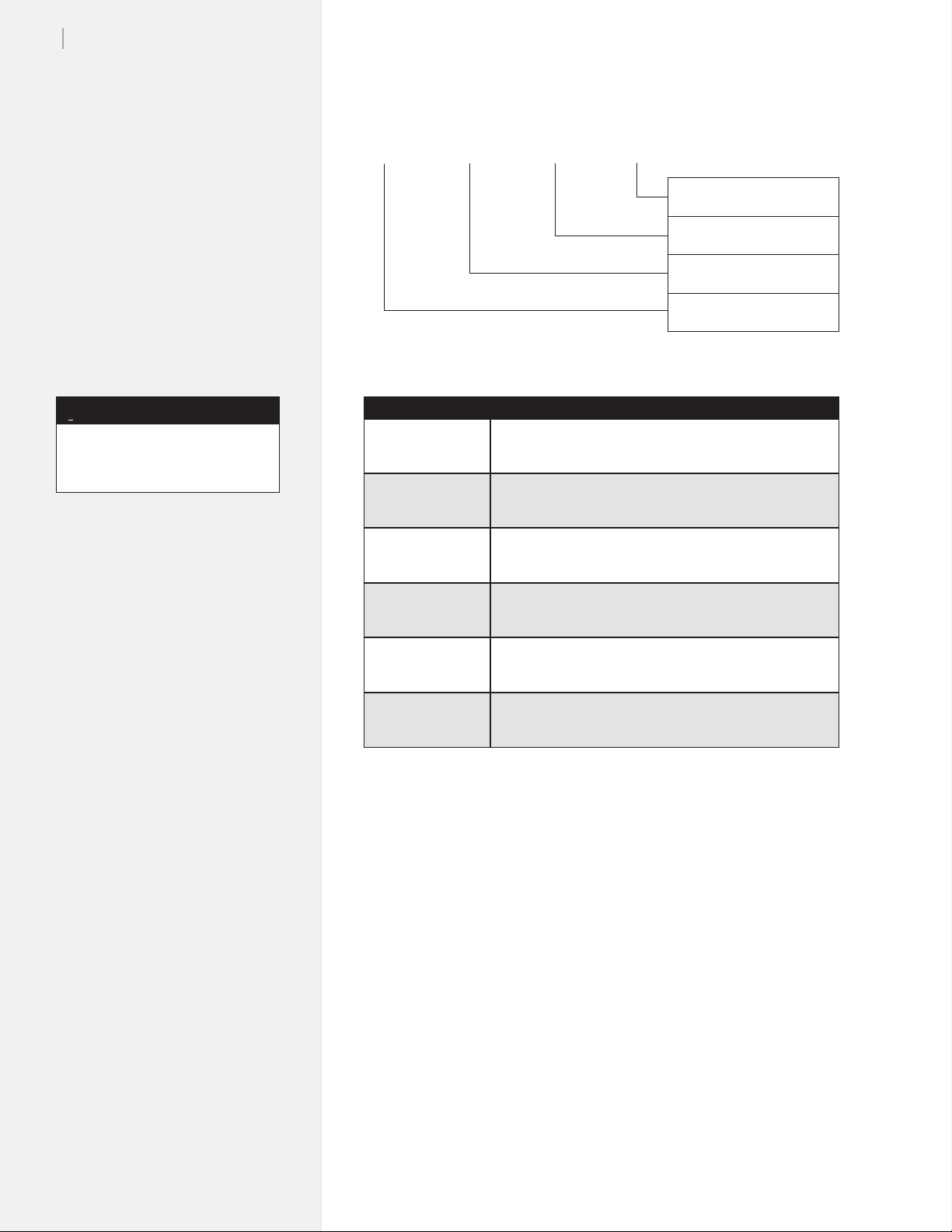

The FlexJet is designed to work in many different production environments. The type of marker printing you do will often determine

your preferred communication method. Two typical methods for

sending markers are:

1. Plot directly from the marker or design software to the

FlexJet. (See Figure 8.)

Unlike other marker printers, the FlexJet is capable of operating

as a stand-alone device with no extra software running on the

computer. This method works if your CAD software includes

a driver for any Ioline product, such as the Ioline 600Ae or the

Summit 2200. It will also work if the CAD software can create a

compatible HPGL- or DM/PL- formatted le.

CAD

Software

HPGL

DM/PL

FlexJet

Figure 8. Workow: output direct from CAD software (without FlexPlot).

Chapter 1: Over view

23

2. Use FlexPlot software to convert les before sending them

to the FlexJet for output.

The FlexJet includes the FlexPlot software which will convert

many different les into a format that is compatible with the

FlexJet. It also provides an advanced marker queue management system and other tools to optimize the performance of the

printer.

CAD

Software

[Network]

FlexPlot

HPGL

DM/PL

DXF

ASTM 6959

STD

(Alternate Conguration)

CAD

Software

+

FlexPlot

FlexJet

Figure 9. Workow using FlexPlot for le conversion and output.

24

Ioline FlexJet Service Manual

Caution

Keep hands and loose

clothing away from all

moving parts of the

printer. Make sure the Service

Station opening in the right end

plate is not obstructed and that

the stall latches are lowered.

Power on

Turn on the computer and the printer to make sure they both work.

The printer power switch is located next to the power cord on the

back of the machine, behind the keypad. When the FlexJet is powered up, the carriage will move toward the left side of the machine,

then return to the opposite side to park in the Service Station. The

OK light will turn red and the Square light will turn green on the

front panel after the start-up process has nished.

Installing FlexPlot and

the Control Center

The FlexJet includes two software interfaces: FlexPlot and the

Control Center. FlexPlot will import and queue marker les from

many design programs to optimize production operations. The

Control Center is an interface for adjusting parameters to optimize

printer performance. The printer comes with a CD-ROM which has

Microsoft Windows® 98/2000/XP versions of the programs as well

as PDF user guides and the required Adobe® Acrobat® reader.

1. Power on the computer and Windows

®

.

2. Insert the Ioline CD-ROM into the CD-ROM drive (usually D:).

3. The installation program should start automatically. If it does

not:

a. Select the Start button.

b. Choose Run.

c. Type

4. Follow the instructions that appear on the screen.

5. The FlexPlot User Guide has details on using the FlexPlot software. In this manual, see the section The FlexJet Control Center

for more details about the Control Center software.

D:\IOSETUP (substitute the correct letter if the CD-

ROM drive letter is not D:) and Click OK.

Chapter 1: Over view

25

The FlexJet Control Center

Overview

The FlexJet Control Center is a utility program that does two things:

n Allows you to adjust settings to tailor output (e.g. scale, line

width) from the computer.

n Provides an interface to send completed les to the printer.

i

To avoid communication port

conicts, do not simultaneously

run more than one application

that communicates with the

printer.

Note

Figure 10. FlexJet Control Center main menu.

Changing system settings

A variety of settings are adjustable to t specic needs:

n Make sure the printer power is on and that the initialization

process is complete. The carriage will park, the keypad OK

light will turn red and the Square light will turn green.

n The Screen Menu displays the primary settings that are adjust-

able. The Menu Bar contains utilities for setting up the Control

Center and calibrating the FlexJet.

n Changes only take effect after one of the Send buttons is

pushed.

26

Ioline FlexJet Service Manual

Control Center menu bar features

File

Download Firmware Allows the user to download the lat-

est rmware version for the FlexJet.

See the FlexJet User Guide for more

information.

Send Plot File Print a PLT or PLX le.

Exit Exit the Control Center.

Communications

Settings Select the COM port and baud rate

to match the printer.

Send Command Permits advanced users to manually

enter commands.

Tools

Cartridge Calibration Displays tools to adjust print

cartridge alignment. See the FlexJet

User Guide for more details.

Reset Machine ID Resets the machine serial number.

A unique key code, only available

from Ioline customer service, is required. It is usually only necessary

if the main logic board is changed.

Size Calibration Allows adjustment of the size cali-

bration settings. See the FlexJet User

Guide for more details.

Set Machine ID Stores the printer serial number in

permanent memory. This step is

required for upgrading the number

of active print cartridges in machines

pre-wired for expansion.

Set Key Code Sets the license key code to enable

inactive print heads in machines prewired for expansion. It requires that

the serial number is stored in permanent memory with the Set Machine

ID function described above.

Help

About Displays Control Center version

information.

Control Center menu options

Software Version

Displays the current rmware version installed in the FlexJet.

Cartridge Count

Displays how many cartridges are in active use by the printer.

Get Plotter Data

Reads and displays the current settings stored in the FlexJet in the

input boxes.

Plotter Data (check box)

Indicates when the displayed settings were successfully downloaded

from the printer. If this box is unchecked, the Control Center was

unable to connect with the FlexJet and cannot display current settings.

Check the connections, baud rate and COM port. Press the Get Plotter

Data button to attempt to download settings if the process failed

during startup.

Chapter 1: Over view

27

Line Width

Controls the weight of the plotted line using line width. Three levels

are available; Thin, Normal, and Thick. Thin lines use less ink and

make ne details like Asian text and small pieces easier to see. Thick

lines use more ink to produce higher contrast lines.

Used in conjunction with the Quality Setting (see below), the FlexJet

provides six options for output quality, to enable you to produce

clearly visible lines using the least possible amount of ink.

Scale

The printer scale ranges from 1% to 999%. The factory default Scale

is 100%. A scale set to 50% prints at half size. Changes do not take

effect until the Set Scale button is pressed. Note: Both X- and Y-Axes

are set independently.

Frame Size

Most design software sends long plots to printers by breaking them

into smaller pieces called frames. In general, design software does this

automatically and adjusts the Frame Size in the printer to match.

The Frame Size setting establishes clipping limits for each data

frame. If the printed size of a plot frame exceeds the frame size set

in the FlexJet, the excess is clipped or thrown away. (If the plot is

clipped, try increasing the Frame Size manually.) The factory-set

X-axis (paper direction) frame size is 46-in (116.8-cm), maximum is

21600-in (54,864-cm). Default and maximum Y-axis (carriage direction) frame size is 72-in (182.9-cm).

28

Ioline FlexJet Service Manual

Quality Setting

Choose Draft or Best to control line density. Draft mode uses 300 DPI.

Best mode uses 600 DPI. A lower DPI setting uses less ink by creating

a fainter line. Higher DPI uses more ink but makes a darker line. Use

this setting in conjunction with the Line Width (see above) to nd a bal-

ance between saving ink and making clearly visible lines.

Measurement Units

Choose between English or Metric units for settings display.

Product components

Chapter 2

Nomenclature

Figure 11. The Ioline Flexjet power supply.

Figure 12. Rear power panel assembly.

Power

cord

plugin

Power

switch

30

Ioline FlexJet Service Manual

Cartridge

wipers

Cartridge

caps

Cartridge

“spit

wells”

Servo motor

Carriage stop

adjustment

screw

Figure 13. Service Station assembly.

Wheels

(Replaceable)

Figure 14. Pinchwheel assembly.

Figure 15. Ink cartridges: HP 51645A.

Loading...

Loading...