Page 1

Service Manual

Ioline

FJ Printer™

& StudioJet™

Page 2

User Notice

Trademarks

Ioline, StudioJet, FJ Printer, FJ-F, FJ-8, FJ-FeX and FJ-8eX are trademarks of Ioline Corporation. HP is

a trademark of the Hewlett-Packard Company. Other product names, logos, designs, titles, words or

phrases mentioned within this publication may be trademarks, service marks, or trade names of Ioline

Corporation or other entities and may be registered in certain jurisdictions including internationally.

Ioline Disclaimer

IOLINE CORPORATION PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES

OR CONDITIONS OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL IOLINE, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES

FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS

AND THE LIKE), EVEN IF IOLINE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES

ARISING FROM ANY DEFECT OR ERROR IN THIS MANUAL OR PRODUCT.

Limit of Liability Statement

This manual is provided for informational purposes only. The contents are subject to change without

notice and Ioline Corporation assumes no responsibility for any errors that may be contained herein.

Ioline has made every effort to make the StudioJet and all models of the FJ Printer easy to operate, maintain, and repair. It is the responsibility of the operator of the printer to monitor the performance of the

printer and maintain it in proper working condition by following the instructions in this manual and in

the product User Guide and to follow all safety precautions and warnings that are described in these publications. Ioline Corporation is not responsible for injuries that may occur as a result of unsafe use. Ioline

Corporation is not responsible for substandard operational performance as a result of failure to maintain

the printer as described in this manual and in the User Guide.

© 2003-2007 Ioline Corporation. All rights reserved. This manual may not be copied, photocopied, reproduced, translated, transmitted or converted to any electronic or machine-readable form in whole or in

part without prior written approval of Ioline Corporation.

Service and Support

If you require assistance with an Ioline product, your local Ioline dealer or authorized service center is ready

to help. Support information is also available 24/7 on the Ioline Web site—or you may contact Ioline directly:

Ioline Corporation

14140 NE 200th Street

Woodinville, Washington 98072 U.S.A.

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacifi c Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

support@ioline.com

www.ioline.com

Part Numbers: (Print) 109308 Rev. 0 • (File) 109307 Rev. 0

Page 3

Ioline FJ Printer™

& StudioJet™

Service Manual

Page 4

Page 5

Images & Illustrations

Figure 1. Proper lifting procedure ...................................................................................... xiii

Figure 2. The Ioline FJ (shown) and FJeX (not shown) Printers Front View. ............ xvi

Figure 3. The Ioline FJ (shown) and FJeX (not shown) Rear View............................. xvii

Figure 4. The Ioline FJ Printer Front View Close-up .................................................... xviii

Figure 5. The Ioline StudioJet Front View .........................................................................xix

Figure 6. Power and communications ports on the Ioline StudioJet .............................. xx

Figure 7. The Ioline FJ Printer. .............................................................................................. 21

Figure 8. Paper direction. ......................................................................................................25

Figure 9. Carriage movement. .............................................................................................. 25

Figure 10. Workfl ow: output direct from CAD software (without FlexPlot). ............ 27

Figure 11. Workfl ow using FlexPlot for fi le conversion and output. ............................. 27

Figure 12. Control Center main menu. ................................................................................ 29

Figure 13. The Ioline FJ Printer power supply. ....................................................................33

Figure 14. Rear power panel assembly..................................................................................33

Figure 15. Pinchwheel assembly..............................................................................................34

Figure 16. Ink cartridges: HP 51645A. ..................................................................................34

Figure 17. FJ Printer logic board. ...........................................................................................34

Figure 18. Printer carriage assembly with cover off. ......................................................... 35

Figure 19. Printer carriage assembly with cover on. ......................................................... 35

Figure 21. Keypad LED error codes. .....................................................................................36

Figure 20. LED lights on the keypad. ..................................................................................... 36

Figure 22. The correct paper feeding path on the Ioline FJ Printer. ..............................43

Figure 23. HP cartridges have an ink level indicator. ............................................................................. 44

Figure 24. The ink cartridge is dirty, dry, or empty. ...........................................................45

Figure 25. The ink cartridge requires cleaning.................................................................... 45

Figure 26. Damaged and dirty print cartridge. ................................................................... 46

Figure 27. The Cartridge Calibration window in the Control Center. ......................... 47

Figure 28. The Motion Adjust window. ................................................................................... 48

Figure 29. The heads are drawing the lines too late on this plot. ..................................48

Figure 30. The Frame Gap window. ...................................................................................... 50

Figure 31. Frame gaps on the plot. ........................................................................................ 50

Figure 32. Occasional frame gaps may indicate that the stand is not level. .................50

Figure 33. The height-adjusting spacer. ................................................................................. 51

Figure 34. The ink stall can crack if the cartridge door is not closed and locked. .....52

Figure 35. If the carriage makes noise, clean or replace the wheel. ............................... 52

Figure 36. A good transitor on the left; the one on the right is blown ........................ 53

Figure 37. Testing the Y-Axis motor. ...................................................................................... 55

Page 6

Figure 38. Mechanical, electrical and electronic diagnostics fl ow chart. ....................... 63

Figure 39. Left cover removal. ................................................................................................ 65

Figure 40. Right cover removal. ............................................................................................. 65

Figure 41. Bottom cover removal steps. ..............................................................................66

Figure 42. Carriage replacement. ...........................................................................................69

Figure 43. Carriage wheel replacement. ............................................................................... 70

Figure 44. Flex cable replacement. ........................................................................................73

Figure 45. Main logic board replacement. ............................................................................ 74

Figure 46. Power supply replacement. .................................................................................. 77

Figure 47. Bottom cover removal steps. ..............................................................................78

Figure 48. X-axis belt replacement. ....................................................................................... 80

Figure 49. Y-axis belt replacement. ........................................................................................ 81

Figure 50. X-motor replacement. .......................................................................................... 83

Figure 51. Y-transmission replacement. ................................................................................................. 84

Figure 52. FJ Printer chassis BOM (exploded view A) ............................................................... 96

Figure 53. FJ Printer chassis BOM (exploded view B). .............................................................. 97

Figure 54. FJ Printer Parts List BOM .................................................................................................. 98

Figure 55. FJ-eX Printer chassis BOM (exploded view A) .....................................................102

Figure 56. FJ-eX Printer chassis BOM (exploded view B) .....................................................103

Figure 57. FJ-eX Printer Parts List BOM. .......................................................................................104

Figure 58. StudioJet chassis BOM (exploded). .............................................................................108

Figure 59. StudioJet Packing List .........................................................................................................109

Page 7

Page 8

Page 9

Table of Contents

Safety & Cautions

Warranty

Policy

Ioline warranty policy ........................................................................................................... xiv

How to use this manual

Where to fi nd information ................................................................................................ xv

What’s in this Service Manual ...................................................................................... xv

Visual Reference Guide

Chapter 1

Overview

Product overview .................................................................................................................. 21

Supported languages ............................................................................................................ 21

FJ Printer Specifi cations ...................................................................................................... 22

FJ-eX Specifi cations .............................................................................................................. 23

StudioJet Specifi cations ....................................................................................................... 24

How the printer works ....................................................................................................... 25

Paper movement .................................................................................................................. 25

Carriage movement ............................................................................................................. 25

Serial number identifi cation ............................................................................................... 25

Glossary .................................................................................................................................. 26

Software setup options ....................................................................................................... 26

Power on .................................................................................................................................... 28

Installing FlexPlot and the Control Center .............................................................. 28

The Control Center ............................................................................................................. 29

Overview ................................................................................................................................ 29

Changing system settings .................................................................................................... 29

Control Center menu bar features .............................................................................. 30

File ......................................................................................................................................... 30

Communications .................................................................................................................. 30

Tools ........................................................................................................................................ 30

Help ......................................................................................................................................... 30

Page 10

Control Center menu options ........................................................................................ 31

Software Version ................................................................................................................... 31

Cartridge Count ................................................................................................................... 31

Get Plotter Data .................................................................................................................. 31

Plotter Data (check box) .................................................................................................... 31

Line Width .............................................................................................................................. 31

Scale ......................................................................................................................................... 31

Frame Size .............................................................................................................................. 31

Quality Setting ...................................................................................................................... 32

Measurement Units .............................................................................................................. 32

Chapter 2

Nomenclature

Product components ........................................................................................................... 33

Chapter 3

Troubleshooting & Testing

General troubleshooting .................................................................................................... 37

Error messages ....................................................................................................................... 37

Control Center software errors ..................................................................................... 38

Keypad error codes .............................................................................................................. 40

Legend ..................................................................................................................................... 40

Power problems ..................................................................................................................... 41

Communications ................................................................................................................... 41

The Printer won’t respond to the computer ................................................................. 41

Serial communication ......................................................................................................... 41

Common problems .............................................................................................................. 42

Paper problems ...................................................................................................................... 47

Regular or intermittent paper tearing ............................................................................. 47

Media tracking ....................................................................................................................... 48

Print quality problems ........................................................................................................ 48

Line quality ............................................................................................................................. 48

Dirty or damaged cartridge ............................................................................................... 50

Cartridge calibration ........................................................................................................... 50

Calibration overview ........................................................................................................... 50

Cartridge alignment ............................................................................................................. 51

Motion adjustment ............................................................................................................... 52

Frame Gap Adjustment ....................................................................................................... 53

Unexplained frame gaps ...................................................................................................... 54

Frame Size Adjustment ........................................................................................................ 55

Ink cartridge stall problems ............................................................................................... 56

Noisy carriage movement ................................................................................................. 56

Mechanical, electrical, andelectronic diagnostics ................................................... 57

Electrical problems ............................................................................................................ 57

Troubleshooting sensors .................................................................................................. 57

General mechanical / electrical issues ............................................................................. 58

Simple electrical diagnostics test: ........................................................................... 59

Motor problems ................................................................................................................... 59

Page 11

Service & support ................................................................................................................. 64

Getting help ............................................................................................................................. 64

Customer service .................................................................................................................. 65

Chapter 4

Repair Procedures

Maintenance procedures ................................................................................................... 67

Repair procedures ................................................................................................................. 67

Requesting service ................................................................................................................ 68

Cover removal procedures ............................................................................................... 69

Carriage Procedures ............................................................................................................ 72

Logic Board Procedures ..................................................................................................... 78

Electrical Procedures .......................................................................................................... 80

Power supply replacement ................................................................................................ 80

Keypad procedures ............................................................................................................... 82

Testing the servo (Y-axis) motor ...................................................................................... 59

Testing the X-axis servo motor ........................................................................................ 60

Logic board assembly troubleshooting ............................................................................ 60

Logic board troubleshooting steps (Revision 2) ............................................................ 62

Left cover removal ............................................................................................................... 69

Right cover removal ............................................................................................................. 69

Left bottom cover removal ................................................................................................ 70

Carriage replacement .......................................................................................................... 72

Carriage Wheel Replacement ............................................................................................ 74

Flex Cable Replacement ..................................................................................................... 76

Logic board replacement .................................................................................................... 78

Note: Follow anti-static procedures ................................................................................ 79

Updating the fi rmware ........................................................................................................ 80

Keypad replacement ............................................................................................................ 82

X-axis belt replacement ...................................................................................................... 84

Y-axis belt replacement ....................................................................................................... 86

X-motor replacement ......................................................................................................... 88

Y-transmission replacement ............................................................................................... 90

Chapter 5

Parts & Drawings

FJ Printer chassis (exploded view A) ............................................................................ 96

FJ Printer Chassis (exploded view B) .......................................................................... 95

FJ Printer Packing List ........................................................................................................ 97

FJ-eX chassis (exploded view A) ................................................................................ 102

FJ-eX chassis (exploded view B) ................................................................................ 103

FJ-eX Packing List .............................................................................................................. 104

StudioJet Chassis ................................................................................................................ 108

StudioJet Packing List BOM .......................................................................................... 109

Index

Page 12

Page 13

The Ioline FJ printer and StudioJet have many fast moving compo-

nents. Please read and follow these safety guidelines before beginning operation of the printer:

Do not try to repair the machine without factory authoriza-

tion. Only qualified service personnel should attempt any

disassembly or access to internal components. If external

mechanical adjustments are necessary, turn off the printer and

disconnect it from all power sources (both the computer and

the wall outlet).

Be careful with hair, jewelry, or loose clothing near the printer.

They can become caught in the mechanical parts.

Safety &

Cautions

Never attempt to move the carriage by hand when the power is

on. Always use the Arrow keys to move the carriage.

To park the carriage

safely in the Service

Station and protect

the print cartridges,

press the Clean button.

Keep hands away

from the carriage

when the printer is in

operation. The car-

riage will automatically move to touch

the left end plate then

back to the right end

(the Service Station

position) when the power is turned on.

Never insert hands or other objects into the Service Station

area on the right side of the printer. The carriage occasionally

enters this area without warning and could collide with an

obstruction, potentially causing and injury.

Be careful when moving or lifting the printer. Moving the print-

er requires at least 2 people. To avoid injury to your fingers, do

not lift the printer by the end plates. Hold the bottom surfaces

of the end covers to lift or move it. See Figure 1.

Keep fingers away from the drive shaft when the printer is in

operation. Serious injury could result.

Figure 1. Hold the bottom surfaces of the end covers to avoid injury to your

fi ngers.

To improve readability, the

StudioJet is mentioned in this

manual only when necessary to

clarify differences in service or

maintenance procedures vis à vis

the FJ Printer. Unless otherwise

noted, instructions pertaining to

the FJ Printer are identical for the

StudioJet.

Note

xiii

Page 14

Warranty

Policy

Ioline warranty policy

Ioline Corporation provides a 12 month parts and labor warranty on

all new equipment and 90 days on repaired units, unless specifi cally

noted otherwise. Every unit is recorded by serial number when it

leaves the factory. The warranty period is based on the serial number of the unit and extends from the date of manufacture up to 12

months, plus an extra 3 months for shelf life. Making the total warranty period 15 months from the date of manufacture.

For warranty service, the end user must work through their dealer.

Ioline Customer Service is available to assist Authorized Dealers

with customer and equipment support.

xiv

Page 15

How to use

Four publications are available to assist you in setting up, operating

maintaining and servicing the FJ Printer:

FJ Printer Quick Start Guide (or StudioJet Quick Start Guide*)

FJ Printer & StudioJet User Guide

FJ Printer Service Manual

FlexPlot User Guide

Where to fi nd information

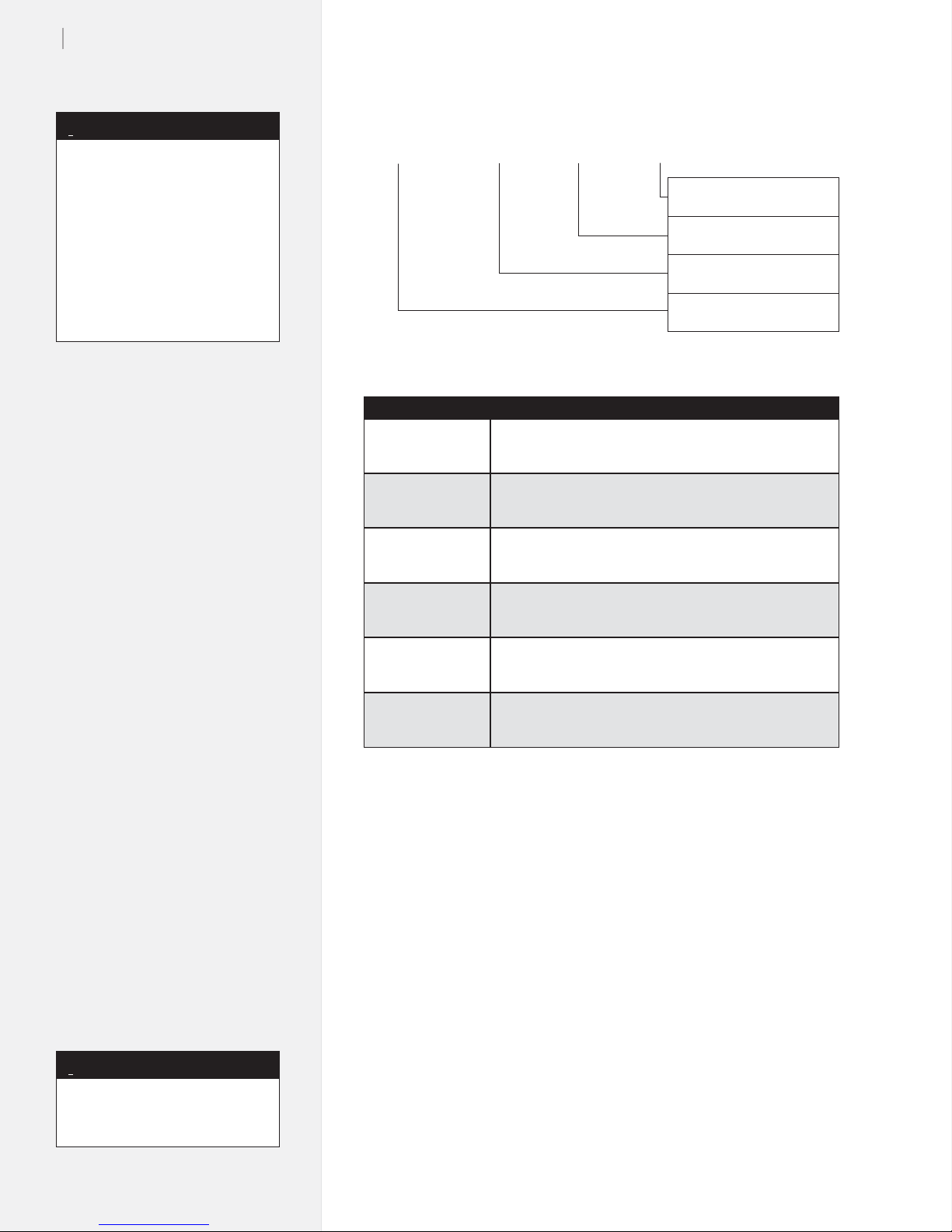

The table below provides a quick directory of topics and resources:

Topic Manual

Assembly & setup Quick Start Guide

Paper loading Quick Start Guide

Removing markers User Guide

The Ioline Control Center (adjusting plot

parameters)

Ioline FlexPlot software FlexPlot User Guide

Design software set-up guides FlexPlot User Guide

Maintenance User Guide

Basic troubleshooting User Guide

Advanced troubleshooting for qualifi ed service

personnel

Specifi cations, part names, drawings FlexPlot Service Manual

User Guide

FlexPlot Service Manual

this manual

What’s in this Service Manual

The FJ Printer & StudioJet Service Manual provides extensive

product specifi cations, testing and repair procedures.

Chapter 1 Introductory information and general specifi cations.

Chapter 2 Descriptive drawings listing part names for the FJ

Printer. This section is intended to supplement the

FJ Printer User’s Guide.

Chapter 3 Troubleshooting and testing guide.

Chapter 4 Details for repair and maintenance of the FJ Printer.

Chapter 5 Technical drawings and reference material.

* The FJ Printer and Studio-

Jet have separate Quick Start

Guides. When directed to consult

the Quick Start Guide, please

select the publication relevant to

your Ioline product.

Note

xv

Page 16

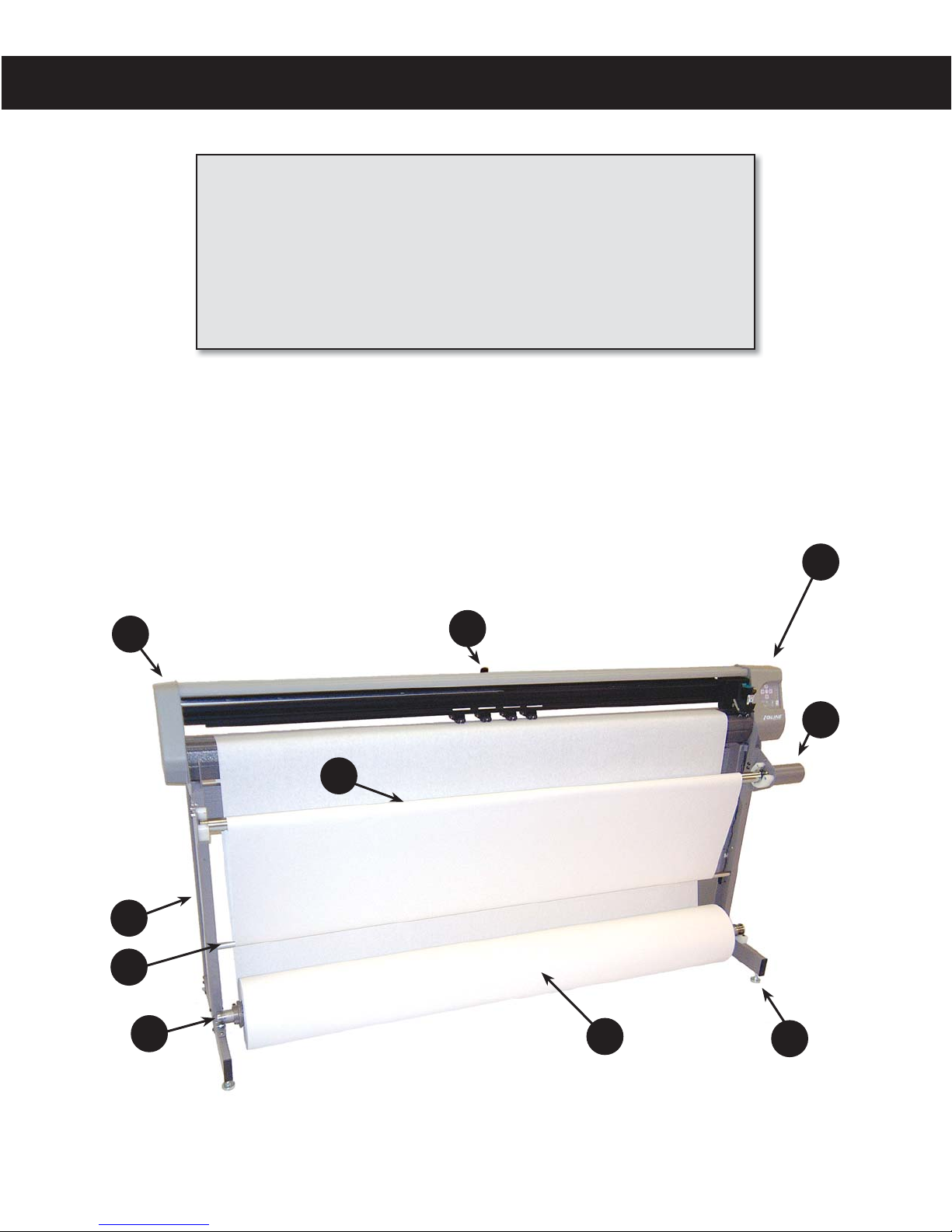

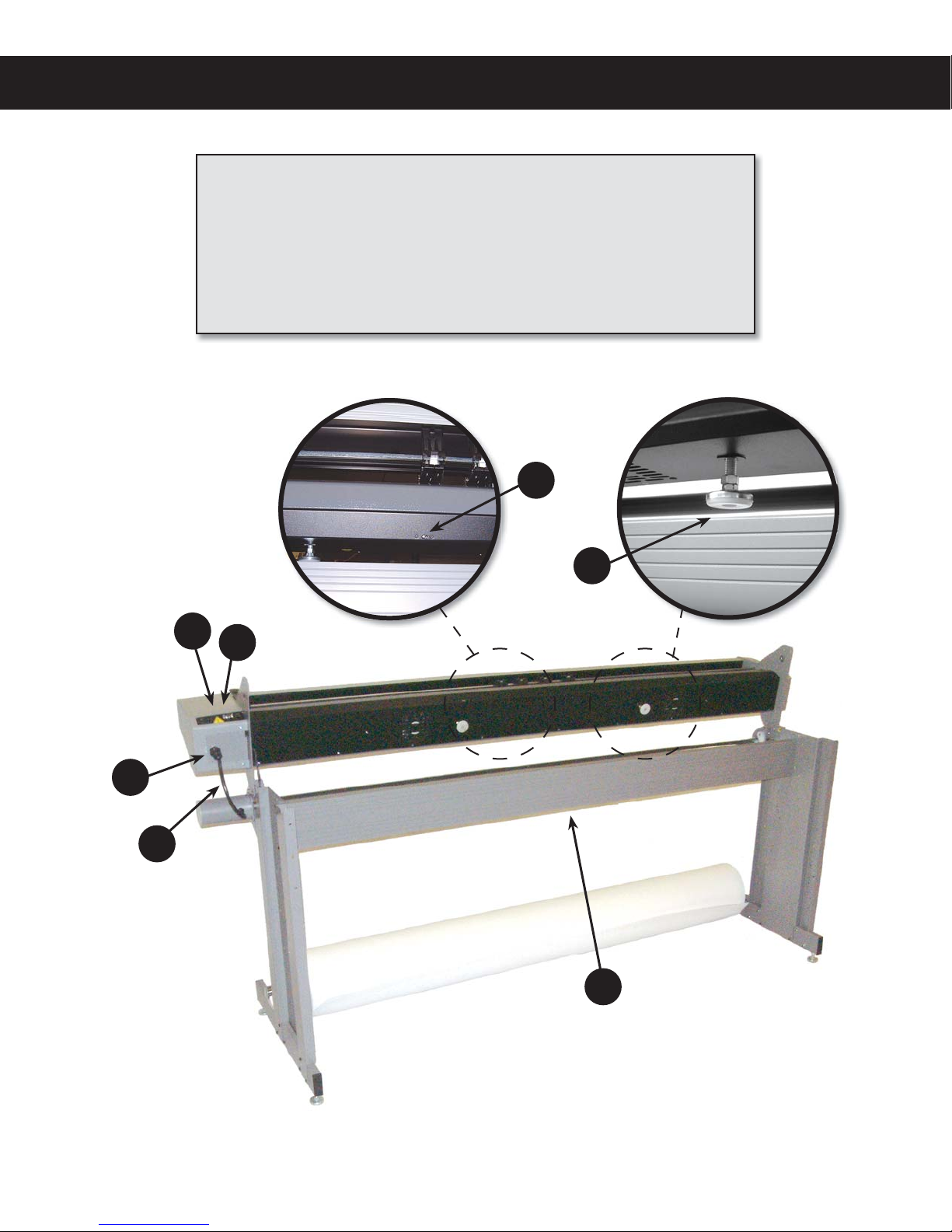

KEY

A

A. Left End Cover

B. Pinchwheel lever

C. Right End Cover

D. Take-up Motor

E. Stand Leveling Foot

F. Feed Roll

G. Take-up Shaft

H. Feed Shaft

I. Dancer Bar

J. Stand

C

B

G

J

I

H

Figure 2. The Ioline FJ (shown) and FJeX (not shown) Printers Front View.

F

D

E

xvi

Page 17

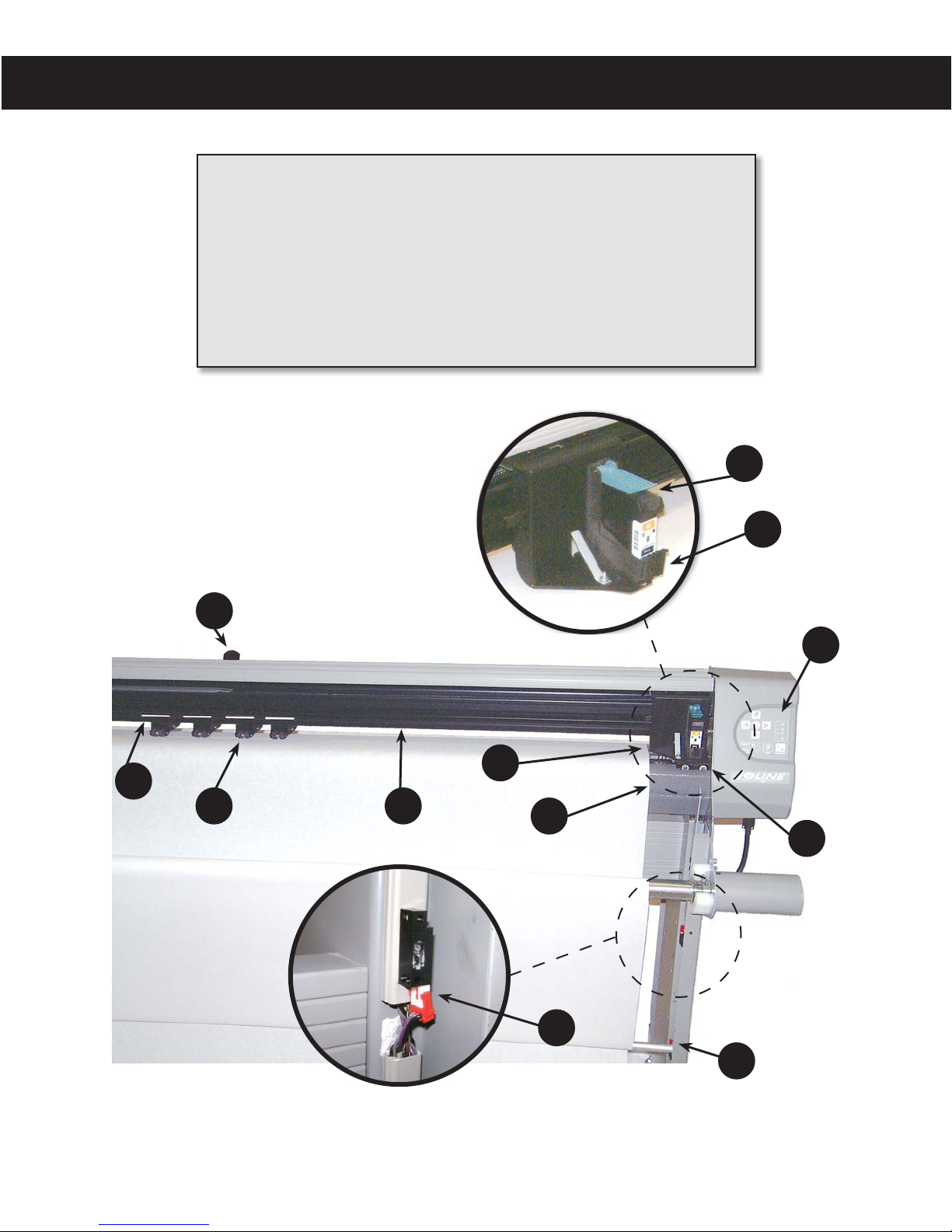

Visual Reference Guide

KEY

K. Take-up Motor Cable

L. Take-up Motor Outlet

M. Power Switch

N. Serial & USB Ports

M

N

O. Paper Out Sensor

P. Platen Leveling Pad

Q. Cross-member*

* The FJ-eX has two cross-members

O

P

L

K

Figure 3. The Ioline FJ (shown) and FJeX (not shown) Rear View (head titled in maintenance position.)

Q

*

xvii

Page 18

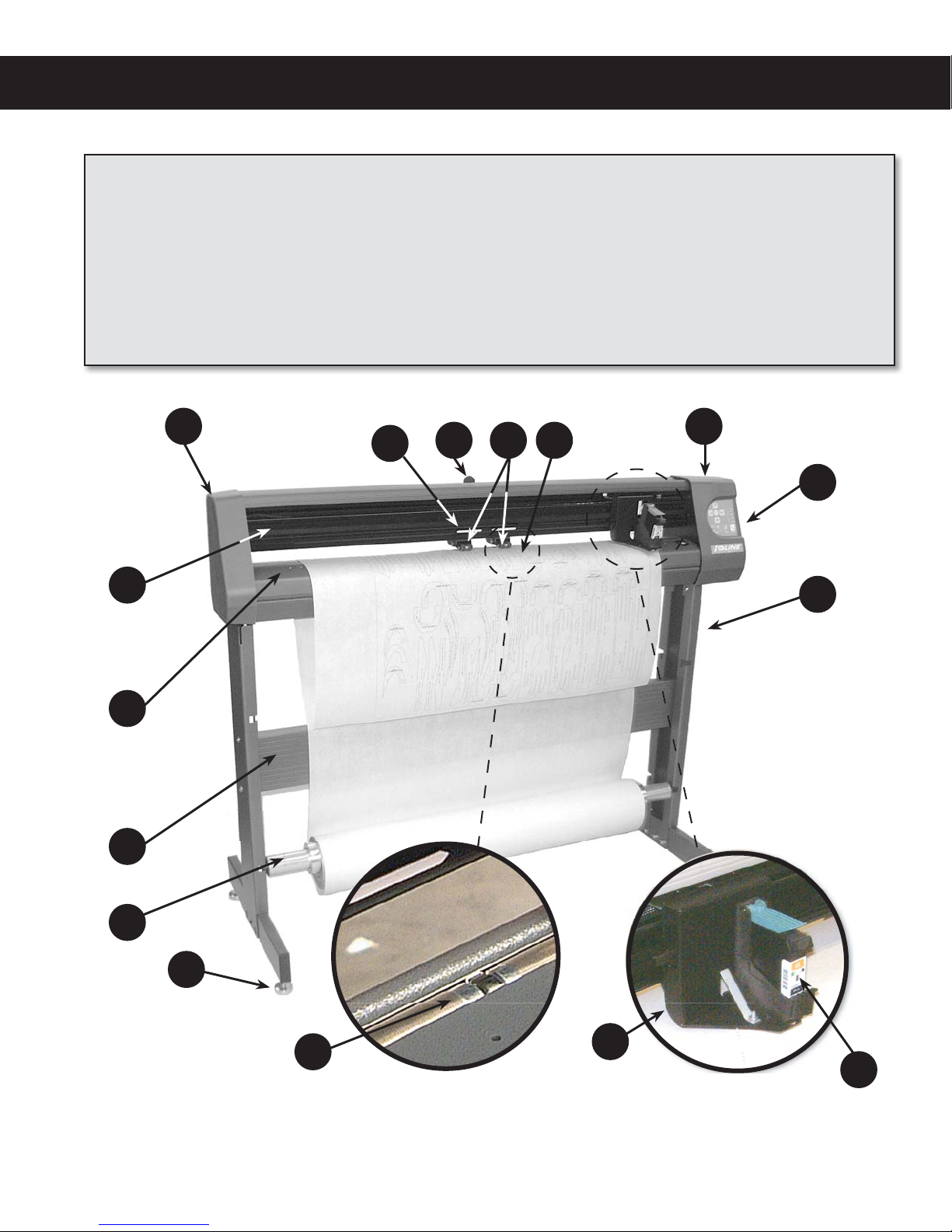

KEY

R. Drive Shaft Marker

S. Pinchwheel Lever

T. Pinchwheel

U. Traverse or Carriage Rail

V. Carriage Assembly

W. Platen

S

X. Ink Cartridge Latch

Y. Ink Cartridge Stall

Z. Keypad

AA. Service Station

BB. Bottom Sensor

CC. Top Sensor

X

Y

Z

R

T

Figure 4. The Ioline FJ Printer Front View Close-up

xviii

U

V

W

AA

CC

BB

Page 19

Visual Reference Guide

KEY

A. Left End Cover

B. Drive Shaft Marker

C. Pinchwheel Lever

D. Pinchwheel

E. Drive Shaft

A

O

F. Right End Cover

G. Keypad

H. Stand Leg

I. Inkjet Cartridge

J. Carriage

B

C

D E

K. Stand Leveling Foot

L. Feed Shaft

M. Cross-member

N. Platen

O. Traverse

F

G

H

N

M

L

K

E

Figure 5. The Ioline StudioJet Front View.

J

I

xix

Page 20

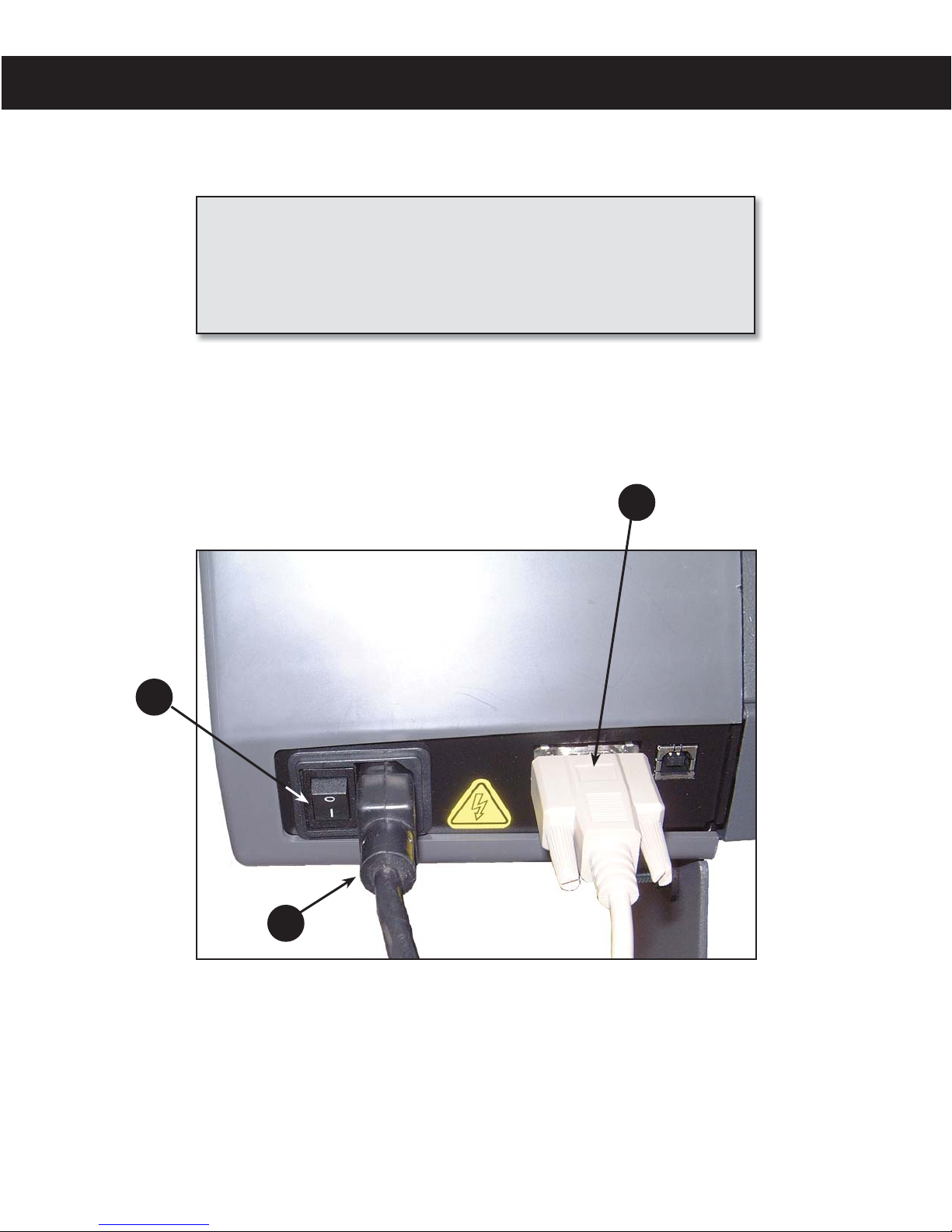

KEY

P

P. Power Switch

Q. Serial (COM) Port

R. Power Cord

Q

R

Figure 6. Power and communications ports on the Ioline StudioJet are located on the back of the right cover.

xx

Page 21

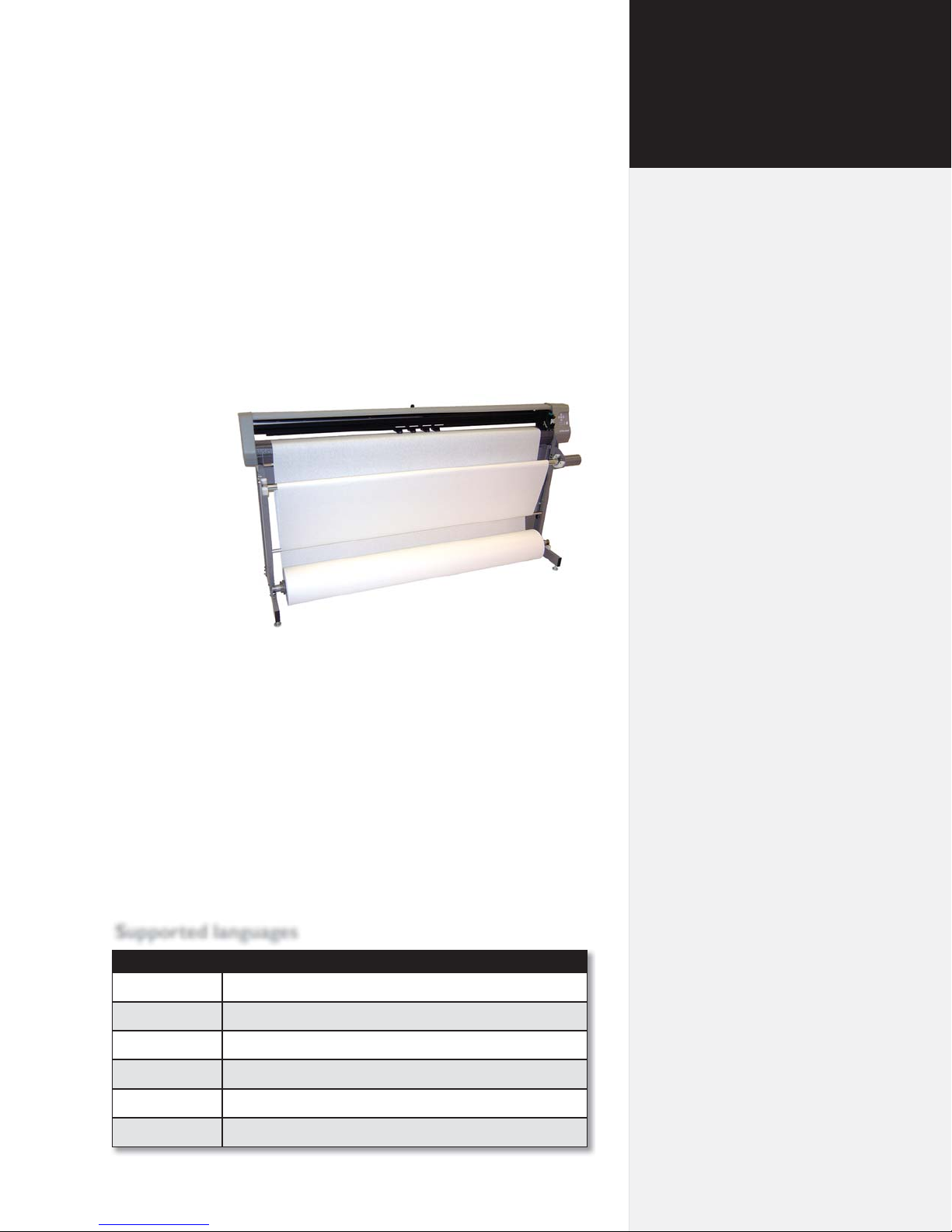

Product overview

The FJ Printer

is most commonly used

in conjunction

with popular

apparel software for printing marker

patterns, used

in the manufacture of clothing. The Printer

also comes

with FlexPlot

software that

allows printing of the most

popular formats such as AutoCAD® ( DXF), CorelDraw!® ( PLT),

Adobe® Illustrator® ( DXF), Lectra® ( ASTM), Investronica® ( ASTM). In

addition, it plots direct to Gerber® and reads Gerber®-compatible fi le

formats ( STD, PLT or ASTM).

Figure 7. The Ioline FJ Printer.

Chapter 1

Overview

The Ioline FJ Printer can handle many different printing operations

up to 72 inches wide and 600 yards long (85.8 inches and 349.9 yards

for the FJ-eX; 44 inches and 600 yards for the StudioJet. Two industry

standard printer languages ( HPGL 7475, and DM/PL) are supported.

The Ioline FJ Printer also supports direct cable connection from

many popular programs such as PAD®, Scanvec® Optitex®, Polytro-

®

, Ioline IPS software, and other applications.

pon

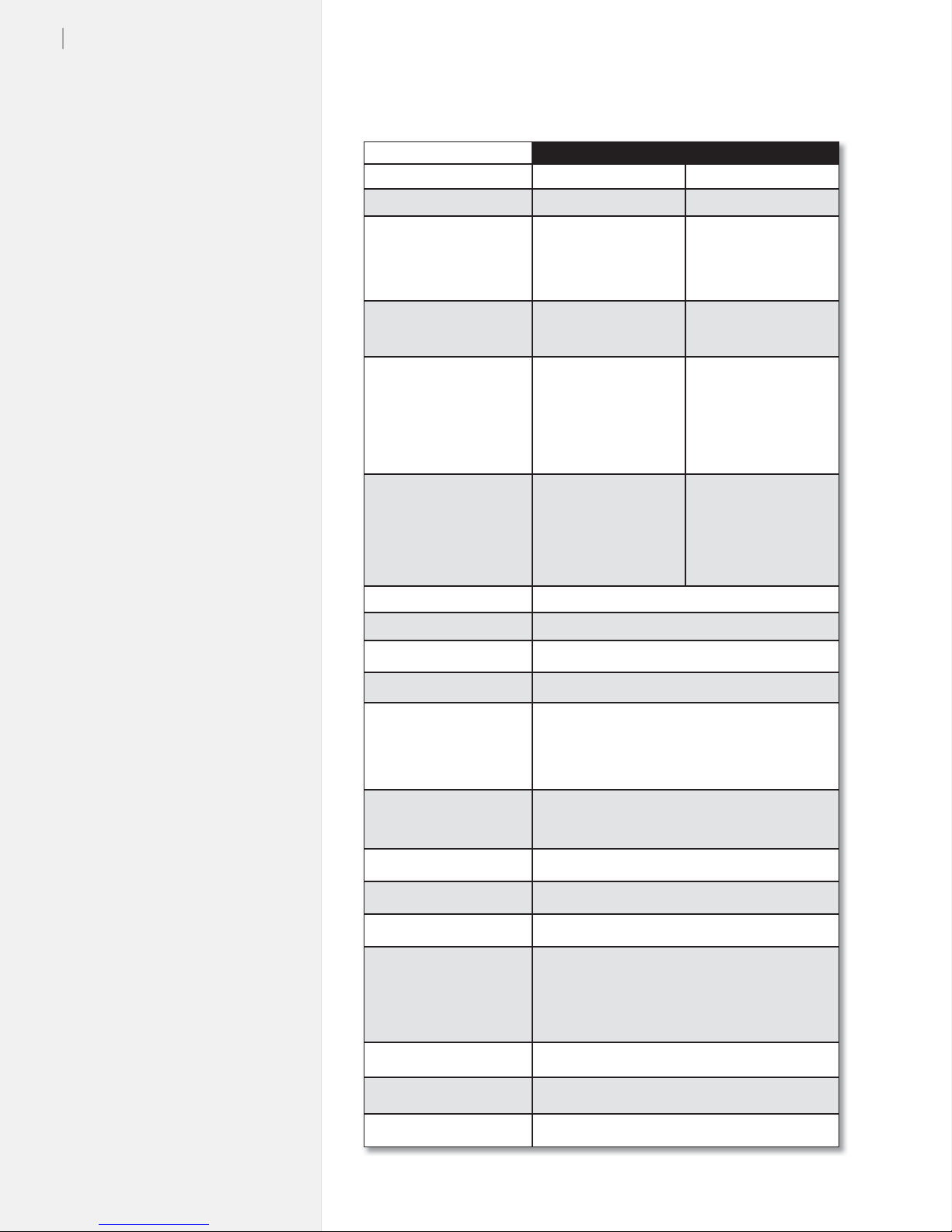

Supported languages

Language Application

HPGL Direct from software or Ioline FlexPlot.

DM/PL Direct from software or Ioline FlexPlot.

DXF Ioline FlexPlot only.

STD Ioline FlexPlot only.

ASTM 6959 Ioline FlexPlot only.

Ioline syntax Direct special control characters for FJ Printer.

Page 22

22

Ioline FJ Printer & StudioJet Service Manual

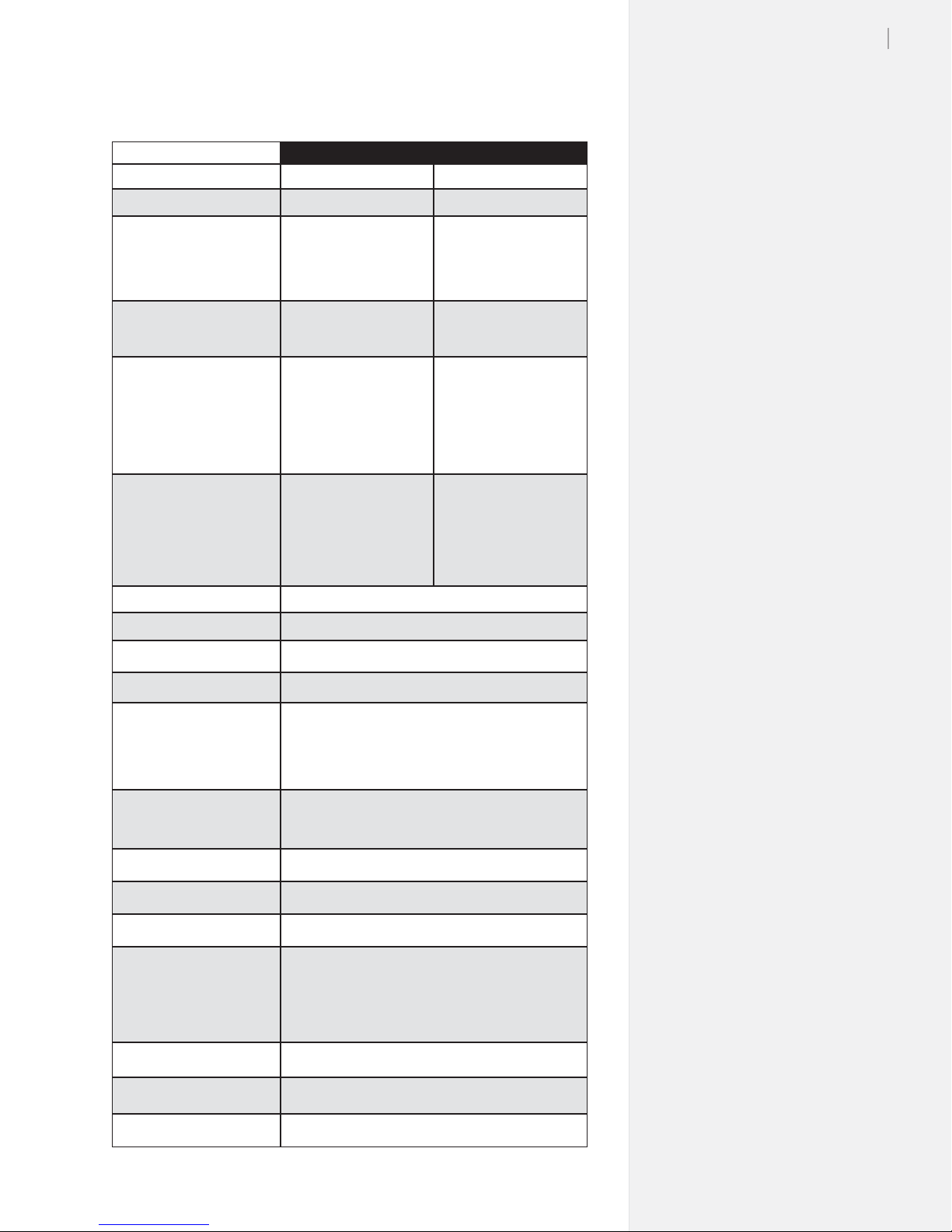

FJ Printer Specifi cations

Metric Empirical

Throughput 422 m/hour 502 lineal yd/hour

Max. plotting width 1.83 m 72 in

Media width

min.

max.

Marker length 548.6 m

Floor space requirements

Height

Width

Depth

.91 m

1.88 m

(Unattended)

2.4 m x .7 m

.7 m

2.3 m

1.17 m

36 in

74 in

600 yds

(Unattended)

96 in x 26 in

27.5 in

90.5 in

46 in

Weight

Actual

Dimensional (US)

Dimensional (Int’l)

106 kg

156 kg

158.2 kg

234 lbs

344 lbs

348.8 lbs

Paper type Recycled to bond

Feed roll position Front fl oor loading

Paper take-up roll position Ergonomic waist-level off-loading from front

Line thickness Thin, normal or thick

Resolution

Best mode:

Draft mode:

600 dpi

300 dpi

Ink cartridges Off-the-shelf

®

HP

51645A cartridges

PC interface USB / Serial ( RS-232)

Protocol HPGL / DM/PL

Languages DM/PL, DXF, HP-GL, HP-GL/2, MicroJet STD, ASTM

Compatibility

Gerber® ( Accumark®, MicroMark®, and Micro-

®

dynamics

Investronica

), Assyst®, AutoDesk® ( AutoCAD®),

®

, IPS, Lectra®, Scanvec® ( Optitex®),

PAD®, Polygon®, Polytropon® ( PolyPattern®),

®

Vetigraph

and others

Power requirements 85-264 VAC, 0.25 KVA, Single phase, 47-440 Hz

Humidity Non-condensing

Warranty 1-year parts and labor

Page 23

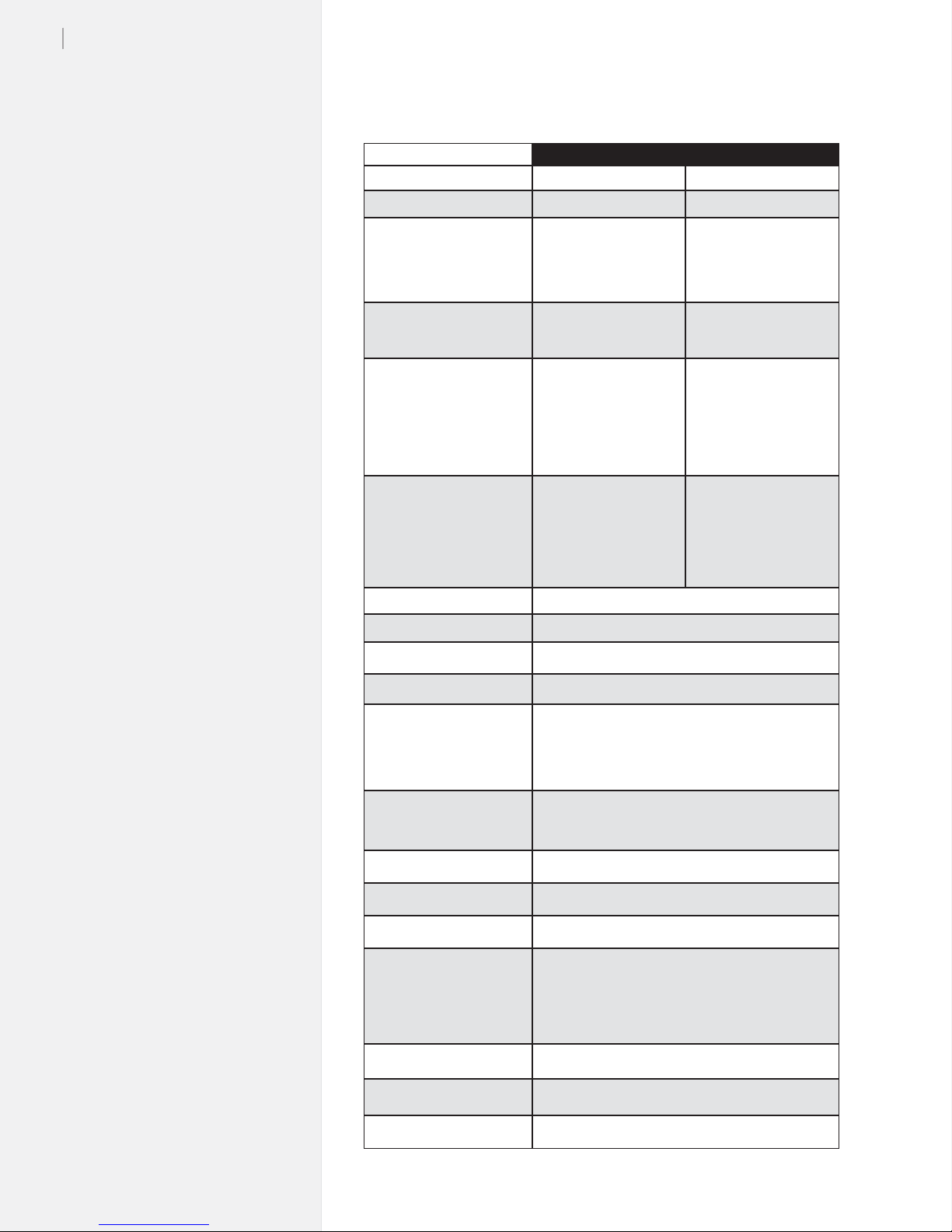

FJ-eX Specifi cations

Metric Empirical

Throughput 452 m/hour 542 lineal yd/hour

Max. plotting width 2.18 m 85.8 in

Media width

Chapter 1: Overview

23

min.

max.

Marker length 320 m

Floor space requirements

Height

Width

Depth

1.2 m

2.18 m

(Unattended)

2.62 m x .7 m

.7 m

2.6 m

1.17 m

47 in

85.8 in

349.9 yds

(Unattended)

103 in x 27.5 in

27.5 in

102.3 in

46 in

Weight

Actual

Dimensional (US)

Dimensional (Int’l)

125 kg

180 kg

190 kg

276 lbs

397 lbs

418.9 lbs

Paper type Recycled to bond

Feed roll position Front fl oor loading

Paper take-up roll position Ergonomic waist-level off-loading from front

Line thickness Thin, normal or thick

Resolution

Best mode:

Draft mode:

600 dpi

300 dpi

Ink cartridges Off-the-shelf

®

HP

51645A cartridges

PC interface USB / Serial ( RS-232)

Protocol HPGL / DM/PL

Languages DM/PL, DXF, HP-GL, HP-GL/2, MicroJet STD, ASTM

Compatibility

Gerber® ( Accumark®, MicroMark®, and Micro-

®

dynamics

Investronica

), Assyst®, AutoDesk® ( AutoCAD®),

®

, IPS, Lectra®, Scanvec® ( Optitex®),

PAD®, Polygon®, Polytropon® ( PolyPattern®),

®

Vetigraph

and others

Power requirements 85-264 VAC, 0.25 KVA, Single phase, 47-440 Hz

Humidity Non-condensing

Warranty 1-year parts and labor

Page 24

24

Ioline FJ Printer & StudioJet Service Manual

StudioJet Specifi cations

Metric Empirical

Throughput 332 m/hour 33.372 lineal yd/hour

Max. plotting width 1.01 m 40 in

Media width

min.

max.

Marker length 548.6 m

Floor space requirements

Height

Width

Depth

.2 m

1.11 m

(Unattended)

2.4 m x .7 m

1.17 m

2.26 m

.66 m

8 in

44 in

600 yds

(Unattended)

96 in x 26 in

46 in

89 in

26 in

Weight

Actual

Dimensional (US)

Dimensional (Int’l)

53 kg

54 kg

53.1 kg

116 lbs

117 lbs

117.1 lbs

Paper type 27# recycled to 150 lb tag board

Feed roll position Front fl oor loading

Paper take-up roll position Ergonomic waist-level off-loading from front

Line thickness Thin, normal or thick

Resolution

Best mode:

Draft mode:

600 dpi

300 dpi

Ink cartridges Off-the-shelf

®

HP

51645A cartridges

PC interface USB / Serial ( RS-232)

Protocol HPGL / DM/PL

Languages DM/PL, DXF, HP-GL, HP-GL/2, MicroJet STD, ASTM

Compatibility

Gerber® ( Accumark®, MicroMark®, and Micro-

®

dynamics

Investronica

PAD

graph

), Assyst®, AutoDesk® ( AutoCAD®),

®

®

, IPS, Lectra®, Scanvec® ( Optitex®),

, Polygon®, Polytropon® ( PolyPattern®), Veti-

®

and others

Power requirements 90-264VAC, 0.25 KVA, Single phase, 47-66 Hz, 80W

Humidity Non-condensing

Warranty 1-year parts and labor

Page 25

How the printer works

The Ioline FJ Printer combines paper and ink cartridge motion to

create vector outputs in a wide 72 in format. The data are sent to the

printer via either a standard RS- 232 serial or USB cable. When a fi le

is sent to the printer, the electronic system translates the vectors into

instructions for the “X” ( paper motion) and “Y” ( Ink cartridge motion) motors. At the same time instructions are sent to the carriage

assembly to apply ink to the paper.

Paper movement

Paper motion is accomplished by pulling paper through the

machine with a traction shaft. The shaft is

connected to the X-axis

motor with a timing belt

transmisison assembly.

The drive-shaft rotates

in one direction.

Figure 8. Paper direction.

Chapter 1: Overview

25

Carriage movement

The Y-Axis transmission powers a timing

belt that transports a V

wheel carriage along

the Y-Axis traverse

extrusion. The ink

cartridges are attached

to the carriage and are

made to apply ink to

the paper by actuating

the electronics of the

ink cartridge. When not

printing, the carriage

assembly is stored in the

Service Station to keep the ink cartridges clean and capped so they

don’t dry out.

Figure 9. Carriage movement.

Serial number identifi cation

Identifi cation of Ioline Corporation products is accomplished by use

of a serial number located on the back of the right side cover on the

printer. You can determine the model and date of manufacture using the following guidelines:

Page 26

26

Ioline FJ Printer & StudioJet Service Manual

* FJ-eX model serial numbers

begin with the code “FJEX”:

Note

FJEX

StudioJet models begin with

“STUDIOJET”:

STUDIOJET

FJ8* 03 26 01

{

Glossary

BOM Bill(s) of Material for Assembly

Bottom Pan Metal housing protecting the underside of the printer.

Carriage The component that holds the ink cartridges. It traveles

Keypad Where the user controls simple printer functions. Carriage

Traverse Assembly The structure that supports and guides the carriage as-

{

along the Y-Axis on the traverse assembly.

and media motion is accessible from here during stop

mode.

sembly.

{

{

Number of machine manufactured in that week

Week of manufacture

Year of manufacture

Model number

An expanded Glossary is available

in the User Guide.

Note

X-Axis The direction of the paper moving through the machine.

Y-Axis The direction of the carriage moving back and forth.

Software setup options

Ioline recommends using FlexPlot for marker making on the FJ

Printer. FlexPlot offers the most robust and fl exible workfl ow

available for creating output. It’s especially useful when many fi le

formats are used, a common situation for service bureaus. To set-up

and learn how to use the software, see the FlexPlot User Guide.

The FJ Printer is designed to work in many different production

environments. The type of marker printing you do will often determine your preferred communication method. Two typical methods

for sending markers are:

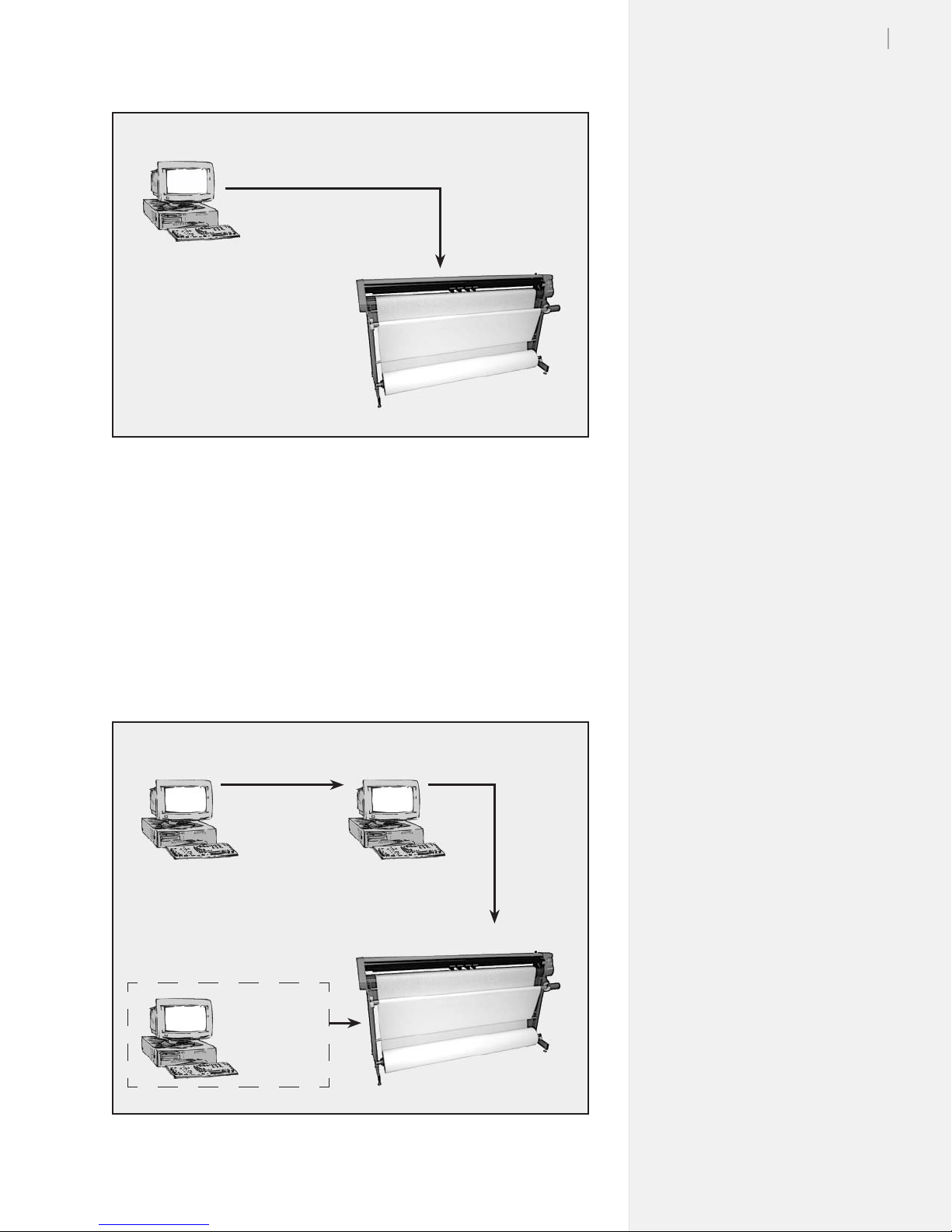

1. Plot directly from the marker or design software to the

printer. (See Figure 10.)

Unlike other marker printers, the FJ Printer is capable of oper-

ating as a stand-alone device with no extra software running

on the computer. This method works if your CAD software includes a driver for any Ioline product, such as the Ioline 600Ae

or the Summit 2200. It will also work if the CAD software can

create a compatible HPGL- or DM/ PL- formatted fi le.

Page 27

CAD

Software

HPGL

DM/PL

FJ Printer

Figure 10. Workfl ow: output direct from CAD software (without FlexPlot).

Chapter 1: Overview

27

2. Use FlexPlot software to convert fi les before sending them

to the printer for output.

The FJ Printer includes the FlexPlot software which will con-

vert many compatible fi le formats. It also provides an advanced

marker queue management system and other tools to optimize

the performance of the printer.

CAD

Software

[Network]

FlexPlot

HPGL

DM/PL

DXF

ASTM 6959

STD

(Alternate Confi guration)

CAD

Software

+

FlexPlot

Figure 11. Workfl ow using FlexPlot for fi le conversion and output.

FJ Printer

Page 28

28

Ioline FJ Printer & StudioJet Service Manual

Caution

Keep hands and loose

clothing away from all

moving parts of the

printer. Make sure the Service

Station area is not obstructed.

Power on

Turn on the computer and the printer to make sure they both work.

The printer power switch is located next to the power cord on the

back of the machine, behind the keypad. When the printer is powered up, the carriage will move toward the left side of the machine,

then return to the opposite side to park in the Service Station. The

OK light will turn red and the Square light will turn green on the

front panel after the start-up process has fi nished.

Installing FlexPlot and

the Control Center

The FJ Printer includes two software interfaces: FlexPlot and the

Control Center. FlexPlot will import and queue marker fi les from

many design programs to optimize production operations. The

Control Center is an interface for adjusting parameters to optimize

printer performance. The printer comes with a CD-ROM which has

Microsoft Windows® 98/2000/XP versions of the programs as well

as PDF user guides and the required Adobe® Acrobat® reader.

1. Power on the computer and Windows®.

2. Insert the Ioline CD-ROM into the CD-ROM drive (usually D:).

3. The installation program should start automatically. If it does

not:

a. Select the Start button.

b. Choose Run.

c. Type D:\IOSETUP (substitute the correct letter if the CD-

ROM drive letter is not D:) and Click OK.

4. Follow the instructions that appear on the screen.

5. The FlexPlot User Guide has details on using the FlexPlot

software. In this manual, see the section The Control Center for

more details about the Control Center software.

Page 29

Chapter 1: Overview

29

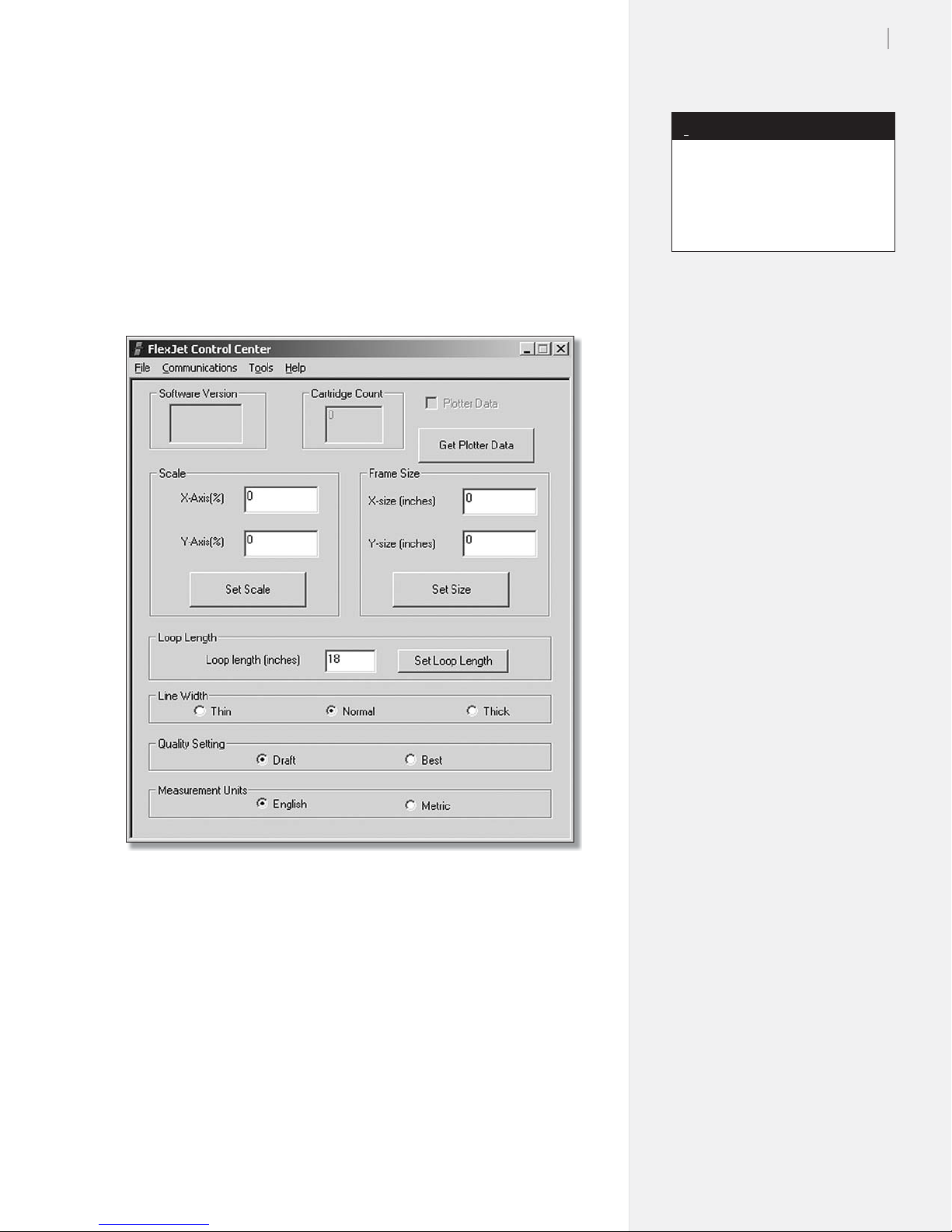

The Control Center

Overview

The Control Center is a utility program that does two things:

Allows you to adjust settings to tailor output (e.g. scale, line

width) from the computer.

Provides an interface to send completed fi les to the printer.

To avoid communication port

confl icts, do not simultaneously

run more than one application

that communicates with the

printer.

Note

Figure 12. Control Center main menu.

Changing system settings

A variety of settings are adjustable to fi t specifi c needs:

Make sure the printer power is on and that the initialization

process is complete. The carriage will park, the keypad OK

light will turn red and the Square light will turn green.

The Screen Menu displays the primary settings that are adjust-

able. The Menu Bar contains utilities for setting up the Control

Center and calibrating the pinter.

Changes only take effect after one of the Send buttons is

pushed.

Page 30

30

Ioline FJ Printer & StudioJet Service Manual

Control Center menu bar features

File

Download Firmware Allows the user to download the

latest fi rmware version. See the User

Guide for more information.

Send Plot File Print a PLT or PLX fi le.

Exit Exit the Control Center.

Communications

Settings Select the COM port and baud rate

to match the printer.

Send Command Permits advanced users to manually

enter commands.

Tools

Aux Sensor Stops printer when paper runs out.

Cartridge Calibration Displays tools to adjust print car-

tridge alignment. See the User Guide

for more details.

Size Calibration Allows adjustment of the size cali-

bration settings. See the User Guide

for more details.

About Your FlexJet Displays license information and

print head activation status.

FlexJet Licensing Enter new license information for

upgrades in this window.

Help

About Displays Control Center version

information.

Page 31

Control Center menu options

Software Version

Displays the current fi rmware version installed in the printer.

Cartridge Count

Displays how many cartridges are in active use by the printer.

Get Plotter Data

Reads and displays the current settings stored in the printer in the

input boxes.

Plotter Data (check box)

Indicates when the displayed settings were successfully downloaded

from the printer. If this box is unchecked, the Control Center was

unable to connect with the printer and cannot display current settings.

Check the connections, baud rate and COM port. Press the Get Plotter

Data button to attempt to download settings if the process failed

during startup.

Chapter 1: Overview

31

Line Width

Controls the weight of the plotted line using line width. Three levels

are available; Thin, Normal, and Thick. Thin lines use less ink and

make fi ne details like Asian text and small pieces easier to see. Thick

lines use more ink to produce higher contrast lines.

Used in conjunction with the Quality Setting (see below), the FJ Printer provides six options for output quality, to enable you to produce

clearly visible lines using the least possible amount of ink.

Scale

The printer scale ranges from 1% to 999%. The factory default Scale

is 100%. A scale set to 50% prints at half size. Changes do not take

effect until the Set Scale button is pressed. Note: Both X- and Y-Axes

are set independently.

Frame Size

Most design software sends long plots to printers by breaking them

into smaller pieces called frames. In general, design software does this

automatically and adjusts the Frame Size in the printer to match.

The Frame Size setting establishes clipping limits for each data

frame. If the printed size of a plot frame exceeds the frame size set

in the printer, the excess is clipped or thrown away. (If the plot is

clipped, try increasing the Frame Size manually.) The factory-set

X-axis (paper direction) frame size is 46 in (116.8-cm), maximum is

21600 in (54,864-cm). Default and maximum Y-axis ( carriage direction) frame size is 72 in (182.9-cm).

Page 32

32

Ioline FJ Printer & StudioJet Service Manual

Quality Setting

Choose Draft or Best to control line density. Draft mode uses 300 DPI.

Best mode uses 600 DPI. A lower DPI setting uses less ink by creating

a fainter line. Higher DPI uses more ink but makes a darker line. Use

this setting in conjunction with the Line Width (see above) to fi nd a bal-

ance between saving ink and making clearly visible lines.

Measurement Units

Choose between English or Metric units for settings display.

Page 33

Product components

Chapter 2

Nomenclature

Figure 13. The Ioline FJ Printer power supply.

Figure 14. Rear power panel assembly.

Power cord pluginPower switch

Page 34

34

Ioline FJ Printer & StudioJet Service Manual

Wheels

(Replaceable)

Figure 15. Pinchwheel assembly.

Figure 16. Ink cartridges: HP 51645A.

X Motor encoder

Y Motor encoder

Main power

Roll feed encoder

Motor

power

Fans:

1,2 & 3

LEDs (4)

Carriage

power

Paper out

/ take-up

sensors

Paper out

2 sensor

Keypad

Comm.

(RS-232)

Heads

1,2 & 3

Board part

number sticker

Figure 17. FJ Printer logic board.

Page 35

Carriage latch

Carriage

Ink

cartridge

Chapter 2: Nomenclature

35

Base

Figure 18. Printer carriage assembly with cover off.

Carriage stall

V-notch

Carriage

Carriage

latch

Carriage

stall

Base

Figure 19. Printer carriage assembly with cover on.

V-notch

(below)

Page 36

36

Ioline FJ Printer & StudioJet Service Manual

This page intentionally left blank.

Page 37

General troubleshooting

This section contains guidelines and testing procedures for resolving

basic operatioinal diffi culties and diagnosing mechanical, electri-

cal and electronic processes. Chapter 4 also contains related repair

procedures.

If the system isn’t functioning correctly, fi rst determine which com-

ponent is causing the problem. Likely diffi culties may involve:

The computer

Chapter 3

Troubleshooting &

Testing

The power cord or communication cables

The apparel/marker design software

The FJ Printer

Changes to the computer operating system or the installation of new

peripherals or software can cause confl icts. If the problem appears to

be with the computer or apparel design software, consult the appropriate documentation or an Ioline dealer.

If the problem is with the printer, begin by making sure power is on and

that the cable between the machines and the PC is connected correctly.

The information in this chapter begins with the simplest and most

common issues, and progresses to more complex and invasive

troubleshooting. If you are unable to resolve a problem after consulting this manual, fi ll out the Diagnostic Record at the beginning of

Chapter 4, then contact Ioline Customer Service.

Error messages

Error messages that are specifi c to the Ioline FJ Printer are divided

into two catagories: Control Center software errors and LED codes.

Software errors present themselves on the computer screen and usually indicate a communication problem. LED codes are visible on the

keypad and can be a green light, a red light or a combination of both.

The keypad LED code table (Figure 21) is helpful for isolating the

cause of obvious external or communication problems. Comprehensive information later in the chapter can help troubleshoot mechanical and electrical diffi culties. Errors caused by the operating system

or the plotting software should be resolved with the software author.

Page 38

38

Ioline FJ Printer & StudioJet Service Manual

Control Center software errors

The FJ Printer did not respond. Do you wish to continue anyway?

The Control Center did not get a response from a FJ Printer on the COM

port it is currently confi gured to use. If the FJ Printer is connected and the

power is on, click ‘Yes’. Follow the directions in the FJ Printer User Guide for

confi guring the COM port and baud rate.

Unable to open communication port. You may need to select a different COM port. Do you wish to continue?

The Control Center did not get a response from a FJ Printer on the COM

port it is currently confi gured to use. If the FJ Printer is connected and the

power is on, click ‘Yes’. Follow the directions in the FJ Printer User Guide for

confi guring the COM port and baud rate.

Incorrect plotter model. Do you wish to continue?

The Control Center did not recognize the printer model connected to the

COM port. Upgrade the Control Center to the latest version. If that does

not resolve the problem, confi rm that ‘FJ Printer Control Center’ is displayed in

the menu bar of the program. If it is not, obtain the correct version from Ioline.

Fatal Error: COM port pointer is NULL Unable to recover.

A serious internal failure in the program or Windows® has occurred. Close all

programs, restart Windows

Unable to change FJ Printer baud rate Do you wish to change baud

rate in Control Center?

The Control Center did not get a response from a FJ Printer on the COM

port it is currently confi gured to use. If the FJ Printer is connected and the

power is on, click ‘Yes’. Follow the directions in the FJ Printer User Guide for

confi guring the COM port and baud rate.

Warning: Unable to open log fi le; Status messages will not be saved.

®

then start the Control Center program.

This error occurrs if the Control Center is unable to write the fi rmware up-

grade process log in the same folder where the fi rmware source fi le is stored

on the PC. It is typical if installing fi rmware from a CD-ROM or if the user does

not have ‘Modify’ or ‘Full’ permissions to the PC fi le system. Copy the fi rmware

to the hard disk and make sure permissions are correct before installing.

Page 39

NOTICE: Your fi rmware is out of date. It is recommended that you

update it as soon as possible, but it is not required. This program will

work with new and old fi rmware. Firmware upgrades are available

from Ioline Customer Service at (425) 398-8282 Pacifi c Standard

Time USA.

The fi rmware in the FJ Printer is obsolete. An upgrade is highly recommended.

Contact Ioline Customer Service to obtain the software and instructions.

FJ Printer is not responding. Please check your cables and baud rate.

The Control Center did not get a response from a FJ Printer on the COM

port it is currently confi gured to use. If the FJ Printer is connected and the

power is on, click ‘Yes’. Follow the directions in the FJ Printer User Guide for

confi guring the COM port and baud rate.

The identifi cation numbers for this board have already been set. You

must use the ‘ Reset Machine ID’ dialog to change them now.

Chapter 3: Troubleshooting & Testing

39

The user is attempting to overwrite an internal license that is already set. Contact

Ioline customer service for assistance.

Page 40

40

Ioline FJ Printer & StudioJet Service Manual

Keypad error codes

Figure 20. LED lights

on the keypad.

Legend

G = Green light

R = Red light

Y = Yellow light

* First generation FJ Printer keypad

lights do not blink.

Y-Blink = Blinking yellow light*

OFF = Unlit

OK

G OFF OFF OFF Ready to Print, Origin Set

R OFF OFF OFF Paused / Offl ine, Keypad Active

R G OFF OFF Power-on reset fi nished.

R OFF Y-Blink OFF Paper Feed Out / Jammed

Y-Blink RROFF X- (paper) axis jam

Y-Blink G R OFF Y- ( carriage) axis jam

Y-Blink G G OFF TU (take-up) jam

OFF R Y-Blink OFF Buffer Overfl ow

Problem/Status

If keypad errors are not shown on

the chart to the right, update the

fi rmware. For more information,

please contact Ioline Customer

Service.

Note

Y-Blink OFF R OFF Init from EPROM failed

OFF RROFF File syntax error

Y-Blink Y-Blink Y-Blink OFF Printer ready to receive fi rmware

Y-Blink OFF OFF OFF Motors off / System Stop

Figure 21. Keypad LED error codes.

Page 41

Power problems

If the printer won’t power on or initialize—or if the fan does not

spin—follow these initial diagnostic steps:

1. Check the power cord. Make sure that it is fi rmly plugged into

the wall and into the back of the printer.

2. Check the voltage at the wall outlet and verifi y that it is within

the operating limits as specifi ed in Chapter 1, Specifi cations.

If there are no obvious power problems, proceed to the Mechanical,

Electrical, and Electronic Diagnostics later in this chapter.

Communications

The Printer won’t respond to the computer

If the printer doesn’t accept commands from the computer, try the

following:

Chapter 3: Troubleshooting & Testing

41

1. Verifi y that the communication cable is correctly connected to the

printer and to the proper communications port on the computer.

2. Change the computer COM port settings to match the printer’s

serial communications settings. (See Serial Communication,

below.)

Serial communication

The serial port on the printer has an adjustable baud rate. Available

speeds are 9600, 19200, 38400, 57600, and 115200. It is critical that the

Control Center, FlexPlot or design software use the same baud rate

that the printer is using.

If there is ever any doubt about what baud rate the printer is using, Ioline

recommends resetting it to the default of 38400. To reset the baud rate:

1. Turn off the power to the printer.

2. Press and hold the Page Advance key (the key below Set Origin)

while turning power on.

3. Continue holding the Page Advance key until the OK light

turns red and the Square light turns green.

If using a terminal program like TeraTerm™ to communicate with

the printer, make sure to use 8 Data Bits, No Parity, 1 Stop Bit, and

Xon/Xoff ( software) Flow Control.

Page 42

42

Ioline FJ Printer & StudioJet Service Manual

Common problems

Good print quality is dependant upon several factors. The type of

paper, environmental conditions, and operator habits are only a

few of the variables that can affect the quality of the plot.

It is important to load paper in the printer—and maintain it—according to the guidelines in the User Guide. The table below summarizes the some of the most common diffi culties users encounter.

The sections following the table examine each issue in greater

depth.

A marker plot doesn’t start at the correct point on the paper

Cause:

1. The origin is not set correctly.

Poor line quality.

Cause:

1. Ink cartridge is improperly

installed.

2. Frame Gap setting is incorrect.

3. Carriage electronics or cables

are damaged.

4. Ink cartridge is dry.

The printer does not complete the marker.

Cause:

1. Outdated software.

2. The frame/panel size is mismatched between the printer

and the design software.

Solution:

1. Position the V-notch where the

Solution:

1. Remove and reinstall ink car-

2. Use the Control Center to

3. Contact Ioline customer service.

4. Clean or replace cartridge.

Solution:

1. For updated fi rmware, please

2. Check the panel size in the

plot should start. Press the Set

Origin key.

tridge.

adjust frame gap as shown in the

Routine Maintenance chapter

of the FJ Printer User Guide.

contact Ioline Customer Service.

software. It should be equal to

the printer panel size.

Take-up shaft stops turning; No take-up during plotting.

Cause:

1. Paper sensor or motor failed.

When paper is out, machine keeps plotting.

Cause:

1. Paper sensor failed.

Solution:

1. Contact Ioline customer service.

Solution:

1. Contact Ioline customer service.

Page 43

Regular or intermittent paper tearing or paper bunches up at bottom.

Chapter 3: Troubleshooting & Testing

43

Cause:

1. Front dancer bar is not installed.

2. Paper gets “yanked” by the

machine during take up.

3. Paper buckles when plotting to

fl oor.

4. Paper roll damaged.

5. Paper not loaded correctly.

6. Platen not level.

7. Outdated fi rmware does not

advance paper at startup.

8. Pinchwheels press on a drive

shaft bearing.

9. Paper sensor failed.

Solution:

1. Install front dancer bar.

2. Make sure the front dancer bar

is below the Take-up Sensor,

then press Set Origin.

3. Clear paper path. Refer to the FJ

Printer User Guide for proper

loading procedures.

4. Inspect the feed paper roll.

Dropping the paper roll on an

end can wrinkle the edge which

can catch the carriage and cause

a tear.

5. Correct paper loading is vital.

Follow the steps in the Opera-

tion chapter of the FJ Printer

User Guide to reset paper align-

ment. Make sure the front silver

dancer bar is BELOW the front

optical sensor before plotting.

6. Make sure the distance between

the print heads and platen

surface is the same at the right,

center and left side of the printer.

Adjust the platen levelers as described in the FJ Printer Quick

Start Guide if necessary.

7. Use the Control Center to

check the fi rmware version and

ensure it is 324 or greater.

8. With power off, raise the

pinchwheels and align them with

the white driveshaft markers on

the traverse.

9. Contact Ioline customer service.

When Set Origin is pressed, paper is pulled tight and rips.

Cause:

1. Paper sensor failed.

When Set Origin is pressed, paper runs quickly and stops.

Cause:

1. Motor failure.

Drive shaft refuses to move when keypad button is pressed.

Cause:

1. Machine is off or unplugged.

2. Motor failure.

Solution:

1. Contact Ioline customer service.

Solution:

1. Contact Ioline customer service.

Solution:

1. Turn on or plug in machine.

2. Contact Ioline customer service.

Page 44

44

Ioline FJ Printer & StudioJet Service Manual

When changing paper rolls make

sure you let the paper rest outside the packaging overnight fi rst.

Note

Jagged scan alignment.

Cause:

1. Cartridge alignment is incorrect.

2. Motion alignment is incorrect.

3. Platen or stand is not level.

4. Loose carriage pulley causing random/uneven gaps between scans.

Poor paper tracking.

Cause:

1. Paper is improperly loaded.

2. Bad paper roll or paper quality.

3. Pinchwheels not in correct

location.

4 Feed paper roll isn’t centered on

feed shaft.

5. Loose paper hubs.

Solution:

1. Use the Control Center to

adjust cartridge alignment as

shown later in this chapter.

2. Use the Control Center to adjust motion alignment as shown

later in this chapter.

3. Follow the directions in the FJ

Printer Quick Start Guide to

level the stand and platen.

4. Contact Ioline customer service.

Solution:

1. Reload and align paper.

2. Replace the paper roll.

3. With power off, raise the

pinchwheels and align them with

the white driveshaft markers on

the traverse.

4. Center the paper roll on feed shaft.

Make sure screws are tight on

both paper hubs.

5. Tighten screws on the paper hubs.

No ink.

Cause:

1. Ink cartridge empty.

2. Clogged print head.

3. Service Station failing to cap

print head (FJ Printer only).

4. Broken ribbon cable.

5. Logic board failure.

Solution:

1. Replace cartridge.

2. Clean the print head, following the instructions under

Cartridge Maintenance and

Handling in the User Guide.

3. Contact Ioline Tech Support for

assistance.

4. Replace the ribbon cable following instructions under the

Carriage Procedures section

later in this chapter.

5. Contact Ioline customer service.

Page 45

Gap between each scan, broken or dotted lines or sections of plot are

missing.

Chapter 3: Troubleshooting & Testing

45

Cause:

1. Frame gap setting is incorrect.

2. Ink cartridge is out of ink, dirty

or the print head is plugged.

3. Ink cartridge is damaged.

4. Ink cartridge bay pins are dirty.

5. Ribbon cable is loose or broken.

6. Service Station refuses to cap

cartridges (FJ Printer only).

7. Logic board failure.

Solution:

1. Use the Control Center to

adjust frame gap as shown in the

Routine Maintenance chapter

of the FJ Printer User Guide.

2. Check ink level indicator.

Replace cartridge if indicator is

black. If cartridge is not empty,

see Cartridge Maintenance

and Handling under the Routine Maintenance chapter in

the FJ Printer User Guide.

3. Replace cartridge.

4. Contact Ioline customer service.

5. Tighten or replace the ribbon

cable following instructions

under the Carriage Procedures

section later in this chapter.

6. Contact Ioline customer service.

7. Contact Ioline customer service.

After plot is sent, machine does not move.

Cause:

1. Plotter is off or unplugged.

2. Wrong baud rate or baud rate

does not match on plotter or

computer.

3. Wrong settings in the software.

4. Data cable is bad.

5. Wrong port being used.

6. Bad fi le.

7. Communication chip on plotter

failed.

During power-up, carriage doesn’t move or moves quickly to the left

or right, then stops.

Cause:

1. Motor failure.

Solution:

1. Plug machine in and turn on.

2. Refer to the Serial Communica-

tion section earlier in this chapter.

3. Check the frame size and other

settings in the software.

4. Replace data cable.

5. In the Control Center, verify

that the assigned port matches

the physical port.

6. Check or recreate the plot fi le.

7. Contact Ioline customer service.

Solution:

1. Contact Ioline customer service.

Page 46

46

Ioline FJ Printer & StudioJet Service Manual

No power when printer is turned on; Keypad lights stay dark.

Cause:

1. The power cord is damaged or

disconnected.

2. Check power supply voltage.

3. The printer is damaged and

needs professional service.

4. A fuse has blown.

5. Power supply failure.

Pauses during printing.

Cause:

1. Vector density is very high due

to fi ne detail or the design soft-

ware is not using fonts embedded in the printer.

2. Communication baud rate is set

very low.

3. Frame length is too big.

Solution:

1. Check the power connection.

2. See Repair Procedures later in

chapter 4.

3. Contact an Ioline distributor or

Ioline Customer Service.

4. Replace fuse.

5. Contact Ioline customer service.

Solution:

1. Reduce vector density, use embedded printer fonts, or increase

communication baud rate.

2. Increase baud rate from the

minimum of 9600 baud to the

default of 38,400 or higher. Make

sure the FJ Printer and the software are set to the same baud

rate.

3. Reduce frame length. Set between 5-in and 35-in.

Carriage refuses to move all the way to the right.

Cause:

1. Service Station failure.

Carriage hits the Service Station.

Cause:

1. Service Station spring is broken.

2. Service Station slider sticks.

Take-up motor will not stop turning.

Cause:

1. Paper sensor failed.

Solution:

1. Contact Ioline Tech Support for

assistance.

Solution:

1. Contact Ioline customer service.

2. Contact Ioline customer service.

Solution:

1. Contact Ioline customer service.

Page 47

Chapter 3: Troubleshooting & Testing

47

Paper problems

Regular or intermittent paper tearing

Common situations that cause paper tearing while the printer is operating include:

The paper was incorrectly loaded in the machine.

A pinchwheel(s) is positioned over a drive shaft bearing.

Figure 22 represents the proper paper path, with the paper after it

is inserted properly and taped to the take-up shaft. The illustration

shows the dancer bar in place.

Pinchwheel Lever

The paper path and instructions for printing to the fl oor is

illustrated in the FJ Printer User

Guide.

Note

Front

Dancer Bar

Take-up

Shaft

Platen

Feed Roll

Proper Paper Path

Figure 22. The correct paper feeding path on the Ioline FJ Printer.

Page 48

48

Ioline FJ Printer & StudioJet Service Manual

Media tracking

Tracking is the process that controls media motion over the platen

and assures accurate lines. If the paper slips under the pinchwheels

or is out of alignment, printing quality will degrade. To resolve

tracking diffi culties try the following suggestions:

Install paper correctly. See the Operation chapter in the User

Guide for more details.

Make sure the paper path and dancer bars are set correctly (as

shown in Figure 22 (and in the User Guide.)

Inspect the paper for wrinkles or folds. Never use paper that is

folded, wrinkled, or torn in any way. It may cause paper jams.

Make sure the pinchwheels are spaced across the paper as out-

lined in the User Guide.

The pinchwheels should never be positioned over bearings on

the drive shaft as paper tearing and bunching will occur. Verify

that the pinchwheels are positioned over treads (e.g. under the

white markers affi xed to the traverse.)

Check to make sure that the printer is level. See the Quick Start

Guide for more information.

The paper may slip when debris accumulates on the drive shaft.

Inspect and clean the drive shaft. Refer to the Routine Mainte-

nance chapter in the User Guide for more information.

Contact an Ioline distributor or Ioline Customer Service if you

are unable to resolve the problem or if the printer is damaged.

Print quality problems

Line quality

In most cases, poor line quality is caused by one of several things:

The ink cartridge is empty, dirty, damaged or dried up.

The Motion Factor or Carriage Calibration needs adjustment.

The platen is not level

If line quality is uneven, try the following:

1. Press Start/Stop then the Clean keys

on the keypad to automatically clean

the cartridges.

2. Inspect the ink level window on

cartridge. If it is black, then the

cartridge is empty. Replace it with a

new one.

3. Remove the cartridge(s) and manually clean the print head with a (deionized) water-moistened, lint-free

cloth. (See Cartridge Maintenance and

Handling in the User Guide.)

Figure 23. HP cartridges

have an ink level indicator.

Page 49

Figure 24. The ink cartridge is dirty, dry, or empty.

Chapter 3: Troubleshooting & Testing

49

4. Plot on higher quality or undamaged (free of wrinkles and

bubbles) paper.

5. Use genuine HP 45 cartridges as recommended by Ioline.

6. Recalibrate cartridges as described below.

7. Level the platen as outlined in the Quick Start Guide.

8. Contact an Ioline distributor or Ioline Customer Service if you

need further help.

Figure 25. The ink cartridge requires cleaning.

Page 50

50

Ioline FJ Printer & StudioJet Service Manual

Dirty or damaged cartridge

Sometimes a cartridge will go bad for no apparent reason. The

cartridge may look perfect and be full of ink, but it will not plot. If

this occurs fi rst try pressing the Clean button on the keypad. Install a

new cartridge and the tests to see if this fi xes the problem.

If this has no effect remove, clean, inspect for damage, then test. If

the cartridge fails again replace it.

Broken circuit

from mishandling

Figure 26. Damaged and dirty print cartridge.

Cartridge calibration

The Cartridge Calibration window is located in the Control Center

and can be accessed in the Tools menu. Step-by-step instructions on

the calibration process are provided in the User Guide.

The examples below show different results and settings of the cartridge calibration window. If the printer is printing poorly, check

some of the examples here for a possible fi x.

Calibration overview

Cartridge Alignment: Aligns the ink cartridges with each other.

On 1-head machines, cartridge calibration is

not neccessary.

Motion Adjustment: Aligns (side to side) each pass of the car-

riage with the next pass.

Frame Gap: Aligns (from top to bottom) each pass of the

carriage.

Page 51

Cartridge alignment

The Control Center includes cartridge alignment settings ( Figure

). These are used for other Ioline inkjet plotter models. Since the

27

FJ Printer only has one print head, you do not need to perform ink

cartridge alignment.

Chapter 3: Troubleshooting & Testing

51

Figure 28. The Cartridge Calibration window in the Control Center.

Page 52

52

Ioline FJ Printer & StudioJet Service Manual

Motion adjustment

To understand Motion Adjustment, think of each reversal in carriage direction as a “pass”. With every pass, each head draws a line

1/2

-in long. If the FJ Printer has 2 heads, it draws a 1-in line for each

pass. A four-head machine will draw a 2-in line.

If the Motion Factor is too low, the

printer will draw the line too late. Visually, this appears as if the line drifts to

the right, as shown in Figure 29. Mo-

tion Factor set too high results in drift

to the left.

Motion Adjustment is done when each

carriage pass doesn’t line up with the

previous one. Lines will “Stair-Step”

back and forth and not look right.

When the carriage is in motion the

‘Motion Adjustment’ will tell the ink

cartridge to print sooner or later depending on the number in the ‘Motion

Adjustment fi eld’ in the FJ8 Control

Center.

Figure 28. The Motion Adjust

window.

Poor motion adjustment

Scan

Scan

= Direction of carriage travel

Figure 29. The heads are drawing the lines too late on this plot.

1. Make sure the plotter is connected to the computer. Press Set

Origin to illuminate the green OK LED on the keypad.

2. Open Control Center.

3. Select ‘Tools/Cartridge Calibration’ on the toolbar.

4. The Cartridge, Motion and Gap Adjustment Window will

open.

5. In the fi eld for Motion Adjustment, type in the number 40 to

start.

Page 53

6. Click the Set Motion button.

7. Click the Close button.

8. Click the File menu then Send File…

9. In the folder C:\ioline\calibration, double-click on the fi le Cali-

bration Grid.plt.

10. The machine will start plotting the fi le.

11. Look at the lines as the carriage goes back and forth. If they line

up, skip to Step 14.

12. Wait for the plot to fi nish and follow Steps 3 and 4 again.

13. In the Motion Adjustment fi eld try a different number. See the

Motion Adjustment chart below for help with the numbers for

this fi eld.

14. Once the lines match you are done. Close the Control Center

and plot normally.

Chapter 3: Troubleshooting & Testing

53

Frame Gap Adjustment

Frame Gap indicates a gap or overlap between each carriage pass. If

the lines are not solid (e.g. appear dashed or dotted), you will need

to adjust the gap distance in the Control Center:

1. Make sure the plotter is connected to the computer. Press Set