Page 1

Copyright © 2000, Ioline Corporation, All Rights Reserved

Printed in the United States of America

PN 107027 R1

November, 2000

All Trademarks Are The Property Of Their Respective Owners

Using Your

Ae Apparel Plotter

Page 2

2

Ioline

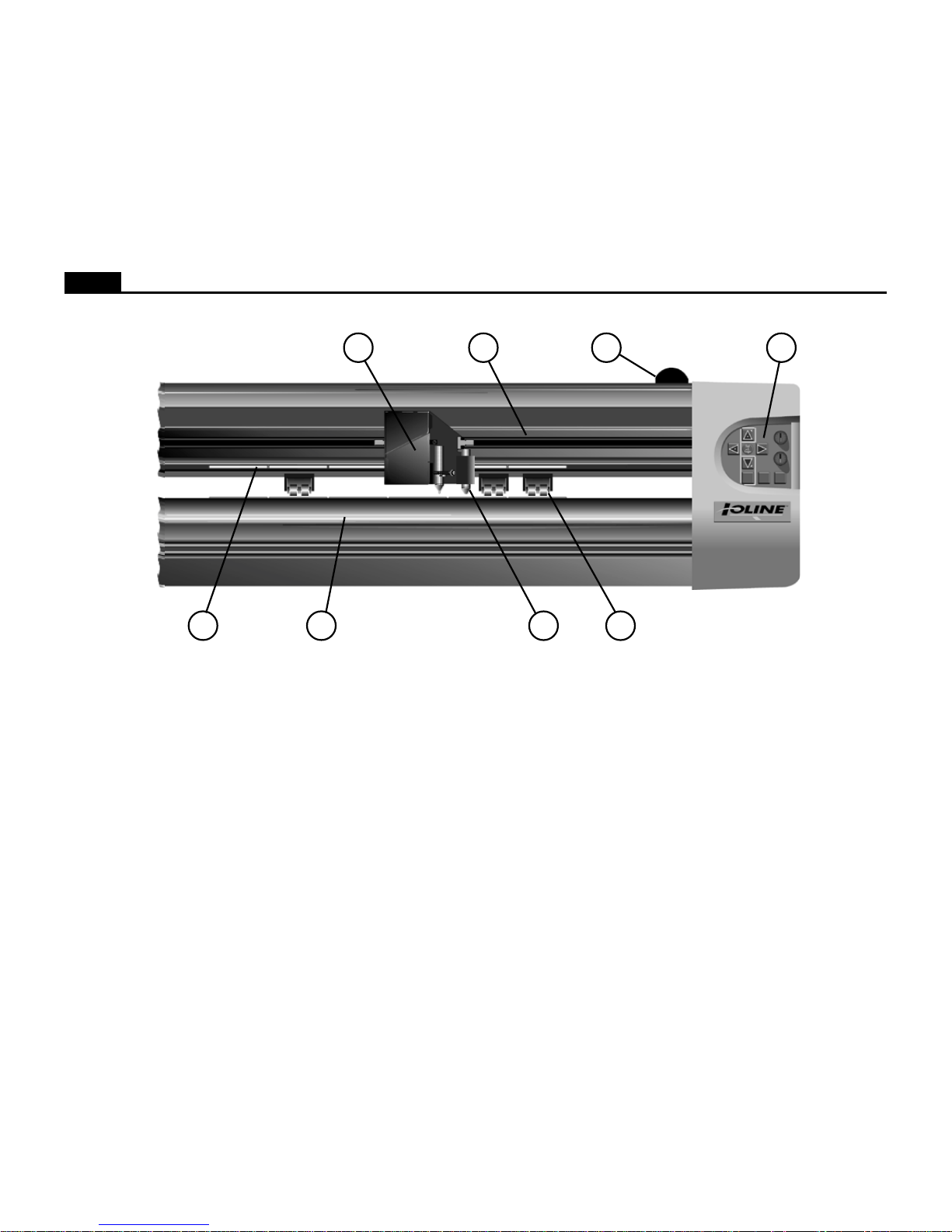

A. Pinchwheel

B. Drive Shaft Marker

C. Carriage

D. Platen

E. Sensor (600Ae only)

F. Carriage Rail

G. Pinchwheel Lever

H. Keypad

Figure 1. The Ioline Model 600Ae Plotter.

DB E

A

HG

F

C

Page 3

3

Ioline

TABLE OF CONTENTS

SAFETY AND PRECAUTIONS ................................ 4

THE IOLINE AE APPAREL PLOTTER .................... 4

How The Ioline Plotter Works .............................. 5

INSTALLATION ........................................................ 6

Unpack the Plotter .............................................. 6

Assemble the Stand ........................................... 6

Attach the Plotter to the Stand.............................6

Connect the Plotter to the Computer ................... 6

Power On ........................................................... 6

Installing the Ioline Control Center ....................... 6

OPERATION............................................................. 7

Keypad Controls .................................................. 7

The Ioline Control Center .................................... 9

Changing System Settings ............................... 10

Menu Bar Features........................................... 10

Screen Menu Options ....................................... 10

Plotting a Marker ................................................ 12

General Guidelines........................................... 12

Installing a Pen ................................................. 12

Power On ......................................................... 12

Paper ............................................................... 12

Guidelines for Plotting Pens.............................. 12

Loading the Feed Roll ...................................... 13

Loading the T ake-Up Shaft ............................... 14

Feeding Paper ................................................. 15

T aping Paper to the Take-Up Shaft.................... 16

T aping Paper (Optional Method) ....................... 17

Positioning the Pinchwheels ............................. 17

Insert the Dancer Bars ...................................... 18

Set an Origin .................................................... 18

Sending Plot Files ............................................ 19

Pausing a Marker Plot ...................................... 19

Canceling a Marker Plot ................................... 19

Removing Markers from the T ake-Up Shaft ....... 20

Reattach Paper to the T ake-Up Shaft ................ 21

ROUTINE MAINTENANCE .................................... 22

Cleaning the Drive Shaft ................................... 22

Calibration........................................................ 22

Cleaning the Platen .......................................... 23

Cleaning the Support Blocks............................. 23

COMMUNICA TION TESTING.................................24

Communication T est ......................................... 24

T esting the Plotter Serial Port............................24

T esting the Computer Serial Port ...................... 24

TROUBLESHOOTING ........................................... 25

General Problems ............................................ 25

Plotting Quality Problems.................................. 25

Loss of Registration Between Frames .............. 27

Tracking ........................................................... 27

Poor Line Quality .............................................. 27

Error Messages................................................ 28

LED Codes ...................................................... 29

T esting the Frame Sensor................................. 30

END NOTES ........................................................... 31

Getting Help ..................................................... 31

The FCC Wants Y ou to Know ... ......................... 32

Y our Comments Are Requested........................ 32

Customer Service............................................. 32

Limit of Liability Statement................................ 32

GLOSSARY ............................................................ 33

INDEX ..................................................................... 35

Page 4

4

Ioline

SAFETY AND PRECAUTIONS

The plotter has many fast moving components. Please read and follow these

safety guidelines before beginning operation of the plotter.

• Do not try to repair the machine without factory authorization. Only qualified service personnel should attempt any disassembly or access to internal components. If external mechanical adjustments are necessary, turn

off the plotter and disconnect it from all power sources (both the computer and the wall outlet).

• Be careful with hair, jewelry, or loose clothing near the plotter. They can

become caught in the mechanical parts.

• Never move the carriage by hand. Use the Arrow keys and let the machine do it.

• Keep hands away from the carriage when the plotter is in operation. The

carriage will automatically move to its right end position when the power

is turned on.

• Be careful when lifting the plotter. Hold the bottom surfaces of the plotter

to lift or move it.

• Keep fingers away from the drive shaft when the plotter is in operation.

THE IOLINE AE APPAREL PLOTTER

Thank you for purchasing an Ioline plotter.

This manual contains instructions and guidelines for setting up, operating

and maintaining the Ioline plotter models 600Ae, 28Ae and Stylist Ae. The

model 600Ae uses a frame sensor to allow ultra long plotting up to 600 yards.

Models 28Ae and Stylist Ae do not use a sensor for frame correction which

limits plotting to 42 yards. The following components are needed to create

plots:

• An Ioline plotter that is installed according to the directions in the Quick

Start Guide.

• A computer system that is properly installed and has a functioning serial

port.

• Design software loaded into the computer according to the installation

instructions. Note: The design software must output plot files in HPGL

7475/7596 or DM/PL format.

• Plotting media and a pen that are within the guidelines stated in the

Operation chapter.

• The Ioline Control Center software. This software is not required but

allows adjustment of plotter settings and can help optimize performance.

The Ioline Control Center will only run on the Windo ws 95/98/NT oper ating systems. Most design software provides drivers for Ioline plotters.

Contact Ioline customer service if you need assistance with drivers.

Page 5

5

Ioline

How The Ioline Plotter Works

Media and pen motion are combined to create vector plots. Files are sent to the plotter via a serial connection with a computer or file server . When a file is sent to the plotter

the electronic logic system translates the vectors into instructions for the X axis (paper motion) and Y axis (pen motion) motors and uses feedback to ensure plot accuracy.

Long plots are accomplished by breaking the plot file into frame segments and rolling the completed frames onto a take-up shaft. The model 600Ae can roll 600 yards onto

the take-up shaft in one plotting sequence. The 28Ae and Stylist Ae can create a mark er no longer than 42 yards b ut can accumulate 100 yards from multiple plot f iles on the

take-up shaft. Long plot accuracy on the 600Ae is maintained by checking an alignment mark on each frame with multiple passes of a sensor fixed to the carriage.

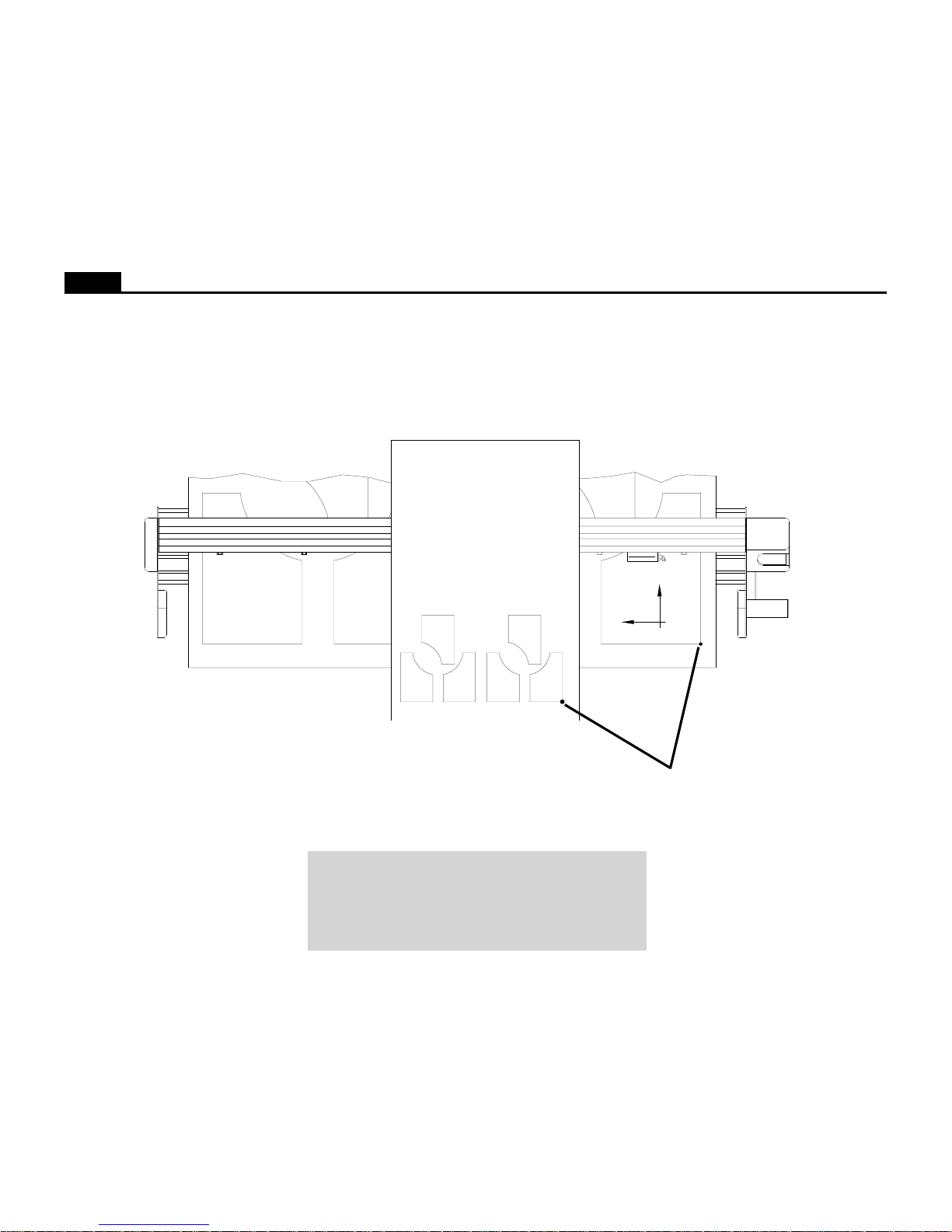

Figure 2. The X and Y axes and Origin (top view).

Note: In this manual the right and left side refers to the right and left

side of the front of the plotter. Design software usually refers to the

Origin (or Start Point) as “lower left” because it is the lower left

corner of a plot. The plot is usually oriented in the plotter rotated 90

degrees counter clockwise as shown in Figure 2. The lower left cor-

ner of the plot is physically on the right side of the plotter.

LEFT EDGE OF PLOT

LOWER EDGE OF PLOT

Y

X

Left Side

of Plotter

Right Side

of Plotter

Origin at Right

Side of Plotter and

Lower Left on Plot

Page 6

6

Ioline

INSTALLATION

The complete setup procedure for Ioline Ae plotters is described in detail in

the Quick Start Guide included with the accessory kit. The following infor-

mation is a brief summary.

Unpack the Plotter

Carefully remove the plotter from the box and place it on a flat-stable surface.

This procedure requires two people. Save all packing materials and the box.

Check the packing list to ensure that all of the accessories are present. See the

Quick Start Guide for more information.

Assemble the Stand

Assemble and level the stand using the hardware included in the accessory kit

and directions outlined in the Quick Start Guide.

Attach the Plotter to the Stand

Caution: Do not hold the plotting head by the bottom edge of the

end plates when attaching it to the stand. Fingers and hands might

get pinched between the end plates and stand legs. Hold the shiny

metal top bars a few inches from the end plates when handling the

head.

Attach the plotter to the stand with the top bars resting in the notches in the

stand legs. Use the hardware as indicated in the Quick Start Guide.

Connect the Plotter to the Computer

Note: Make sure the computer and the plotter have the power turned

off. Ioline recommends using a surge protector power strip for the

plotter and the computer.

Connect the plotter to the computer with a serial cable. A serial cable is provided in the accessory kit. The serial port on the computer is either a 9 pin or

25 pin male receptacle. If the computer only has 9 pin serial ports, a 9 to 25

pin adapter is necessary. Use the adaptors included in the accessory kit. See

the Quick Start Guide for more connection information.

Select the correct port in the design software or the Control Center after the

cables are correctly connected to the computer and plotter. Consult the design

software manual or the dealer for further information.

Power On

Important: Keep hands and loose clothing away from all moving

parts of the plotter.

Turn on the computer and the plotter to make sure they work. The plotter

power switch is located next to the power cord on the back of the machine,

behind the keypad. The carriage will move toward the keypad side of the

machine when the power is turned on. The red LED on the front panel will

light when the start-up process is finished.

Installing the Ioline Control Center

The Control Center is an interface for adjusting parameters to optimize plotter performance. The plotter comes with a CD-ROM which has the Microsoft

Windows® 95, 98 and NT (3.51 or greater) version of the Ioline Control Center

program.

1. Turn on the power to the computer.

2. Start Windows®.

3. Insert the Ioline CD-ROM into the CD-ROM drive (usually D:).

4. The installation program should start automatically. If it does not:

a. Select the Start button.

b. Choose Run.

c. Type D:\IOSETUP (substitute the cor rect letter if the CD-ROM dri ve

letter is not D:) and Click OK.

5. Follow the instructions that appear on the screen.

6. The Operation chapter of this manual has details on using the Ioline

Control Center software.

Page 7

7

Ioline

Figure 3. The Plotter Keypad.

OPERATION

KEYPAD CONTROLS

The keypad allows access to the main plotter functions.

Start/Stop

The Start/Stop key controls communication between the computer and the plotter. If the Start/Stop key is pressed dur ing plotting (Stop mode, red LED) the machine will stop plotting when

the current vector is finished. The Arrow keys are active when in

Stop mode. When the Start/Stop key is pressed again, (Start mode,

green LED) plotting will resume exactly where it stopped.

ST ART green light Arrow keys inoperable, plotter

online (ready to receive instructions).

STOP red light Arrow keys operable, plotter offline

(not ready to receive instructions).

Arrow Keys

Pressing the Arrow keys moves the material back and forth or the

carriage from side to side. The arrow keys will not w ork unless the

plotter is in Stop mode (see Start/Stop above).

Set Origin

The Set Origin key sets the initial origin or starting position for

the marker. It is best to set a ne w origin before plotting each marker .

To set a new origin, press Start/Stop until the keypad LED is red

(Stop mode). Use the Arrow keys to move the pen to the desired

origin of the plot. Press the Set Origin key. The plotter will then

accept plot files.

Speed

Use the Speed knob on the front panel of the plotter to adjust the

speed. Turn the knob clockwise to increase the speed, or counterclockwise to decrease the speed. Set the speed according to the

type of plotting and material being used. See the Plotting a Marker

section of this manual.

Force

Adjust the force by using the Force knob on the front panel. Turn

the Force knob clockwise to increase the force exerted on the pen.

See the section on Plotting a Marker for the recommended settings. The range of force available at the knob is adjustable in the

Control Center. The available range is 1 - 275 grams.

Note: Using too much force can cause excessive drag

which could damage the pen or tear the paper.

Figure 4. Origin Point.

Note: Design software usually refers to the origin as “lower

left” because it is the lower left corner of a marker. Because the plot is usually oriented as shown, it is physically on the right side of the plotter.

Page 8

8

Ioline

Set Gap

The Set Gap button allows the user to manually adjust the amount

that the plotter will compensate for the normal slipping (frame

gap) that occurs during frame advances. The frame gap distance is

primarily affected by the size of the feed roll, paper type, and

humidity. The advantage of using the Set Gap button to adjust

frame gap the ability to correct gapping during plotting. Frame

gap is also adjustable from the Control Center. The Set Gap button has additional functions on the 600Ae.

Setting the Frame Gap with the Set Gap button:

Note for 600Ae: This function only works when the frame

sensor is disabled in the Control Center. See the section

Sensor Options above for more details.

1. Prepare the plotter to receive a plot file. See the section Pre-

pare to Plot for more details.

2. Send a plot file to the plotter that has at least three frames.

3. After the second frame starts plotting, press the Set Gap button. The plotter will move the carriage and material to the

center of the last horizontal mark made at the beginning of

the second frame.

4. Move the material with the vertical Arrow keys until the pen

is over the middle of the horizontal mark made at the end of

the first frame.

5. Press the Set Gap button to resume plotting with the new

frame gap setting. The keypad LED should turn green. The

frame gap setting will not take affect until the current frame is

complete.

6. Visually check the gap setting by checking for a gap or overlap between the second and third frame.

7. This process is accessible anytime during plotting. The plotter will finish a frame advance cycle before recognizing that

the Start/Stop button was pressed.

Note: The Set Gap measurement is lost when the power

to the plotter is turned off.

Additional Set Gap button functions on the 600Ae:

Note: These functions only work when the frame sensor

is enabled in the Control Center. See the section Sensor

Options above for more details.

• Sensor Test (not available during plotting):

1. Load the plotter with paper. See Prepare to Plot for details.

2. Press the Start/Stop button until the keypad LED turns red

(Stop mode).

3. Use the keypad Arrow keys to position the carriage so that

the pen is over the paper near the right side of the machine.

4. Press the Set Gap button.

5. The plotter will draw a frame alignment mark and continu-

ously scan the mark until the Start/Stop button is pressed

again. If the sensor finds the mark it will beep. This function is

useful for adjusting sensor height.

6. If no beep is heard the sensor might need adjustment, cannot

sense the ink color in use, or is defective. Use black ink or

contact the distributor or Ioline Customer Service for details.

• Find Lost Sensor Mark:

Material slippage may cause the frame alignment mark to

move beyond the area where the frame sensor looks for it. If

the plotter is unable to find the mark with the frame sensor it

will enter lost mark mode. The keypad LED will turn solid

green and the plotter will emit a continuous beeping sound.

If this error occurs before the frame advance:

1. Check that the pen is drawing dark lines. Red ink will not

work with the sensor. Replace the pen if the mar k is very light.

2. If the lines are dark, help the plotter find the mark by positioning the carriage using the horizontal Arrow keys. Move the

carriage so the mark is lined up with the frame sensor in the

direction of paper movement (X). The plotter disables material (X) movement so the vertical Arrow k e ys will not w ork.

3. Press the Set Gap button. The plotter will look for the mark

and, if it finds it, will continue plotting.

4. Pressing the Start/Stop button will cancel lost mark mode,

ignore the missing mark, and continue with the previously

stored alignment correction measurement.

Page 9

9

Ioline

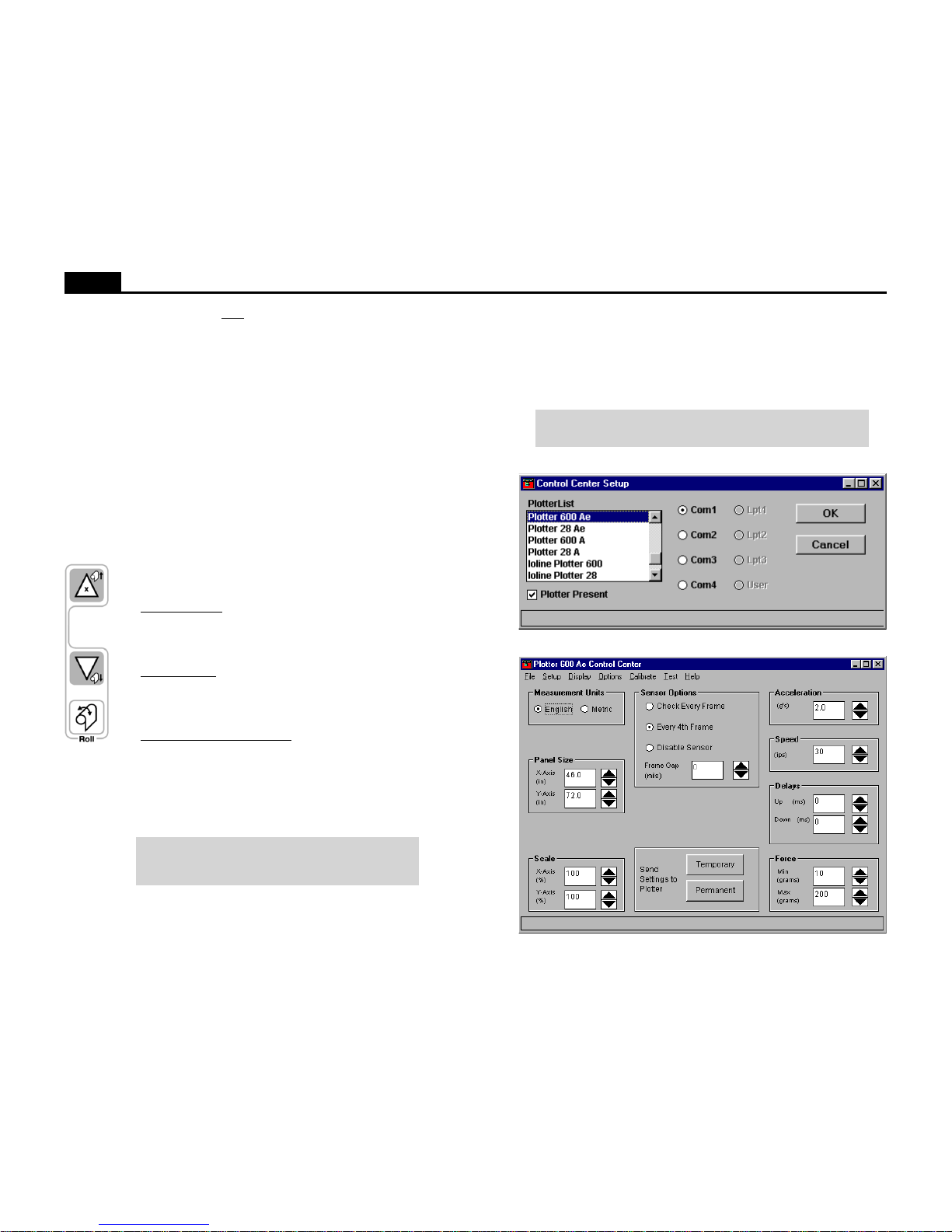

THE IOLINE CONTROL CENTER

The Ioline Control Center is a utility program that does three things:

• Allows adjustment of settings to tailor output from the computer.

• Provides an interface to send completed plot files to the plotter.

• Includes several diagnostic tests for troubleshooting.

Figure 5. Control Center Setup Screen.

Note: T o a void communication port conflicts, do not simultaneously

run more than one application that communicates with the plotter.

Figure 6. Control Center Main Menu (model 600Ae shown).

If this error occurs after the frame advance:

1. Check that the pen has ink and is drawing dark lines. Higher

force may darken the line. Red ink will not work with the

frame sensor. Replace the pen if the sensor lines are very light.

2. If the lines are dark, help the plotter find the mark by positioning the material with the vertical Arrow keys so that the mark

is ½ inch below (in front of) the frame sensor. The plotter

disables carriage (Y) movement so the horizontal Arrow keys

will not work.

3. Press the Set Gap button. The plotter will look for the mark

and, if it finds it, will continue plotting.

4. Pressing the Start/Stop button will cancel lost mark mode,

ignore the missing mark, and continue with the previously

stored alignment correction measurement.

Roll

The Roll keys are used to rotate the take-up shaft.

Roll Up Material – Press the Start/Stop button until the keypad light is red. Press and hold the Roll button and the Up

Keypad Arrow. The plotter will pull paper onto the take-up

roll until the end of the service loop is reached.

Unroll Material – Press the Start/Stop button until the keypad light is red. Press and hold the Roll button and the Down

Keypad Arrow. The plotter will unroll paper from the takeup roll onto the floor until the keys are released.

Automatic Unroll (600Ae only) – Press the Start/Stop button

until the keypad light is red. Press and hold the Roll button

and the Down Keypad Arro w. W ith the other hand, press and

release the Up Keypad Arrow. Stop pressing all b uttons. The

plotter will automatically unroll paper for one minute then

stop. To cancel automatic mode, press the Start/Stop or any

Arrow key.

Note: For more details on removing plotted markers from

the take-up shaft see Removing Markers from the TakeUp Roll later in this chapter.

Page 10

10

Ioline

Changing System Settings

A variety of settings are adjustable to fit specific needs:

• The plotter must be in Start mode (green LED on) when changing system settings. Press the Start/Stop key and make sure the green light is on

before changing any settings.

• The Screen Menu displays the primary settings that are adjustable. The

Menu Bar contains utilities and less common plotter settings.

• The selected changes will be in effect only after one of the Send Settings

buttons is pushed.

Note: Some design software can override the Control Center settings. Check to see if it has by pressing the Update Display button

before and after a plot is completed. If the settings change, use the

design software to modify plotting parameters.

Menu Bar Features

The Ioline Control Center provides comprehensive help files to explain the

functions of the software options. Below is a brief summary Menu Bar items.

File

Send Cut/Plot File Send a plot (.plt) file to the plotter.

Open Settings File Restores saved settings files.

Save Settings As Allows user to save settings f iles.

Exit Exits the Control Center program.

Setup

Plotter Setup Allows user to select the correct plotter model.

Port Setup Allows user to select the communications port.

Display

Plotter Settings Allows user to view current plotter settings.

Factory Defaults

Allows user to view and restore original factory settings.

ROM Version Displays installed ROM version.

Memory Buffer Displays installed memory b uffer size.

Options

HPGL Setting Allows user to select HGPL language.

Install New Firmware

Installs new firmware into the plotter.

Calibrate

Calibrate Plotter Allows user to calibrate plotter.

Test

Communication Test Allows user to test communications.

Computer Port T est Allows user to test computer port.

Plotter Port Test Allows user to test plotter port.

Help

Contents Lists contents of help files.

About Provides Control Center version information.

Screen Menu Options

Measurement Units

English or Metric units are available when adjusting settings.

Panel Size

The Panel Size is the maximum area the plotter can use for plotting before

advancing the paper . In general, set it to the same value as the design software

frame size (sometimes called panel, frame, tile, page, etc.).

Important: Never set the plotter panel size smaller than the software frame size; the plot will clip and the plotter may jam or tear

paper. Plotting with the plotter panel size set larger than the design

software frame size will make the plot the correct size but will make

the feed and take-up loops unnecessarily long.

The factory set (and maximum) X-axis panel length is 46 inches (116.8 cm)

long. The maximum Y-axis panel width is 72 inches (182.9 cm) wide. Note:

The material moves along the X-axis; the carriage moves along the Y-axis.

Scale

The factory-set Scale is 100%. The plotter will produce a plot in the exact size

of any plot file that is sent. If the scale is 50%, the plotter will produce a plot

that is half the intended size. The scale of the plotter can range from 1% to

999%. Note: Both X and Y axes are set independently.

Sensor Options (model 600Ae only)

Sensor Options control how the model 600Ae plotter uses the sensor to correct normal paper slipping during frame advance. Paper characteristics and

humidity are a few of the factors that affect slipping. Scanning e very frame is

useful for difficult materials. On high quality paper , Checking e very 4th frame

will increase throughput without compromising frame alignment.

Check Every Frame – When this option is checked the plotter uses the frame

sensor to check the alignment mark during every frame advance. This is the

most accurate but the slowest way to use the sensor during plotting. This

mode may also improve performance when plotting on materials that slip

when pulled off of the feed roll.

Every 4th Frame – When this option is checked the plotter uses the frame

sensor to check the alignment mark during every 4th frame advance. This

mode is less accurate than checking after every frame but increases throughput by an average of 10%.

Disable Sensor – Disables the frame sensor. Set the Frame Gap during plotting with the Set Gap keypad button (see the Keypad section) or manually

before plotting in the Control Center (see the Frame Alignment section).

Page 11

11

Ioline

Frame Gap (Alignment)

Setting the Frame Gap compensates for the normal gap/overlap that occurs

between frames during frame advance. Use a Frame Gap setting on the 28Ae

and Stylist Ae or on the 600Ae when the sensor is disabled (see above).

Note: Frame gap is also adjustable during plotting with the Set Gap

button on the keypad. Only use the following procedure to adjust

frame gap when the plotter is not plotting markers.

1. Prepare the plotter to receive a plot file. See the section Plotting a Marker

for more details.

2. Send a plot file to the plotter that has at least three frames.

3. When the plot is complete, use a ruler to accurately measure the gap or

overlap between the solid and dashed lines between he second and third

frames.

4. Set an origin on the plotter by pressing the Set Origin button. Make sure

the keypad LED is green (Start mode).

5. Start the Ioline Control Center program.

6. If the frames are separated enter the measurement as a negative number in

the frame gap field. For overlapping enter the measurement as a positive

number in the frame gap field.

Example: If the plot shows an overlap of .200 inches, set the frame

gap in the Control Center to 200 (positive). If the plot shows a gap of

.200, set the frame gap in the Control Center to -200 (negative).

7. Press Send Permanent in the Control Center to send the value to the

plotter.

8. Perform test plots to verify that the gap setting is correct. Repeat if necessary.

Send Settings to Plotter: Temporary

After changing any setting, the changes must be sent to the plotter. If Send

Settings to Plotter: Temporary is selected, all of the displayed settings will

be used for the current session. When the plotter is turned off these settings

will be lost and the previous permanent settings will be in effect when the

plotter is turned on again. If any settings are changed, repeat the Test Plot

procedure to ensure that the results are satisfactory.

Send Settings to Plotter: Permanent

If Send Settings to Plotter: Permanent is selected, all of the displayed settings will be sent to the plotter and will be saved for all subsequent sessions,

even after turning off the plotter.

Acceleration

The factory set acceleration is 2.0 g. The acceleration setting determines how

quickly the pen will reach full speed when starting or ending a plot line. Use

the Control Center to change the setting within a range of 0.1 to 2.0 g. Use

lower acceleration settings when trying to achieve maximum accuracy.

Speed

Speed refers to pen and media speeds during plotting. Lower speed settings

will improve the line quality but will reduce throughput. The factory default

speed is 30 ips (inches per second) or 76 cm/sec on the 600Ae and 20 ips

(inches per second) or 51 cm/sec on the 28Ae and Stylist Ae. The setting range

is 1 to 30 ips (2.5-76 cm/sec) on the 600Ae and 1 to 20 ips (2.5-51 cm/sec) on

the 28Ae and Stylist Ae.

Up/Down Delays

The factory set up and down delays are both 0 milliseconds (ms) or 0 thousandths of a second. The delay setting controls the amount of time, in milliseconds, the plotter pauses after lifting or lowering the pen. Under normal

circumstances this setting will not require adjustment.

Force

The minimum and maximum force settings for the Force control knob on the

keypad is adjustable. The factory set and default minimum is 10 grams. The

maximum value is 275 grams. The default maximum force is 200 grams.

Page 12

12

Ioline

PLOTTING A MARKER

Before plotting a marker, turn the plotter on, load it with paper, install a pen,

and set an origin. These steps are outlined below. In most cases the design

files are sent directly from the design software to the plotter. If necessary, use

the Ioline Control Center software to send design files, adjust settings and

test plotter communication.

General Guidelines

1. Good paper loading makes good plots. Please see the following sections

about properly loading paper.

2. Do not set the plotter panel size smaller than the software frame size; the

plot will clip and the plotter may jam or tear paper.

3. Use only enough force to make a clear line. Excessive pen force might

cause misalignment problems over the range of a long plot or tear the

paper.

4. Enable the frame sensor on the 600Ae plotters to ensure accuracy over

long markers.

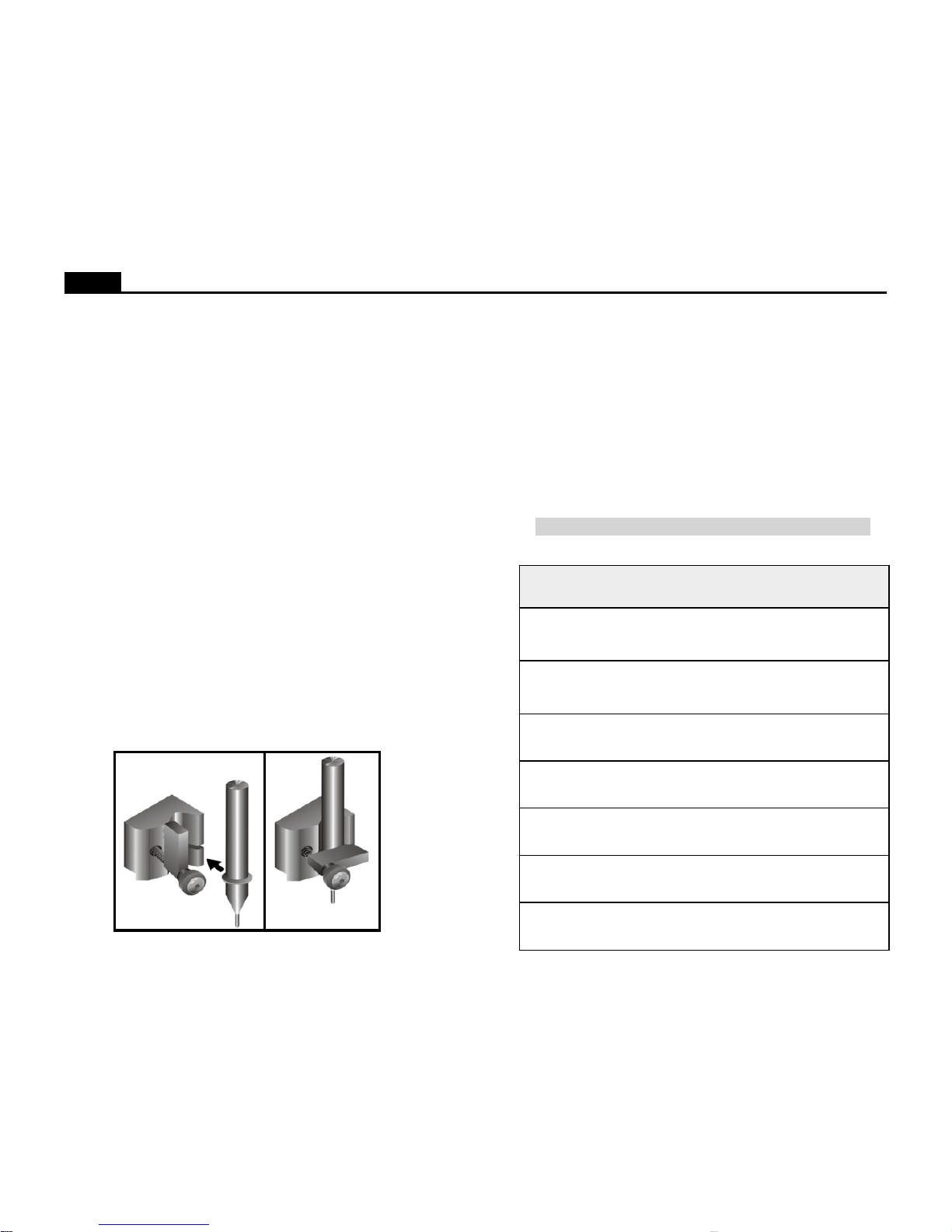

Installing a Pen

1. Rotate the clamp screw until there is enough room to insert the pen.

Make sure that the clamp is rotated up out of the way.

2. If using a plotter pen, slip the flange into the slot in the carriage jaw. If

using a regular pen, position the tip so that it is 1/8 inch (3 mm) off of the

platen when the jaw is in the up position. The jaw can hold any pen with

a maximum barrel diameter of 7/8 inch (22 mm). Do not use pens with red

ink.

3. Tighten the clamp screw until the pen is secure.

Power On

Turn on power to the computer and the plotter. The plotter power switch is

located next to the power cord on the back. The carriage will mo ve to the right

end plate when the power comes on. Keep hands and loose clothing away

from moving parts. The front panel light will turn red when plotter is ready.

Paper

Ioline recommends 27 - 35 pound recycled or bond paper, 36” to 74” (91 to

188 cm) wide.

Guidelines for Plotting Pens

Refer to the table below for recommended settings for a variety of pen types.

Remember that force values are for starting reference only and require testing.

Figure 7. Installing a Pen in the Carriage Jaw.

repaP neP deepS ecroF

smarg

stnemmoC

-yaLrepuSIMB

tnelaviuqero™talF

dnobytilauqhgih

elyts-PH

tniopllab

mumixaM08-06/punepsm51

nepsm51

syalednwod

"dnuoR®CIB

citS

tniopllab

mumixaM002-081

"drofnaS

eiprahS

mumixaM001-07

"elyts-PH

pitrebif

muideM001-07

___pitcitsalP______toN

dednemmoceR

___pitcimareC______toN

dednemmoceR

___/knidiuqiL

pitlateM

______toN

dednemmoceR

Important Note: Do not use red ink pens.

Page 13

13

Ioline

Loading the Feed Roll

1. Before loading a new paper roll always make sure the drive shaft is clean.

See the Preventative Maintenance section in the user guide for more

details.

2. Place a paper hub in each end of the paper roll. Use a rubber mallet to

insert the hubs.

3. Slide the feed shaft through the paper hubs and the paper roll. If a paper

hub falls out, press it firmly back into the end of the paper roll and set it

with a rubber mallet.

Figure 8. Installing the feed shaft.

4. This step is very important. Center the paper roll on the feed shaft by

sliding the feed shaft left or right through the paper roll. Make sure the

hubs remain securely in place.

5. Use the supplied hex wrench to tighten both screws on each paper hub.

6. Lift the feed shaft and paper roll into the support blocks. Make sure the

paper unrolls from behind and towards the plotter.

Support Block

Feed Shaft

Paper Roll

(Unrolls from Behind)

Paper Hub (2)

Flanged Coupling

Support Block

Page 14

14

Ioline

Loading the Take-Up Shaft

Caution: Never touch the take-up key or flanged coupling while

they are rotating. Serious personal injury could result.

1. Turn on power to the plotter.

2. If the take-up shaft has plotted markers on it, remove them. See Unload-

ing Completed Markers later in this section for details.

3. Rotate the take-up key with the Roll arrow keys until it is oriented perpendicular to the support block opening as shown below.

4. If rolling up more than 42 yards on the take-up shaft (model 600Ae only),

install the paper guide flanges. Make sure the hub with the thumbscrew is

on the outside of the flange.

5. Put the take-up shaft into the front support blocks with the flanged coupling at the right (keypad) end.

6. Rotate the shaft until the slot in the flanged coupling is aligned with the

take-up key. When the shaft slot and the key are aligned, push the takeup shaft into place until it is seated in the support block.

Figure 9. Installing the take-up shaft in the support blocks.

Position Take-Up

Key as Shown

Rectangular Slot

Support Block

Paper Guide Flange

with Hub Facing Out

Take-Up Shaft

Flanged Coupling

Page 15

15

Ioline

Feeding Paper

The figure below represents the proper paper paths. The diagram on the left

shows the paper after it is inserted properly and taped to the take-up shaft. The

figure on the right shows the result after the dancer bars are inserted and an

origin is set with the Set Origin keypad button.

1. On the model 600Ae, slide each of the paper guide flanges toward the

outside ends of the take-up shaft to create enough room for the width of

the paper.

2. If the pinchwheels are lowered, raise them by pushing the pinchwheel

lever away from the machine.

3. Turn on the power to the plotter if it is not already on.

Proper Paper

Path

Paper Path When

Ready to Plot

Platen

Take-up Shaft

Front Top Bar

Rear Top Bar

Feed Roll

Pinchwheel Lever

Figure 10. The correct paper feeding path on the Ioline Ae Plotters.

4. Pull a long leader of paper off of the paper roll and insert it through the

stand, behind the plotting head, over the rear top bar, and between the

platen and pinchwheels.

5. Temporarily lock the paper in place by pulling the pinchwheel lever

toward the machine to lower the pinchwheels. Refer to the figure below

for help with the proper paper path.

Page 16

16

Ioline

Taping Paper to the Take-Up Shaft

1. Stand in front of the machine.

2. Attach a short piece of masking tape to the center of the dust cover on top

of the machine.

3. Grasp the front edge of the paper. Push the pinchwheel lever to raise the

pinchwheels.

4. Hold the front edge of the paper with both hands and pull 20” (51 cm) of

paper over the platen and shiny top bar and under the take-up shaft (see

Figure 10 for the proper paper path).

Figure 11. Taping the paper to the take-up shaft.

Note: If the paper is not evenly aligned, the first few frames may not

line up properly. Misalignment is automatically corrected after plotting two or three frames. If this problem causes difficulties the optional method described below can improve frame alignment.

5. Align the paper by gently moving it left and right until the tension feels

even. Attach the paper to the take-up shaft with the tape stuck to the

dustcover.

6. Tape the right and left ends (about 2” or 5 cm in from the edge) to the

take-up shaft.

Tape the Paper

in Three Places

Page 17

17

Ioline

1. Stand in front of the machine.

2. Attach a piece of masking tape to the front of edge of the paper from

beneath.

3. While holding the front edge with both hands about 2’ apart, raise the

chart wheel lever, and pull about 18” - 20” (46-51 cm) of paper over the

platen and shiny top bar and under the take-up shaft (see Figure 10).

4. Lower the chart wheel lever.

5. Insert the rear dancer bar. See Figur e 13.

6. Press the Set Origin key on the keypad. Gently pull the middle of the

front edge of the paper to start the machine pulling paper from the feed

roll. As the paper feeds forward guide it o v er the shiny front top bar. The

paper will reverse direction and form a feed loop in the rear. The plotter

will enter Start mode (green LED) when it is finished.

7. If the paper is not long enough to be wrapped under the take-up shaft and

taped to the front (see Figure 11) more paper must be pulled forward.

Press the Start/Stop key until the LED turns red (Stop mode). Use the

down Arrow key to pull enough paper to attach the middle of the paper

to the center of the take-up shaft. Use masking tape to attach the right and

left ends (about 2” or 5 cm in from the edge) to the take-up shaft.

Positioning the Pinchwheels

Pinchwheel position depends on the width of the paper. Always place pinchwheels over a drive shaft segment. Use the white markers attached to the

carriage rail to find drive shaft segments when they are covered by paper. An

example of chart wheel position on 72 inch (183 cm) paper is included below .

Different paper sizes require different pinchwheel positions. Experiment to

find the proper positions remembering to place two pinchwheels near both

edges of the paper.

1. Ensure that the paper is loaded as described in the previous steps.

2. Raise the pinchwheels (if they are not up) by pushing the lever away from

the machine.

3. Make sure that the paper roll is centered on the feed shaft.

4. Move the pinchwheels to the proper position. See the figure below for an

example. Do not place a pinchwheel over any smooth portion of the

drive shaft. Use the white markers on the carriage rail to find drive shaft

segments when they are covered by paper.

Figure 12. Positioning the pinchwheels for 72” (183 cm) paper.

Note: It is important for these procedures that the paper roll is cen-

tered on the feed shaft.

Outer Pinchwheels

Inner Pinchwheel

White Driveshaft Markers

72 Inch Paper

Note: This method is useful for accurate alignment of the first few

frames but is not always necessary.

Taping Paper (Optional Method)

Page 18

18

Ioline

Front Dancer

Bar (Long)

Rear Dancer

Bar (Short)

Insert the Dancer Bars

1. Lower the pinchwheels (if they are not down) by pulling the lever toward

the machine.

2. Ensure that the keypad LED is red. If the keypad LED is green, press the

Start/Stop button.

3. Insert the short rear dancer bar into the rear dancer bar channels.

4. Insert the long front dancer bar into the front dancer bar channels.

5. Press the down Arrow key until the front dancer bar falls into a take-up

loop formed by the paper. Pull enough media to form a loop that is about

12” (30 cm) deep.

6. Move the paper flanges (model 600Ae only) to about 1/16” (1.5 mm)

from the edges of the paper. Tighten the flange thumb screws.

Figure 13. Inserting the dancer bars.

Important: Do not turn the feed or take-up roll by hand during

plotting.

Set an Origin

1. Ensure that a pen is installed in the carriage jaw. See the previous section,

Installing a Pen, for more details.

2. Use the left and right Arrow keys to move the carriage to the desired

starting location. Make sure the pen will start to the left of the right most

pinchwheel.

3. Press the Set Origin key . The plotter will pull paper from the feed roll and

create a feed loop in the rear. The keypad LED will turn green when the

plotter is ready to receive a file.

4. The plotter is ready to receive a plot file when the Set Origin sequence is

complete.

Front Dancer

Bar Channel

Rear Dancer

Bar Channel

Page 19

19

Ioline

Sending Plot Files

When the apparel design is complete, send the pattern (as a marker plot, .plt,

file) to the plotter. Make sure the power is on and that the paper is loaded.

Also, be sure that a new origin is set with the Set Origin keypad button and

that the plotter is in Start mode (green LED).

• From the Design Software

In most cases the apparel design software will be used to create a marker plot

file and send the data directly to the plotter. Some software packages also

allow changes to plotting parameters. Be sure to follow the software instructions.

• From the Ioline Control Center

The Ioline Control Center software can be used to send a completed marker

plot file to the plotter. Open the Ioline Control Center as described earlier in

this chapter.

1. From the menu bar select File.

2. Select Send Plot File.

3. Enter the correct path and file name of the plot that will be sent to the

plotter. For example, the path might be:

C:\IOLINE\<file name>.plt

4. Select OK.

Pausing a Marker Plot

1. Pause a plot by pressing the Start/Stop key.

2. The keypad LED will change from green to red.

3. When plotting is paused the carriage, paper, and take-up roll can be

moved with the keypad Arrow keys. When the Start/Stop k ey is pressed

again (red LED changes to green) the plotter will return the carriage and

paper to the last plotting position.

Canceling a Marker Plot

• From the Apparel Design Software

1. Press the Start/Stop key to place the plotter in Stop mode (red LED).

Plotting will stop when the current vector finishes drawing.

2. Abort sending the plot from the apparel design software (refer to the

apparel design software manual or consult the software dealer). If this

step is skipped the plot will continue when a new origin is set with the Set

Origin keypad button.

3. Position the carriage and paper for a new plot file and press the Set

Origin key. The plotter will delete the plot data it has already received

but has not yet drawn. New feed and take-up loops will form.

• From the Ioline Control Center

1. Press the Start/Stop key to place the plotter in Stop mode (red LED).

Plotting will stop when the current vector finishes drawing.

2. Cancel the plot in the Control Center software by clicking on the Abort

button. The file may have already finished downloading to the plotter.

Skip this step if that has occurred.

3. Use the keypad Arrow keys to position the carriage for the start of a ne w

plot file.

4. Press the Set Origin key to make the plotter delete the plot data it has

already received but has not yet drawn. This also prepares the plotter to

receive the next plot file.

5. New feed and take-up loops will form.

Important: Do not pull paper tight between the drive shaft and the

take-up shaft while plotting is paused. Do not turn the feed roll or

take-up roll by hand while plotting is paused.

Page 20

20

Ioline

Removing Markers from the Take-Up Shaft

Note: Except when the feed roll is changed, it is best to leave the

pinchwheels down when removing completed markers from the takeup roll. Leaving the pinchwheels down will help keep the paper

aligned with the feed roll and reduce the time between plotting

operations.

1. Remove the front dancer bar.

2. Press the Start/Stop key until the keypad LED changes to red (Stop

mode).

3. Cut the paper with the included cutting tool. Use the colored groove in

the front of the platen as a guide.

Use one of the following methods to remove completed markers:

Method 1: Unroll with the Shaft in Place

1. With the power off, rotate the take-up shaft by hand until the rectangular

opening in the flanged coupling is perpendicular to the opening in the

support block (see Figure 9).

2. Remove the shaft from the support blocks. Important: removing a full

take-up shaft may require two people.

3. The paper is wound so that when unrolled the plotted image is facing up.

The markers can be unrolled directly onto the cutting table with the takeup shaft in place in the roll.

Method 2: Manual Unroll with the Roll Arro w Keys

1. Press and hold the Roll key then press the Unroll arrow key.

2. Release the Roll key but continue to hold the Unroll key until all of the

markers are unwound. The unroll speed will increase after a few seconds

of rotation.

3. Remove the tape holding the paper on the take-up shaft.

Method 3: Automatic Unroll with the Roll Keys (600Ae only)

1. Press and hold the Roll key then press the Unroll arrow key.

2. Press and hold the Roll Up arrow key for 2 seconds with the other hand.

3. Release all of the keys.

4. The automatic unroll feature will continue for 1 minute and then stop.

5. Repeat this procedure until all of the markers are unwound.

6. Cancel the automatic unroll feature at any time by pressing any keypad

key except the Roll arrow keys.

Method 4: Remo ving The Shaft

The shaft can be removed from the roll of completed markers without unwinding. The take-up shaft must be freed from the plotted roll before it can be

removed. This is accomplished manually or automatically with the take-up

motor.

• Manually F reeing The Take-Up Shaft:

1. Tape the loose end of the roll down so that it cannot flap freely.

2. Rotate the take-up shaft by hand until the rectangular opening in the

flanged coupling is perpendicular to the opening in the support block

(see Figure 9). Remove the shaft.

3. Stand the roll on end with the flanged coupling pointing up. Rotate the

take-up shaft counter clockwise (opposite to the direction that the paper

was rolled on the machine). See Figure 14.

4. The larger the roll, the more rotations are required to free the shaft. When

the shaft freely rotates, lay the roll on the ground.

5. Continue to twist the shaft counter clockwise while pulling it out of the

paper roll until it is free.

Figure 14. Manually freeing the take-up shaft.

Note: The take-up shaft is very heavy when many plots are rolled up.

Get help removing the plotted paper roll from the machine.

Page 21

21

Ioline

1. Use the vertical keypad Arrow keys to drive enough paper forward to

drape over the shiny top bar and wrap under and around the take-up shaft.

2. If the paper will not move far enough forward, press the Set Origin key on

the keypad.

3. Gently pull the middle of the front edge of the paper to start the machine

pulling paper from the feed roll.

4. Guide the paper over the shiny top bar as it is pulled forward. The paper

will reverse direction and a feed loop will form in the rear.

5. Use the keypad Arrow keys as described above until enough paper is

available.

6. Follow the guidelines described in the Taping Paper to the Take-Up

Shaft section above.

• Automatically F reeing The Take-Up Shaft with the Motor

Note: The take-up shaft is very heavy when many plots have been

rolled up. T wo or more people may be required to remo ve the plotted

paper roll from the machine.

1. Tape the loose end of the roll down so that it cannot flap free.

2. While one person lifts from the bottom and holds the paper roll still, press

the Roll key and the Up Arrow key on the keypad to rotate the take-up

shaft opposite to the direction that the paper was rolled on the machine.

The automatic unroll feature mentioned above can be used.

3. The larger the roll, the more rotations are required to free the shaft. When

the shaft freely rotates in the roll, stop turning the take-up shaft. If the

plotter jams (single blinking green LED) then do not unwind the roll

with the motor. See Manually Freeing the Take-Up Shaft above.

4. Rotate the take-up shaft by hand until the rectangular opening in the

flanged coupling is perpendicular to the opening in the support block

(see Figure 9). Remove the shaft and lay it on the ground.

5. Continue to twist the shaft counter clockwise while pulling it out of the

paper roll until it is free.

Reattach Paper to the Take-Up Shaft

Note: Except when the feed roll is changed, it is best to leave the

pinchwheels down when removing completed markers from the takeup roll. Leaving the pinchwheels down will help keep the paper

aligned with the feed roll and reduce the time between plotting

operations.

Page 22

22

Ioline

ROUTINE MAINTENANCE

Cleaning the Drive Shaft

Warning: Do not use any water, brushes with metal bristles or cleaning agents (except alcohol) to clean the plotter. P ay special attention

to keeping the drive shaft bearings free of all liquids

Clean the drive shaft regularly to make sure the plot remains accurate. To

clean the drive shaft:

1. Turn off the plotter and disconnect the power cord.

2. Gently remove any accumulated dust and residue with a stiff non-metal

bristle brush.

Calibration

Over time, plotters may require calibration to account for normal wear. This

will ensure that the plotter output closely matches the design intent.

Prepare the Plotter

1. Load the plotter with paper that is greater than 46 inches wide according

to the instructions in the Operation section. Install a pen in the carriage.

2. Move the carriage with the Arrow keys so that the pen is to the left of the

right most pinchwheel.

3. Put the plotter in Start mode (green LED) by pressing the Set Origin key.

The machine will pull a panel of paper off of the roll. See the Operation

chapter for more details on preparing to plot.

Gather the Calibration Data

1. Open the Ioline Control Center program.

2. Select Calibrate, Calibrate Plotter from the Control Center menu bar . A

window like Figure 16 will appear.

Figure 15. Cleaning the Drive Shaft.

3. Select Calibration Plot to plot the factory stored calibration plot. The

plotter will draw a box that is 40” (102 cm) long on the X axis and 30”

(76 cm) wide on the Y axis. See Figure 17.

Figure 16. Calibration screen.

Note: The Scale command does not effect the calibration values.

Page 23

23

Ioline

Cleaning the Platen

As the plotter is used, dust and paper residue will accumulate on the platen.

This debris may accumulate as often as every two weeks.

1. Turn off power to the plotter.

2. Dampen a lint-free cloth with isopropyl (pharmacy) alcohol and gently

wipe the platen until any accumulated residue is removed. Use antistatic

spray instead of isopropyl alcohol if desired.

Cleaning the Support Blocks

Dust and paper residue will accumulate on the take-up and feed shaft support

blocks. Perform this procedure when debris inhibits easy rotation of the shafts.

1. Turn off the power to the plotter.

2. Remove the feed shaft and the take-up shaft.

3. Dampen a lint-free cloth with isopropyl (pharmacy) alcohol and gently

wipe the support blocks until any accumulated residue is removed.

4. Wipe down both ends of the feed shaft and the take-up shaft before reinstalling them.

4. Precisely measure both sides (X) and the top and bottom (Y) of the box in

either inches or centimeters (dependent on the Measurement Units setting) and record the results. Better accuracy in measurement equals better calibration.

5. Take the average of the horizontal (Y) values by adding them together

and dividing by 2. Repeat this procedure for the vertical (X) values.

Example:

If X1 = 39.750 in. and X2 = 39.700 in.

The sum is 79.450 in. (39.750 in. + 39.700 in. = 79.450 in.).

The average is 39.725 in. (79.450 in. / 2 = 39.725 in.)

The X calibration value is the average, 39.725 in.

Enter the Calibration Data:

1. Enter the measured values in the boxes in the Calibration window. Make

sure the plotter is in Start mode (green LED). Select the Set Calibration

button.

2. The plotter will send the calibration values to the plotter and the new

Calibration Setting will be displayed in the boxes in the window.

3. Click on Done when finished.

Figure 17. The Calibration Box and Measurements.

Note: Only use Reset Calibration to restore original factory cali-

bration settings.

Y1

Y2

X1 X2

~40 in.

Figure 18. Do Not Touch the Take-Up Key While it is Moving.

Warning: Never touch the take-up key or flange coupling while

they are rotating (see Figure 18). Serious personal injury could result.

Page 24

24

Ioline

Testing the Plotter Serial P ort

The diagnostic module is required for this test.

1. Connect the diagnostic module directly to the plotter COM port.

2. From the Control Center main menu, select Test, Plotter Port Test.

3. Turn on the plotter while holding down the Roll key on the keypad.

Continue holding down the Roll key until the plotter beeps and the light

flashes three times. The plotter is now in Test Mode.

4. Press any Arrow key on the keypad to transmit and receive characters.

Verify that the plotter beeps.

5. Turn off the plotter at the end of the test. This will exit Test Mode. If this

test fails, the plotter port is faulty .

Testing the Computer Serial Port

The diagnostic module is required for this test.

1. Connect the diagnostic module directly to the COM port on the computer. If the computer COM port has a nine pin connector, use a 9 pin to

25 pin adapter between the COM port and diagnostic module.

2. From the Control Center main menu, select Test, Computer Port Test.

3. Verify that the COM port selected is the cor rect one. If it is not, select the

proper COM Port.

4. Verify the CTS handshake line is on.

5. Press any key on the computer keyboard and verify that the character

transmitted equals the character received.

6. Select the Exit button at the end of the test. This will exit Test Mode. If

this test fails, the computer port is faulty.

COMMUNICATION TESTING

There are three communication diagnostic tests available in the Control Center. These tests are designed to help determine if a communication problem

exists and to isolate where the problem is occurring.

A diagnostic module is required to run two of these tests. It will work on both

the computer and plotter serial (COM) ports. It is available from Ioline or an

authorized dealer.

Communication T est

This test will determine if communication is working between the computer

and the plotter on the serial (COM) port. Run this test from the Control Center, Test menu. The diagnostic module is not required to run this test.

1. Turn the plotter off. Connect the plotter to the computer with a serial port

cable. See the section Connect the Plotter to the Computer in the Quick

Start guide for more details.

2. Start the Ioline Control Center. Select Test, Communication Test from

the menu bar at the top of the window.

3. Turn on the plotter while holding down the Set Gap key on the keypad.

Hold down the Set Gap key until the plotter beeps and the light flashes

three times. The plotter is now in Test Mode.

4. Press the Start/Stop key on the plotter and verify that the handshake line

(CTS) status displayed on the computer screen toggles On/Off. Leave

the handshake line On.

5. Press the Roll key to switch the plotter into Echo mode. The green light

will come on.

6. Press a key on the computer and verify that the character transmitted

equals the character received. If the characters match then the connection

between the plotter and computer is working properly.

7. Select Exit in the Control Center after the communication test is com-

plete.

8. Turn off the plotter at the end of the test. This will exit Test Mode.

9. The next two tests are not necessary if serial (COM) port testing is successful.

Page 25

25

Ioline

TROUBLESHOOTING

If the system is not working correctly the problem could be with the computer,

the cable, the design software, or with the plotter. Changes to the computer

operating system or the installation of new peripherals or software might

cause conflicts. If the computer or the design software are causing a problem,

consult the computer or software manuals or call the manufacturer or dealer.

If the problem is with the plotter, begin by making sure power is on and that

the cable between the machines is connected correctly. Test the connection

with the methods described in the Communication Testing section. Consult

the following charts for more detailed troubleshooting techniques.

General Problems

Plotting Quality Problems

Good plotting quality is dependent upon a number of different factors. The

type of paper, en vironmental conditions, and operator habits are only a few of

the variables that can affect the quality of a plot. It is important that the plotter

is loaded and maintained according to the guidelines in the Operation chapter. Below is a summary of the most common difficulties:

.nodenrutsirettolpehtnehwrewopoN

:esuaC

degamadsidrocrewopehT.1

.detcennocsidro

dnadegamadsirettolpehT.2

.ecivreslanoisseforpsdeen

:noituloS

drocrewopehtkcehC.1

.noitcennoc

rorotubirtsideniloInallaC.2

.ecivreSremotsuCeniloI

.repapehtnotnioptcerrocehttatratst’nseodtolprekramA

:esuaC

.testonsinigiroehT

:noituloS

ehtsserP nigirOteS ehthtiwyek

tolpehterehwdenoitisopnep

.tratsdluohs

egralasevaeldnatolprekramehtetelpmoctonseodrettolpehT

.semarfneewtebpag

:esuaC

erawtfosngisedlerappaehT

ehtnahtregraltessiezisemarf

eht(gnittesezislenaprettolp

emarfmumixamdnatesyrotcaf

.)mc8.611ro”64siezis

:noituloS

gnittesezislenapehtesaercnI

retneClortnoCehthtiw(

fognittesehthctamot)erawtfos

roerawtfosngisedlerappaeht

erawtfosngisedlerappaehtrewol

ehthctamotgnittesezisemarf

.gnittesezislenap

.sneppahgnihtontubtnessieliftolprekramafI

:esuaC

sahmelborpnoitacinummocA

nisirettolpehtroderrucco potS

.edom)DELder(

:noituloS

ehtnostroplairesehterusekaM

erarettolpehtdnaretupmoc

derugifnocdnadetcennoc

ehtsserP.ylreporp nigirOteS

nirettolpehttupotyek tratS

spooldeeF.)DELneerg(edom

.mroflliw

.citarresituptuoehtdnatnessieliftolprekramA

:esuaC

tnessaweliftolprekramehT

egaugnalrettolpgnorwehthtiw

.gnittes

:noituloS

ngisedlerappaehterusekaM

otteserarettolpehtdnaerawtfos

rehtie(egaugnalrettolpemaseht

.)6957LGPHro5747LGPH

rettolpeht(kramsixaemarfatcetedtonseodrosnesemarfehT

.)neergsiDELdapyekehtdnaspeebelbiduastime,gninoitcnufspots

:esuaC

otelbanusawrosnesemarfehT

.kramtnemngilaemarfehtdnif

:noituloS

noitcessedoCDELehteeS

.woleb

ehtesU paGteS otyekdapyek

ehteeS.kramtsolehtdnif

noitarepO eromrofnoitces

.sliated

Page 26

26

Ioline

.gniteemyletelpmoctonerastolpehtnosenilehtfosrenrocehT

:esuaC

.gnippilssirepapehT.1

eraseulavyalednwod/puehT.2

.yltcerrocnites

ootsignittesecrofnepehT.3

.wol

:noituloS

kcehC.tfahsevirdehtnaelC.1

tonerasleehwhncipehttaht

.tfahserabrogniraebarevo

.yalednwod/puehttsujdA.2

.ecrofnepehtesaercnI.3

toneraslenapehtroslenapneewtebtnedivesipalrevoropagA

.dengila

:esuaC

.gnippilssirepapehT.1

pagemarfrodelbasidrosneS.2

.teston

:noituloS

dnatfahsevirdehtnaelC.1

leehwhcnipehtegnahc

.noitisop

ehtnirosnesehtelbanE.2

emarfehttesroretneClortnoC

.pag

.gnittolpgnirudrepapehtsraetneP

:esuaC

.yrdsinepehT.1

ylbissop,nekorbsipitnepehT.2

.hgihoottesecrofnepoteud

.hgihoottessiecrofnepehT.3

ehtnokcutssisirbedrotriD.4

.nep

esuacebgnilbbubsirepapehT.5

.gnikrowtonerasnafeht

ehtesuacebgnilbbubsirepaP.6

.gnippilssirepap

eraseulavyalednwod/puehT.7

.yltcerrocnites

egdeehtotesolcootgnittolP.8

.repapehtfo

:noituloS

.nepehtecalpeR.1

dnaecrofnepehtesaerceD.2

.nepehtecalper

.ecrofnepehtecudeR.3

.nepehtecalperronaelC.4

rorotubirtsideniloInatcatnoC.5

.ecivreSremotsuCeniloI

nehttfahsevirdehtnaelC.6

leehwhcnipehtegnahc

.noitisop

satsujdA.stluafedotteseR.7

.yrassecen

ehtedisninigirowenateS.8

.sleehwhcniptsomthgir

(This Page Intentionally Left Blank)

Page 27

27

Ioline

Loss of Registration Between Frames

Loss of accuracy between the frames of a completed marker plot may indicate

a loss of registration during frame advance. Check the following items to ensure that the plotter is setup properly:

• Make sure the frame sensor is enabled in the Control Center (model

600Ae only) or check the Frame Gap (see the Operation section for more

details). If the frame sensor is OFF mark the check box and send settings

to the plotter so that it functions properly.

• The frame/panel size may be mismatched between the plotter and the

design software. Check that the frame size in the software is equal to or

lower than the default panel size of 46” (116.8 cm).

Registration problems can also arise from the paper slipping under the

pinchwheels or from other tracking problems. If everything appears to be

setup properly see Tracking below.

Tracking

Tracking is the process that controls the media motion over the platen and

assures accurate lines and frame matching. If the paper is slipping under the

pinchwheels or is not aligned, plotting quality and frame registration are

degraded. To resolve tracking difficulties try the following suggestions:

• The paper must be installed correctly. See the Operation chapter for more

details.

• Inspect the paper for wrinkles or folds. Never use any paper that is folded,

wrinkled, or torn in any way.

• Check the take-up shaft to see if the roll of completed marker plots exceeds the height of the paper guide flanges (greater than 600 yards). If the

take-up roll diameter is greater than the paper guide flanges the paper

will have to be removed before sending the next plot file. See Removing

Completed Markers from the Take-Up Roll in the Operation chapter.

• Reducing the speed and acceleration settings in the Control Center can

resolve some tracking problems.

• Make sure the pinchwheels are spaced across the paper as outlined in the

Operation chapter.

• The inner pinchwheels must not be positioned over the bearings in the

drive shaft because paper tearing and bunching will occur.

• Check to make sure that the plotter is level. See the Setup chapter.

• The chart wheel pressure on the drive shaft creates an impression on the

marker. The underside of the completed marker plot will always have

visible drive tracks which should be identical. If one drive track is more

pronounced or markedly different than the others there may be a chart

wheel or drive shaft problem.

• The paper may be slipping because debris has accumulated on the drive

shaft preventing proper paper traction. Inspect and clean the drive shaft.

Refer to the Preventative Maintenance chapter.

• Contact an Ioline distributor or Ioline Customer Service if damaged equipment is causing tracking difficulty or if the plotting quality problem cannot be resolved.

Poor Line Quality

If the marker plot line quality is uneven try the following suggestions in

order:

1. Use the keypad force knob to select a pen force that produces adequate

line quality.

2. Increase the Pen Down Delay.

3. Replace the pen with a new one.

4. Adjust the plotting speed values in the Control Center software.

5. Plot on a higher quality paper.

6. Refer to the Operation chapter to check that the pen is recommended by

Ioline.

7. Check the white plotting strip under the pen. Have it replaced if it is

damaged.

8. Contact an Ioline distributor or Ioline Customer Service for further help.

Page 28

28

Ioline

Error Messages

Error messages that are specific to the plotter are divided into two categories;

Software Errors and LED Codes. Software errors present themselves on the

computer screen and usually indicate a communication problem. LED codes

are visible below the keypad on the front panel of the plotter and can be green,

red or a combination of both. The LED Codes table in this section explains

the type and meaning of each error. Other errors can occur with the operating

system or the plotting software and should be resolved with the software

vendor.

Software Errors:

.xMOCnepotondluoC

:esuaC

nepot'ndluocretneClortnoCehT

A.esuroftropMOClaireseht

elbaliavatonsitahttroplaires

.detcelessaw

:noituloS

sitahttropMOClairesatceleS

.elbaliava

.tneserprettolpkcehcdnatropMOCputeS

:esuaC

tahtseriuqernoitarepotsalehT

ehtotdetcennocebrettolpeht

retneClortnoCehttubtroplaires

.tidniftondluoc

:noituloS

detcennocsirettolpehteruseB

ehttaht,troplairesdetcelesehtot

ehttahtdna,nosiDELneerg

.gninoitcnufsielbaclaires

.xMOCotdetcennoctonrettolpronotonDELneerG

:esuaC

ehtdeneporetneClortnoCehT

ategtondluoctubtropMOC

.rettolpehtmorfesnopser

:noituloS

detcennocsirettolpehteruseB

ehttaht,troplairesdetcelesehtot

tahtdna,neergsiDELdapyek

.gninoitcnufsielbaclaireseht

firaeppayamegassemsihT

detpmettasinoitacinummoc

ehtsisihtfI.gnittolpgnirud

hsinifottolpehtroftiawesac

.niagaelifrognittesehtdnesdna

ehtotdetcennoctahtsaemasehttonsirettolpdetcelesehT

.retupmoc

:esuaC

hctamtonnacretneClortnoCehT

tratstanesohcsawtahtrettolpeht

gniruddnuofenoehthtiwpu

.noitazilaitini

:noituloS

ehtmorfrettolptcerrocehttceleS

.wodniwputesehtnitsilrettolp

.retalroX.XfonoisrevMORasdeenretneClortnoCfonoisrevsihT

:esuaC

tonsiMORrettolpehT

lortnoCehthtiwelbitapmoc

.esuniyltnerrucretneC

:noituloS

ahtiwdeppihssirettolpehT

otdengisedsitahtretneClortnoC

MORcificepshtiwnoitcnuf

sruccororresihtfI.snoisrev

ehtenimretedoteniloItcatnoc

erawtfosdnaMORtcerroc

.noitanibmoc

Page 29

29

Ioline

.*gnipeebsuounitnoc,DELneergdiloS

:esuaC

otelbanusawrosnesemarfehT

ehT.kramnoitartsigerehtdnif

rosnesemarfderetnesahrettolp

.edomrorre

sikniehtroyrdsinepehT.1

.kcalbton

yldabrognilbbubsirepaP.2

.dengilasim

ehtniesoolsirosnesehT.3

.degamadrotekcarb

:noituloS

wenahtiwnepehtecalpeR.1

ehtsserP.nepknikcalb

potS/tratS emarfpiksotyek

otdeecorpdnanoitartsiger

.emarftxeneht

repaptsujdadnakcehC.2

.tnemngila

ecivreSremotsuCeniloIllaC.3

otrosliatedtnemtsujdarof

tnempiuqenayfitnedi

.melborp

LED Codes

* The 600Ae makes multiple attempts to find each frame mark. The

plotter will continue to plot if one frame mark is missed. If a second

frame mark is missed during the next two frame advances, the plotter will enter frame sensor error mode. The ke ypad LED will remain

solid green but plotting will stop and the machine will beep continuously.

See the section describing the Set Gap button for more options to

handle a lost frame mark.

...taeper,esuap,DELdergniknilbelbuoD

:esuaC

rowolfrevoreffuB

.melborpsnoitacinummoc

:noituloS

sastsetnoitacinummocmrofreP

ehtnideniltuo gnitseT

snoitacinummoC dneS.noitces

ehtmorfeliftlp.rekrameht

yfirevotretneClortnoC

.noitacinummoc

DELderdnaneerggniknilbgnitanretlA

:esuaC

.rorrexatnysegaugnalrettolP

:noituloS

ehtdnarettolpehttahterusekaM

ehtotteseraerawtfosretupmoc

ehtdneS.egaugnaltolpemas

lortnoCehtmorfeliftlp.rekram

.noitacinummocyfirevotretneC

seliftolpfiruccoyamrorresihT

tneserasegaugnaltnereffidni

.ylevitucesnoc

...taeper,esuap,DELneerggniknilbelgniS

:esuaC

llorpu-ekatro)sixaY(egairraC

roaidemdelpmurcoteudmaj

.noitomgnikcolbstcejborehto

:noituloS

gnisuacstcejboroaidemraelC

.maj

...taeper,esuap,DELdergniknilbelgniS

:esuaC

oteudmaj)sixaX(tfahStirG

stcejborehtoroaidemdelpmurc

.noitomgnikcolb

:noituloS

gnisuacstcejboroaidemraelC

.maj

Page 30

30

Ioline

Testing the Frame Sensor

A malfunctioning frame sensor might cause the frames to misalign on a 600Ae.

The following procedure will help determine if a problem has developed.

This test is not available during plotting.

Note: These functions only work when the frame sensor is enabled in

the Control Center. See the section Sensor Options above for more

details.

1. Load the plotter with paper. See the section Prepare to Plot for more

details.

2. Press the Start/Stop button until the keypad LED turns red (Stop mode).

3. Use the keypad Arrow keys to position the carriage so that the pen is

over a clean section of paper.

4. Press the Set Gap button.

5. The plotter will draw a frame alignment mark and continuously scan the

mark until the Start/Stop button is pressed again. If the sensor finds the

mark it will beep. This function is useful for adjusting sensor height.

6. If no beep is heard the sensor might need adjustment or is defective.

Contact an Ioline distributor or Ioline Customer Service for details.

(This Page Intentionally Left Blank)

Page 31

31

Ioline

Please gather the following information about your plotter

before contacting Ioline or the dealer for technical support.

Name:

Company Name:

Phone Number: Fax:

Model:

Serial Number:

Date of Purchase:

Dealer:

Type of Material Used:

Type of Computer:

Type of design software:

New Software or Peripherals:

Service History (if any):

Note: Ioline Customer Service contact information is listed on the

last page of this section.

END NOTES

Getting Help

Ioline is committed to providing the highest quality service and support to its

customers. If you need assistance with an Ioline plotter, a number of resources

are available:

1. First, refer to this User Guide for answers to your specific questions.

2. Consult the support section of the Ioline web site: www.ioline.com.

3. For additional assistance, contact your local dealer or Ioline Customer

Service. Contact information is listed on the following pages of this User

Guide.

Any warranty servicing of this product not specifically described in this manual

must be authorized in writing by Ioline Customer Service. You may obtain

service by calling or faxing Ioline Customer Service. The technicians will

help you determine the nature of the problem. If factory repair is necessary,

you will receive a RMA (Return Material Authorization). Please gather the

information indicated in the next column before contacting Ioline or your

dealer.

1. When returning a machine, carefully package the equipment in its original container or equivalent. You may purchase shipping containers from

Ioline by contacting Ioline Customer Service. Ioline is not responsible

for any damage due to inadequate or improper packaging.

2. Carefully wrap and secure all items in the shipping container to prevent

damage. Seal the container and note the RMA number near the address

block.

3. Ship the container using FED-EX or another approved carrier. COD SHIP-

MENTS ARE NOT ACCEPTED. An Ioline representative will contact

you prior to the start of work with an estimate of repair cost. All repairs

are warranted for 90 days.

Page 32

32

Ioline

Your Comments Are Requested

Ioline Corporation is interested in comments on our documentation and products. Please send corrections or suggestions to:

IOLINE CORPORATION

14140 NE 200th Street

Woodinville, WA 98072 USA

Voice: 1.425.398.8282

Fax: 1.425.398.8383

www.ioline.com

info@ioline.com

This User Guide is provided for informational purposes only. The contents are

subject to change without notice, and Ioline Corporation assumes no responsibility for any errors that are contained herein. No part of this User Guide may

be copied, disseminated, or distributed without the express written consent of

Ioline Corporation.

Customer Service

Ioline Corporation is committed to providing quality service and support to

our customers. If you need assistance with an Ioline product, contact your

local dealer or Ioline authorized service center. You may also contact the

Ioline Customer Service Department

Monday through Friday

7:00 A.M. - 5:00 P.M. U.S. Pacific Time

Voice: 1.425.398.8282

Fax: 1.425.398.8383

techsupport@ioline.com

www.ioline.com

Ioline has many years of experience working with designers, graders and

marker makers. Feel free to contact us if you have questions or to share information.

Limit of Liability Statement

It is the responsibility of the operator of the plotter to monitor the performance of the plotter and maintain it in proper working condition by following

the instructions in this User Guide. It is the responsibility of the operator of

the plotter to follow all safety precautions and warnings that are described in

this User Guide. Ioline is not responsible for injuries that may occur as a result

of unsafe operating procedures. Ioline is not responsible for substandard operational performance as a result of failure to maintain the plotter as described

in this User Guide.

The FCC Wants You to Know...

This equipment generates and uses radio frequency energy and, if not installed and used properly (in strict accordance with manufacturer instructions),

it may cause interference to radio and television reception. Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. If this equipment

does cause interference to radio or television reception - which can be determined by turning the equipment off and on - you are encouraged to try to

correct the problem by one or more of the following measures:

• Use only shielded interface cables.

• Reorient the receiving antenna.

• Relocate the host computer with respect to the receiver.

• Move the host computer away from the receiver.

• Plug the host computer into a different outlet so that the host computer

and receiver are on different branch circuits.

If necessary, consult the dealer or an experienced radio/television technician