Page 1

Ioline 300/350HF Systems

Quick Start Guide

The Quick Start Guide is intended to help a new user of an Ioline

300/350HF System get setup and running quickly. Please note that

there are important notices, directions, troubleshooting, and other information in the electronic PDF 300/350HF User Guide and 301 Software

User Guide manuals available online in the 300/350HF support page

at ioline.com/support/300-350hf-support/. Adobe Acrobat Reader® is

required to view the User Guides and other electronic documents provided by Ioline.

Important Cautions

n The 300 and 350HF are powerful cutting machines. To avoid serious injury; keep ngers,

loose clothing and any objects that might get tangled in moving parts away from the

cutter during operation.

n Before using, make sure that the cutter has 9-in of clearance in front and behind the

table to give the moving tray adequate space.

n Do not try to repair the machine without factory authorization.

n Never attempt to move the Carriage by hand when the power is on.

n Be careful when moving or lifting the machine, it is heavy!

© 2019 Ioline Corporation. All rights reserved.

September 10, 2019 FILE P/N: 107070 R8 PRINT P/N: 107077 R10

Page 2

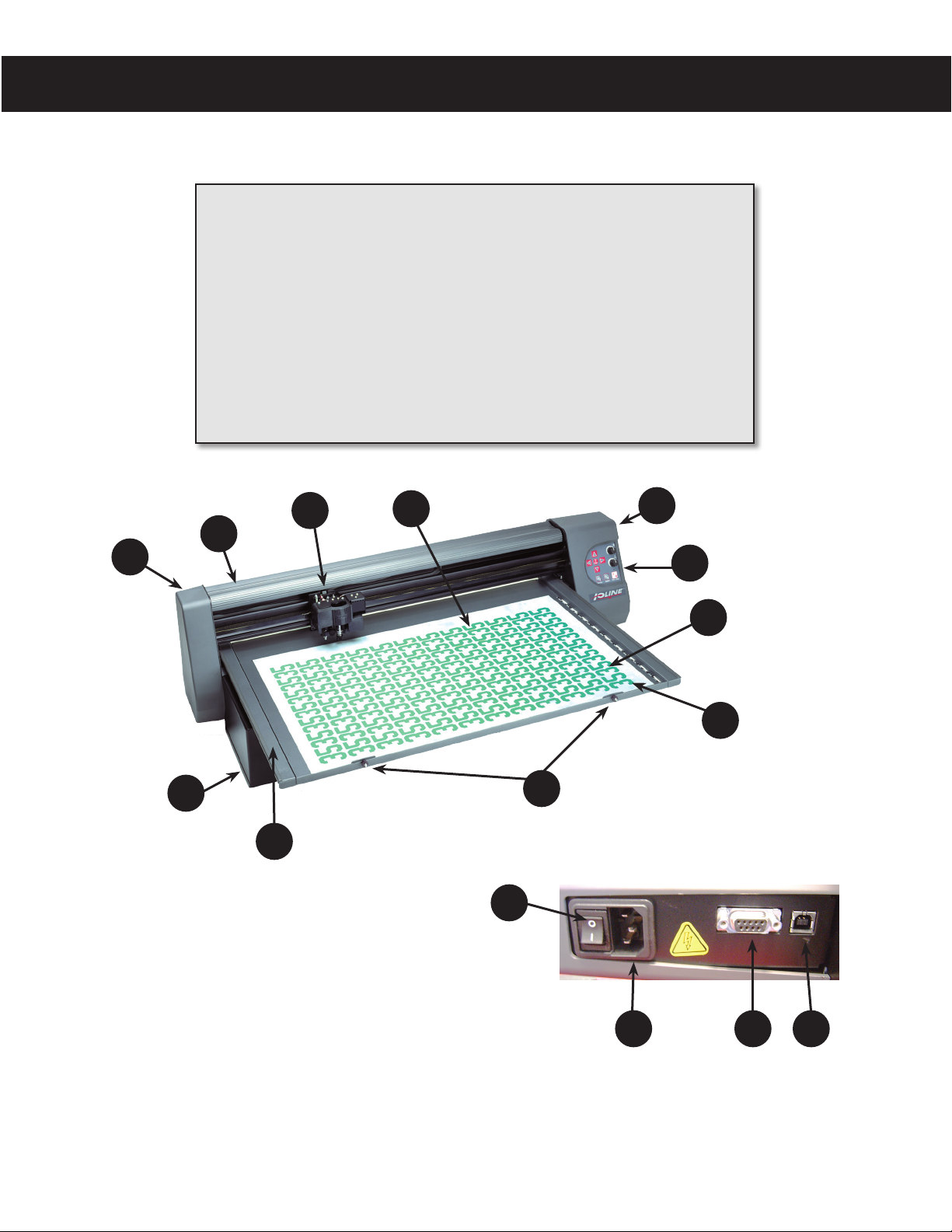

Visual Reference Guide

KEY

A

A. Left end cover

B. Dust cover

C. Carriage (design may

vary)

D. Adhesive sheet, mounted

E. Right end cover

F. Keypad

G. Tray (removable)

C

B

D

H. Origin (starting point)

I. Thumb nuts (2)

J. Table (non-removable)

K. Leg (2)

L. Power switch

M. Power connector

N. Serial port

O. USB port

E

F

G

H

K

I

J

L

M

2

Front view of the 300 System and a close-up photo of the port and power switch on the back of the machine.

N O

Page 3

Assembly

This Quick Start Guide shows how to assemble and set up the Ioline

300/350HF Systems. Consult the Acrobat® PDF 300/350HF System

User Guide, available online at ioline.com, for more detailed infor-

mation about installation and operation. Adobe® Acrobat® viewer is

required to read Ioline User Guides.

3

Unpacking the 300/350HF System

Follow the enclosed instruction sheet to remove the cutter and accessory kit from the box. To avoid injury, always lift the cutter with

two people. Check the packing list and save all packing materials.

1. Set the cutter on a stable surface.

2. If you purchased an extra tray, lift it off the Table and set it

aside.

3. Remove the 4 shipping lock screws holding the Table in place

(see gure below).

Remove the shipping screws from the Table

4. Remove all the packing material from around the carriage.

Caution

The 300 and 350HF Systems are heavy and could

cause injury if they fall. A

minimum of two people are required to safely unpack and move

the cutter.

i

Save the box and all packing materials. New boxes are expensive!

Note

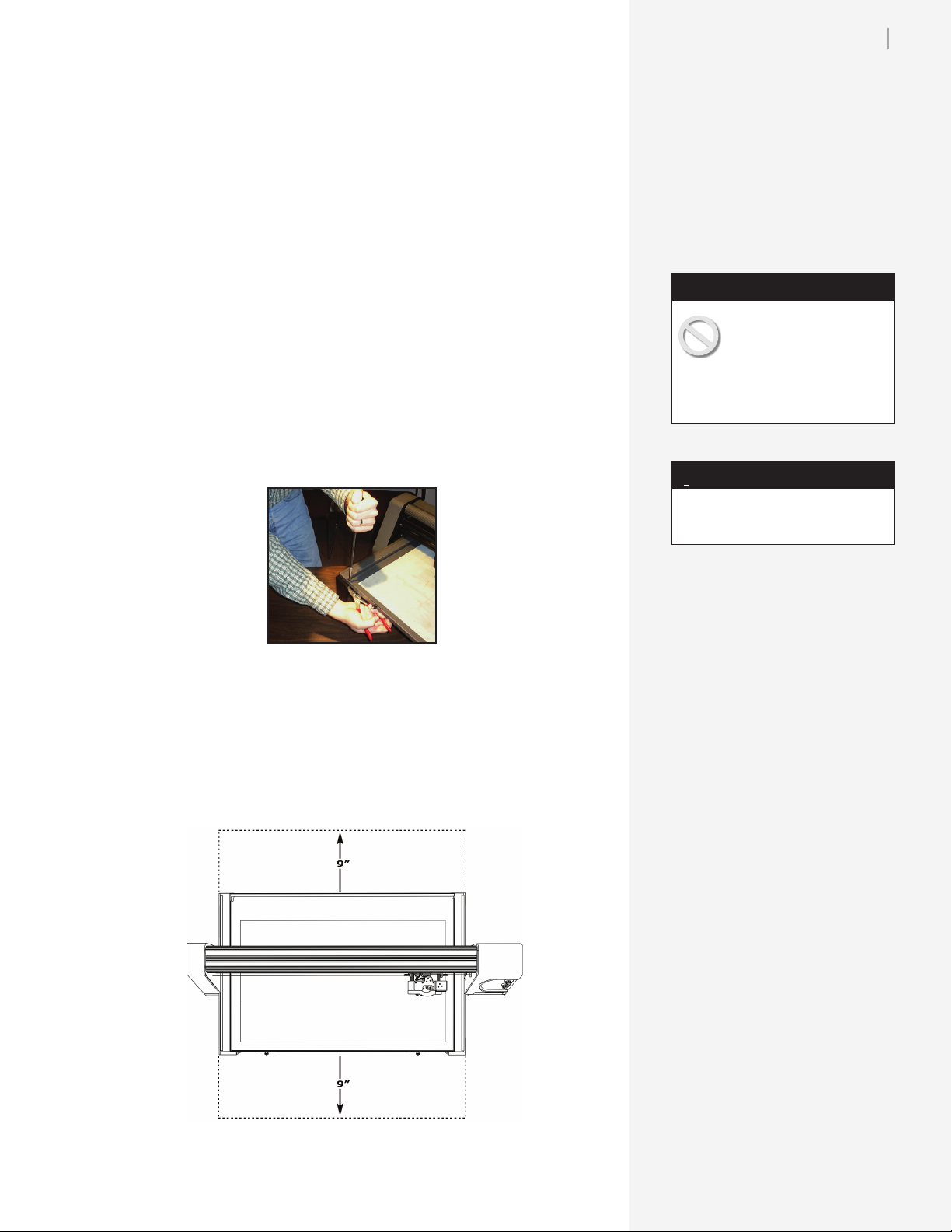

Prepare the Production Area

Clean the table top and clear any obstacles. Place the cutter 9-inches

away from the wall to allow the material tray to move freely forward and back. See the gure below.

Top view of the machine showing the area to keep clear for tray movement

Page 4

4

Ioline 300/350HF Quick Start Guide

Step 1: Install the Software

1. Make sure that machine power is turned off by pressing the ‘0’

end of the power switch on the back of the right end cover.

Power switch

set off to ‘0’

Make sure the power switch is OFF.

2. Visit the online Ioline software setup page at ioline.com/setup.

3. Click on the picture of the 300/350HF cutter then follow the

steps listed in the Setup tab.

4. Follow the self-guided installation instructions for each installation program. If prompted, answer ‘Yes’ or ‘OK’ to all questions about installing drivers.

i

Older 300 and 350HF Systems

used a parallel key rather than

USB, as shown below:

Note

5. The 301 installation program will place an icon on the desktop

for the 301 Software

The 301 software icon is placed on the desk-

top when installation is nished.

6. Restart the computer only if instructed.

7. Connect the Ioline 301 Software key to a USB port on the PC

(see gure below). Ioline recommends NOT using a USB hub

for the key. Windows will likely show messages about driver

installation when the key is inserted the rst time.

Install the drivers, then insert the USB key into the PC.

8. The PDF User Guide and this Quick Start Guide and software

manuals are available under the Manuals tab on the product

support page. Acrobat Reader, is required to view manuals.

9. The optional Ioline Control Center software is available on the

Downloads tab of the support page. This utility is normally

not required unless detailed machine setup is necessary or for

troubleshooting.

Page 5

Step 2: Connect the cutter to the PC

1. Insert the power cord into the power inlet on the cutter, then

plug it into a wall socket or power strip (see gure below).

5

Power cord

inlet

The power cord inlet, serial port and USB port on the rear panel of the cutter.

Cutter serial port

(9-pin female)

Cutter USB

port

2. Connect the USB cable supplied in the Accessory Kit to the cutter.

3. Verify that the cutter is positioned at least 9

inches away from the wall or other objects,

then turn the cutter power on. The Table

will move backward and the carriage to the

right. Wait for the keypad light to turn red,

indicating that the cutter has nished initializing.

4. Connect the USB cable to an empty USB

port on the computer.

5. Driver installation messages might appear

while the computer connects to the machine.

Rear view of the

PC USB ports.

Press OK and/or restart if requested.

Step 3: Install an adhesive sheet

1. Check the light on the cutter keypad and press Start/Stop if it is

not red. Use the Arrow keys on the keypad to move the Table

all the way forward.

2. If the tray is installed in the Table, loosen the thumb nuts and

remove the tray by lifting up in the front and pulling forward.

Place the tray on a stable surface.

3. Choose an Adhesive Sheet (and backing material, if required)

that are appropriate for the material you plan to cut. See Figure

Below to identify proper sheet and backing types. More information about choosing Adhesive Sheets is also available in the

300/350HF System User Guide.)

Page 6

6

Ioline 300/350HF Quick Start Guide

High Tack

(HT)

Medium Tack

(MT)

Low Tack

(LT)

Ultra Low Tack

(ULT)

2-sided Backing

(2S)

1-sided Backing

(1S)

Adhesive Sheet and backing material guidelines.

Scrim felt, leather, etching and stencil

board. Order 107076

A general purpose sheet, use with most

twills. Order 107295

Heatseal-backed or thin and fragile

materials. Order 107093

Paper or paper-backed materials. Order

108300

Adds adhesive to non-backed materials.

Order 107089

Stabilizes thin materials. Order 106227

i

Always remove the tray from the

cutter when removing or installing adhesive sheets. Not doing so

may damage the tray, table and/

or blade.

Note

Align the adhesive sheet with the L-shaped Tray alignment marks.

4. Peel the white backing paper off of the Adhesive sheet. The

STRIPED SIDE of the adhesive sheet should face up. With

the exposed side facing the Tray, align the corners of the sheet

with the engraved “L” shaped marks in the Tray (see gure at

right).

5. Smooth the adhesive sheet down until it is smooth. Leave the

paper cover on the top of the adhesive sheet until ready to apply material for cutting.

Page 7

Step 4: Install the material and tray

7

1. Remove the striped cover from the Adhesive Sheet and carefully apply fabric to the Tray. Smooth all bubbles out of the

material (see gure below). Remember to remove material and cover

the adhesive sheet with the striped paper sheet when the cutter is not

in use.

Apply the material on top of the Adhesive Sheet on the Tr a y.

i

DO NOT leave twill and other

materials stuck on the adhesive

sheet when not cutting. If left too

long, the adhesive on the sheet

will make a strong bond to the

material which makes removal

difcult. This might also ruin the

material and the adhesive sheet.

Note

2. Slide the Tray onto the Table with the thumb nuts facing the

front of the machine. Make sure the rear lip of the Tray ts

tightly under the rubber strip in the rear of the Table. The

thumb nut posts should drop smoothly into the slots on the

front of the Table.

3. Press the Tray down into the Table and tighten the thumb

nuts. Make sure the tray seats all the way into the table.

CORRECT

ü

INCORRECT

X

4. Use the Arrow keys on the keypad to position the carriage and

Table so that the blade over the Origin (usually the lower right

corner of the Table, see the Visual Reference Guide section). This

is where cutting will start.

5. Press Set Origin on the keypad. The light on the keypad will

turn green.

Page 8

8

Ioline 300/350HF Quick Start Guide

Caution

The blades are very sharp

and the tip is fragile. Use

caution when inserting

them into the blade holder.

i

You can substantially extend the

life of the blade by making sure

to adjust it to the proper depth

for the material you are cutting

and setting down-force pressure

as low as necessary to get a clean

cut, This also reduces the possibility Tr a y damage.

Note

Step 5: Select and adjust the blade

1. Choose one of the included blades in the Accessory Kit to

match the type of material loaded on the tray. The table below

shows information to help choose the correct blade.

Reduces fraying and pulling on fragile

30o Blade

0.094-in offset

45o Blade

0.094-in offset

60o Blade

0.094-in offset

2. Unscrew the foot (see

gure at right) from the

blade holder.

3. Insert the blade into the

blade holder (see gure

at right) by pinching the

shaft of the blade. DO

NOT touch the blade

tip, it is very sharp. The

blade will resist at first

then slide freely to a

hard stop when properly

inserted.

or exible materials.

300: Order 321 (PN 106988-5)

350HF: Order 324 (PN 107418-5)

General purpose blade. Cuts some

thick materials.

300: Order 322 (PN 106989-5)

350HF: Order 325 (PN 107419-5)

For cutting thick and stiff materials.

350HF: Order 326 (PN 107420-5)

Blade selection guidelines.

Blade

Blade

Holder

Foot

i

The are great accessories for the

300 and 350HF that make your

business even more productive.

Extra Blade Holder (107080)

Allows quick change between two

cutting depths when switching

materials.

Extra Removable Tray (107662)

Increase throughput by weeding

one tray while cutting on another.

Precision Weeding Tool (106143)

Swiss made superior quality tweezers with sharp tips for fast and

precise weeding.

i

Check our website, give us a call,

or send an email...

Accessories

NEED HELP?

4. Gently turn the foot onto

Installing the blade in the blade holder.

the blade holder until just

before the tip of the blade

protrudes from the opening in the foot.

5. Insert the blade holder in the

jaw then tighten the clamp.

6. Follow the steps in the

300/350HF System User Guide

to adjust the blade exposure

and force. Note: this step is

very important!

7. Proceed to the 301 User Guide

to learn about preparing files

and sending them to the cutter.

The machine is ready to

Material

Adhesive Sheet

A properly adjusted blade.

Blade

Foot

cut a le!

Ioline Corporation Woodinville, Washington U.S.A.

M-F, 7:00 A.M. - 5:00 P.M. U.S. Pacic Time

Voice: 1.425.398.8282 Fax: 1.425.398.8383

support@ioline.com www.ioline.com

Loading...

Loading...