Page 1

300 System

CORPORACORPORA

CORPORA

CORPORACORPORA

TIONTION

TION

TIONTION

Contents

• Unpack the Cutter

• Cutter Connections

• Computer Connections

• Install Ioline Software

• Install an Adhesive Sheet

• Apply Cloth and Install the Tray

• Choose a Blade

C

Quick Start Guide

This quick start guide has instructions for

setting up and using the Ioline 300 System. Please consult the 300 System User

Guide and the 301 Software User Guide

for more information about getting the

most out of your Ioline product.

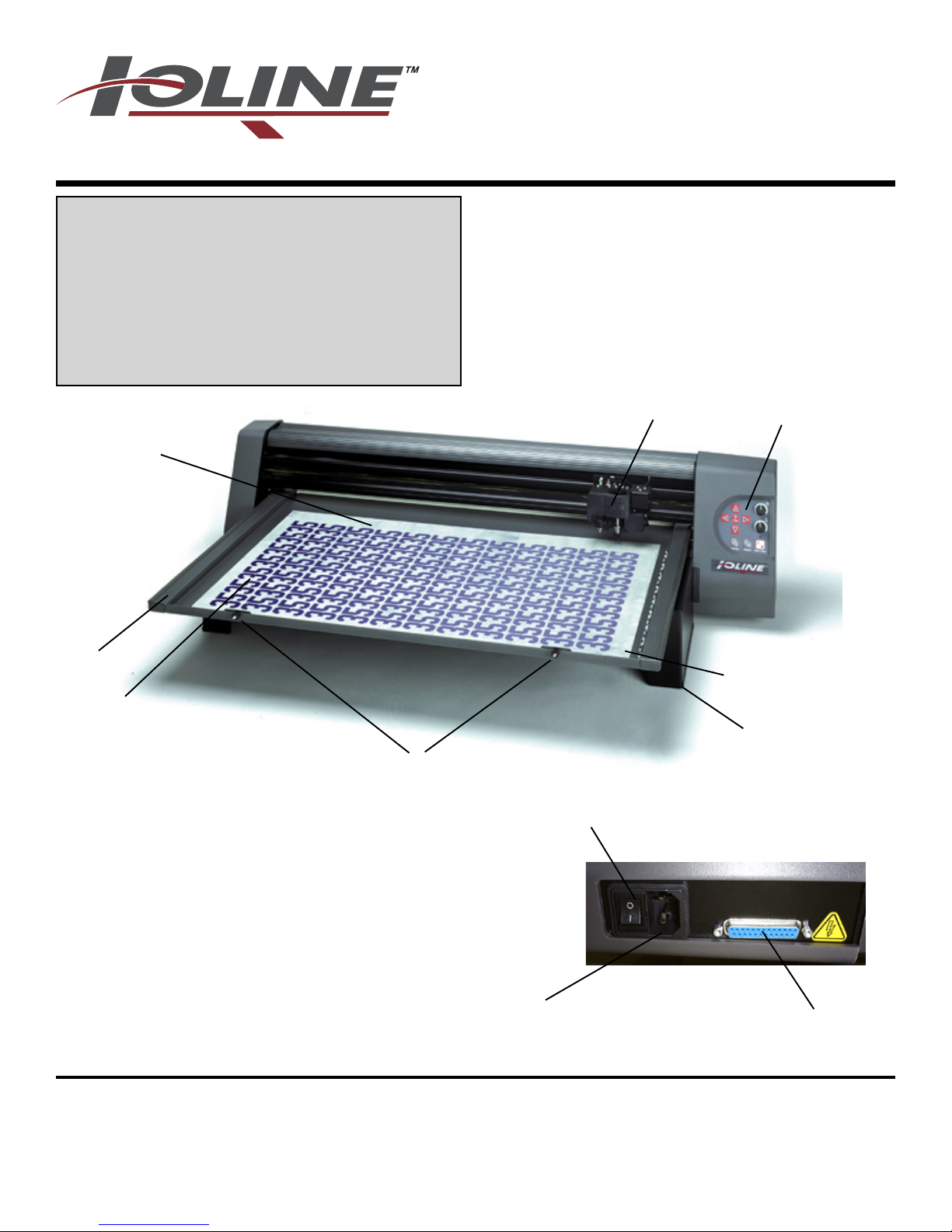

E

D

B

A

A. Tray (removable)

B. Table (non-removable)

C. Adhesive Sheet, Mounted

D. Keypad

E. Carriage

F. Serial Port

G. Power Connector

H. Power Switch

J. Most Cuts Start Here (Origin)

K. Thumb Nuts (2)

L. Leg (2)

14140 N.E. 200th Street, Woodinville, WA 98072, USA

Part Number: PRINT:107077r5 • FILE:107070r3

J

L

K

H

G

F

IOLINE CORPORATION

Voice: 1.425.398.8282 • Fax: 1.425.398.8383

info@ioline.com • www.ioline.com

Page 2

2 300 Quick Start Guide

Unpack the Cutter

1. Remove the machine and all accessories from the box using the

included instruction sheet.

2. Set the 300 on a stable surface.

Lift the Tray from the Table.

3. Remove the 4 screws holding the

Table in place for shipping. Fig. A.

4. Cut the tie wrap that holds the

Carriage in place and remove all

packing material. Fig. B

5. Make sure the cutter has a minimum of 9” clearance in front and

behind the Legs of the plotter.

IMPORTANT: Save the shipping

box and all of the contents.

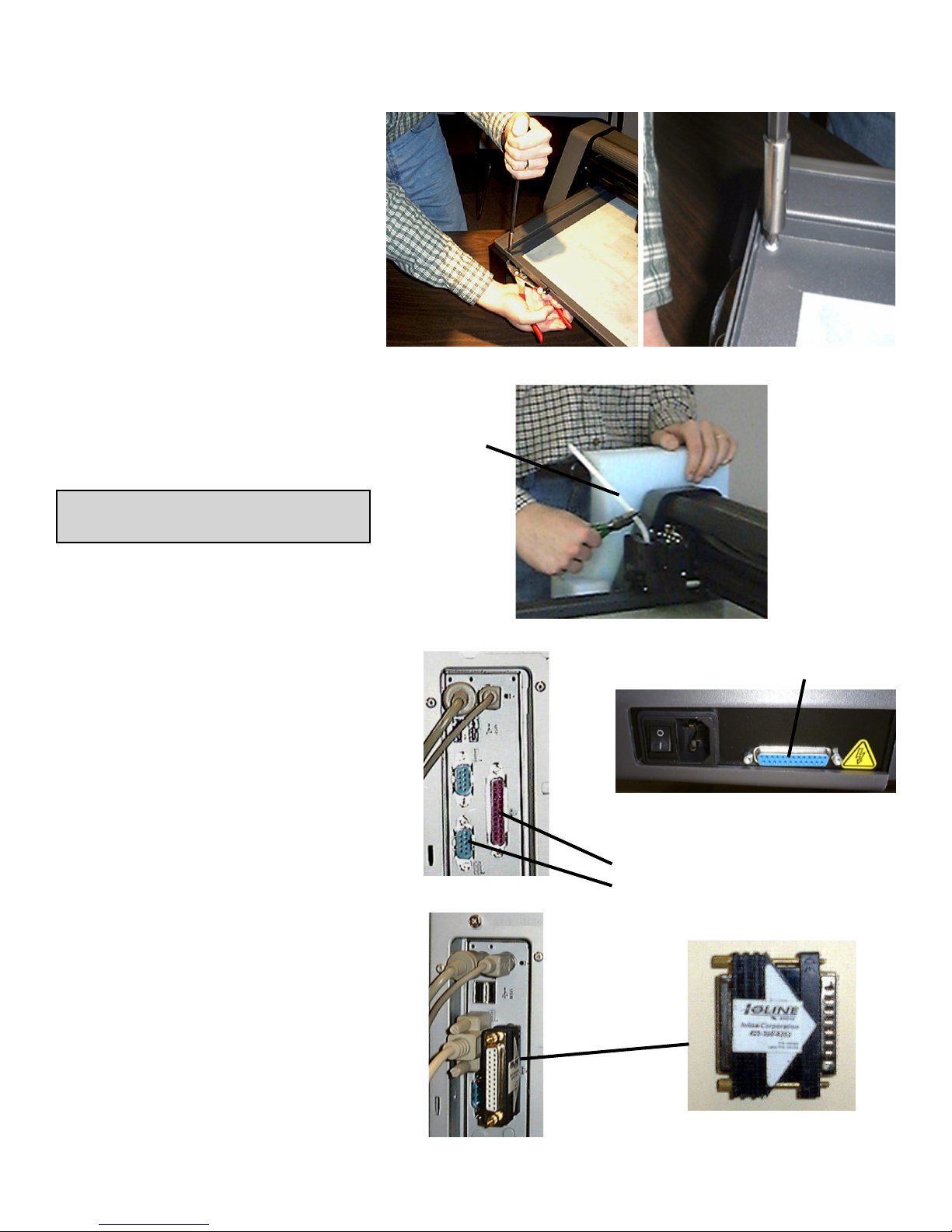

Cutter Connections

1. Insert the power cord into the 300

then plug it into a wall socket or

power strip. Fig. C.

2. Connect the supplied serial cable

to the cutter. Fig. C.

3. Turn the cutter power on. The

Table will move to the back and

the Carriage to the right. The

Keypad light will turn red when the

cutter is finished initializing.

Figure A: Removing the shipping screws (4) from the Table.

Tie Wrap

Figure B: Cut the shipping tie wrap holding the Carriage.

Plotter Serial Port: 25 Holes (Female)

Figure C: The rear panel on the 300. Power

Switch, Power Connector, and Serial Port.

Computer Connections

1. Power off the computer. Connect the Ioline 301 Software Key

to the Parallel Port (25 holes).

Figs. D, E & F.

2. Connect the serial cable to the

port on the computer. Use a 925 pin adapter if required. Fig. E.

3. The cable configuration between

the cutter and computer should

resemble the photo in Figure E.

4. Turn the computer power on.

Figure D: Back of computer:

Parallel Port and Serial Port.

Figure E: Cable configuration for the

300 and 301 on the computer.

Computer Parallel Port: 25 Holes (Female)

Computer Serial Port: 9 or 25 Pins (Male)

Figure F: Ioline 301 Software

Key (installed in the Parallel Port

on the computer).

Page 3

300 Quick Start Guide 3

Install Ioline Software

1. Insert the 300 Software CD-ROM into the

CD-ROM drive.

2. The installation should start automatically.

If it does not, go to Start Menu>Run.

Click on Browse and choose the CD-ROM

drive (usually D:\). Select iosetup.exe then

Open and Run.

3. Follow the self-guided installation instructions to install the Ioline Control Center,

301 Software, Acrobat Reader, and all

manuals. Fig G.

4. A window may appear asking to install

Hardlock drivers. Answer ‘Yes’ to all questions.

5. Restart the computer if requested. All icons

chosen in the installation will appear on

the desktop. Fig. H.

Install an Adhesive Sheet

1. Ensure that the light on the 300 Keypad is

red. Press Start/Stop if it is not. Use the

Arrow keys on the Keypad to move the

Table all the way forward.

2. If the Tray is installed in the Table, loosen

the Thumb Nuts and remove it by lifting

up in the front and pulling forward. Place

the tray on a stable surface.

3. Choose an adhesive sheet and backing

material (if required) that will work with

the material planned for cutting. Table 1

is a guide for choosing the proper sheet

and backing types. There is more information about choosing adhesive sheets

in the 300 System User Guide.

Figure G: The 300 software installation screen.

Figure H: Ioline Software Icons.

kcaThgiH

)TH(

kcaTmuideM

)TM(

kcaTwoL

)TL(

dediS2

)S2(gnikcaB

dediS1

)S1(gnikcaB

Table 1: Adhesive sheet and backing material application table.

.slliwttsomhtiw

,rehtaelniht,tlefmircS

.draoblicnetsdnagnihcte

dnanihtrodekcablaestaeH

.slairetameligarf

.slairetamdekcabevisehda

.slairetamnihtezilibatS

esu,teehsesopruplarenegA

-nonotecafrusevisehdasddA

4. Peel the backing paper off of one side.

With the exposed side facing the Tray,

align the corners of the sheet with the “L”

shaped marks in the tray. Fig. J.

5. Smooth the adhesive sheet down until all

bubbles are removed. Leave the paper

cover on the top of the adhesive sheet

until ready to apply material for cutting.

Figure J: Align the adhesive sheet with the System 300 alignment marks.

Page 4

4 300 Quick Start Guide

Apply Cloth & Install the Tray

1. Remove the cover from the Adhesive Sheet

and carefully apply fabric to the Tray. Smooth

all bubbles out of the material. Fig. K.

2. Slide the Tray onto the Table with the Thumb

Nuts facing the front of the machine. Make

sure the rear lip of the Tray fits tightly under

the white strip in the rear of the Table. The

thumb nut posts should drop smoothly into

the slots on the front of the Table.

3. Press the Tray down into the Table and

tighten the Thumb Nuts.

4. Use the Arrow keys on the Keypad to position the Carriage and Table so that the knife

is in lower right corner of the Table. This is

where cutting will start.

5. Press Set Origin on the Keypad. The light

on the Keypad will turn green.

Figure K: Applying material to the Tray.

edalB123

889601NP

tesffo"490.0-°03

nogniyarfsecudeR

dnaslairetameligarf

elbixelfnognillup

.slairetam

Choose a Blade

1. Find the included 322 blade in the accessory

kit. Table 2 shows blade usage information.

2. Unscrew the Foot (Figure N) from the Blade

Holder.

IMPORTANT: The Blades are very sharp and

the tip is fragile. Use caution when inserting

them into the Blade Holder.

3. Insert the Blade into the Blade Holder (Figure N). It will resist at first then slide freely

to a hard stop when properly inserted.

4. Gently turn the Foot onto the Blade Holder

until just before the tip of the blade protrudes

from the opening in the foot.

5. Follow the steps in the 300 System User

Guide to adjust blade exposure and force.

This step is very important!

Blade

Blade

Holder

edalB223

989601NP

tesffo"490.0-°54

.edalbesopruplareneG

.slairetamkcihtstuC

Table 2: Blade application table.

Foot

6. The 300 is ready to cut!

TIP: Properly adjusted blade depth and force

will substantially increase the life of the

blade, adhesive sheet and reduce the

chance of damaging the tray.

Figure N: Blade installation into

the Blade Holder.

A

M

d

a

h

t

e

e

s

i

v

e

s

h

e

e

t

Figure P: A Properly adjusted

Blade.

F

B

o

l

a

o

d

t

e

r

i

a

l

t

o

c

u

t

Loading...

Loading...