TM

Flare

High-Speed CMOS Area Scan Camera Series

2M280 / 4M140

CoaXPress

Copyright © 2011 IO Industries Inc. All rights reserved.

Flare is a pending trademark of IO Industries Inc.

User's Manual

Revision 2.0

2

Flare CXP User's Manual

Notice

The material contained in this manual consists of information that is proprietary to IO

Industries Inc. and may only be used by the purchasers of the product and IO Industries Inc.

authorized distributors or resellers. IO Industries Inc. makes no warranty for the use of its

product and assumes no responsibility for any errors that may appear or for damages

resulting from the use of the information contained in this manual. IO Industries Inc. reserves

the right to make changes to this manual at any time without notice.

Warranty

The Flare CL product family is warranted for one (1) year from the date of purchase unless

otherwise agreed in writing. If the product proves to be defective during this warranty period,

IO Industries Inc. will, at its discretion, either repair or replace the product at no cost. In the

case where a new device is to be provided but the product has been discontinued, a product

with similar or better performance capabilities and features will be provided. This warranty

shall not apply to any damage, defect or failure caused by improper use or inadequate

maintenance of the product.

Certifications

FCC Class A Digital Device or Peripheral – Information to User

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

WARNING

Changes or modifications not expressly approved by IO Industries Inc. could void the user's

authority to operate the equipment.

CE Compliance

This equipment has been certified to conform to the requirements of Council Directive

89/336/EC for electromagnetic compatibility and to comply with the following European

Standards:

• Immunity: EN55024:1998, A1:2001

• Emissions: EN55022:1998 Class A / CISPR 22:1997

All IO Industries Inc. products bearing the CE mark have been declared to be in conformance

with the applicable EEC Council Directives. Note that the use of interconnect cables that are

IO Industries Inc. www.ioindustries.com Revision 2.0

3

not properly grounded and shielded may affect CE compliance.

Flare CXP User's Manual

About IO Industries Inc.

Established in 1991, IO Industries Inc. designs high performance digital imaging products for

applications in manufacturing, research, vehicle-mounted systems, and video game content

creation. Products include PC-based, standalone and peripheral DVR systems; and high

speed CMOS area scan digital cameras.

Contact Information

IO Industries Inc.

12-1510 Woodcock St.

London, Ontario

N6H 5S1 CANADA

Tel: (519) 663-9570

Fax: (519) 663-9571

Sales: sales@ioindustries.com

Technical Support: support@ioindustries.com

IO Industries Inc. www.ioindustries.com Revision 2.0

4

Flare CXP User's Manual

Table of Contents

1 Introduction..............................................................................................................................6

1.1 Camera Highlights...........................................................................................................6

1.2 Sensor Specifications......................................................................................................7

1.3 Cover Glass Transmittance.............................................................................................8

1.4 Monochrome and NIR Spectral Response.....................................................................9

1.5 Color Spectral Response...............................................................................................10

1.6 Bayer Pattern.................................................................................................................10

2 Mechanical............................................................................................................................11

2.1 Mechanical Specifications.............................................................................................12

2.2 Lens Adapter..................................................................................................................12

2.3 Power.............................................................................................................................13

2.4 External Triggers............................................................................................................14

2.5 LED Status Indicator......................................................................................................16

3 Camera Control.....................................................................................................................17

3.1 Register Map..................................................................................................................17

3.2 CoaXPress Output Format............................................................................................24

3.3 Image Windowing..........................................................................................................24

3.4 Image Sub-Sample........................................................................................................26

3.5 Exposure Mode..............................................................................................................27

3.5.1 Free-run programmable exposure.........................................................................27

3.6 Edge-triggered programmable exposure.......................................................................28

3.7 Edge-triggered level-controlled exposure......................................................................29

3.8 Edge-triggered double exposure...................................................................................30

3.9 Frame Period and Exposure .........................................................................................31

3.10 High Dynamic Range Modes.......................................................................................36

3.10.1 Interleaved HDR Exposure Mode........................................................................36

3.10.2 Piecewise HDR Exposure Mode..........................................................................37

3.11 Offset and Gain.............................................................................................................39

3.11.1 Digital Offset........................................................................................................39

3.11.2 Analog Gain.........................................................................................................39

3.11.3 ADC Gain and Ramp Voltage..............................................................................39

3.11.4 Digital Gain..........................................................................................................40

3.12 Image Flipping.............................................................................................................40

3.13 Test Pattern..................................................................................................................41

3.14 Sensor Artifacts............................................................................................................45

3.14.1 Horizontal Line......................................................................................................45

3.14.2 Black Sun.............................................................................................................46

3.15 Bad Pixel Replacement...............................................................................................46

3.16 Command Memory......................................................................................................47

3.17 Camera Reset..............................................................................................................47

3.18 Control Packet CRC....................................................................................................47

IO Industries Inc. www.ioindustries.com Revision 2.0

5

3.19 Device Discovery.........................................................................................................47

4 Optional RS-485 Control.......................................................................................................48

4.1 RS-485 Command Summary........................................................................................48

5 Accessories...........................................................................................................................54

6 Document Revision History...................................................................................................54

7 Firmware Revision History....................................................................................................55

Flare CXP User's Manual

IO Industries Inc. www.ioindustries.com Revision 2.0

6

Flare CXP User's Manual

1 Introduction

The Flare CoaXPress (CXP) series is a family of high-speed CMOS area scan cameras

designed for a broad range of applications. Table 1 shows the camera models covered in this

manual.

Model Resolution Color Output Format

2M280MCX

2M280CCX Bayer

2048 x 1088

2M280CCX-NF Bayer, no IR cut filter

2M280NCX Near Infrared

4M140MCX

4M140CCX Bayer

2048 x 2048

4M140CCX-NF Bayer, no IR cut filter

4M140NCX Near Infrared

Table 1. Covered Flare CXP models

Monochrome

Monochrome

1.1 Camera Highlights

➢ CXP-3 single and dual link output configurations

➢ 2MP max. 280 fps (8-bit), 224 fps (10-bit) - 2M280

➢ 4MP max. 140 fps (8-bit), 112 fps (10-bit) - 4M140

➢ Pipelined global shutter with Correlated Double Sampling (CDS)

➢ High sensitivity with low noise

➢ Multiple High Dynamic Range (HDR) modes

➢ 10-bit ADC resolution (selectable 8/10-bit output)

➢ Programmable and triggered exposure control

➢ Multiple windows with up to 8 separate Regions Of Interest (ROI)

➢ Image Sub-sampling

➢ Rugged aluminum case

➢ C-mount lens adapter, or optionally use T- or CS-mount

➢ Minimum exposure times of 16 µs

➢ Analog (up to 1.6x) and digital (up to 16x) gains

➢ Low power (4.5W @ 24V), Power Over CoaXPress (PoCXP)

CoaXPress

CXP-3

Single and Dual Link

IO Industries Inc. www.ioindustries.com Revision 2.0

7

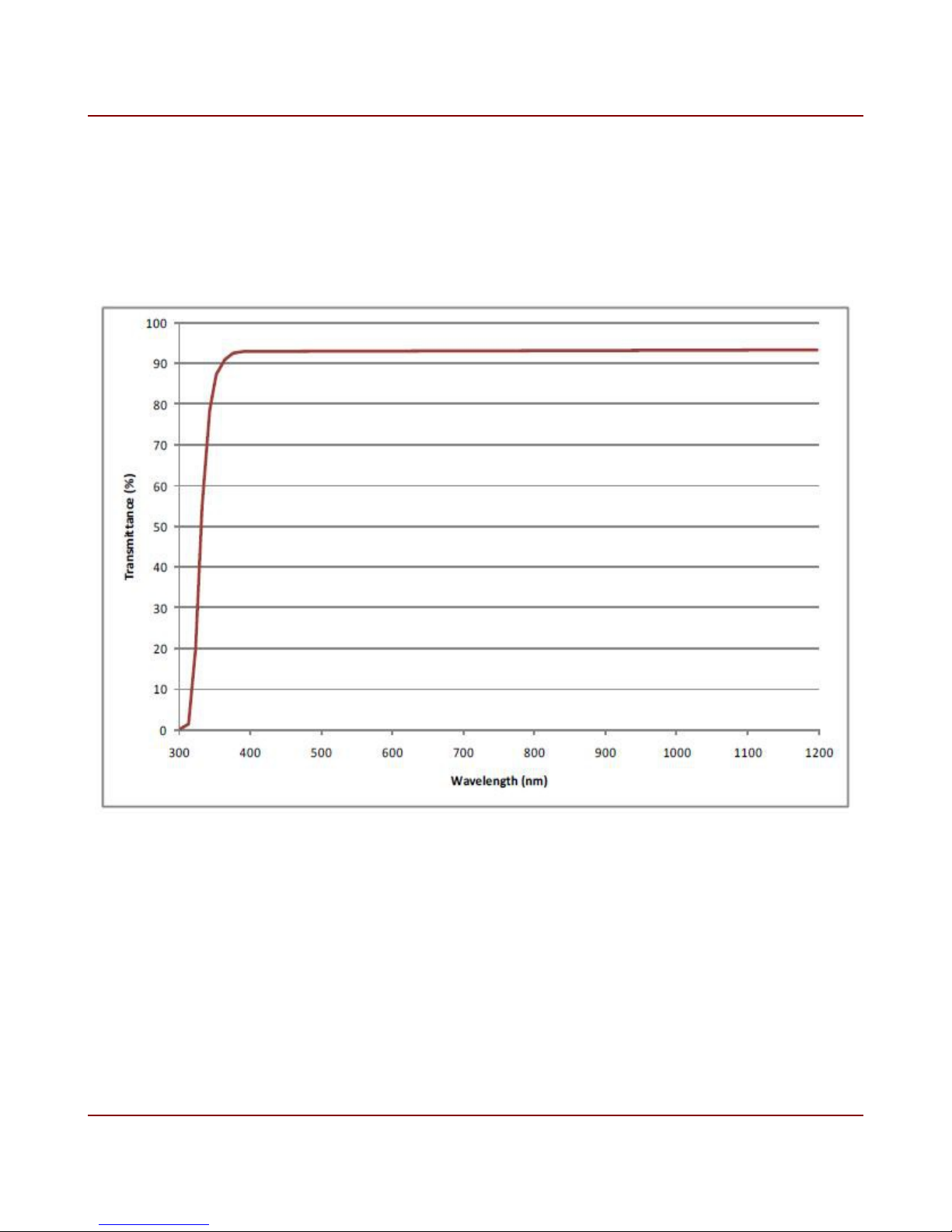

1.2 Sensor Specifications

Specification 2M280 4M140

Effective Pixels 2048 x 1088 2048 x 2048

Optical Format 2/3" 1"

Pixel Pitch 5.5 x 5.5 µm

Full Well Charge 13.5 Ke-

Conversion Gain 0.075 LSB/e-

Sensitivity 5.56 V/lux.s

Temporal Noise 13 e-

Dynamic Range 60 dB

Parasitic Light Sensitivity < 1/50000

Fill Factor < 50% (with micro lenses)

Flare CXP User's Manual

2

Quantum Efficiency < 50% @ 550nm (with micro lenses)

Dark Current Signal 125 e-/s (at 25ºC)

DSNU 3 LSB/s (10-bit)

Fixed Pattern Noise < 1 LSB RMS (10-bit)

PRNU < 1% of signal

Cover Glass Plain D263

Bad Columns ( > 100 pixels) 0

Bad Rows ( > 100 pixels) 0

Bad Pixels

Dark Image: > 6 x FPN Value

Bright Image: < 80% Swing

Cluster Defects ( > 1 pixel) 0

max. 100 max. 200

Table 2. Sensor specifications

IO Industries Inc. www.ioindustries.com Revision 2.0

8

Flare CXP User's Manual

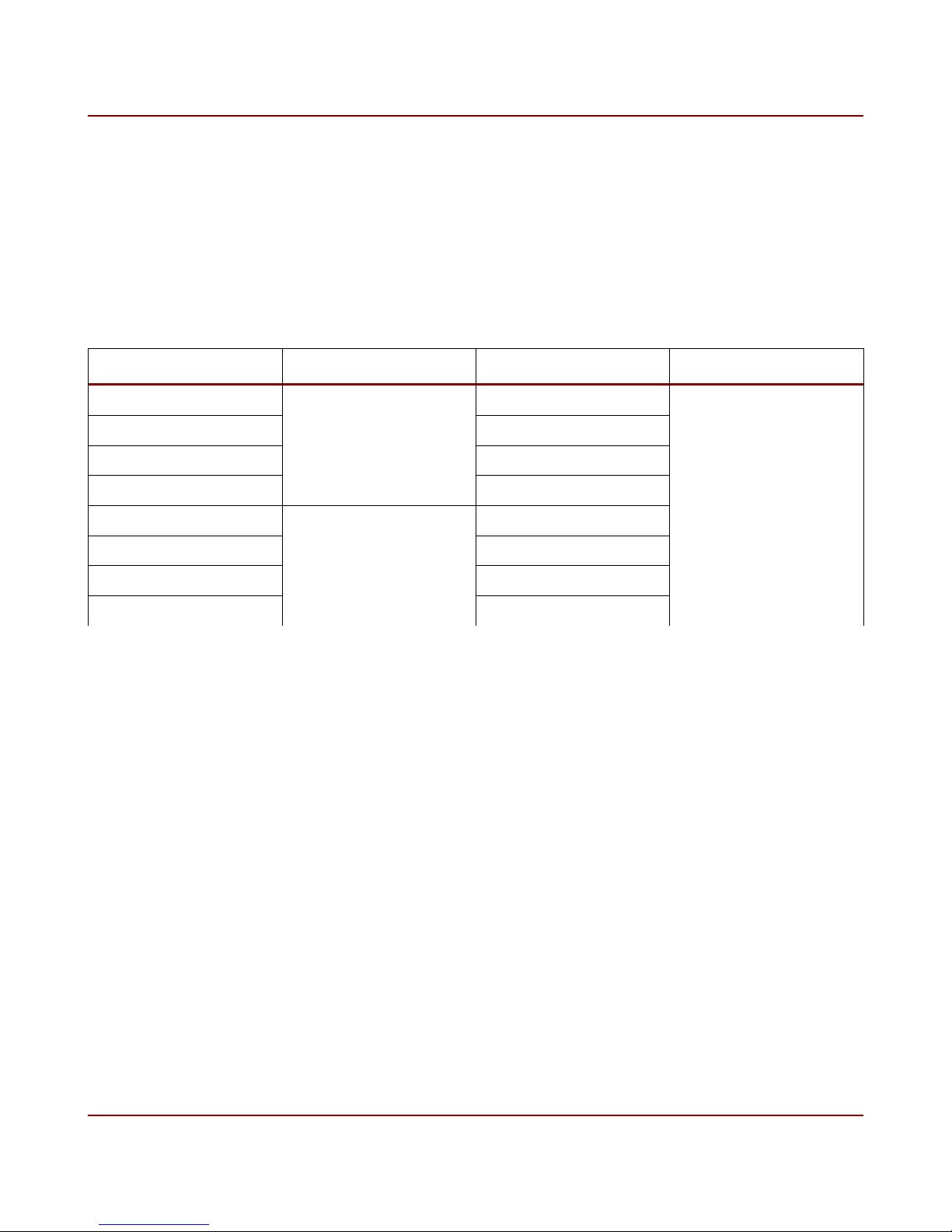

1.3 Cover Glass Transmittance

Plain D263 cover glass is used on all models. The glass transmittance is shown below. The

glass refraction index is 1.52.

Figure 1. Cover Glass Transmittance

IO Industries Inc. www.ioindustries.com Revision 2.0

9

Flare CXP User's Manual

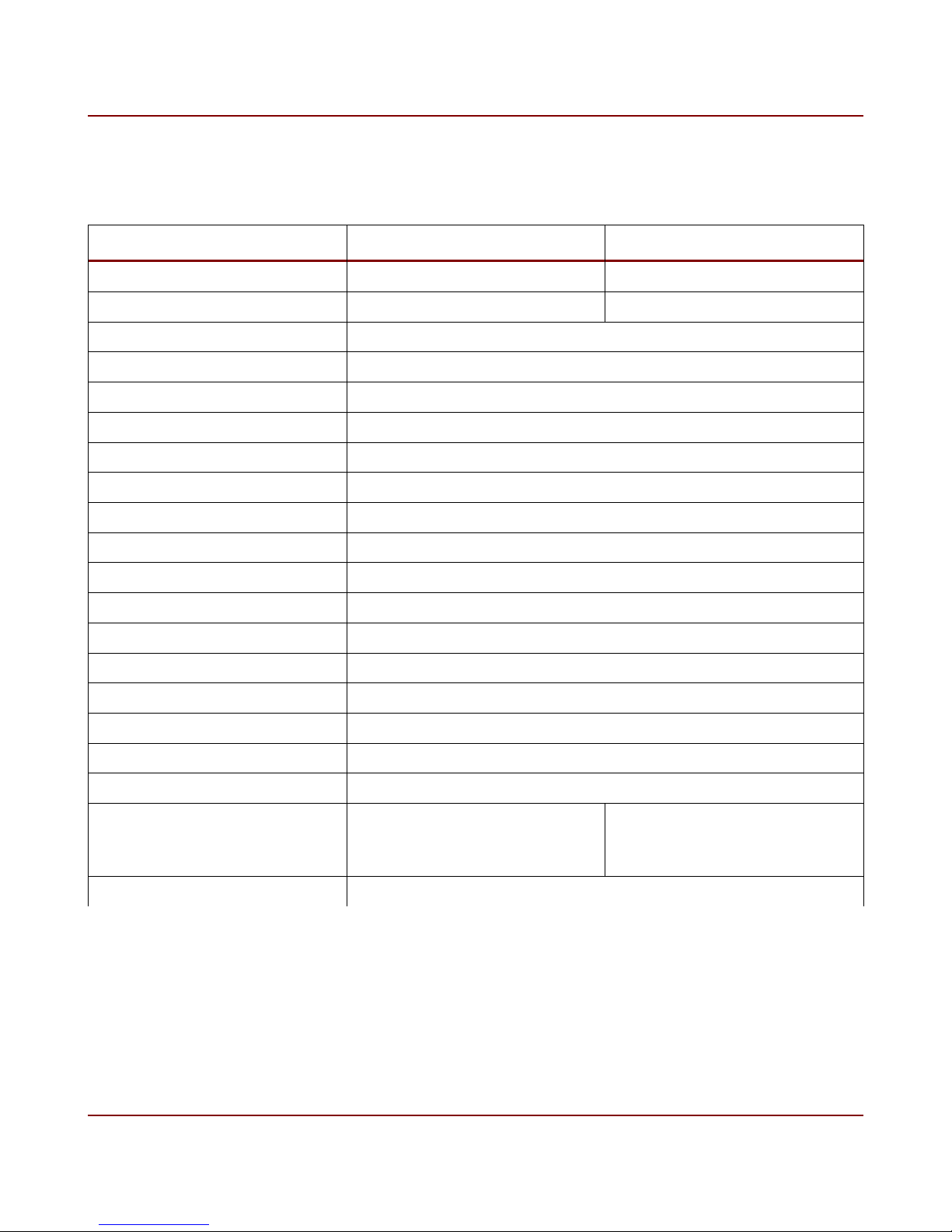

1.4 Monochrome and NIR Spectral Response

A typical spectral response of monochrome 2M280 and 4M140 cameras (normal device) and

near infrared cameras (E12 device), with D263 cover glass, are shown below.

Figure 2. Monochrome and NIR spectral response

IO Industries Inc. www.ioindustries.com Revision 2.0

10

Flare CXP User's Manual

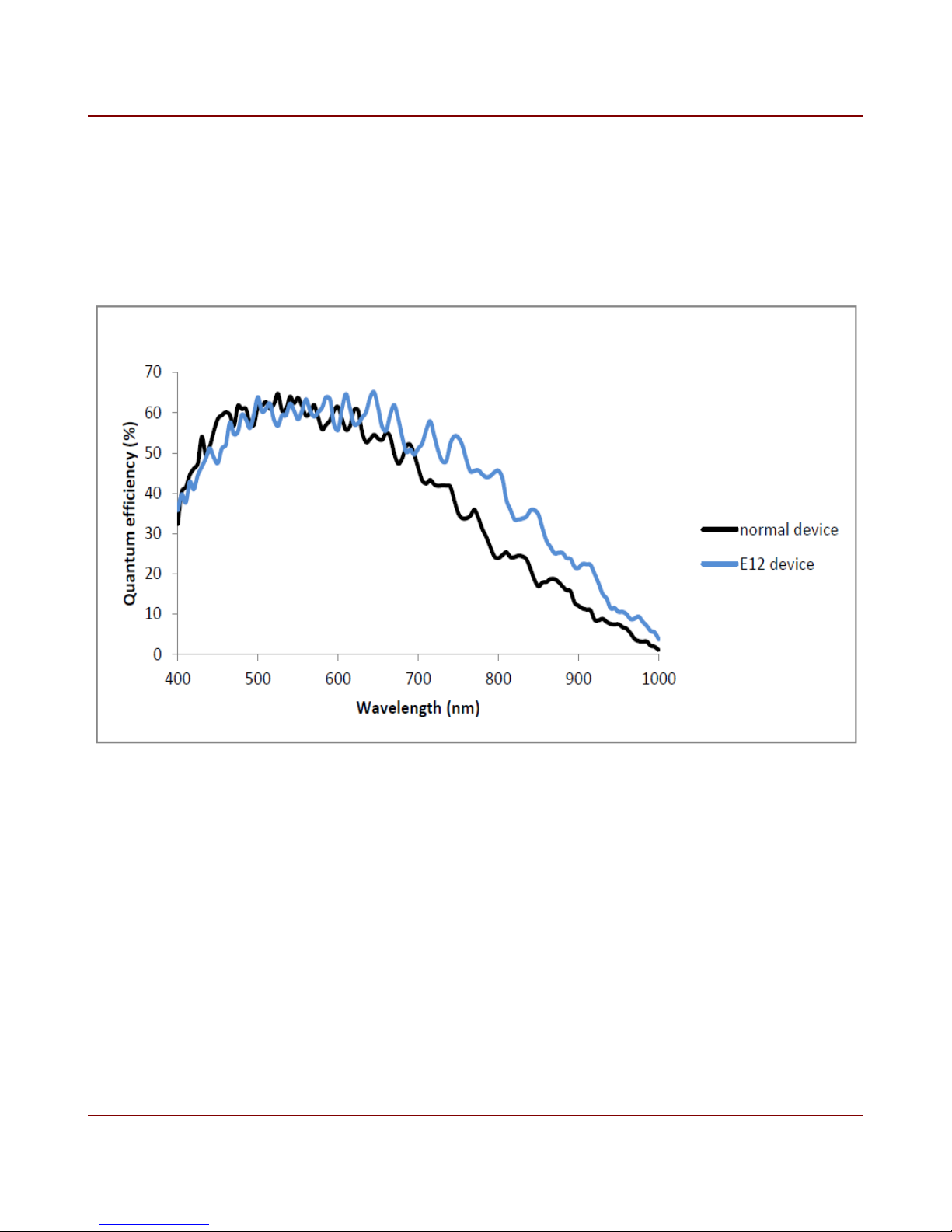

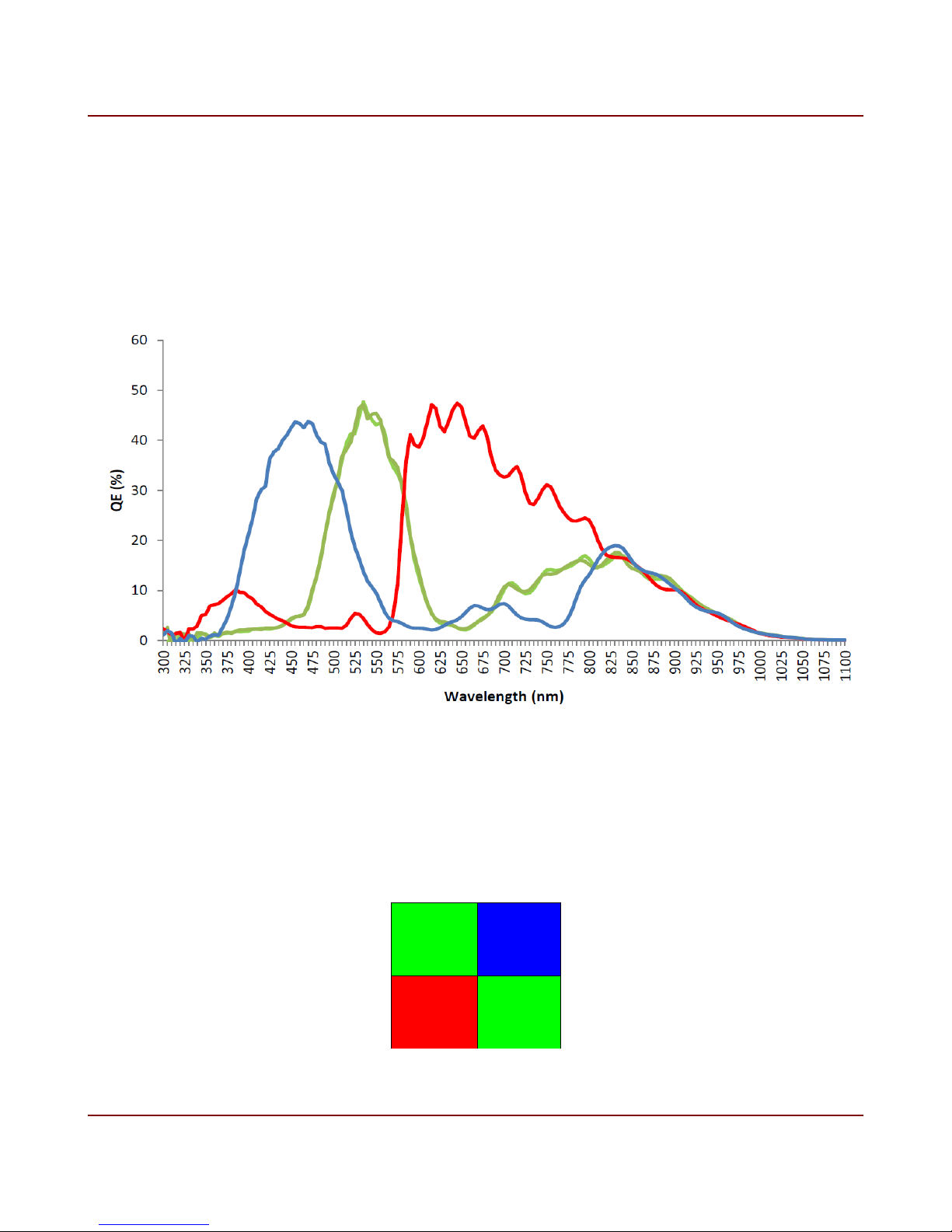

1.5 Color Spectral Response

A typical spectral response of the color 2M280 and 4M140 cameras, with D263 cover glass

and color filters is shown below. Flare color CXP models come standard with an IR cut filter

in the optical path to obtain good color separation. The cutoff wavelength of the filter is

645nm.

Figure 3. Color spectral response

1.6 Bayer Pattern

The 2M280 and 4M140 are both available in color. The Bayer pattern is shown in figure 4.

G

Pixel

(1,1)

R

Pixel

(1,2)

Figure 4. Bayer color filter array pattern

IO Industries Inc. www.ioindustries.com Revision 2.0

B

Pixel

(2,1)

G

Pixel

(2,2)

11

Flare CXP User's Manual

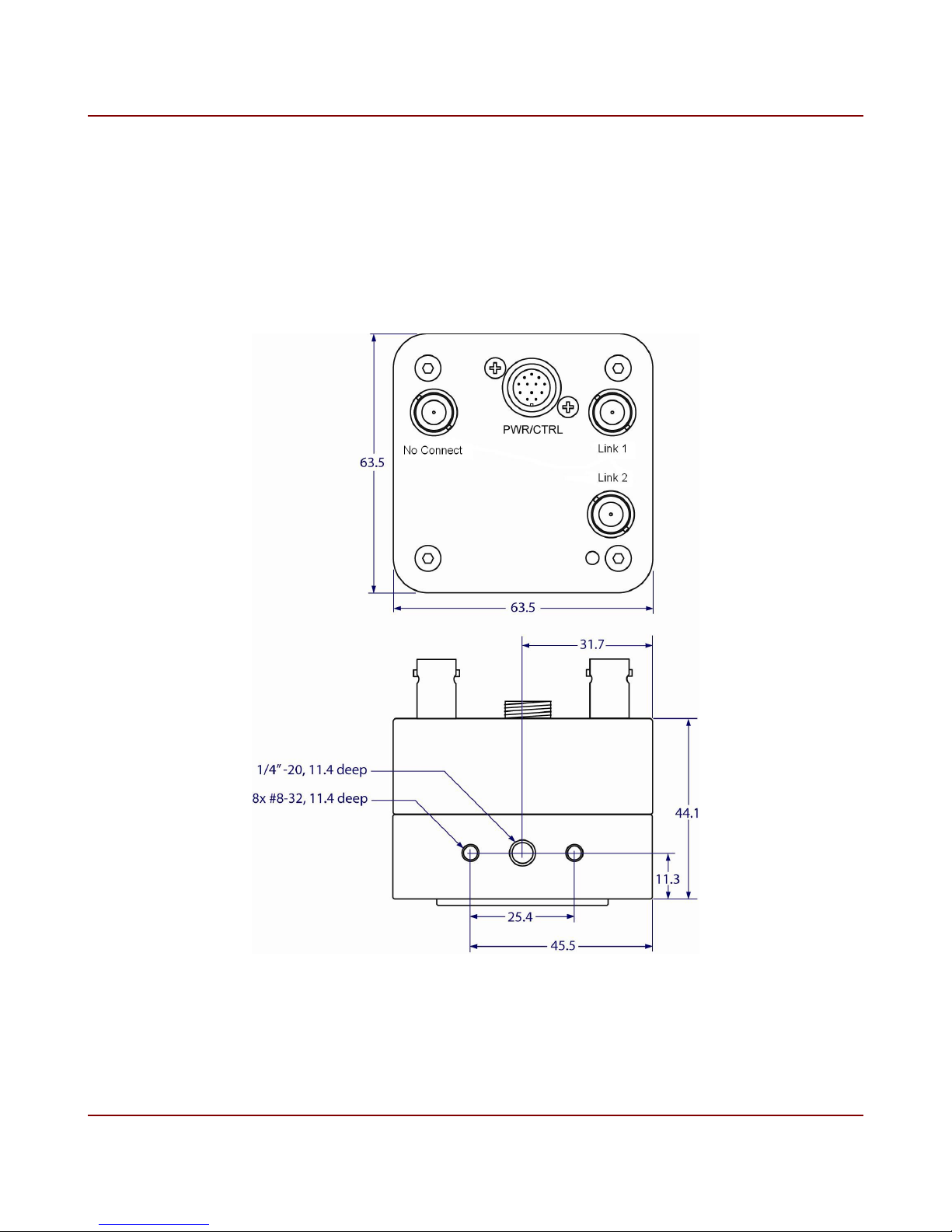

2 Mechanical

Camera housings are made with high precision from machined aluminum. Mechanical

drawings are shown in figure 5.

Figure 5. Mechanical drawings

IO Industries Inc. www.ioindustries.com Revision 2.0

12

Flare CXP User's Manual

2.1 Mechanical Specifications

Summary of mechanical specifications are shown in table 3. Mounting holes on all sides of

the camera provides many mounting options.

Specification Description

Size 63.5 mm x 63.5 mm x 44.1 mm

Weight 318 g

Mounting Holes Bottom - 1x 1/4"-20 (tripod)

All sides - 2 x #8-32, separation 1"

Power Connector 12-pin threaded Hirose

Mating connector part # HR10A-10TPA-12S(73)

Video Output 2 x standard BNC

Table 3. Mechanical specifications

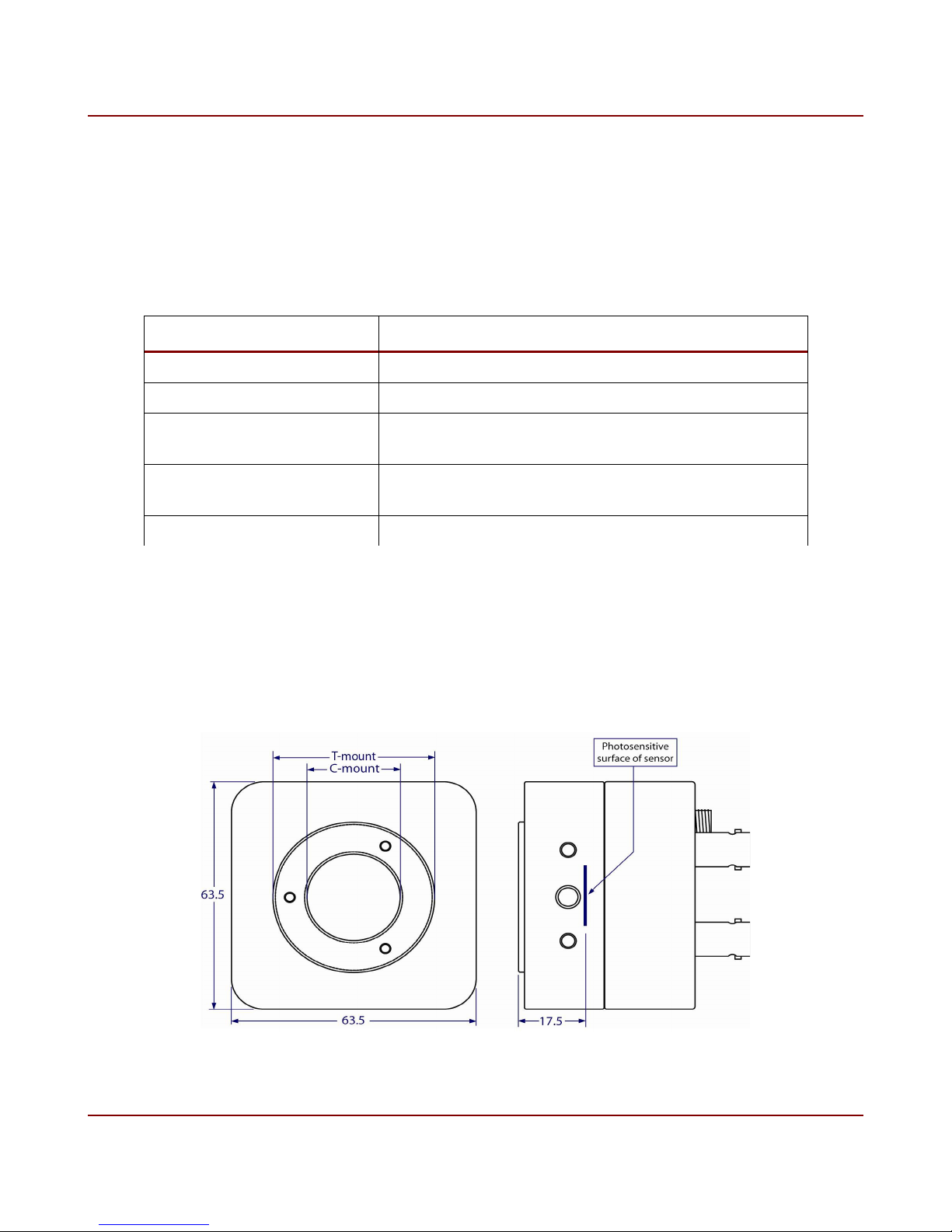

2.2 Lens Adapter

Aluminum C-mount lens adapter precisely calibrated to standardize focal length to sensor,

see figure 6.

Figure 6. Lens adapter

IO Industries Inc. www.ioindustries.com Revision 2.0

13

The position of the lens adapter is set using specialized equipment to ensure the proper back

focus of each camera. Three set screws (M2.5 - 1.3mm hex) on the front of the adapter are

used to firmly hold the ring adapter in place. In most cases it is not recommended to change

the position of the adapter ring. In rare cases the back focus can be adjusted to improve

image sharpness when using lower cost zoom lenses or custom optics.

The size of adapter ring is T-mount, with standard threading. It is possible to use a T-mount

extension tube with T-mount lenses; commonly Telephoto Zoom and Telescope lenses.

Between the adapter ring and the sensor there is another section of C-mount threading. With

a spacer ring (Edmund Optics spacer ring kit G54-461) this section can be used for a CSmount lens. This section can also be used to insert a filter in the optical path of the camera.

Flare CXP User's Manual

2.3 Power

Flare CXP cameras are powered using a 12-24 V ± 10% DC power source. The power

connector is shown in figure 7, and the pinout is shown in table 4.

The camera can optionally be powered over the coax cable (PoCXP) from a compliant frame

grabber on the Link 1 connector only. It is recommended to remove the power adapter from

the camera power connector when using the camera in a PoCXP configuration.

Pin Description Pin Description

1 Trigger Input 1 7 Trigger Return

2 RS485+ 8 Trigger VCC

3 12-24 V 9 RS485-

4 12-24 V 10 Trigger Out 1

5 GND 11 NC

6 GND 12 NC

Table 4. Power connector pinout Figure 7. Power connector

IO Industries Inc. www.ioindustries.com Revision 2.0

14

Flare CXP User's Manual

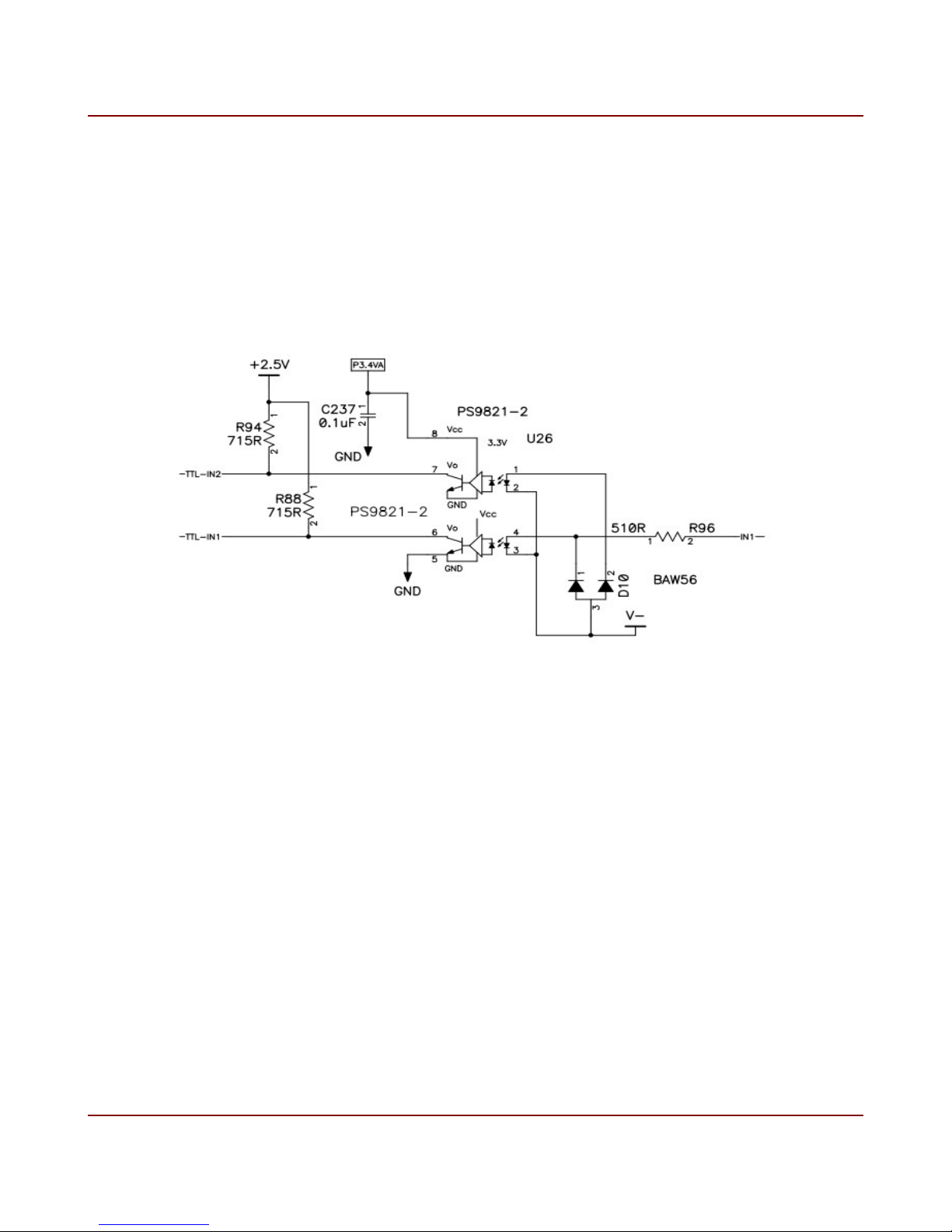

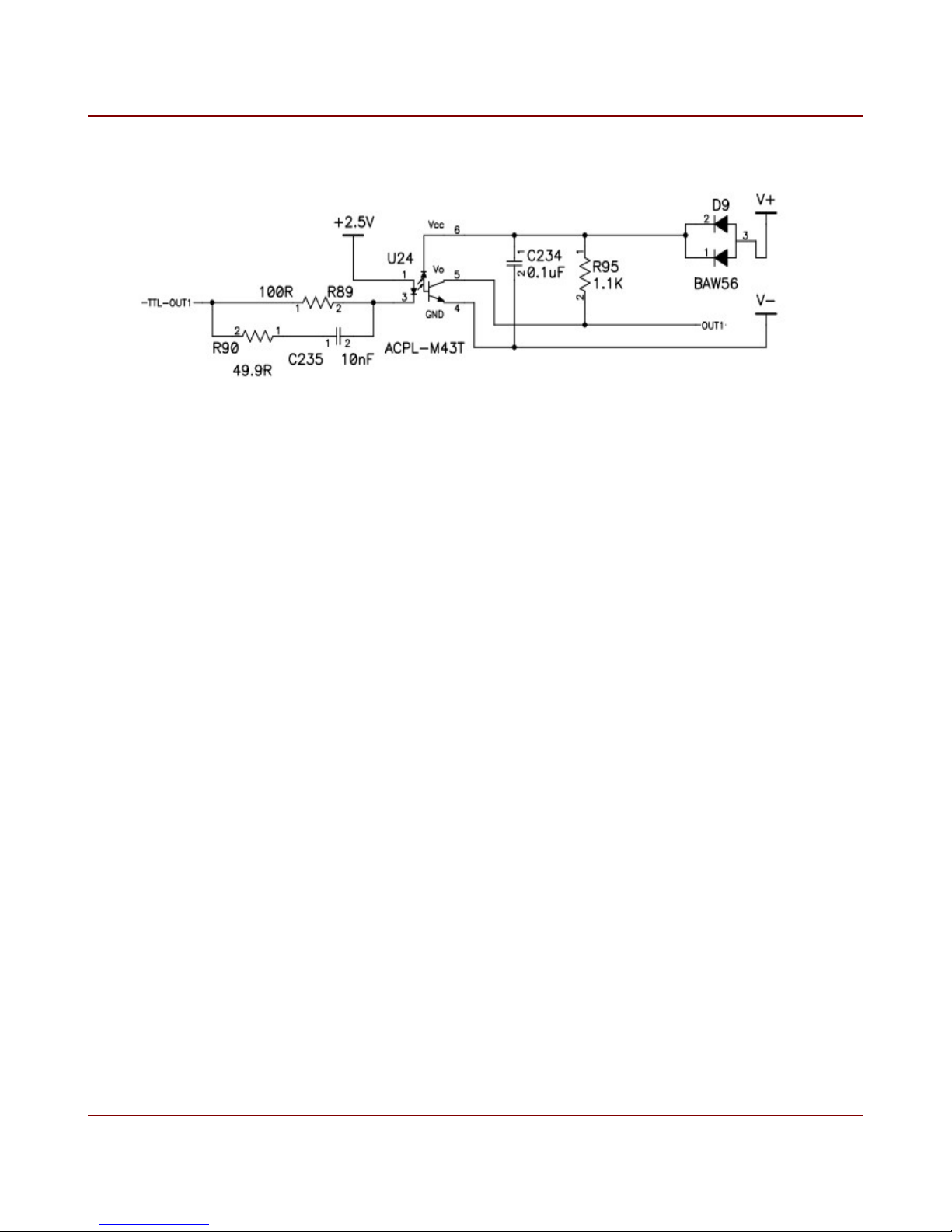

2.4 External Triggers

There is one opto-isolated input on the power connector, pin 1. Only ground must be

provided as a reference for the input. The voltage range on the input is 4.5 to 7.5 V, and the

input delay is approximately 100 ns. The input current range is 6 to 12 mA. The circuit

diagram for the opto-isolated input is shown in figure 8.

Figure 8. Opto-isolated input circuit diagram

The opto-isolated input circuit uses a high-speed photocoupler from Renesas Technology

Corporation, part # PS9821-2. Note TTL-IN2 is not used.

There is one opto-isolated output on the power connector (pins 10 and 9). Power (4.5 to 15

V) and ground must be provided for this output. The maximum output delay is approximately

1 µs. An external pull-up resistor is not required, but if one is used it must be greater than 2

kΩ. The circuit diagram for the opto-isolated output is shown in figure 9.

IO Industries Inc. www.ioindustries.com Revision 2.0

15

Flare CXP User's Manual

Figure 9. Opto-isolated output circuit diagram

The opto-isolated output circuit uses a single channel high speed digital optocoupler (Avago

Technologies part # ACPL-M34T).

IO Industries Inc. www.ioindustries.com Revision 2.0

16

Flare CXP User's Manual

2.5 LED Status Indicator

A tri-color (orange/green/red) LED on the back of the camera is used to indicate operational

status. Table 5 summarizes the operating states indicated by the LED.

LED State Description

Solid Orange Camera is initializing.

Fast flash alternate

Green/Orange

(20ms on, 60ms off)

Solid Green Connected, no data being transferred.

Fast flash Green

(20ms on, 60ms off)

Fast flash Red

(20ms on, 60ms off)

Table 5. LED status

Connection in progress, waiting for StreamPacketSizeMax

bootstrap register to be written with a non zero value.

Will be shown for a minimum of 1 second.

Data being transferred.

Camera error. Issue with internal flash memory or image

sensor.

IO Industries Inc. www.ioindustries.com Revision 2.0

17

3 Camera Control

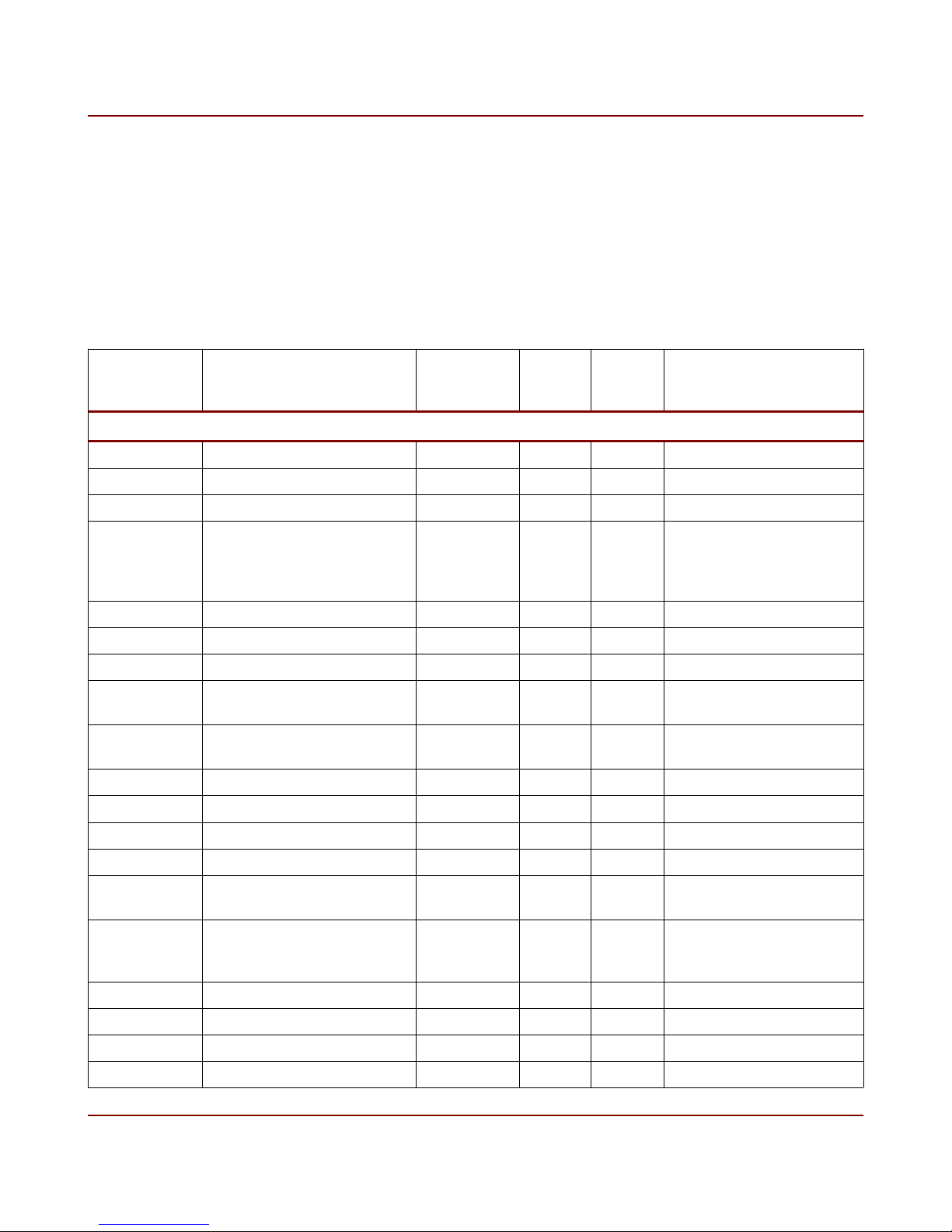

3.1 Register Map

The register map for the Flare CXP cameras is shown in table 6.

Flare CXP User's Manual

Address Name / Description Group Access Length

Description

(bytes)

Bootstrap Registers

0x00000000 Standard Support R 4 Returns 0xC0A79AE5

0x00000004 Revision Support R 4 0x00010000

0x00000008 XmlManifestSize Support R 4 0x00000001

0x0000000C XmlManifestSelector Support R/W 4 0x00000000

Currently only 1 manifest in

camera's non-volatile

memory

0x00000010 XmlVersion Support R 4 0x00010000

0x00000014 XmlSchemaVersion Support R 4 0x00010100

0x00000018 XmlUrlAddress Support R 4 0x00006000

0x0000001C Iidc2Address Support R 4 0x00000000

Not used

0x00002000 DeviceVendorName Genicam R 32 Returns string:

IO Industries Inc

0x00002020 DeviceModelName Genicam R 32 Flare xMxx0 xCX

0x00002040 DeviceManufacturerInfo Genicam R 48 NULL

0x00002070 DeviceVersion Genicam R 32 NULL

0x00002090 DeviceFirmwareVersion Genicam R 32 Returns firmware version

0x000020B0 DeviceID Genicam R 16 Returns device serial

0x000020C0 DeviceUserID Genicam R/W 16 NULL from factory, saved

0x00003000 WidthAddress CXP R 4 Returns 0x40000004

0x00003004 HeightAddress CXP R 4 0x40000008

0x00003008 AcquisitionModeAddress CXP R 4 0x00000000

0x0000300C AcquisitionStartAddress CXP R 4 0x10000020

IO Industries Inc. www.ioindustries.com Revision 2.0

number

to non-volatile memory

when written

18

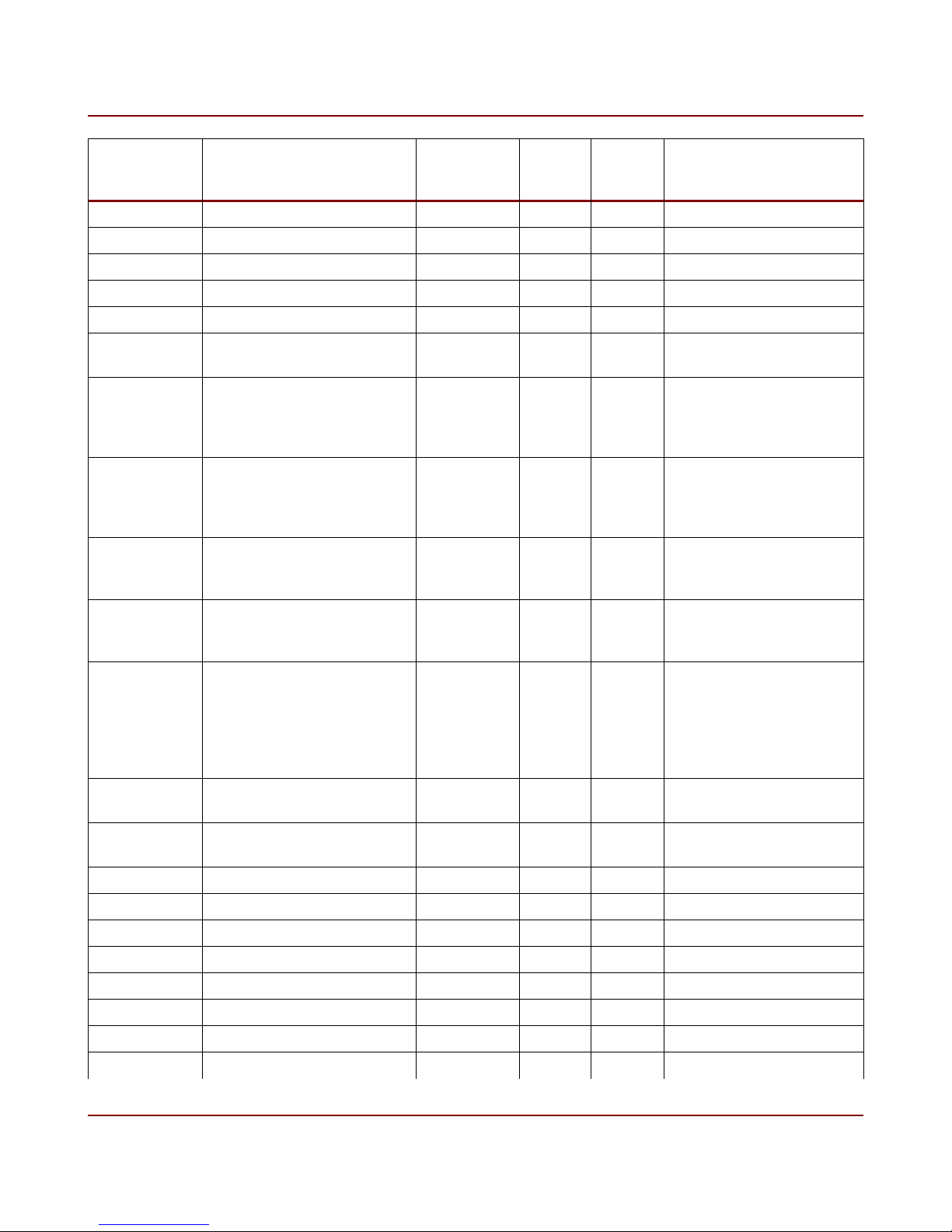

Flare CXP User's Manual

Address Name / Description Group Access Length

Description

(bytes)

0x00003010 AcquisitionStopAddress CXP R 4 0x10000024

0x00003014 PixelFormatAddress CXP R 4 0x40000000

0x00003018 DeviceTapGeometryAddress CXP R 4 0x20000000

0x0000301C Image1StreamIDAddress CXP R 4 0x00007000

0x00003020 Image2StreamIDAddress CXP R 4 0x00007004

0x00004000 ConnectionReset CXP W 4 Write 0x00000001 to reset

connection

0x00004004 DeviceConnectionID CXP R 4 Returns 0x00000000 on

Master Link, and

0x00000001 on Extension

Link

0x00004008 MasterHostConnectionID CXP R/W 4 Returns 0x00000000 after

connection reset, or last

writen value on Master Link

since power up

0x0000400C ControlPacketSizeMax CXP R 4 Max control packet size is

1024 bytes. Returns

0x00000400

0x00004010 StreamPacketSizeMax CXP R/W 4 Write any value, max

packet size used is 2044

bytes

0x00004014 ConnectionConfig CXP R/W 4 Only 3.125Gbps supported

and up to two links. Write

this register to change the

number of links:

1 link – 0x00010038

2 links 0x00020038

0x00004018 ConnectionConfigDefault CXP R 4 Reflects ConnectionConfig

register

0x0000401C TestMode CXP R/W 4 Not implemented (v04

firmware)

0x00004020 TestErrorCountSelector CXP R/W 4 -

0x00004024 TestErrorCount CXP R/W 4 -

0x00004028 TestPacketCountTx CXP R/W 8 -

0x00004030 TestPacketCountRX CXP R/W 8 -

0x00004038 ElectricalComplianceTest CXP R/W 4 -

0x0000403C HsUpconnection CXP R 4 No high-speed uplink

IO Industries Inc. www.ioindustries.com Revision 2.0

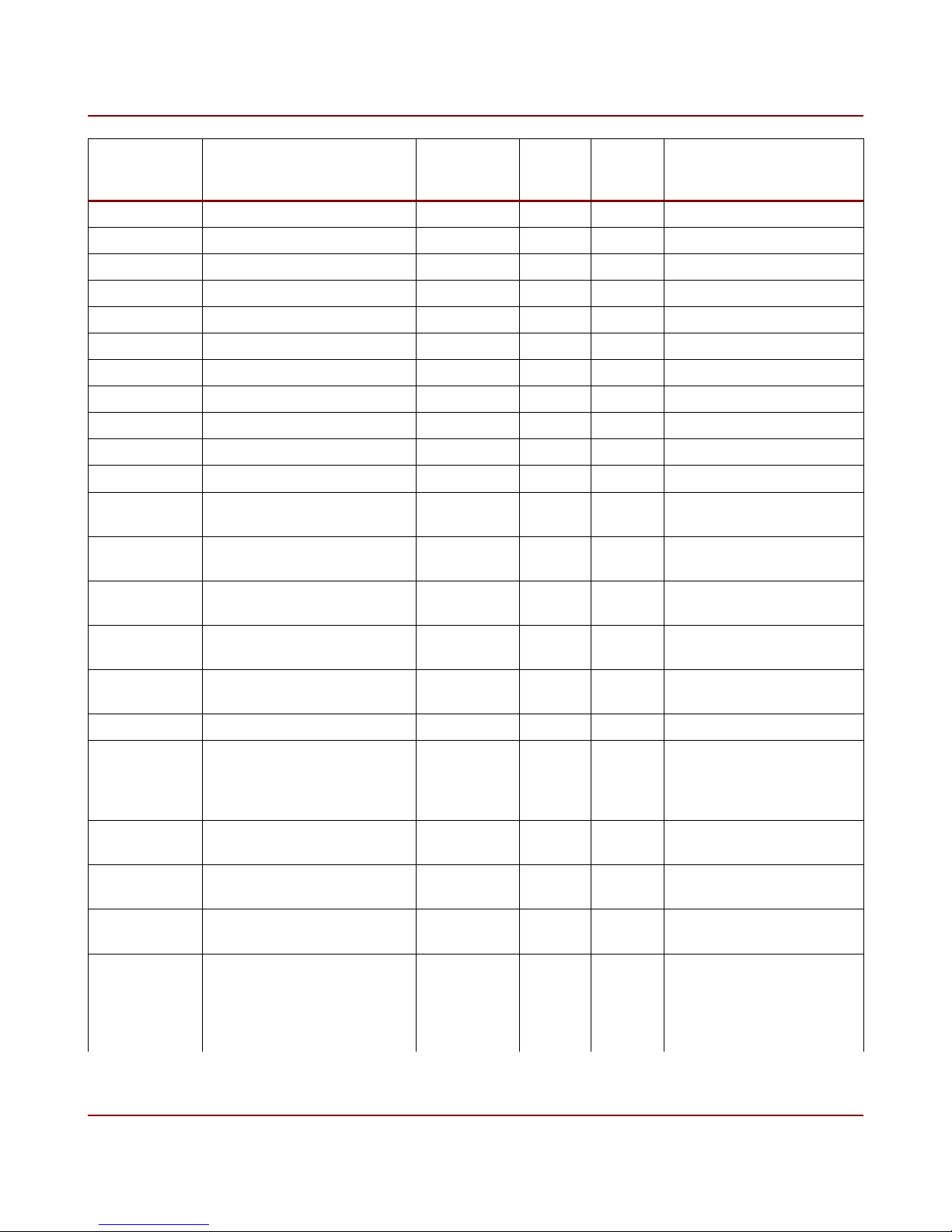

19

Flare CXP User's Manual

Address Name / Description Group Access Length

Description

(bytes)

Command/Status Registers

0x00006000 XML URL String - R - Read to first NULL

character. Example URL:

“Local:IOIndustries_Flare_

2M280CCX_v04.xml;60000

000;95584”

0x00007000 Stream ID #1 R 4 Returns 0x00000001

0x00007004 Stream ID #2 R 4 0x00000000

0x10000020 Acquisition Start W 4 Write 0x00000001 to start

imaging

0x10000024 Acquisition Stop W 4 Write a 0x00000001 to stop

imaging

0x20000000 Tap Geometry R 4 Returns 0x00000000

0x20000004 Width (Current HR) R 4 Returns current horizontal

resolution of the output

image

0x20000008 Height (Current VR) R 4 Returns current vertical

resolution of the outpout

image

0x2000000C Window Update Status R 4 After the Set Window

register is written, if all

settings are valid this

register will return 0. A

value of 1-8 indicates

which window settings are

invalid

0x30001008 Min HR R 4 Minimum horizontal

resolution (16 pixels)

0x30001010 Min VR R 4 Minimum vertical resolution

(4 lines)

0x30001078 Min Frame Period R 4 Minimum frame period, in

µs

0x3000107C Min Exposure 1 R 4 Minimum exposure time 1,

in µs

0x30001080 Min Exposure 2 R 4 Minimum exposure time 2,

in µs

0x30001084 Min Exposure 3 R 4 Minimum exposure time 3,

in µs

0x30002008 Max HR R 4 Maximum horizontal

resolution

IO Industries Inc. www.ioindustries.com Revision 2.0

20

Flare CXP User's Manual

Address Name / Description Group Access Length

Description

(bytes)

0x30002010 Max VR R 4 Maximum vertical

resolution

0x30002078 Max Frame Period R 4 Maximum fame period, in

µs

0x3000207C Max Exposure 1 R 4 Maximum exposure time 1,

in µs

0x30002080 Max Exposure 2 R 4 Maximum exposure time 2,

in µs

0x30002084 Max Exposure 3 R 4 Maximum exposure time 3,

in µs

0x40000000 Pixel Format R/W 4 0 – 8bit

1 – 10bit

0x40000004 Number of Windows R/W 4 Range 1 to 8

0x40000008 Output Horizontal Resolution R/W 4 Horizontal resolution of all

windows

0x4000000C ROI-1 HR Start R/W 4

0x40000010 ROI-1 Vertical Resolution R/W 4

0x40000014 ROI-1 VR Start R/W 4

0x40000018 ROI-2 HR Start R/W 4

0x4000001C ROI-2 VR R/W 4

0x40000020 ROI-2 VR Start R/W 4

0x40000024 ROI-3 HR Start R/W 4

0x40000028 ROI-3 VR R/W 4

0x4000002C ROI-3 VR Start R/W 4

0x40000030 ROI-4 HR Start R/W 4

0x40000034 ROI-4 VR R/W 4

0x40000038 ROI-4 VR Start R/W 4

0x4000003C ROI-5 HR Start R/W 4

0x40000040 ROI-5 VR R/W 4

0x40000044 ROI-5 VR Start R/W 4

0x40000048 ROI-6 HR Start R/W 4

0x4000004C ROI-6 VR R/W 4

0x40000050 ROI-6 VR Start R/W 4

0x40000054 ROI-7 HR Start R/W 4

0x40000058 ROI-7 VR R/W 4

IO Industries Inc. www.ioindustries.com Revision 2.0

21

Flare CXP User's Manual

Address Name / Description Group Access Length

Description

(bytes)

0x4000005C ROI-7 VR Start R/W 4

0x40000060 ROI-8 HR Start R/W 4

0x40000064 ROI-8 VR R/W 4

0x40000068 ROI-8 VR Start R/W 4

0x4000006C Sub-Sample R/W 4

0x40000070 Exposure Mode R/W 4

0x40000074 HDR Mode R/W 4

0x40000078 Frame Period R/W 4 Frame period, in µs

0x4000007C Exposure 1 R/W 4 Exposure time 1, in µs

0x40000080 Exposure 2 R/W 4 Exposure time 2, in µs

0x40000084 Exposure 3 R/W 4 Exposure time 3, in µs

0x40000088 Piecewise HDR Number of

Slopes

0x4000008C Piecewise HDR Voltage 1 R/W 4 Range 0x00000041 -

0x40000090 Piecewise HDR Voltage 2 R/W 4 Range 0x00000040 -

0x40000094 Trigger Source R/W 4 0 – CoaXPress

R/W 4 Range 2 - 3

0x0000007F

0x0000007F

1 – Trigger Input 1

0x40000098 Trigger Edge R/W 4 0 – falling

1 - rising

0x4000009C Black Level Offset R/W 4

0x400000A0 Analog Gain R/W 4 0 – x1.0 gain (default)

1 – x1.2

2 – x1.4

3 – x1.6

0x400000A4 Digital Gain R/W 4 Range 16-256

Gain applied = (value)/16

0x400000A8 ADC Gain R/W 4 Range 0x00000018 t o

0x0000003B

0x400000AC ADC Ramp Voltage R/W 4 Range 0x00000066 to

0x00000073

0x400000B0 Image Flip R/W 4 0 - No image flipping

1 - Image flipping in X

2 - Image flipping in Y

3 - Image flipping in X and

Y

IO Industries Inc. www.ioindustries.com Revision 2.0

22

Flare CXP User's Manual

Address Name / Description Group Access Length

Description

(bytes)

0x400000B4 Opto1 Output Select R/W 4 0 - Disabled (low)

1 - INTE1

2 - INTE2

3 – Internal frame valid

4 – Internal line valid

0x400000B8 Test Pattern R/W 4 0 – off, sensor data

1 – dynamic monochrome

2 – static monochrome

3,4 – reserved

5 – dynamic bayer

6 – static bayer

0x400000BC Horizontal Line Correction R/W 4 0 – off

1 – on

2 – on, output line number

3 – on, add HLC Add value

to line

0x400000C0 HLC Adjust R/W 4 Bit 3 - Sign bit ('0' - add, '1'

- subtract)

Bits 2:0 - Value (0-7)

0x400000C4 Black Sun Correction R/W 4 0 – off

1 – on

0x400000C8 Bad Pixel Correction R/W 4 0 – off

1 – on

0x400000CC Frame Number R/W 4 Replaces first 8 pixels in

image with 8-bit frame

number

0x400000D4 CRC Check Enable R/W 4 0 – do not check control

packet CRC

1 – check control packet

CRC, and report error if

received value does not

match calculated value

0x41000000 User Set Selector R/W 4 Range 0 – 8

0x41000004 User Set Default Selector

(Power-up user set)

0x41000008 User Set Save W 4

0x4100000C User Set Load W 4

0x41000010 Camera Reset W 4

0x41000014 Set Windows W 4

0x50000000 User Set 1 Name R/W 32

0x50000020 User Set 2 Name R/W 32

W 4

IO Industries Inc. www.ioindustries.com Revision 2.0

23

Flare CXP User's Manual

Address Name / Description Group Access Length

(bytes)

0x50000040 User Set 3 Name R/W 32

0x50000060 User Set 4 Name R/W 32

0x50000080 User Set 5 Name R/W 32

0x500000A0 User Set 6 Name R/W 32

0x500000C0 User Set 7 Name R/W 32

0x500000E0 User Set 8 Name R/W 32

Table 6. Register map

Description

IO Industries Inc. www.ioindustries.com Revision 2.0

24

Flare CXP User's Manual

3.2 CoaXPress Output Format

The CoaXPress downlink outputs are running at CXP-3, or 3.125Gbps. The camera can run

with a single Master link or with two output links, Master + Extension. Write the

ConnectionConfig register to change the number of outputs. For single link write

0x00010038, and for dual link write 0x00020038. The frame period and exposure times will

automatically be adjusted to reflect the change in output bandwidth.

In either mode the output pixel format can be 8 or 10-bit. When using an 8-bit output pixel

depth the sensor is operating with 10-bit ADCs, and only the 8 most significant bits are

outputted.

3.3 Image Windowing

The Flare CXP camera supports up to 8 separate non-overlapping windows. Image

windowing can be used to increase the frame rate of the camera and reduce the amount of

data received by the frame grabber or recording system.

The window parameters are stored in internal registers and are only applied to the sensor and

readout path when the set windows register is written, with any value.

The number of windows can range from 1 to 8 windows, and is set by writing the Number of

Windows register, address 0x40000004.

The horizontal resolution of all windows is the same, and is set between 16 and 2048 in

increments of 8, by writing the Output Horizontal Resolution register, address 0x40000008.

The horizontal start of each window is set individually using the 8 ROI-x HR Start registers.

The default is to start on the first column, set value to 1, and the settings can range up to

2033 in increments of 8.

The vertical start and resolution of the windows are all set independently, using ROI-x VR

Start and ROI-x Vertical Resolution registers, respectively. The minimum resolution is 4 lines,

and the windows cannot overlap.

If there is a bad register value when the Set Windows register (0x41000014) is written, a nonzero value corresponding to the incorrect window will be reflected in the Window Update

Status register, address 0x2000000C. A value of 0 in the status register is confirmation that

the windows were set correctly. If a value is incorrect and the windows are not set, the

register values will return to the last known good value.

An example of 8 sub-windows using the 4M140 is shown in figure 10. The register values

used to generate these 8 sub-windows is shown below:

IO Industries Inc. www.ioindustries.com Revision 2.0

25

➢ Number of Windows - 0x00000008

➢ Output Horizontal Resolution - 0x00000100

➢ ROI-1 HR Start – 0x00000001

➢ ROI-1 Vertical Resolution – 0x00000100

➢ ROI-1 VR Start – 0x00000001

➢ ROI-2 HR Start – 0x00000101

➢ ROI-2 Vertical Resolution – 0x00000100

➢ ROI-2 VR Start – 0x00000101

➢ …

➢ ROI-8 HR Start – 0x00000701

➢ ROI-8 Vertical Resolution – 0x00000100

➢ ROI-8 VR Start – 0x00000701

➢ Set Window – 0x00000001

Flare CXP User's Manual

Full Image Size (4M140 - 2048x2048)

Figure 10. Example of image windowing with 8 sub-windows

IO Industries Inc. www.ioindustries.com Revision 2.0

8 Sub-Windows

256x256 per window

256x2048 overall

26

Flare CXP User's Manual

3.4 Image Sub-Sample

The Sub-Sample register is used to enable image sub-sampling. Set to 0x00000001 to

enable sub-sampling. Every second pixel and every second line are skipped for a

monochrome camera when sub-sampling is enabled. With a Bayer color camera the skipping

is performed in pairs to preserve the Bayer pattern. See figure 11.

The frame rate increases when image sub-sampling is used and the field of view of the

camera remains the same. The frame rate increase depends on the image horizontal

resolution and the CoaXPress output format. The minimum increase in frame rate is

approximately 2 times, and can be up to almost 4 times.

Figure 11. Image sub-sampling example

IO Industries Inc. www.ioindustries.com Revision 2.0

27

Flare CXP User's Manual

3.5 Exposure Mode

The exposure mode of the camera is controlled using the Exposure Mode register, address

0x40000070, and there are four options:

➢ Free-run programmable exposure (register = 0x00000000)

➢ Edge-triggered programmable exposure (0x00000001)

➢ Edge-triggered level-controlled exposure (0x00000002)

➢ Edge-triggered double exposure (0x00000003)

3.5.1 Free-run programmable exposure

In free-run exposure mode an internal timer is used to control the exposure time of a frame.

The primary exposure time is set in microseconds using the Exposure 1 register, address

0x4000007C. The range of the allowable exposure time will change when the frame period

changes (Frame Period register, also in microseconds). The timing for this mode, with High

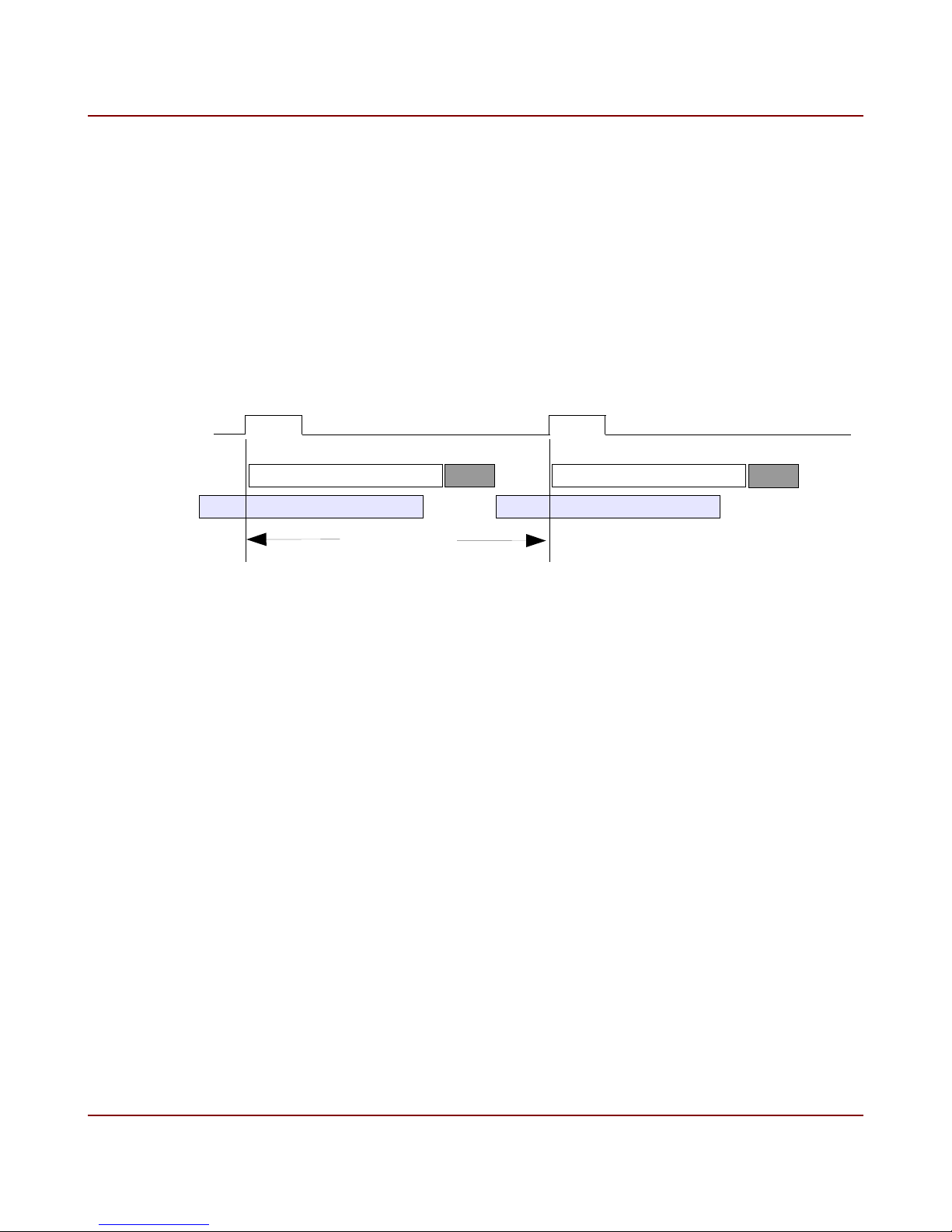

Dynamic Range exposure modes disabled, is shown in figure 12.

Exposure Time, Frame N

FOT

Exposure Time, Frame N+1 FOT Exposure Time, Frame N+2

Readout Time, Frame N

Frame Period

Readout Time, Frame N+1

Figure 12. Free-run exposure timing

In figure 12 the example timing is shown with the exposure time less than the readout time.

The fully pipelined architecture of the sensor allows for the next integration period to start

while the previous frame is being read out. There is a Frame Overhead Time (FOT) period

after exposure ends and before the readout of the frame begins. The next exposure cannot

start in the FOT period. The FOT varies with output formats and the image horizontal

resolution, see tables 7 and 8.

IO Industries Inc. www.ioindustries.com Revision 2.0

28

Flare CXP User's Manual

3.6 Edge-triggered programmable exposure

In edge-triggered programmable exposure mode an internal timer is used to control the

exposure of a frame, however, exposure does not start until the active edge of the input

trigger is seen. The primary exposure time is set using the Exposure 1 register, and the time

is set in microseconds. The frame period command has no effect in this mode. The range of

the exposure time will be set according to the maximum frame period allowed for the current

output format. The timing for this mode, with High Dynamic Range exposure modes disabled,

is shown in figure 13.

Input Trigger

(rising edge)

Exposure Time, Frame N FOT

Readout Time, Frame N-1

Frame Period

Exposure Time, Frame N+1

Readout Time, Frame N

FOT

Figure 13. Edge-triggered programmable exposure timing

Exposure starts when the active edge of the input trigger is seen. The active edge can be set

to rising or falling (Trigger Edge register). The trigger used can be the CoaXPress input

trigger received on the uplink signal (Trigger Source register, value 0x00000000) or the opto-

isolated input on the power connector (Trigger Source register, value 0x00000001). There is

a Frame Overhead Time (FOT) period after the exposure ends, same as free-run mode, and

then readout of the frame begins.

The minimum pulse width of the input trigger is 200 ns. The delay from the active edge of the

trigger to the start of exposure is approximately 200 ns.

Exposure of the next frame cannot start until the readout of the current frame begins. Also

exposure cannot end during the readout of the previous frame. The camera will not look for a

new trigger pulse until N microseconds have elapsed after readout begins, where N =

Readout Time - Exposure Time, if the exposure time is less than the readout time. With large

swings in exposure time it is likely that a trigger will be ignored to keep the correct timing on

the sensor.

IO Industries Inc. www.ioindustries.com Revision 2.0

29

Flare CXP User's Manual

3.7 Edge-triggered level-controlled exposure

In edge-triggered level-controlled exposure mode the exposure of the frame is controlled by

the active state of the input trigger. The frame period and exposure commands have no effect

in this mode. The High Dynamic Range exposure modes are not available in this mode. The

timing for this mode is shown in figure 14.

Frame Period

Input Trigger

(active high)

Exposure Time, Frame N Exposure Time, Frame N+1

FOT

FOT

Readout Time, Frame N-1

EOT EOT

Readout Time, Frame N

Figure 14. Edge-triggered level-controlled exposure timing

In this mode exposure starts when the input trigger transitions into the active state. Exposure

continues until the trigger transitions into the non-active state. The active state can be set to

low or high (Trigger Edge register).

There is a Frame Overhead Time (FOT) period after the sensor is triggered to stop integration

before the readout starts. When the sensor enters this FOT period there is a portion of time

where the photodiodes are still being exposed to light before the charge is transferred to the

storage elements. This Exposure Overhead Time (EOT), shown in figure 16, is a known

constant value and only depends on the CoaXPress output format. For programmable

exposure modes this time is included in the exposure time value.

The minimum pulse width is 1 µs.

Exposure of the next frame cannot start until the readout of the current frame begins. Also

exposure of the next frame cannot end during the readout of the current frame. To ensure

this condition is met the camera does not look for the end of exposure transition until the

readout of the current frame has completed.

IO Industries Inc. www.ioindustries.com Revision 2.0

30

Flare CXP User's Manual

3.8 Edge-triggered double exposure

In edge-triggered double exposure mode two frames are captured in rapid succession when a

single trigger edge is seen. This type of exposure mode is typically used in Particle Image

Velocimetry (PIV) and Particle Tracking Velocimetry (PTV) applications.

The first frame's exposure starts when the active trigger edge is detected and the exposure

time is set in the Exposure 1 register. The first frame corresponds to the 'short' exposure

frame. After the Frame Overhead Time period of the first frame, exposure of the second

frame automatically starts and the duration is equal to the frame readout time. The second

frame corresponds to the 'long' exposure frame. Starting the second frame exposure

automatically ensures the smallest time between the frame exposures. The timing of this

mode is shown in figure 15.

Trigger

(rising)

Programmed

Exposure Time,

Frame N

FOT

EOT

Automatic Exposure Time,

Frame N+1

Readout Time, Frame N

FOT

EOT

Programmed

Exposure Time,

Frame N

Readout Time, Frame N+1

FOT

EOT

Inter-frame Time

Figure 15. Edge-triggered double exposure timing

The inter-frame time between exposures is equal to the Frame Overhead Time (FOT) minus

the Exposure Overhead Time (EOT). See table 7 for the minimum inter-frame times for the

2M280 and table 8 for the 4M140. The minimum inter-frame time for the fastest 2M280

configuration is 21 µs. The minimum inter-frame time for the fastest 4M140 configuration is

48 µs.

IO Industries Inc. www.ioindustries.com Revision 2.0

31

Flare CXP User's Manual

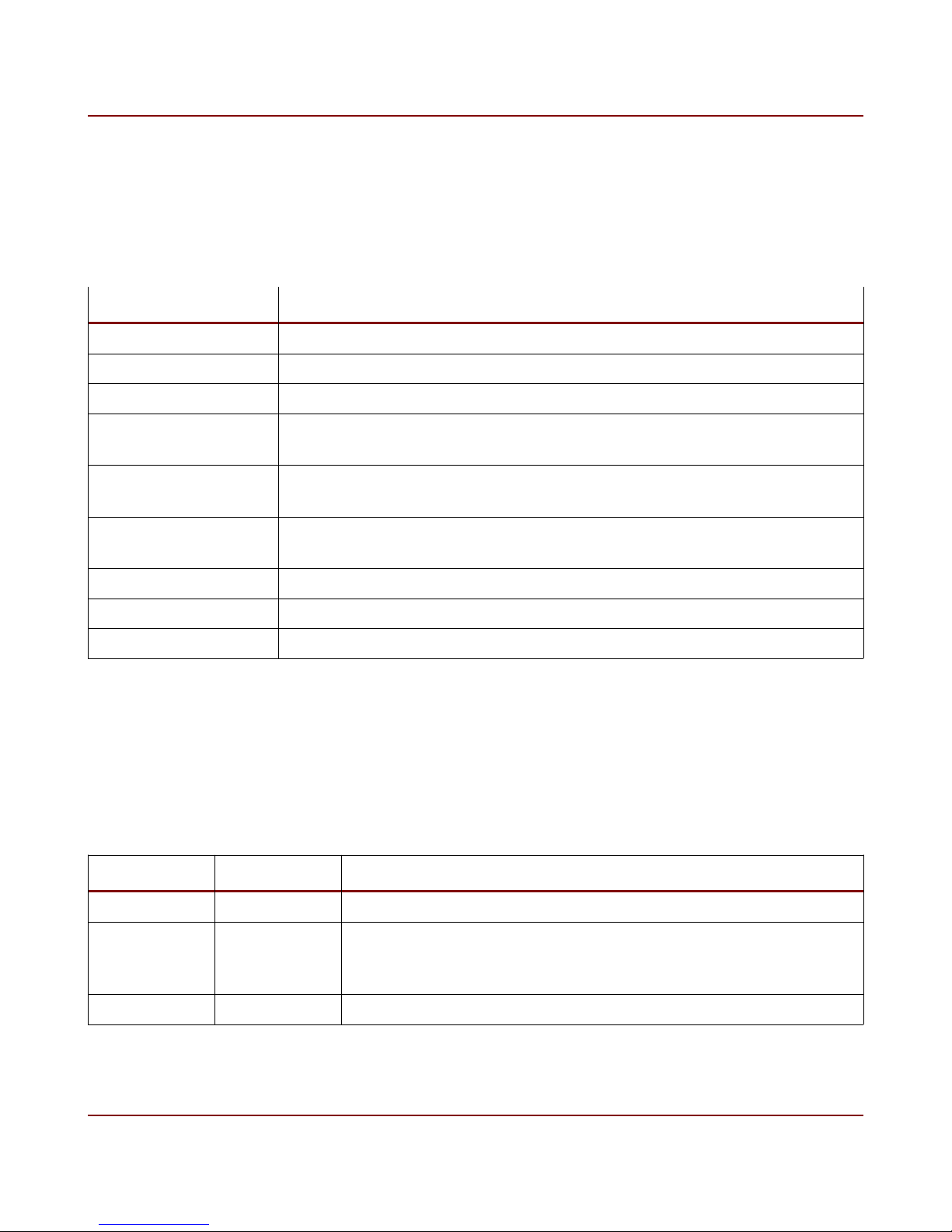

3.9 Frame Period and Exposure

The frame period in free-run exposure mode is controlled with the Frame Period register,

address 0x400000078. The frame period is specified in microseconds. The minimum frame

period of the camera (maximum frame rate) is determined by the output format and the

resolution. Assuming free-run operation and that the exposure time is less than the readout

time the frame period is calculated as follows:

➢ Frame Period = Frame Overhead Time + Readout Time

The Frame Overhead Time (FOT) depends on the output format and the horizontal resolution.

Table 7 shows the FOT period for the 2M280 given the configuration of the camera. Table 8

shows the FOT period for the 4M140.

The Exposure Overhead Time (EOT) which is included in the programmable exposure times,

and which must be considered in the level-controlled exposure, is also shown in tables 7 and

8.

The readout time of a frame is equal to the number of lines in the output image multiplied by

the line time. Line times are also shown in tables 7 and 8.

IO Industries Inc. www.ioindustries.com Revision 2.0

32

Flare CXP User's Manual

CoaXPress Output

Format

Single Link

1 x CXP-3

10-bit

8-bit

Horizontal Resolution FOT

(in µs)

2048 ≥ HR > 1792 49 15 6.88 34

1792 ≥ HR > 1536 43 14 6.14 29

1536 ≥ HR > 1024 38 12 5.38 26

1024 ≥ HR > 896 42 15 3.44 27

896 ≥ HR > 768 37 14 3.07 23

768 ≥ HR 33 12 2.69 21

2048 ≥ HR > 1792 61 19 8.6 42

1792 ≥ HR > 1536 54 17 7.59 37

1536 ≥ HR > 1280 46 14 6.45 32

1280 ≥ HR > 1024 38 12 5.38 26

1024 ≥ HR > 896 52 19 4.3 33

896 ≥ HR > 768 46 17 3.79 29

EOT

(in µs)

Line Time

(in µs)

Minimum

Inter-Frame

Time (in µs)

768 ≥ HR > 640 39 14 3.23 25

640 ≥ HR 33 12 2.69 21

2048 ≥ HR > 1792 42 15 3.44 27

Dual Link

2 x CXP-3

8-bit

10-bit

1792 ≥ HR > 1536 37 14 3.07 23

1536 ≥ HR 33 12 2.69 21

2048 ≥ HR > 1792 52 19 4.3 32

1792 ≥ HR > 1536 46 17 3.79 29

1536 ≥ HR > 1280 39 14 3.23 25

1280 ≥ HR 33 12 2.69 21

Table 7. 2M280 FOT, EOT and line time periods

IO Industries Inc. www.ioindustries.com Revision 2.0

33

Flare CXP User's Manual

CoaXPress Output

Format

Single Link

1 x CXP-3

10-bit

8-bit

Horizontal Resolution FOT

(in µs)

2048 ≥ HR > 1792 83 15 6.88 68

1792 ≥ HR > 1536 74 14 6.14 60

1536 ≥ HR > 1024 65 12 5.38 53

1024 ≥ HR > 896 76 15 3.44 61

896 ≥ HR > 768 68 14 3.07 54

768 ≥ HR 60 12 2.69 48

2048 ≥ HR > 1792 104 19 8.6 85

1792 ≥ HR > 1536 92 17 7.59 75

1536 ≥ HR > 1280 78 14 6.45 64

1280 ≥ HR > 1024 65 12 5.38 53

1024 ≥ HR > 896 95 19 4.3 76

896 ≥ HR > 768 84 17 3.79 67

EOT

(in µs)

Line Time

(in µs)

Minimum

Inter-Frame

Time (in µs)

768 ≥ HR > 640 71 14 3.23 57

640 ≥ HR 60 12 2.69 48

2048 ≥ HR > 1792 76 15 3.44 61

Dual Link

2 x CXP-3

8-bit

10-bit

1792 ≥ HR > 1536 68 14 3.07 54

1536 ≥ HR 60 12 2.69 48

2048 ≥ HR > 1792 95 19 4.3 86

1792 ≥ HR > 1536 84 17 3.79 67

1536 ≥ HR > 1280 71 14 3.23 57

1280 ≥ HR 60 12 2.69 48

Table 8. 4M140 FOT, EOT and line time periods

IO Industries Inc. www.ioindustries.com Revision 2.0

34

Flare CXP User's Manual

The camera re-calculates the allowable range for the frame period when the output format or

resolution is changed. The camera will also adjust the current frame period to the new

minimum value. The range for the exposure times is also re-calculated, and if any current

setting is outside of the range it will be adjusted to the maximum time.

Frame rate calculation example:

➢ 2M280 in Dual Link 8-bit with a single window set to 1280 x 720 (no sub-sample)

• Frame Period = FOT + Readout Time

• = 33 µs + 720 (2.69 µs)

• = 1970 µs

• Frame Rate = 1 / Frame Period = 507.6 Hz

Note that the camera uses a 4.10 fixed point value for the line time to calculate the frame

period, so the actual frame period reported by the camera may be slightly different than those

calculated using floating point math.

Tables 9 shows some sample frame rates. Even with a larger FOT the 4M140 frame rates

are within ½ Hz of the 2M280 rates, at the same resolution.

Maximum Frame Rate

(Hz)

Single

8-bit

2048

x

2048*

82 134 133 255 280 756 1476

1600

x

1200*

1920

1080

x

Resolution

1280

x

720

1024

x

1024

640

x

480

320

x

240

Link

1 x CXP-3

56 108 106 141 224 756 1476

140 266 266 508 359 756 1476

Dual Link

10-bit

8-bit

2 x CXP-3

10-bit

112 215 212 508 359 756 1476

Table 9. Sample frame rates (* 4M140 only)

IO Industries Inc. www.ioindustries.com Revision 2.0

35

In programmable exposure modes the minimum exposure time is set to the Exposure

Overhead Time (EOT) plus 1 µs. In level-controlled exposure mode the minimum trigger

pulse is 1 µs resulting in the same minimum exposure times as the programmable modes.

Table 10 shows the minimum exposure times at full resolution. When the smallest horizontal

resolution 'zone' shown in tables 7 and 8 is used both the 2M280 and 4M140 have minimum

exposure times of 13 µs.

Flare CXP User's Manual

CoaXPress Output

Format

Single Link

1 x CXP-3

Dual Link

2 x CXP-3

Table 10. Minimum exposure times at full resolution

8-bit 16

10-bit 20

8-bit 16

10-bit 20

Min Exposure Time (in µs)

2M280/4M140

IO Industries Inc. www.ioindustries.com Revision 2.0

36

Flare CXP User's Manual

3.10 High Dynamic Range Modes

The HDR Mode register, address 0x40000074, is used to enable a High Dynamic Range

(HDR) exposure mode. The following modes are available:

➢ Interleaved (0x00000001)

➢ Piecewise (0x00000002)

Set the register to zero for normal exposure.

3.10.1 Interleaved HDR Exposure Mode

The Interleaved HDR mode is useful when there are both under and over exposed areas

within a frame. The Interleaved HDR mode will increase the dynamic ranges within these

dark and bright spots revealing detail that would not be seen otherwise.

In Interleaved HDR mode the even and odd lines have different exposure times. The odd

lines (1, 3, 5, ..) are exposed for the programmed time set by the Exposure 1 register. The

even lines (2, 4, 6, ...) are exposed for the programmed time set by the Exposure 2 register.

For a color camera the exposure times apply to pairs of lines to preserve the Bayer pattern.

One exposure time should be set high to see the detail in the dark areas of the image. The

second exposure time should be set low to see the detail in the bright areas of the image. An

'image fuse' filter is required on the host side to combine these two 'fields' into dramatic HDR

images.

Note an image fuse conversion filter comes standard with IO Industries Inc. CoreView©

and Streams© software packages.

For the best results the two fields should be separated and individually scaled up to the full

image size. For a color camera the Bayer demosaicing conversion should be done first. Next

the images can be 'fused' together by averaging the pixels from the two frames. Exposure

times can be used for the multiplication factor for each frame for a more accurate image fuse

(instead of 0.5 when simply averaging).

IO Industries Inc. www.ioindustries.com Revision 2.0

37

Flare CXP User's Manual

3.10.2 Piecewise HDR Exposure Mode

The Flare CXP camera can achieve a high optical dynamic range using the piecewise

exposure mode. This HDR mode is useful when there are over exposed areas within a

frame. The piecewise exposure mode will prevent pixels that are being exposed to large

amounts of light from over saturating while not influencing the response of the darker pixels.

Pixels which reach a programmed voltage will be clipped, while dark pixels will be left

untouched. The clipped pixels are held at this voltage for a programmed period of time. The

programmed voltage and exposure time correspond to a 'kneepoint' which creates another

piece, or slope, in the response curve. Up to two kneepoints can be programmed resulting in

3 slopes in the response curve. An example of piecewise exposure with 2 kneepoints and 3

slopes is shown in figure 16.

Pixel

Reset

Total Exposure

Time

Pixel

Sample

Vhigh

Vkp1

Vkp2

Vlow

Kneepoint 1

Exposure

Figure 16. Example pixel response in Piecewise HDR exposure mode

IO Industries Inc. www.ioindustries.com Revision 2.0

Kneepoint 2

Exposure

38

In figure 16 the green line represents a darker pixel that is not influenced by the kneepoint

settings and will have a normal response. The red line represents a bright pixel which would

be saturated in normal exposure. In piecewise exposure mode the bright pixel reaches the

first kneepoint voltage (Vkp1 in figure) and is held there until the first kneepoint exposure time

starts. The bright pixel continues exposure until it reaches the second kneepoint voltage

(Vkp2 in figure) where it is held again. Finally the pixel continues exposure when the start of

the second kneepoint exposure time is reached.

Table 11 summarizes the registers used in piecewise HDR exposure mode.

Flare CXP User's Manual

Register Range Description

HDR Mode

Exposure 1

Piecewise HDR

Number of Slopes

Piecewise HDR

Voltage 2 (pv2)

Exposure 2 (ex2)

Piecewise HDR

Voltage 1 (pv1)

Exposure 3 (ex3)

0 - 2 0 - Normal exposure

1 - Interleaved HDR mode

2 - Piecewise HDR mode

- Total exposure time in microseconds

2 - 3 Number of slopes.

2 - Kneepoint 1 enabled

3 - Kneepoints 1 and 2 enabled

0x40 - 0x7E Voltage setting for kneepoint 1.

Kneepoint 1 used in both slope cases.

Must be less than setting for kneepoint 2 when using

three slopes.

- Kneepoint 1 exposure time in microseconds.

Pixels are held at the pv2 voltage until (ex1 - ex2)

time has elapsed.

0x41 - 0x7F Voltage setting for kneepoint 2.

Must be greater than kneepoint 1.

- Kneepoint 2 exposure time in microseconds.

Pixels are held at the pv1 voltage until (ex1 - ex3)

time has elapsed.

Must be less than kneepoint 1 exposure time.

Table 11. Summary of registers used in Piecewise HDR exposure mode

IO Industries Inc. www.ioindustries.com Revision 2.0

39

Flare CXP User's Manual

3.11 Offset and Gain

3.11.1 Digital Offset

The dark level offset can be programmed using the Black Level Offset register, address

0x4000009C. The dark level at the output of sensor equals (70 + setting - 16383), Valid

offset setting range is 0 to 16383 (0x3FFF). The offset is a digital value added to the output

signal after the analog to digital conversion. Note that this register always reflects a 10-bit

pixel value range.

3.11.2 Analog Gain

An analog gain can can be applied using the Analog Gain register, address 0x400000A0.

Valid range is 0 to 3, and the corresponding gain values are shown in table 12. The analog

gain is applied by a Programmable Gain Amplifier (PGA) in every column before the analog to

digital conversion.

agn setting Gain

0 x 1 (0 dB)

1 x 1.2 (+1.6 dB)

2 x 1.4 (+2.9 dB)

3 x 1.6 (+4.1 dB)

Table 12. Analog gain settings

3.11.3 ADC Gain and Ramp Voltage

The sensors in the Flare CXP camera series use column ramp Analog to Digital Converters

(ADC). A ramp generator provides the ramp for the ADC reset and pixel measurements

(Correlated Double Sampling). The ADC Gain register can be used to change the slope of

this ramp, producing a 'digital gain'. The ADC Ramp Voltage register can be used to change

the starting voltage of the ramp generator signal. The ADC Gain setting of each camera is

calibrated at the factory to match a desired bit/e value and provide quality, high dynamic

range images. This are advanced settings and in general should not be changed.

The ADC Gain register is savable to the user sets. To load the factory calibrated value write

IO Industries Inc. www.ioindustries.com Revision 2.0

40

the register with a value of 0x00000000. With the parameter set to zero the factory value will

be loaded into the register. The ADC Ramp Voltage register can also be restored to the

factory setting by writing 0x00000000 to the register.

Flare CXP User's Manual

3.11.4 Digital Gain

A digital gain can be applied using the Digital Gain register, address 0x400000A4. The range

on the register value is between 16 and 256, and the digital gain applied to the pixels is as

follows:

➢ Digital Gain = (register value) / 16

The range of the digital gain is 1x (0 dB) up to 16x (+24 dB). The default setting is 16 giving

unity gain. The digital gain is applied to 10-bit pixels read out from the sensor.

3.12 Image Flipping

The output image from the Flare CXP camera can be flipped in the X and/or Y direction using

the Image Flip register, 0x400000B0. Table 13 shows the image flipping options.

Register

Description

Value

0x00000000 No image flipping

0x00000001 Image flipped in X direction

0x00000002 Image flipped in Y direction

0x00000003 Image flipped in both X and Y directions

Table 13. Imaging flipping settings

Figure 17 shows an example of image flipping.

IO Industries Inc. www.ioindustries.com Revision 2.0

41

Flare CXP User's Manual

NO FLIP

Figure 17. Image flipping example

Image flip in the X direction can be useful in an inspection application where two cameras are

placed on either side of the material flow. One camera can be set to image flip in the X

direction resulting in both cameras seeing the flow of material in the same direction. This may

simplify processing software algorithms and aid in an operators view of the material.

Image flip in the X and Y direction is useful when the camera has to be installed upside down.

X DIRECTION

Y DIRECTION X+Y DIRECTION

3.13 Test Pattern

The Flare CXP cameras have a test pattern mode to aid in testing connectivity between the

camera and a frame grabber. The options for the Test Pattern register, address 0x400000B8,

are shown in table 14.

Register Value Description

0x00000000 Image from sensor

0x00000001 Bayer color test pattern with moving lines (dynamic)

0x00000002 Bayer color test pattern without moving lines (static)

0x00000003 or

0x00000004

0x00000005 Dynamic monochrome test pattern

0x00000006 Static monochrome test pattern

Table 14. Test pattern settings

IO Industries Inc. www.ioindustries.com Revision 2.0

Reserved

42

In test pattern mode the camera frame rate is the same as in normal operation. All exposure

modes can be used when the test pattern is enabled. The test pattern image is always a

continuous image with a horizontal resolution set by the Horizontal Resolution register, and a

vertical resolution set by the total of the ROI-1 to ROI-8 Vertical Resolution registers for active

windows. The sensor is not disabled when the test pattern is on. Effects of some

commands, such as gain or high dynamic range modes, may not be visible in the test pattern

image, however, when the test pattern is disabled the images from the sensor will still be

affected.

The horizontal blanking period on the output of the test pattern is set to match the sensor line

rate.

The monochrome test pattern is a count up pattern. The counter starts at zero and counts up

to 0xFF (8-bit output configuration) or 0x3FF (10-bit output configuration), and then starts over

at zero again. Pixel values are repeated 8 times in both single and dual link configurations.

There is a moving horizontal and vertical line in the image. Every image the horizontal line

moves one line down compared to the previous image. The vertical line moves to the right by

8 pixels every image. Both lines are always present in the image. When the previous frame

has the horizontal line in the last line of the image, the next frame will have the horizontal line

in the first line. The moving lines help in testing the robustness of a system to bit errors by

creating high frequency change in the pixel values at the receiver.

Flare CXP User's Manual

A typical monochrome test pattern, with moving lines, is shown in figure 18.

IO Industries Inc. www.ioindustries.com Revision 2.0

43

Flare CXP User's Manual

Figure 18. Typical monochrome test pattern with moving lines (dynamic)

The bayer test pattern is very similar to the monochrome test pattern. The bayer pattern is a

count up pattern (0x00-0xFF in 8-bit mode and 0x000-0x3FF in 10-bit mode), but the count up

values are only assigned to one color plane at a time, while the other colors are set to zero.

The result is color bands with increasing brightness, starting with green, followed by blue and

finally red. The width of the color bands are 256 pixels wide. A typical bayer test pattern, with

moving lines, is shown in figure 19.

IO Industries Inc. www.ioindustries.com Revision 2.0

44

Flare CXP User's Manual

Figure 19. Typical Bayer test pattern with moving lines (dynamic)

IO Industries Inc. www.ioindustries.com Revision 2.0

45

Flare CXP User's Manual

3.14 Sensor Artifacts

The sensor manufacturer have identified some known artifacts with the CMV2000 and

CMV4000 sensors. The horizontal line and black sun artifacts are discussed in the following

sections, along with the algorithms built into the Flare CXP camera series to correct them.

For more information on these artifacts check the sensor manufacturer's website,

www.cmosis.com.

3.14.1 Horizontal Line

The horizontal line artifact may occur when exposure of the next frame starts during the

readout of the current frame. The effect is visible in the line addressed for readout when

exposure of the next frame begins. The effect is a positive or negative offset in the line

addressed for readout.

The horizontal line artifact has been observed in all output formats, but is most likely to occur

at higher frame rates. If the exposure time is set to the maximum value, for a given frame

period, the line will occur in the fourth line of the image.

During the readout period of a line there is a 'slot time' where the start of exposure can start

without producing the line effect. When the Horizontal Line Correction algorithm is enabled,

Horizontal Line Correction register set to 0x00000001 , the start of exposure will be delayed

to line up with the slot time. This will cause up to one line time period delay in the start of

exposure. The algorithm also handles the case when multiple exposure signals are used in

the High Dynamic Range exposure modes. To disable the algorithm set the Horizontal Line

Correction register to zero.

The slot time can vary slightly when different ADC ramp values are set. Use the HLC Adjust

register to move the programmed slot time. Values between 0x00000000 and 0x00000007

are added to the slot time, and when the parameter is set between 0x00000008 and

0x0000000F the parameter value minus 8 is subtracted from the slot time.

The analog gain setting also has an effect on the slot time, but this is handled in the camera

firmware automatically.

NOTE that when using the fastest sensor clock (smallest horizontal resolution zone from

tables 7 and 8) there may be no slot time where the line is invisible for both the CMV2000

and CMV4000 sensors.

The line number can be outputted from the camera by setting the Horizontal Line Correction

register to 0x00000002. The first two pixels of the last line are overwritten with the line

number, which ranges from 1 to N, where N is the last line in the image. The first pixel

represents the bottom 8 bits of the line count, if running in a 10-bit pixel depth the two most

significant bits are set to zero. The second pixel represents the upper 8 bits of the line count.

The line count is only 12 bits so the 4 most significant bits of the second pixel will be set to

IO Industries Inc. www.ioindustries.com Revision 2.0

46

zero when using a output pixel depth of 8 bits, and the 6 most significant bits will be set to

zero when using a 10-bit pixel depth.

To add an offset to the affected line set the Horizontal Line Correction register to 0x00000003.

In this mode the value stored in the HLC Add register will be added to the line.

IO Industries has tested Version 3 CMV4000 sensors and even with the in-sensor correction

algorithm the horizontal line artifact is still faintly present at the highest clock speeds.

Flare CXP User's Manual

3.14.2 Black Sun

The 'Black Sun' effect occurs when a very bright spot is aimed at the sensor, and the center of

the bright spot becomes dark instead of saturated white. This effect is caused by a saturated

reset level from the intense photons, resulting in a pixel value of zero from the Correlated

Double Sampling (CDS) step in the sensor.

This effect can be reduced or eliminated by reducing the light falling on the sensor by closing

the lens iris.

A second option built into the Flare camera firmware is to reduce the time between the pixel

reset and reset sample. Both the CMV2000 and CMV4000 have recommended defaults for

this time resulting in the best CDS result. When the Black Sun correction is turned on, Black

Sun Correction register set to 0x00000001, the time between the pixel reset and reset sample

is cut in half. This reduction in time will lessen or eliminate most Black Sun effects. To

disable the correction set the register to zero, default. The noise in the image will increase

with the Black Sun correction enabled.

3.15 Bad Pixel Replacement

Each camera is tested for defective pixels. These pixels can be 'dead' pixels (pixel value of

zero when sensor is fully saturated), 'hot' pixels (pixel value of 0x3FF when no light is hitting

sensor) and non-uniform pixels which react to light but vary significantly from the average of a

constant greyscale image.

The bad pixel replacement algorithm running in the camera can be enabled or disabled with

the Bad Pixel Correction register, 0x00000000 - disabled or 0x00000001 - enabled. By

default the algorithm is enabled. This command is saved to the user sets.

The algorithm replaces the bad pixels by using an average of neighboring pixels in the

horizontal direction. The list of bad pixels is stored in non-volatile memory in the camera,

which can be read and updated by users. The algorithm can correct up to 255 pixels.

IO Industries Inc. www.ioindustries.com Revision 2.0

47

Flare CXP User's Manual

3.16 Command Memory

The Flare CXP cameras use non-volatile memory to store up to 8 user command sets. To

save the current camera settings to one of these user sets, first set the User Set Selector

register to one of the user profiles, 1 to 8, and write a one to the User Set Save register. To

load from one of the user sets first set the User Set Selector register followed by a write of

one to the User Set Load register.

For convenience, and to easily remember what settings are programmed in a user set, the

Flare CXP cameras store a unique 32 byte name for each user set. The eight profile names

are stored in non-volatile memory and can ber read or written using the User Profile X Name

registers starting at address 0x50000000.

Also stored in the camera (in FPGA block ram) is a factory set of commands. To load the

factory profile set the User Set Selector register to zero and write a one to the User Set Load

register. For both the 2M280 and 4M140 the factory set of commands is full resolution,

normal free-run exposure in dual link 8-bit output format.

To set the power-up profile write the User Set Default Selector register with a value from 1 to

8 for one of the user profiles or 0 for the factory profile.

3.17 Camera Reset

Write a 1 to the Camera Reset register to fully reset a Flare CXP camera. When the reset

command is received the camera will reload various settings from memory (serial number,

ADC ramp values, etc), reload the bad pixel table, and then load the power up profile. The

discovery process on the frame grabber will have to be re-initiated after the reset completes.

3.18 Control Packet CRC

For the complexity, and to relax a closed system frame grabber design, the CRC value in the

uplink control packets are not checked by default. To enable the CRC check write a 1 to the

CRC Check Enable register, address 0x400000D4. The register is saveable to the user

profiles.

3.19 Device Discovery

To start imaging the Flare CXP cameras require the StreamPacketSizeMax bootstrap register

to be written with a non-zero, and a one must be written to the Start Acquisition register.

When sending out frames the led on the back of the camera will be flashing green.

IO Industries Inc. www.ioindustries.com Revision 2.0

48

Flare CXP User's Manual

4 Optional RS-485 Control

The Flare CoaXPress cameras can optionally be controlled through the RS-485 interface. A

simple ASCII command protocol is used. Below are some key points about the serial control:

➢ 8-bit, 9600-460800 baud, 1 stop bit and no parity.

➢ All sent commands end with a carriage return (0Dh), which can also be sent at any

time to reset the uart receiver state machine within the camera and return it to an

idle/ready state.

➢ Commands are 3 ASCII characters followed by the setting or simply a carriage return

when no settings are associated with the command.

➢ A space is sent between the command and the setting.

➢ All settings are in hexadecimal.

➢ All commands letters are in lower case (including settings hex values a-f).

➢ To query a command a carriage return is sent after the last command character.

➢ Successful commands return ACK (06h, generally seen as a dash (-) in terminal

programs), invalid or rejected commands return NAK (15h, generally seen as plus sign

(+) in terminal programs).

➢ A query returns the command, the current value, the minimum and maximum allowable

values within brackets, a carriage return and finally an ACK.

➢ Get camera parameters command (gcp) returns all command settings.

➢ Help command (hlp) returns list of all available commands and brief description.

➢ The CoaXPress configuration registers (StreamPacketSizeMax and AcquisitionStart)

must be disabled by setting the dcx command to 1. This command is savable to the

user sets.

Examples:

1 - Set frame period to 4000 µs (250 Hz):

Command: per 000fa0<CR>

Response: <ACK>

2 - Query frame period:

Command: per<CR>

Response: per 000fa0 (000b78,0f4240)<CR>

<ACK>

4.1 RS-485 Command Summary

IO Industries Inc. www.ioindustries.com Revision 2.0

49

Flare CXP User's Manual

Table 15 summarizes all available commands. The presence and size of a command's

parameters are shown with the letter 'Y' (see Format column). Each letter 'Y' represents a

hexadecimal digit from 0 to f.

Command Format Description Notes

CoaXPress

Output Format

Number of

Windows

Number of

Columns

Start Pixel 1 hs1 YYY Starting pixel for window 1 Start pixel of image when only using 1

Line Start 1 vs1 YYY Starting line for window 1 Start line of image when only using 1

Number of

Lines 1

Start Pixel 2 hs2 YYY Starting pixel for window 2

Line Start 2 vs2 YYY Starting line for window 2

Number of

Lines 2

cxf Y CoaXPress output format 0 – Single link 8-bit

1 – Single link 10-bit

2 – Dual link 8-bit

3 – Dual link 10-bit

Note all modes are CXP3 (3.125Gbps).

nwd Y Number of windows Up to 8 non-overlapping windows.

hrx YYY Horizontal resolution Applies to all windows. Must be mod 8,

with min of 16.

window.

window.

Minimum number of lines is 4.

vr1 YYY Number of lines for window 1 Number of lines in image when only

using 1 window.

vr2 YYY Number of lines for window 2

Start Pixel 3 hs3 YYY Starting pixel for window 3

Line Start 3 vs3 YYY Starting line for window 3

Number of

Lines 3

Start Pixel 4 hs4 YYY Starting pixel for window 4

Line Start 4 vs4 YYY Starting line for window 4

Number of

Lines 4

Start Pixel 5 hs5 YYY Starting pixel for window 5

Line Start 5 vs5 YYY Starting line for window 5

Number of

Lines 5

Start Pixel 6 hs6 YYY Starting pixel for window 6

vr3 YYY Number of lines for window 3

vr4 YYY Number of lines for window 4

vr5 YYY Number of lines for window 5

IO Industries Inc. www.ioindustries.com Revision 2.0

50

Flare CXP User's Manual

Command Format Description Notes

Line Start 6 vs6 YYY Starting line for window 6

Number of

Lines 6

Start Pixel 7 hs7 YYY Starting pixel for window 7

Line Start 7 vs7 YYY Starting line for window 7

Number of

Lines 7

Start Pixel 8 hs8 YYY Starting pixel for window 8

Line Start 8 vs8 YYY Starting line for window 8

Number of

Lines 8

Image Sub-

Sample

Exposure Mode mde Y Exposure modes In modes 1 and 2 set the per command

High Dynamic

Range

vr6 YYY Number of lines for window 6

vr7 YYY Number of lines for window 7

vr8 YYY Number of lines for window 8

sub Y Image sub-sample Reduces output resolution by 1/4.

Skip every second pixel and line (pairs

in color camera).

Does not modify hrx or vrx settings.

0 - off, 1 - on

to the expected trigger rate, which will

change the exposure range.

0 - Free Run Programmable Exposure

1 - External Trigger Programmable

Exposure

2 - External Trigger Level Exposure

3 - External Trigger Double Exposure

hdr Y High Dynamic Range mode 0 - Normal exposure

1 - Interleaved HDR mode

mde 0/1 - ex1 used for odd rows, ex2

used for even rows

mde 2/3 - not available

Frame Period per YYYYYY Frame period in microseconds Range of period depends on:

Exposure Time 1ex1 YYYYYY Primary exposure time in

Exposure Time 2ex2 YYYYYY Secondary exposure time in

IO Industries Inc. www.ioindustries.com Revision 2.0

microseconds

microseconds

2 - Piecewise HDR mode

mde 2/3 - not available

- output configuration

- resolution

- sub-sampling

Used in exposure modes 0 and 1.

Interleaved: exposure time of odd rows.

Piecewise: total exposure time.

Used in HDR modes only.

Interleaved: exposure of even rows.

Piecewise: kneepoint 1 exposure.

51

Flare CXP User's Manual

Command Format Description Notes

Exposure Time 3ex3 YYYYYY Tertiary exposure time in

microseconds

Number of

Slopes

Kneepoint 2 pv1 YY Kneepoint 2 voltage Sets kneepoint 2 voltage in Piecewise

Kneepoint 1 pv2 YY Kneepoint 1 voltage Sets kneepoint 1 voltage in Piecewise

Trigger Source

1

Trigger

Edge/Level 1

Digital Offset off YYYY Dark level offset applied to output

Analog Gain agn Y Analog gain applied by

pns Y Number of Piecewise HDR slopes Placements of kneepoints in X direction

tr1 Y Select primary trigger 0 – CXP trigger

te1 Y Trigger 1 Edge/Level select 0 - Falling (mde 1), Low (mde 2)

signal

Programmable Gain Amplifier (PGA)

in every column

Piecewise: kneepoint 2 exposure.

is controlled by Vlow settings, and

slope of segments is controlled by

exposure times.

HDR mode

HDR mode

1 - Opto-1

Exposure Modes:

0 - not used

1 - Starts primary exposure

2 - Starts and sets exposure time

3 - Starts 'dark frame' exposure

1 - Rising (mde 1), High (mde 2)

Valid off setting range is 0 to 16383

(0x3FFF). The dark level at the output

of sensor equal (70 + setting – 16383).

This value is always in terms of ADC

output of 10 bits.

0 - x1 gain (default)

1 - x1.2

2 - x1.4

3 - x1.6

Digital Gain dgn YYY Digital gain applied to sensor input

ADC Ramp adc YY ADC Ramp Range 24-59 (0x18-0x3B)

ADC Ramp

Voltage

Image Flipping flp Y Image flipping in X and/or Y

rmp YY ADC Ramp Voltage Range 102-115 (0x66-0x73)

IO Industries Inc. www.ioindustries.com Revision 2.0

up to 16x

direction

Range 16-256

Gain applied = (value)/16

Controls ramp generator starting

voltage for reset and pixel

measurements (CDS)

0 - No image flipping

1 - Image flipping in X

2 - Image flipping in Y

3 - Image flipping in X and Y

52

Flare CXP User's Manual

Command Format Description Notes

Opto-1 Output

Select

Test Pattern pat Y Enable test pattern 0 - off (image from sensor)

Horizontal Line

Correction

HLC

Adjustment

HLC

Add

Black Sun

Correction

Bad Pixel

Replacement

op1 Y Select output signal for Optocoupled

Output #1 (pin 10)

hlc Y Horizontal line artifact correction 0 – off

hrg Y Horizontal line 'slot time' adjustment Bit 3 - Sign bit ('0' - add, '1' - subtract)

hla Y Horizontal line add value Value added to line with artifact when

bsc Y Black sun artifact correction 0-off

bpx Y Bad pixel replacement algorithm 0-off

0 - Disabled (low)

1 - INTE1

2 - INTE2

3 – Internal frame valid

4 – internal line valid

1 – color bars on with moving lines

2 – color bars on without moving lines

3,4 – reserved

5 - mono ramp with moving lines

6 - mono ramp without moving lines

1 – on

2 – on, overwrite first two pixels of last

line with line number

3 – on, add hla value to line with artifact

Bits 2:0 - Value (0-7)

hlc is set to 3. Applies to internal 10-bit

data path, regardless of output pixel

depth.

1-on

1-on

Frame Number fnm Y Overwrite first 8 pixels with a frame

number

Disable

CoaXPress

Configuration

Check

Command CRC

Serial Port

Echo

dcx Y Disable CoaXPress configuration From the CXP interface the

crc Y Enable check of command packet

CRC

ech Y Enable serial port echo 0-off

0-off

1-on

StreamPacketSizeMax and

AcquisitionStart registers must be

written for the camera to start imaging.

With dcx set to 1 a packet size of 1024

bytes is automatically used, and

acquisition is enabled.

0-off

1-on

1-on

IO Industries Inc. www.ioindustries.com Revision 2.0

53

Flare CXP User's Manual

Command Format Description Notes

Serial Port

Baud Rate

Profile Number pnm Y Profile number Profile used when issuing a sav or a

Set Power-up

Profile

Save to User

Set

Load from User

Set

Reset Camera rst Complete camera reboot Loads from power-up profile.

Set Windows swd Applies current internal window

Camera Model cam Returns camera model Read only.

Serial Number ser Returns camera serial number Read only.

sbd Y Set serial port baud rate 0 – 9600

1 – 19200

2 – 38400

3 – 57600

4 – 115200 (factory default)

5 – 230400

6 – 460800

When changing baud rates an <ACK>

will be sent at the current baud rate

before switching.

lod command.

pup Y Power-up user set page or factory

page

sav Save current settings to user set

number in pnm command

lod Load settings from user set number

in pnm command

settings to output

0 - Factory page

1-8 - User set page

Firmware

Version

Get Camera

Parameters