trk4000 / trk4000d / trk8000

HW Installation Manual

ioimage, the ioimage logo, ioimage analytics®, ioiware, ioibox, trk10, trk10d, trk100, trk100d, trk200, trk4000,

trk4000rm, trk4000d, and trk8000, ioiware command center, ioiware setup, ioibox lvm300, ioicam wdc100dn,

ioicam mmp100dn, and ioicam xptz100dn, are trademarks of ioimage Ltd. Products and trademarks

mentioned herein are for identification purposes only and may be registered trademarks of their respective

companies. Specification is subject to change without notice.

2004-2007© ioimage Ltd. All rights reserved

Proprietary Rights and Non-Disclosure

This Guide is delivered subject to the following restrictions and conditions:

This document contains proprietary information belonging to ioimage Ltd. This information

is supplied solely for the purpose of assisting explicitly the licensee of the ioibox units.

No part of this document contents may be used for any other purpose, disclosed to any

third party or reproduced by any means, electronic or mechanical, without the express

prior written permission of ioimage Ltd.

Disclaimer

Specifications and information in this Guide is subject to change without notice.

Copyright 2007 ioimage Ltd., all rights reserved.

Trademarks and Copyrights

This Guide and its contents are herein is owned by ioimage, Ltd., all rights reserved.

This Guide and its contents are herein is owned by ioimage, Ltd., all rights reserved.

ioimage, the ioimage logo, ioimage analytics®, ioiware, ioibox, trk10, trk10d, trk100,

trk100d, trk200, trk4000, trk4000rm, trk4000d, and trk8000, ioiware command center,

ioiware setup, ioibox lvm300, wdc100dn, ioicam mmp100dn, and ioicam xptz100dn,

are trademarks of ioimage Ltd. Products and trademarks mentioned herein are for

identification purposes only and may be registered trademarks of their respective

companies. Specification is subject to change without notice.

ioimage makes no representations whatsoever about any other products or trademarks

mentioned in the manual.

2004-2007© ioimage Ltd. All rights reserved

i

Document Scope and Purpose

This document is intended for installation by technical users who have a basic

understanding of CCTV camera/video equipment and LAN/WAN network connections.

Installation should follow safety, standards, and electrical codes as well as the laws that

apply where the ioibox and ioicam units are being installed.

The purpose of this document is to provide instructions and installation procedures co ncerning how

to connect the hardware and if required, configure the ioibox unit to be connected to an existing

LAN/WAN network. After completion of the hardware installation, additional setup configurations

are required for operation of the ioibox unit. For more information on ioibox unit setup and

configuration, refer to the ioibox trk4000, trk4000d, or trk8000

HTML Edition Setup User Guide.

ii

Contents

Document Conventions....................................................................................................................1

Cautions and Warnings ....................................................................................................................2

Electrical Safety Notice ................................................................................................................4

Preventing EMI.............................................................................................................................4

Introduction.......................................................................................................................................4

Overview ......................................................................................................................................5

Items Included in the Package.....................................................................................................6

Indoor and Outdoor Installation Considerations...........................................................................7

Indoor Installation.....................................................................................................................7

Outdoor Installation..................................................................................................................7

Cabling.........................................................................................................................................8

Video Cable .............................................................................................................................9

Electric/Power Supply Cables..................................................................................................9

Hardware Description – ioibox Unit................................................................................................11

ioibox IP Block............................................................................................................................12

trk4000 Unit Front Panel............................................................................................................13

trk4000 Unit Back Panel.............................................................................................................14

trk4000d Unit Front Panel..........................................................................................................16

trk4000d Unit Back Panel...........................................................................................................17

trk8000 Unit Front Panel............................................................................................................19

trk8000 Unit Back Panel.............................................................................................................20

External devices interfaces – ioibox Channel Assignments.......................................................22

Package Accessories.................................................................................................................24

Workflows.......................................................................................................................................25

Pre-Install Workflow ...................................................................................................................25

Installation Workflow ..................................................................................................................26

Post Install..................................................................................................................................27

Overview of Alarm Inputs (Dry Contacts).......................................................................................27

Overview of Relay Outputs.............................................................................................................27

Overview of RS232 and RS485 Connections ................................................................................28

PTZ Control................................................................................................................................29

Installation.......................................................................................................................................29

Unit Mounting.............................................................................................................................29

Rack Requirements...............................................................................................................32

Connecting the ioibox Unit.........................................................................................................32

Connecting to the Network.....................................................................................................32

Connecting the Video Source (camera).................................................................................34

Connecting Relay Outputs.....................................................................................................34

Relay Contacts Schematic ................................................................................................36

Connecting Alarm Inputs (Dry Contacts)...............................................................................38

Connecting PTZ Cameras .....................................................................................................40

Connecting ioibox Unit Video Output to an Analog Device...................................................46

Connecting the External Protective Earth Terminal...................................................................46

Connecting the Power Supply....................................................................................................46

Setting the ioibox IP ...................................................................................................................47

Setting the IP Using HTML Setup..............................................................................................48

Setting the IP Using the SiteConfigurator Application................................................................49

ioibox unit Network IP Assignment Modes – DHCP/Manual......................................................50

Resetting ioibox Units.................................................................................................................51

Hard Reset Using the Reset Button on the Unit....................................................................51

Hard Reset Power Down/Power Up......................................................................................51

Camera Installation & Tips .............................................................................................................52

iii

Appendix.........................................................................................................................................58

Connecting Leads to a Spring Clamp Terminal Block...............................................................59

Troubleshooting..........................................................................................................................60

How to Ping a ioibox Unit from a Workstation............................................................................63

Connector Mapping Tables........................................................................................................64

Specifications.............................................................................................................................65

Who to Contact...........................................................................................................................68

List of Figures

trk4000 Front Panel........................................................................................................................13

trk4000 Back Panel ........................................................................................................................14

trk4000d Front Panel......................................................................................................................16

trk4000d Back Panel ......................................................................................................................17

trk8000 Front Panel........................................................................................................................19

trk8000 Back Panel ........................................................................................................................20

trk4000 External Device Interfaces (Relay Output and Alarm Input) Channel Assignment...........22

trk4000d External Device Interfaces (Relay Output and Alarm Input) Channel Assignment.........23

trk8000 External Device Interfaces (Relay Output and Alarm Input) Channel Assignment...........23

External device is triggered on the event of intrusion in a detection zone.....................................28

ioimage units secured in rack with mounting screws.....................................................................31

Relay Output Connection ...............................................................................................................35

Relay Contacts Schematic for the trk4000 unit..............................................................................36

Relay Contacts Schematic for the trk8000 and trk4000d unit........................................................36

Alarm Input Connection..................................................................................................................39

PTZ control lines connected with the adapter cable RS485 lead-wires.........................................41

PTZ Control Lines connected with the DB9 RS232 adapter cable................................................43

Connecting a Wire to a Terminal Block..........................................................................................59

RS232/485 Pin Diagram.................................................................................................................64

iv

Document Conventions

The following document conventions are used throughout this manual:

WARNING is a precautionary message that indicates a procedure or condition where there

A

are potential hazards of personal injury or death

Caution is a precautionary message that indicates a procedure or condition where there

A

are potential hazards of permanent damage to the equipment and or loss of data.

Note is useful information to prevent problems, help with successful installation, or to

A

provide additional understanding of the products and installation.

A

Tip is information and best practices that are useful or provide some benefit for installation

and use of ioimage products.

1

Cautions and Warnings

This section contains information that indicates a procedure or condition where there are pote ntial

hazards. These may be hazards associated with a task or procedure a user is carrying out or about

to carry out.

WARNINGS and CAUTIONS are distributed throughout this document, whenever applicable, to

alert the user of potentially hazardous situations.

Although the ioibox unit is designed and manufactured in compliance with all applicable safety

standards, certain hazards are present during the installation of this equipment.

Definitions:

• Warning:

A WARNING is a precautionary message that indicates a procedure or condition

where there are potential hazards of personal injury or death.

• Caution:

A CAUTION is a precautionary message that indicates a procedure or condition

where there are potential hazards of permanent damage to the equipment and or loss

of data.

Failure in part or in whole of the installer, owner, or user in any way to follow the prescribed

procedures or to heed WARNINGS and CAUTIONS shall absolve ioimage Ltd., and their agents

from any resulting liability.

SAVE THESE INSTRUCTIONS: Retain all safety and operating instructions for future use.

To avoid injury or possible damage to hardware components, read and follow all instructions

marked on the product and in the documentation before you install or connect the ioibox unit to a

power source.

Warning:

The ioibox unit cover is an essential part of the product. Do not open or remove this cover.

Never operate the ioibox unit without the cover in place. Operating the ioibox unit without the

cover in place poses a risk of fire and shock hazards

Warning:

To prevent injury or damage to the ioibox unit, do not insert any objects into the vents of the

ioibox unit

.

Warning:

The ioibox unit uses a three-wire power cord to make sure that the product is properly

grounded when in use. The plug on this cord will only fit into a grounding-type outlet. This is

a safety feature. If the intended power outlet does not support three prongs, one of which is a

ground, contact an electrician to install the appropriate outlet. NEVER remove or otherwise

attempt to defeat the ground pin of the power cord. Do not operate the ioibox unit in the

absence of a suitably installed ground conductor

2

.

Warning:

If you use an extension cord with this system, make sure that the total ampere rating on the

products plugged into the extension cord does not exceed the extension cord ampere rating

Warning:

Only qualified trained personnel should service and repair this equipment.

Warning:

Assure the connected electrical power source uses a circuit breaker or fuse no larger than

120 VAC, 15A U.S. and 240 VAC, 10A international are used on the phase conductors (all

current-carrying conductors.).

.

Warning:

Read the installation instructions before you connect the ioibox unit to a power source

Caution:

To avoid damage from overheating or unit failure, do not block the vents of the ioiboxes, and

assure, there is sufficient temperature regulation to support the ioibox unit requirements

(cooling/heating). Ambient operating temperature should be kept in the range 0°c to 50°c.

.

3

Electrical Safety Notice

In the following situations, the electric power should be turned off and appropriate repairs,

replacements, or remedies should be taken.

• The power cord or plug is damaged, frayed or shows heavy wear

• The ioibox unit has been physically crushed or deformed

• The ioibox unit has been exposed to water

• The ioibox unit has been exposed to fire, intense heat or heavy smoke

• Electrical connections of the ioibox unit become abnormally hot or smoke

• The ioibox unit has been dropped, damaged or shows signs of loose internal parts.

• The ioibox unit power light fails to illuminate or the ioibox unit does not operate

properly

• The ioibox unit shows signs of damage from exposure to fumes or vapors

Preventing EMI

When wires run for a significant distance in an electromagnetic field, Electromagnetic Interference

(EMI) can occur

Note:

• Poor quality or worn wiring can result in Radio Frequency Interference (RFI)

.

• Strong EMI, (e.g. lightning or radio transmitters) can destroy the ioiboxes, and can

pose an electrical hazard by conducting power through lines and into the system

To remedy EMI, consult RFI experts.

.

Introduction

The installation of the ioibox unit hardware is the first phase of making a ioibox unit operational in a

security plan. The goal of hardware installation is to physically place the unit, connect it to other

devices in the system and to establish network connectivity in preparation for phase two of the

installation process which is the camera setup and configuration of the ioibox.

When finished with the ioibox unit hardware installation, you will need to refer to the ioimage HTML

Edition Setup User Guide to complete the second phase of installation, which is the setup and

configuration of the ioibox unit.

4

Overview

There are several requirements that should be properly addressed prior to installation. The

following specifications are requirements for proper installation and operation of ioibox units:

• Ambient Environment Conditions: Keep the ioibox unit in a clean and dry indoor

environment. Operating temperature should be maintained within 0°c to 50°c.

Operating humidity 5% to 95% (non-condensing). The ioibox unit should be kept

indoors or in a shielded enclosure dry and free from water conden sation. To prevent

overheating, avoid positioning the ioibox unit near heaters or heating system outputs

and avoid exposure to direct sunlight. Keep the ioibox unit free from dust, dirt, smoke,

and exposure to EMI.

• Accessibility: The location should allow easy access to unit connections and cables.

Leave at least 33 cm (1 foot) behind the unit to allow for easy cable access.

• Safety: Cables and electrical cords should be routed in a manner that prevents safety

hazards, such as from tripping, wire fraying, overheating, etc. Assure that nothing

rests on the ioibox cables or power cords

be indoor connections that require being shielded from outdoor cable connections.

. All cables connected to the TRK unit shall

• Ample Air Circulation: Leave enough space around the ioibox unit to allow free air

circulation.

• Proximal Location: ioiboxes should be placed in locations that are optimal for the

type of video cabling used between the unit and the cameras and external devices.

Using a cable longer than the manufacturer’s specifications for optimal video signal

may result in degradation of color and video parameters.

• Physical Security

ioiboxes provide threat detection for physical security systems. In order to ensure

ioiboxes cannot be disabled or tampered with, the systems should be installed with

security measures regarding physical access by trusted and un-trusted parties.

• Network Security

ioibox units transmit over IP to security personnel for video surveillance. Proper

network security measures should be in place to assure networks remain operating

and free from malicious interference. ioibox units are intended for installation on the

backbone of a trusted network.

• Electrostatic Safeguards

ioibox units as well as other equipment connected to it (relay outputs, alarm inputs,

racks, carpeting, etc) shall be properly grounded to prevent electrostatic discharge.

5

Items Included in the Package

This section describes the items that are included in the ioibox unit package.

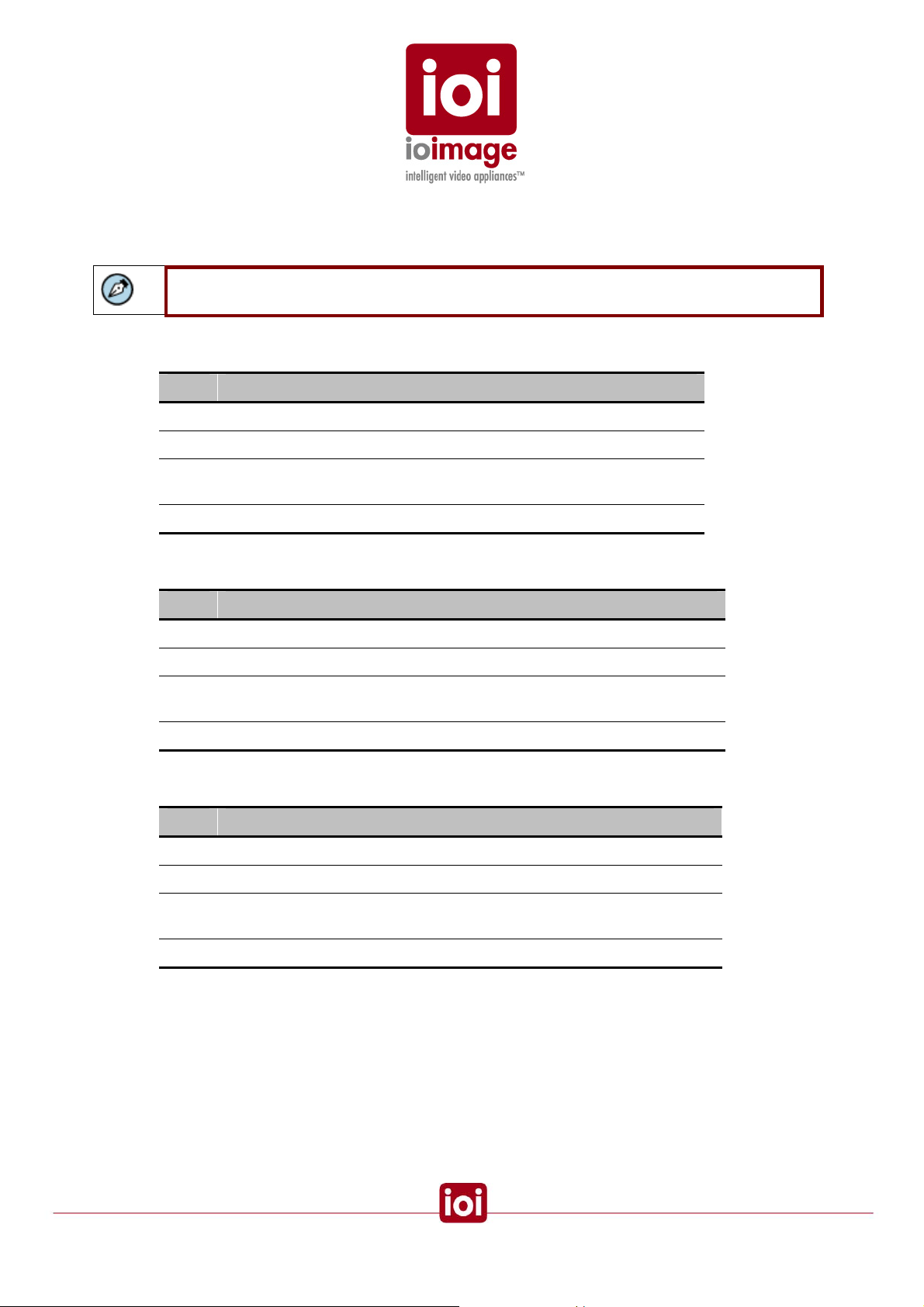

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

The trk4000 unit package contains the following:

QTY Description

1 ioibox trk4000 unit

1 IEC power cord (C13)

2 Terminal-block spring-clamp-connectors for Alarm Input and Relay

Output wire termination

1 Documentation and utilities CD

The trk4000d unit package contains the following:

QTY Description

1 ioibox trk4000d unit

1 IEC power cord (C13)

4 Terminal-block spring-clamp-connectors for Alarm Input and Relay

Output wire termination

1 Documentation and utilities CD

The trk8000 unit package contains the following:

QTY Description

1 ioibox trk8000 unit

1 IEC power cord (C13)

4 Terminal-block spring-clamp-connectors for Alarm Input and Relay

Output wire termination

1 Documentation and utilities CD

6

Indoor and Outdoor Installation Considerations

The following sections provide insight and key information that should be considered when installing the

ioibox units:

• Indoor Installation (page 7)

• Outdoor Installation (page 7)

Caution

To avoid damage from overheating or unit failure, assure, there is sufficient temperature

regulation to support the ioibox unit requirements (cooling/heating). Ambient temperature

should be kept in the range 0°c to 50°c.

Indoor Installation

The following are additional consideration for an indoor installation.

• There must be a fuse or breaker at the starting point of the electrical wiring

infrastructure.

• For indoor installations, such as industrial installation, the ioibox units must be

protected from elements, such as damaging fumes, metallic dust, extreme

temperatures, soot, moisture, over spray, etc.

.• ioibox units should not be placed near or on radiators and heat sources

Outdoor Installation

The following are additional consideration for an outdoor installation.

• For any outside wiring installation, always use weatherproof equipment, such as

boxes, receptacles, connectors, etc.

• For electrical wiring use the properly rated sheathed cables for conditions which the

cable will be exposed to (e.g. moister, heat, UV, and physical requirements, etc.)

• ioibox units must be protected from weather conditions. Units should be installed

within secure weatherproof storage, such as an outdoor communi cation cabinets,

junction boxes, or system cabinets.

• Plan ahead to determine where to install weatherproof outlet boxes and ioibox unit

storage. Whenever possible ground weatherproof boxes to an outdoor ground.

• Outdoor boxes should provide some form of a security locking mechanism.

• Look for an enclosure/casing suited for protecting the ioibox as needed for your

installation environment. It is recommended that a rating of IP65 / NEMA 4 or greater

be used. The following table provides National Electrical Manufacturers Associat ion

(NEMA) and Institute of Petroleum ratings. These are US and European ratings that

indicate an enclosures ability to withstand certain environmental conditions:

Rating Description

IP54 / NEMA 2 Protected against splashing water and the ingress of most dust

7

Rating Description

IP65 / NEMA 4 Completely protected against the ingress of dust and against water jets

NEMA 4X Same as NEMA 4 with the added benefit of being corrosion proof

IP67 / NEMA 6 Can be immersed in water under defined conditions and com pletely protected

against the ingress of dust

Cabling

Cabling should be routed for the shortest path and minimizing impedance. Cabling routes should be

planned for the fewest bends. Avoid unnecessary connections and use only approved connectors in

locations that provide accessibility.

The following sections discuss different considerations for the different cabling types:

Video Cable (page 9)

Electric/Power Supply Cables (page 9)

8

Video Cable

Use the appropriate connectors for indoor an outdoor cabling. Cables should be maintained at

scheduled intervals, connections should be secu red, and worn or damaged cables should be

replaced to assure optimally low impedance.

Recommended Cable Specifications:

• 75 coaxial cable impedance

Note

Using a cable longer than the manufacturer’s specifications for optimal video signal may

result in degradation of color and video parameters.

Warning

To avoid damage to the system and system interference, a certified electrician must assure

that the ground voltage (ground loops and foreign stray voltage) is comparable among all

connected system components (ground isolation transformer may be required to solve

ground loop problems). This relates to all grounded devices as well as the shield of video

cables and equipment racks.

Electric/Power Supply Cables

The following should be considered for electrical wiring and cable s:

Warning

To prevent bodily injury or possible death, shut off the electrical current at the main switch

before tying-in wiring.

Warning:

The ioibox unit uses a three-wire power cord to make sure that the product is properly

grounded when in use. The plug on this cord will only fit into a grounding-type outlet. This is

a safety feature. If the intended power outlet does not support three prongs, one of which is a

ground, contact an electrician to install the appropriate outlet. NEVER remove or otherwise

attempt to defeat the ground pin of the power cord. Do not operate the ioibox unit in the

absence of a suitably installed ground conductor

.

9

• Check the local codes regarding indoor or outdoor wiring. Electrical wiring should be

installed in accordance with local codes and safety requirements.

• Electrical infrastructure and wiring should be installed by a licensed Electrician.

• Electrical cabling must contain a grounding conductor. All electrical components and

devices must be grounded for complete safety, especially for outdoor installations. To

help prevent electric shock, the power supply should be connected to properly

grounded electrical outlets. Electrical cords with three-prong plugs to help en sure

grounding. Do not use adapter plugs or remove the grounding prong from a cable.

• Many local codes now require outdoor electrical circuits to be protected with GFIs,

(Ground Fault Interrupters). Check your local code. GFIs are required in most areas

for outdoor circuits. Follow the manufacturer's instructions for the installation of the

type of GFI you decide to use.

• Ensure that power cables are rated for the ioiboxes voltage and current requirements.

The voltage and current rating of the cable should be greater than the ioibox unit

ratings defined in this guide and marked on the product.

• To help protect the ioiboxes and connected system components from sudden,

transient increases and decreases in electrical power, use a surge suppressor, li ne

conditioner, or uninterruptible power supply (UPS).

• For underground wiring, always bury any underground cable at least 18" deep, but

24" is preferable. Cables buried at least 24" deep are less likely to be bothered or dug

up.

• Always use at least type UF sheathed cables for installations requiring underground

electrical wiring.

• There must be a fuse or breaker at the starting point of the electrical wiring

installation.

• ioibox units must have the external protective earth terminal permanently connected

to protective earth according to local regulations and codes. For more information,

Connecting the External Protective Earth Terminal (page 46).The protective

see

grounding conductor should be aluminum. The lug of the protective grounding

conductor should be aluminum; washers and screws should be hi Cr stainless steel,

or 12% Cr stainless steel, or Cr on, Ni on steel, tin or steel.

• External protective earth stud must be permanently connected to the protective earth.

• US + Canada - INSTALLATION CODES

This device must be installed according top the latest version of the country national

electric codes. For North America, equipment must be installed in accordance to the

applicable requirements in the US National Electrical Code and the Canadian

Electrical Code.

• North America power connection: “select a power supply cord that is UL Listed and

CSA Certified: 3 – conductor, 18 AWG, terminated in a molded on plug cap rated 125

V, 15 A, with a minimum length of 1.5m (six feet) but no longer than 4.5m.”

• A readily accessible Listed branch circuit overcurrent protective device rated 20 A

must be incorporated in the building wiring.

• Select a power supply cord that is UL Listed and CSA Certified: 3 - conductor, [18

AWG], terminated in a molded on plug cap rated 125 V, [15 A], with a minimum length

of 1.5m [six feet] but no longer than 4.5m.

10

Hardware Description – ioibox Unit

ioibox unit converts analog cameras into streaming MPEG-4 over IP came ras and transforms

inanimate cameras into smart proficient cameras that identify threats, track intruders, and take

action automatically. The ioibox unit contains an embedded DSP platform, (no PC based

processing) that provides intelligent-video analysis and tracking software for running algorithms and

real-time audio and video MPEG-4 encoding and streaming.

The DSP must be configured through the IP connection of the ioibox unit in order for the unit to

operate ioimage module features. The built-in modules include:

• Intrusion Detection for detecting intruder scenarios

• PTZ Tracking for transforming pan/tilt/zoom cameras into self-directed intruder-

tracking systems

• Unattended Baggage Unattended Threat Detection for detecting left-behind

baggage scenarios

• Object Removal Object Removal Detection for detecting if an object has been

removed

• Stopped Vehicle No Parking/Stopped vehicle tracking for detecting if a vehicle is in

violation of parking and standing rules

The following ioibox unit hardware panels are described in the following sections:

• trk4000 Unit Front Panel (page 13)

• trk4000 Unit Back Panel (page 14)

• trk4000d Unit Front Panel (page 16)

• trk4000d Unit Back Panel (page 17)

• trk8000 unit Front Panel (page 19)

• trk8000 unit Back Panel (page 20)

Further information on the dry contact channel assignments is covered in the External Devices

Interfaces – ioibox Channel Assignments

section (page 22).

11

ioibox IP Block

The ioiboxes use one or more IPs for network connection. On the ioibox units, the distribution of

channels per IP is as follows:

trk4000 trk4000d trk8000

Number of IPs per unit (Block Count) 2 4 4

Number of channels per IP 2 1 2

ioibox

Unit

trk4000 CH 1 & 2 CH 3 & 4 N/A N/A

trk4000d CH 1 CH 2 CH 3 CH 4

trk8000 CH 1 & 2 CH 3 & 4 CH 5 & 6 CH 7 & 8

This internal grouping of channels is referred to as a Block.

IP 1 IP 2 IP 3 IP 4

12

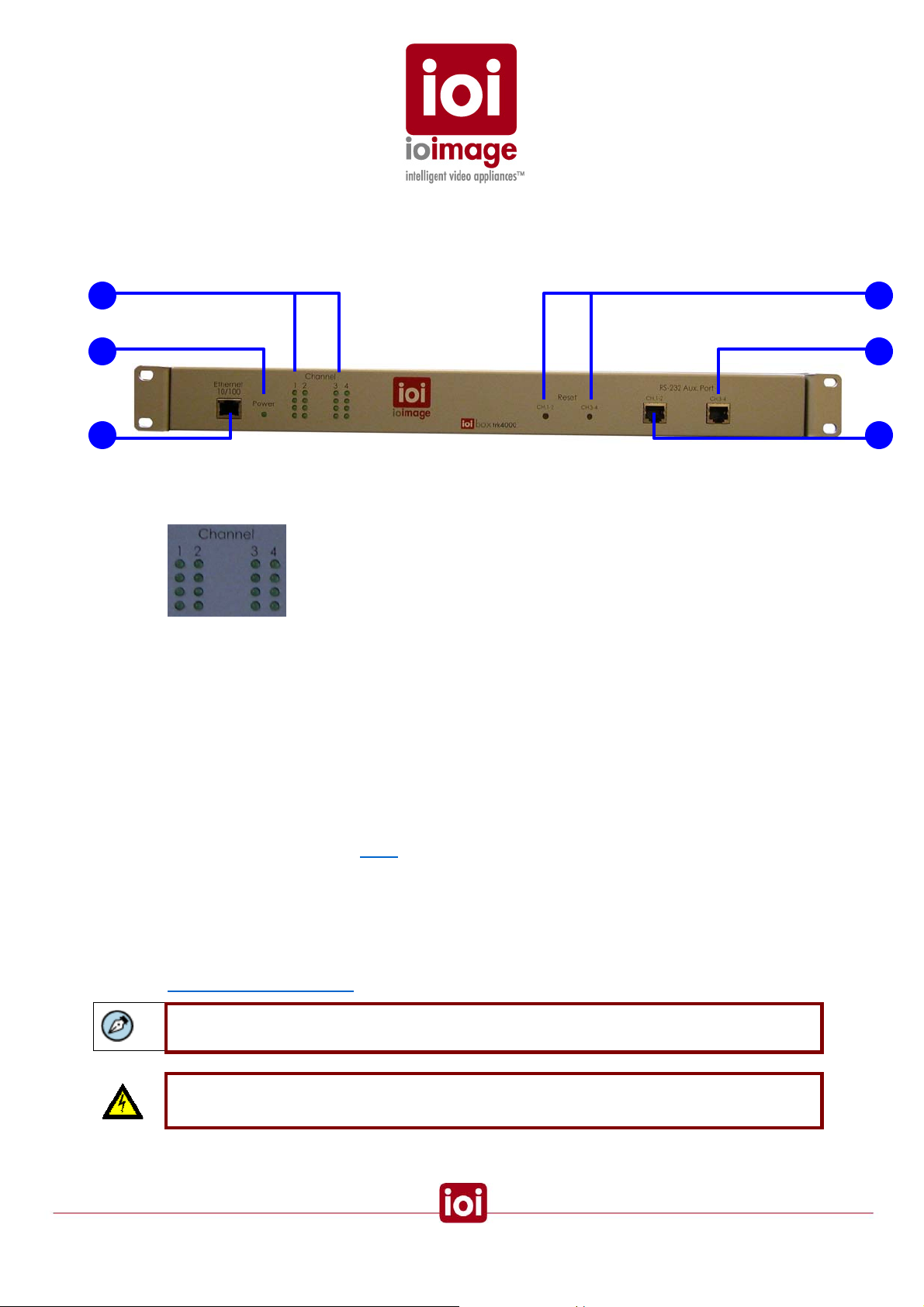

trk4000 Unit Front Panel

This section provides a short description of the trk4000 Unit front panel connections and

features.

1

2

4

5

3 6

trk4000 Front Panel

1.

LED INDICATORS

Indicator lights for each of the four channels. Each channel has a column of lights.

A Power Indicator

B Operating Light

LED POWER INDICATOR

2.

C Unassigned

D Unassigned

The light indicator for power.

3. Ethernet 10/100

Ethernet port for connecting an Ethernet cable to a local or wide area network

(LAN/WAN). There will be two IPs handled through this single connection: Channels 1

& 2 are Block 1 (first IP – Default 192.168.123.10) and Channels 3 & 4 are Block 2

(second IP – Default 192.168.123.11).

4.

Reset

Small opening that allows access to the button for hard-reset. Using a small pointed

object, such as a ballpoint pen, press to reset the ioimage Unit. Each reset button

affects two channels on the

Block as labeled.

RS232 Channels 3 & 4

5.

Serial port that supports one RS232 connection (RS232-1 setting). Primarily used for

connecting PTZ control. Note Channels 3 & 4 are on the second Block IP

configurations.

For more information on the pin-out for front panel RJ45 connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

13

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

RS232/485 Channels 1 & 2

6.

Serial port supports one RS232 connection (RS232-1 setting). Primarily used for

connecting PTZ control. Note Channels 1 & 2 are on the first Block IP configurations.

For more information on the pin-out for front panel RJ45 connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to RS232 DB9 can be purchased as a separated accessory

trk4000 Unit Back Panel

This section provides a short description of the trk4000 Unit back panel connections and features.

1

2

3

4

6

2

1

4

3

trk4000 Back Panel

5

7

1

2

3

4

5 8

2

1

4

3

AUDIO IN

1.

Input audio standard RCA jack (female RCA connector) for receiving sound from

external devices such as a line-level microphone (1V RMS).

2.

AUDIO OUT

T

Output audio standard RCA jack (female RCA connector) for transmitting sound to

external devices such as an amplified loudspeaker.

3.

VIDEO IN

Video input for receiving analog video signal from a standard video source, such as

from a camera or device.

14

4. VIDEO OUT

Video output for transmitting analog video signal to an analog video display, analog

video matrix, or analog video recording device. You can connect an analog monitor to

this port for viewing ioimage Unit video.

5.

RS232/485

Serial port that can be split-out for up to two connections (RS232 and RS485 support).

Primarily used for connecting PTZ control. Note Channels 1 & 2 are on the first Block

IP configurations and Channels 3 & 4 are on the second Block IP configurations.

For more information on the RJ45 pin-out for the back panel connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

6. POWER

The power plug for connecting the IEC cord (C13/C14).

7. Alarm Inputs and Relay Outputs

Alarm Inputs

(1-8) Terminal-block-connector port for plugging in terminal block connectors. Supports

up to four input connections (a set of two wires for each) for external relay devices. The

right terminal of the two is a grounded common. For example, fire sensors, PIR, fence

sensors, etc. For more information and channel assignment, see the

Inputs section (page 38) and External Device Interfaces – ioibox Channel Assignments

(page 22).

Relay Outputs

Terminal-block-connector port for plugging in terminal block connectors. Supports

output of optoisolated signal for up to two connected external relay devices. For

example, an electrical door lock relay.

NO1, NO2 are leads for “NORMALLY OPEN” relay configurations

NC1, NC2 are leads for “NORMALLY CLOSED” relay configurations

C1, C2 are leads for COMMON wire relay configurations for either NC or NO relay. For

more information and channel assignment, see the

(page 34) and

External Device Interfaces – ioibox Channel Assignments (page 22).

Connecting Relay Outputs section

Connecting Alarm

Protective Earth Terminal

8.

ioibox must have the external protective earth terminal permanently connected to

protective earth according to local regulations and codes. For more information, see

Connecting the External Protective Earth Terminal (page 46).

15

trk4000d Unit Front Panel

This section provides a short description of the trk4000d unit front panel connections and features.

1

2

3

trk4000d Front Panel

LED INDICATORS

1.

Indicator lights for each of the four channels. Each channel has a column of lights.

4

5

A Power Indicator

B Operating Light

C Unassigned

D Unassigned

LED POWER INDICATOR

2.

The light indicator for power.

3. Ethernet 10/100

Ethernet port for connecting an Ethernet cable to a local or wide area network

(LAN/WAN). There will be four IPs handled through this single connection: Channel 1

Default 192.168.123.10, Channel 2 Default 192.168.123.11, Channel 3 Default

192.168.123.12, and Channel 4 Default 192.168.123.13.

4.

RESET

Small opening that allows access to the button for hard-reset. Using a small pointed

object, such as a ballpoint pen, press to reset the ioimage Unit. Each reset button

affects two channels on the

Block as labeled.

16

5. RS232/485

Serial port that supports one RS232 connection (RS232-1 setting). Primarily used for

connecting PTZ control. Note each channel is on a separate Block IP configuration.

For more information on the pin-out for front panel RJ45 connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

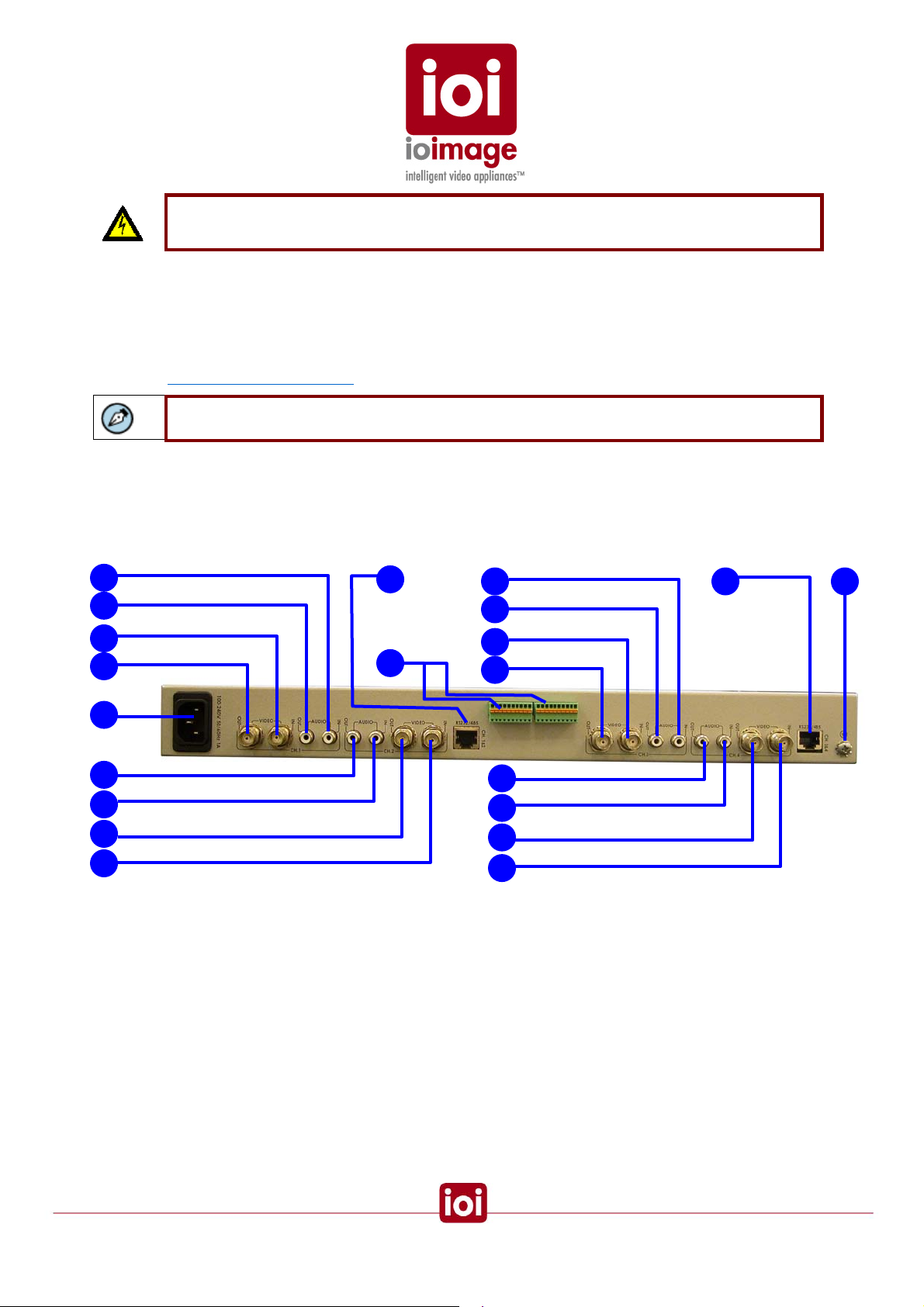

trk4000d Unit Back Panel

This section provides a short description of the trk4000d Unit back panel connections and features.

5 5

2

1

4

3

6

4 4

1 1

2 2

5

trk4000d Back Panel

7

3 3

5

2

1

4

3

8

VIDEO IN

1.

Video input for receiving analog video signal from a standard video source, such as

from a camera or device.

17

2. VIDEO OUT

Video output for transmitting analog video signal to an analog video display, analog

video matrix, or analog video recording device. You can connect an analog monitor to

this port for viewing ioimage Unit video.

3.

AUDIO IN

Input audio standard RCA jack (female RCA connector) for receiving sound from

external devices such as a line-level microphone (1V RMS).

4.

AUDIO OUT

T

Output audio standard RCA jack (female RCA connector) for transmitting sound to

external devices such as an amplified loudspeaker.

5.

RS232/485

Serial port that can be split-out for up to two connections (RS232 and RS485 support).

Primarily used for connecting PTZ control. Note Channels 1 & 2 are on the first Block

IP configurations and Channels 3 & 4 are on the second Block IP configurations.

For more information on the RJ45 pin-out for the back panel connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

6. POWER

The power plug for connecting the IEC cord (C13/C14).

7. Alarm Inputs and Relay Outputs

Alarm Inputs

(1-8) Terminal-block-connector port for plugging in terminal block connectors. Supports

up to four input connections (a set of two wires for each) for external relay devices. The

right terminal of the two is a grounded common. For example, fire sensors, PIR, fence

sensors, etc. For more information and channel assignment, see the

Connecting Alarm

Inputs section (page 38) and External Device Interfaces – ioibox Channel Assignments

(page 22).

Relay Outputs

Terminal-block-connector port for plugging in terminal block connectors. Supports

output of optoisolated signal for up to two connected external relay devices. For

example, an electrical door lock relay.

NO1, NO2 are leads for “NORMALLY OPEN” relay configurations

NC1, NC2 are leads for “NORMALLY CLOSED” relay configurations

C1, C2 are leads for COMMON wire relay configurations for either NC or NO relay. For

more information and channel assignment, see the

(page 34) and

External Device Interfaces – ioibox Channel Assignments (page 22).

Connecting Relay Outputs section

18

8. Protective Earth Terminal

ioibox must have the external protective earth terminal permanently connected to

protective earth according to local regulations and codes. For more information, see

Connecting the External Protective Earth Terminal (page 46).

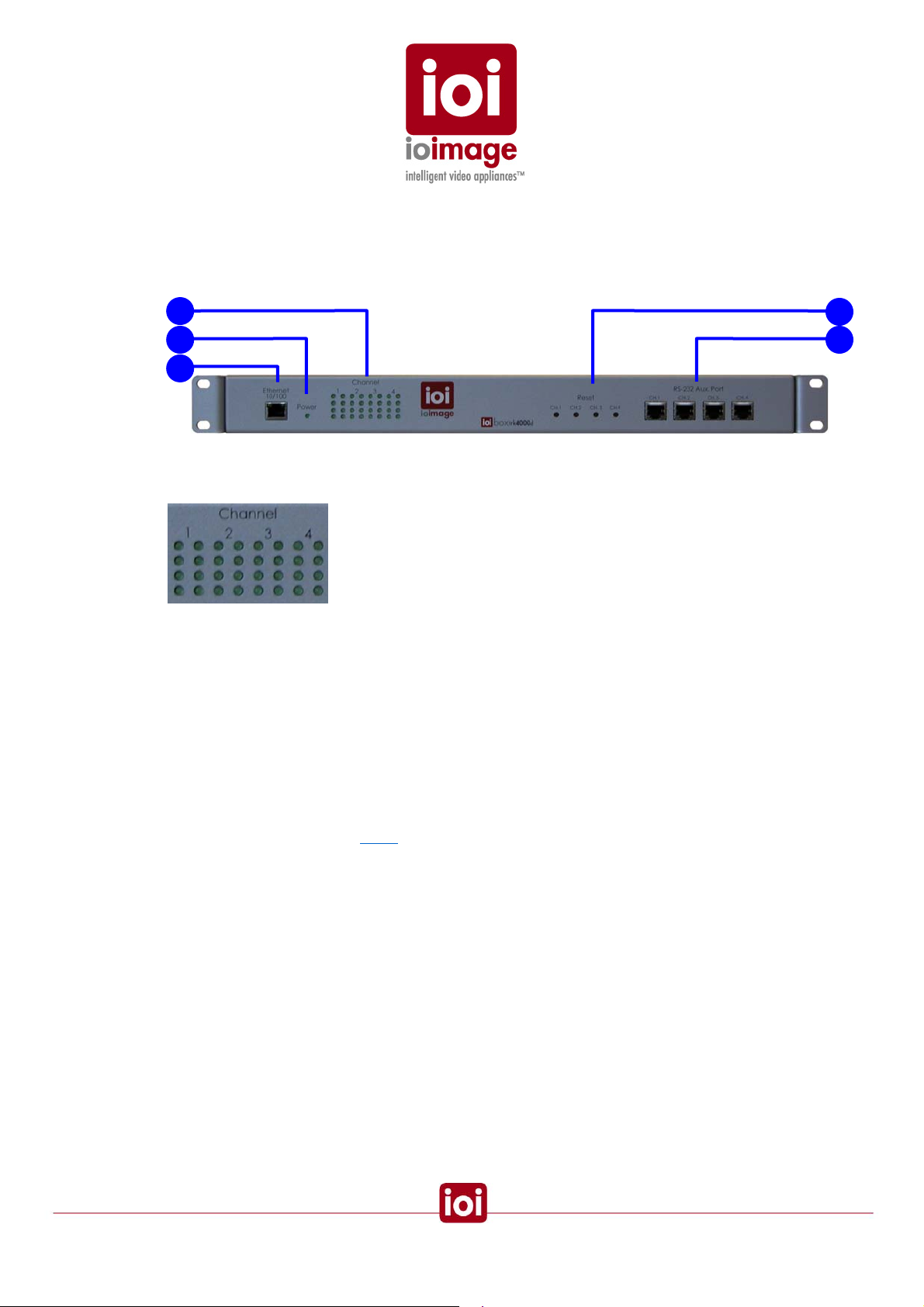

trk8000 Unit Front Panel

This section provides a short description of the trk8000 unit front panel connections and features.

1

2

3

trk8000 Front Panel

4

5

RESET

1.

Small opening that allows access to the button for hard-reset. Using a small pointed

object, such as a ballpoint pen, press to reset the ioimage Unit. Each reset button

affects two channels on the

Ethernet 10/100

2.

Block as labeled.

Ethernet port for connecting an Ethernet cable to a local or wide area network

(LAN/WAN). There will be four IPs handled through this single connection: Channels 1

& 2 are Block 1 (first IP – Default 192.168.123.10) and Channels 3 & 4 are Block 2

(second IP – Default 192.168.123.11). Channels 5 & 6 are Block 3 (third IP– Default

192.168.123.12) and Channels 7 & 8 are Block 4 (fourth IP– Default 192.168.123.13).

3.

LED POWER INDICATOR

The light indicator for power.

4.

LED INDICATORS

Indicator lights for each of the four channels. Each channel has a column of lights.

A Power Indicator

B Operating Light

C Unassigned

D Unassigned

5.

RS232/485 Channels

Serial port that can that supports one RS232 connection (RS232-1 setting). Primarily

used for connecting PTZ control. The RS232/485 ports will be configured under

different Blocks as follows: Channels 1 & 2 are Block 1 (first IP), Channels 3 & 4 are

Block 2 (second IP), Channels 5 & 6 are Block 3 (third IP) and Channels 7 & 8 are

Block 4 (fourth IP).

For more information on the pin-out for front panel RJ45 connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

19

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

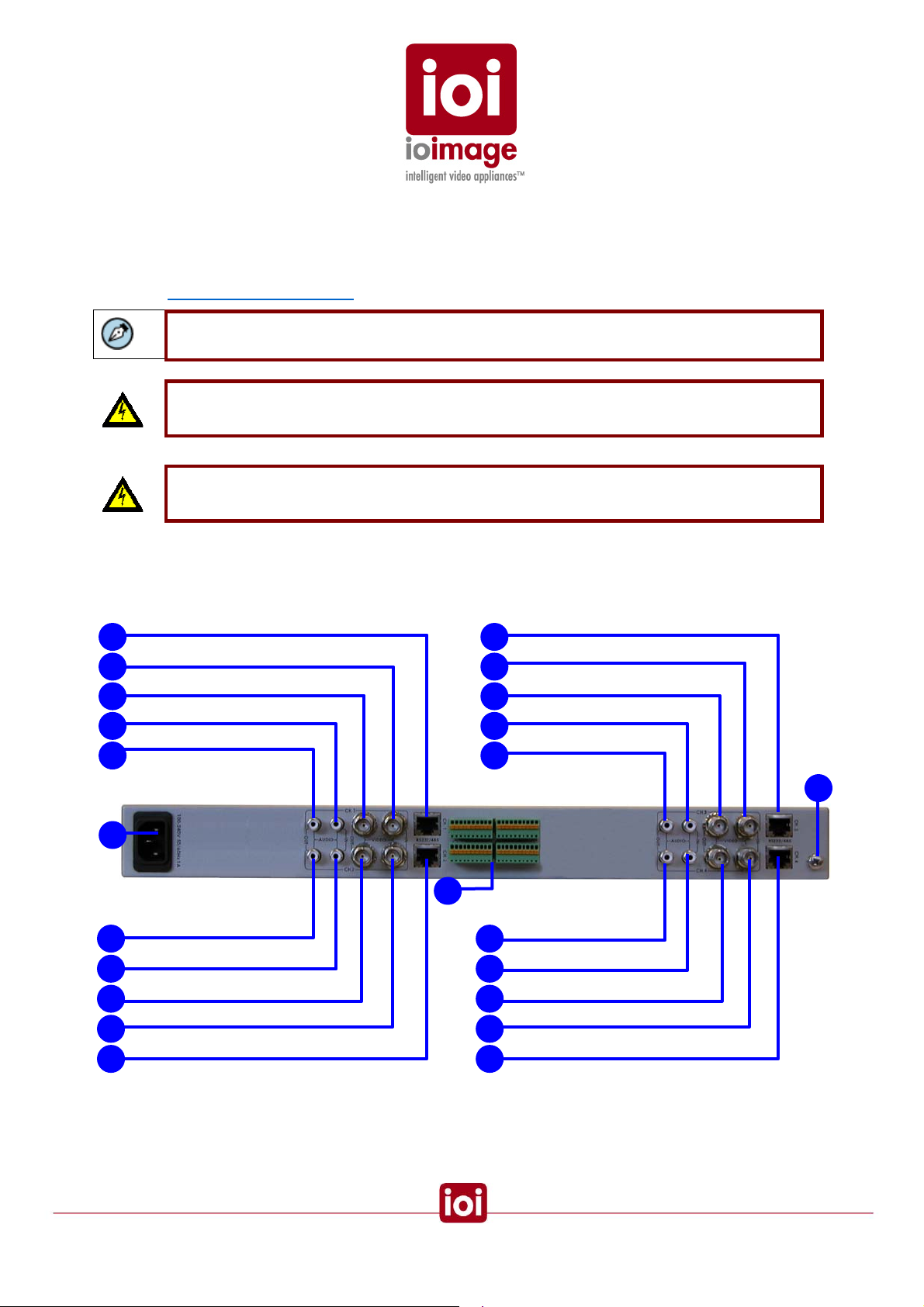

trk8000 Unit Back Panel

This section provides a short description of the trk8000 unit front panel connections and features.

2

1

5 5

2

1

4

3

4

3

2

1

6

7

1 1

2 2

3 3

4

3

5

trk8000 Back Panel

4

3

4 4

1 1

2 2

5

4

3

4

3

2

1

8

20

VIDEO OUT

1.

Video output for transmitting analog video signal to an analog video display or analog

video recording device. You can connect an analog monitor to this port for viewing

ioibox unit video.

2.

VIDEO IN

Video input for receiving analog video signal from a standard video source, such as

from a camera or device.

3.

AUDIO OUT

T

Output audio standard RCA jack (female RCA connector) for transmitting sound to

external devices such as an amplified loudspeaker.

4.

AUDIO IN

Input audio standard RCA jack (female RCA connector) for receiving sound from

external devices such as a line-level microphone (1V RMS).

5.

RS232/485 Channels

Serial port that can be split-out for up to two connections (RS232 and RS485 support).

Primarily used for connecting PTZ control. The RS232/485 ports will be configured

under separate Blocks as follows: Channels 1 & 2 are Block 1 (first IP), Channels 3 & 4

are Block 2 (second IP), Channels 5 & 6 are Block 3 (third IP) and Channels 7 & 8 are

Block 4 (fourth IP).

For more information on the RJ45 pin-out for the back panel connections, see the

Connector Mapping Tables section (page 64).

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

6. POWER

The power plug for connecting the IEC cord (C13/C14).

21

7. Alarm Inputs and Relay Outputs

Alarm Inputs

(1-8) Terminal-block-connector port for plugging in terminal block connectors. Supports

up to four input connections (a set of two wires for each) for external relay devices. The

right terminal of the two is a grounded common. For example, fire sensors, PIR, fence

sensors, etc. For more information and channel assignment, see the

Inputs section (page 38) and External Device Interfaces – ioibox Channel Assignments

(page 22).

Relay Outputs

Terminal-block-connector port for plugging in terminal block connectors. Supports

output of optoisolated signal for up to two connected external relay devices. For

example, an electrical door lock relay.

NO1, NO2 are leads for “NORMALLY OPEN” relay configurations

NC1, NC2 are leads for “NORMALLY CLOSED” relay configurations

C1, C2 are leads for COMMON wire relay configurations for either NC or NO relay. For

more information and channel assignment, see the

(page 34) and

Connecting Alarm

Connecting Relay Outputs section

External Device Interfaces – ioibox Channel Assignments (page 22).

8. Protective Earth Terminal

ioibox must have the external protective earth terminal permanently connected to

protective earth according to local regulations and codes. For more information, see

Connecting the External Protective Earth Terminal (page 46).

External devices interfaces – ioibox Channel Assignments

The interfaces to external devices (Relay Outputs and Alarm Inputs) are configured using the

ioimage HTML Edition Setup and are distributed between the Channels of the ioibox unit. In order

to configure the external interfaces you will need to know where it is connected on the rear panel

terminal block and which channel it is connected to. In addition, the assignment of each channel to

a respective block IP will be important to note.

The external devices by default are not activated and will not work until they (Relay Outputs and

Alarm Inputs) are configured in the HTML setup.

The following diagrams show the channel assignment for each of the unit models:

CH3 & 4 CH1 & 2

trk4000 External Device Interfaces (Relay Output and Alarm Input) Channel Assignment

22

CH1 CH3

CH2 CH4

trk4000d External Device Interfaces (Relay Output and Alarm Input) Channel Assignment

CH5 & 6 CH1 & 2

CH7 & 8 CH3 & 4

trk8000 External Device Interfaces (Relay Output and Alarm Input) Channel Assignment

23

Package Accessories

• ioibox unit Power Cord

IEC power cord (C13/C14).

• Terminal-block spring-clamp-connectors for Relay Output and Alarm Input wire

termination.

• Adapter Cable (Optional)

An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

• CD

CD includes Documentation

24

Workflows

This section contains the following sections:

• Pre-Install Workflow (page 25)

• Installation Workflow (page 26)

• Post Install Workflow (page 27)

Pre-Install Workflow

Pre-install for ioiboxes usage

1. Install video cameras.

2. Determine ioibox unit storage. Install boxes and associate equipment if needed.

3. Install electrical infrastructure (conduit, electrical wirin g, boxes, breakers, grounded

outlets, switches, UPS, surge protector, grounds, etc.).

4. Establish or Install LAN/WAN network access for ioibox unit location (network wiring,

ports, wireless, WAP (Wireless Access Point), etc.).

5. Install wiring between interfaces to external devices (Relay Outputs, Dry contact Alarm

Inputs) and the ioibox location.

6. Install video monitors and the wiring to connect to the ioibox unit location.

7. Install wiring between PTZ controller leads and the ioibox unit location.

8. Connect the workstation computer to the network.

The unit is delivered from manufacture with a pre-configured IP

address. Change the pre-configured IP address to match your network IP

mapping before connecting the unit to the network.

It is possible to access the HTML Edition Setup menu in the unit by

connecting from a laptop/PC directly to the unit using a network cable and

typing the IP address on an IE web browser

Pre-install for stand-alone using only the analog video output

1. Install video cameras.

2. Determine ioibox unit storage. Install boxes and associate equipment if needed.

3. Install electrical infrastructure (electrical wiring, boxes, breakers, grounded outlets,

switches, UPS, surge protector, grounds, etc.).

4. Turn on the cameras, matrix switcher, monitors as well as any external devices

(connected to the units through Relay Outputs and Alarm Inputs).

25

Installation Workflow

1. Write down the ioibox IP address.

2. Assemble the video cameras, associate equipment, and ioibox in the camera casing.

Connect necessary internal wiring among the associated devices.

3. Mount the video unit (includes mounting brackets, casing, camera, pan/tilt/zoom, and

ioibox.) Note: ensure necessary cooling, shelter and ventilation to maintain proper

ambient environment. The trk1 and trk1 must be protected from weather conditions.

4. Connect the infrastructure wiring to the devices inside the camera casing, including

ioibox to network, video, relay output, alarm input (dry contact), power, etc.

5. Note which cameras and dry contacts (Relay Outputs and Alarm Inputs) are connected

with descriptions.

6. Turn on the cameras and monitors as well as any dry contacts (Relay Outputs and

Alarm Inputs).

7. Access the unit using a supported web browser software (Internet Explorer 6 or

greater).

8. If you choose to make changes to the ioibox network, access the unit IP and make

changes in the setup area of the HTML software.

Note

In order for the unit to detect and track, the channel must be armed with an active rule

defined in the setup. For more information, refer to the HTML Edition Setup User Guide.

26

Post Install

The following general workflow outlines the tasks that will need to be done after the install of

ioiboxes. These post install procedures are mentioned in this document but are co vered in greater

detail in the ioibox HTML Edition Setup User Guide. Please refer to these guides for more detail.

1. Configure the unit using its built in HTML setup application. Configure the unit, and

camera including Relay Outputs, Alarm Inputs, etc. For more information, refer to the

ioibox HTML Edition Setup User Guide.

2. Connect monitoring compu t ers with a supported web browser or supported RTSP

device. If using analog only connect to the analog monitors.

Overview of Alarm Inputs (Dry Contacts)

Alarm Inputs of the ioiboxes allow interaction among the ioiboxes, cameras, and external devices.

The units can receive input signals (dry contact close/open) from external devices. For example,

fire alarms, PIR, magnetic sensors, fence sensors, break glass stations, control valve sensors,

mercury switches, etc and use them for triggering automatic actions.

CAUTION

To avoid damage to the system and system interference, a certified electrician must assure

that the ground voltage (ground loops) is comparable among all connected system

components.

CAUTION

Assure the common ground terminal connection for alarm inputs is connected in the right

terminal connector socket of an Alarm Input pair

Specification: Dry Contacts (max. 24VDC 100mA) IN

Overview of Relay Outputs

An external device can be connected to the Relay Output terminal block of the unit. In response to

events such as alarm inputs, intruder alarms, poor visibility, etc. signals can be sent to operate

external devices.

CAUTION

To avoid damage to the system and system interference, a certified electrician must assure

that the ground voltage (ground loops) is comparable among all connected system

components.

27

The following diagram depicts an incident response Relay Output scenario using a Normally Open

configuration for an automatic road barrier.

External device is triggered on the event of intrusion in a detection zone

Caution

Consideration and care needs to be given regarding how the security officers will reset,

command, and override incident responses. For example, if the system detects someone

walking in a detection zone and automatically executes a lockdown, security officers may

need a bypass for the lockdown.

Overview of RS232 and RS485 Connections

The RS262/485 connections made to the ioibox via its serial ports that can be split-out for two up

to two connections (RS232 and RS485 support). Dual connections split from one port to provide the

ability to connect two devices, such as a PTZ camera. Primarily used for connecting PTZ control

wires.

For more information on the pin-out, see the

RS232/RS485 connections can be utilized from custom programs that use the ioimage-API

(application program interface). For more information, refer to the ioimage-API User Guide.

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

Connector Mapping Tables section (page 64). The

Warning: The RS232 standard specifies a maximum open-circuit voltage of +/-25 volts.

Exceeding this voltage can cause permanent damage to the unit.

Warning: The RS485 standard specifies a maximum voltage of +12 V and -7 volts.

Exceeding this voltage can cause permanent damage to the unit.

28

There are two possible combinations of connections converted from a single RJ45 port as follows

using the adapter cable:

• Two RS232 connections

• One RS485 connection and one RS232 connection

PTZ Control

The ioibox units support connection of control lines to the RS232/485 port (controller wire leads) for

a PTZ camera. Once connected the PTZ camera can be controlled from remote from within th e

ioimage-Monitor and ioimage HTML Edition Setup using the built-in PTZ Remote Control Panel.

For more information on connecting the PTZ camera control lines, see the

Connecting PTZ

Cameras section (page 40).

Installation

Installation of ioiboxes contains several steps. These steps are described in the following sections:

• Connecting the ioimage unit (page 32)

• Connecting the Power Supply (page 46)

• Setting the ioimage unit IPs (page 47)

• Resetting ioimage units (page 51)

Unit Mounting

Warning: To prevent injury when mounting or servicing ioiboxes in a rack, precautions

should be taken to ensure that the rack unit is stable.

The following guidelines to help ensure safety:

• Observe the following precautions for rack stability and safety.

• Refer to the rack installation documentation accompanying the rack for specific

warning and caution statements as well as procedures.

Component refers to any hardware unit mounted in the rack.

29

• Do not attempt to move large racks alone. Use a minimum of two people for moving a

rack.

• Wheeled racks should be moved slowly over level floors. Caution should be given for

obstacles on the floor that may cause interference in the wheels and may be cause

for moving racks to topple. Additionally, caution should be given for overhead

obstacles that may catch the moving ioiboxes and topple them, such as tethered

wiring, door jams, or overhead conduits.

• For Electrical Safety, cords and cabling should be kept free from the wheels and

should not become pinched, cut, chafed, or crushed during movement.

• Ensure that the rack is level and stabilized before extending a component from the

rack.

• Do not overload the AC supply branch circuit that provides power to the rack. The

total rack load should not exceed 80% of the branch circuit rating.

• Ensure sufficient airflow for rack components.

• Do not step, stand, or climb on the rack or installed ioiboxes at any time, such as

when servicing other systems and components in a rack. Use an appropriate

stepstool.

• Do not hang or suspend items from the rack, which the rack was not intended to

support, such as hanging spools of wires, etc that may imbalance and destabilize the

rack.

• If a rack is only holding one unit, the unit should be mounted at the bottom of the rack

to assure greater stability.

• When mounting ioiboxes in a partially filled rack, load the rack from the bottom to the

top.

• If the rack wheels can be locked, assure they are locked to stabilize the rack before

adding, removing or servicing mounted ioiboxes.

• If stabilizing devices are provided with the rack, they should be installed before

mounting or servicing rack-mounted ioiboxes. In areas prone to earthquakes,

appropriate measures should be taken to secure racks for earthquake readine ss,

such as securing the racks to the walls.

30

Rack

mounting

screws

ioimage units secured in rack with mounting screws

31

Rack Requirements

• Racks should measure a minimum of 19” wide and 35.5” (0.9m) deep.

• Racks should be ventilated

• Racks should be grounded

• Racks should enable a Technician access to front and rear of the ioiboxes

• ioiboxes should be supported by fixed ventilated shelf or server rails

• ioiboxes shouldn’t rest on Video Patch Panels.

• ioiboxes should be mounted to the front of the rack with four server-mounting screws.

Connecting the ioibox Unit

This section contains explanations and procedures for connecting the ioiboxes. Note that the power

connection is recommended to be the last step of the first phase of hardware installation.

This section contains the following:

• Connecting to the Network (page 32)

• Connecting the Video Source (page 34)

• Connecting Relay Outputs (page 34)

• Connecting Alarm Inputs (page 38)

• Connecting PTZ Cameras (page 40)

• Connecting ioimage unit Video Output to a Analog Device (page 46)

• Connecting the External Protective Earth Terminal (page 46)

• Connecting the Power Supply (page 46)

Connecting to the Network

Before connecting the ioibox unit to the network assure that the LAN/WAN supports the ioibox unit

Block IPs and will allow the each Block to communicate with remote workstations where the

ioimage-Monitor or ioimage HTML Edition Setup are used.

By default, ioiboxes are shipped with a factory set Block IPs and MAC addresses labeled on the

ioibox unit package and the automatic network IP configuration mode supporting DHCP

connectivity is disabled.

This means if the ioibox unit is connected to a DHCP network, the static IPs labeled on the ioibox

unit package will not be used.

32

The default IP numbers are as follows:

Unit Channel Default IP

trk4000/d 1 & 2 192.168.123.10

3 & 4 192.168.123.11

trk8000 1 & 2 192.168.123.10

3 & 4 192.168.123.11

5 &6 192.168.123.12

7 & 8 192.168.123.13

If the network uses DHCP, the ioibox unit will request and use the IP numbers provided by the

DHCP.

If the network uses DHCP, the ioibox unit will request and use the IP number provided by the

DHCP.

If your network uses a firewall, you must configure the firewall to support communication among the

ioiboxes and the system software.

• HTTP

o Used for: Commands, Re quests, Replies and notifications

o IP port: 80

• NTP

o Used for: Time synchronization with a network time server using SNTP

o IP port: 123

• RTSP

o Used for: RTP session setup

o IP port:554

• RTP

o Used for: Multimedia streaming

o IP port: 2000 to 65535

• Multicast UDP

o Used for: Units self publishing

o IP address: 224.9.9.9

o IP port: 57346

To Connect an ioibox unit to the Network

:

• Connect one end of the Ethernet cable to the network port and the end to

the Ethernet 10/100 port labeled “1” on the front of the ioibox unit.

Related Links

How to Ping a ioibox unit from a Workstation (page 63)

33

Connecting the Video Source (camera)

The ioibox unit accepts video input from analog cameras and devices.

To Connect a Video Source to the ioibox unit

1. Securely connect the video cable to the output of the camera or device.

2. Connect the other cable end to ioibox unit VIDEO IN connection on the back of the

ioibox unit.

Tip

For ioibox units, be certain to note which camera is connected to each channel of a Block

(pair of channels that has an individual IP). This information will help during configuration in

the ioimage Setup.

Note

For PTZ cameras, you will need to connect the control lines of the PTZ camera in order to

use the pan, tilt, and zoom operability. For more information, see the

Camera Control Lines (Remote Control) procedure (page 40).

Connecting PTZ

Connecting Relay Outputs

For incident responses and device automatic commanding through the ioibox, you can connect

external devices, such as door locks, lights, etc. to the Normally Open or Normally Closed relay

outputs of the unit.

Relay outputs connected to the ioiboxes can be assigned as automatic incident responses to

events and alerts received on the ioiboxes. These are events such as intruder alarms, poor signal,

low visibility, etc. For example, an intruder is detected in a courtyard, as an automatic incident

response, exit doors are locked and security shutters are closed.

For more information on incident responses and relay outputs, refer to the ioimage HTML Edition

Setup User Guide.

Caution

To prevent damage to the ioibox units, do not exceed the voltage and current ratings for

Relay terminals.

CAUTION

To avoid damage to the system and system interference, a certified electrician must assure

that the ground voltage (ground loops) is comparable among all connected system

components.

34

Relay Output Specifications

• Maximum current 1A @ 24VDC

• Maximum current 0.5A @ 125VAC

Terminal Block Connectors

Relay Output Connection

Relay Terminals

for Relay Devices

(Up to 8 connected devices)

If the Relay Output wires are in a shielded, cable, connect the shielded wire to any of the common

terminals.

35

Relay Contacts Schematic

Terminal Block 1 Terminal Block 2

Relay Contacts Schematic for the trk4000 unit

Terminal Block 1

Terminal Block 2

Relay Contacts Schematic for the trk8000 and trk4000d unit

Terminal Block 3

Terminal Block 4

36

• NC1…NC

n

These are the terminals for connecting the wire that leads to the external device that

is on a circuit that is “Normally Closed”.

• NO1…NO

n

These are the terminals for connecting the wire that leads to the external device that

is on a circuit that is “Normally Open”.

• C1…C

n

(COMMON)

These are the second of the pair of connections made for an external device. These

terminals are for connecting the wire that leads to COMMON terminal of the external

device when connecting either a Normally Open or Normally Closed device.

A Relay Output terminal has two options for connecting a device:

• Option 1 is for a Normally Closed configuration.

• Option 2 is for a Normally Open configuration.

Output supports optoisolated signal for up to two connected external device relays, such as a n

electrical door lock relay.

Signals can be sent as continuous (intermittent) or single pulse.

37

Connecting Alarm Inputs (Dry Contacts)

The ioibox unit support connection of alarm devices for receiving input signals. This allows the

ioiboxes to automatically work with external alarm devices. Connected alarm devices becom e

available for the ioibox-HTML Live View allowing security personnel to receive alerts from the

connected external devices and trigger automatic responses.

CAUTION

Assure the common ground terminal connection for alarm inputs is connected in the right

terminal connector socket of an Alarm Input pair.

CAUTION

To avoid damage to the system and system interference, a certified electrician must assure

that the ground voltage (ground loops) is comparable among all connected system

components.

38

Alarm Input Terminals

for Alarm Devices

(up to 8 devices)

Common

Ground

Common

Ground

Side Two

Common ground terminal

for connecting the second

of a pair of wires for an

alarm device

Alarm Input Connection

Note that the Alarm Inputs are configured for use in the ioimage setup.

If the Alarm Input wires are in a shielded, cable, connect the shielded wire to any of the “B”

terminals.

39

Connecting PTZ Cameras

Connection of the PTZ camera control lines to the ioibox unit can be made either with a RS232 or

an RS485 to the proper connection to the RJ45 serial port.

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

If an RS232 cable is being used, the connection between the ioibox unit and the PTZ camera

requires use of an RS232 to RS485/RS232 bi-directional converter to be used.

This converter should meet the following requirements:

• Equipped with a DCE/DTE switch

• A minimum simplex and half duplex support

• Must support TxON from the ioibox unit to the PTZ camera

Once connected, the camera can be configured in the ioimage setup. This configuration allows PTZ

control of the specified camera using a remote PTZ controller.

The connection capabilities of the ioibox unit provide up to two connections to the RJ45 using the

adapter cable. Connections can be either RS232 or RS485 standard depending on which cable

connection you use.

The following are example procedures for connecting a Pelco Spectra III DD53CBW-X control lines.

As PTZ cameras vary, the procedure for other PTZ cameras may be different.

40

Connecting PTZ Camera Control Lines to RS485 lead-wires

The following diagram shows the ioibox unit and the PTZ connection using an RS485 connection

on the adapter cable.

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

PTZ control lines connected with the adapter cable RS485 lead-wires

Connecting a PTZ Camera to the RS485 connection of the adapter cable (example

procedure)

1. Using a terminal block or similar device connect the wires as follows:

a) Connect the Rx+ lead from the PTZ camera to the yellow wire (Tx+ lead) of the

adapter cable.

b) Connect the Rx- lead from the PTZ camera to the orange wire (Tx- lead) of the

adapter cable.

41

2. Plug the RJ45 male end (ioimage RS232 DB9 to RJ45) into the ioibox unit RS232/485

port.

42

Connecting PTZ Camera Control Lines to RS232 DB9 connection

The following is an example procedure for connecting a Pelco Spectra III DD53CBW-X control

lines. As PTZ cameras vary, the procedure for other PTZ cameras may be different.

The following diagram shows the ioibox unit and the PTZ connection using an RS232 and a RS232

to RS485/RS-422 bi-directional converter.

Note: An adapter cable RJ45 to 2 x RS232 DB9 + 1 RS485 lead wires can be purchased as

a separated accessory

PTZ Control Lines connected with the DB9 RS232 adapter cable

43

Connecting a PTZ Camera to the RS232 DB9 to RJ45 adapter of the ioibox unit (Example

Procedure)

1. Insert and clamp the control lines to the terminal block of the converter (RS232 to

RS485 bi-directional converter):

a) Connect the RX- Spectra lead to the TX- of the ATEN.

b) Connect the RX+ Spectra lead to the TX+ of the ATEN.

2. On the converter (RS232 to RS485), position the DCE/DTE switch to the DTE position.

3. On the converter (RS232 to RS485), position the DTS/TX/RX switch to the RX/TX-on

position.

44

4. Connect the converter (RS232 to RS485 bi-directional converter) to the adapter

RS232 D825 to DB9)

(

5. Attach DB9 female end to the (adapter cable - RS232 DB9 to RJ45) male adapter.

Adapter Cable

6. Plug the RJ45 male end (RS232 DB9 to RJ45) into the ioibox unit RS232/485 port.

45

Connecting ioibox Unit Video Output to an Analog Device

ioibox or ioicam unit analog video output can be monitored or recorded on analog devices. The

output analog video contains the video from the camera combined with On Screen Display (OSD)

overlays such as, tracking boxes and trails, time stamp, alarm, camera status, et c. These OSD can

be enabled and customized using the ioibox Setup application. For more information, refer to the

ioimage HTML Edition Setup User Guide.

To Connect an Analog Device to the ioibox unit Analog Video Output

• Using video coax 75

to the analog device video input of the external device (e.g. the VIDEO IN

of a monitor)

cable, connect to the VIDEO OUT of the ioibox-unit

Connecting the External Protective Earth Terminal

ioibox units must have the external protective earth terminal permanently connected to protective earth

according to local regulations and codes.

The protective grounding conductor should be aluminum. The lug of the protective grounding conductor

should be aluminum; washers and screws should be hi Cr stainless steel, or 12% Cr stainless steel, or

Cr on, Ni on steel, tin or steel.

External protective earth stud must be permanently connected to the protective earth.

US + Canada - INSTALLATION CODES

This device must be installed according top the latest version of the country national electric codes. Fo r

North America, equipment must be installed in accordance to the applicable requirements in the US

National Electrical Code and the Canadian Electrical Code.

To Connect the External Protective Earth Terminal

1. On the back right side of the ioibox unit, loose the screw of the protective earth

terminal.

2. Attach a properly rated ground cable according to local code requirements and tighten

the screw.

3. Assure that the other end of the ground cable is connected to protective earth

according to local regulations and codes.

Connecting the Power Supply

Connecting the electrical power to the ioibox unit is recommended as the last connection to be

made. Before connecting to the power, please review

section

Electrical safety should always be observed.

To Connect the Power

1. Connect the power from a properly rated power supply to the Power connector on the

unit panel.

Electric/Power Supply Cables (page 9) sections.

:

46

Cautions and Warnings (page 2) and the

2. Verify that the power LED on the front panel of the ioibox unit is lit.

Setting the ioibox IP

There are two connectivity methods for configuring the ioibox IP and network settings:

1. Over the network (switch/hub)

If you need to change the default IP, gateway or the subnet mask, you can do this over

the LAN/WAN network using a web browser when the following conditions are met:

• The IP of the machine accessing the ioibox-HTML setup application using

a Web Browser or running the ioimage SiteConfigurator application fits to

the subnet mask 255.255.255.0

• The network allows or has been configured for the factory shipped IP to be

visible to the machine where the ioibox-HTML setup application is

accessed from a Web Browser or where the SiteConfigurator is installed.

2. By a stand-alone computer connected to the ioibox if the following conditions are met:

• Windows 2000/XP/Vista with a 10/100 Ethernet port

• If the computer’s IP fits to the subnet mask 255.255.252.0

• The computer’s local area connection settings allow or have been

configured to support the factory shipped IP to be visible.