IO-Homecontrol HPWH 200 COZY, HPWH 270 COZY, HPWH 200 COIL COZY, HPWH 270 COIL COZY User's Installation And Operation Manual

Page 1

Documentation for

installation and

operation

HPWH 200 COZY

HPWH 200 COIL COZY

HPWH 270 COZY

HPWH 270 COIL COZY

Heat pump water heater

Page 2

WARNINGS

This appliance is not designed for use by people (including children) of

reduced physical, sensory or mental capacity, or those inexperienced or not

understanding this manual unless they have received prior instruction or

supervision from someone responsible for their safety, about the use of the

appliance.

Children must be supervised to ensure they do not play with the appliance.

This appliance may be used by children of 8 years or over, and by people of

reduced physical, sensory or mental capacity, or those inexperienced or

ignorant if they are properly supervised or if they have been given

instructions about the safe use of the appliance, and made aware of the

associated risks. Children must not play with the appliance. Children must

not clean or maintain the appliance without supervision.

INSTALLATION

WARNING: Product heavy, handle with care:

1/Install the appliance in a frost-free room. The warranty does not cover

destruction of the appliance through excess pressure caused by a blockage in

the safety valve.

2/Ensure that the wall on which it is mounted can support the weight of the

appliance filled with water.

3/If the appliance has to be installed in a room or location with an ambient

temperature always above 35°C, this room must be ventilated.

4/Place the appliance in an accessible place.

5/Refer to the installation diagrams.

The size of space needed for the

appliance to be correctly installed

is specified in the chapter installation.

It is mandatory for the water heater

to be fixed to the floor using the

fixing attachment provided.

The user keep this manual

1

Page 3

WARNINGS

WATER CONNECTION

A new safety unit must be installed at the intake to the water heater, in a

frost-free environment, with dimensions of 3/4" and with pressure of 7 bar -

0.7 MPa, compliant with local regulations in force.

A pressure reducer (not supplied) is needed when pressure is more than 5

bar (0.5 MPa) and it will be placed on the main supply.

Connect the safety unit to a drain pipe kept in the open air, in a frost-free

environment, with a permanent downward gradient, to remove any

expansion water from the heating process, or drainage water from the waterheater.

The operating pressure of the heat exchanger circuit must not exceed 3 bar -

0.3 Mpa, and its temperature must not be higher than 85°C.

ELECTRIC CABLING

Before removing the cover, always make sure that the power is turned off, to

prevent any risk of injury or electric shock.

There must be an omni-polar power cut-off (circuit-breaker or fuse) fitted

upstream of the electrical installation, compliant with local rules in force

(30mA differential circuit-breaker). The system must be earthed. A special

terminal, marked , is provided for the purpose.

French law strictly forbids connection of a product fitted with a cable and

plug.

MAINTENANCE - REPAIR

Drainage: Cut the power and cold water supplies, open the hot water valves

then operate the safety unit's drain valve.

The drainage device has a pressure limiting device that must be operated

regularly to remove any scale deposits and check it is not blocked.

If the power cable is damaged, the manufacturer, the after-sales service or

similarly qualified people must replace it, for safety's sake.

This manual is also available from the customer service department (contact

details shown on appliance).

2

Page 4

Contents

OVERVIEW

1. Important recommendations

2. Content of package

3. Handling

4. Working principles

5. Technical data

6. Dimensions – structure

7. Parts list

INSTALLATION

1. Water heater installation

2. Uncased installation (ambient air)

3. Cased installation (2 ducts)

4. Semi-cased installation (1 duct on air exit)

5. Not Allowed configurations

6. Hydraulic connection

7. Air connection

8. Electric connection

9. Connection of optional equipment

10. Commissioning

Operation

1. Interface

2. Description of pictograms

3. Main menu

4. The operating modes

Maintenance

1. Advice to the user

2. Service

3. Open the water heater for maintenance

4. Trouble shooting

Warranty

1. Scope of warranty

2. Warranty conditions

4

4

4

5

5

6

7

8

9

9

10

11

12

13

14

16

17

18

21

25

25

25

26

27

28

28

28

29

30

33

33

34

3

Page 5

Overview Installation Operation Maintenance Warranty

Description

1. Important recommendations

1.1. Safety directives

Installation and commissioning work on thermodynamic water-heaters may pose hazards because of highpressure and live electrical parts.

Thermodynamic water heaters must be installed, brought into service and maintained by trained and

qualified personnel only.

1.2. Transport and storage

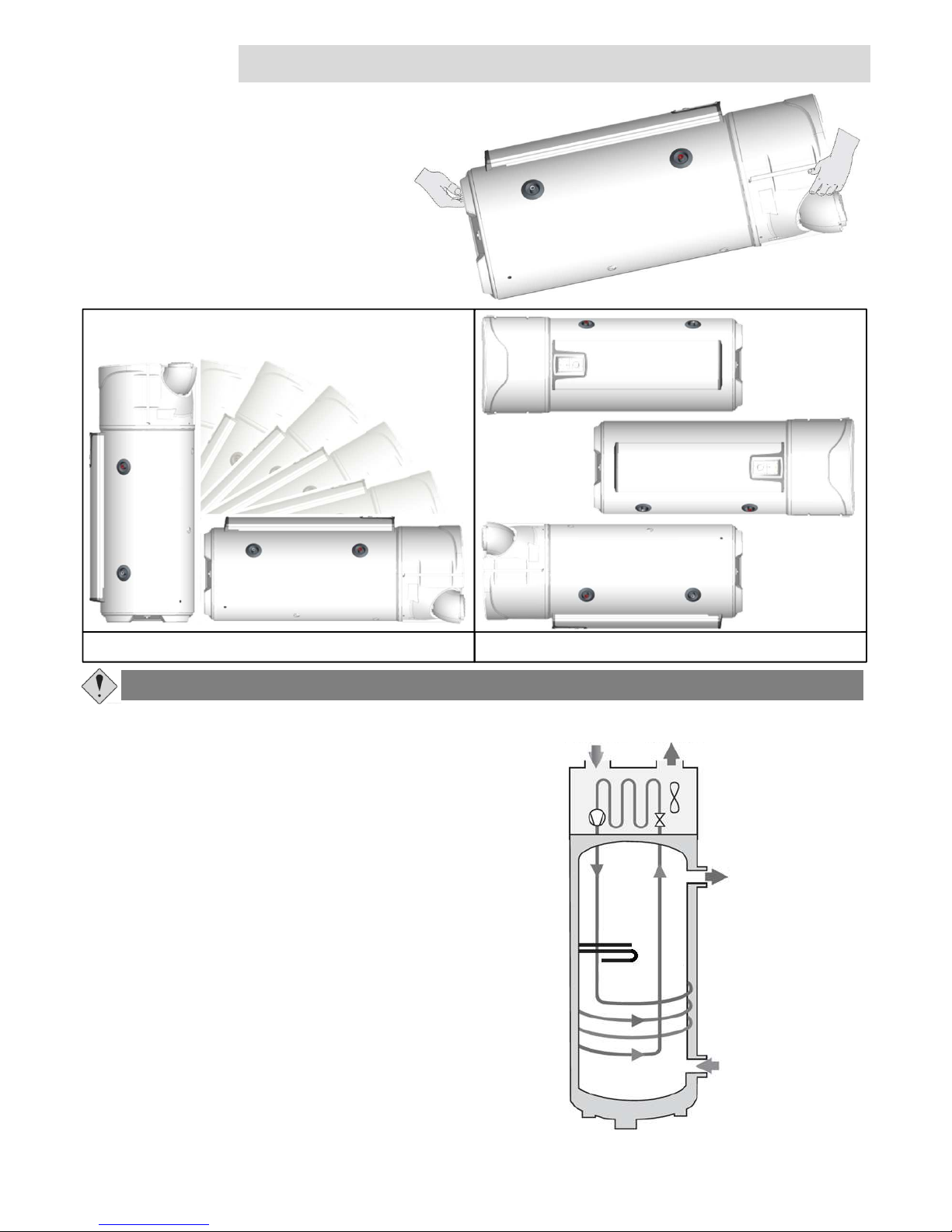

The product may be turned through 90° on one side. The side permitted is

shown clearly on an information label placed on the product packaging. The

product must not be turned on the other sides. An inclination indicator is used

to check that the product has been transported and handled in accordance

with our recommendations. We recommend you should be careful to respect

these instructions. Our commercial warranty will not apply if the inclination

indicator is red. We will not be responsible for any fault in the product

resulting from transport or handling of the product in a way that does not

comply with our recommendations.

2. Content of package

Water heater

1 tube for condensates (2m)

1 Manual

1 bag with insulation sleeve with 2 seals to be fitted to the

hot water outlet

Coil model only: an other additional insulation sleeve is

provided to be fitted to the recirculation fitting.

1 metal strap and screw to fix the device on the ground

1 safety valve to be installed on cold water pipe

(not to be used in France)

1 connection for evacuation of the condensates

4

Page 6

Overview Installation Operation Maintenance Warranty

3. Transport

The product integrates several handles to

facilitate handling to the installation site.

To transport the boiler to the installation

site, always use the lower grips and top

handles as shown.

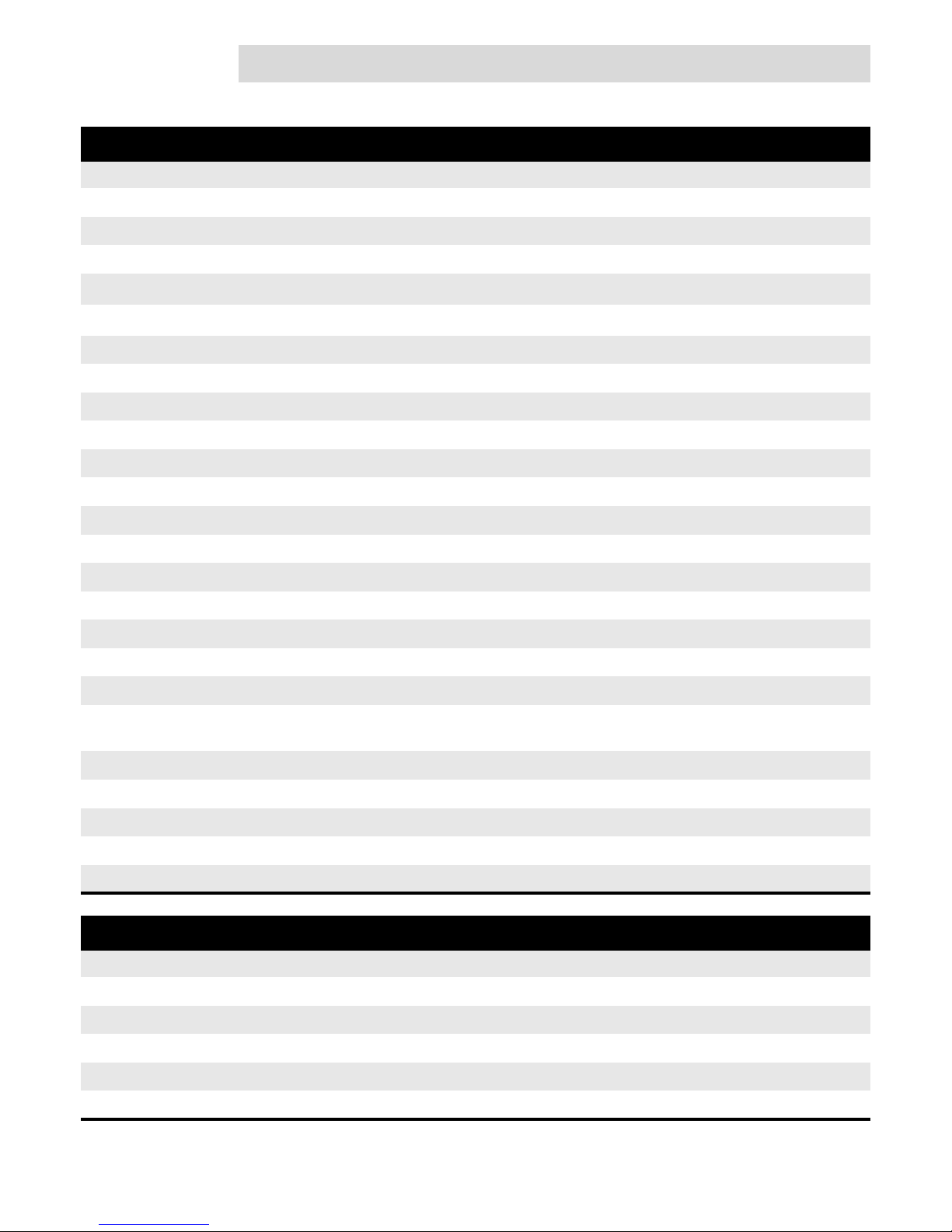

4. Working principles

The heat pump water heater uses unheated air to heat

domestic hot water.

The coolant in the heat pump sets up a thermodynamic

cycle which allows the energy from the unheated ambient

air or the outside air to be transferred to the water in the

cylinder.

The air is passed through the device by a fan, ventilating the

various components including the evaporator.

As it passes through the evaporator, the coolant evaporates

and conveys calories to the intake air.

The compressor compresses the coolant causing its

temperature to rise.

This heat is transmitted by the condenser to the domestic

water stored in the cylinder.

The coolant expands in the thermostatic expansion valve

and cools down. It is then once again ready to receive heat

in the evaporator.

The colder the air, the harder it is to withdraw calories from

it. Similarly, the higher the hot water setting, the harder it is

for the heat pump to return the calories withdrawn

Observe the recommendations and handling on the packaging of the water heater.

☺ Positions accepted Positions forbidden

Air flow

intake

Air flow

exhaust

Hot water

connection

Cold water

connection

5

Page 7

Overview Installation Operation Maintenance Warranty

5. Technical data

Model 200 liters 270 liters

Dimensions ( Height x Width x Depth) mm 1609 x 620 x 665 1949 x 620 x 665

Empty weight (model without coil) kg 85 93

Empty weight (model with coil) kg 100 108

Nominal capacity L 200 270

Hot and cold water connection ¾ ″ M

Coil’s connection 1″ M

Coil’s heating surface m² 1,2

Coil’s power at T

Primary

60°C and flow 1,5m3/h kW 16

Anticorrosion system ACI Hybrid

Rated water pressure Bar 8

Electrical connection (voltage/frequency) - 230V single phase 50 Hz

Maximal total power absorbed by the device W 2465

Maximal power absorbed by the heat pump W 665

Power absorbed by the auxiliary electrical unit W 1800

Heat pump water temperature setting range °C 50 to 62

Heat pump user temperature setting range (air temperature) °C -5 to +43

Duct diameter mm 160

Air flow (without duct) at low speed m3/h 300

Air flow (without duct) at high speed m3/h 390

Load losses acceptable on ventilation circuit, without affecting

performance

Pa 25

Sound power level dB(A) 50,3

Sound pressure level at 2m dB(A) 33,5

R134a refrigerant capacity kg 1,25 1,35

Hot water quantity at 40° : V40td in 8h(Off-peak) L 312 347

Hot water quantity at 40° : V40td in 14h (Off-peak+6h) L 579 607

Performance at 7°C air temperature (EN 16147)

Coefficient of performance (COP) - 2,8 2,9

Tapping cycle - L XL

Standby power input (Pes) W 27 30

Heating up time (th) h.min 7h54 10h41

Reference hot water temperature (T

ref

) °C 54 52,9

Flowrate (air) m

3

/h 305,7 287,6

This device is compliant with directives 2004/108/CEEon electromagnetic compatibility and 2006/95/CEE on low voltage.

6

Page 8

G

Overview Installation Operation Maintenance Warranty

6. Dimensions

Ind MODEL

200

STD

200

ECH

270

STD

270

ECH

A Condensate outlet 1221 1221 1562 1562

B Total height 1609 1609 1949 1949

C Cold water inlet 304 462 304 462

D Hot water outlet 961 961 1300 1300

E Total width 620 620 620 620

F Total depth 665 665 665 665

G

Distance between

air inlet and outlet

418 418 418 418

H Coil inlet - 581 - 581

B

A

D

C

E

F

60°

Dimensions in mm

H

104

7

Page 9

Overview Installation Operation Maintenance Warranty

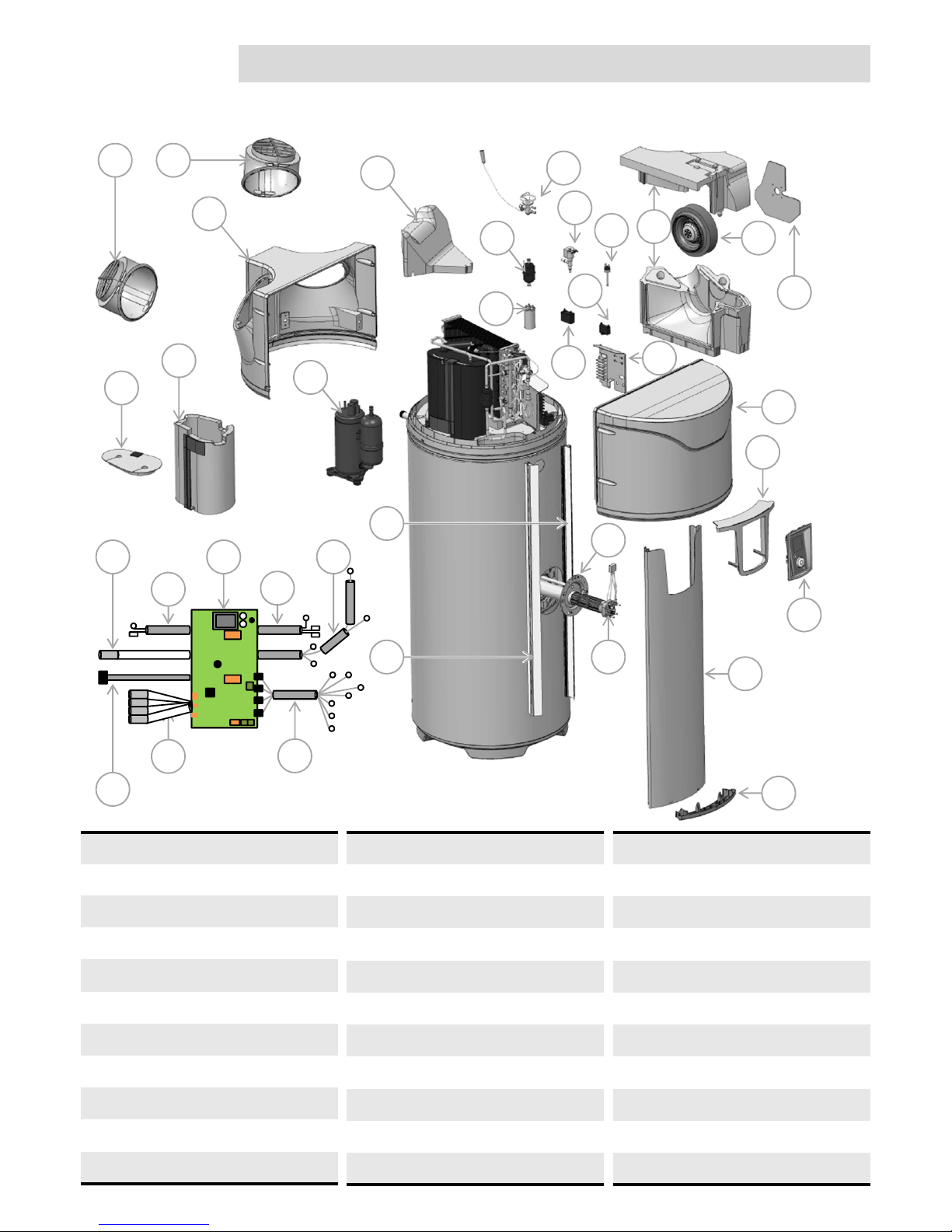

7. Parts list

1

2

3

5

4

6

7

8

9

10

11

12

13

14

15

16

33

18

1

19

18 20

21

22

23

24

1 Adjustable inlet and outlet

2 Rear cover

3 Spoiler

4 Filter

5 Capacitor 15µF

6 TX valve

7 Fan scroll casing

8 Hot gas valve assembly

9 Pressure switch

10 Fan

11 Fan plate support

23 Front column

24 Lower column plug

25 ACI wire

26 Regulation controller PCB

27 Compressor wire

28 Water sensor wire

29 Electrical backup wire

30 Heat pump sensors wire

31 Fan wire

32 Controller wire

33 Compressor jacket cover

12 Capacitor 1,5µF

13 Capacitor 4µF

14 Terminal connection block

15 Front cover

16 Compressor

17 Compressor jacket

18 Guide support rail

19 Hybrid heating sleeve

20 Electrical heating element

21 Controller desk

22 Controller

17

2625

28

30

32

29

27

31

8

Page 10

The device has to be installed on a flat and horizontal floor and

should not be in contact with a wall.

Overview Installation Operation Maintenance Warranty

Installation

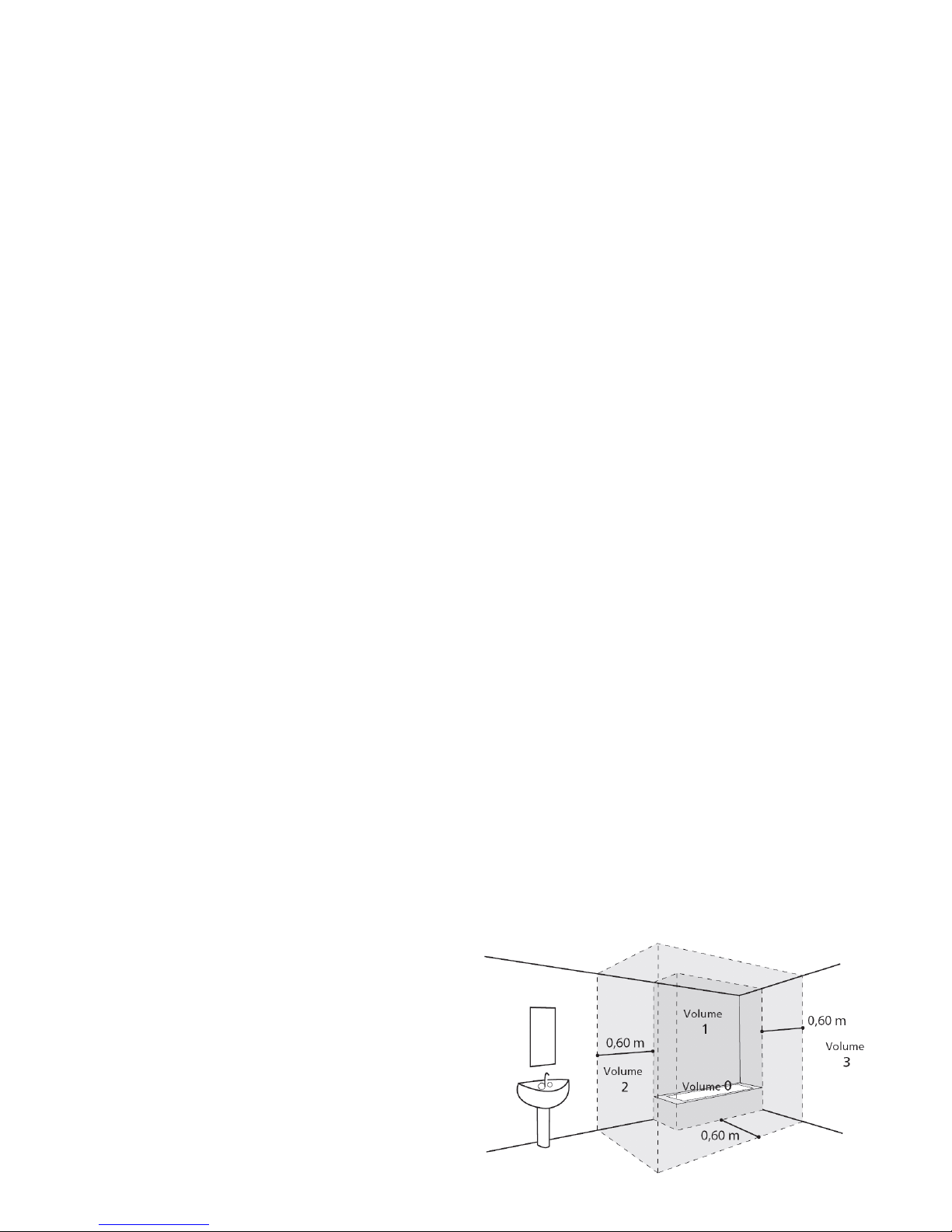

Whatever installation configuration is selected the place of installation has to conform to the protection level

IP X1B, complying to the prescriptions of NFC 15-100 ( or local equivalent ).

The floor has to support a load of 400 kg minimum (surface below the water heater).

The non-respect of installation guidelines can cause poor performances of the system.

1. Product installation

The device has to fixed (according article 20 of EN 60335-1) on the ground with the supplied

dedicated metal strap.

It is mandatory to install a retention basin below the water heater if installed above a living area.

License plate placed

over the hot water pipe

has to be easily visible.

Before filling with water

the water heater has to

be levelled.

Fix the water heater

with the supplied

metal strap.

Minimum height from ground to ceiling to

tilt the device :

200L : 1681mm

270L : 2007mm

9

Page 11

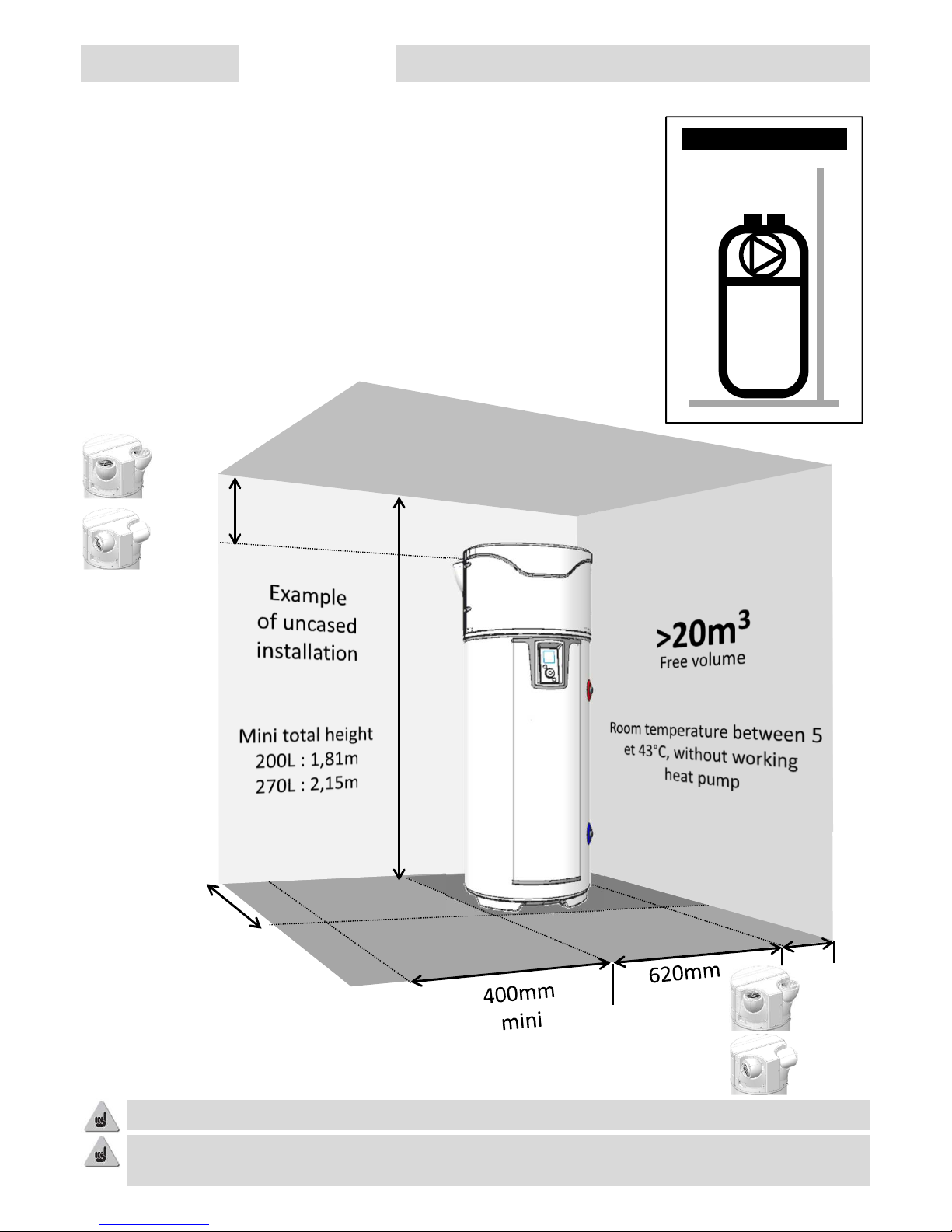

2. Installation uncased (Ambient air).

670mm

mini

Overview Installation Operation Maintenance Warranty

Unheated room with ambient temperature > 5° C and insulate the heated

rooms of the dwelling.

Parameter « Air pipes » to be set on « Inner/Inner »

Recommended room = underground or partially underground, room where

average yearly temperature is > 10° C°.

Keep a free space of 500 mm in front of electric compartment and 300 mm around hydraulic

connections to allow easy access for maintenance.

Examples :

• Garage : recovery of free calories from combustion engine or of domestic

devices.

• Washing room : reduce humidity of the room and recover lost calories of

washing machine and dryer.

It is mandatory to respect indicated distances to prevent air looping .

Inner/Inner

Mini

200mm

Mini

100mm

Mini

200mm

Mini

400mm

10

Page 12

Overview Installation Operation Maintenance Warranty

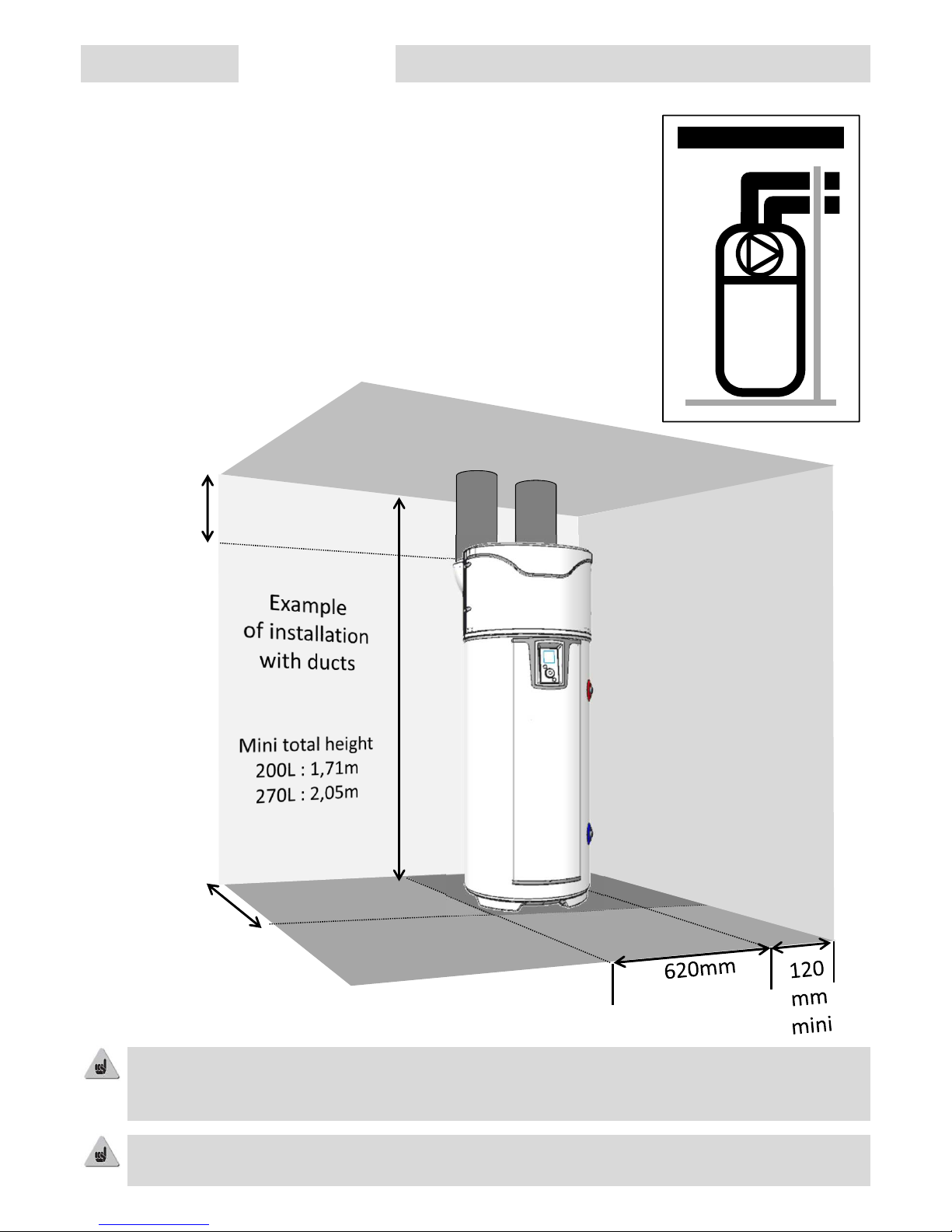

3. Installation cased (2 ducts).

Room at minimum frost free (T > 1°C).

Parameter « Air pipes» to be set « Outer/Outer »

Recommended room : living area (the heat loss of the water heater

remains in heated area), close to external walls. Avoid installation of water

heater and/or ducts near to sleeping rooms.

Examples :

• Washing room,

• Storage room,

• Cupboard in entry area.

670mm

mini

Keep a free space of 500 mm in front of electric compartment and 300 mm around hydraulic

connections to allow easy access for maintenance.

100mm

mini

Respect the maximum length of ducts. Use insulated rigid ducts.

Plan grids at air entry and exit to avoid intrusion of objects or animals.

Attention, entry or exit grids with manual closing device are forbidden.

Outer/Outer

11

Page 13

Overview Installation Operation Maintenance Warranty

4. Installation semi – cased (1 duct for air exit).

non heated room with ambient temperature > 5° C and insulated to the

heated rooms of the dwelling.

Parameter « Air pipes » to be set on « Inner/Outer ».

Recommended room = underground or partially underground, room where

average yearly temperature is > 10° C°.

The pressure reduction in the room generated by the air extraction causes fresh air entry through

doors and windows. Plan an air entry (Ø 160mm) from outside to avoid air sucking from heated

living area.

In winter time the renewed air can cool the room.

Keep a free space of 500 mm in front of electric compartment and 300 mm around hydraulic

connections to allow easy access for maintenance.

670mm

mini

Examples :

• Garage : recovery of free calories from combustion engine or of domestic

devices

• Washing room : reduce humidity of the room and recover lost calories of

washing machine and dryer.

Inner/Outer

12

Page 14

5. Prohibited configurations

Overview Installation Operation Maintenance Warranty

• Water heater extracting air from heated room.

• Connection to a heat recovery ventilation unit.

• Connection of the ducts to the attic.

• Duct on outside air and air exit indoor.

• Connection to an underground air duct.

• Water heater installed in a room together with a boiler connected to a chimney with natural draft and 1

duct to outside.

• Direct air connection to a cloth drying machine.

• Installation in dusty rooms.

• Intake of air with solvents or explosive materials.

• Direct air connection to cooking hoods with polluted and fatty air.

• Installation in a room where freezing temperature can occur.

• Objects stacked on the top of the device.

13

Page 15

6. Hydraulic connection

Overview Installation Operation Maintenance Warranty

Cold water inlet is marked with a blue collar and the hot water outlet has a red collar. Both have a thread gas

dia. 20/27 (3/4").

For regions with a lot of scale (Th>20°f), we recommend to treat the water. The hardness after softener has to

be higher than 15°f. The use of a softener does not influence the warranty if the softener is approved for the

country of installation and set to the rules of art, with regular checking and maintenance.

Local criteria of drinking water quality have to be respected.

The use of a circulation loop should be restrained. Such an installation may disturbs the stratification

inside the tank. This triggers more working cycles for the heat pump and the potential use of the

electric backup heater.

6.1. Cold water connection

Before connection check that the piping is clean without any particles from installation.

The installation has to include a new safety valve set to 7 bar ( 0,7 Mpa ), compliant to EN 1487 and

connected directly on the cold water inlet.

No hydraulic device (stop valve, pressure reduction, flexible...) is allowed between the safety valve

and the cold water inlet of the water heater.

As water can flow from the safety valve the drain

should be kept in open air. In any type of installation

there should be a cold water stop valve, before the

safety valve.

The overflow of the safety valve has to be connected

to the used water evacuation through a siphon.

Installation has to be in a frost-free environment. The

safety valve has to be operated regularly to check the

working condition (1 - 2 times per month).

The installation should be equipped with a pressure

reduction if the main water supply pressure is higher

than 5 bar (0,5 MPa). The pressure reducing device

has to be installed at the beginning of the distribution

network (before the safety valve). We recommend a

supply pressure of 3 - 4 bar (0,3 to 0,4 MPa.

☺ OK ☺ OK

KO

Pressure reduction

Water supply

Safety valve

Cold water

inlet

Siphon

14

Page 16

6.2. Hot water connection

Overview Installation Operation Maintenance Warranty

If the installation is made with synthetic pipes (e.g. : PER, multi-layer…), install mandatory a

thermostatic control valve at the connection pipes of the water heater. The setting should be done in

relation with the specification of the installed piping.

Do not connect copper tubes directly on the tank connection. You have to fit the supplied insulation

union (included in the supply).

In case that the tank connection is corroded without this protection the warranty will not apply.

The use of a siphon to connect to sew water is mandatory (the siphon must not be made with the

supplied tube).

6.5. Condensate evacuation

Depending on the degree of humidity in the air you can get

up to 0,25l/h of condensation. The evacuation of condensate

should not been made directly to sew water because of

possible corrosive gasses damaging the exchanger fins and

water heater parts.

The temperature drop of the air passing through the exchanger forms condensation from humidity

in the air. The condensed water is evacuated on the rear of the tank using the supplied plastic tube.

6.3. Connection of circulation loop

Do not connect copper tubes directly on the tank connection. You have to fit the supplied insulation

union (included in the supply).

In case that the tank connection is corroded without this protection the warranty will not apply.

If the circulation connection is not used install the plug and seal on this connection (included in the

supply).

6.4. Connection of primary circuit (for water heater with coil)

Protect the circuit against over pressure due to water expansion during heating with a safety valve 3

bar – 0,3MPa, or an expansion vessel open type (atmospheric pressure) or a closed expansion vessel.

The nominal circuit pressure should not exceed 3 bar – 0,3MPa, the temperature not higher than

85°C. If the coil is connected to solar panels use an adapted water glycol mix to protect against frost

and corrosion : e.g. « TYFOCOR L ». If the circuit is equipped with stop valves on the coil entry and

exit do never close both valves simultaneously to avoid the risk of over-pressure in the coil.

15

Page 17

7. Air connection

Overview Installation Operation Maintenance Warranty

If the volume of the installation room is not sufficient the water heater can be connected to ducts with a

diameter 160 mm. If the ducts are not insulated this could generate condensation in the ducts during

operation. The use of insulated ducts is mandatory.

If the water heater is ducted the parameter setting has to be adapted.

The total pressure drop of ducts and accessories for air intake and exit has to be less than 150 Pa.

The recommended length of ducts has to be respected.

Position of the air intake and exit.

❶ Unscrew the fixing

screws of the air

connection, then turn in

the required direction.

❸ Rotate again by

120°, position to the

opposite sides.

❷ Rotate by 120°,

position to the rear.

A poor duct installation (duct compressed, length or number of bends too high…) can reduce the

performance. Thus the use of flexible ducts is not recommended.

The ducts can be fitted

directly on the

positionable air in/outlets.

EXIT

Note : The positionable air connections allow to reduce or avoid the duct bends. For further information on the

positionable air connections, see the § « Positioning of the water heater ».

❹ Do not position the

air connection partially

face to face.

Position not allowed as

cold air will be recycled !

☺ ☺

Number of bends 90°

Total duct length with air intake and exit (ATL catalogue)

ALUMINIUM SEMI RIGID PEHD;;;;;;;;;;;;;;

0 8m 19m

1 7m 16m

2 5m 12m

16

Page 18

Overview Installation Operation Maintenance Warranty

8. Electric connection

Refer to the electric connections diagram below and on page 34.

Never supply power directly to the heating element.

The water heater must not be switched on before complete filling with water.

The water heater must be connected to electricity supply permanently.

The water heater has to be connected on single phase 230 V alternative current. Connect the water heater

with a cable with rigid conductors with section of 1,5 mm². The installation is composed of :

• A 16A omni-polar circuit breaker with contacts opening at minimum 3mm,

• A 30mA differential circuit breaker.

If the power cable is damaged, the manufacturer, the after-sales service or similarly qualified people must

replace it, to avoid danger.

The security thermostat fitted to the auxiliary electric heating element must not be repaired in other places

as our factory. Failure to respect this clause invalidates the warranty.

The device must be installed in accordance with the national electrical installation rules.

3x 1,5mm²

16A

Connection to earth is mandatory.

Electric connection diagram

17

Page 19

Overview Installation Operation Maintenance Warranty

9. Connection of optional equipment

Water heaters with a coil can be connected to a gas / fuel oil

boiler. In this configuration, the water heater commands the

heat generation to the boiler.

The connection of the boiler has to be made on the contacts C1

and C2 of the wiring board.

Always switch-off power before any operation.

9.1. Connection to a boiler.

A dedicated cable channel exists for the connections. Please use it.

To access the wiring board read the instructions to remove the front cover.

When associated with a photovoltaic system you can store the

excess energy produced in the water heater as hot water. Once

the photovaltaic panels produce enough energy, the inverter

sends a signal to the water heater which switchs into a special

mode ( PV ) activating the heat pump. If the inverter signal stops,

the water heater switches automatically back to the previous

operating mode. In this PV mode the set temperature is changed

to 62 ° C (no modification possible) and on the display appears

«PV».

The water heaters linked to a photovoltaic installations has to be

connected to the inverter module.

The connection to the inverter is done with B1 and B2 of the

wiring board.

9.2. Connection of a photovoltaic station.

Diagram potential 230V

Diagram dry contact

Electric power supply

Boiler connection

dry contact

A1

A2

B1

B2

C1

C2

Power supply

Photovoltaic connection

contact 230V~

A1

A2

B1

B2

C1

C2

Power supply

Photovoltaic

connection

dry contact

A1

A2

B1

B2

C1

C2

A1

A2

B1

B2

C1

C2

18

Page 20

Overview Installation Operation Maintenance Warranty

Photovoltaic connection: contact 230V

Photovoltaic connection: dry contact

Electricity supplier

Signal 230V~ - 50Hz

Power threshold (mini) = 700W

Inverter PV panels

Signal 230V~ - 50Hz

Available power

Connect

to

B1 B2

Junction

box

Electricity supplier

Signal 230V~ - 50Hz

Power threshold (mini) = 700W

Inverter

PV panels

Dry contact

Available power

Connect

to

B1 B2

Junction

box

19

Page 21

For thermal solar operation the water heater (models with

« solar» exchanger)has to be connected to the solar station. In

this configuration, the water heater receives the signal to operate

the electric backup from the solar station. All other functions are

not active. This connection should not be used for an automatic

multi-energy operation.

The connection to the solar station should be done on the

contacts B1 and B2 of the connection board.

9.3. Connection to a solar station.

Electric power supply

Solar contact 230V~

A1

A2

B1

B2

C1

C2

Overview Installation Operation Maintenance Warranty

9.4. Installation of the solar sensor

Take off the plastic cap and the

foam plug located near the

exchanger connections.

Push the sensor through the

plastic cap (the cap has dedicated

perforations).

Insert the sensor in the sensor

slot and make sure that it is in

correct position in the bottom of

the sensor slot.

Replace the foam plug and clip

the plastic cap.

❶

❷

❸

❹

❺

20

Page 22

Overview Installation Operation Maintenance Warranty

10. Commissioning

10.1. Filling of the tank

Open one or several hot water taps.

Open the cold water tap on the security group (make sure that the drain valve is closed).

When water starts flowing from the hot water taps close them. The tank is full.

Check the connections for possible leaks.

Check the correct function of valves and safety group by opening them several times in order to eliminate

possible particles.

❶

❷

❸

❹

❺

10.2. First operation

Switch on the power supply.

Check that no error message appears on the screen.

At the first switching on the setting instructions are shown on the display. Follow thoroughly the

instructions on the display to set the parameters (Date and time, Air ducts, Installation, circulation loop,

Photovoltaic system, operation range, Anti-legionella system).

When the parameters are set check the functions of the water heater (see § « Checking of operation »).

❶

❷

❸

❹

If the water heater has been tilted wait for minimum 1h before operation.

To return later to the settings, check the paragraphs « Setting of the installation » or « Parameters of

installation ».

Check the information

Follow the instructions

Access to settings

Lock the settings

Navigate - +

Reduce/Increase the values

Return to previous screen

Confirm

MENU

21

Page 23

Overview Installation Operation Maintenance Warranty

10.3. Settings of the installation.

• Date and time

Set the day and confirm. Proceed in the same way for the month, the year, the hour and the minutes.

• Operation time

This parameter defines the allowed working hours for the operation of the heat pump, the electric backup

and, if existing, the hydraulic backup depending on the need of DHW :

Start of the machine any time of the day,

Start of the machine during the programmed period only.

• Connectivity

The Water Heater can be paired with devices using and remotely controlled.

• Language

Setting possible in French, English, Flemish, Spanish, Portuguese, German, Italian et Polish.

• Additional electric backup

Allows to activate or not the use of the electric backup. If not activated, the water heater will never use the

electric backup; in case of low air temperature a lack of hot water is possible.

Access again to the various settings of the installation : +

Permanent 24h/24h

Programming

Settings

10.4. The parameters to set on installation.

(If not set during the first commissioning)

The parameters can be used in MODE INSTALLER

Press and hold the button MENU and rotate the knob a half turn to the

right.

To exit the installer mode, proceed in the same way or wait for

3 minutes.

Access to parameters

Settings

❷

rotate

1/2 turn

to the

right

❶ press and hold

• Air pipes (aeraulics operation) :

This parameter defines the type of aeraulics connection:

Air intake and exit are not connected to air ducts (ambient air)

Air intake and exit are connected to air ducts (fully ducted)

Air exit is connected to an air duct (semi ducted)

• Installation (for models with coil) :

The internal coil is not used

The internal coil is connected to a boiler managed by the water heater

The internal coil is connected to a solar system

In « Connected to boiler» mode , you have to define the degree of priority in the operation of the boiler and

the heat pump in 4 levels :

The backup operates at the end of heating up in case of low air temperature (<7°C)

The backup operates at the end of heating up and ± early depending on air °C

The heat pump works on the start of heating up and stops ± early depending on air °C

The heat pump works on the start of heating up and for air temperature > 10°C.

Thermodynamics only

Connected to boiler

Connected to solar sys.

Inner/Inner

Outer/Outer

Inner/Outer

HP prioritized

HP optimized

Boiler optimized

Boiler prioritized

22

Page 24

Overview Installation Operation Maintenance Warranty

• PV system (Photovoltaic)/Smart-grid :

This parameter activates the pairing of the water heater with a photovoltaic installation. This operating mode

allows the forced start of the heat pump when the photovoltaic inverter sends a signal to the water heater.

The regulation switches automatically to the previous operating mode 30mn after the loss of the photovoltaic

signal.

During the signal reception the set temperature is automatically raised to 62°C (can not be changed).

• Exhaust air :

Allows to activate the air extraction function (2 speed : 300 or 390m3/h). When the water heater does not

heat the tank, the ventilator turns to evacuate the ambient air to the outside (only possible to activate if the

aeraulics connection is set to Indoor/Outdoor).

• Anti-Legionella function :

Allows to activate the function of water disinfection several times per month.

The water temperaturereaches 62°C one to four times per month depending on the setting.

• EMERGENCY-mode :

When activated the water heater operates only on the electric backup heater.

• Circulation cycle:

This mode is mandatory when a circulation loop is installed.

The set temperature changes to 65°C and the operation of the heat pump is adapted to this use.

The heat pump is allowed to work permanently (programming is not available).

10.5. Functional check

Functional check is available in MODE INSTALLER

Press and hold the button MENU and turn the knob half a turn to the

right.

To exit the mode installer, proceed the same way or wait for

10 minutes.

Access to parameters

Test

❷

Rotate

1/2 turn

to the

right

❶ Press and hold

Actuator

Compressor

Start the ventilator then the compressor

Slow operation

Operate the ventilator at low speed

Fast operation

Operate the ventilator at high speed

Defrosting valve Open

Check the click noise of the motor

Compressor + defrosting.

Start the ventilator then the compressor and

click noise of the hot gas valve

Additional electric backup

Start the electric backup heater

Additional boiler

Close the dry contact commanding the

boiler

Temperature sensor

Display the temperatures : incoming air, top

evaporator, bottom evaporator, exit

compressor, hot water

Fan

The TEST menu allows to operate all components of the product.

23

Page 25

Mode MANUAL :

This mode allows to define the desired hot water quantity by selecting the set temperature. The set

temperature is also displayed as equivalence of showers : about 50 L of hot water).

When the mode ECO is not activated, the water heater favors the operation of the heat pump. However if the

air temperature is low or the water consumption high, the electric (or boiler) backup can be used at the end

of the heating cycle to reach the set temperature.

When the mode ECO is activated, the water heater works exclusively with the heat pump in the air

temperature range of -5 to +43°C. The electric backup heater is not used. This function maximizes the energy

savings but can cause a lack of hot water.

Whatever setting of ECO, the electric backup heater is used automatically if the air temperature is outside the

working range to assure a sufficient hot water volume.

Overview Installation Operation Maintenance Warranty

10.6. Choice of operating mode

Press the button to access the menu

Mode

Mode AUTO (only available on installations «heat pump only ») :

This operating mode manages automatically the choice of energy allowing to maximize economies while

supplying a sufficient hot water comfort level.

The water heater analyses the water consumption of the previous days to adapt the hot water production as

required. It reacts to unplanned events by launching working cycles during the day to assure enough hot

water. The set temperature varies automatically between 50 and 62°C according to the consumption profile.

The water heater chooses preferably the heat pump. The electric backup can automatically be added to

provide the correct hot water volume.

10.7. Locking of interface

Press for some seconds to lock/unlock the interface.

Mode MANUAL on installation « Solar backup »

This mode allows the work of the heat pump in combination with a solar backup. However the

simultaneous working of the heat pump and the solar backup can damage the product. The heat

pump must be used in periods when solar energy is not available (to do this use the programming

mode of the water heater)

This mode is not available on installations « boiler backup » and « solar backup »

The mode ECO activated/not activated can’t be changed on installations « Boiler backup »

The mode BOOST : this mode activates the heat pump and all other available energy sources (boiler backup if

set, electric backup) at the same time to reach the maximum set point of 62°C.

The mode ABSENCE : this mode maintains the hot water temperature above 15°C by using the heat pump.

The boiler and electric backup can be used if the heat pump is not available.

24

Page 26

Overview Installation Operation Maintenance Warranty

Operation

1. Interface.

Display the information

Follow the instructions

Access to settings

Lock the settings

Navigate - +

Reduce/Increase the values

Return to previous screen

Confirm

2. Description of pictograms.

Fast heating confirmed

Absence registered / in operation

Present hot water temperature

Waiting

Warning

Electric backup working

Heat pump working

Boiler backup working

Reception of signal on solar system

contact

Reception of signal on photovoltaic

/ Smart-grid contact

MENU

25

Page 27

Overview Installation Operation Maintenance Warranty

3. Main menu.

Access to

settings

Follow instructions

displayed on screen

Navigate in the MENU

Reduce the

values

OK

Confirm

Increase

the values

Increase the hot water production during the period :

Set the number of days BOOST should work (from 1 to 7).

At the end of the set period, the water heater resumes the initial operating mode.

BOOST can be stopped at any moment :

Stop BOOST

Choose the operating mode:

Select AUTO or MANUAL (see § « The operating modes »

Program absence period:

Allows to indicate the water heater

• a permanent absence starting from the present day.

• a programmed absence (set the starting date and the return date). The day before return

a anti-legionella heating cycle starts.

During the absence period, the water temperature remains above 15°C.

This function can be interrupted at any moment:

Stop absence

Display the energy savings :

Allows to display the working level of the heat pump and of the electric backup during the

last 7 days, the last 12 months, since commissioning.

Display the electric consumption :

Allows to display the energy consumption in kw/h, of the last days, the last months, the

last years.

Display the parameters :

Allows to display the registered settings.

Set the date and time :

Set the day and confirm. Set the month, the year, the hour and the minutes.

Set the periods of operation :

Allows to define periods when the water heater may start.

Connectivity :

The Water Heater can be paired with devices using and remotely controlled.

Set the language :

French, English, Dutch, Spanish, Portuguese, German, Italian and Polish.

Additional Electric backup heater :

Allows to deactivate the use of the electric backup heater.

26

Page 28

SMART Energy Function :

A heat pump uses the available energy in the air and

transfers this energy through an exchanger around

the tank to the water. The heat pump performance is

higher when the exchange parameters are more

favorable; i.e. air temperature higher or tank

temperature lower. Our regulation evaluates

permanently the air and water temperature and what

energy source is more economical. The function

SMART Energy can decide to start heating with the

heat pump and to finish heating up with the boiler

backup.

-5 0 5 10 15 20 25 30 35 40 43

62

T°water

T°air

Priority HPOptimize

HP

Optimize

boiler

Priority

boiler

Overview Installation Operation Maintenance Warranty

4. The operating modes.

AUTO: The set temperature varies automatically between 50 and 62°C according to the consumption profile.

The water heater chooses preferably the heat pump. The electric backup can automatically be added to

provide the correct hot water volume.

MANUAL – ECO Not activated: The set temperature is fixed by the user between 50 and 62°C. The water

heater chooses preferably the heat pump. The electric backup can automatically be added to provide the

correct hot water volume.

MANUAL – ECO Activated: The set temperature is fixed by the user between 50 and 62°C. The water heater

chooses preferably the heat pump to maximize the energy savings. The electric backup is allowed to work if

the air temperature is out of the operating range.

4.1 The installation mode « Heat pump only » :

MANUAL : The set temperature is fixed by the user between 50 and 62°C. The water heater chooses

preferably the heat pump. The boiler backup can be activated automatically to provide the correct hot water

volume. If the backup through the boiler is not available (e.g. boiler switched off), the electric backup will be

activated.

4.2 The installation mode « Boiler backup » :

The water heater works only during the period when the solar system does not supply energy (when the solar

system signal is off). During the periods of solar production, the hot water production is operated with the

internal coil, the heat pump and the electric backup are not working.

MANUAL – ECO Not activated : The set temperature is fixed by the user between 50 and 62°C. The water

heater chooses preferably the heat pump. The electric backup can automatically be added to provide the

correct hot water volume.

MANUAL – ECO Activated : The set temperature is fixed by the user between 50 and 62°C. The water heater

chooses preferably the heat pump to maximize the energy savings. The electric backup is allowed to work if

the air temperature is out of the operating range.

4.3 The installation mode « Solar backup » :

The electric backup will never work if the parameter « Electric backup » is deactivated.

The Smart Energy function can be set on 4 different management levels:

The backup operates at the end of heating up in case of low air temperature (<7°C)

The backup operates at the end of heating up and ± early depending on air °C

The heat pump works on the start of heating up and stops ± early depending on air °C

The heat pump works on the start of heating up and for air temperature > 10°C.

60

55

50

45

40

30

35

25

20

15

Heat

pump

Boiler

HP prioritized

HP optimized

Boiler optimized

Boiler prioritized

27

Page 29

Overview Installation Operation

Service, Maintenance and Repair

If the absence mode cannot be used it could be necessary to drain the water heater if the device is switched

off. Proceed as follows:

1. Advice to the user.

The device has to be disconnected from mains before opening the cover.

Maintenance Warranty

Switch off power supply.

Open a hot water tap.

Close the cold water inlet.

Open the drain valve on the

security group.

❶

❸

❷

❹

In order to maintain the performances of your water heater, we advice to service it regularly.

2. Service.

By the USER :

What When How

Security group 1 to 2 times per month Operate the safety valve.

Check that water evacuation is ok.

General 1 time per month Check external shape of your device : no Error code

displayed, no leakage on the connections...

By the INSTALLER :

What When How

Ducts 1 per year Check if the device is ducted.

Check if the ducts are well positioned and not

deformed.

Condensates evacuation 1 per year Check the cleanness of the condensates evacuation

tube.

Electric connections 1 per year Check that any internal and external cable connections

are not loose and that all connectors are plugged in.

Electric backup 1 per year Check the correct function of the electric backup by

measuring the power.

Scaling Every 2 years If the supply water is hard clean the deposited scale.

28

Page 30

To access to the heat pump

compartment :

Remove 4 screws on the front,

Tilt the hood to the front.

Overview Installation Operation Maintenance Warranty

Only a refrigeration engineer is permitted to have access to the expansion valve adjustment screw.

If the expansion valve is adjusted without approval from the constructor, the product warranty may

be invalidated.

it is not recommended to touch the expansion valve setting until all other repair solutions have been

exhausted.

What When How

Thermal exchange of the

heat pump

Every 2 years* Check the correct working of the heat pump.

Components of the heat

pump

Every 2 years* Check the ventilator operation on it’s 2 speeds and the

hot gas valve.

Evaporator Every 2 years* Clean the evaporator with a nylon brush and products

neither scratching nor corrosive.

Refrigerant Every 5 years* Check the refrigerant quantity.

By the REFRIGERATION ENGINEER :

3. Open the water heater for maintenance.

❶

❷

❶ ❷

* In case of dusty environment increase the maintenance frequency.

To access the regulation:

Remove the clipped bottom plug of the front column,

Unscrew the 2 screws on each side of the column,

Slide the column down for 10 centimeters to liberate the interface support,

Press the center of the column to open and remove from the guiding rails.

❶

❷

❸

❹

❶ ❸❷ ❹

29

Page 31

Overview Installation Operation Maintenance Warranty

If there is a problem, lack of heating or release of fumes from the water outlet, cut the power supply and

notify your installer.

4. Trouble shooting.

Displayed Code Reason Result Service action

Error 03

Water temperature

probe defect or out

of measuring range

Reading of water

temperature

impossible : no

heating up.

Check the connection (A1) of the probe

(immersion sleeve).

If required replace the probe.

Error 07

No water in the tank

or ACI connection

open

No heating up

Fill the tank with water.

Check the connection (AC) of the cables, the

water conductivity.

Error 09

Water temperature

too hot (T>80°C)

Risk to trigger the

mechanical security

thermostat : no

heating up

Check the real temperature at a tap (T>80°C).

Check the connection (A1) and the position of

the temperature probe (immersion sleeve).

Check that the electrical backup is not

working permanently. Reset the mechanical

security device if necessary.

Water too cold

Cold water

temperature too

cold(T<5°C)

HP stopped.

Heating with electric

backup.

Resetting automatically at T>10°C. Control the

situation of the installation room (frost-free).

Error 21

Air intake probe

defect or out of

measuring range

HP stopped.

Heating with electric

backup.

Check the connections (A4) and the position

of the air intake probe. If necessary replace

the probe cable harness.

Error 22

Evaporatortop

probe defect or out

of measurement

range (-20 to 110)

HP stopped.

Heating with electric

backup.

Check the connections (A4) and the correct

contact of the probe to the tube.

Check the operation of the ventilator and that

it turns easily without any stop.

Error 23

Evaporator bottom

probe defect or out

of measurement

range (-20 à 110)

HP stopped.

Heating with electric

backup.

Check the connections (A4) and the correct

contact of the probe to the tube.

Check the operation of the ventilator and that

it turns easily without any stop.

Error 25

Pressure switch open

or compressor

thermal safety

HP stopped.

Heating with electric

backup.

Check the compressor connections (R1),

pressure switch, starting capacitor (15mF) and

the hot gas valve (T2). Control the resistance

of compressor windings.

Repairs have to be done exclusively by a qualified installer.

4.1. Error codes.

The alarm can be paused or reset by pressing OK.

30

Page 32

Displayed Code Reason Result Service action

Error 27

Compressor

probe defect or

short circuit

HP stopped.

Heating with

electric backup.

Check the connections (A4) and the position of the

compressor probe. If necessary replace the probe

harness.

Error 28

Default on

defrosting

HP stopped.

Heating with

electric backup.

Check the cleanness of the evaporator.

Check the refrigerant R134a charge (defrosted).

Check the operation of the ventilator.

Check the correct evacuation of condensates.

Check the hot gas valve connections (T2) and it’s

function (TEST menu).

Error 29

Flow temperature

of the

compressor too

high

HP stopped.

Heating with

electric backup.

Control the resistance of compressor windings.

Check the cleanness of the evaporator.

Check the refrigerant R134a charge.

Check that the air circulates without any obstacles.

Error 30

HP operates

without stop

more than 24h or

lack of power.

HP stopped.

Heating with

electric backup.

Check the cleanness of the evaporator.

High consumption or circulation loop or leak on hot

water circuit.

Check the connections (A4) and the correct contact

of the probes to the tubes.

Check the charge, the overheat value (5 minimum),

the defrost operation…

Control the resistance of compressor windings.

Overview Installation Operation Maintenance Warranty

Default Possible reason Diagnosis and service

Water not hot enough. Power supply is not permanent.

Set temperature too low.

Mode ECO selected & air

temperature out of range.

Electric backup or supply cables

(partially) defect.

Check that the device receives

permanently electric current.

Check that no cold water flows into

the hot water circuit (mixing tap

defect).

Select a higher set temperature.

Select the mode AUTO. Check the

periods of programming.

Check the resistance of the heating

element on the plug, and the good

shape of the cables.

Check the security thermostat.

4.2. Other failures without error code display.

31

Page 33

Default Possible reason Diagnosis and service

No heating

No hot water

No power supply to the water

heater : fuse, cabling…

Check the voltage on the power

supply cable

Check the parameters of the

installation (see periods of

operating)

Hot water volume not sufficient Water heater layout too small

Operation in ECO mode

Check the programmed periods

and reception of Night / Low Tariff

signal.

Select AUTO mode

Low pressure on the tab. Filter of security group clogged.

Tank full of scale.

Clean the filter (see §

maintenance).

Remove the scale from the tank.

Water dripping out of the security

group when the water heater is not

heating

Security group damaged or

clogged.

Supply pressure too high

Replace the security group

Check that the supply pressure

after the water counter does not

exceed 5 bar (0,5 MPa), if it does

install a pressure reducer set to 3

bar (0,3 MPa) at the start of the

water network.

The electric backup heater does not

work.

Mechanical security thermostat

was triggered.

Thermostat defect

Backup heater defect.

Reset the security thermostat on

the heating element.

Replacer the thermostat

Replace the element

Condensate overflow. Condensates evacuation clogged Clean the evacuation

Bad smell No siphon installed on the security

group or on condensates

evacuation

No water in the siphon of the

security group

Install a siphon

Fill the siphon

Vapor on the hot water tap Electric backup works permanently Shut off the electricity supply and

call the installer.

Interface does not work or display

problems

No power supply

Interface defect

Control the power supply.

Replace interface.

Overview Installation Operation Maintenance Warranty

After maintenance or repair, check the correct operating of the water heater.

32

Page 34

Overview Installation Operation Maintenance Warranty

Warranty

The following faults are excluded from this warranty: :

• Abnormal environmental conditions::

• Various damage caused by impact or dropping during handling after leaving the factory..

• Placing the appliance in a place exposed to frost or bad weather (damp, aggressive or poorly

ventilated environments).

• Use of water with aggressiveness criteria as defined by DTU Plumbing 60 - 1 additive 4 hot water

(chlorine rate, sulfates, calcium, resistivity and total alkali level)..

• Water with Th < 15° f.

• Water pressure higher than 5 bar (0,5 MPa).

• Electrical power with significant voltage spikes (mains, lightning, etc.).

• Damage from undetectable problems caused by choice of location (places difficult to access) and

that could have been avoided if the appliance were repaired immediately.

• Installation does not comply with regulations, standards, professional rules, especially:

• Safety unit distant or rendered inoperative (pressure reducing valve, non return valve or valve, ...,

placed upstream of the safety group).

• Missing or incorrectly fitted new safety unit NF-D 36-401 or equivalent, modification of calibration,

etc. …

• Missing dielectric union (cast iron, steel or insulating) on hot water connection pipes, leading to

their corrosion.

• Faulty electrical connection ( NF C 15-100 or equivalent ): incorrect grounding, inadequate cable

section, connection of flexible cables without metal terminations, failure to respect connection

diagrams specified by the Manufacturer.

• Powering up the appliance without first filling it (dry heating).

• Placing the appliance without consideration of manual instructions.

• External corrosion caused by poor sealing on pipes.

• Installation of a circulation loop.

• Wrong parameter setting for a ducted installation.

• Duct configuration not compliant to our instructions.

• Faulty maintenance: :

• Abnormal scaling of heating elements or safety units.

• No maintenance of safety unit, leading to excess pressure.

• No cleaning of evaporator or condensate evacuation.

• Modification of original equipment, without notifying constructor, or use of spare parts not

recommended by manufacturer.

1. Scope of warranty application.

A device being allegedly the origin of a damage has to remain on the place of installation for an

expert visit, the person supporting the damage has to inform his insurance.

33

Page 35

2. Warranty conditions.

Overview Installation Operation Maintenance Warranty

The water heater must be installed by a person qualified to professional standards, in accordance with

standards in force and the conditions of our technical departments..

It will be used in the normal way, and regularly maintained by a specialist.

Under these conditions, our warranty is implemented by free exchange or supply to our distributor or installer

of parts acknowledged as faulty by our departments, or of the whole appliance if necessary, excluding labor

costs, transport charges and any compensation for warranty extension.

Our warranty takes effect from the date of purchase (according to invoice), and where there is no

documentary evidence, the date used will be that of manufacture as shown on the water heater information

plate, plus six months.

The warranty on the replacement part or water heater (under warranty) ends at the same time as the part or

water heater replaced.

N.B.: Costs or damages caused by a faulty installation (freezing, safety unit not connected to waste water

discharge, no holding tank, for instance) or problems with access cannot in any case be blamed on the

manufacturer.

The provisions of this warranty do not exclude the purchaser's enjoyment of the legal warranty against

defects and hidden faults, that apply in all cases under the terms of articles 1641 ff of the French Civil Code.

The supply of spare parts necessary for the use of our products will be assured for 7 years after the

production of the last unit.

APPLIANCE END OF LIFETIME:

• Before dismantling shut off power supply and drain the tank.

• The combustion of some components can liberate toxic gas, do not burn the appliance.

• At the end of lifetime the appliance has to be collected by a sorting center for electric and

electronic devices equipped for the refrigerant reclaiming. To learn more about existing recycling

centers, contact the local recycling organizations.

• The enclosed refrigerant must not be liberated into the atmosphere. Any degassing operation is

formally prohibited.

The GWP (Global Warming Potential) of R134a is 1430.

Failure of a component does not in any case justify replacement of the appliance. Replace the faulty

part.

WARRANTY :

Water heater : 5 years (tank tightness, electronic PCB, electric backup and probes).

Heat pump : 2 years (except probes : 5 years).

34

Page 36

1

2

3

4

5

6

7

8

910

11

12

13

14

15

16

17

18

19

20

21

22

1

Probe oulet pipe of compressor

2 Probe supply air

3 Probe evaporator top

4 Probe evaporator bottom

5 Evaporator

6 Ventilator

7 Capacitor ventilator start

8 Capacitor small speed ventilator

17 Controller

18 Regulation PCB

19 Customer wiring board

20

Permanent power supply cable

Not supplied :

21 Connection cable PV / Smart Grid / Solar

22 Connection cable boiler

9

Compressor connections

10 Compressor overheat protection

11 Pressostat

12 Capacitor compressor start

13 Hot gas valve motor

14 Electric backup heater

15 Immersion sleeve water probe

16 Security thermostat

ELECTRIC DIAGRAM

35

Page 37

Page 38

Page 39

Page 40

U05xxxxx_B – Mars 2016

Loading...

Loading...