Page 1

Page 2

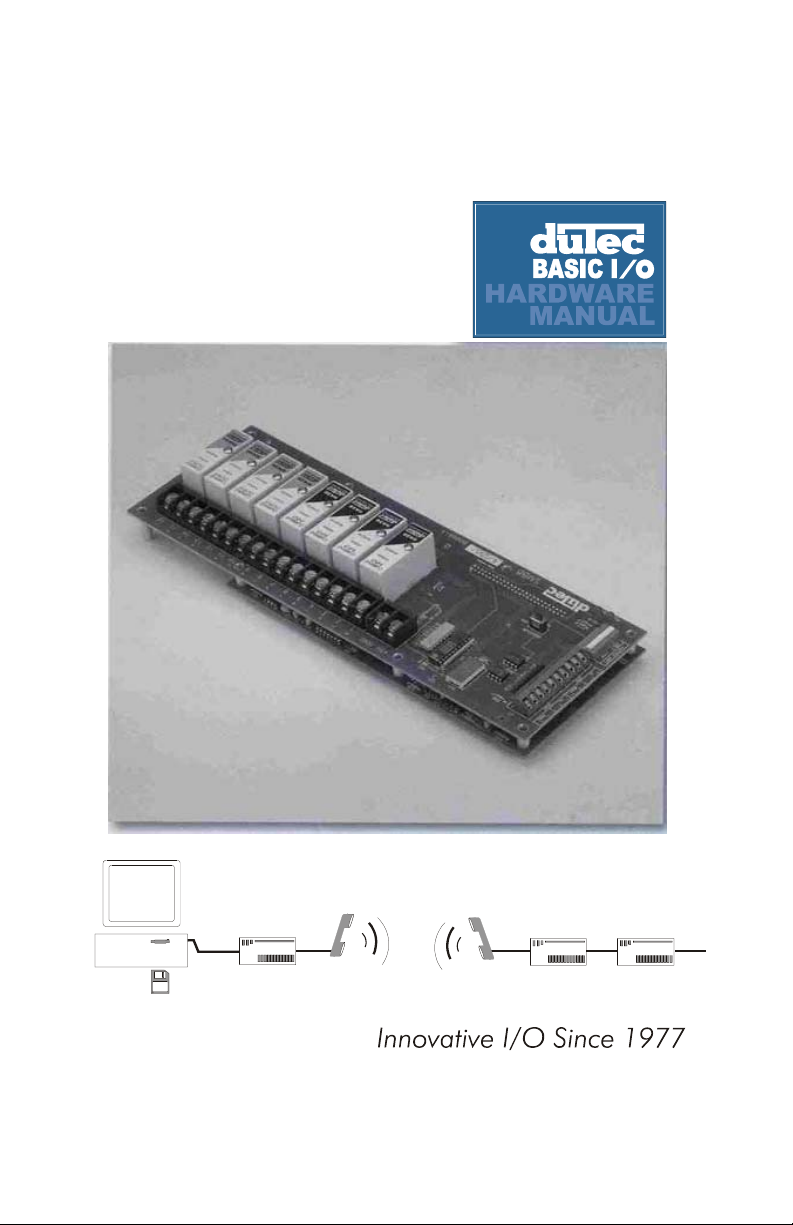

Basic I/O Product Family

NOTICE:

This document contains two separate users manuals.

The first section should be used for the BIO4, BIO8, and BIO16 products.

The second section should be used for the BIO4AD, BIO8AD, and the BIO16AD

products.

If you find that you have any questions with the setup or installation of any duTec

product please feel free to call us:

Phone: 800-248-1632

or

E-mail: info@dutec.net

Page 3

Page 4

Vol.1 Table of Contents

The Basic I/O ........................................................... 1 - 1

ANALOG INPUTS .............................................. 1 - 2

DIGITAL INPUTS............................................... 1 - 4

DIGITAL OUTPUTS: ............................................ 1 - 5

SYSTEM THROUGHPUT ........................................ 1 - 6

COMMUNICATION PROTOCOL .................................. 1 - 8

Available I/O Modules ............................................ 1 - 9

DIAGNOSTICS ................................................ 1 - 10

PHYSICAL CHARACTERISTICS ................................. 1 - 10

PRODUCT TEST ............................................... 1 - 11

Warranty: ..................................................... 1 - 11

MOUNTING ........................................................... 2 - 1

POWER WIRING ....................................................... 2 - 2

COMMUNICATING WITH THE BASIC I/O ................................. 2 - 3

Multidrop ...................................................... 2 - 4

Repeat......................................................... 2 - 4

RS-422 ........................................................ 2 - 5

RS-485 ........................................................ 2 - 5

RS-485 Programming ............................................. 2 - 6

COMMUNICATION WIRING ............................................. 2 - 7

Network load V.S. Noise suppression ........................................ 2 - 8

Network Bias Resistors ........................................... 2 - 8

RS-422 HOST TO BASIC I/O ...................................... 2 - 9

BASIC I/O TO BASIC I/O RS-422 ................................. 2 - 10

RS-485 Host to BASIC I/O ....................................... 2 - 11

BASIC I/O to BASIC I/O RS-485 (Multidrop only) .................... 2 - 12

BASIC I/O Setup ....................................................... 2 - 13

Analog/ Digital ................................................. 2 - 14

Addresses ..................................................... 2 - 14

Baud Rates .................................................... 2 - 14

Protocol Handshake Types ........................................ 2 - 15

Network Type Switch ............................................ 2 - 16

-i-

Page 5

Vol. 1 Table of Contents

Communication verification............................................... 2 - 18

Hardware error codes .................................................... 2 - 19

Hardware watchdog ..................................................... 2 - 19

Sensor/ Actuator I/O wiring ............................................... 2 - 19

Analog Inputs: ................................................. 2 - 20

Analog Outputs: ................................................ 2 - 22

Digital Inputs: .................................................. 2 - 23

Digital Output Wiring............................................ 2 - 24

-ii-

Page 6

The Basic I/O 1

THE BASIC I/O:

BASIC I/Os are a family of small, industrial grade, remote data acquisition and control

systems which exchange data with a Host computer via a serial communications link.

Controlled by a wide range of software running on a Host computer, Basic I/Os are located

near the sensors and actuators. The serial link eliminates the need for expensive and noise

prone signal wiring between field sensors and actuators, and a central control room.

Each BASIC I/O system consists of one logic board connected to a 4, 8, or 16 position I/O

module mounting rack. This combination is then field configurable to accept either analog or

digital electrically isolated input or output modules which can interface to a wide variety of

sensors and actuators.

BASIC I/O networks can service over 4000 analog and/or digital I/O lines in various

combinations.

User selected serial communications between the Host and the first BASIC I/O can be RS422 or RS-485. These communications links allow the units to operate up to 5000 feet apart.

Baud rates from 300 to 38,400 are available.

The BASIC I/O instruction set core complies 100% with that of the OPTO- 22 Optomux ™

With this ASCII character, speak-only-when-spoken-to protocol, a Host transmits inquiry

requests to the BASIC I/O to determine the status of its various process inputs. Similarly, the

software in the Host computer makes control decisions and transmits instructions to the

BASIC I/O, which in turn, makes the proper changes to its various outputs. Both the Host and

its communications link are essential elements in this data acquisition and process control

scheme.

Software for use with the BASIC I/O system can be obtained from a variety of sources.

Nearly every third party SCADA software vendor has developed a driver which is compatible

with this system. In addition, the communication protocol employed by the BASIC I/O

product is a published ASCII printable standard. This makes developing your own software a

simple matter. duTec also offers a software solution called EASY I/O. With this package,

custom QuickBASIC source code is generated to fit the signals generated to fit the signals

located on the BASIC I/O. Once configured, a simple data acquisition program is

automatically generated. This sample can then be altered to fit the particular needs of the user.

1-1(Vol.1)

.

Page 7

The Basic I/O 1

A notable feature of the BASIC I/O is its ability to gather data and perform ranging and

statistical operations on raw data before it is sent to the Host. The Host can thus spend less

time manipulating data and more time gathering it. The following sections discuss the

different signals the BASIC I/O can handle.

ANALOG INPUTS:

duTec analog input modules are 100% isolated and accept a wide range of voltages, currents,

the outputs of thermocouples, RTDs, and 590 type temperature probes.

BASIC I/O instructions provide linearized thermocouple and RTD sensor data. Engineering

unit conversion is performed by the host software, such as duTec’s EASYIO program

generator.

The BASIC I/O samples individual analog inputs at the constant rate of samples per second.

The effective sample rate per channel is determined by the total number of channels to be

sampled.

Analog input instruction types are:

Input Value Determines signal levels, with 12 bit (1 part in 4096) resolution

Offsets Input values can be software offset or “Zeroed” with 12 bit (1 part in

4096) resolution over the module’s specified range.

Gain/Slope The amplitude of input values can be software multiplied by factors

ranging from 0.25 to 4.0.

Range Limits The occurrence of input values falling out of user defined upper or

lower limits can be flagged.

Minimums The minimum level of input values can be captured.

Maximum The maximum level of input values can be captured.

Averages Can calculate average input amplitude for 1-65,535 samples.

Temperature Provides linear temperature in C for thermocouples, RTD and type

590 temperature probes.

Thermocouple modules provide cold reference junction compensation.

1-2(Vol.1)

Page 8

The Basic I/O 1

ANALOG OUTPUTS:

Analog output modules are 100% isolated. These self-sourcing modules provide the voltage or

current necessary to drive standard instrumentation loads. All are updated every 10 Ms, or 100

times per second.

Analog output instruction types are:

Level Value Can set output levels, as a fraction of the module’s full scale

range, and are specified with 12 bit (1 part in 4096) resolution.

Waveforms Can provide square, triangle, sawtooth or ramp waveforms,

Maximum and Minimum amplitudes, as a fraction of the output

module’s full scale range, are specified with 12 bit (1 part in

4096) resolution. Waveform periods are specified from 0.1 to

6,553 seconds (about 109 minutes).

1-3(Vol.1)

Page 9

The Basic I/O 1

DIGITAL INPUTS:

Digital input modules detect the presence or absence of a field signal. Module types vary from

AC to dry contact sense. Because the industry standard modules are optically isolated, the

response time performance of digital input instructions can be limited by the delay in the input

modules themselves. Some modules can have rise and fall times of up to 40 milliseconds.

Digital input instruction types are:

Read Read the On or Off state of all inputs. This data is

updated every 10 Milliseconds.

Edge Detection Off-to- On and On-to-Off transitions can be detected

within 1 millisecond of their occurrence. Action is

only reported every 10 milliseconds.

Pulse Widths BASIC I/Os can report pulse width measurements

from .01 seconds to 46.6 hours. Minimum resolution

is .01 seconds (Pulse widths up to 10.9 minutes).

Either on or off pulses can be measured.

Pulse Counting Pulses can be counted up to a total of 65,535. To be

reliably counted, pulses must have a minimum On and

Off time of 1 millisecond. Thus the maximum

counting rate for a 50% duty cycle square wave is

once every 2 milliseconds (500Hz).

Frequency Direct frequency measurements can be made on

digital inputs at rates of up to 500 Hz with a user

specified time base of from .01 to 2.55 seconds.

1-4(Vol.1)

Page 10

The Basic I/O 1

DIGITAL OUTPUTS:

Digital output modules, commonly referred to as solid state relays, control external AC or DC

power sources. A dry-contact (mechanical relay) with very low contact resistance is also

available.

Digital output instruction types are:

Set outputs Can set individual or multiple outputs On or Off.

Pulse Generator Can generate 1 to 65,535, 50% duty cycle pulses whose equal

On and Off periods can range from 0.01 to 2.55 seconds.

Resolution can be reduced by a factor of 1-256 on a system

wide basis to increase the maximum pulse width available.

Modifiers:

One Shot Can generate On or Off pulse durations of up to 10.9 minutes

Delayed Can generate delayed On or Off outputs after delaying up to

Square wave Can generate square waves with programmable On and Off

with a resolution of 0.01 seconds. Resolution can be reduced by

a factor of 1-256 on a system wide basis increasing duration up

to 46 hours. Re-triggering is available.

10.9 minutes with a resolution of 0.01 seconds. Resolution can

be reduced by a factor of up 1-256 on a system wide basis

increasing the delay before changing state up to 46.6 hours. Retriggering is available.

periods. On and Off periods have a base range from 0.01

seconds to 10.9 minutes. Resolution can be reduced by a factor

of 1-256 on a system wide basis increasing duration to 46.6

hours

.

1-5(Vol.1)

Page 11

The Basic I/O 1

SYSTEM THROUGHPUT:

Input data throughput is the time from beginning of the first character of an input instruction

to the end of the last character of the response. The processing time of the Host computer will

affect the effective throughput.

Output Execution throughput is the time from the beginning of the first character of an

instruction until the actual output changes. Because the instruction acknowledgment occurs

before the outputs actually change state, the processing time of the host computer controlling

output instructions can reduce the effective throughput. This is even possible at 38,400 baud

to instruct the BASIC I/O to turn a digital output on and then immediately instruct it to turn

back off so quickly that the module never actually gets activated

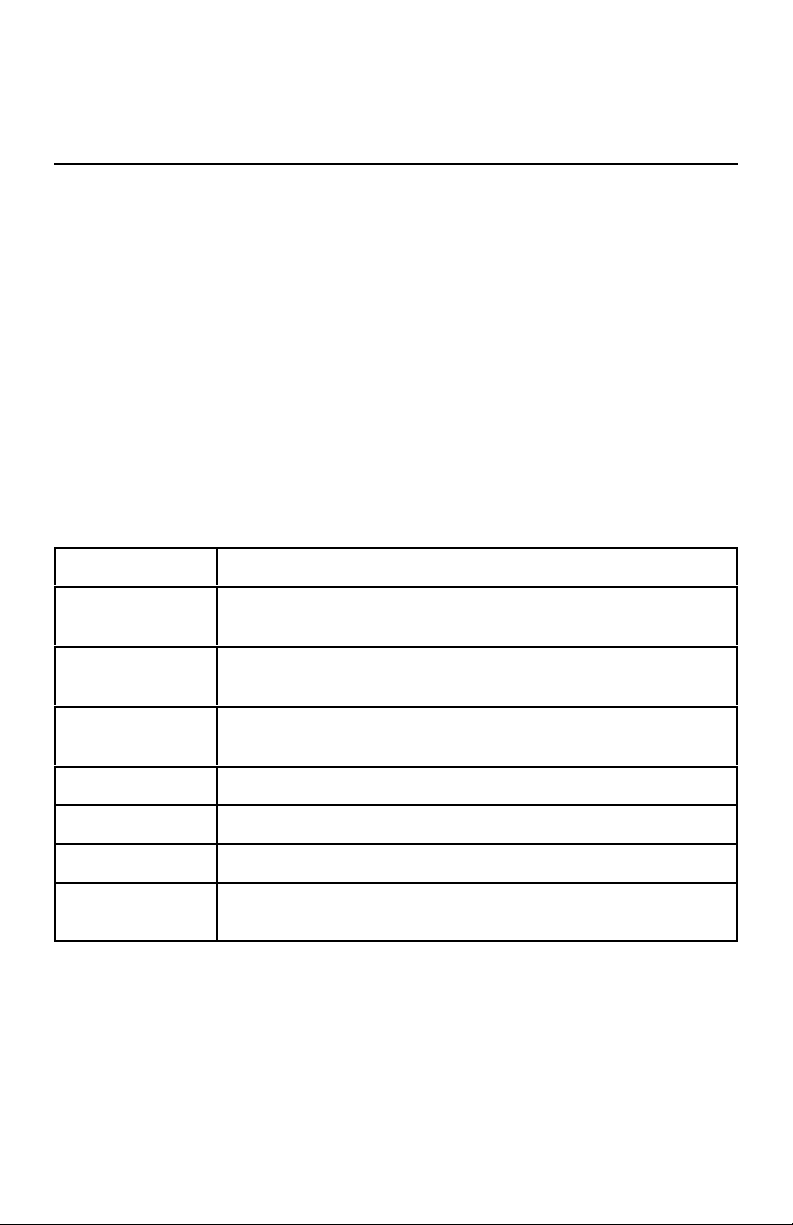

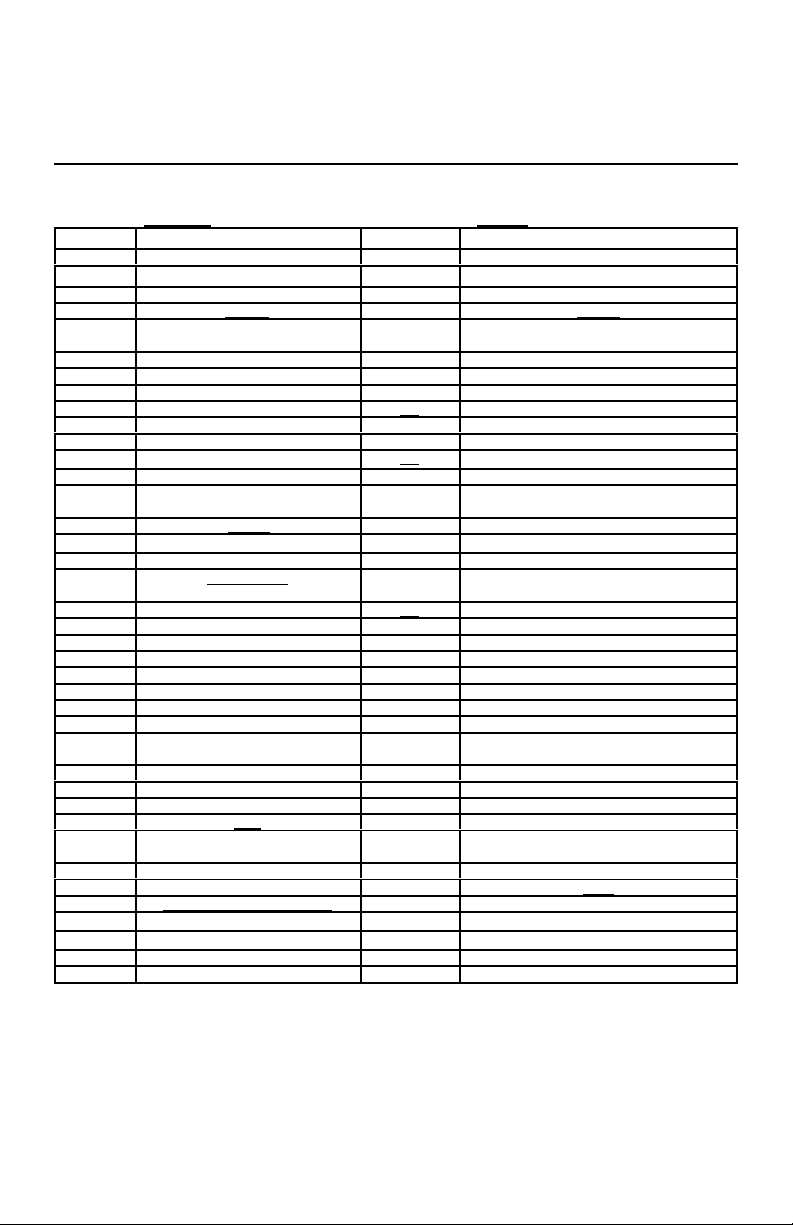

Tables below show milliseconds per channel and channels per second for 1 and 16 I/O

channel cases

Baud Rate mSec/

300 501 2 501 32 379 3 379 42

600 251 4 251 64 195 5 195 82

1200 126 8 126 127 104 10 104 154

2400 64 16 64 252 58 17 58 277

4800 32 31 32 496 35 29 35 458

9600 17 60 17 962 23 43 23 682

19200 9 113 9 1816 18 56 18 902

38400 5 204 5 3261 15 67 15 1076

Baud Rate mSec/

300 639 2 2639 6 484 1984 2 8

600 323 3 1323 12 250 4 1000 16

1200 164 6 664 24 134 7 509 31

2400 85 12 335 48 75 13 263 61

4800 46 22 71 94 46 22 140 114

9600 26 39 88 181 32 32 78 204

19200 16 63 47 339 24 41 48 335

38400 11 91 27 602 21 48 32 494

.

1 Channel 16 Channels 1 Channel 16 Channels

Input (Digital M) Output (Digital J)

Chan/Sec mSec/

Chan

Input (Analog L) Output (Analog S)

1 Channel 16 Channels 1 Channel 16 Channels

Chan/

Chan

Sec

THROUGHPUT TABLES

Chan/ Sec mSec/

16 Ch

mSec/

Chan/ Sec mSec/

16 Ch

Chan

Chan

.

Chan

/Sec

Chan

/Sec

mSec/

16 Ch

mSec/

16 Ch

Chan /Sec

Chan /Sec

1-6(Vol.1)

Page 12

The Basic I/O 1

It should be noted that the values in the preceding throughput tables and the following

equations reflect only the communications overhead and inherent processing delay of the

BASIC I/O equipment. In practice, a significant amount of overhead will be devoted to other

processing tasks such as screen updates, Data logging, etc... Typically these other tasks

become the limiting factor in the “overall” throughput.

The equations below can be used for determining the hardware’s role in throughput for any

number of channels. (t is in Milliseconds) Throughput for digital I/O is independent of the

number of channels.

Digital Input Data

t digital Input = 1000*((150/Baud Rate) +0.001)

Digital Output Execution

Throughput for analog I/O varies with the number of channels, n.

Analog Input Data

Analog Output Execution

For determining the throughput for systems with a mixture of analog and digital data inputs

and the execution of analog and digital outputs, it is necessary to determine the time for each

instruction using these equations. The sum of these, t, In milliseconds, is the time required to

provide the service required by all instructions.

Dividing this sum into 1000 (milliseconds) yields the number of cycles per second.

(Digital M) Time for 1-16 channels:

(Digital J) Time for 1-16 channels:

t digital Output = 1000 ((110/Baud Rate) +0.012)

(Analog L) Time for n channels:

t analog Input = 1000 *(((150 + 40 * n)/Baud Rate) + 0.006)

(Analog S) Time for n channels:

t analog output = 1000 *(((110 + 30 *n)/Baud Rate) + 0.017)

t=t digital Input + t digital Output + t analog Input + t analog Output

Complete cycles/ Sec = 1000/ t

1-7(Vol.1)

Page 13

The Basic I/O 1

COMMUNICATION PROTOCOL:

The BASIC I/O Communication Protocol is 100% compatible with the Opto-22 Optomux™

protocol. This ASCII printable serial protocol uses a “speak-only-when-spoken-to” format

where only the host can initiate an information exchange. Each BASIC I/O unit installed in a

network has a unique address. This address is embedded in the instruction generated by the

host computer. Every BASIC I/O chassis receives the instruction but only the unit which is

set to the address found in that instruction will respond. Every string of data whose length is

greater than one character is followed by a checksum to ensure data integrity. This protocol

also provides an instruction verification mode for further data transmission reliability.

As a result of the specific nature of the BASIC I/O communications protocol, the RS-422 or

RS-485 network can be shared with other devices whose protocol is similar.

A knowledge of serial communications, hexadecimal to decimal conversion, and string data

manipulation is required to compose custom user generated Host software. DuTec’s EASY

I/O software is designed to minimize these obstacles.

1-8(Vol.1)

Page 14

The Basic I/O 1

ANALOG INPUTS, 12 BIT ANALOG OUTPUTS, 12 BIT

IIF10K-B Input 300Hz -10KHz OV1 Output 0-1V, self-sourcing

Frequency

IF2.5K-L Input 0-2.5KHz OV5 Output 0-5V, self-sourcing

IF5K-l Input 0-5KHz OV10 Output 0-10V, self-sourcing

IF10K-L Input 0-10KHz

IV25M Input 0-25mV OI420 Output 4-20mA, self-sourcing To 275 Ohm

IV50M Input 0-50mV

IV100M Input 0-100mV

IV1 Input 0-1V

IV5 Input 0-5V AC

IV5B Input Bipolar +/-5V IAC5 Input 90-140Vac

IV10 Input 0-10V IAC5A Input 180-280Vac

IV10B Input Bipolar +/-10V DC

IVAC Input 28-140Vac IDC5D Input 3-32Vdc Fast, >500Hz

IVAC-A Input 56-280Vac IDC5S* Input Dry Contact Sense Built-in Isolated

II420 Input 4-20mAdc

IIAC5 Input 0-5Aac

ITCE Type E 0 To 435 C AC

ITCJ Type J 0 To 700 C OAC5 Output 12-140Vac, 3.5A

ITCJ-1 Type J -80 To 750 C OAC5A Output 24-280Vac, N.C.(Normally Closed)

ITCK Type K -100 To 924 C OAC5J Output 20-280Vac, 6.0A

ITCK-1 Type K -110 To 1250 C

ITCR Type R 0 To 960 C DC

ITCR-1 Type R 0 To 1760 C ODC5 Output 5-60Vdc, 3.5A

ITCS Type S 0 To 1034 C ODC5A Output 4-200Vdc, 1.0A

ITCS-1 Type S 0 To 1760 C ODC5R Electro-Mechanical 0.5A Relay Form A,

ITCT Type T -200 To 224 C

I TCT-1 Type T -120 To 400 C

ITCT-2 Type T 0 To 150 C IDC5Z* Input +/-200mV, 0-10KHz Digital**

ITR10 10 Ohm Cu -55 To 150 C

ITR100 100 Ohm Pt -55 To 350 C

ITR100-1 100 Ohm Pt 0 To 100 C Fuses

ITP590 -188.4 To 150 C FM-1 Fuse assembly, 1.0A

ITP590-1 -50.0 To 150 C FM-3 Fuse assembly , 3.0A

Voltage

Voltage

Current

Thermocouple

RTD

Type 590 Temperature Sensor FM-06 Fuse Assembly 0.062A

Available I/O Modules

Current

load.

DIGITAL INPUTS

Voltage Source

IDC5NP Input 10-32 Vdc, 15-32Vac Non-Polarized

DIGITAL OUTPUTS

Normally Open (NO)

SPECIAL PURPOSE

SPS-1* Sensor Power Supply 18-24 Vdc, 30mA

TI01 Digital Input/ Output Test Module with Field

Switch and LED

SUPPORT PRODUCTS

FM-5 Fuse assembly, 5.0A

* When selecting a power supply for the system assume 25mA for standard digital modules and 100 mA

for marked with an *** The IDC5Z module is used for low-level signals and will pass signals at the rate

of 10KHz The BASIC I/O however, is limited to signals up to 500Hz.

1-9(Vol.1)

Page 15

The Basic I/O 1

DIAGNOSTICS:

To confirm internal operations and communications link integrity, a set of built-in diagnostics

test key system functions each time power is applied. Diagnostics reduce both installation

debugging and operation troubleshooting.

A hardware watchdog timer insures safe shutdown in the event of processor or software

failures by turning all outputs OFF. Normally ON modules are available for those loads that

must remain ON.

PHYSICAL CHARACTERISTICS

Power Requirements

Voltage: 5.0-5.4Vdc

Current: 250mA +25mA Per digital module.

Note that the current draw of some specialized digital modules Such as the IDC5S or the

ODC5R, can be substantially larger Than 25mA. Consult the specific module data sheet for

this Value when sizing power supplies.

Operating Temp. 0 C to 60 C Contact factory for other operating temp

Ranges

Humidity 95% non-condensing

Weight 22 oz. Max (BIO16) Not including modules.

BASIC I/Os are ready to install, only dc power, communication and sensor or actuator wiring

is required

1-10(Vol.1)

Page 16

The Basic I/O 1

PRODUCT TEST

Every BASIC I/O is burned-in at 70 °C while operating in a network for a period of 24 hours

prior to shipment.

Every analog I/O module is operated and tested while it’s ambient operating temperature is

cycled over the specified operating range of 0°C to 60°C for a period of 24 hours.

BASIC I/O Models:

BIO4 4 Position BASIC I/O Unit Includes SLB Logic Board and SMB4 Module board

less modules and power supply.

BIO8 8 Position BASIC I/O Unit Includes SLB Logic board and SMB8 module board

less modules and power supply.

BIO16 16 Position BASIC I/O Unit Includes SLB logic board and SMB16 module board

less modules and power supply.

Warranty: duTec warrants its products to be free of defects in materials and

workmanship for a period of two (2) years from date of shipment.

DuTec may, at its option repair or replace all materials found to be

defective. All repair or replacement must be performed by duTec

personnel. Any parts determined by duTec to be defective as a result

of abuse, attempts to repair, or misuse by the customer will be repaired

at the expense of the customer.

1-11(Vol.1)

Page 17

NOTES

The Basic I/O 1

1-12(Vol.1)

Page 18

Setup & Installation 2

MOUNTING:

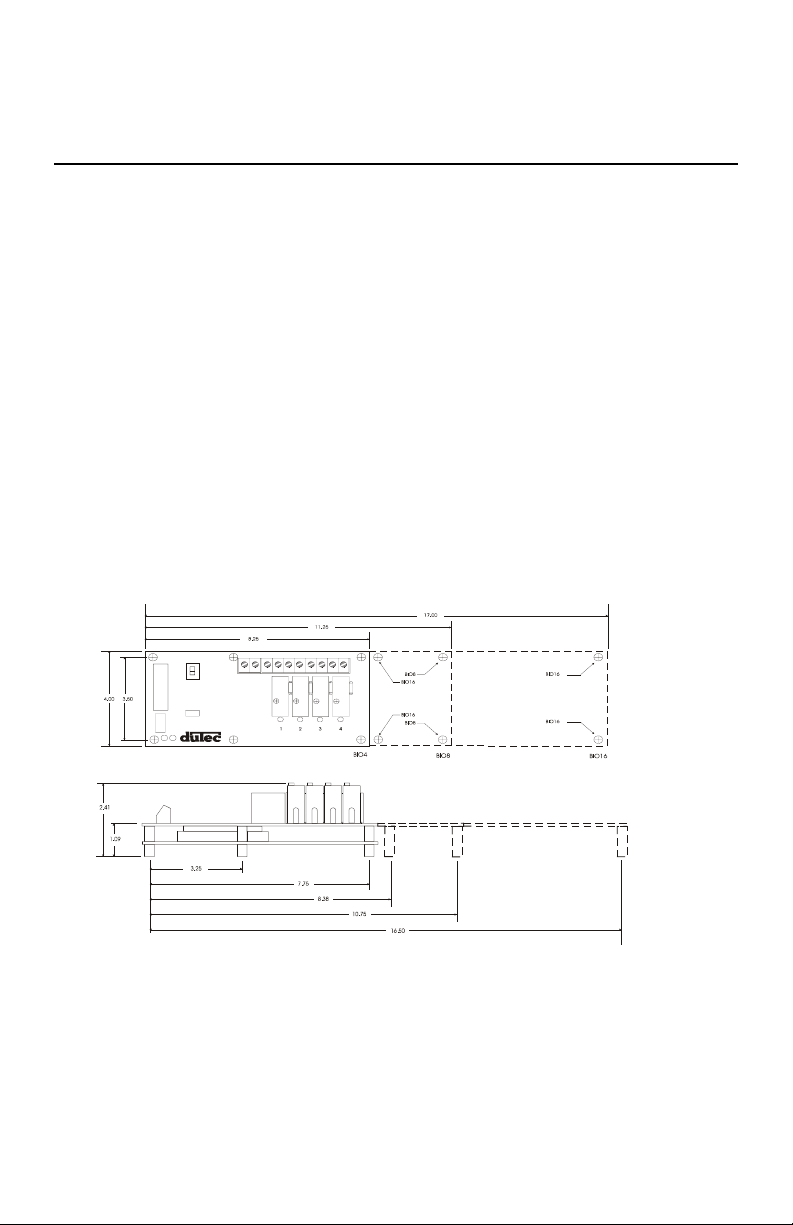

BASIC I/Os come in 4, 8, and 16 channel versions. Figure 2-1 below shows the footprint of

each BASIC I/O. Using corner holes, the unit can be mounted with 4- #6 or #8 round head or

pan head screws. The BIO16 version has two additional mounting holes located near the

center of the board as well. Hole locations in relation to the overall dimensions for each are

shown below. Since the same BASIC I/O boards are used for digital or analog applications,

the same mounting dimensions and panel space are used for both.

FIGURE 2-1 BASIC I/O FOOTPRINT

2-1(Vol.1)

Page 19

Setup & Installation 2

POWER WIRING:

Power connections are made at the 2 position terminal block located on the module board

marked +5V and GND No. 8 captive wire clamps accept 10-16 AWG wire or spade lugs.

+5V GND

Power wiring conventions:

+ of the power source to the +5V terminal

- of the power source to the terminal marked GND

Power requirements

Voltage: 5.0- 5.4Vdc

Current: 250 mA + 25mA per digital module or 250 + 200mA per analog

module.

Note that the current draw of some specialized digital

modules such as the IDC5S or the IDC5Z, can be

substantially larger than 25 mA. Consult the specific

module data sheet for this value when sizing power

supplies.

Practices: In general it is good practice to reserve the +5Vdc power supply

exclusively for the task of powering one or more BASIC I/O units. As

with any microprocessor based equipment, reasonably clean power is

required for reliable operation. Sharing power with other devices such

as field signal transducers and contact excitation should be avoided.

2-2(Vol.1)

Page 20

Setup & Installation 2

COMMUNICATING WITH THE BASIC I/O:

The BASIC I/O is designed to serve as an intelligent I/O front end for a Host computer

(Typically a P.C.). The host and BASIC I/O communicate over a serial link. This interchange

is half-duplex in nature; that is to say the host and BASIC I/O will never be transmitting at

the exact same time. Further, the communications protocol is considered “speak-only-whenspoken-to”; the Host must poll the BASIC I/O whenever it needs fresh data. This polling is

accomplished when the host sends an instruction to the BASIC I/O. The BASIC I/O will then

generate a reply. Each valid instruction will illicit a corresponding response. The integrity of

this communication is verified using message content checksums.

The serial communication is a form of ASCII printable characters and makes heavy use of the

hexadecimal numbering system. The format of the ASCII characters used is: One start bit,

eight data bits, one stop bit, and no parity.

2-3(Vol.1)

Page 21

Setup & Installation 2

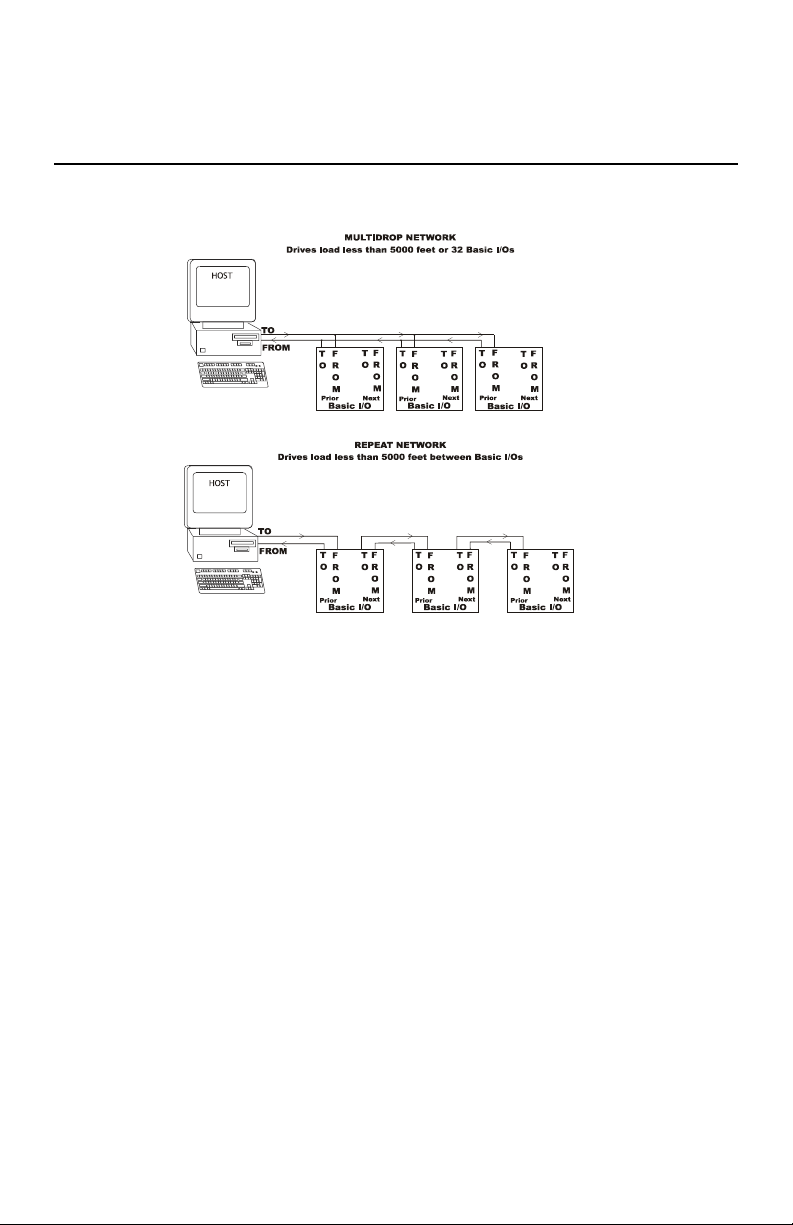

BASIC I/Os can be networked together to obtain up to 4096 I/O points of data. These serial

networks can be either multidrop or repeat.

Figure 2-3 Multidrop V.S. Repeat networks

Multidrop:

Multidrop networks can be up to 5000 ft long end-to-end.

Each station is passively located on the network and represents one “Drop” or

load to the host communication driver.

A multidrop network will tolerate loss of power to any one station without

effecting the rest of the network..

RS-485 can only be multidrop

Signal boost may be necessary depending on line conditions and number of

drops.

Repeat:

Repeat networks can be as long as 5000 ft between each unit.

Each station plays an active role in communications to other units. If power is

removed from a unit in a repeat network, communications to units “downstream”

from it will be lost as well.

2-4(Vol.1)

Page 22

Setup & Installation 2

The serial communications link between a Host computer and a network of BASIC I/Os is

made up of either a single (RS-485 half-duplex) or Dual (RS-422 full duplex) shielded twisted

pair (s) of wires whose shields are connected to a signal common conductor. This

communications link should in turn have an overall shield which is isolated from the signals

(including signal ground) and connected to earth or chassis ground at one location. The most

common cause of difficulty experienced by customers in the field is improperly installed

communications wiring.

RS-422:

Advantages:

Easier to implement in software since host driver need not be controlled.

Can be either Multidrop or Repeat

No turn-around delay required.

Disadvantages:

Requires five conductor wire instead of three

RS-485:

Advantages

Needs only 3 wire conductor

Disadvantages:

:

Host 485 driver control must be implemented requiring tricky serial port manipulations

Can only be Multidrop

Usually requires turn around delay implementation.

2-5(Vol.1)

Page 23

Setup & Installation 2

RS-485 Programming:

The BASIC I/O will work equally well when connected to either RS-422 or RS-485.

However special host programming considerations may be necessary when implementing an

RS-485 network. Unlike RS-422 where both the transmit and Receive signals have their own

differential pair of conductors, RS-485 utilizes only one

conductors is used bidirectionally and handles both transmit and receive signals. In order for

this to be possible, the transmitter for each device on this type of network must be enabled and

disabled whenever a message is to be sent. The transmitter for the BASIC I/O is designed to

handle this control automatically. However, the transmitter control for most popular RS-485

cards that are installed in the Host computer must be controlled by the user program. This

control is not straight forward and may impact the overall system throughput with inherent

delay periods. The following is a typical instruction/ response transaction between a host

computer and a BASIC I/O using RS-485.

1) The Host computer enables its RS-485 transmitter (usually via the RTS line)

2) The Host then sends an instruction to the BASIC I/O in the form of an ASCII printable

string.

3) Once the Host determines that the string has been completely sent, the RS-485

transmitter is disabled.

4) Every BASIC I/O on the network receives the instruction and begin to decode it. That

particular BASIC I/O addressed begins to construct a response.

differential pair. The single pair of

5) Once the carriage return is of the instruction is received, the BASIC I/O begins to

transmit a response.

6) The Host receives the response and takes the appropriate action.

This interaction is heavily dependant on asynchronous timing. Usually, the Host software has

no real means of determining that the instruction has been completely sent. This means that

the program must calculate the

2-6(Vol.1)

Page 24

Setup & Installation 2

approximate time necessary to transmit the entire instruction before the RS-485 driver is

disabled. Since the BASIC I/O can respond very quickly to the instruction, the Host must

disable the driver as soon as possible in order to receive the BASIC I/Os response. RS-485

communications can be tricky at best and should be seriously considered before being

adopted. Third party software users should make sure that the package they have chosen

supports the particular RS-485 communications card to be used.

COMMUNICATION WIRING:

The Host to first BASIC I/O can be RS-422 or RS-485. Most Host computers come

equipped with an RS-232 serial port. A choice must be made to either equip the host with an

RS-422 or RS-485 card or to use an external RS-232 to RS-422/ 485 converter.

For ranges less than 5000 feet, both RS-422 and RS-485 networks can operate in multidrop

mode. For ranges greater than 5000 feet, RS-422 (NOT RS-485) networks can operate in

repeater mode. In this mode, the distance between individual units can be up to 5000 feet. The

trade-off for using the repeat mode is that the powering down of any single unit disables

communications with all units further “downstream” from the host.

A network of BASIC I/O’s must be made up of units which are configured as either all

multidrop or all repeat.

2-7(Vol.1)

Page 25

Setup & Installation 2

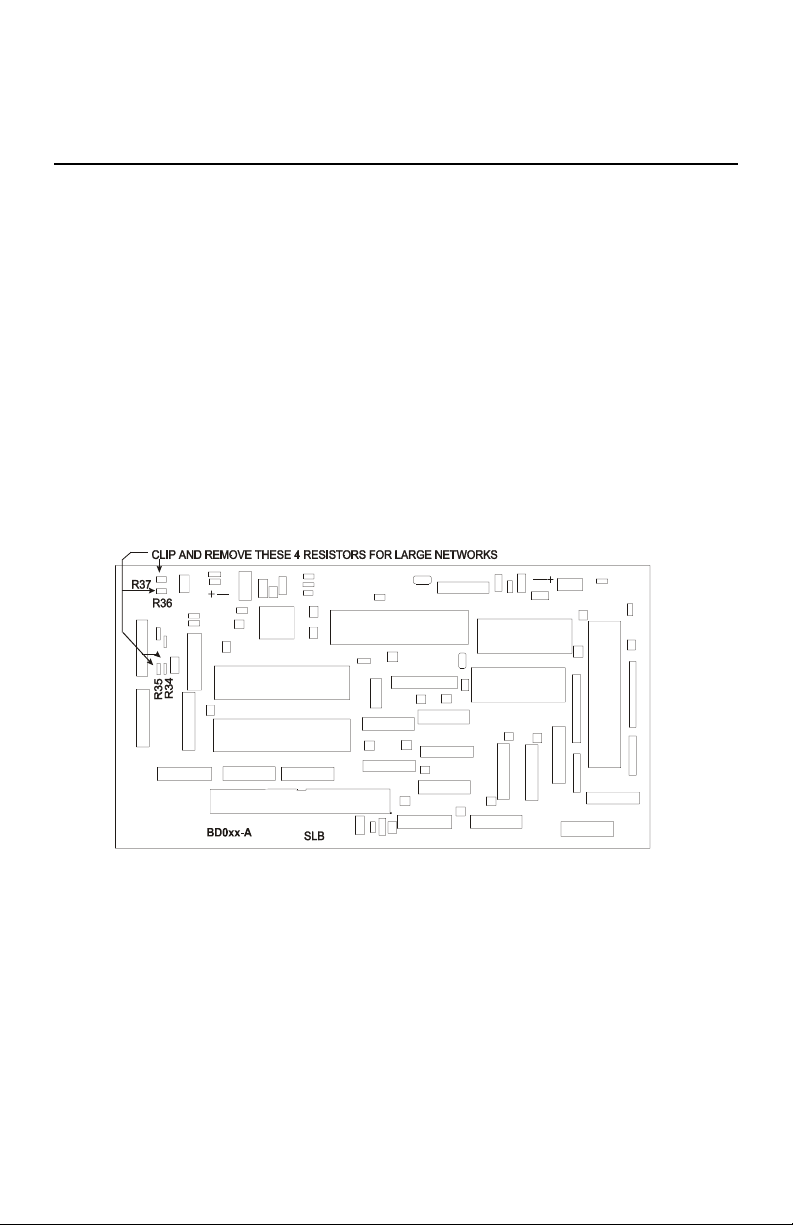

Network load V.S. Noise suppression:

In order to improve RS-485 Bus noise immunity, particularly under tri-state conditions, a pair

of “Network Bias Resistors” have been installed in each BASIC I/O unit. This design feature

has been implemented in order to satisfy the majority of our customers. If it is necessary to

multidrop more than eight BASIC I/O units(but ultimately less than thirty-two devices), It

will be necessary to remove these network bias resistors so as to not exceed the maximum bus

loading. However, in order to retain noise immunity, the network bias resistors should remain

installed in at least one BASIC I/O on the network. Figure 2-4 below shows the location of

the four network bias resistors.

R34 is the 1.5k from prior +bias resistor

R35 is the 1.5k from prior - bias resistor

R36 is the 1.5k from next + bias resistor

R37 is the 1.5k from next - bias resistor

Figure 2-4 Network Bias Resistor Locations

2-8(Vol.1)

Page 26

Setup & Installation 2

RS-422 HOST TO BASIC I/O:

Figure 2-5 RS-422 Host to BASIC I/O wiring

Figure 2-5 shows two individually shielded twisted pairs of AWG 24. Each pair has a ground

wire connected to its shield. These drain wires are then connected to the signal grounds at

each unit. A Separate

tied to earth ground at one location. An example of acceptable wire for this application would

be Belden 8162. In a perfect world with no electrical noise and equal ground potentials

everywhere, the ground connection is not required. However, omitting this signal ground in

industrial applications can lead to costly debugging.

These connections are made by placing a 1/4 inch stripped wire into the openings of the wire

clamp terminal block and tightening the screw. This terminal block will accept gauges from

14 to 30AWG.

An alternate means for network connection is to use the 10 pin male connector located behind

the clamp terminal block. This connector mates with Molex shell number 50-57-9005, and

uses pins number 16-02-0103.

In addition to the Host-To-BASIC I/O wiring, the installer should confirm that the network

type switches are set in the correct position: Multidrop, Repeater, or Last Unit.

shield encases the entire cable. The drain wire for this over-all shield is

2-9(Vol.1)

Page 27

Setup & Installation 2

BASIC I/O TO BASIC I/O RS-422 MULTIDROP OR REPEATER

Figure 2-6 RS-422 BASIC I/O-To-BASIC I/O multidrop

Figure 2-6 shows two individually shielded twisted pairs of AWG24. Each pair has a drain

wire connected to its shield. These drain wires are then connected to the signal grounds at

each unit. A separate

tied to earth ground at one end. An example of acceptable wire for this application would be

Belden 8162. In a perfect world with no electrical noise and equal ground potentials

everywhere, the ground connection is not required. Omitting this signal ground in industrial

applications can lead to unstable operation and costly debugging.

These connections are made by placing a 1/4 inch stripped wire into the openings of the wire

clamp terminal block and tightening the screw. This terminal block will accept gauges from

14 to 30 AWG.

An alternate means of network connection is to use the ten pin male connector located behind

the clamp terminal block. This connector mates with Molex shell number 50-57-9005, and

uses pins 16-02-0103.

In addition to the BASIC I/O to BASIC I/O wiring, the installer should confirm that the

network type switches are set in their correct position: Multidrop, Repeater, or Last unit.

NOTE: The number of BASIC I/Os that can be networked in a multidrop configuration

before a signal amplifier (An external repeater) is needed depends greatly on external factors.

Repeater networks are unlimited.

shield encases the entire cable. The drain wire for the over-all shield is

2-10(Vol.1)

Page 28

Setup & Installation 2

RS-485 Host to BASIC I/O:

Figure 2-7 RS-485 To-BASIC I/O

Figure 2-7 shows one individually shielded twisted pair of AWG 24. Each pair has a drain

wire connected to its shield. These drain wires are then connected to the signal grounds at

each unit. A separate shield encases the entire cable. The drain wire for the over-all shield is

tied to earth ground at one end. An example of acceptable wire for this application would be

Belden 8162. In a perfect world with no electrical noise and equal ground potentials

everywhere, the ground connection is not required. Omitting this signal ground in industrial

applications can lead to unstable operation and costly debugging.

These connections are made by placing a 1/4 inch stripped wire into the openings of the wire

clamp terminal block and tightening the screw. This terminal block will accept gauges from

14 to 30 AWG.

An alternate means of network connection is to use the ten pin male connector located behind

the clamp terminal block. This connector mates with Molex shell number 50-57-9005, and

uses pins 16-02-0103.

In addition to the BASIC I/O to BASIC I/O wiring, the installer should confirm that the

network type switches are set in their correct position: Multidrop, Repeater, or Last unit.

2-11(Vol.1)

Page 29

Setup & Installation 2

BASIC I/O to BASIC I/O RS-485 (Multidrop only):

Figure 2-8 RS-485 BASIC I/O to BASIC I/O Multidrop

Figure 2.8 shows one individually shielded twisted pair of AWG 24. Each pair has a ground

wire connected to its shield. These drain wires are then connected to the signal grounds at

each unit. A Separate

tied to earth ground at one location. An example of acceptable wire for this application would

be Belden 8162. In a perfect world with no electrical noise and equal ground potentials

everywhere, the ground connection is not required. However, omitting this signal ground in

industrial applications can lead to costly debugging.

These connections are made by placing a 1/4 inch stripped wire into the openings of the wire

clamp terminal block and tightening the screw. This terminal block will accept gauges from

14 to 30AWG.

An alternate means for network connection is to use the 10 pin male connector located behind

the clamp terminal block. This connector mates with Molex shell number 50-57-9005, and

uses pins number 16-02-0103.

In addition to the Host-To-BASIC I/O wiring, the installer should confirm that the network

type switches are set in the correct position: Multidrop, Repeater, or Last Unit.

NOTE: The number of BASIC I/Os that can be networked in a multidrop configuration

before a signal amplifier (An external repeater) is needed depends greatly on external factors.

Repeater networks are unlimited.

shield encases the entire cable. The drain wire for this over-all shield is

2-12(Vol.1)

Page 30

Setup & Installation 2

BASIC I/O setup:

BASIC I/O setup is accomplished with a sequential display and pushbutton. Below is a

diagram of the location of these components.:

Figure 2-9 BASIC I/O Connectors, Switches and Indicators.

Unit type (digital or analog), Unit address, baud rate, and 2 or 4 pass protocols are all

pushbutton configurable and appear on the sequential display. After line power application

and the performance of system diagnostics, there is a five second period during which these

setup values any be changed. Changed values are automatically saved on a non-volatile

EEPROM.

2-13(Vol.1)

Page 31

Setup & Installation 2

Analog/ Digital:

The BASIC I/O system must be configured to accept either Analog or Digital I/O modules.

The current I/O type is displayed on the sequential display and is indicated by the character

following the “U”. The unit will display a”1" if the unit is configured as digital and a”2" if the

unit is analog. This value is stored in EEPROM and need only be set once. The factory default

I/O type is digital. Changing the BASIC I/O I/O type is explained after the description of

addresses, baud rates, hand-shaking, and network types.

Addresses:

Each host instruction includes an address made up of two hexadecimal characters (00h to

Ffh). This address determines which chassis is to execute the instruction being sent; all other

chassis are to ignore the instruction. Each BASIC I/O chassis has a unique address. The

factory default address is “00". Changing the BASIC I/O address is explained after the

description of baud rates, hand-shaking, and network types.

Baud Rates:

Any One of the standard baud rates of 300, 600, 1200, 2400, 4800, 9600, 19200, or 38400 can

be used for the serial network communications. The sequential display indicates the letter H

followed by the baud rate divided by 100. BASIC I/Os are shipped at 9600 baud; the

sequential display indicates H096. Changing the BASIC I/O baud rate is explained after the

description of hand-shaking and network types.

2-14(Vol.1)

Page 32

Setup & Installation 2

Protocol Handshake Types:

Two protocol handshake types are available, 2 pass and 4 pass.

2 Pass: The host transmits an instruction to a BASIC I/O.

If the instruction is correctly received (i.e. valid address, instruction type

and correct checksum) the BASIC I/O executes the instruction and

returns the letter “A” and a cr or, where data is to be returned, the letter

“A”, then the data, followed by a two character checksum ending with a

cr.

4 Pass: The host transmits an instruction to a BASIC I/O.

If the instruction is correctly received (i.e. valid address, but not

necessarily the correct instruction type nor checksum), the BASIC I/O

returns an “A” followed by the Echo of the instruction and does not

execute it.

If the host then transmits an E, the instruction is executed in the same

manner as the 2 pass. If the Hos transmits any other character to any unit

on the network, the instruction is disregarded.

The sequential display indicates the letter P followed by 2 or 4. BASIC I/Os are shipped in 2

pass mode; the sequential display indicates P2. The actual setting of the handshake protocol

type is detailed following network type switch.

2-15(Vol.1)

Page 33

Setup & Installation 2

Network Type Switch:

Based upon the selected network configuration, each BASIC I/O must be setup before

communications can begin. This is done with the network switches shown below. The three

basic communication connections for individual BASIC I/Os are:

L1 Repeater

Used in RS-422 networks to extend

range to5000 feet between units

L2 Multidrop

Used in RS-422 or RS-485 networks.

Provides a total network range of 5000

feet.

L3 Last Unit

Must be used in RS-422 and RS-485

networks for the unit most distant from

the host

If there is only one BASIC I/O in a network it is designated L3.

For the network layout, the sequential display indicates the letter “L” followed by “1", “2", or

“3". As shipped, BASIC I/Os are setup as “l3", Last Unit. This parameter is not changed by

push button but is displayed as “l1", “L2", or “L3" after the dip switches have been set and the

unit has undergone a power cycle.

When the unit is configured for “L3" a network termination resistor is placed across the

differential receiver. A value of 150 Ohms was selected to suit most applications. A detailed

analysis of transmission line effects (reflections), which is beyond the scope of this document,

would be necessary to select the ideal termination resistor for any given application.

If the customer wishes to terminate the communication bus externally (at the terminal block

location) then it is imperative that no BASIC I/O network switches be set to “L3".

EIA standards dictate that the total bus impedance for RS-485 can be no less than 60 Ohms.

2-16(Vol.1)

Page 34

Setup & Installation 2

Setup via Pushbutton:

The pushbutton, located on the logic board (see figure 2-9) is used to configure the unit

address, baudrate, and network pass type.

During the diagnostic test period following the application of power, the sequential

display shows “GO GO GO GO GO

appears, places the unit in the setup mode.

The BASIC I/O then flashes: U100

The underlined values represent setup parameters that can be changed.

The digit following the U represents whether the unit is analog/digital

where 1 indicates digital and 2 indicates analog. The initial configuration

is default 1 or digital..

The next two digits indicate the unit address; initially set to address 00h

The three digits after H is the baudrate divided by 100; initially set for

9600 baud.

The 1 digit after P is the handshake protocol type; initially set for 2 pass

The value of each setup character can be changed, as they appear in sequence, by pumping

the pushbutton. As the button is pressed, the display will cycle through the possible values for

each character. When the desired character is displayed simply wait for a brief period for the

display to blank. The next character position to be changed will then appear on the display.

The display continues to cycle through until there is a full cycle with no changes. The BASIC

I/O then stores all values in EEPROM for automatic use following subsequent power cycles.

The unit is now in the operational mode and the sequential display becomes:

/ “ Pumping the pushbutton once while the/

H096 P2

U1

=00 H096 L3 P2

The underlined values represent setup parameters that can be changed

If any desired changes were not completed, line power can be recycled and the setup via

pushbutton can be repeated if necessary.

2-17(Vol.1)

Page 35

Setup & Installation 2

Communication verification:

Network Debugging:

Most startup problems are related to the communication link. The installer is urged, after both

the communications wiring and configuration have been completed, to test the network before

installing I/O modules.

To test the serial communications link, the host transmits the abbreviated test instruction:

>NNA?? For each BASIC I/O address on the network, where NN is the address of each

BASIC I/O. This appears on the Sequential display after the U1 or U2.

Both the Host and the BASIC I/O under test are used to verify wiring, system configuration

and operation. If the addressed unit returns an A, acknowledgment, the communications link

is operational and the selected address is correctly configured. All addresses on the network

should be tested by the same means.

If the A acknowledgment is not returned, the behavior of the two network traffic displays

should be investigated.

The left LED (RECV) should blink on every BASIC I/O when the host transmits an

instruction. This should occur regardless of baud rate. If there is no indication of network

traffic, the failure can be anywhere from the host’s hardware of software to the BASIC I/O.

Generally the failure of the receive light to blink when the host transmits can be attributed to

faulty communications wiring. Locating the cause of the failure should start from the host.

The right LED (marked TRANS) blinks only when the addressed BASIC I/O responds to a

host instruction. If the Trans LED blinks, but the host does not receive an A acknowledgment,

the return circuit is suspect.

If an instruction is sent to the BASIC I/O and the RECV LED flashes but the TRANS LED

does not flash in response, first verify that the Baud rate

are correct, disconnect the wires attached to the “ TO PRIOR + and -” terminals. And resend

the command. If the BASIC I/O Trans LED still does not flash in response to a host request,

contact duTec for service. If the BASIC I/O Trans LED does flash in response to a host

instruction, the return circuit from the BASIC I/O to the host should be verified. If this test is

not successful the host’s receiving hardware should be tested.

2-18(Vol.1)

and Unit address are correct. If both

Page 36

Setup & Installation 2

Hardware error codes:

When the BASIC I/O is initially powered up, it goes through an internal self test. If any of the

self-diagnostics fail, the unit will report an appropriate error code on the sequential display

and halt.

Error Code 3

If a solid 3 appears in the sequential display, recycle power without touching the pushbutton.

This does not mean that there is a problem, it means it is in factory test mode. Recycle power

without holding down the pushbutton.

Other error codes

If 0, 1, 2, 4,6, or 7 appear on the display permanently there is a problem. Recycle power. If

that does not resolve the error condition, please call duTec at 800-248-1632.

Hardware watchdog

The hardware watchdog acts automatically in the event of a hardware or firmware failure and

responds within one second. The hardware watchdog turns all outputs off, and resets the

BASIC I/O. Do not confuse this with the programmable communication watchdog delay

instruction.

Fuses

A plug-in 5 amp, UL rated, fuse is installed between the minus field ierminal and the I/O

module. These fuses are generally only needed to protect output modules. Optional fuse

values are available for special output protection requirements. Fuses are installed in sockets

located on the module board next to the module. Thermocouples and RTD inputs do not

utilize ther terminal block and therefore do not make use of the fuse.

Sensor/ Actuator I/O wiring

Analog or digital modules can be placed at any module position. However it is good practice

for noise pickup, debugging and maintenance reasons to group and wire similar module types

together. For minimum crosstalk between input and output wiring, input modules should be

located at one end followed by output modules.

Modules should NEVER Be installed or removed while power is applied to the BASIC I/O.

Following insertion in their respective sockets, modules should be secured with the captive

screw.

2-19(Vol.1)

Page 37

Setup & Installation 2

Analog Inputs:

Note: analog modules normally run hot to the touch.

Correct polarity connections are essential to proper operation of all the analog inputs.

Connections to terminals marked with a + must be more positive than the terminals marked

with a -. Thermocouples and RTDs are connected directly to modules with special connectors

which insure correct polarity.

Analog input module status indicators are On dimly, when input modules are installed, wired

correctly, and their input signal is within the module’s valid range. If these conditions are not

met, the indicator light may be on brightly, off or may flicker.

The wiring and operation of analog input modules can be verified by the host issuing a

Configure as Input instruction, setup H, followed by a read input value instruction, Analog L.

See the software protocol manual

Figure 2-10, figure 2-11, and figure 2-12 show the wiring for various types of analog inputs.

With the exception of thermocouples and RTD modules, connections are made via the black

terminal strip. In the case of thermocouples and RTDs mating connectors are included. There

must be nothing connected to the screw terminals corresponding to these module positions.

The source of analog input voltage or current is external to the BASIC I/O with the exception

of ITP590, ITR10, ITR100, and ITR100-1.

or quick reference card for instruction details.

Figure 2-10 AC Current and Voltage Wiring.

2-20(Vol.1)

Page 38

Setup & Installation 2

Figure 2-11 Analog Voltage and Current input Wiring

Figure 2-12 Temperature Input Wiring

2-21(Vol.1)

Page 39

Setup & Installation 2

Analog outputs:

Modules should NEVER be installed or removed while power is applied to the BASIC I/O.

Following insertion in their respective sockets, modules should b secured with their captive

screw. Correct polarity is essential to proper operation.

Note: Analog modules run hot to the touch.

Both voltage and current output modules provide their own isolated power output. This

eliminates the need for external power supplies and insures electrical isolation between each

output. This also makes it possible to wire voltage outputs in series to obtain larger voltage

swings.

The wiring of analog output modules can be verified by the host issuing a configure as outputs

instruction, Setup 1, followed by a set output level analog J instruction. See software protocol

manual , or Quick reference card for instruction details.

Module status indicators for analog outputs blink briefly as outputs are updated. It should be

noted that the status indicator only follows the logic instruction to the modules and does not

show that the module or its fuse is present. Outputs can only be verified by observing the

output device or by a multimeter or oscilloscope measurement.

OI420 analog output modules provide the current into loops with total resistance less than 275

ohms. If the loop resistance exceeds 275 ohms, an external power supply must be added to the

loop as shown in figure 2-13 correct polarity is essential. The added voltage should be a

nominal 1 volt for each added 50 ohms of loop resistance in excess of 275 Ohms. The total

added voltage can be up to 5 volts larger than the nominal calculation without damage. The

voltage regulation of the added supply can be as poor as +/-10% without affecting accuracy.

Figure 2-13 Analog Voltage and Current Output Wiring

2-22(Vol.1)

Page 40

Setup & Installation 2

Digital Inputs:

Modules should never be installed while power is applied to the BASIC I/O.

With the exception of IDC5S digital input modules, input sensing current comes from a source

external to the BASIC I/O. IDC5S input modules provide their own current for sensing

contact closures. They can be DESTROYED

The IDC5 and IDC5D input modules are polarity sensitive and operate only when the +

terminal is more positive with respect to the - terminal. Polarity does not affect the

performance of the IAC5, IAC5A, or the IDC5S input modules.

Because the field side of input modules are totally isolated from each other, like polarities can

be wired common to make use of a single power supply.

The wiring and operation of digital input modules can be verified by closing the individual

input sensing contacts and observing the changes on the module status indicators. They are on

when the module circuit is energized. Their wiring can also be verified at the host by issuing a

configure as input instruction, setup H, followed by a read all modules instruction, digital M.

See software protocol manual

, or quick reference card for instruction details.

if an external source is used.

Figure 2-14 Digital Input Wiring

2-23(Vol.1)

Page 41

Setup & Installation 2

Digital Outputs:

Modules should NEVER be installed or removed while power is applied to the BASIC I/O.

The power for ODC5, ODC5A, OAC5, and OAC5A digital output modules comes from a

source external to the BASIC I/O.

Because they contain a protective reverse diode, the ODC5 and ODC5A output modules are

polarity sensitive and operate correctly only when the + terminal is positive with respect to the

- terminal. A DC digital output module connected backwards conducts current through its

protective diode and therefore cannot be controlled.

Polarity does not affect the performance of the OAC5 and OAC5A Digital output modules.

Because the field sides of output modules are totally isolated from each other, like polarities

can be wired common to make use of a single power supply.

The wiring of digital output modules can be verified by the host issuing a configure as output

instruction, control 1, followed by an output on/ off digital J, instruction. See software

protocol manual or quick reference card for instruction details.

The module status indicator should follow the instruction. It should be noted that the status

indicator only follows the logic instruction to the modules and does not show that the module,

its fuse, or that external power is present. Outputs can only be verified by observing the

device or by a multimeter or oscilloscope measurement.

Figure 2-15 Digital Output Wiring

2-24(Vol.1)

Page 42

Vol.1 Index

2 Pass .......................................................... 2 - 15, 2 - 17

4 Pass ................................................................ 2 - 15

Address.......................................................... 1 - 8, 2 - 17

Addresses ............................................................. 2 - 14

ANALOG INPUTS ............................................1 - 2, 1 - 9, 2 - 20

ANALOG OUTPUTS ..........................................1 - 3, 1 - 9, 2 - 22

Analog/ Digital ......................................................... 2 - 14

Analog/digital.......................................................... 2 - 17

BASIC I/O Models...................................................... 1 - 11

Baud rate ............................................................. 2 - 14

Baudrate .............................................................. 2 - 17

COMMUNICATION PROTOCOL .......................................... 1 - 8

Communication verification............................................... 2 - 18

Communications protocol ................................................. 2 - 3

Data throughput ......................................................... 1 - 6

Debugging ............................................................ 2 - 18

DIAGNOSTICS ........................................................ 1 - 10

DIGITAL INPUTS.................................................. 1 - 4, 1 - 9

Digital Outputs ................................................ 1 - 5, 1 - 9, 2 - 24

Error codes ............................................................ 2 - 19

Frequency ............................................................. 1 - 9

Fuses................................................................. 2 - 19

Last Unit.............................................................. 2 - 16

Modules ............................................................... 1 - 9

MOUNTING ........................................................... 2 - 1

Multidrop .................................................... 2 - 4, 2 - 7, 2 - 16

Network ..........................................................2 - 9-2 - 12

Network bias resistors .................................................... 2 - 8

Network Debugging ..................................................... 2 - 18

Network termination resistor .............................................. 2 - 16

Network type switches ...................................... 2 - 10, 2 - 11, 2 - 12

Noise suppression ........................................................ 2 - 8

Power ................................................................. 2 - 2

Power Requirements .................................................... 1 - 10

PRODUCT TEST ....................................................... 1 - 11

PROTOCOL...................................................... 1 - 8, 2 - 15

Repeat................................................................. 2 - 4

Repeater ......................................................... 2 - 7, 2 - 16

RS-422 ........................................................... 2 - 5, 2 - 9

RS-422 .............................................................. 2 - 10

RS-485 ................................................ 2 - 5, 2 - 6, 2 - 11, 2 - 12

Sample rate ............................................................ 1 - 2

Serial communications .................................................... 2 - 5

SYSTEM THROUGHPUT ................................................ 1 - 6

Temperature ....................................................... 1 - 2, 1 - 9

Test.................................................................. 2 - 18

Thermocouple ..................................................... 1 - 2, 1 - 9

THROUGHPUT ......................................................... 1 - 6

Page 43

Page 44

BASIC I/O AD Nov. 24, 2004

Copyright:

Copyright 1995- duTec Inc. All rights reserved. However any part of this

document may be reproduced, provided that DuTec Inc. is cited as the source.

The contents of this manual and the specifications herein may change without

notice.

Trademarks

The DuTec logo, and the BASIC I/O AD are trademarks of DuTec Inc.

Notice to the User

The information contained in this manual is believed to be correct. However

DuTec Inc assumes no responsibility for any of the circuits described herein,

conveys no license under any patent or other right and makes no

representations that the circuits are free from patent infringement. DuTec Inc.

makes no representation or warranty that such applications will be suitable for

the use specified without further testing or modification.

duTec Inc. general policy does not recommend the use of its products in life

support applications where failure or malfunction of a component may directly

threaten life or injury. It is a condition of sale that the user of duTec Inc

products in life support applications assumes all risk of such use and

indemnifies duTec Inc. against all damage.

Warranty

duTec Inc. warrants its products to be free of defects in materials and workmanship

for a period of two (2) years from the shipment date. DuTec Inc. , at its option will

repair or replace all material found to be defective. All repair or replacement must be

performed by duTec Inc. personnel. Any parts determined by duTec Inc.. To be

defective as the result of abuse, attempts to repair, or misuse will be repaired at the

expense of the customer. DuTec Inc. will not be liable for any consequential,

incidental, or special damages.

Page 45

Vol 2 Table of Contents

Overview ..............................................................1 - 1

Capacity .......................................................... 1 - 1

I/O signal compatibility .............................................. 1 - 2

Diagnostics ........................................................ 1 - 2

Communications watchdogs ........................................... 1 - 2

Easy setup......................................................... 1 - 2

Protocol Compatibility ...............................................1 - 3

Available I/O functionality ................................................. 1 - 4

Analog Input Functions .............................................. 1 - 4

Analog outputs ..................................................... 1 - 4

Digital inputs ......................................................1 - 5

Digital outputs .....................................................1 - 5

Extended capabilities ................................................ 1 - 6

Specifications ...........................................................1 - 7

Communications....................................................1 - 7

Power ............................................................1 - 7

Environment .......................................................1 - 7

Ordering Information .....................................................1 - 7

Options ...........................................................1 - 7

Available I/O Modules .................................................... 1 - 8

Installation ............................................................ 2 - 1

Mounting ......................................................... 2 - 1

Power Wiring ...................................................... 2 - 2

Designing the Network.................................................... 2 - 3

Multidrop ......................................................... 2 - 3

Repeat............................................................ 2 - 3

RS-422 ...........................................................2 - 4

RS-485 ...........................................................2 - 4

RS-485 Programming ................................................2 - 5

Communication Wiring ................................................... 2 - 6

Network load V.S. Noise suppression ........................................2 - 7

Network bias resistors ............................................... 2 - 7

Network Type Switches ...................................................2 - 8

Repeat............................................................ 2 - 9

Multidrop ......................................................... 2 - 9

Last Unit .......................................................... 2 - 9

Communications Wiring ................................................. 2 - 10

Host to BASIC I/O AD-RS .......................................... 2 - 10

Page 46

Vol 2 Table of Contents

RS-485 Host to BASIC I/O AD ....................................... 2 - 11

BASIC I/O AD TO BASIC I/O AD RS-422 ............................. 2 - 12

BASIC I/O AD to BASIC I/O AD RS-485 .............................. 2 - 13

Installing the I/O modules ................................................ 2 - 14

Module Wiring ......................................................... 2 - 15

Analog Inputs ..................................................... 2 - 15

Analog outputs .................................................... 2 - 17

Digital Inputs ..................................................... 2 - 18

Digital Outputs ....................................................2 - 19

Chassis Setup ........................................................... 2 - 1

Setup pushbutton ................................................... 3 - 1

Sequential display .................................................. 3 - 1

Baud rate ......................................................... 3 - 3

Protocol Handshake Types ............................................ 3 - 3

Changing Setup Parameters ................................................ 3 - 4

Communication Verification ............................................... 3 - 5

Page 47

Introduction 1

Overview

BASIC I/O ADs are a family of small, industrial grade, remote data acquisition and control

systems which exchange data with a Host computer via a serial communications link.

Controlled by a wide range of software running on a Host computer, BASIC I/O ADs are

located near the sensors and actuators. The serial link eliminates the need for expensive and

noise prone signal wiring between field sensors and actuators, and a central control room.

In applications such as remote process monitoring, factory automation, and energy

management, a variety of signals must be transmitter over long distances. Instead of requiring

expensive, multi-conductor, sensor wiring for each signal, cabling costs can be reduced

significantly by using BASIC I/O ADs and a single communications circuit.

One of the most useful features of the BASIC I/O AD is that in addition to gathering raw

data, it can be instructed to perform many ranging and statistical operations upon the data

before it is given to the host, thus allowing the host to spend less time manipulating data and

more time gathering it. Also the BASIC I/O AD is able to spend more time exposed to the

data which in turn allows it to base its responses to the host on more samples of data. The

BASIC I/O AD may also be directed to manipulate outputs in specific ways to produce

delayed or repetitive effects.

Capacity:

Each BASIC I/O AD system consists of one logic board connected to a 4, 8, or 16 position

I/O module mounting rack. This combination is then field configurable to accept either analog

or digital electrically isolated input or output modules which can interface to a wide variety of

sensors and actuators.

BASIC I/O AD networks can service over 4000 analog and/or digital I/O lines in various

combinations.

Product Test:

Every BASIC I/O AD is burned-in at 70°C while operating in a network for a period of 24

hours prior to shipment.

Every analog I/O module is operated and tested while it’s ambient operating temperature is

cycled over the specified operating range of 0°C to 60°C for a period of 24 hours. A computer

record is generated for every analog I/O module.

1-1(Vol.2)

Page 48

Introduction 1

I/O signal compatibility:

BASIC I/O ADs use duTec I/O modules to match signal requirements exactly. With a direct

interface to sensors, no external signal conditioning is required. Furthermore, all duTec

modules feature total electrical isolation, both module to logic and module to module. Analog

modules are available to measure:

! Millivolts DC to hundreds of volts AC

! Milliamps DC to amps AC

! Frequency to tens of Khz

! Temperature with all popular thermocouples and restive

temperature devices

A full range of industry standard digital modules are available for AC, DC, and dry contact

inputs and outputs to hundreds of volts.

Thermocouple modules provide a cold reference junction compensation. BASIC I/O AD

instructions provide linearized thermocouple and RTD sensor data. Engineering unit

conversions are handled at the host lever.

Diagnostics:

To confirm internal operations and communications link integrity, a set of built-in diagnostics

test key system functions each time power is applied. Diagnostics reduce both installation

debugging and operation troubleshooting.

A hardware watchdog timer insures safe shutdown in the event of processor or software

failures by turning all outputs OFF. Normally ON modules are available for those loads that

must remain ON.

Communications watchdogs:

The BASIC I/O AD can be instructed to implement alarm and fail-safe states in the event of a

communication failure.

Easy setup:

The BASIC I/O AD uses a pushbutton and an on board LED indicator to configure the unit

address, analog VS digital map and baud rate.

1-2(Vol.2)

Page 49

Introduction 1

Protocol Compatibility:

The BASIC I/O AD instruction set core complies 100% with that of the OPTO- 22 Optomux

™ . With this ASCII character, speak-only-when-spoken-to protocol, a Host transmits inquiry

requests to the BASIC I/O AD to determine the status of its various process inputs. Similarly,

the software in the Host computer makes control decisions and transmits instructions to the

BASIC I/O AD, which in turn, makes the proper changes to its various outputs. Both the Host

and its communications link are essential elements in this data acquisition and process control

scheme.

Originally the protocol only allowed for all analog or all digital I/O chassis. Depending on

application requirements, each BASIC I/O AD can respond to pup to three different function

addresses. With their abbreviations they are:

MC Master Unit Control function address

MD Master Unit Digital I/O function address

MA Master Unit Analog I/O function address

It is this multiple function addressing capability of BASIC I/O ADs that allows them to

utilize, without modification, software developed for competitive products. Similarly BASIC

I/O ADs can operate simultaneously on the same network with these products.

1-3(Vol.2)

Page 50

Available I/O functionality:

Introduction 1

Analog Input Functions

Input value Determines signal levels, with 12 bits resolution

1

Offsets Input values can be software offset, with 12 bits resolution,

over the module’s specified range.

Gain/ Slope The amplitude of input values can be software multiplied by

factors ranging from 0.25 to 4.0.

Range Limits The occurrence of input values falling out of user defined upper

or lower limits can be flagged.

Minimums The minimum level of input values can be captured.

Maximums The maximum level of input values can be captured.

Averages Can calculate average input amplitude for 1-65,535 samples.

Temperature Can linearize in, °C, inputs from thermocouples and RTDs.

Will also return temperature probe data.

Analog outputs

Level Value Can set output levels, as a function of the module’s full scale

range, and are specified with 12 bits resolution.

Waveforms can provide square, triangular, sawtooth, or ramp waveforms.

Maximum and minimum amplitudes, as a fraction of the output

module’s full scale range, are specified with 12 bits

resolution. Waveform periods are specified 0.1 to 6,553 Sec

(109 Min). All waveforms are made up of at least ten

segments.

1 One part in 4095

1-4(Vol.2)

Page 51

Introduction 1

Digital inputs

Read Read the on or off of all inputs

Pulse widths The duration of a single or total on/off time of consecutive

pulses can be resolved to the nearest 0.00 seconds for a max

total of 10.9 minutes, or 46.6 hours with multiplied resolution.

Positive or negative edges initiate measurements. The time

scale can be multiplied by a factor of 1-256 on a system wide

basis.

Pulse counting Pulses can be counted up to a total or 65,535. To be reliably

counted, pulses must have minimum on and off times of 1

mSec. Thus the maximum counting rate for a 50% duty cycle

squarewave with equal on and off times for a total of 2 mSec.

Would be 500Hz.

Edge detection Off to on and on to off transitions can be detected within 1

mSec. Of their occurrence. Action is only reported every

10mSec.

Note: The response time performance of digital input instructions can be limited by the

delay in the input modules themselves which can nave on plus off delays of up to 40 mSec.

Digital outputs

Set Outputs Can set individual or multiple outputs on or off Modifiers

One Shot Can generate on or off pulse durations of up to 655.35 seconds

with a resolution of 0.01 seconds. Resolution can be further

multiplied by a factor of 1-256on a system wide basis.

Delayed Can generate on or off pulse durations of up to 655.35 seconds

with a resolution of 0.01 seconds. Resolution can be further

multiplied by a factor of 1-256on a system wide basis.

1-5(Vol.2)

Page 52

Introduction 1

Squarewave Can generate squarewaves with programmable On and Off

periods. On and Off periods have a base range from 0.01 to

2.56 seconds. Resolution can be further multiplied by a factor

of 1-256 on a system wide basis. Re-triggering is available.

Pulse Generator Can generate 1-65,535, 50% duty cycle pulses whose equal on

and off periods can range from 0.01 to 2.55 Sec. Resolution can

be further multiplied by a factor of 1-256 On a system wide

basis.

Extended capabilities:

In addition to operating under the control of a host, Option/L of the BASIC I/O AD has the

ability to perform local control functions without the host. Local control functions (LCFs) can

insure the continued safe operation of closed loop control should the host of its

communication link fail. In addition, LCFs can substantially reduce Host computational load

or communications traffic.

Once characterized, Local Control Function blocks enable the BASIC I/O AD to perform

control tasks without the constant involvement of the host computer. After configuration and

activation via the host instructions, LCFs take data from their input ports, perform

computations and send the results to their outputs where they may drive output modules, or

other BASIC I/O AD internal functions.

Utilizing the LCF’s to perform simple logic tasks such as analog comparisons, summations,

differences, sequence generating or state machine operations eliminates the need for

programmable controllers or special purpose circuitry. This capability allows a more effective

use of the host computer and its communication link because the LCFs handle the operation

of the designated control function. In the meantime the host is only required to monitor

over-all system status and generate the system displays and reports. This is particularly

valuable for systems using modems for communications.

1-6(Vol.2)

Page 53

Introduction 1

Specifications

Network Communications:

duTec supports two standards for transmitting serialized I/O data between the host computer

and the BASIC I/O ADs at baud rates to 38,400.

Maximum Distance

Serial Link Feet Meters

RS-422 /485 5,000 1,524

Physical Characteristics:

Power Supply 5Vdc@<5A

Environment Temperature 0-60 C

Humidity 95% Non-Condensing

Options /L Local Control

Function (LCF)

Ordering Information

Specify duTec products by model number, e.g.,

BIO4AD

BIO8AD

BIO16AD

Options are specified by a series of suffixes to the model number, preceded by a slash for

example:

BIO8AD/L

1-7(Vol.2)

4 Position BASIC I/O AD

8 Position BASIC I/O AD

16 Position BASIC I/O AD

Page 54

Introduction 1

Frequency

I F10K-B Input 300Hz-10KHz OV1 Output 0-1V, self-sourcing

IF2.5K-L Input 0-2.5KHz OV5 Output 0-5V, self-sourcing

IF5K-l Input 0-5KHz OV10 Output 0-10V, self-sourcing

IF10K-L Input 0-10KHz Current

Voltage OI420 Output 4-20mA, self-sourcing To 275

IV25M Input 0-25mV

IV50M Input 0-50mV

IV100M Input 0-100mV AC

IV1 Input 0-1V IAC5 Input 90-140Vac

IV5 Input 0-5V IAC5A Input 180-280Vac

IV5B Input Bipolar +/-5V DC

IV10 Input 0-10V IDC5D Input 3-32Vdc Fast, >500Hz

IV10B Input Bipolar +/-10V IDC5S * Input Dry Contact Sense, Built-in Isolated

IVAC Input 28-140Vac IDC5NP Input 10-32 Vdc, 15-32Vac Non-

IVAC-A Input 56-280Vac

Current

II420 Input 4-20mAdc AC