Page 1

IW-RJ472-05

User’s Manual

Page 2

Table of Contents

PREFACE ....................................................................................................................................... 1

SAFETY INFORMATION ................................................................................................................. 1

CAUTION ...................................................................................................................................... 2

SPECIFICATIONS ............................................................................................................................ 3

1 Product Introduction ............................................................................................................. 4

1.1 Box Contents ............................................................................................................................ 4

1.2 General Information ................................................................................................................. 5

1.2.1 Front Panel Controls and Indicators .......................................................................................................... 6

1.2.2 Rear Panel Configuration ........................................................................................................................... 7

1.2.2.1 Expander (Host) Configuration ............................................................................................................ 8

2 Hardware Installation ........................................................................................................... 9

2.1 Removing and Inserting the Top Cover ...................................................................................... 9

2.1.1 Open the cover of the chassis .................................................................................................................... 9

2.1.2 Close the cover of the chassis .................................................................................................................... 9

2.2 Removing and Installing a Hard Drive ...................................................................................... 10

2.2.1 Installing a Hard Drive .............................................................................................................................. 10

2.2.2 Removing a Hard Drive ............................................................................................................................ 11

2.3 Removing and Installing the Fan Module................................................................................. 12

2.3.1 Removing the Fan Module ....................................................................................................................... 12

2.3.2 Installing the Fan Module ........................................................................................................................ 13

2.4 Removing and Installing the PSU+FAN Module ........................................................................ 13

2.4.1 Removing the PSU+FAN Module .............................................................................................................. 13

2.4.2 Installing the PSU+FAN Module ............................................................................................................... 14

2.5 Removing and Installing the Host & Disk Expander Module .................................................... 15

2.5.1 Removing the Host Expander Module ..................................................................................................... 15

2.5.2 Installing the Host Expander Module ...................................................................................................... 15

2.5.3 Removing the Disk Expander Module ..................................................................................................... 16

2.5.4 Installing the Disk Expander Module ....................................................................................................... 17

2.6 Rail Installation ....................................................................................................................... 19

2.6.1 The Type of Rail Kit ................................................................................................................................... 19

2.6.2 Slide Rail ................................................................................................................................................... 19

2.6.2.1 Take out the Inner Rail and Slide the Intermediate Rail Back ............................................................ 19

Page 3

2.6.2.2 Attach the Inner Rail to the Chassis .................................................................................................... 19

2.6.2.3 Mount the Rail Bracket to the Cabinet ............................................................................................... 20

2.6.2.4 Insert the Chassis to the Cabinet ........................................................................................................ 20

2.7 External Cable Management Arm Installation ......................................................................... 22

2.7.1 Parts Required .......................................................................................................................................... 22

2.7.2 Mounting Bracket Installation ................................................................................................................. 22

2.7.3 Support Arm Installation .......................................................................................................................... 23

2.7.4 Cable Management Arm Installation ....................................................................................................... 25

2.7.5 Completing Installation ............................................................................................................................ 27

2.7.6 Insert the Chassis to the Cabinet External Cable Management Arm Installation .................................. 27

3 Expander Board Introduction (Host & Disk) ......................................................................... 28

3.1 Expander Board (Host) ............................................................................................................ 28

3.2 Expander Board (Disk) ............................................................................................................ 29

4 User Interface Introduction ................................................................................................. 30

4.1 Overview ................................................................................................................................ 30

4.2 Key Features ........................................................................................................................... 30

4.3 Software Management ........................................................................................................... 31

4.3.1 System Management Structure ............................................................................................................... 31

4.3.2 Serial Port Management .......................................................................................................................... 32

4.3.3 Network Management ............................................................................................................................. 35

4.3.4 Version Information ................................................................................................................................. 41

4.3.5 System Status ........................................................................................................................................... 43

4.3.6 Network Settings ...................................................................................................................................... 44

4.3.7 Disk Information ....................................................................................................................................... 45

4.3.8 Zone Setting .............................................................................................................................................. 46

4.3.9 Firmware Upgrade .................................................................................................................................... 48

4.3.10 Web Console ........................................................................................................................................ 54

4.4 Appendix A ............................................................................................................................. 55

4.5 Appendix B ............................................................................................................................. 55

5 Compatibility Lists .............................................................................................................. 57

6 Technical Support ................................................................................................................ 57

Page 4

1

PREFACE

Thank you for choosing the InWin IW-RJ472-05. This manual is written for system technicians who

are responsible for installation, troubleshooting, managing and repairing this server chassis. This

document provides the overview of all the features of the chassis, a list of accessories or other

components you may need to finish the installation, troubleshooting methods and instructions on

adding and removing components on the InWin IW-RJ472-05. For the latest version of this manual,

you may visit InWin’s server website to download the latest updated version.

SAFETY INFORMATION

To ensure a safe and smooth operation of your InWin IW-RJ472-05, it is essential that you choose

an appropriate location for the system, provide an appropriate operating environment and supply

an adequate amount power for all components of the system. As you plan for installation, follow

the guidelines below to ensure that the system and its environment are safely and appropriately

positioned for efficient operation and service. Your system should be installed and serviced only by

a qualified technician.

Environment selection: The system is designed to operate in a typical office environment:

• The location should be clean, dry and free of airborne particles.

• It should be situated in a well-ventilated room, and away from sources of heat including direct

sunlight and radiators.

• It should be kept away from sources of vibration or physical shock.

• The space should be accommodated with a properly grounded wall outlet, and with sufficient

space to access the power supply cords.

• The operating environment temperature should be around 0°C to 40°C (32°F to 104°F).

Heed safety instructions: Before working with InWin IPC/Storage server products, we strongly

recommend you use this guide as a reference and follow the safety instructions. The instructions in

this manual will help you ensure and maintain compliance with existing product certifications and

approvals. Follow the described, regulated components mentioned in this manual. Use of non-UL

listing products or other regulators may not comply with product regulations in the region(s) in

which the product is sold.

System power on/off: The power button DOES NOT totally turn off the system AC power. To

remove the power of the system, you must unplug the AC power cord from the outlet or the

system’s power supply units. Make sure the power cord is unplugged before you open the chassis

or add/remove any components.

Hazardous conditions, devices and cables: Hazardous electrical conditions can be present on/in

power supply units and their cables. Disconnect the power cord and any other device attached to

the server before opening the case. Failing to follow safety procedures will increase the risk of

personal injury or equipment damage.

Page 5

2

Electrostatic discharge (ESD) and ESD protection: In most cases, ESD may damage disk drives,

electronic boards and other parts. We recommend that you conduct installation only at an ESD

free space. If not possible, perform ESD protection protocol by wearing an anti-static wrist straps

attached to the ground on any unpainted metal surface on your server during operation.

Installing or removing jumpers: A jumper is a short length conductor used to close, open or bypass

part of an electronic circuit. Jumpers on InWin backplanes have a small tab on top that you can

pick up with your fingertips. Grip the jumper carefully, and plug the jumper to cover the jumper

pins on the backplane. Once you need to remove the jumper, grip the jumper and carefully pull

without squeezing.

CAUTION

To avoid damage and maintain your safety, please read the following terms listed below:

1. Do not populate hard drives and turn on the power until the system has

stabilized.

Make sure hard drives and other components are properly connected before

turning on the system.

2. Tighten or loosen all screws with a screwdriver.

3. Apply the correct screws packed in the accessory box.

4. For your safety, please have at least two people lift and place the unit in its

designated area.

5. Before mounting the unit to the cabinet, make sure the rail is installed correctly.

6. When installing and removing any module or part, please use the handles.

Page 6

3

SPECIFICATIONS

Model Name

IW-RJ472-05

Standard

EIA-RS310D

Dimensions (D x W x H)

w/o Front Door

914.4 x 482.6 x 176 mm

(36" x 19" x 7")

Storage

External: Hot-swap 3.5" x 72 (SAS 12Gbps)

Power Supply

(PSU+FAN Modules)

Supports

▪ Form Factor: High efficiency redundant PSU

▪ Watt: 1100W

Cooling Fan

(PSU+FAN Modules)

80 x 38 mm PWM x 6

12G Expander Module

1 or 2

Host/Expansion Port

6 x Mini SAS HD (SFF-8644) for each 12G expander module

Management

Smart fan, thermal monitor, HDD monitor, voltage monitor, alarm

warning

SES

Supports SES-2 (SCSI Enclosure Service)

Maintenance

Supports management by Ethernet (Optional) and RS-232

HDD Power Management

HDD sequential power on

Temperature

0ºC to 35ºC

Material

Material: SGCC

Thickness: 1.0 mm

Rail Kit

Supports 28" tool-less & ball-bearing slide rail

* The actual product is subject to change without prior notice. In Win Development Inc. reserves the

right to make any final modifications.

Page 7

4

1 Product Introduction

1.1 Box Contents

Page 8

5

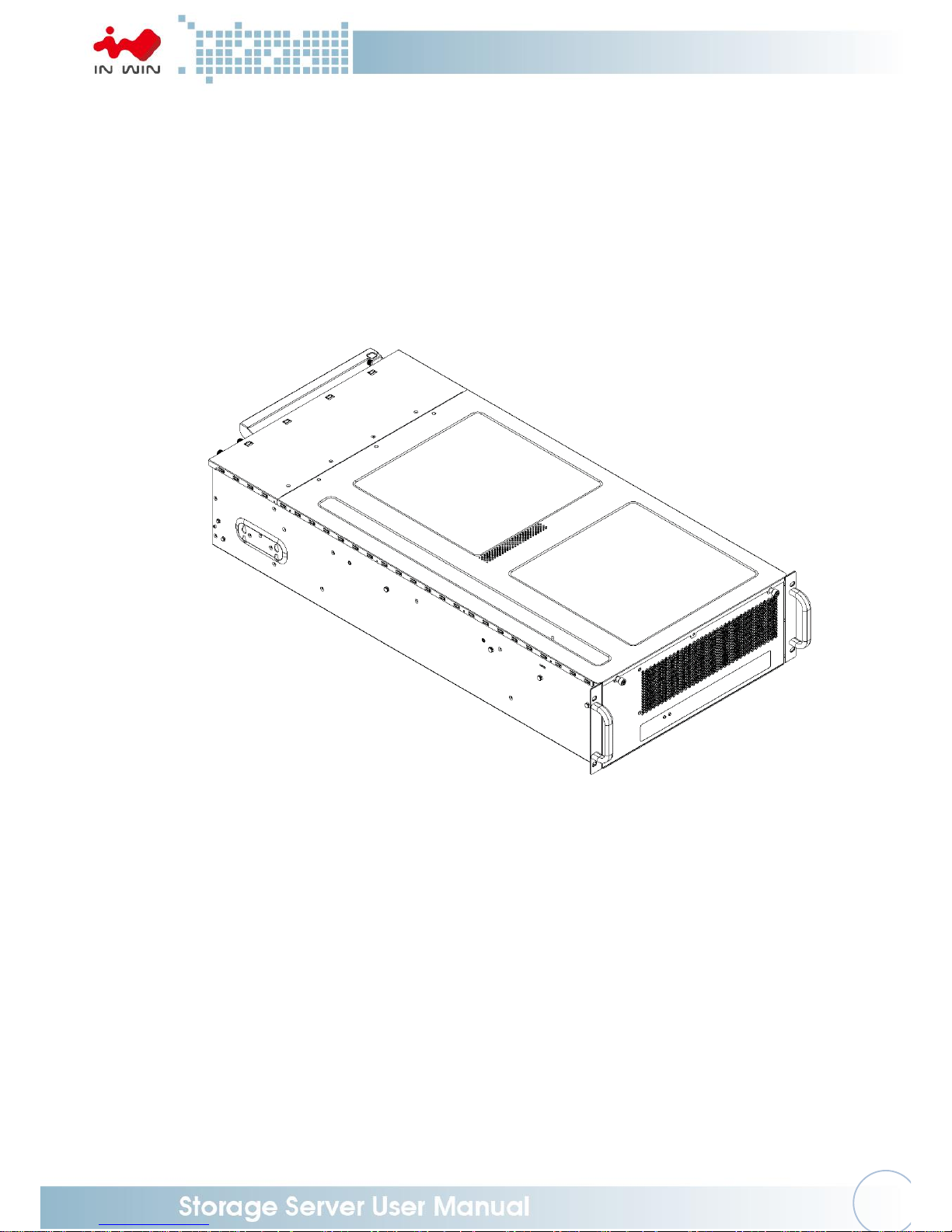

1.2 General Information

Designed for high scalability and high availability in storage applications, the IW-RJ472-05 JBOD

enclosure is a high density 4U rackmount storage chassis with 72 tool-less bays, dual hot-swap

SAS 12G expander modules, six Mini SAS HD (SFF-8644) for each 12G expander module, six PSU

+Fan module fans, dual redundant 1100W power + fan module, and GUI supports via Ethernet

board (Optional).

Page 9

6

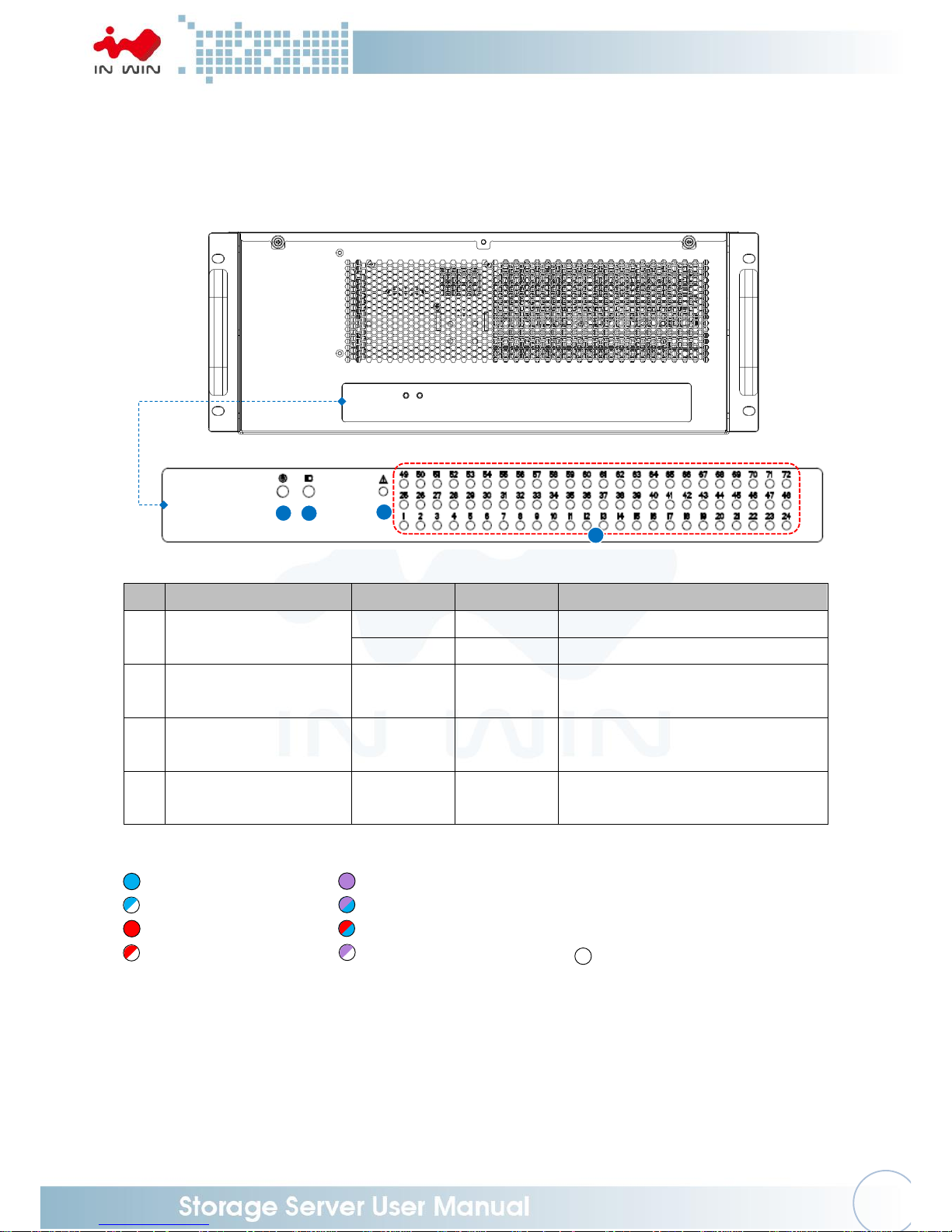

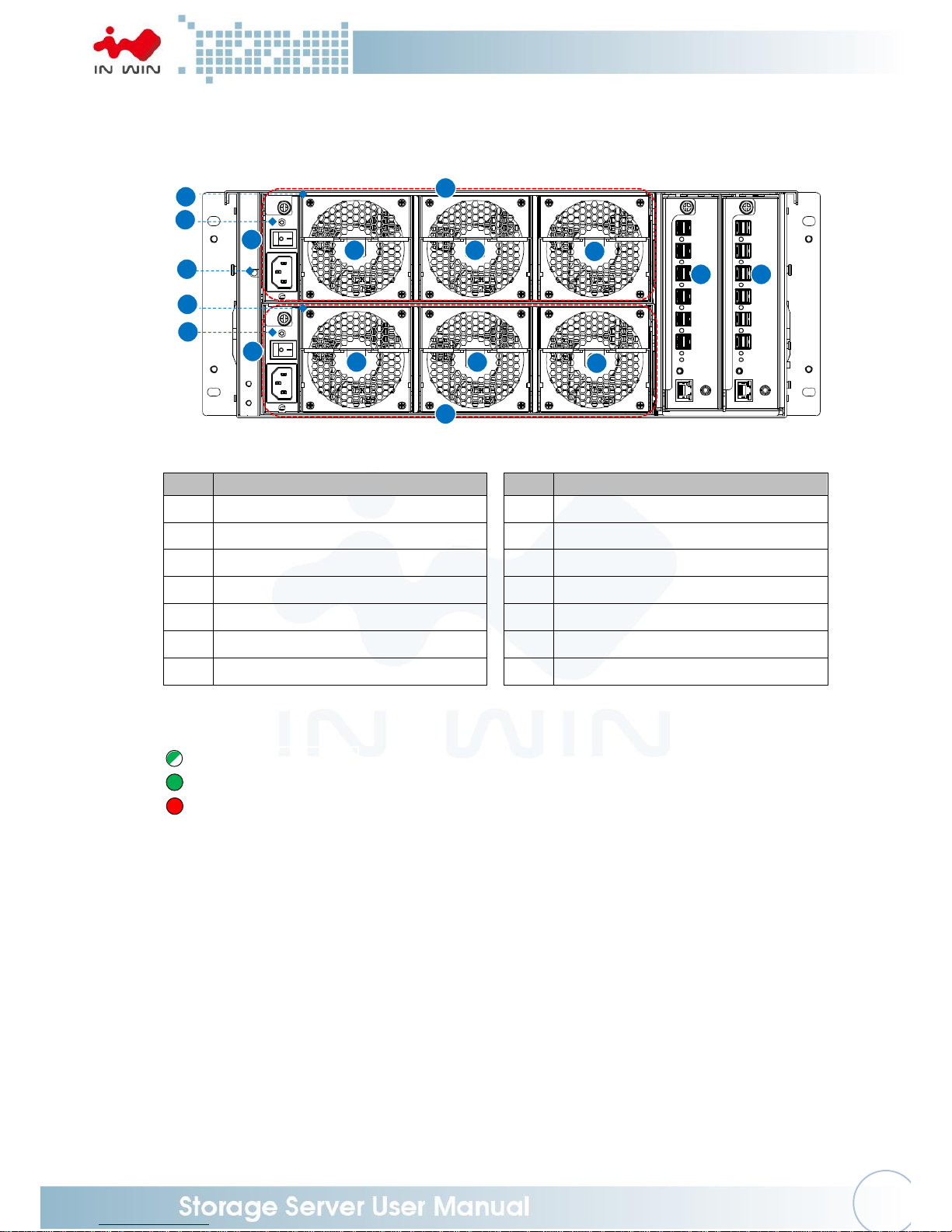

1.2.1 Front Panel Controls and Indicators

The front panel includes control buttons and LED indicators.

No.

Name

Color

Status

Description

1

Power On/Off Button

with LED

Blue

Solid on

System is powered on

N/A

Off

System is off

2

Chassis ID Button with

LED

Blue

Solid on

Press the button to activate chassis

identification

3

Status LED

Red

Solid on

System maintenance (PSU, fan

malfunction)

4

Drives Status LEDs for

Bays 1-72

Follow the

table below

Drive Status LED:

(Solid) Drive Online

(Solid) RAID Drive

(Blink) Drive Activity

(Blinking Purple on Solid Blue) RAID Active / Rebuild

(Solid) Drive Failed

(Alternating Blink) Drive Faulty / RAID Failure

(Blink) Drive Missing

(Blink) Drive Locate

Drive Offline / Removed

1 2 3

4

Page 10

7

1.2.2 Rear Panel Configuration

No.

Item

No.

Item

1

Power Module 1 (PSU+FAN Module)

8

Fan Module 6 (PSU+FAN Module)

2

Power Module 2 (PSU+FAN Module)

9

Primary expander Module

3

Fan Module 1 (PSU+FAN Module)

10

Secondary expander Module

4

Fan Module 2 (PSU+FAN Module)

11

Power Module Handle

5

Fan Module 3 (PSU+FAN Module)

12

Power Switch

6

Fan Module 4 (PSU+FAN Module)

13

PSU Alarm Mute Button

7

Fan Module 5 (PSU+FAN Module)

14

PSU Status LED

PSU Status LED:

Power Standby

Power On

Loss of Power

3

5

7

4

6

8

9

10 1 2

11

12

13

12

14

14

11

Page 11

8

1.2.2.1 Expander (Host) Configuration

No.

Name

Description

1

SAS Port LEDs

Host HBA/RAID card connection

2

SAS Host Ports

External Uplink, Connect to HBA/RAID card

3

SAS Expansion Ports

External Downlink, Connect to cascading JBOD

4

Expander Module Status LED

Heartbeat

5

ID LED / Button

Press the button to activate chassis identification

6

Expander Serial Port (RS-232)

RS-232 Support

7

Network Management Port

Connect to Ethernet remote monitoring

8

Expander Module Handle

SAS Port LEDs:

Expander Module Status LED:

ID LED:

SAS Connection On

Heartbeat

ID on

SAS Activity

4 7 5 6 2 3 1

8

Page 12

9

2 Hardware Installation

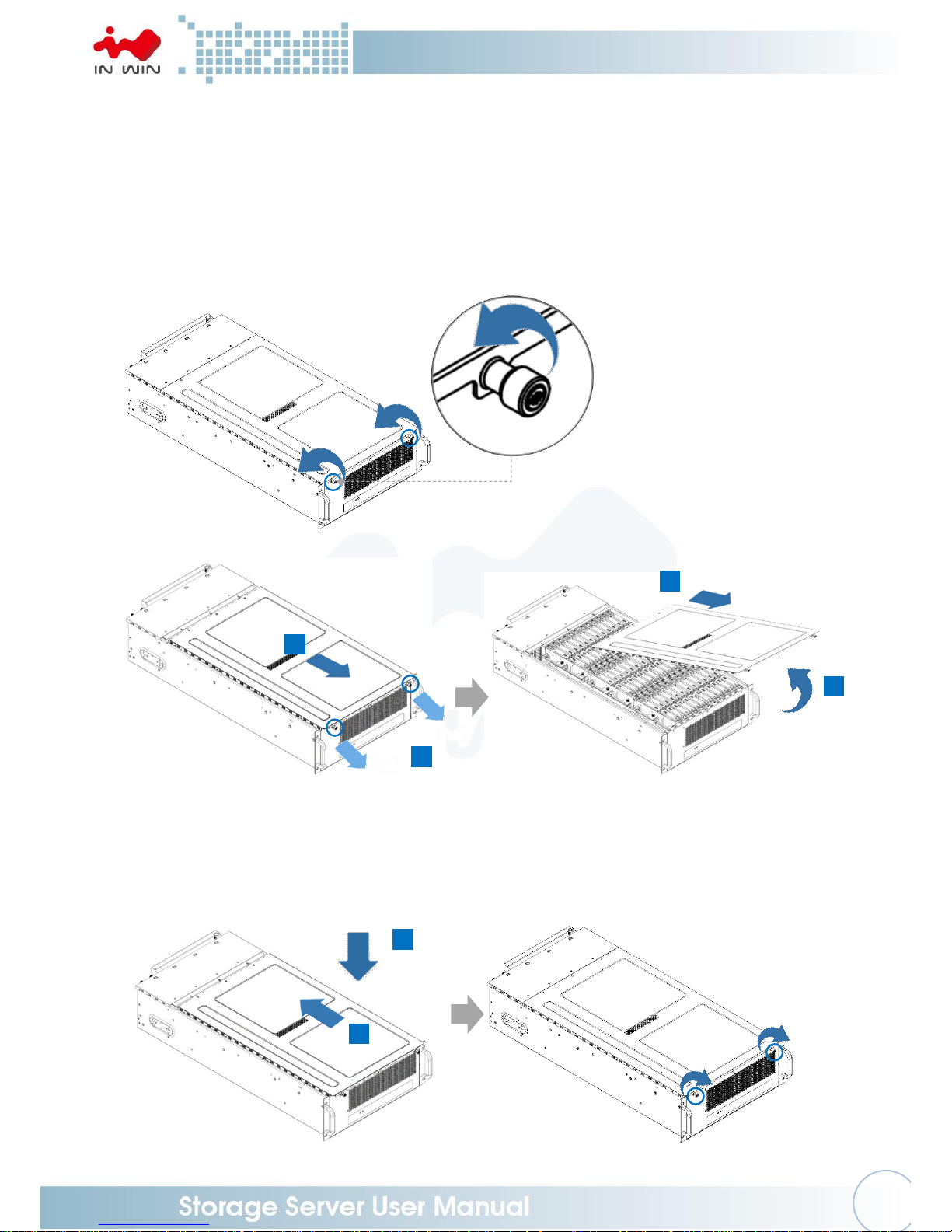

2.1 Removing and Inserting the Top Cover

2.1.1 Open the cover of the chassis

NOTE: Please open the top cover only when necessary and close it within 1 minute

to prevent the system from HDD overheating.

Step 1: Loosen the thumbscrews of the top cover.

Step 2: Pull the thumbscrews to release the top cover.

Slide and tilt the cover upward from the front and lift to remove.

Step 1:

Step 2:

2.1.2 Close the cover of the chassis

Step 1: Place down the top cover, then slide and match to the proper location.

Step 2: Tighten the screws to secure the top cover.

Step 1:

Step 2:

Pull

Pull

1 2 1 2 1

2

Page 13

10

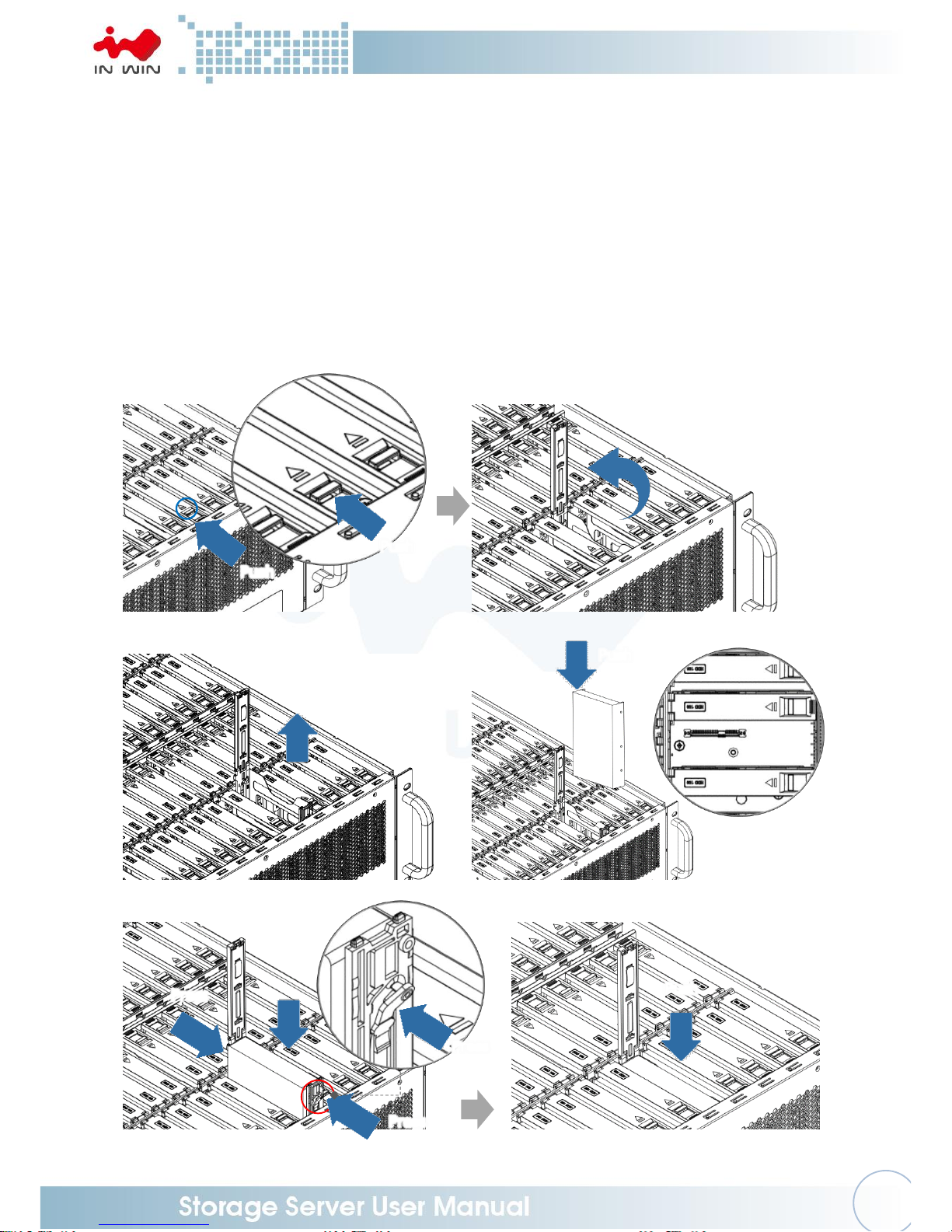

2.2 Removing and Installing a Hard Drive

The IW-RJ472-05 JBOD features tool-less trays, users can easily swap drives without any

screws.

2.2.1 Installing a Hard Drive

Step 1: Release the latch in the direction of the arrow on the tray.

Open the disk tray cover and pull it outward as a handle.

Step 2: Pull up the tray until it clicks.

Step 3: Fully insert the HDD into the tray from the correct disk port orientation.

Step 4: Align the HDD screw holes and plug in the pins on the side of the tray.

Keep the tray pins against the HDD screw holes and push the disk tray back

to the location.

Step 5: Release the latch to close the cover to lock.

Step 1

Step 2

Step 3

Step 4

Push

Pull

Push

Press

Press

Push

Push

Press

Push

Page 14

11

Step 5

2.2.2 Removing a Hard Drive

Step1: Release the latch in the direction of the arrow on the tray.

Open the disk tray cover and pull it outward as a handle.

Step2: Pull up the tray until it clicks.

Step3: Pull the hard drive out carefully.

Step4: Lower the disk tray back. Release the latch to close the cover to lock.

Step 1

Step 2

Step 3

Pull

Pull

Push

Push

Push

Page 15

12

Step 4

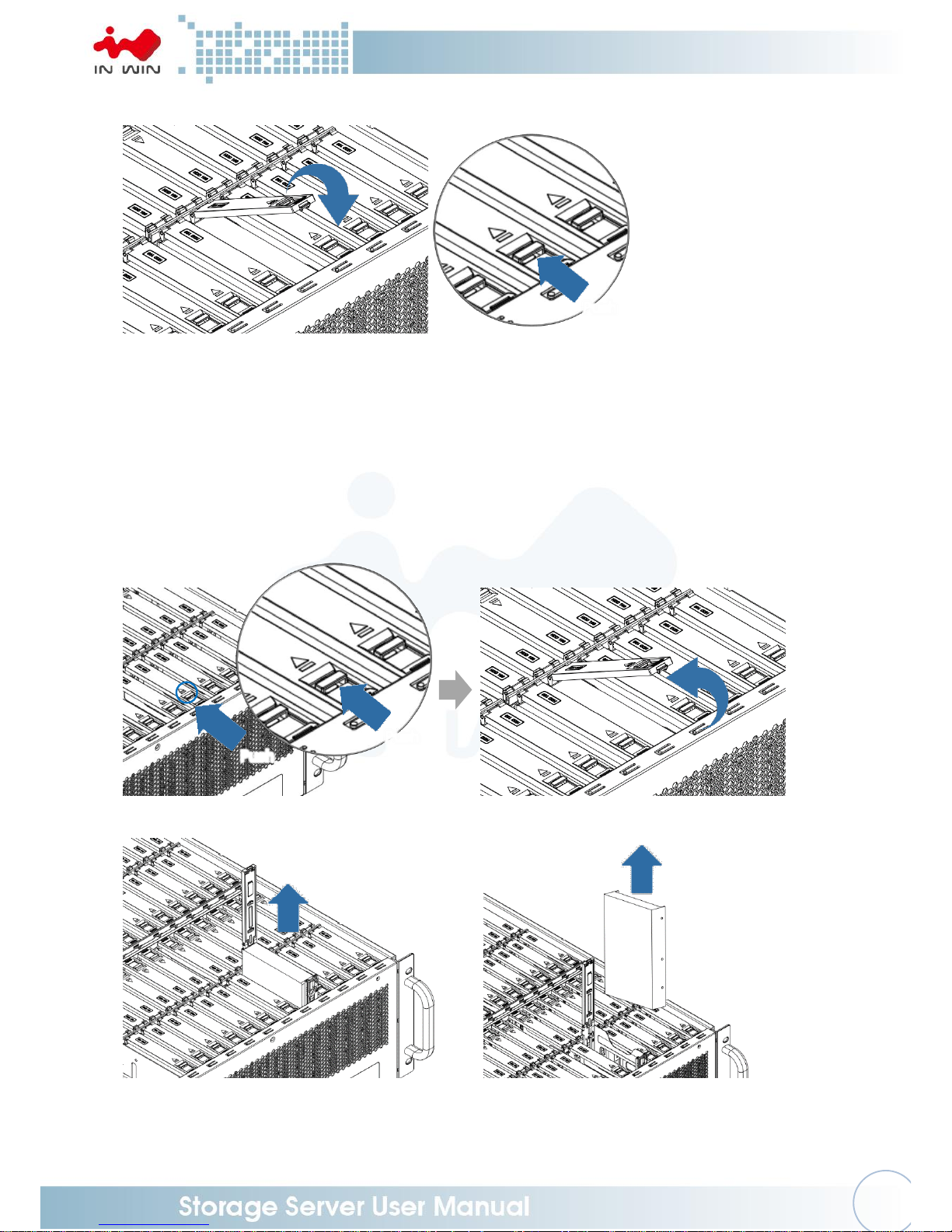

2.3 Removing and Installing the Fan Module

The IW-RJ472-05 JBOD has built-in fan modules that support hot-swappable and

redundant features, which is easy to maintain with the tool-less design.

2.3.1 Removing the Fan Module

Step 1: Loosen the thumbscrew of the fan module.

Step 2: Press the handle and pull out the fan module with the slot.

Step 1

Step 2

Push

Pull

Page 16

13

2.3.2 Installing the Fan Module

Step 1: Push the fan module back into the slot until it clicks.

Step 2: Secure the thumbscrews in place and tighten.

Step 3: Connect the fan to the backplane.

Step 1

Step 2

2.4 Removing and Installing the PSU+FAN Module

The IW-RJ472-05 hosts dual built-in redundant 1100W PSU + FAN modules. Each

module cage contains one power supply and three fan modules. With this function, the

system is capable of still functioning if one of the modules fail. To replace it, the user

only needs to release the failed module, then insert a functional module.

NOTE: The two PSU modules’ output wattage must be the same.

To ensure the stability of use, if the PSU module fails, it is recommended to replace

the PSU with the fan modules together.

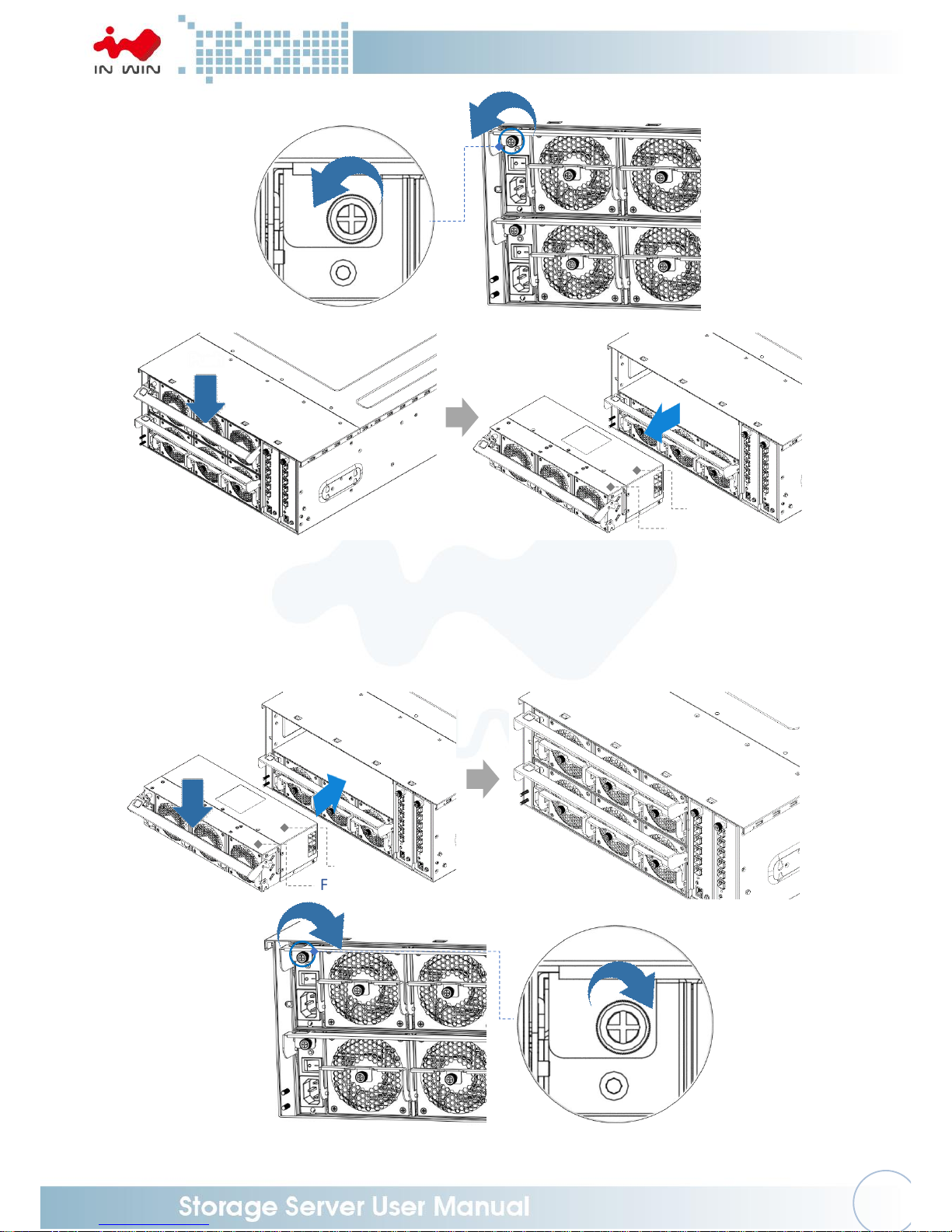

2.4.1 Removing the PSU+FAN Module

Step 1: Loosen the thumbscrew of the PSU+FAN module cage at the back.

Step 2: Push down the handle and use the handle to pull out the cage.

Push

Page 17

14

Step 1

Step 2

2.4.2 Installing the PSU+FAN Module

Step 1: Push the PSU+FAN module cage back until it clicks.

Step 2: Tighten the thumbscrew to secure the cage.

Step 1

Step 2

Push

Pull

Push

PSU

Fan

PSU

Fan

Page 18

15

2.5 Removing and Installing the Host & Disk Expander Module

The IW-RJ472-05 JBOD is accommodated with pre-installed dual redundant host

expander and six redundant disk expander modules. The internal expander is primary;

external will be the secondary. The host expander module includes an Ethernet

management module, which allows users to monitor and maintain the system. Also, the

redundant module can minimize downtime should any on the expanders fail.

2.5.1 Removing the Host Expander Module

Step 1: Loosen the thumbscrew of the host expander module.

Step 2: Rotated the expander module lever outward.

Step 3: Pull out the expander module.

Step 1

Step 2 Step 3

2.5.2 Installing the Host Expander Module

Step 1: Push the expander module into the cage until it clicks back to the original

location.

Step 2: Rotated the lever back into position.

Step 3: Tighten the thumbscrew.

Pull

Page 19

16

Step 1

Step 2 Step 3

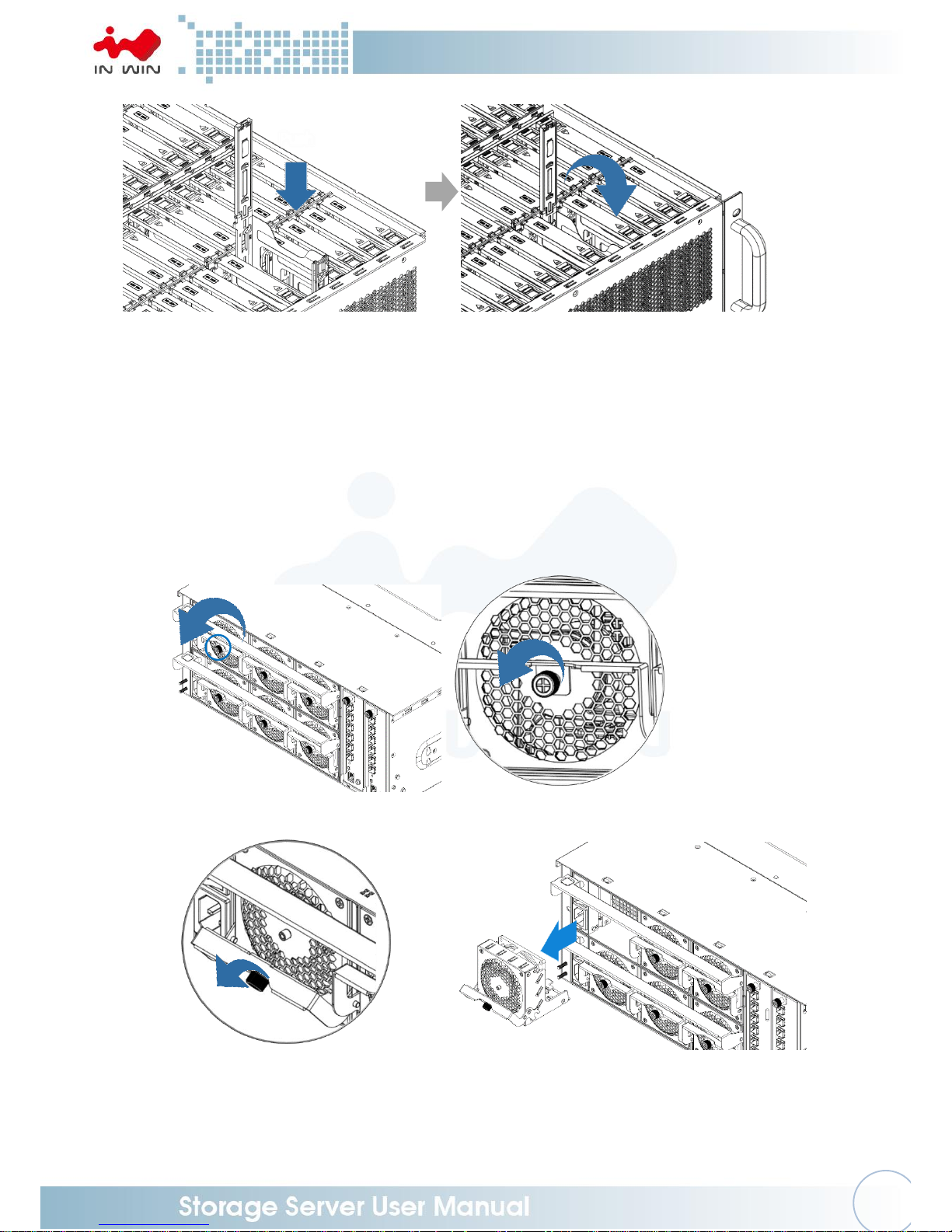

2.5.3 Removing the Disk Expander Module

NOTE: Please open the top cover only when necessary and close it within 1 minute

to prevent the system from HDD overheating.

Step 1: Open the top cover of the chassis. (Please refer to 2.1.1)

Step 2: Remove the cable from the disk expander module.

Step 3: Loosen the thumbscrew of the module.

Step 4: Rotate the disk expander module handle outward.

Step 5: Pull out the disk expander module.

Step 2

Unplug the

Cables

Push

Unplug the

Cables

Page 20

17

Step 3

Step 4

Step 5

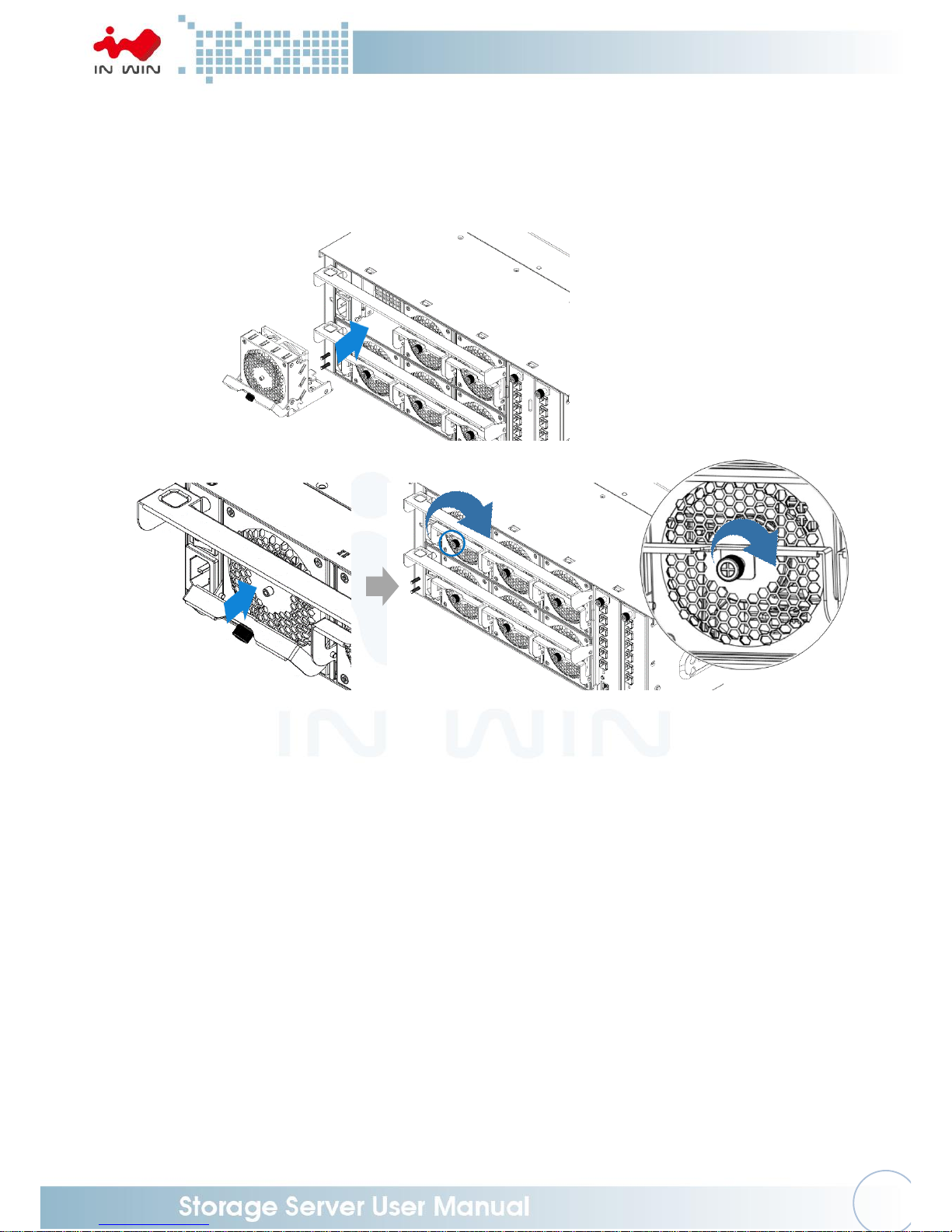

2.5.4 Installing the Disk Expander Module

Step 1: Place the disk expander module into the cage until it clicks.

Step 2: Put the thumbscrew into position and tighten the thumbscrew.

Step 3: Connect the cable to the disk expander module.

Step 4: Close the top cover of the chassis. (Please refer to 2.1.2)

Step 1

Pull

Push

Page 21

18

Step 2

Step 3

Connects the

Cables

Connects the

Cables

Page 22

19

2.6 Rail Installation

The IW-RJ472-05 JBOD is a high density 4U rackmount storage model, which supports

EIA-RS310D standard cabinets and chassis racks. InWin provides standard slide rails for

mounting the JBOD chassis to cabinets.

2.6.1 The Type of Rail Kit

Please follow the instructions to install the rails on the cabinet or chassis rack

according to the rail type you ordered.

2.6.2 Slide Rail

2.6.2.1 Take out the Inner Rail and Slide the Intermediate Rail Back

Step 1: Pull out the inner rail until it reaches the stop. Release the blue

slide tab to unlock.

Step 2: Continue pulling the inner rail until the second stops. Release the

white slide tab to remove the inner rail.

Step 3: Pull the latch on the middle rail upward and retract the middle rail

back.

Step 1 ~ 2

Step 3

2.6.2.2 Attach the Inner Rail to the Chassis

Step 1: Align the chassis sidewall standoffs to the inner rail keyholes. Slide

the inner rail toward the front until the standoff snaps into place,

securing the rail to the chassis.

Step 2: Repeat the same action on the other side.

Step 3: When removing the inner rail:

Pull up the latch and slide the inner rail forward. Remove the

keyhole from the standoff to detach the inner rail. (Action and

in the figure)

Step 1~3

Page 23

20

2.6.2.3 Mount the Rail Bracket to the Cabinet

Step 1: Extend the rail bracket over the rear rack of the cabinet.

Step 2: Pull out the rear hook on the end of the outer rail, align and push

the rail bracket pins into the post holes on the rack. Then, pull

back the hook on the end of the outer rail.

Step 3: Extend the opposite side of the rail bracket to the front rack of the

cabinet.

Step 4: Hang the front hooks of the outer rail at the front of the rack post

holes. Pull the rail bracket pins that go into the front post holes on

the rack until they click.

Step 5: The other side of the rail is symmetrical, repeat the installation

steps 1-4.

Step 6: Once you would like to detach the bracket, pull outward on the

front and rear hooks of the outer rail to release the bracket.

Repeat the same action to the other side.

Step 1~5

Step 6

2.6.2.4 Insert the Chassis to the Cabinet

Step 1: Pull out the middle rail to the stop position.

Step 2: Move the ball bearing retainer to the front end of the middle rail,

it should click into the locked position.

Step 3: Insert the inner rails of the chassis into the middle rails on the

both sides of the rack.

Page 24

21

Step 4: Push the chassis to the stop position, then release the blue slide

tab (by either pulling the tab forward or pushing the tab back) to

continue.

Step 5: Until reaching the second stop position, release the blue slide tab

again to continue.

Step 6: Push the chassis into position on the rack completely. Make sure

that the front end of the chassis is aligned with the edge of the

rack to complete the installation.

NOTE: Heavy Handle with Care!

Use the removable handle rivets into the holes in the side of the case and move upward until

it clicks to secure before transporting.

Page 25

22

2.7 External Cable Management Arm Installation

2.7.1 Parts Required

Please use the following parts from the accessory package to install the external

cable management arms.

2.7.2 Mounting Bracket Installation

Step 1: Align the quick-release extension bracket (G-2-1) to the cabinet mounting

bracket(G-1) screw holes, tighten with two round head screws(H).

Step 2: Align the quick-release extension bracket (G-2-2) to the second cabinet

mounting bracket(G-1) screw holes, tighten with two round head screws(H).

Page 26

23

2.7.3 Support Arm Installation

Support Arm C-1

Step 1: Align the support arm(C-1) hexagon head screw to the cable management

stop bracket (D) elliptical hole and fasten it down.

Step 2: Insert the latch of the cable management stop bracket (D) into the quick-

release extension bracket (G-2-1) on the cabinet mounting bracket(G-1).

(Refer to 2.7.2 Step 1)

* When removing, press the blue dot to pull out.

Step 3: Align the opposite side hexagon head screw of the support arm(C-1) with

the quick-release extension bracket (G-2-2) and fasten it down.

Page 27

24

Step 4: Insert the quick-release latch (B-1) into the quick-release extension bracket

(G-2-2) on the cabinet mounting bracket(G-1). (Refer to 2.7.2 Step 2)

* When removing, press the blue dot to pull out.

Support Arm C-2

Step 1: Place the support arm(C-2) hexagon head screw down to the middle

hollow of the support arm(C-1) and fasten it.

Step 2: Align the swivel pin (E) with the end of the screw hole of the support

arm(C-2) and tighten the swivel pin screw (J).

Page 28

25

Step 3: Put the chassis mounting bracket(F) along the end of chassis. Align the

screw holes and tighten the flat head screws(K).

Step 4: Secure the swivel pin (E) to the chassis mounting bracket (F).

2.7.4 Cable Management Arm Installation

Step 1: Insert the quick-release latch (B-1) into the right of the cable-management

arm (A).

* The purple fastener of the cable-management arm is facing up.

* When removing, press the blue dot to pull out.

Page 29

26

Step 2: Insert the quick-release latch (B-2) into the other side of the cable-

management arm (A).

* When removing, press the blue dot to pull out.

Step 3: Insert the other side of the quick-release latch (B-2) into the chassis mount

bracket(F).

* When removing, press the blue dot to pull out.

Page 30

27

2.7.5 Completing Installation

Step 1: Place the chassis in the cabinet.

Step 2: According to the required depth position, the hole is locked on the fixing

bracket of the cabinet (There are two screws on the left and right, which

need to be in the same position).

Step 3: Tighten the flat head screw(I) to secure the mounting bracket (G-1) to the

cabinet.

* For more detailed dynamic installation instructions, see the RJ472 Rail CMA -

Assembly Live Video File. (Link)

2.7.6 Insert the Chassis to the Cabinet External Cable Management Arm Installation

Step 1: Pull out the middle rail to the stop position.

Step 2: Move the ball bearing retainer to the front end of the middle rail, it should

click into the locked position.

Page 31

28

3 Expander Board Introduction (Host & Disk)

3.1 Expander Board (Host)

Location

Description

JS1-JS4

(HOST)External Uplink

MINI SAS HD Connector

JS5-JS6

(Expansion)External Downlink

MINI SAS HD Connector

LED1-LED6

PHY LINK LED

LED7

Status LED

CN1

Programming (Factory only)

SW1

ID SW/LED

SW2

System Reset (Factory only)

SW3

Flash burn-in test (Factory only)

CON2

Management LAN port

JD1

EXP Smart Console mode

JD2

EXP Debug Console mode

JD4

System Debug Console Mode

EFN1

Expander Fan

BT2

RTC Battery

Page 32

29

3.2 Expander Board (Disk)

Location

Description

JD1

Programming (Factory Only)

JD2

Console Debug Mode

JD3

Console Smart Mode

JC1

MB Fan Control

JC2

PMBUS

JC3

Front Panel Signal Connector

EFN1

Expander Fan connector

LED11/12/13

(LED11-13) JS1-JS3 PHY LED

LED01

Expander Heart Beat LED

JS1-JS3

JS1-JS2: Internal Mini-SAS HD Up Link

JS3: Internal Mini-SAS HD Down Link

JM1

Power Mode Select

Page 33

30

4 User Interface Introduction

4.1 Overview

InWin’s JBOD System is a high performance, reliable storage system with sensors to

monitor system health.

We provide state-of-the-art management functionality for users to monitor and manage

JBOD systems efficiently and flexibly.

Users can manage JBOD systems through serial port and/or Ethernet according to the

system configuration on the system. We support varieties of network protocols for

network management including Telnet, SSH, Web-GUI, SNMP and SMTP. We also

support active system alert function by sending information to the email addresses

specified in the system, so the users can be informed of any changes of the systems in a

timely manner.

This users’ manual is for all series of InWin JBOD systems including RJ-212, RJ-224, RJ316, RJ-424, RJ-448, RJ-460 and RJ-472. It provides the information and instructions of

frequent use function. Please refer to the table of contents to find the topics you are

interested in.

4.2 Key Features

•Reliable High Data Rate Support (up to 12Gbps)

SAS 12Gbps support and SATA3 6Gbps support to provide a reliable high-performance

data rate.

•Dual Expanders Support

System can accommodate dual expanders to support data redundancy capability.

•Power Redundancy

System can accommodate 2 sets of power modules as redundancy. Either power

module could work independently while the peer is out of order or not installed.

•Hot-swappable Power Module

The PSUs are hot-swappable. No need to shut down the system for PSU replacement

when required.

•Hot-swappable Fan Modules

The fan modules are hot-swappable. No need to shut down the system for fan module

replacement when required.

•Faulty System Alarm

The Faulty System red LED indicator on the front panel illuminates along with a

beeping sound while there is faulty part(s) in the system.

The beeping sound can be muted by pressing the mute button on the front or rear

panel.

•Hot-swappable HDDs

Page 34

31

The HDDs are hot-swappable. No need to shut down the system for HDD installation

and/or replacement when needed.

•Smart Fan Control

The fan modules possess a smart control feature set by the firmware to provide seven

levels of speed RPM according to the detected system temperature.

•Zoning

This system support feature divides disk drives into two or more different groups

depending on the system preference. Each group can own users-configurable number

of HDDs independently. This feature enables single JBOD to serve multiple hosts.

•Cascading

There are cascading ports on the Expander for cascading another JBOD system to

expand disk space when more space is required.

4.3 Software Management

4.3.1 System Management Structure

InWin’s JBOD Systems supports an out-of-band Network Management feature,

which enables a rich set of protocols and a flexible way for SAS Expander

management anytime from anywhere.

4.3.1.1 Ethernet Management

The Bridge Expander is equipped with a network management port

allowing users to manage JBOD systems from a remote location.

With a proper IP address setting, users can manage the system through

Telnet, SSH, Web-GUI and SNMP remotely.

Page 35

32

The rich set of network protocols are leveraged for flexible remote

management. The supported protocols including Telnet, SSH, Web-GUI,

SNMP and SMTP enables various ways to manage the system.

Please be sure the IP address of the system is correctly configured to

enable network access. Our system’s supports are Static IP address or

DHCP dynamic IP address as per users’ configuration.

4.3.1.2 Serial Port Management

A 3.5mm audio jack serial port (RS-232) on the Expander module enables

users to manage the system through terminal console applications such

as Tera Term, Putty, etc. Users need to prepare a DB9 RS-232 adapter on

host and connect to a serial cable shipped along with the system to gain

access to the serial port management. Use CLI commands to manage the

system through serial console.

4.3.2 Serial Port Management

The RS-232 port on the Expander module provides a serial connection for users to

manage the JBOD system with terminal application such as Tera Term, Hyper

Term…etc. To manage the JBOD system through the serial port, configure the

terminal console as per the settings below to connect it.

Baud Rate : 115200

Data : 8 bit

Parity : None

Stop Bit : 1 bit

Flow Control : None

Page 36

33

4.3.2.1 CLI Commands

Some useful CLI commands are listed below

■ Network Management Layer

The “/mgmt.s#” prompts in the Console Terminal, which means the

system is now in the network management level. Under this level, users

can manage the network setting such as configuring the IP address and

enabling/disabling services.

The “list” command to displays all the Ethernet layer commands the

system supports.

The “help” command lists the description of the commands.

Type command without argument to display the current status.

Type command with “?” to display the usage of the command.

Type command with argument to configure the setting of the command.

Note:

Page 37

34

■ Expander Management Layer

The “cd expander0” changes the directory for bridge expander

management. In this layer, users can manage SAS Expander settings

“cd ..” to change the directory back to the upper layer. It’s typically used

for jumping back to the network management layer from expander

management layer.

The “?” or “help” displays the CLI commands for the SAS Expander.

Type “command” to display the current status of the command.

Type “? <command>” to display usage of the command.

Any changes that have been made only available until system reboot. Please be

sure to type ‘save’ command to store the configuration so the changes will be

kept for next system boot.

Page 38

35

As the design, there are three internal expanders inside the chassis

expanded from the bridge expander. Users can also get into the internal

expander management when required.

Type “cd expander1” to manage 1st expander.

Type “cd expander2” to manage 2nd expander.

Type “cd expander3” to manage 3rd expander.

Note:

4.3.3 Network Management

The Ethernet port on Expander module is to provide Network Management in

various protocols such as Telnet, SSH, Web-GUI and SNMP. It also provides an

email notification while an alarm is in effect by properly configuring the SMTP

information.

The default settings of the network information are as listed below:

IP Address : 192.168.100.1 (Static IP Address)

Subnet Mask : 255.255.255.0

Gateway : 192.168.100.254

Username : admin

Password : default

* Please be sure the system IP network is reachable by the management host.

* Users can make changes of the settings to meet the network environment.

* For security reasons, we strongly recommend users to change the password

immediately before the system is put online.

Note:

4.3.3.1 Telnet

■ The Telnet service is enabled by default. It shares the same level of CLI

commands as it is through the serial console terminal.

Users can disable the Telnet support on web GUI or with CLI commands if

there are security concerns.

In CLI, in “mgmt.s” layer type “service telnet 0” to disable telnet service.

■ The difference compared with serial console is that Telnet sessions

require a Credential (Username and Password) to gain access to it.

Please jump back to “mgmt.s” layer by typing “cd ..” every time before you can

jump to another expander management layer.

The factory default IP address is static address 192.168.100.1. If there is a DHCP server

in the IP network, users can simply change the IP address on web GUI or through serial

console.

In serial console, type “dhcp 1” in “mgmt.s” layer to enable dynamic IP address for the

system. Type “save” it so the setting is kept for the next system boot.

Page 39

36

Refer to the above session for the default credential information.

■ Below is a reference capture of a tenet session.

4.3.3.2 SSH

■ The SSH service is enabled by default. It provides the same level of CLI

commands as it is through serial console or Telnet session.

■ SSH provides a secure connection between host and the JBOD system. It

is enabled by default on most Linux OSes. There are some freeware SSH

tools for Windows such as Putty, Tera Term, …etc.

■ Below is the Tera Term example to establish the SSH session.

Page 40

37

Page 41

38

4.3.3.3 Web-GUI

■ The Web-GUI is the easiest way to manage the JBOD system. It is enabled

by default on this system.

■ Users can simply open the web browser and give the JBOD management

IP address in the URL address field to start managing.

Login Page

Version Page

Page 42

39

System Page.

4.3.3.4 SNMP

■ The SNMP is a popular network device management protocol that is

widely used by IT people to manage mass amounts of systems, devices

and equipment which are embedded with a SNMP agent.

■ The InWin JBOD system’s management module is implemented by a

SNMP agent with v1 and v2c support.

■ Users need to configure the same read and write community string in the

JBOD system as the SNMP manager so the system can be managed by the

SNMP Manager.

■ An InWin proprietary MIB, which defines system information, is required

for the SNMP Manager so the OID is accessible.

Page 43

40

Below is the proprietary MIB file:

inwin-jnm.mib

■ SNMP Settings on the System

Users can change the SNMP settings through CLI and Web-GUI.

‧Check and configure via CLI

‧Check and configure via Web

■ SNMP Manager

Any SNMP Managers can be used to manage the system by properly

configuring the system settings including IP address, read community

string and write community string to match the settings in the system.

And Compiling the InWin JBOD MIB file to the SNMP manager is

necessary. Below is an example to browse the system MIB with a free

SNMP Manager tool.

Page 44

41

4.3.4 Version Information

Users can check the system hardware and firmware version through various ways

with CLI commands, Web GUI and SNMP.

4.3.4.1 CLI (UART, Telnet and SSH)

■Type the “version” command on “mgmt.s” Layer to display all the version

information including Ethernet firmware version, Expander firmware

version and MFG CFG file version.

Page 45

42

4.3.4.2 Web-GUI

■ Type system IP address on Web Browser URL address field to gain access to the

system. After logging in, click “Version” on the left pane to view the system

version information on the right pane. Scroll down to view all information if the

display is out of page.

Page 46

43

4.3.5 System Status

The System Status is to display the status of the system sensors including

temperature, voltage, fan speed and power supply. All the SAS Expander modules

are equipped with sensors to monitor system health and control environmental

cooling systems accordingly.

4.3.5.1 CLI (UART, Telnet and SSH)

■ Type “encl sensor” command in “mgmt.s/expander0” layer to display the

System sensors’ readings and their status.

■ Please note that the Expander temperature sensors “Exp Die” is the

silicon core temperature and the temperature sensors “BPx-Sensor x” are

on the backplanes.

■ There are mechanisms communicating between primary and secondary

domain expander modules so the peer side module sensors information

can be exposed at the same screen.

4.3.5.2 Web-GUI

■ Type the system IP address on the web browser URL filed to gain access to

the system. After logging in, click “System” on the left panel to view the

system status information on the right panel. Scroll down to view all

information if the display is out of page.

Page 47

44

4.3.6 Network Settings

The Network settings is for configuring system network information such as

DHCP/Static IP Address selection, Network Services, Mail configuration and SNMP

configuration.

4.3.6.1 CLI (UART, Telnet and SSH with Ethernet Board)

■ There are a couple network setting commands on ”mgmt.s” layer such as

“ipaddr”, “gateway”, “netmask”, …etc. to view and configure the settings

respectively.

■ Please be sure to apply the “save” command so the settings are saved for the

next system reboot.

4.3.6.2 Web-GUI

■ Type the system IP address on the web browser URL field to gain access to the

system. After logging in, click the “Network” button on the left panel to view the

network information on the right panel. Scroll down to view all information if

the display is out of page.

Page 48

45

4.3.7 Disk Information

The disk information is to show the disk drives’ status on the system, including Bay

id, Phy id, SAS Address, Link speed and current status.

4.3.7.1 CLI (UART, Telnet and SSH)

■ Type the “phyinfox -s” command on “mgmt.s/expander0” layer to display

the system hard disk drives’ status on the system.

Page 49

46

4.3.7.2 Web-GUI

■ Type the system IP address on the web browser URL field to gain access to

the system. After logging in, click the “Disk” button on the left panel to

view the disk drives information on the right panel. Scroll down to view all

information if the display is out of page.

4.3.8 Zone Setting

The Zoning feature supports the function to divide disk arrays into multiple groups.

Once the zoning feature is enabled, the specific-wide port is hard-coded and

designed to join the specific group as the access port of the specific group.

RJ-212, RJ-316, RJ-224 and RJ-448 support 2-group zoning.

RJ-472 supports up to 6-group zoning.

RJ-460 does not support zoning.

4.3.8.1 CLI (UART without Ethernet Board)

■ For the RJ-472-05 system,

Type “ucfg.zone” command in “mgmt.s/expander0” layer to show the

zoning status.

Type “ucfg.zone enable n” command in “mgmt.s/expander0” layer to

enable the zoning setting where n= 2, 3 and 6.

Type “ucfg.zone disable” command in “mgmt.s/expander0” layer to

disable the zoning setting.

Page 50

47

Note:

4.3.8.2 Web-GUI

■ Type the system IP address on the web browser URL field to gain access to

the system. After logging in, click the “Zone” button on the left panel to

view and configure the zoning setting of the system on the right panel of

the page.

■ Click “Enable” to enable zoning and click “Disable” to disable zoning. After

configuration is selected, click “Apply” to reset the Expander to take

effect.

Zoning configuration with CLI in serial console or Telnet session requires a system reboot

to take effect.

In Web-GUI, Expanders would be reset when applied.

Zoning configuration needs to be set on both domains manually to make them work

consistently.

Page 51

48

4.3.9 Firmware Upgrade

The firmware upgrade function provides a way to update system firmware when

necessary.

There are 3 firmware for the InWin JBOD system:

1. Network Management Firmware

2. SAS Expander Firmware

3. SAS Expander MFG CFG file

There are a couple of ways to upgrade the system firmware according to the HW

configurations. Please note that the upgraded firmware won’t take effect until a

system reboot

Note:

Be careful NOT to power off the system when conducting system firmware upgrade.

Power loss during firmware upgrade would somehow crash system firmware.

In case firmware crash occurs, call help from technical support.

Page 52

49

4.3.9.1 CLI (Telnet or SSH)

Users are able to upgrade management firmware, SAS Expander firmware

and MFG CFG file through TFTP or Xmodem when using CLI commands.

Below the examples are with TFTP server.

All sorts of firmware upgrades going through TFTP would be intelligently

upgraded to the right hardware. More conveniently, all Expanders

(including Bridge Expander and internal expanders, they are sharing the

same firmware and MFG file) can be upgraded at the same time when

upgrade command is applied and committed.

To upgrade through TFTP, open a TFTP server on your console host and

specify the path in TFTP server to the directory where the firmware is

stored. Please be sure the TFTP server is reachable to the JBOD system.

■ Management Firmware upgrade

Type “upgrade <tftp_server_ip> <filename>” command to start

Management Firmware upgrade.

Page 53

50

■ SAS Expander Firmware

It’s the same as for Management firmware by using the Expander

Firmware filename instead in command.

“upgrade <tftp_server_ip> <filename>”

Page 54

51

■ SAS Expander MFG CFG file

Same as Management firmware by using the Expander MFG CFG file

filename in command.

“upgrade <tftp_server_ip> <filename>”

4.3.9.2 Web-GUI

■ Upgrade system firmware through Web-GUI is much easier than other

ways. Just simply select the firmware by file browser and click ‘Apply’ to

start.

All the firmware including Network Management firmware, SAS Expander

firmware and MFG CFG file apply the same way to upgrade.

After system upgrade, be sure to reboot system to take effect the new

firmware which has been upgraded to the hardware.

■ Click the “Tool” button on the left panel and scroll down to “Software

Upgrade,” the session is on the right panel.

Page 55

52

Click the “Choose File” button to select the firmware being upgraded

from file browser and click “Open” to commit.

The firmware can be management firmware, SAS Expander firmware or

SAS Expander MFG CFG file. The system would intelligently detect the

firmware type and upgrade to the right hardware.

Click the “Upgrade” button to start the firmware upgrade.

Page 56

53

Web would direct to a page telling the firmware is upgrading.

After upgrade is done, Web will direct to the Login page.

A system reboot is require to take effect.

Page 57

54

4.3.10 Web Console

Web console provides an easy way for users to apply CLI commands to a specific

SAS Expander without needing a console terminal.

4.3.10.1 Utilize Web Console

■ Login into Web-GUI then click “Console” on the left panel.

Then, on the right panel, select the SAS expander that you would like to

apply the command to and fill the command to the rightest square.

Click “RUN” to apply commit the command to expander.

The output of the command would appear on the lower square.

To clear the console output, click the “Clear” button.

Page 58

55

4.4 Appendix A

Management Firmware CLI Commands

Function

Command

cd

changes control path to management board or expander control path

date

display or set current date/time

dhcp

display or set DHCP client

dns

display or set DNS server

gateway

display or set router (example: 192.168.100.254)

ipaddr

display or set Ethernet IP address (example: 192.168.100.100)

list

list path commands or control path

mail

display or set send mail parameters

netmask

display or set Ethernet IP netmask (default: 255.255.255.0)

passwd

change password

reboot

reboot management board

save

save configuration to NVRAM

service

display or set service (Telnet/SSH/WEB/SNMP)

upgrade

upgrade management board or expander software

useradd

add new user account

userdel

delete a user account

userlist

list user account

version

display management board's information

4.5 Appendix B

SAS Expander Firmware Useful CLI Commands

Function

Command

Enclosure Info

encl [Info-Type]

- Info-Type:

rev : Show H/W & S/W revision

sensor : Show enclosure sensor state

pd : Show disk phy state

pmon : phy signal monitoring

(Omit Info-Type to dump all)

cmfg : Show MFG embeded in FW

Zone Configuration

ucfg.zone < [state] | enable | disable >

When enabled:

-- Disks are divided into 2 zones

-- Each BRC exposes disks in one zone

Page 59

56

Function

Command

(Primary: Zone #1 ; Secondary: Zone #2)

Console Select

con [ 0 .. 2 | 'n' | 'p' | '?' ]

'n', 'p': switch to next/previous console,

'?' : display current console ID

(Omit parameter to select 1st console)

Show/Set the current

date [ set <newdate(*)> |

Date and Time

send [<SasAddrHi(H)> <SasAddrLow(H)>] |

recv [<SasAddrHi(H)> <SasAddrLow(H)>] ]

- no arguments, output local expander date/time and

uptime

- 'set <newdate(*)>' Set local expander date/time using

format for <newdate> of YYYYMMDDHHMMSS

- 'send [sas_addr]' If sas_addr set then set the remote

expander's clock using the local expander's current clock

value. If sas_addr not specified then set clock for all

expanders in the domain.

- 'recv [sas_addr]' If sas_addr set then fetch the remote

expander's current clock and output the result. If

sas_addr not specified then get and output the current

clock for all expanders in the domain.

Reset the Expander

reset [watchdog]

Display phy info.

phyinfox [ -i [(1 .. NumBpc] ] | -s

-i : show phy info of BPC expander

-s : show SES Array Device info of CSE BRC

(bridge console only)

Configuration Update

mfgdl

Download and Update MFG configuration.

(feed it with 'MFG image file')

Firmware Update

fwdl

Download and update firmware

Display info for all phys

phyinfo [help|edfb|power|cable]

[up|<PhyNum(D)>]

- no arguments displays default output

- 'help' displays detailed help information

- 'edfb' subcommand displays EDFB info

- 'power' subcommand displays power mgmt info

- 'up' filters to display connected phys only

- 'cable' subcommand displays cable mgmt info

Page 60

57

Function

Command

- <PhyNum> is a valid phy index and filters the output to

display info about that phy

Display or Reset All

counters [config|event|reset]

- no arguments displays phy error counters and generic

broadcast counters

phy counters

- 'config' subcommand displays phy event configuration

- 'event' subcommand displays phy event counters

- 'reset' subcommand resets all phy counters

Display Expander

sasaddr [-d]

SAS Address

('-d': also show virtural ports address)

Show POST info

showpost

Show MFG Revision

showmfg

Show firmware revision

rev

5 Compatibility Lists

To reach the best performance and avoid system failure, InWin strongly recommends users to

choose the components from InWin’s compatibility list. All the components are tested in

InWin’s lab, and assured the components are complementary with InWin’s chassis.

You can download the latest updated device compatibility list from InWin’s website:

https://www.in-win.com/en/ipc-server

6 Technical Support

If you need help with installation or troubleshooting, you can contact your local InWin partner,

or send an e-mail to InWin’s local contacts for technical assistance.

Loading...

Loading...